#CNC machining prototyping

Text

Aluminum Prototype Machining: Precision at Every Stage

Explore the pinnacle of precision with Sanwo Metal's aluminum prototype machining services. Our advanced CNC machining capabilities ensure the highest level of accuracy and detail in every prototype. Discover how our expertise and dedication to quality streamline your prototyping process, bringing your designs to life with unparalleled precision.

#low volume cnc machining#custom machined aluminum parts#cnc machining prototyping#custom cnc milling parts#aluminum prototype manufacturing#aluminum prototype machining#low volume production#low volume manufacturing

1 note

·

View note

Link

CNC machining prototyping is the new age process of producing prototypes of the new products that are about to be launched in the market. The advantage of this process is that it reduces loss of time and material. Also, it brings down the overall cost of the final product.

0 notes

Text

Get the Finest Precision with CNC Machining

In a subtractive manufacturing technique known as CNC machining, materials are precisely shaped and cut into the necessary shapes. CNC machining automates the production process in contrast to conventional machining, which mainly depends on manual intervention, leading to improved precision, repeatability, and efficiency.

Using computer-aided design (CAD) software, a digital design is produced at the start of the process. The design acts as a guide for how the CNC machine should operate. The design is then transformed into a machine-readable format, often a G-code program, which gives instructions for the CNC machine after it is complete.

The ultimate product's needs are taken into consideration while selecting the material, which may be made of metals, polymers, or composites. By sawing the material into the required sizes, either manually or automatically, the material is prepared.

The prepared material is firmly secured to the work table of the CNC machine. The CNC program is entered into the machine's controller once the cutting tools, such as drills, mills, or lathes, are mounted during the CNC machining process.

After the machine is configured, the CNC controller reads the G-code program and gives precise instructions to the machine's motors to move the cutting tools. The cutting tools execute operations including drilling, milling, turning, and more to remove material in line with the design parameters.

Throughout the machining process, quality control procedures are used to make sure that the part's dimensions, tolerances, and surface finishes adhere to the necessary standards. To check accuracy, you could use measurement equipment like calipers, micrometers, or coordinate measuring machines (CMMs).

The advantages of CNC machining

The excellent precision and accuracy of CNC machining is well known. The process is computer-controlled, which guarantees consistent and dependable outcomes, making it perfect for applications that call for precise tolerances and complex geometries.

CNC machines can deal with a variety of materials, such as composites, metals, plastics, and wood. This adaptability makes it possible to produce a variety of components for different businesses.

Complex items may be produced fast and effectively using CNC machining. Once set up, the device can run alone with little assistance from a person. This shortens the production process and increases output in general.

It is possible to produce identical components with great repeatability using CNC prototype machining. Manufacturers can reliably make huge numbers of components because of the CNC program's ability to be stored and used again.

Main source: https://cneasteel.wordpress.com/

#CNC Machining#CNC Machining process#CNC Machining Techniques#CNC Prototype Machining#CNC Machining China

2 notes

·

View notes

Text

Sheet Metal Fabrication

When it comes to sheet metal fabrication, you need quality you can trust. That's why you should turn to Nagualmetal for all your sheet metal needs. We use the best materials to create high-quality sheet metal products that will stand the test of time. Get outstanding results with Nagualmetal's sheet metal fabrication services today! Read more : https://nagualmetal.en.alibaba.com/productgrouplist-924878740/Sheet_Metal_Fabrication.html?spm=a2700.shop_plgr.88.11.646d7b2cmd1SpG

#cnc machining service#progressive stamping die#sheet metal fabrication#plastic injection mold#prototype fabrication

0 notes

Text

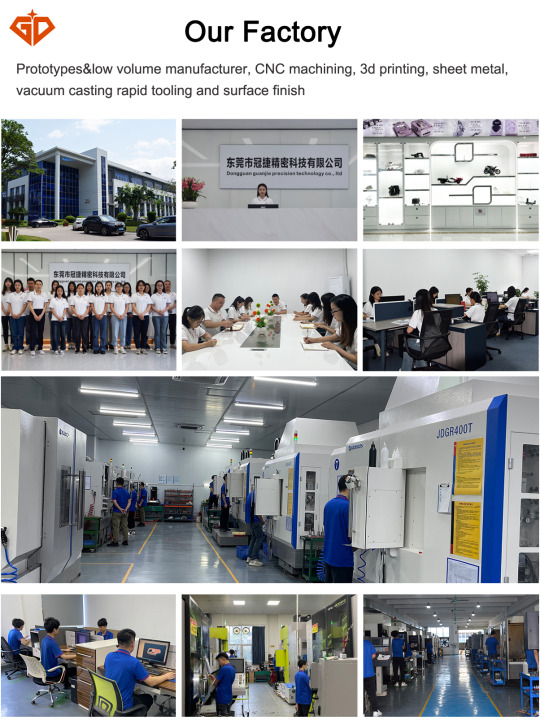

GD prototyping Simultaneous 5-axis CNC milling is an advanced processing technique that can manufacture high-precision and complex part.If you need to know more please contact me, thank you:[email protected]

#cnc milling services#5 axis machining#cncmachining#prototyping#cnc machining parts#cnc machining services#cnc machining

0 notes

Text

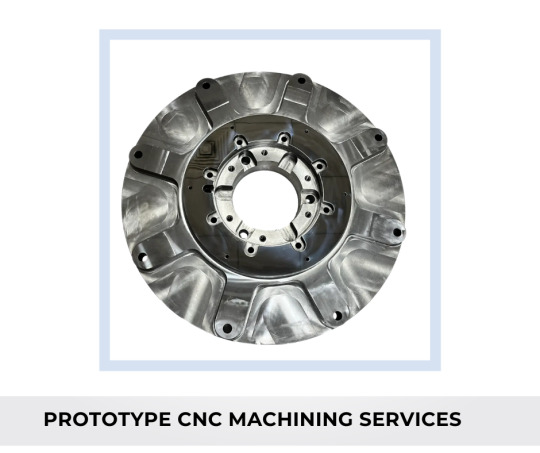

The Power of Prototype CNC Machining Services

In the realm of product development, the transition from idea to reality plays a critical and exciting part. Prototype CNC machining services have a pivotal role to play in bridging this gap as it offers a precise and efficient way to transform your conceptual designs into tangible objects.

What is Prototype CNC Machining?

CNC (Computer Numerical Control) machining uses computer-controlled machines

to precisely remove material from a solid block, converting it into a three-dimensional representation of your design. Prototype CNC machining services

are meant to create these initial models, allowing you to:

Physical Version of Your Design: Hold a physical version of your concept in your hands. This enables a deeper understanding of form, function, and user interaction.

Test Functionality: Make an evaluation of the mechanical aspects of your design,

identify potential flaws, and refine your concept before you commit to mass production.

Gather Feedback: Prototype models are excellent tools for user testing and collecting valuable feedback from potential customers or stakeholders.

Refine and Iterate: The physical prototype allows for adjustments and modifications before you make an investment in large-scale production runs.

Benefits of Prototype CNC Machining:

Precision and Accuracy: CNC machining offers high-quality precision that ensures your prototype closely resembles your digital design.

Versatility of Materials: A wide range of materials can be used, from metals and

plastics to wood and even certain composites. Thus you can test different materials

and their suitability for your final result.

Rapid Prototyping: In comparison to traditional manufacturing methods, CNC machining offers a faster turnaround time. This allows you to iterate on your

design fast and efficiently.

If you are looking for top-rated CNC machining services at affordable prices you can count on ProtoTech Machininng Co.,Limited. They assure you of exceptional quality and top-notch service. They provide their customers with high-quality machining solutions. They always maintain stringent control over product quality.

1 note

·

View note

Text

📦Unlocking Business Opportunities: ARRK’s Comprehensive Services📦

ARRK is a global company offering comprehensive product development services from design, and prototype to production. Our innovative technologies and engineering expertise help our customers deliver the highest quality products to the market.

📈About ARRK: Get the best Product Development Services 📈

ARRK is a global company offering comprehensive product development services from design, and prototype to production. Our innovative technologies and engineering expertise help our customers deliver the highest quality products to the market.

ARRK offers a wide range of services aimed at supporting businesses in bringing their products from conception to market. These services include:

3D PRINTING

Our 3D printing service and additive manufacturing solutions cover any requirement with the help of advanced technology and a variety of high-quality materials, as well as our signature design and engineering expertise. Our capability is a prototype ready for evaluation or production, and the differentiation relies on the various processes we manage.

VACUUM CASTING

Easily reproduce your design with the vacuum casting process by using a 3D printed or machined master to create RTV silicone rubber molds. This is a cost-effective solution with consistent prototypes, be it in small quantities or in the region of hundreds.

CNC MACHINING

Computer Numerical Control (CNC) machining is when software controls machinery to make precision cuts by removing material from a workpiece to create unique parts. Plastic and metal components can be prototyped or produced with our medium or low-volume CNC machining

MICROWAVE MOLDING

Microwave Molding is a quick manufacturing process that works by micro pelletizing a thermoplastic resin to create prototypes. The fine particles are heated and melted in a silicone mold similar to our Vacuum Casting solution. The result is a lot faster and ready for the evaluation process.

By emphasizing their global reach, comprehensive services, innovative technologies, and engineering expertise, you convey a strong message about their commitment to assisting customers in delivering top-tier products. It's concise and highlights ARRK's strengths effectively.

LIGHTING PROTOTYPE

As prototyping experts, we rely on our engineering skills and manufacturing technology to make lighting prototype models that reach high-quality standards and accomplish design guidelines. Optics, electronics, mechanics, and analysis convene to produce excellence.

INJECTION MOLDING

Our high to low-volume injection molding services allow companies to get as many custom parts as needed since this process’s main features are repeatability and competitiveness. Injection molding works by injecting melted plastic into a mold, cooling it afterward, and solidifying it. It’s generally a mass-production solution. If you want to get more information about product development, you can navigate to this website.

DIE CASTING

Die casting is a process that inserts molten metal under high pressure into reusable molds called dies to produce high-quality components for multiple purposes. ARRK can create complex, accurately dimensioned parts with this low-cost and effective solution as a die casting manufacturer.

By emphasizing their global reach, comprehensive services, innovative technologies, and engineering expertise, you convey a strong message about their commitment to assisting customers in delivering top-tier products. It's concise and highlights ARRK's strengths effectively.

💼 Connect with Us Today! 💼

From concept to creation, ARRK is your one-stop destination for comprehensive product development services. Reach out to us via our official channels:

🏢 Business Address: Block E-10-01, Oasis Ara Damansara, Jalan PJU 1A/7, Ara Damansara, Petaling Jaya, Selangor, 47301 Malaysia

📞 Phone: +60 377347692

🌐 Website: ARRK Official Website

🕘 Hours of Operation: Monday-Friday: 8:30 am-5:30 pm

Social Media: Don't forget to follow us on social media for the latest updates, tips, and success stories:

👍 Facebook: ARRK Business

🔗 LinkedIn: ARRK

🕊️ Twitter: ARRK

Choose ARRK and embark on a journey where innovation meets precision, ensuring your ideas are not just realized, but perfected at every stage of the product development process.

#rapid manufacturing company#rapid prototyping and manufacturing#3d printing prototype service#cnc cutting machine supplier

1 note

·

View note

Text

Exploring CNC Machining in Prototyping and CNC Turning: Understanding How to Use It and Its Limitations

Why is CNC machining considered an important manufacturing technology, and how much impact does it make on various sectors' production and prototype processes?

What are the various methods in this field—like CNC turning—and what are the particular uses, benefits, and drawbacks of each one?

These are some of the major questions to maximize the use of CNC machining in prototype, it is essential to be aware of these prior to the product development. Check these as we explore CNC machining, its usages and limitations in CNC turning and prototyping.

CNC Machining's Flexibility in Prototyping:

Prototyping has never been more adaptable because of CNC machining, which gives designers the ability to convert ideas quickly and precisely into working prototypes. CNC machining makes it easier to produce exact features, complicated designs, and personalized parts by using computer-controlled devices. Such flexibility provides designers the ability to rapidly check ideas and explore with different design versions.

How is CNC machining used in prototyping?

CNC machining is great for making quick changes to prototypes. Designers can test lots of different designs fast and keep improving them. Because CNC machines work automatically, it makes the prototyping process faster and helps products get developed quicker.

How does CNC machining handle different shapes?

CNC machines can make all sorts of shapes, from basic to really detailed ones, with accuracy. This is very useful in prototyping when designs are often complex.

What kinds of materials can CNC machining work with?

In CNC machining, you can use a lot of different materials like metal, plastic, and other stuff. This lets designers pick the best material for their prototypes, so they can make sure their prototypes have the right strength and work the way they want them to.

Despite all its advantages, CNC machining has limitations that could affect its efficiency in certain situations. Let us look into these constraints to have a better understanding of how to effectively go through CNC machining as understanding its limitations is important.

Here are some of the Limitations in Prototyping:

Cost Considerations: While CNC machining offers rapid prototyping capabilities, it can be relatively expensive, particularly for low-volume production runs. Material costs, machine setup time, and programming expenses contribute to the overall cost of CNC prototyping.

Design Constraints: Even though CNC machining has many uses, designers must stick to certain guidelines. It is important to consider how tools can reach parts, how parts are positioned, and how exact the machine is. Designers must consider these guidelines to ensure that their prototypes can be built without issues or additional costs.

Making Precise Prototypes with CNC Turning: Using CNC turning to create prototypes is similar to using a special machine that shapes round parts by spinning them against a sharp tool. It's part of CNC machining, which involves computers controlling machines. While CNC turning shares similarities with other CNC methods, it has its own advantages and disadvantages when making prototypes.

Making Rotating Parts Easily: CNC turning is a good method at making parts that spin, like shafts, pins, and bushings, with great accuracy and speed. This is helpful when we're making prototypes with lots of spinning parts.

Material Removal Rates: Compared to other machining techniques, CNC turning boasts impressive material removal rates, enabling rapid fabrication of cylindrical components. This efficiency accelerates prototyping timelines and enhances productivity.

Surface Finish and Tolerance Control: CNC turning delivers superior surface finishes and tight tolerance control, ensuring that prototypes meet exact specifications. This precision is essential for functional prototypes that require precise fits and smooth surfaces.

But here are few limitations in CNC Turning that must be taken care as well:

Limitations to Rotational pieces: CNC turning works effectively for making rotational components, however it can only be used on pieces that have rotational symmetry. Non-rotational features and complex designs may call for additional machining steps or other production methods.

Limitations on Tool Access and Design: CNC turning has limitations on tool access and component mechanics, especially for features that are far from the rotational line. To lessen these constraints, designers must carefully analyze component position and tooling methods.

CNC machining, including CNC turning, is a valuable tool for prototyping, allowing designers to create precise models efficiently. While it offers benefits like quick design changes, material flexibility, and complex shapes, it also has drawbacks such as costs and design limitations. Understanding how CNC machining works in prototyping enables designers to maximize its benefits, driving innovation and speeding up product development.

At HLH Rapid, we have CNC services perfect for quickly making prototypes and small batches of parts.

Learn more about our factory that has more than 150 advanced machines like mills, lathes, and grinders, ensuring we can make parts exactly how you would want them. Plus, we check the quality at every step to guarantee the best results, drop an email at [email protected] or simple visit our site; https://hlhrapid.com/get-a-quote/

0 notes

Text

#cnc-machining#best-prototype-companies#prototype-machining-services#cnc-components-manufacturers#custom-cnc-aluminum-parts#stainless-steel-cnc-machining-services#cnc-machining-services#cnc-machining-companies-near-me

0 notes

Text

The Importance of High-tech Rapid Prototyping

In the industrial industry, precision is not only desirable—it is essential. Consider a situation in which parts of a jet engine are even marginally machined incorrectly or misaligned. The repercussions can be disastrous and might cause the engine to fail in midair. Precision becomes the key to success in sectors like aerospace, automotive, and medical where safety and dependability are non-negotiable. Put simply, it's the capacity to manufacture parts or components that precisely conform to given dimensions, tolerances, and quality requirements. It takes state-of-the-art equipment, painstaking attention to detail, and highly competent operators to achieve this degree of accuracy. This is the sweet spot for Precision CNC Machining.

So how precisely can CNC machining accomplish such high precision levels?

Computerized Control: Advanced computer software is the brains of CNC machining, translating digital design requirements into exact motions and orders for the milling tools. This removes the possibility of human error and guarantees the highest level of precision in each cut, drill, and mill.

Superior Quality Equipment: Modern spindles, tools, and cutting implements that are designed to provide exact results are standard on CNC machines. These devices may operate at extremely tight tolerances, which are sometimes expressed in microns, guaranteeing an accurate reproduction of even the minutest features.

Consistency: The ability of CNC machining and High-tech Rapid Prototyping to manufacture similar components with little variance is one of its main advantages. A machine program that has been developed and tuned may be repeated endlessly with reliable outcomes. In fields where stability and dependability are critical, this degree of constancy is priceless.

Advanced Techniques: Multi-axis milling, turning, EDM (Electrical Discharge Machining), laser cutting, and other state-of-the-art methods are all included in CNC machining. With unmatched accuracy and efficiency, manufacturers can handle complicated geometries and materials thanks to these procedures.

Quality Assurance: CNC systems frequently include integrated quality control mechanisms including automated inspections, feedback loops, and real-time monitoring in addition to accurate machining. This reduces waste and rework by guaranteeing that any deviations from the intended standards are quickly identified and fixed. It is impossible to exaggerate the value of accuracy in production. Precision by Precision CNC Machining Manufacturer plays a crucial role in today's competitive economy, as it ensures everything from satisfying regulatory requirements and consumer expectations to assuring product performance and dependability.

Follow our Facebook and Twitter for more information about our product

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company

1 note

·

View note

Text

Maximize Efficiency with Prototype CNC Machining

youtube

Createproto Rapid System Limited stands as your beacon of trust for Prototype CNC Machining, where speed, precision, cost-effectiveness, and versatility converge. Get a quote now!

0 notes

Text

Excellence in Aluminum Prototype Manufacturing

Trust Sanwo Metal for aluminum prototype manufacturingservices that exceed expectations. Our expertise in CNC machining ensures rapid and precise prototyping, allowing you to test and refine your designs with confidence. Discover how our innovative solutions accelerate your product development process.

#low volume cnc machining#custom machined aluminum parts#cnc machining prototyping#custom cnc milling parts#aluminum prototype manufacturing#aluminum prototype machining#low volume production#low volume manufacturing

1 note

·

View note

Link

The author is associated with CNC machining prototyping that involves making prototypes of products with computer technology. A prototype is a sample of a ready-to-launch product.

0 notes

Text

Using the Potential of CNC Machining

In the constantly changing field of product development, efficiency, accuracy, and innovation are always sought after. CNC Prototype Machining is the core of this endeavor; this revolutionary technology has completely changed the way prototypes are imagined, created, and executed.

Redefining Precision: The Advantage of CNC

The unmatched accuracy of CNC prototype machining is its foundation. CNC machines are outfitted with the newest technology and are directed by exact CAD/CAM instructions to do jobs with minuscule accuracy. With CNC machining, every detail is painstakingly and precisely carved, whether it be for drilling precise holes or sculpting complex designs.

Innovation Acceleration: Accelerating the Development Cycle

Speed is crucial in the fast-paced environment we live in today. The days of protracted production schedules and never-ending revisions are over thanks to CNC prototype machining. CNC machines help engineers and designers to iterate quickly and bring things to market more quickly than ever before by optimizing the prototype process. This shortened development cycle encourages innovation and experimentation while simultaneously shortening time-to-market.

Unleashing Versatility: From Idea to Actuality

The adaptability of prototype CNC Machining China is among its most impressive features. CNC machines can easily mold a wide range of materials into working prototypes, whether they are made of metal, plastic, wood, or composite materials. The options are endless, ranging from sophisticated consumer electronics to delicate aircraft components.

Filling the Void: From Concept to Manufacturing

In addition to prototypes, CNC machining is essential for bridging the gap between production and design. CNC machines facilitate the process of moving from concept to mass manufacture by producing parts that are ready for production and of superior quality. Prototypes are guaranteed to be workable solutions prepared for practical implementation, not only functional mock-ups thanks to this smooth connection.

Promoting Innovation in All Sectors

Prototype CNC Machining has a significant influence that goes much beyond the boundaries of a particular sector. CNC machines are pushing innovation across a wide variety of sectors, from consumer products and medical devices to aerospace and automobiles. The future of manufacturing is being shaped by CNC prototype machining, which is at the forefront of innovations such as supply chain revolutions, improved product performance, and the ability to enable new design patterns.

#CNC Machining#CNC Machining process#CNC Machining process China#CNC Machining Techniques#CNC Prototype Machining#CNC Prototype Machining China#CNC Machining China

1 note

·

View note

Text

Progressive Stamping Die

Take metal manufacturing to the next level with Progressive Stamping Die! Our high-quality dies are made to last and are perfect for any custom metal project. Unlock the potential of metal manufacturing with Progressive Stamping Die today! Visit : https://nagualmetal.en.alibaba.com/productgrouplist-919732885/Progressive_Stamping_Die.html?spm=a2700.shop_plgr.88.10

#cnc machining service#progressive stamping die#sheet metal fabrication#plastic injection mold#prototype fabrication

0 notes

Text

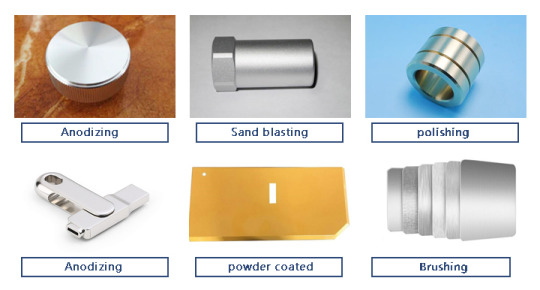

We are a Prototypes&low volume manufacturer, provide CNC machining, 3d printing, sheet metal, vacuum casting rapid tooling and Injection Molding.If you need it for your recent projects, please contact me:[email protected]

#prototyping#cncmachining#5 axis machining#cnc milling services#sheet metal#sheet metal fabrication#sheet metal manufacturing

0 notes