#CNCMillingMachine

Explore tagged Tumblr posts

Text

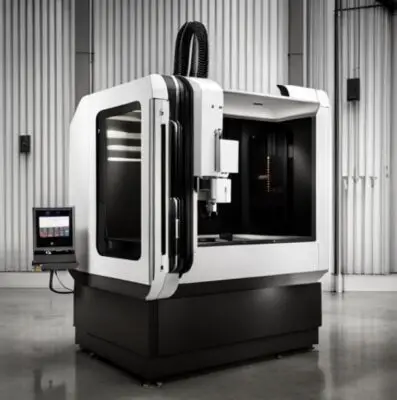

Unlock Precision with Vertical CNC Milling Machines!

Engineered for accuracy and productivity, these machines offer:

✅ Vertical spindle for superior control

✅ High-speed machining with precision cuts

✅ Easy programming & automation

✅ Ideal for metal, plastic & composite components

Shape the future of manufacturing—vertically!

For more details, visit - https://www.yashmachine.com/blog/main-features-of-vertical-cnc-milling-machines/

#yashmachine#CNCMillingMachine#VerticalMilling#PrecisionMachining#ManufacturingTech#CNCsolutions#EngineeringExcellence

0 notes

Text

Accuracy in Every Cut – Testron Specimen Milling Machine

Get unparalleled accuracy and productivity in specimen preparation with the Testron Specimen Milling Machine. With applications across automotive, aerospace, medical, and electronics industries, this tabletop CNC-controlled unit provides high-precision machining for prototyping, mass production, tool making, and custom part production.

Why Opt for Testron's Specimen Milling Machine?

CNC-Controlled Accuracy – Provides perfect and repeatable machining.

High-Speed Milling – Spindle speed adjustable up to 24,000 rpm for ultimate efficiency.

Advanced Cooling System – High-flow refrigeration lengthens machine life.

Improved Safety Features – Guard doors, safety locks, and pre-programmed machining programs.

Clean Work Area – The swarf extraction system provides uninterrupted operations.

Durable, precise, and efficient, the Testron Specimen Milling Machine is the best choice for manufacturers who seek perfection in every cut.

#CNCMillingMachine#SpecimenMillingMachine#MaterialTestingEquipment#PrecisionMilling#QualityControlEquipment#MetalTesting#LaboratoryEquipment#IndustrialMachinery#TestingSolutions#CNCTechnology

0 notes

Text

CNC Milling Machines Market - From Prototype to Production

The CNC milling machines market is dynamically developing under the growing demand for precision manufacturing and the search for efficiency in industries. Continuous improvements in computer numerical control have made these machines indispensable in modern manufacturing, in which high quality with accuracy, flexibility, and speed are required. By all standards, the growth of CNC milling machines allows insight into the trends of automation and digitalization that shape today's manufacturing landscape.

CNC milling machines have altogether revolutionized manufacturing processes since they can perform very precise and complex machining operations. It is unlike the traditional operation of manual mills since CNC milling processes are controlled by a programmed computer to carry out the entire complex milling procedure. This allows the making of very complex designs with a high repeatability rate. This is where the value in the aerospace, automotive, electronic, and medical equipment industries comes in; basically, any field where accuracy and virtual perfection are paramount. The main reason why CNC milling has been widely adopted by industries is that it will make good workpieces with close tolerances.

The development of CNC milling machines has been increasing in many areas because of increased demand for automation and efficiency of manufacturing processes. CNC milling machines become a great option not only for automation but also for improvement in productivity for businesses requiring the enhancement of profit margins by reducing operational costs. They are continuously running machines that perform different kinds of operations independent of manning, and also aid in material savings by cutting accurately and in the right relationship. Putting advanced functionalities in them like multi-axis machining and automated implementation changes adds to their versatilities and efficiency in operation, making them very vital components in any modern manufacturing process.

The market is expected to grow with the advancement in CNC technology. Advancements in software and hardware are developing even better and more user-friendly CNC milling machines. For example, advances in control systems and user interfaces that make the operator easily program and operate the machine have reduced the amount of learning, hence increasing productivity. In addition, innovations in the field of materials science and engineering allow for the manufacturing of more durable and reliable components, thus increasing the performance and lifetime of CNC milling machines.

Growth in the market for CNC milling machines is closely tied to larger trends regarding Industry 4.0 and smart manufacturing. This means that the integration of Internet of Things technology and data analytics into several CNC machines completely changes the traditional manufacturing processes. Smart CNC milling machines can collect data and analyze it in real-time to provide a lot of useful insight into machine performance, its maintenance needs, and production efficiency. This now enables manufacturers to predict equipment failure and improve product quality, thus optimizing operations.

Author Bio -

Akshay Thakur

Senior Market Research Expert at The Insight Partners

0 notes

Text

How do you process carbon fiber brake discs?#carbonfiber #brakedisc #cncmachine #cncmachining #cnc #machine #cncmachinist #cncmillingmachine #cncrouter #cncporn #cncmill #cncmilling #cncplasma #cnclathe #cnccutting #cnclaser #cnctools #machinist #tools #cncprogramming #mold #components #machinetools #jinsucnc #5axis #cncoperator #factory #machining #fyp

#cnc milling#cncmachine#cncmachine tools#cncmachining#cncmill#cncrouter#cnctool#machine#cnc lathe#tool

5 notes

·

View notes

Video

youtube

#millingmachine #universalmillingmachine #VMC #CNCmillingmachine #X6140 ...

0 notes

Text

VMC 850 cnc milling machine delivery to Slovenia.

UnionTech CNC Machinery continues to provide you with the best prices and service.

www.union-cnc.com

#cncmillingmachine

#vmc850

0 notes

Text

Zhejiang Guangxu numerical control equipment Co.,Ltd., established in 2011, is located in Hangzhou, the beautiful leisure capital of China, only 100 kilometers away from Port of Shanghai and Port of Ningbo. The company is a national high-tech enterprise integrating R&D, production, sales and service. The company has a self-built workshop of 15000 square meters and a team of nearly 200 people. We always adhere to the business philosophy of "faith and innovation" for 15 years, through the unremitting efforts of all employees, we have already established 7 branches in Shanghai, Hangzhou, Hefei etc., and also set up 4 super large equipment showing center with more than 1000 square meters area.

#cncmachining#cncmachine#cncmachinery#cncmanufacturing#cncmillingmachine#cncmilling#cncmachiningparts#cnctools#cncoperator#drilling

1 note

·

View note

Text

When CNC machining meets the FIFAU20WorldCup, imagine what interesting stories will happen? 🤭⚽️🏆

#Prototool #manufacturer #machining #cncmachining #cuttingtools #industry #quality #CNCMillingMachine #CNCMachining #CNCMachine #CNC #CNCMachinist #FresadoraCNC #MaquinistaCNC #UsinagemCNC #FraiseuseCNC #MachinisteCNC #CNClathe #CNCsystem #MetalProcessing #MachineParts #MillingCutter #Mold #Machine #productdesign #fifaworldcup

0 notes

Text

What You Should Know Before Buying a CNC Mill

Are you considering the purchase of a CNC (Computer Numerical Control) mill? With increasing options in precision machining and manufacturing, these specialized tools can provide powerful capabilities for detail-oriented work. Before taking the plunge into investing in a CNC mill, there are important points to consider such as cost and performance; understanding what is available on the market will help you make an informed decision. In this blog post, we'll explore some of the key features to look out for when buying a CNC mill so that you can find one that meets your needs while staying within budget.

What is a CNC Mill and how does it work? A CNC mill is a machine used in manufacturing that employs computer-controlled engineering to produce highly precise parts and products. CNC mills utilize instructions in the form of numerical software to control the cutting process of a workpiece. The machine typically consists of a bed, spindle, motor, cutting tools, and worktable. The cutting tools, which range in shape and size, rotate at high speeds, shaving away material from the workpiece to create the desired shape. The CNC mill allows for incredibly accurate and reliable production, making it ideal for creating complex and intricate parts for various industrial applications. The machine can be programmed to cut and shape a variety of materials, including metals, plastics, and composites, to create three-dimensional objects of nearly any shape. The CNC mill works by utilizing a combination of computer software and hardware to control the process. A CAD (computer-aided design) program creates a digital model of the part or product, which is then translated into a series of instructions in G-code. The G-code provides the instructions for the CNC mill to precisely move the cutting tools and worktable, ultimately creating the desired shape. Once the G-code is loaded into the CNC mill's computer, the machine begins cutting, precisely following the programmed instructions. The operator monitors the process, making adjustments as necessary to ensure the workpiece is produced to specifications. The CNC mill provides a highly automated and precise way of manufacturing complex parts and products. By using a combination of computer software and hardware, the machine produces accurate and reliable results, meeting the demands of modern manufacturing processes. What are the Different Types of CNC Mills and Their Uses? Computer Numerical Control (CNC) mills are essential tools in modern-day manufacturing. CNC mills operate with the use of software and computer programs, which allow them to execute precise cutting and shaping of materials. Different types of CNC mills are available, and they come with varying capabilities to perform diverse functions. Here are the different types of CNC mills and their uses: 1. Vertical Milling Machine: Vertical milling machines are designed to work with flat or rectangular metal surfaces. The spindle is positioned vertically, enabling a wide range of cutting possibilities such as drilling, tapping, and milling. This type of mill is perfect for manufacturing large quantities of flat or rectangular parts. 2. Horizontal Milling Machine: This mill is suitable for cutting and shaping materials from different angles. The spindle is positioned parallel to the worktable, allowing for precision cutting, drilling, and boring. Horizontal milling machines are excellent for producing parts in bulk quantities. 3. Bed Milling Machine: Bed milling machines have a vertically adjustable spindle that moves along the Z-axis. The bed can move along the X and Y-axis, allowing the machine to cut along different paths. Bed milling machines are ideal for creating parts with various shapes and sizes. 4. Turret Mill: A turret mill has a rotating spindle with a cutting tool at the end. This machine has a table that can be moved vertically and horizontally, giving it the capacity to cut and shape intricate forms. Turret mills are perfect for delicate jobs that need fewer cuts and a more precise finish. 5. CNC Router: CNC routers are designed to remove material from a workpiece, allowing it to be formed into a particular shape or pattern. It uses a rotating cylindrical tool that moves along multiple axes, providing precision cutting for objects like wooden decorative pieces, furniture parts, signboards, and architectural moldings. Different CNC mills are available for specific purposes, and the choice of the type depends on the materials, shapes, and productivity needs. While operating CNC mills may require skillful expertise, success hinges on selecting the right type of CNC machine for the particular task at hand. Benefits of Using a CNC Mill for Manufacturing Standard benefits: - Increased accuracy and precision of parts compared to manual methods. - Reduced production time with automated processes. - Ability to produce complex shapes with ease. Emotional benefits: - Feel confident in the quality of your products due to increased accuracy and precision. - Enjoy the satisfaction of creating high-quality parts quickly and efficiently using CNC Mill for Manufacturing technology. Advantages and Disadvantages of CNC Milling Computer Numerical Control (CNC) milling is a type of precision engineering process that utilizes computer-controlled cutting tools to remove material from the workpiece. CNC milling has become a popular manufacturing method due to its accuracy, efficiency, and versatility. However, just like any other manufacturing process, CNC milling has its own advantages and disadvantages that must be considered. Advantages: 1. Precision and Accuracy: CNC milling machines are capable of producing complex and intricate shapes with high precision and accuracy. This is because the cutting tools are guided by the computer, which ensures that the dimensions are consistent throughout the production process. 2. Flexibility: CNC milling machines are extremely versatile and can produce a wide range of products. It is possible to create different shapes, sizes, and forms without the need for different setups. 3. Consistency: CNC milling machines can produce identical parts with high consistency. This means that once the program for a particular part has been created, it can be easily replicated with the same level of accuracy every time. 4. Efficiency: CNC milling machines are highly efficient and can produce a high volume of parts within a short time. This helps to reduce production time and costs. 5. Automation: The use of CNC milling machines reduces the need for manual labor, which can lead to a reduction in costs and an increase in productivity. Disadvantages: 1. High Cost: CNC milling machines are expensive to purchase, install, and maintain. This makes it difficult for small businesses and startups to invest in this technology. 2. Complex Programming: CNC milling machines require complex programming to operate. This means that operators need to have specialized skills and knowledge to use them effectively. 3. Dependence on Electricity: CNC milling machines rely on electricity to operate. This means that power outages or fluctuations can result in downtime and production delays. 4. Limited Material Handling: CNC milling machines are limited in their ability to handle certain types of materials. This means that operators will need to use different machines for different materials, leading to increased costs and longer production times. 5. Lack of Flexibility: While CNC milling machines are highly flexible, they can be limited in their ability to produce certain types of shapes and materials. This means that some parts may need to be produced through other methods, leading to longer production times and increased costs. CNC milling has revolutionized the manufacturing industry by providing accurate and efficient production of various parts and products. However, it is important to consider the advantages and disadvantages of this technology before investing in it. By weighing these factors carefully, businesses can make informed decisions about whether CNC milling is the right choice for their production needs.

Factors to Consider When Purchasing a CNC Mill If you're looking to purchase a CNC mill, there are several factors that you should consider before making your final decision. A CNC mill is a computer-controlled machine that uses rotating tools to remove material from a workpiece. It offers many benefits, such as increased accuracy, repeatability, and automation, which improves efficiency and saves time. Here are the factors that you should take into account when purchasing a CNC mill. 1. Machine Size: The size of the CNC mill that you choose will depend on the size of the workpieces that you're planning to mill. If you're working with large pieces of material, you'll need a larger machine that can handle the size and weight of the workpiece. Conversely, if you're working with small pieces, you'll need a smaller machine to ensure accurate and precise cuts. 2. Machine Capability: Different CNC mills have varying capabilities. You should choose a machine that has the capabilities that you need for your specific application. Factors to consider include the number of axes, spindle speed, and cutting capacity. If you're working with complex parts that require multiple cutting operations, you'll need a machine that has a high number of axes to achieve the required cuts accurately. 3. Machine Accuracy: Precision and accuracy are critical in CNC milling. When purchasing a CNC mill, ensure that it has the required tolerances and accuracy level for your application. The accuracy of a CNC mill is usually measured in microns, so choose a machine with an accuracy level that meets your needs. 4. Machine Price: The price of a CNC mill can vary significantly depending on its capabilities, size, and accuracy. Ensure that you have a budget in mind before purchasing a machine, and choose a machine that offers the best value for your needs. Avoid choosing a machine based on price alone, as lower-priced machines may not have the required capabilities or accuracy levels. 5. Machine Support: When purchasing a CNC mill, ensure that the manufacturer offers excellent after-sales support, including installation, training, and maintenance. Ensure that the manufacturer has a good reputation in the market and is known for providing high-quality and reliable machines. Purchasing a CNC mill is a significant investment, and it's essential to consider several factors before making your final decision. Ensure that you choose a machine that has the required capabilities, accuracy, and support to meet your specific needs. How to Operate a CNC Mill Safely CNC mills are powerful machines that operate on computer-aided designs (CAD) to produce precise cuts and shapes in a variety of materials, including wood, metal, and plastics. However, the safety of the operator and those around the machine should always be a top priority. Here are some guidelines for operating a CNC mill safely: 1. Familiarize yourself with the machine: Before operating the mill, it is important to read and understand the owner's manual. Make sure you know the location of all the emergency buttons, switches, and other safety features. Additionally, make sure you are knowledgeable about the materials and tools that will be used during the milling process. 2. Wear appropriate safety gear: Before operating the CNC mill, it is essential to wear appropriate safety gear. This includes safety glasses, earplugs, gloves, and a dust mask to protect yourself from flying debris, loud noise, and harmful dust particles. 3. Secure the workpiece: Ensure that the workpiece is securely fastened to the mill bed before starting the milling process. Use clamps or other securing devices to prevent the workpiece from moving during the operation. 4. Program the CNC mill: A program must be written and loaded into the CNC machine before it can operate. Always double-check the program for errors before running the machine. Pay careful attention that the program does not exceed the limits of the machine’s settings. 5. Stand clear of the machine: Once the milling process begins, stand clear of the machine and never hold the material by hand. Never lean or get too close to the machine while it is operating, and always remove any loose clothing or jewelry. 6. Monitor the milling process closely: Always be vigilant while the machine is operating to ensure everything is running smoothly. Watch for unusual noises or vibrations, which may indicate something is wrong with the machine or tooling. 7. Clean the work area: Once the milling process is complete, ensure that the work area is clean, and the machine is properly turned off. Remove any remaining debris and relabel the program for future use. Taking the necessary safety precautions before and during milling is vital to reduce the risk of accidents and injury. By following these guidelines, you can ensure the safe and efficient operation of your CNC mill. Conclusion: When shopping for a CNC mill, aspiring machinists and hobbyists should put careful consideration into the budget, performance, brand, and model quality that best suits their specific needs. While this process may seem daunting at first, it ultimately ensures that buyers receive a machine that meets their desires in terms of speed, accuracy, available features and more. Furthermore, some manufacturers offer free trials on certain models to give interested customers an opportunity to test before they buy. Before making any actual purchase decisions or commitments with the seller, prospective buyers should always read reviews or contact other satisfied users for guidance. Ultimately, all those seeking a CNC mill should be dedicated to researching their options thoroughly in order to find the perfect model for their project needs! Read the full article

0 notes

Photo

Little upgrade time for my 2 @inceptionmachines low profile vice. The time saving and repeat accuracy of using a side stop is worth its weight In gold. #machiningcenter #instamachining #cncmachined #cncroutermachine #precisionmachining #intags #cncmachine #cncmachineshop #cncroutercutting #5axismachining #cncmachining #highspeedmachining #cncmachines #manualmachining #machiningporn #cncmillingmachine #cncrouters #cncrouter #cncrouterparts #enginemachining #woodmachining #cncmilling #mkmachining #machininglife #cncmachinetools #machining https://www.instagram.com/p/CgEx13ijM7d/?igshid=NGJjMDIxMWI=

#machiningcenter#instamachining#cncmachined#cncroutermachine#precisionmachining#intags#cncmachine#cncmachineshop#cncroutercutting#5axismachining#cncmachining#highspeedmachining#cncmachines#manualmachining#machiningporn#cncmillingmachine#cncrouters#cncrouter#cncrouterparts#enginemachining#woodmachining#cncmilling#mkmachining#machininglife#cncmachinetools#machining

0 notes

Text

Unlock the future of precision engineering with our Vertical CNC Milling Machine! Designed for high rigidity and stability, it features a precision three-axis feeding system and a high-speed spindle for unmatched accuracy. With a fast tool-changing mechanism, efficient cooling system, and advanced electric control, this machine is your ultimate partner in manufacturing excellence.

For more details, visit - https://www.yashmachine.com/product/cnc-milling-vmc/wm-series-vertical-cnc-milling-machine-2

0 notes

Text

Copper mold sample test made by CNC milling machine. #copper #cncmachine #cncmachining #cnc #machine #cncmachinist #cncmillingmachine #cncrouter #cncporn #cncmill #cncmilling #cncplasma #cnclathe #cnccutting #cnctools #machinist #tools #cncprogramming #mold #components #machinetools #jinsucnc #5axis #cncoperator #factory #machining #aluminum #instagram #fyp

#cnc milling#cncmachine#cncmachine tools#cncmachining#cncmill#cncrouter#cnctool#machine#cnc lathe#tool

6 notes

·

View notes

Video

youtube

#millingmachine #universalmillingmachine #VMC #CNCmillingmachine #X6140 ...

0 notes

Photo

Another Wood pattern milling CNC machine 2040 mmodel ready to ship 👉 Applications: wood and foam patterns. 🎉 CNC inquiry whatsapp 008618660407625 #foammodels #foampatterns #foammoulds #foundrypatterns #patternshop #foam #woodpatterns #woodmoulds #woodmodels #foundry #woodmodel #castmodels #castpatterns#cncmachines #cncrouters #cncroutermachines #cncmillingmachine #patternmaker https://www.instagram.com/p/B_CD1TyDmLB/?igshid=1seqaprb7cjya

#foammodels#foampatterns#foammoulds#foundrypatterns#patternshop#foam#woodpatterns#woodmoulds#woodmodels#foundry#woodmodel#castmodels#castpatterns#cncmachines#cncrouters#cncroutermachines#cncmillingmachine#patternmaker

0 notes

Text

Yash Machine Tools is your trusted partner for high-quality machine tools, offering a diverse range to meet the unique manufacturing needs of industries worldwide. From all kinds of lathe machines to CNC lathes, machining centers, and CNC milling machines, we deliver precision, durability, and efficiency. Explore our extensive product range and elevate your manufacturing process with cutting-edge technology designed for excellence.

For more details, visit - https://www.yashmachine.com/about-us

#YashMachineTools#cncmillingmachine#millingmachine#drillingmachine#cnclathemachine#LatheMachines#weldingmachine#DrillBitGrinder#chamfermachine#toolgrinder#sheetmetalmachine#sheetbendingmachine#pressbrake

0 notes