#MetalTesting

Explore tagged Tumblr posts

Text

The Vital Role of Metal Testing

Introduction

In a world driven by infrastructure, machinery, and manufacturing, metals are the backbone of countless industries — from aerospace and automotive to construction and energy. However, the reliability of these metals hinges on rigorous testing to ensure they meet stringent safety and performance standards. This is where metal testing services play a crucial role. By offering precise analysis and assessment, these services provide valuable insights into a material’s composition, durability, and integrity.

What Are Metal Testing Services?

Metal testing services involve a series of laboratory analyses and field assessments designed to determine the physical, mechanical, and chemical properties of metal components. These tests help verify whether a metal or alloy is suitable for its intended application and complies with regulatory or industry standards.

Testing is essential during various stages of a product’s lifecycle — design, manufacturing, quality control, failure analysis, and even recycling.

Key Types of Metal Testing

Chemical Analysis

Determines the elemental composition of metals and alloys.

Common methods include X-ray fluorescence (XRF), optical emission spectrometry (OES), and atomic absorption spectroscopy (AAS).

Mechanical Testing

Assesses a metal’s strength, ductility, hardness, and fatigue resistance.

Popular tests include tensile testing, impact testing (Charpy/Izod), and hardness testing (Brinell, Rockwell, Vickers).

Non-Destructive Testing (NDT)

Evaluates the material’s integrity without altering or damaging it.

Techniques include ultrasonic testing, magnetic particle inspection, radiographic (X-ray) testing, and dye penetrant inspection.

Corrosion Testing

Measures how a metal reacts to environmental elements over time.

Essential for industries exposed to harsh conditions such as marine, oil & gas, and chemical processing.

Microstructural Analysis

Uses microscopy to examine grain size, phase distribution, and inclusions within the metal.

Helps in understanding failures, welding defects, and heat treatment effectiveness.

Why Metal Testing Matters

Ensures Safety and Compliance: Testing helps prevent catastrophic failures in critical applications such as bridges, pipelines, or aircraft components.

Supports Quality Assurance: Manufacturers rely on test results to maintain consistent quality and traceability across production runs.

Reduces Downtime and Costs: Early detection of flaws can prevent costly recalls, repairs, or operational shutdowns.

Enhances Product Performance: Engineers use test data to refine designs and select the best materials for specific conditions.

Applications Across Industries

Metal testing services are vital to:

Aerospace: Verifying high-performance alloys for structural and engine parts.

Automotive: Ensuring crash-worthiness and fatigue resistance in frames and safety systems.

Construction: Assessing structural steel and reinforcing bars for buildings and bridges.

Oil & Gas: Testing pipeline materials for stress and corrosion resistance.

Medical Devices: Confirming the biocompatibility and durability of surgical tools and implants.

The Future of Metal Testing

With the rise of advanced materials and digital technologies, metal testing is evolving. Automation, AI-assisted data analysis, and 3D imaging are transforming how tests are conducted and interpreted. As industries demand higher precision and faster turnaround times, the metal testing field is embracing innovation to meet new challenges.

Conclusion

Metal testing services are more than just a checkpoint — they are a fundamental part of modern engineering and manufacturing. By providing critical data on material properties and performance, these services help industries build safer, stronger, and more reliable products. Whether it’s for ensuring a skyscraper stands tall or an aircraft soars safely, metal testing lays the foundation of trust in every structure and component.

0 notes

Text

Accuracy in Every Cut – Testron Specimen Milling Machine

Get unparalleled accuracy and productivity in specimen preparation with the Testron Specimen Milling Machine. With applications across automotive, aerospace, medical, and electronics industries, this tabletop CNC-controlled unit provides high-precision machining for prototyping, mass production, tool making, and custom part production.

Why Opt for Testron's Specimen Milling Machine?

CNC-Controlled Accuracy – Provides perfect and repeatable machining.

High-Speed Milling – Spindle speed adjustable up to 24,000 rpm for ultimate efficiency.

Advanced Cooling System – High-flow refrigeration lengthens machine life.

Improved Safety Features – Guard doors, safety locks, and pre-programmed machining programs.

Clean Work Area – The swarf extraction system provides uninterrupted operations.

Durable, precise, and efficient, the Testron Specimen Milling Machine is the best choice for manufacturers who seek perfection in every cut.

#CNCMillingMachine#SpecimenMillingMachine#MaterialTestingEquipment#PrecisionMilling#QualityControlEquipment#MetalTesting#LaboratoryEquipment#IndustrialMachinery#TestingSolutions#CNCTechnology

0 notes

Text

Ferro Silicon Testing: Ensuring Quality and Performance

Ferro Silicon Testing is essential to ensure the quality, composition, and performance of this crucial alloy used in steelmaking and foundries. Ferro silicon, a combination of iron and silicon, enhances strength, reduces oxidation, and improves overall metal properties.

Key Aspects of Ferro Silicon Testing

✔ Chemical Composition Analysis – Determines silicon, iron, and trace elements for quality control.

✔ Impurity Detection – Identifies unwanted elements affecting performance.

✔ Physical Property Testing – Examines density, granulation, and other characteristics.

✔ Spectrometric Analysis – Uses Optical Emission Spectroscopy (OES) and X-ray Fluorescence (XRF) for precise results.

Regular Ferro Silicon Testing ensures compliance with industry standards, enhances production efficiency, and improves final product reliability. Reliable testing methods help manufacturers maintain consistency and meet customer requirements.

For precise and accurate Ferro Silicon Testing, trust MPPL Standards for advanced and reliable testing solutions!

#FerroSiliconTesting#metaltesting#SteelQuality#AlloyAnalysis#QualityControl#industrialtesting#mpplstandards

0 notes

Text

Spectrometer for Steel Industries: Ensuring Quality and Precision

A Spectrometer for Steel Industries plays a vital role in analyzing metal composition, ensuring quality, and maintaining industry standards.

Key Benefits

✔ Accurate Metal Analysis – Detects elements in steel with high precision. ✔ Improves Quality Control – Ensures compliance with industry regulations. ✔ Enhances Efficiency – Speeds up production by providing instant results.

Steel manufacturers rely on spectrometers for reliable, efficient, and precise metal testing. For advanced and accurate spectrometry solutions, choose Metal Power – your trusted partner in metal analysis!

#metalanalysis#SteelQualityControl#steelmanufacturing#metaltesting#steel industry#metalpower#SpectrometerForSteelIndustries

0 notes

Text

Eddy Current Testing Machine-Magkraftndt

Magkraftndt Eddy Current Testing Machine uses electromagnetic induction to detect hidden flaws in metal materials. It’s quick, non-invasive, and accurate, helping ensure the quality and safety of components without causing any damage or affecting their performance.

#Magkraftndt#mpi machine#eddycurrenttestingmachine#nondestructivetesting#metaltesting#testingtechnology#magneticmahine#demagnetizermachine#magnafluxmpimachine#eddycurrentparticletestingmachine#mpimachinemanufacturer

0 notes

Text

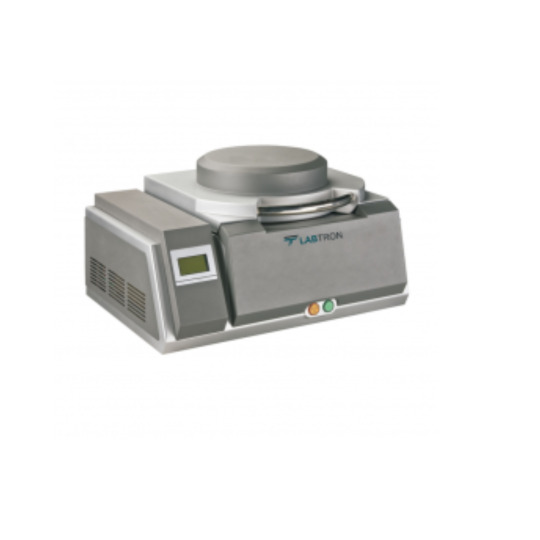

Labtron Alloy Analyzer is a top-tier XRF spectrometer offering unmatched precision. With a UHRD/SDD detector and vacuum system, it analyzes elements from Na to U, measuring 0.01-99.99%. Ideal for minerals, alloys, RoHS, plating thickness, and more. Precision 0.05%; Temp: 15-30°C.Precision Up to 0.05% . Precision Up to 0.05% .

0 notes

Text

¿Qué son las pruebas de análisis metalúrgico y por qué las necesito?

El análisis metalúrgico es el estudio de piezas metálicas o componentes metálicos en piezas no metálicas. Básicamente, describe la composición de sus piezas o componentes y determina su elegibilidad para el uso previsto. Esto se debe a que cuando un metal se trata térmicamente, su estructura puede cambiar. El análisis metalúrgico examina las piezas a nivel microscópico para asegurarse de que la composición sea correcta o para identificar el tipo de aleación que puede ser el componente.

El análisis metalúrgico está diseñado para detectar defectos internos o superficiales, evaluar la microestructura y garantizar que el metal cumpla con los estándares. El análisis se puede realizar antes o después de que falle una pieza y se encuentra entre los muchos servicios metalúrgicos en metaltest

0 notes

Text

Tailoring the Rockwell Hardness Tester to Your Specific Needs: Customizable Options from Multitek Technologies

Multitek Technologies offers customizable options to tailor the Rockwell Hardness Tester to specific needs, making it an excellent choice for those who require a customized solution

The company understands that every customer has unique requirements and offers customizable solutions to meet those needs

Customized Rockwell Hardness Testers from Multitek Technologies offer a range of benefits, including greater accuracy and reliability, improved efficiency, and reduced costs

Multitek Technologies can help customers customize their Rockwell Hardness Tester to meet their specific requirements, providing excellent support throughout the process

Also offer AMC services for all machines that developed at multitek Lab.

For more information or to place an order, feel free to navigation our website at https://www.multitek.in or give us a call at +91-7836009888 or direct drop an email at [email protected]

Learn more how Rockwell Hardness Tester Work : https://www.youtube.com/watch?v=tOTuNt141Kc&t=30s

Subscribe our YouTube Channel for getting updates: https://www.youtube.com/@multitektechnologies

#Rockwell #HardnessTester #IndustrialEquipment #MultitekTechnologies #HardnessTesterMachine #MechenicalEngineering #Metallurgy #Metrology #MetalEngineering #RockwellTester #MetalTesting #MetalHardnessTester #AutomotiveIndustry #Automobile #Forging

#Rockwell Hardness#Hardness Tester#Digital Rockwell#Hardness Tester Machine#Metallurgical Hardness Tester#Mechenical Equipment#Industrial Equipment

1 note

·

View note

Text

Best Testing Lab in India | Testing Lab in Delhi - Standard Testing Lab (STL) Standard Testing Laboratories Best Testing Lab in Delhi, India

standardtestinglab, Fertilizer Testing, Building Material Testing Lab, Pollution, and environment test, Rubber, and plastic test, Electrical Testing, NDT Testing, Soil Testing, Water and wastewater testing, Metal Testing, Toy Testing, NABL Testing Lab.etc

1 note

·

View note

Text

Torrent Laboratory explains why heavy metal toxicity testing is crucial for the environment

Heavy metal pollution, the negative impact to our water supplies, is a serious concern. The human origins of heavy metal pollution in water supplies is the result of numerous activities including our burning of fossil fuels, vehicle exhaust, mining, agricultural applications

Visit our website here :

https://torrentlab.com/why-is-heavy-metal-toxicity-testing-necessary-for-the-environment/

#torrent#torrentlaboratory#heavymetal#heavymetalpollution#heavymetaltesting#metaltesting#heavymetaltoxicity

0 notes

Photo

MicroAnalysis - Sample Preparation class

0 notes

Photo

Contact us to book elemental impurity analysis in your drug formulations. Our team is up-to-date with the current global regulatory standards for permitted levels of trace metals. Their expertise coupled with our state-of-the-art instruments ensures we provide you with accurate, high quality results. Impurities can lead to delays in development. It is essential to evaluate pharmaceutical products for high concentration of elemental impurities - trace metal/heavy metal testing of elements such as lead and arsenic that are significant toxicological concern. The FDA and ICH provide recommendations for testing impurities and acceptable impurity limits.

0 notes

Text

The Classical (Wet) Chemistry Laboratory

Classical Chemistry at MPPL uses precise wet chemical methods adhering to global standards for accurate metal and mineral analysis. Divided into Hot and Cold Zones, it ensures controlled environments for tasks like titrimetric and gravimetric analysis. Equipped with certified reference materials and expert chemists, the lab guarantees high reliability, validated methods, and compliance with industry protocols.

0 notes

Text

Metal Testing Equipment Supplier: Ensuring Accuracy & Quality

Reliable metal testing equipment is crucial for industries like manufacturing, automotive, and construction. A trusted metal testing equipment supplier provides advanced tools to analyze material composition, strength, and quality.

Key Offerings of a Metal Testing Equipment Supplier

Spectrometers – For precise chemical analysis of metals.

Hardness Testers – To measure the durability of metal surfaces.

XRF Analyzers – For non-destructive elemental analysis.

Ultrasonic Testers – To detect internal flaws and inconsistencies.

Why Choose a Reliable Supplier?

High-quality, calibrated equipment for accurate results.

Technical support and after-sales service.

Compliance with industry standards.

Choosing the right supplier ensures efficient and reliable metal testing, helping businesses maintain high-quality production standards. Metal Power offers advanced and accurate metal testing solutions to meet your industry needs. Contact us today to find the best testing equipment for your requirements!

0 notes

Text

PLC Controlled Magnaflux MPI Machine-Magkraftndt

A PLC-controlled Magnaflux MPI machine uses magnetic particle inspection (MPI) to find surface defects in metal parts. The PLC automates the process, providing precise control, better efficiency, and consistent flaw detection, which ultimately improves quality control in manufacturing.

#magkraftndt#mpi machine#Plccontrolledmagnafluxmpimachine#magneticparticletestingmachine#aerospaceinspection#metaltesting#magneticmachine#eddycurrenttestingmachine#demagnetizermachine#mpimachinemanufacturer.

0 notes

Photo

SGNCO is involved in performing the quality testing of metal, non-metal to various kinds of Alloy Testing to meet the specifications of its intended use. Our quality control and pre-shipment inspection processes work towards improving the efficiency of the production stages, enabling manufacturers to compete better in the industry.

0 notes