#CNCparts

Photo

#cse • @kaylaperformance Kaylaperformance for NSK musclemotorcycle and dynamite garage at motorbike expo Verona 2023 proudly made in Italy 🇮🇹 #kaylaperformance #performancepartharley# harleyparts #cncparts #fatbobworld #clubstyle_m8 #clubstyle_europe #clubstyle #fxlrs #fxlrst #fxfbs #performancesoftail #verona #harley #softailgram #softailm8 #vtwinvisionary #harleydavidson #harleydavidsonlowriders #fxlrs_page #harleylowriders #europe #harleycustomparts #clubstylesoftail #lowrider_s #harleydavidsondaily #motorbikeexpo #lowriderst #ohlinsharleydavidson https://www.instagram.com/p/CoA-zzWIxxd/?igshid=NGJjMDIxMWI=

#cse#kaylaperformance#performancepartharley#cncparts#fatbobworld#clubstyle_m8#clubstyle_europe#clubstyle#fxlrs#fxlrst#fxfbs#performancesoftail#verona#harley#softailgram#softailm8#vtwinvisionary#harleydavidson#harleydavidsonlowriders#fxlrs_page#harleylowriders#europe#harleycustomparts#clubstylesoftail#lowrider_s#harleydavidsondaily#motorbikeexpo#lowriderst#ohlinsharleydavidson

23 notes

·

View notes

Video

youtube

KD Hardware offers multi-axis machining services, specializing in precision parts production with complex geometries. Their advanced equipment allows simultaneous movement across multiple axes, ensuring high accuracy and efficiency. This service is ideal for industries requiring intricate components, such as aerospace, automotive, and medical.

Link: https://kd-cncmachining.com/Services/Multi-axis-linkage-machining-service.html

Contact: [email protected]

#youtube#5axismachining#multiaxismachining#multiaxiscncmachining#fiveaxismachining#multiaxiscnc#accuratemachining#precisionmachining#CNCmilling#millling#cncparts#3axiscncmachining#turningmachining

0 notes

Text

Precision Sheet Metal Manufacturing: Future Directions in the Industry

As the global market grows and evolves, the demand for product customization has intensified. Many leading companies are concentrating on their core areas—brand management, product design, and marketing—while outsourcing non-core functions to specialized manufacturing service providers. This strategy has fostered the emergence of manufacturing service companies, such as Foxconn and Flextronics, which are now prominent players in the global manufacturing landscape.

Precision metal components have become indispensable in these outsourced products, playing a crucial role in both the aesthetics and functionality of end products. With rising precision requirements, manufacturing service providers are increasingly specializing in precision manufacturing, leveraging their technological and cost advantages. Even industry giants like Foxconn and Flextronics rely on these specialized firms for manufacturing and technical support, thereby enhancing their overall competitiveness and shaping China's precision metal manufacturing sector.

One key area of focus within this industry is precision sheet metal manufacturing, which is essential for delivering high-quality, accurate metal components. This process utilizes CNC and sheet metal technologies, employing various cold-working techniques such as cutting, stamping, bending, welding, riveting, assembling, and forming to process thin metal sheets (typically less than 6mm thick) to meet stringent customer requirements for product accuracy and functionality.

Compared to traditional sheet metal manufacturing, precision sheet metal fabrication offers several distinct advantages:

High Precision Requirements for Downstream Industries Precision sheet metal services cater to high-tech sectors such as telecommunications, aerospace, solar energy, and semiconductors, where precision is critical. For instance, the accuracy of communication base station antennas directly affects signal transmission and reception, while solar power systems require precise metal components to ensure optimal light concentration and photoelectric conversion efficiency. For example, a 300-watt solar panel demands a backplate thickness tolerance within 0.5% and no deformation under 4000-volt high-pressure tests. Additionally, these industries impose stringent requirements on the visual quality of products, including color consistency and smoothness of lines.

Need for High-Precision Equipment and Molds Precision manufacturing demands advanced equipment, such as flexible manufacturing systems, CNC punching machines, CNC bending machines, friction welding equipment, and robots for assembly and welding. The automation and precision of these devices ensure the accuracy of sheet metal products. For example, CNC punching machines can maintain a forming error of ±1.5mm for plates measuring 1.1m x 1.4m. Mold accuracy is also crucial, typically requiring precision within microns (0.01mm).

Focus on Accurate Unfolding Processes Precision sheet metal manufacturing utilizes cutting-edge tools like laser cutters and CNC bending machines, revolutionizing traditional processing methods. Traditionally, sheets were roughly unfolded before bending, then resized and further processed, leading to inefficiencies and material waste. In contrast, precision sheet metal fabrication involves precise unfolding, cutting all shapes, holes, and slots before bending, which enhances efficiency and quality but demands higher precision in unfolding diagrams.

High-Quality Production Environment A high-quality production environment is essential for ensuring the reliability and stability of precision sheet metal products. Precision equipment is sensitive to temperature changes, which can affect device accuracy and, consequently, product quality. Furthermore, downstream industries like telecommunications and solar energy require strict controls on carbon emissions, airborne dust levels, and equipment insulation to ensure stable operation of the final products.

As a professional in the field, I believe that the evolution of precision sheet metal manufacturing reflects broader trends in the industry. The increasing demand for high precision, coupled with advancements in technology, is driving the sector towards greater specialization and innovation. This focus on precision not only enhances product quality but also strengthens the competitive edge of manufacturing service providers globally.

#CNCmachining#CNCmanufacturing#PrecisionMachining#CNCtechnology#MachineShop#CustomMachining#CNCparts#MetalFabrication#CNCengineering

1 note

·

View note

Text

Hi, are you interested in hardware parts? We can provid high-quality products and customer service. We have advanced equipments and perfect supporting facilities. If you want to know our items please visite our website http://tiyoo.cn/.

0 notes

Text

"Glowing Secrets of CNC Machining: Revealing the Special Tools for Metal Part Brightening"

Dive into the enchanting realm of CNC machining as we unveil the magical tools and processes that bring sheer radiance to metal components. Follow our blog to discover how these exceptional cutting tools transform ordinary parts into gleaming treasures. #CNCmachining #MetalBrightening #MagicalTools

#CNCmachining#MetalBrightening#MagicalTools#cncmilling#productdevelopment#instamachinist#autodesk#cncparts#innovation

0 notes

Photo

Custom Machined Titanium Parts

These are custom machined titanium parts, produced as per customer’s drawings.

They can be made from pure titanium or titanium alloys.

0 notes

Video

youtube

Custom Stainless Steel Hex Bolts

#hexbolts #CNCMachinedbolts #hexscrews #slothexbolts #cnchexbolts #customhexagonscrews #customscrews #cncscrews #cncparts #Mechanicalparts #autoparts #Automobileparts #precisionhexbolts #boltsinspection #boltsmanufacturers #CHE #Fastener

Email:[email protected]

1 note

·

View note

Text

Custom Stainless Steel CNC Machine Parts

We are not only the fastest manufacturing supplier to process prototypes, but also the most reliable source of parts produced on demand.Why is this important? From proof-of-concept to short-term production, you have a single source of suppliers.

In addition to tighter tolerances, hardware assembly, first piece inspection(FAI)reporting, material certification, and additional polishing options such as anodizing and chromate plating, we offer more competitive prices in higher quantities.It is a CNC machining designed around your project needs-whether it is prototyping or production.

Item name: Stainless Steel Parts

Material: plastic and metal

Tolerance : ±0.1 mm

Product Size: Customaziable

Process way: CNC Machining

Surface Treatment: Polish, Sandblast

Devery Time: 6 days

Available 3D files format: Pro/E, Solidworks, Unigraphics, Catia, Auto CAD, *.igs, *.stp, *.stl, *.x-t

Payment term: T/ T ( 50% Prepaid, pay the balance before shipment) , Paypal, L/C, Western Union)

Shenzhen Hengzhi Model Design Co., Ltd

4 reasons to turn to a prototype lab for machining production parts

1. Reduce the price of a single piece, increase the quantity

Reduce part costs when you order mass-produced parts.

2. Inspection Reports and Certifications

Get additional quality assurance from traditional FAI reports, CoC documents and AS9100 certifications.

3. More finishing options

Choose from complete parts from one supplier for anodizing and chromate plating.

4. Supply Chain Flexibility

Order only the quantity you need per month (starting with quantity 15) to avoid storage fees.

Welcome to contact me!! Leave your info for the design price!!

#cncparts#3dprinting#customparts#stainlesssteelparts#cncmachineparts#cncmachine#customdesign#designprice

2 notes

·

View notes

Link

#cncmachining#CNCParts#industrial#MachineParts#CNC Turned parts#CNC Milling Parts#CNC Spare Parts#Aluminium CNC Parts#CNC Auto Parts#Aluminium#Steel#Brass#copper#uk

1 note

·

View note

Photo

#cse • @kaylaperformance Naked 🏁 #kaylaperformance #performancepartharley# harleyparts #cncparts #fatbobworld #clubstyle_m8 #clubstyle_europe #clubstyle #fxlrs #fxlrst #fxfbs #performancesoftail #performanceharley #harley #softailgram #softailm8 #m8 #harleydavidson #harleydavidsonlowriders #fxlrs_page #harleylowriders #harleycustom #harleycustomparts #clubstylesoftail #lowrider_s #harleydavidsondaily #europe #lowriderst #ohlinsharleydavidson https://www.instagram.com/p/CoPCBPgo4nY/?igshid=NGJjMDIxMWI=

#cse#kaylaperformance#performancepartharley#cncparts#fatbobworld#clubstyle_m8#clubstyle_europe#clubstyle#fxlrs#fxlrst#fxfbs#performancesoftail#performanceharley#harley#softailgram#softailm8#m8#harleydavidson#harleydavidsonlowriders#fxlrs_page#harleylowriders#harleycustom#harleycustomparts#clubstylesoftail#lowrider_s#harleydavidsondaily#europe#lowriderst#ohlinsharleydavidson

9 notes

·

View notes

Video

youtube

Milling and Turning Services—KD Hardware

Welcome to consult KD Hardware related services!

📞 Contact us: [email protected]

🌐 Visit our website: www.kd-cncmachining.com

#youtube#turningmachining#cncturningservice#cncturning#largecncturning#custommachiningswissmachining#cncparts#cncpartsmanufacturing#swisscncmachining#swissscrewmachining#cncworking#turninginmachining#turningcomponents#cncmillingturning#cncmachining

0 notes

Text

1 note

·

View note

Text

Mass custom production of hardware parts🥰🥰🥰

WHATSAPP:+86 18307397759

0 notes

Text

CNC Machined Titanium Parts

This is customized CNC machined Titanium parts,it is made from forged titanium Grade 5 blocks and then CNC turned.

https://www.hosnti.com/custom-cnc-titanium-parts/

CNC Machined Titanium Parts

0 notes

Video

youtube

Dacromet Self-Locking Barrel Nuts

E-mail:[email protected]

#barrelnuts#sleevenuts#locknuts#sleeveselflocknuts#customnuts#flatheadrivetnuts#chinahexsocketbarrelnuts#carbonsteellocknuts#hexnuts#sleeveinsertnuts#cncparts#autoparts#titaniumbarrelnuts#Chuanghefastener

0 notes

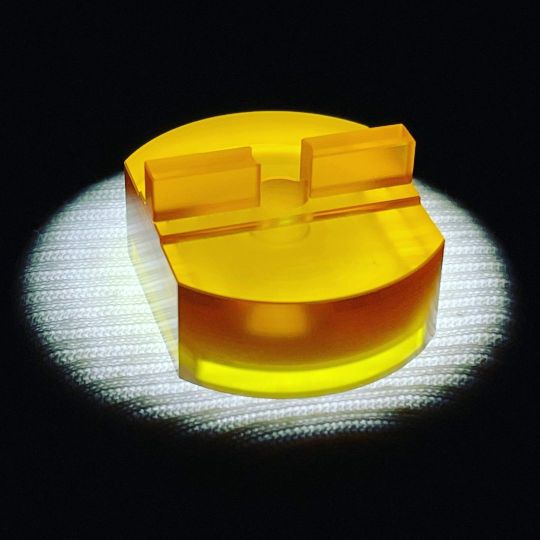

Photo

Did a job for a local company here in Modesto called SunOpta, Inc. They are a leading global company focused on natural food, indredient sourcing, organic food, and specialty foods. I was provided the opportunity and introduced to Senior Plant Engineer, Patrick Fischer via @sonnygirlcnc with Rexel Automation Solutions. There are many OEM parts that cannot be sourced because of global supply chain issues for their automated palletizing systems. Even if all OEM parts were available for them to order, most don’t last long from the 24-7 production stress and environmental factors. So @rpmcorporation is stepping in to help reverse engineer them with a more robust goal and better choice of materials for the different environments they are in. The part in my post is a steam regulating valve key, machined from Ultem 1000 that is part of a bigger housing assembly for their CIP process. Patrick has waited over 2 months for the original OEM manufacturer to get him replacements of this exact part or an ETA on delivery with zero luck. So with the introduction from @sonnygirlcnc, we were able to get our foot in the door and after today’s delivery of parts/plant tour, their go to shop is officially @rpmcorporation. We also did a Teflon version so they could test which material will hold up better though both are rated well for such high temps from something like steam. Appreciation to both Sonny and Patrick for the opportunity to earn the business of such a huge company, SunOpta, Inc. . . . . #automation #rexel #cip #automatedpackaging #cipsolutions #tertrapak #automationsolutions #palletizer #systemintegration #cleaninprogress #sunopta #modestofoodproduction #localsourcing #americanmade #ultem #teflon #reverseengineering #cncmachining #cncdesign #cncparts #chemicalenvironments (at Sunopta Aseptic) https://www.instagram.com/p/CVReoC5FXgM/?utm_medium=tumblr

#automation#rexel#cip#automatedpackaging#cipsolutions#tertrapak#automationsolutions#palletizer#systemintegration#cleaninprogress#sunopta#modestofoodproduction#localsourcing#americanmade#ultem#teflon#reverseengineering#cncmachining#cncdesign#cncparts#chemicalenvironments

0 notes