#Capsule Blistering Machine

Explore tagged Tumblr posts

Text

Tablet Capsule Blister Packing Machine

youtube

Tablet Blister Packing Machine (capsule blistering machine) including pharmaceutical blistering machine is cGMP machine uses for packing of smaller and regular shaped solid articles such as pharmaceutical tablets, capsules, draggers etc., in blister packs using PVC-Alu packaging materials. The Blister Forming, Product Feeding and Sealing operations are continuous by rotary motion while the indexing and punching operations are of intermittent reciprocating motion. The output capacity of the machine depends on the product characteristics and thus on the type of feeding device. In case of slightly curved or flat tablets up to 10mm diameter an output of 240 packs per minute can be optimally achieved.

Adinath is one of the leading blister packaging machinery manufacturers in India offers complete range of single-track blistering machine and double track blistering machine. These machines use for packaging of tablets in blisters and capsules in blisters. It is also called and Tablet Blister Packing Machine and Capsule Blister Packing Machine.

0 notes

Text

How Automated Pharmaceutical Packaging Machines Are Revolutionizing Drug Production in India

The pharma industry in India is now building a global success story. Ranked third in volume and 14th in value, India is a pharmaceutical powerhouse that is currently supplying over 50% of the global demand for vaccines and another significant share of generic drugs worldwide. As this sector accelerates, so does the demand for speed, safety, precision, and smarter medicine packaging.

This has, in turn, created a higher demand for the pharmaceutical packaging machines. These machines are the unsung heroes that work quietly behind the scenes to protect drugs, extend shelf life, prevent contamination, and meet compliance standards.

In today’s fiercely moderated and regulated, export-driven Indian pharma market, packaging isn’t just a final step; it is a frontline warrior ensuring brand credibility and patient safety.

To maintain this demand, manual packaging has become passé. Now, automated packaging solutions are continuously transforming how medicines are being prepared for the market, with benefits spanning across hygiene, output, traceability, and efficiency. At the heart of this shift is Nichrome, a trusted packaging machine manufacturer and supplier, known for engineering innovation and providing consistent support to the pharmaceutical sector.

From tablets and capsules to ointments and sachets, Nichrome machines offer precision, speed, and smart packaging technology that meets today’s needs and foresees tomorrow’s challenges.

Pharmaceutical Packaging – The Protective Layer of Trust

It’s not just about putting pills in a box when it comes to pharmaceutical packaging. It is about protecting lives, as it plays a crucial role in ensuring the safety, stability, and usability of medicines across their lifecycle, from manufacturing to consumption.

Why is Pharmaceutical Packaging so important?

Contamination Prevention – Safeguards from moisture, air, light, and microbial exposure that can degrade the product.

Accurate Dosage – Maintains the exact amount of dosage per unit, especially vital in tablet packaging, capsule packaging, and sachet packaging.

Enhances Tamper Evidence – Helps in building consumer trust by offering easily visible signs if a product has been previously opened or altered.

Patient Compliance – Allows for clear instructions, proper labelling and smart packaging that can help patients/medical professionals follow the correct dosages schedules.

Extends Shelf Life – Preserves product efficacy and safety over time, especially for sensitive formulations like suspensions and creams.

Traceability Support – Helps trace products through the supply chain, vital for recalls, audits, and regulatory approvals.

Global Compliance – Supports adherence to multiple medical norms like Good Manufacturing Practices (GMP), WHO, and FDA guidelines that are necessary for domestic and export markets.

What products need specialised packaging?

Tablets and capsules

Powders (e.g., ORS, nutritional supplements)

Liquids and suspensions

Ointments and gels

Single-use doses via sachets, stick packs, or tubes

What are the hidden risks of poor packaging?

Inaccurate labelling can cause wrong dosages

Damaged packs can result in contaminated products

Leaky containers cause reduced efficacy

Regulatory penalties or market bans can occur from even a single non-compliance

Robust medicine packaging isn’t just good practice; it is a critical business strategy in today’s competitive market. When done right, it not only protects the product but also your brand and, most importantly, your patients.

Manual Drug Packaging Challenges: Why can’t it keep up?

At first glance, manual drug packaging can appear to be a very cost-effective and simple option, especially for startups and small-scale pharma units. It offers a low initial investment and doesn’t require any complex machinery or specialised training, but beneath the surface, the limitations of manual processes have revealed themselves quickly. Let’s tally up the pros with the cons:

Pros:

Low upfront investments make manual drug packaging suitable for businesses with tight budgets

With Simple operations, it is ideal for small-scale, low-volume production runs

Cons:

Prone to human errors, in dosage, labelling and sealing accuracy

Time-consuming and inefficient, causing slower output per batch

Labour-intensive, as it requires more manpower, increasing operational costs

Inconsistent results with higher rejection rates due to non-uniform packaging

Since it is difficult to maintain hygiene standards manually, there are greater contamination risks

Non-compliance issues, since it is harder to align with GMP, WHO, and FDA regulations

No traceability to support serialization or batch tracking for exports

Not feasible for growing production needs with limited scalability options

In the highly competitive and regulated pharma industry, manual methods often fall short. As global markets demand faster turnarounds and tighter compliance, manual packaging becomes a bottleneck rather than a solution.

Therefore, today, upgrading to automated pharmaceutical packaging machines isn’t just about improving productivity; it is about staying relevant, reliable, and ready for the future.

Rise of Automated Pharmaceutical Packaging Machines: Making precision meet progress

The days of packaging being manual, repetitive, and slow-moving are long gone. Today, automated pharmaceutical packaging machines have vastly redefined the landscape by ushering in an era where speed meets precision and compliance meets convenience.

These are more than your average machines; they are almost like intelligent packaging companions, outfitted with robotics, vision sensors, servo-driven controls, and data-enabled diagnostics. These machines don’t just pack; they inspect, adjust, align, and ensure that every pack meets the gold standards of pharma packaging.

Why is automation winning the race?

High-speed packaging - thousands of units are sealed, sorted, and labelled in minutes, without a dip in quality.

Precision dispensing - minimal deviation guarantees uniformity in dosage and weight

Reduction of manual contact - improves hygiene and eliminates the risk of contamination—crucial in GMP-compliant environments.

Integration with vision systems, serialisation, and barcoding ensures traceability, anti-counterfeiting, and regulatory compliance.

From WHO to FDA norms, automated systems make it easier to tick every compliance checkbox.

What about the challenges?

Automation does require a higher initial investment, along with skilled personnel for operating and maintaining these machines. However, these are quickly outweighed by the benefits like reduced wastage, higher output, minimal rejections, and audit-readiness.

Whether you are looking at the blister packaging machine, a capsule counting and filling machine, or a sachet packaging machine, automation has now become essential. And with our advanced packaging technology, India’s pharma industry is stepping confidently into the future.

Nichrome’s Pharma Packaging Machines: Making innovation meet implementation

At Nichrome, we believe that pharmaceutical packaging is more than just a process; it is a promise. For over 4 decades, we’ve led the charge in India packaging innovation, delivering custom pharmaceutical packaging machines that combine speed, accuracy, and hygiene with unmatched reliability.

Our deep domain expertise in the pharmaceutical sector allows us to offer machines that can easily cater to every stage of medicine packaging, be it powders, liquids, tablets, or ointments. Each of our machines is thoughtfully engineered, keeping the industry standards and guidelines in mind.

Let’s take a closer look at our specialised lineup:

Blister Packaging Machine: This high-speed machine delivers precision cavity filling, robust sealing, and minimal material wastage, making it ideal for tablet packaging and capsule packaging. Features include servo-based indexing, inline coding, and an easy-to-clean structure, making it perfect for both large-scale and contract manufacturing units.

Sachet Packaging Machines (Multilane Stick Pack Machine): A go-to solution for ORS powders, rehydration salts, protein supplements, and liquid suspensions. It is available in 3-side seal, 4-side seal, and stick pack formats. These machines offer flexibility with high output, making them ideal for single-dose sachets that demand accuracy and hygiene.

Tube Filling Machine: Built for creams, gels, and ointments, this machine ensures air-tight fills without leaks or dosage variation. Its precise fill control, minimal changeover time, and robust build make it a favourite for pharma and personal care applications.

Capsule Counting and Filling Machine: It features smart rejection systems, sensor-based counting, and dust-free operation, with its high-speed operations. Excellent for packaging and compliance with serialization norms.

Powder & Liquid Filling Machines: Our servo-based auger fillers and volumetric liquid fillers offer high-precision fills with reduced wastage. They are designed for consistent fill weight and tamper-proof packaging of syrups, suspensions, and dry powders.

Each machine is compact, operator-friendly, and equipped with smart diagnostics. Plus, with our strong post-sales support, remote monitoring capabilities, and nationwide service network, seamless operations for you are always assured. When it comes to drug packaging India, relies on Nichrome packaging machines that are the prescription for performance, precision, and peace of mind.

Time to Consider Automatic Packaging Machines: The right fit for you

Now you may still wonder whether or not our state-of-the-art automatic packaging machines are the right fit for you or not. Well, let’s quickly break it down for you:

Startups & SMEs: Manual machines may be working fine for you now, but they will limit your scale. A good auto packaging machine with modular upgrades can easily give the head start that your business needs.

Mid to Large Pharma Units: To meet the export norms, improve travelability, reduce manual dependency, automating with pharmaceutical packaging machines is essential.

Key Decision Factors:

Projected production volumes

Regulatory compliance needs

Quality control requirements

Skilled manpower availability

With pharma automation, even niche manufacturers can achieve big-league efficiency.

Nichrome Advantage: Powering Smart Packaging with Real-time Intelligence

As pharmaceutical packaging embraces the digital shift, Nichrome Data Over Internet (NDOIT) emerges as a game-changer, fusing IoT capabilities with cloud-based intelligence to power smarter operations. Here's how NDOIT is revolutionising the landscape:

Real-time Data Logging - Enables instant data collection from packaging lines—monitor performance, uptime, and quality metrics in real-time.

Cloud-based Connectivity - Uses public, private, or hybrid cloud models to store and analyse data—accessible from anywhere, anytime.

Remote Monitoring & Predictive Maintenance - Helps detect issues before they become breakdowns—boosting uptime, reducing rejections, and enhancing machine longevity.

With NDOIT, Nichrome transforms every packaging machine into a smart, self-aware unit, equipping pharmaceutical companies with the tools to scale securely, operate efficiently, and lead confidently in a data-driven world.

Conclusion: Wrapping the future right with automation

The future of pharma is fast, smart, and safe; therefore, if you are in pharma production, your packaging line should be the strongest link and not the weakest.

As automated pharmaceutical packaging machines are powering this revolution, robust drug packaging machines have become a strategic investment. So, are you ready to upgrade your pharmaceutical packaging?

Contact us today to explore our cutting-edge automated packaging machines because with Nichrome machines, you don’t just automate—you elevate.Let’s take your packaging from manual to magnificent—because at Nichrome, we don’t just pack, we package the future.

#pharmaceutical packaging machines#automated packaging solutions#packaging machine manufacturer#automated pharmaceutical packaging machines#blister packaging machine#capsule counting and filling machine#sachet packaging machine#Tube Filling Machine#Powder & Liquid Filling Machines#automatic packaging machines#Nichrome Data Over Internet (NDOIT)

0 notes

Text

Advanced Blister Packing Machines South Africa – Powered by Pharmateq

Blister packing machines play a critical role in the pharmaceutical, nutraceutical, and medical device industries, offering safe, tamper-evident packaging for a wide range of products. In South Africa, the demand for reliable and efficient blister packing technology is steadily rising, driven by increasing regulatory requirements and the need for enhanced product integrity. Pharmateq, a leading provider in this space, supplies state-of-the-art blister packing machines that are engineered for performance, precision, and compliance with global standards.

Pharmateq’s Blister Packing Machines South Africa are designed with modern production environments in mind. Whether it’s for small-batch runs or high-volume production lines, these machines deliver consistent sealing, precise product placement, and minimal material wastage. The company offers both semi-automatic and fully automatic solutions, tailored to meet the needs of local manufacturers seeking flexibility, scalability, and automation in their packaging processes. Each system is supported by comprehensive training and after-sales service, ensuring smooth integration and long-term reliability.

Choosing Pharmateq means investing in innovation and dependability. The company’s commitment to quality and customer satisfaction has made it a trusted name for blister packing machines across South Africa. With a strong understanding of regional market dynamics and a focus on GMP-compliant technology, Pharmateq helps clients streamline their packaging operations while maintaining high safety and hygiene standards. For businesses looking to upgrade their packaging infrastructure, Pharmateq offers a competitive edge through expertise, cutting-edge machinery, and exceptional service.

#pharmaceutical machinery supplier#capsule filling machines South Africa#tablet press machines South Africa#lab-scale tablet presses#blister packing machines South Africa#pharmaceutical powder granulators#tablet counting machines South Africa#fluid bed dryers pharma#capsule polishing machines#Pharmateq

1 note

·

View note

Text

Are you looking for blister packing machines? V.M. Services offers advanced solutions for pharmaceutical and industrial packaging needs. From manual blister packing machines to tablet and capsule blister packing machines, the company is among the trusted blister packing machine manufacturers in India. Check out affordable blister packing machine prices and efficient, user-friendly systems customized for tablets, capsules, and small-batch productions. Visit our website - https://www.vmservices.co.in/ or call 9825413488 for blister packing machines in India.

0 notes

Text

Super Monkey Ball: Banana Rumble details playable characters, customization

From Gematsu

SEGA has released a new trailer, information, and screenshots for Super Monkey Ball: Banana Rumble introducing the game’s playable characters and customization.

Get the details below.

Playable Characters

AiAi – The carefree and well-rounded commander-in-chimp of the group. When he’s not busy playing around, AiAi loves to kick back, relax, and enjoy a delicious banana or two, or three.

MeeMee – Always positive, kind-hearted, and reliable. MeeMee is the heart of the team who is always at the ready to help those in need. Her ability to stop on a dime makes her ideal for navigating the trickiest of courses.

Baby – Highly intelligent for his age, Baby is a cool monkey who uses his nimble size and fast reflexes to deal with complicated courses.

GonGon – A former rival, now best friend to AiAi training to become the strongest ape in the world. Using his incredible power, he can barrel through all obstacles and opponents who dare stand in his way.

YanYan – Furry-ously fast and fearless, yet a little shy, this fun-loving lemur is a martial arts expert who was trained by her father, the strongest ape in the world.

Doctor – A scatterbrain known for his crazy inventions, nothing, not even amnesia, can slow this super smart simian down. His expertise in the Spin Dash will leave all opponents as dazed as he looks.

Palette – The newest member of the bunch, Palette is an adventurer who encounters AiAi and the gang and convinces them to join her on a journey to find the Legendary Banana. Her lightning quick speed and spin dash abilities help her create shortcuts and clear courses at a blistering pace.

In Adventure Mode, players will also meet Fes, Tee, and Val, members of the infamous Gala family and treasure hunters with a penchant for seeking rare and valuable artifacts. The trio have set their sights on the relics that AiAi and his gang are working tirelessly to collect, in an epic race to locate the greatest treasure of them all: the Legendary Banana.

Customization Galore

Super Monkey Ball: Banana Rumble introduces a bunch of customization items for players to choose from, with more than 300 items ready to be unlocked including headwear, clothing, accessories—even their monkey balls. Many of these items can be purchased in the in-game shop using points earned from playing the game regularly, either locally or online. Additionally, those who play Battle Mode online against random opponents can earn a daily bonus through Lucky Monkey Lottery! This virtual capsule machine allows players to draw a single ball containing one of dozens of unique items, with more items to be added in the future. There are even special seasonal items planned, with exciting surprises planned throughout the year. Finally, when you’re ready to make a mark, try out the in-game Photo Mode to snap a picture and show off your style with friends!

Super Monkey Ball: Banana Rumble is due out for Switch on June 25.

Watch the trailer below. View the screenshots at the gallery.

Characters Trailer

youtube

7 notes

·

View notes

Text

Top Blister and Packaging Tray Manufacturer in India

If you’re looking for reliable and high-quality packaging solutions in India, Uno Plast is the name you can trust. We specialize in creating blister packaging trays and custom plastic trays that cater to a wide range of industries. With years of experience, modern technology, and a commitment to customer satisfaction, we provide packaging options that are not just functional but also visually appealing. Whether you need standard designs or customized trays, we ensure that every product meets your unique needs.

Blister Packaging: Protect and Display with Confidence

Blister packaging is one of the most effective ways to protect and showcase products. At Uno Plast, we use top-grade materials like HIPS, PET, and PVC to create packaging that’s durable and reliable. Our blister packs are widely used across industries such as pharmaceuticals, electronics, cosmetics, and food.

Here’s what makes our blister packaging a great choice:

Keeps Products Safe: It protects items from dust, moisture, and damage, keeping them in perfect condition.

Custom Fit: We create blister packs in various shapes, sizes, and colors to fit your product perfectly.

Eco-Friendly Options: Materials like PET and PVC are recyclable, ensuring we do our part for the environment.

Our popular blister packaging options include:

Clamshell Blisters: Ideal for tamper-proof packaging.

Slide Blisters: Great for small items like cosmetics or tools.

Two-Part Blisters: Easy to assemble and securely seal products.

Plastic Trays: Versatile and Durable Packaging

Our plastic trays are designed to be practical, durable, and visually appealing. Whether you’re packaging chocolates, sweets, or industrial parts, Uno Plast’s trays deliver on both quality and functionality.

We use food-grade materials to ensure safety for edible products while maintaining high standards for all types of trays. Here’s why our plastic trays stand out:

Custom Designs: We create trays that match the exact dimensions of your products.

Enhances Presentation: Sleek and clean designs improve the overall look of your packaging.

Built to Last: Made with high-quality materials, our trays are durable and reliable.

Our plastic tray options include:

Food Packaging Trays: Perfect for sweets, chocolates, and baked goods.

Industrial Packaging Trays: Designed to protect and organize machine parts.

Gift Packaging Trays: Customizable designs to make festive occasions special.

Why Choose Uno Plast?

Uno Plast isn’t just a packaging manufacturer—we’re your partner in delivering high-quality solutions. Here’s what makes us the best choice:

Premium Materials: We use top-grade materials, ensuring safety and durability for every product.

Advanced Technology: Our state-of-the-art equipment ensures precision and consistency.

Tailored Solutions: We customize every detail to meet your specific needs, from color to size.

Affordable Prices: High-quality packaging doesn’t have to break the bank. We offer competitive pricing without compromising quality.

On-Time Delivery: We value your time and ensure prompt delivery for every order.

Sustainable Practices: Our use of recyclable materials reflects our commitment to the environment.

Industries We Serve

Our blister packaging and plastic trays are trusted by various industries:

Pharmaceuticals: Secure blister packaging for tablets and capsules.

Food and Confectionery: Elegant trays for chocolates, sweets, and bakery items.

Electronics: Durable trays for small components.

Cosmetics: Attractive blister packs for beauty and skincare products.

Automotive: Sturdy trays for machine parts and accessories.

Quality You Can Rely On

At Uno Plast, quality is not just a priority—it’s our promise. Every product goes through rigorous quality checks to ensure it meets the highest standards. From the initial design to the final product, we pay attention to every detail to ensure you receive packaging that exceeds your expectations.

Whether you need a small batch of custom trays or large-scale production, our team works closely with you to deliver exactly what you need.

How to Get Started

Finding the perfect packaging solution for your products is simple with Uno Plast. Visit our website to explore our complete range of blister packaging and plastic trays:

Blister Packaging

Plastic Trays

If you have specific requirements, feel free to contact us. Our team is always ready to assist you.

Conclusion

Uno Plast has earned its reputation as one of the leading manufacturers of blister packaging and plastic trays in India. Our commitment to quality, innovation, and customer satisfaction sets us apart.

Whether you’re packaging food, electronics, or industrial parts, our products ensure protection and elevate presentation. Trust Uno Plast to deliver packaging solutions that not only meet but exceed your expectations. Let’s create something great together!

2 notes

·

View notes

Text

Excellence in Machinery for Pharmaceuticals, Cosmetics, Chemicals, & Nutraceuticals

Welcome to Adinath International – your trusted partner in high-performance machinery for Pharmaceuticals, Cosmetics, Chemicals, and Nutraceuticals!

🔧 About Us Since 2005, Adinath has been designing, manufacturing, and supplying world-class filling, processing, packaging, and labeling equipment. We serve a wide industrial spectrum, including injectables, liquid orals, tablets, capsules, ointments, creams, and herbal & nutraceutical products.

🛠️ Product Range We offer a full suite of machinery: ampoule/vial/bottle washing, servo-driven filling (liquids, powders, capsules), tablet presses, granulators, mixers, cappers, labelers, blister packers, and turnkey production lines for pharmaceuticals, cosmetics, chemicals, beverages, dairy, and more.

💡 Tailored Solutions & Support Every machine is engineered for simple operation—even with semi-skilled staff—and custom-built to meet stringent regulatory demands. Our expert team backs you with installation, commissioning, validation, and AMC services.

🔬 R&D & Innovation Continuously investing in R&D, Adinath develops cutting-edge solutions that respond directly to customer feedback and evolving industry standards.

✅ What You’ll Discover in This Video:

• A walkthrough of our state-of-the-art machinery lines • Examples of turnkey production systems in action • Insights into our design philosophy, quality processes, and after-sales support

For more details, visit us at - https://www.adinath.co.in/

#AdinathInternational#PharmaMachinery#CosmeticMachinery#ChemicalProcessingEquipment#NutraceuticalMachinery#FillingMachines#PackagingMachinery#TabletPress#CapsuleFillingMachine#LiquidFillingMachine#GMPCompliant#TurnkeySolutions

0 notes

Text

Pharma Machine Manufacturer & Supplier in India | IRM Enterprise Pvt. Ltd – Trusted Pharma Machine

IRM Enterprise Pvt. Ltd stands as a prominent Pharma Machine Manufacturer in India, offering a comprehensive range of pharmaceutical machines that meet stringent industry standards and cater to the needs of pharmaceutical producers across the globe.

Leading the Way in Pharmaceutical Machines

IRM Enterprise Pvt. Ltd has carved a niche in the Indian pharmaceutical machinery industry through its innovative approach, superior engineering, and commitment to quality. As one of the most reputed Pharma Machine Suppliers, the company offers equipment that serves the full spectrum of pharma production – from formulation and granulation to tablet compression, capsule filling, liquid processing, and packaging.

The pharmaceutical industry demands precision machinery capable of handling complex formulations and high production volumes without compromising on hygiene and efficiency. IRM Enterprise delivers on all fronts, offering tailored solutions to both small-scale manufacturers and large-scale pharmaceutical corporations.

Wide Range of Pharma Machines Offered

IRM Enterprise Pvt. Ltd specializes in a vast portfolio of pharmaceutical machines engineered to optimize production, minimize downtime, and ensure regulatory compliance. Key offerings include:

Tablet Compression Machines: These machines are essential in compressing granulated powders into tablets of uniform size and weight. IRM’s tablet press machines are known for their robustness, user-friendly interface, and high output efficiency.

Capsule Filling Machines: Designed to accurately fill powder, granules, or pellets into capsules, these machines ensure dose consistency. Available in both semi-automatic and fully automatic variants, they serve diverse production needs.

Liquid Filling and Sealing Machines: Perfect for filling oral and injectable liquids, these machines guarantee precise fill volumes and sterile sealing – critical in maintaining drug efficacy.

Granulation Equipment: Including high shear mixers, fluid bed dryers, and oscillating granulators, these machines prepare the base material for tablet or capsule formation.

Powder Processing Machines: From blenders to mills and sifters, IRM Enterprise manufactures a full range of equipment that ensures uniform mixing and size reduction of pharmaceutical powders.

Packaging Solutions: IRM offers a variety of machines for blister packing, strip packing, labeling, and cartoning. These machines help maintain product integrity and extend shelf life.

Why Choose IRM Enterprise Pvt. Ltd as Your Pharma Machine Partner?

As a trusted Pharma Machine Manufacturer in India, IRM Enterprise Pvt. Ltd brings several advantages that set them apart:

✅ Unmatched Engineering Expertise

Backed by years of experience and a skilled R&D team, IRM Enterprise incorporates the latest technological advancements into every machine they produce.

✅ Compliance with International Standards

All machines are designed to comply with GMP (Good Manufacturing Practices), WHO, and other international standards, ensuring acceptance in global markets.

✅ Customization for Diverse Requirements

Every pharmaceutical production unit has unique needs. IRM provides customized machinery solutions that align perfectly with specific production goals and space constraints.

✅ Durability and Reliability

The machines are built with high-grade stainless steel and precision components to ensure long-lasting performance with minimal maintenance.

✅ After-Sales Support and Training

IRM Enterprise is not just a machine supplier but a long-term partner. They offer complete installation support, operator training, and prompt after-sales service to ensure smooth operation.

Serving the Indian and Global Market

IRM Enterprise Pvt. Ltd is not just a Pharma Machine Manufacturer for the Indian market but has extended its reach across international borders. With exports to Asia, Africa, the Middle East, and parts of Europe, the company has become a reliable name worldwide. Their commitment to delivering technologically advanced and cost-effective solutions makes them a preferred Pharma Machine Supplier in competitive international markets.

Future-Ready Manufacturing Solutions

The pharmaceutical sector is constantly evolving with the integration of automation, data tracking, and smart controls. IRM Enterprise is well-prepared to meet these future demands by offering machines embedded with Industry 4.0 features. With innovations like PLC-based automation, touchscreen interfaces, real-time data monitoring, and remote diagnostics, their pharmaceutical machines are designed for the future of smart manufacturing.

Industries Served

IRM Enterprise caters to a diverse clientele, including:

Pharmaceutical manufacturers

Nutraceutical companies

Biotech firms

Ayurvedic and herbal medicine producers

Research laboratories

Veterinary medicine manufacturers

Each sector requires high levels of hygiene, accuracy, and scalability—features IRM’s machines are specifically designed to deliver.

Commitment to Sustainability and Clean Manufacturing

IRM Enterprise is equally focused on sustainability, integrating energy-efficient designs and reducing waste in the manufacturing process. Their pharma machines are designed to reduce power consumption, optimize material usage, and promote eco-friendly operations—ensuring a greener footprint for your manufacturing unit.

Quality Assurance and Certifications

Every machine undergoes rigorous quality checks at every stage of production. IRM Enterprise is ISO-certified and adheres to strict QA/QC protocols. Their machines meet national and international compliance standards, giving clients peace of mind and assurance of consistent performance.

In a competitive and quality-driven industry like pharmaceuticals, the importance of reliable, high-performance machinery cannot be overstated. IRM Enterprise Pvt. Ltd, as a trusted Pharma Machine Manufacturer in India, stands as a beacon of quality, innovation, and customer satisfaction. Their comprehensive range of pharmaceutical machines is a testament to their dedication to excellence and their deep understanding of the industry's evolving needs.

Whether you're looking to set up a new pharmaceutical manufacturing unit or upgrade existing equipment, IRM Enterprise Pvt. Ltd is your ideal partner for world-class machinery and ongoing support.

Ready to Upgrade Your Pharmaceutical Production?

Get in touch with IRM Enterprise Pvt. Ltd, your trusted Pharma Machine Manufacturer and Supplier in India, for top-of-the-line pharmaceutical machines tailored to your needs.

Let’s build the future of pharmaceutical manufacturing—together.

For more info: https://www.karnavatiengineering.com/

Call Now: 7567876473

Email id: [email protected]

Location: S. No. 342, Nani Kadi, Taluka - Kadi, Dist - Mehsana, Gujarat - 382715, India

#Pharmaceutical Machines#Pharma Machine#Pharma Machine Manufacturer#Pharma Machine Manufacturer in India#Pharma Machine Suppliers

0 notes

Text

Our Blister Packaging Machine offers smooth, noiseless performance with low power consumption and easy operation. Available in Model 150 and 300, it delivers up to 300 packs per minute – perfect for tablets and capsules. Customisable to your needs, it's the ideal choice for efficient pharmaceutical packaging.

For more details, visit - https://www.bhagwatipharma.com/blister-packaging-machinery/

#BhagwatiPharma#BlisterPackagingMachine#PharmaPackaging#TabletCapsulePacking#HighSpeedPackaging#PharmaceuticalMachinery

0 notes

Text

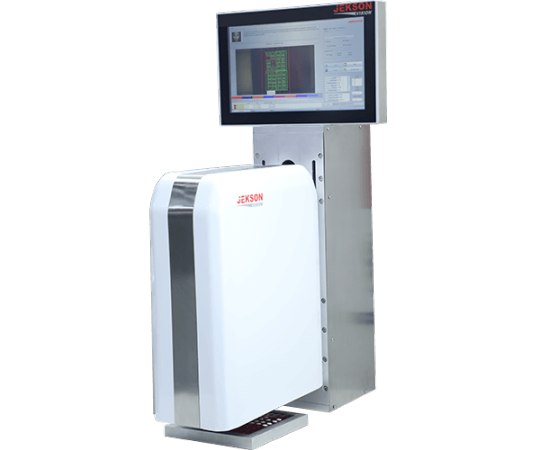

Choosing the Right Blister Inspection System for Your Pharmaceutical Manufacturing Needs

In the pharmaceutical industry, precision, safety, and compliance are non-negotiable. As global demand for high-quality medications continues to rise, so does the pressure on pharmaceutical manufacturers to deliver defect-free products. One critical step in ensuring product quality and packaging integrity is the use of a blister inspection system. These systems help manufacturers detect defects in blister packs, improve production efficiency, and maintain compliance with stringent regulatory requirements.

However, not all blister inspection systems are created equal. Choosing the right solution involves a thorough understanding of your production needs, regulatory obligations, and technological requirements.

Why a Blister Inspection System Is Essential

A blister inspection system is a vision-based quality control technology that inspects each blister pack on the production line. These systems detect a variety of issues, including:

Missing or misaligned tablets or capsules

Color or shape mismatches

Cracked or broken tablets

Foreign objects or contamination

Seal integrity or printing defects

By identifying and rejecting defective products in real time, blister inspection systems reduce waste, prevent recalls, and ensure only compliant products reach consumers. This not only improves quality assurance but also supports compliance with Good Manufacturing Practices (GMP) and regulations from agencies like the FDA and EMA.

Key Considerations for Choosing the Right Blister Inspection System

Selecting the ideal blister inspection system requires a comprehensive evaluation of your current and future production needs. Below are the key factors to consider:

1. Product and Packaging Specifications

Start by analyzing your product’s characteristics and the types of blister packs used. Important considerations include:

Tablet or capsule size, shape, and color

Material and design of blister packs (e.g., PVC, aluminum, thermoformed)

Number of cavities per pack

Size and speed of your production line

Ensure the system can accurately inspect the range of products you manufacture, including future product variations.

2. Inspection Capabilities

Modern blister inspection systems offer a variety of inspection features. Look for systems that can perform:

Presence/absence checks

Color and shape verification

Foreign object detection

3D inspection for depth analysis

Foil seal and print quality verification

Some systems even use artificial intelligence (AI) or machine learning algorithms to adapt to product variations and improve defect detection over time.

3. Camera and Illumination Technology

Image quality is crucial for accurate inspection. Choose a system with:

High-resolution cameras

Multiple camera angles (top, bottom, side) if needed

Proper lighting configurations (e.g., backlighting, coaxial, dome lighting)

Infrared or UV lighting for specialized needs

These components ensure consistent performance under different environmental and product conditions.

4. Speed and Throughput Requirements

The inspection system must keep pace with your production line. High-speed lines require systems with fast processing capabilities and real-time rejection mechanisms. Make sure the system’s speed matches your output without compromising accuracy.

5. Ease of Integration

Your chosen blister inspection system should integrate smoothly with existing production lines. Consider:

Footprint and physical compatibility with your equipment

Compatibility with Programmable Logic Controllers (PLCs)

Ability to interface with Manufacturing Execution Systems (MES)

Support for Industry 4.0 and digital traceability standards

Modular and customizable systems can offer more flexibility during integration.

6. User Interface and Usability

A user-friendly interface is important for line operators and quality control personnel. Look for systems with:

Intuitive touchscreens and dashboards

Recipe management for different products

Real-time alerts and visual defect indicators

Easy access to data logs and inspection reports

Ease of use reduces training time and increases productivity.

7. Compliance and Validation Support

Your blister inspection system must help you meet regulatory standards, including:

FDA 21 CFR Part 11 for electronic records

GMP requirements for automated inspections

Full audit trails and time-stamped images of defects

Validation documentation (IQ/OQ/PQ protocols)

Work with vendors that provide validation assistance and ensure the system meets industry-specific guidelines.

8. Service, Support, and Training

Post-installation support is just as important as the system itself. Choose a vendor that offers:

Prompt technical support and remote diagnostics

Spare parts availability

Operator training and refresher courses

Preventive maintenance programs

Good vendor support reduces downtime and extends the system’s lifecycle.

Cost Considerations

While cost is always a factor, it should be evaluated in the context of value. A cheaper system may lack critical features or fail to meet regulatory needs, resulting in long-term losses. Conversely, a high-quality system with robust capabilities can deliver substantial ROI through defect reduction, compliance, and improved efficiency.

When budgeting, consider:

Initial investment and installation costs

Licensing or software fees

Maintenance and calibration expenses

Upgrade potential and scalability

Case in Point: Making the Right Choice

A mid-sized pharmaceutical manufacturer recently expanded production of a new pediatric medication in chewable form. The company needed a blister inspection system capable of:

Inspecting multi-color tablets

Detecting minor cracks and defects

Logging images for traceability

Seamlessly integrating with an older production line

After evaluating several options, they selected a system with dual cameras, AI-enhanced detection, and a compact frame. Integration was completed in two weeks, resulting in:

A 40% reduction in defective packs

Streamlined compliance audits

Improved operator confidence with the user-friendly interface

Conclusion

Selecting the right blister inspection system is a critical decision for pharmaceutical manufacturers committed to product quality, compliance, and operational excellence. By considering your production needs, regulatory requirements, and system capabilities, you can ensure a solution that not only fits your current processes but also supports your future growth.

Whether you’re updating a legacy line or building a new facility, investing in the right inspection technology today lays the foundation for reliable, efficient, and compliant operations tomorrow.

1 note

·

View note

Text

Capsule Production Line

Machines for powder mixing, capsule filling, capsule polishing, sorting, inspecting, and packaging make up the capsule production line (also known as the capsule filling line) and capsule packaging line. Every machine complies with cGMP regulations. Additionally, the food supplement, herbal, nutraceutical, and cosmetic industries use pharmaceutical capsule production lines.

Adinath range consist Semi Automatic Capsule Filling Line as well as Fully Automatic Capsule Filling Line.

We are giving here below information of each individual machine in Capsule Filling Line:

Capsule Production Line Video

youtube

Adinath range of capsules production machines consist Manual Capsule Filling Line, Semi Automatic Capsule Filling Line and Fully Automatic Capsule Production Line. There are different production lines ranging from 5000 capsules per hour to 150000 capsules per hour. For detailed information on each individual machines please click here

Double Cone Blender

A double cone blender, sometimes known as a double cone mixer, is ideal for blending various types of powders. It also includes a medicinal powder mixer. By turning the vessel continually, the products are tumble distributed. Stainless steel 304, 316, or mild steel can be used to make blenders, depending on the specifications. The vessel features two conical frustums on either side of its shell. A manual butterfly valve is located on one side for discharge, and a lid with clamps for quick closing and opening is on the other for charging. Both inside the vessel and on the cylindrical shell wall is a central baffle. The vessel is designed with zero retention. Operating mechanisms of the machine include a motor with a reduction gearbox, a vessel set on a Plummer block, and a specifically made chain sprocket. A limit switch that is linked with the motor on the safety guard guarantees safe operations.

youtube

Manual Capsule Filling Machine

The manual capsule filling machine, also known as the manual capsule filler, is a robust and easy-to-use device made of premium stainless steel. The machine features 300 holes in 25 x 12 combinations, all built of SS 304/316 constructions that adhere to GMP standards. With the use of several machines and interchangeable parts, the machine can fill capsules ranging in size from #00 to #5. The assembly process has been designed to provide easy disassembly for cleaning purposes. The machine requires highly trained individuals to assemble its precision-machined components, even though all operations are manual. Widely used machines in R&D labs, research facilities, pilot batch manufacturing, herbal and nutraceutical preparations, Unani and Ayurvedic medications, etc.

youtube

Semi Automatic Capsule Filling Machine

The Semi Automatic Capsule Filling Machine, also known as the Semi Automatic Capsule Filler, is specifically built to meet the precise manufacturing needs of contemporary pharmaceutical procedures. It includes a ring type capsule filling machine. The device offers a high degree of automation along with more precise filling weight measurements. The Capsule Filling Machine can be used to fill capsules with powder, granules, or pellets of any size. The machine is built in accordance with GMP guidelines, has a stainless steel exterior, and can produce between 25000 and 47000 capsules per hour, depending on the size of the capsule and the operator’s skill level.

youtube

Automatic Capsule Filling Machine

Up to 150000 capsules can be filled per hour using a range of powder formulations by an automatic capsule filling machine, which also includes a completely automatic capsule filling machine. With exceptional accuracy, this machine model can fill the full spectrum of hard gelatin capsule sizes 00 to 5 with powder, pellets, and granules either individually or in any mix of powder and pallets. For improved accuracy, the Automatic Capsule Filler forms a slug using tamping pin technology and inserts it into a hard gelatin capsule.

youtube

Capsule Blistering Machine

Tablets and capsules are packaged in blister packs using a capsule blister packing machine, also known as a pharma blistering machine. The pharmaceutical sector, regardless of size, can benefit greatly from our machines due to their exceptional quality, dependability, performance, and affordability.

youtube

Capsule Counting Machine

Capsule counting machines, also known as capsule counters, are used to fill and count capsules in rigid containers and poly bags. One form of capsule counter is the dish type. Every disc is made to order in accordance with the precise specifications provided by the client. To ensure that pills and capsules are filled without dust, an optional dust extractor is supplied to remove dust particles from the passageway to the container. A capsule counting machine can fill and count from one to a thousand capsules into bags or containers. Widely used machines in R&D labs, research facilities, pilot batch manufacturing, herbal and nutraceutical preparations, Unani and Ayurvedic medications, etc.

youtube

#Semi Automatic Capsule Filling Line#Fully Automatic Capsule Filling Line#Double Cone Blender#Manual Capsule Filling Machine#Semi Automatic Capsule Filling Machine#Automatic Capsule Filling Machine#Capsule Blistering Machine#Capsule Counting Machine#Youtube

0 notes

Text

How Automated Pharmaceutical Packaging Machines Are Revolutionizing Drug Production in India

The pharma industry in India is now building a global success story. Ranked third in volume and 14th in value, India is a pharmaceutical powerhouse that is currently supplying over 50% of the global demand for vaccines and another significant share of generic drugs worldwide. As this sector accelerates, so does the demand for speed, safety, precision, and smarter medicine packaging. This has, in…

#automated packaging solutions#automated pharmaceutical packaging machines#automatic packaging machines#blister packaging machine#capsule counting and filling machine#Nichrome Data Over Internet (NDOIT)#packaging machine manufacturer#pharmaceutical packaging machines#Powder & Liquid Filling Machines#Sachet packaging machine#Tube Filling Machine

0 notes

Text

Pills, Powders & Precision: How Nichrome is Redefining Pharmaceutical Packaging in Bangladesh

In the dynamic world of pharmaceuticals, packaging of every pill, capsule and ointment counts. One misguided step, and the negative ramifications could be more than expensive — they could be catastrophic. That’s why when it comes to packaging machine suppliers in Bangladesh, there’s one name that’s stirring the pot with innovation and precision—Nichrome Packaging Solutions.

We don’t just package medicines—we package safety, accuracy, regulatory compliance, and trust. Whether it is powder packaging machines, ointment tube filling machines, blister card packaging, or capsule filling machine integrations, Nichrome is the future of pharma packaging, with reliability and flair.

#packaging machine suppliers in Bangladesh#powder packaging machines#ointment tube filling machines#blister card packaging#or capsule filling machine

0 notes

Text

The Power of High-Speed Rotary Packaging Machines

In today's fast-paced manufacturing world, speed and efficiency are no longer just competitive advantages—they're essential for survival. As industries evolve to meet the rising demands of global consumers, packaging plays a critical role in the production process. One innovation that has significantly transformed the packaging landscape is the high-speed rotary packaging machine. These mechanical marvels are driving productivity, ensuring consistency, and reducing labor costs across multiple industries. Let’s explore how these powerful machines are revolutionizing packaging as we know it.

What Are High-Speed Rotary Packaging Machines?

High-speed rotary packaging machines are advanced systems designed to automate the process of forming, filling, and sealing packages at exceptional speeds. Unlike traditional linear machines, rotary machines operate in a circular or rotary fashion, enabling continuous motion packaging. pouch packaging machines This not only boosts output rates but also ensures a more compact footprint and higher efficiency.

Typically used in industries such as food and beverage, pharmaceuticals, cosmetics, and consumer goods, these machines are capable of handling various package types including pouches, sachets, bags, and even bottles, depending on the machine design.

Key Features That Set Rotary Machines Apart

High-Speed Output As the name suggests, speed is the hallmark of rotary packaging machines. Capable of completing hundreds of cycles per minute, these machines dramatically increase throughput, helping manufacturers meet large-scale production goals with ease.

Precision and Consistency Automation ensures that every package is filled, sealed, and labeled with unmatched precision. This reduces product waste and improves overall quality control, which is especially crucial in regulated industries like pharmaceuticals and food.

Versatility Many rotary systems come equipped with interchangeable parts or modular designs, allowing for quick changeovers between different products or packaging formats. This flexibility is a major benefit in dynamic markets where product lines frequently evolve.

Compact Footprint By organizing the packaging process in a circular layout, rotary machines occupy less floor space compared to linear systems. This makes them ideal for manufacturers with space constraints.

Reduced Downtime These machines are designed for continuous motion, which translates to less downtime. vacuum packaging machine Some models also include features like automatic film alignment, error detection, and tool-less changeovers to further enhance uptime.

Industries Benefiting from High-Speed Rotary Packaging

1. Food and Beverage

Whether it’s single-serve snacks, coffee pods, or liquid beverages, rotary packaging machines ensure that food items are packaged quickly and safely. These machines support vacuum sealing, nitrogen flushing, and tamper-evident sealing—key features that preserve freshness and extend shelf life.

2. Pharmaceuticals

In the pharmaceutical sector, speed must never compromise accuracy. Rotary machines used here are engineered for precise dosing and strict hygiene standards. They are often used to package tablets, capsules, and powders into blister packs or sachets.

3. Cosmetics and Personal Care

From face creams to shampoos and lotions, the cosmetics industry benefits from rotary machines for filling and sealing both flexible and rigid packaging. Their precision helps ensure every unit looks professional and meets branding requirements.

4. Chemical and Industrial Goods

Even in heavy-duty sectors like chemicals or automotive products, rotary machines are utilized for packaging adhesives, lubricants, and cleaning agents. Specialized designs can handle corrosive or viscous substances with ease.

The Economic Impact: Why Speed Matters

High-speed rotary packaging machines are not just a technological upgrade—they're a strategic investment. Here’s why:

Lower Labor Costs: Automation reduces the need for manual labor, helping manufacturers save on wages, training, and human error correction.

Faster Time-to-Market: Quicker packaging allows for faster product launches and better responsiveness to market trends.

Improved ROI: Though the initial cost of a high-speed rotary machine can be significant, the return on investment is high thanks to reduced waste, lower overhead, and faster production.

Environmental Considerations

Sustainability is becoming a driving force in packaging decisions. High-speed rotary machines contribute to green initiatives in several ways:

Efficient Use of Materials: These machines optimize material usage, reducing film waste and over-packaging.

Energy Efficiency: Newer models are designed to consume less power while delivering higher output.

Compatibility with Eco-Friendly Films: Many machines can work with biodegradable or recyclable materials, helping companies align with sustainability goals.

Trends and Innovations

As technology continues to evolve, rotary packaging machines are becoming smarter and more efficient. Here are some emerging trends:

Integration with IoT: Modern machines are equipped with sensors and connectivity features that allow real-time monitoring, predictive maintenance, and data-driven optimization.

Artificial Intelligence (AI): AI algorithms can help fine-tune operations by predicting jams, adjusting speeds, or identifying inconsistencies.

Robotic Integration: Robotics are being paired with rotary systems for tasks like automated loading/unloading and quality inspection.

Choosing the Right Machine: What to Consider

When selecting a high-speed rotary packaging machine, manufacturers should consider several factors:

Production Needs: Define the desired output speed and volume.

Product Type: Different machines handle liquids, powders, or solids differently.

Package Style: Whether you need stand-up pouches, flat sachets, or spouted bags, make sure the machine supports your preferred format.

Space Availability: Assess your factory layout to ensure a suitable fit.

Budget and ROI: Factor in the total cost of ownership, not just the upfront price.

Conclusion

The power of high-speed rotary packaging machines lies in their ability to combine speed, accuracy, and flexibility in one compact unit. As industries face mounting pressure to deliver more, faster, and with greater sustainability, these machines are stepping up to the challenge. Investing in rotary packaging technology isn't just about keeping up—it's about staying ahead.

Whether you're a small manufacturer looking to scale or a large enterprise seeking to optimize efficiency, embracing this cutting-edge machinery could be the key to unlocking your full production potential.

0 notes

Text

Blister Packing Machine for Pharmaceutical and Consumer Goods Packaging | V.M. Services

Explore high-quality blister packing machines at V.M. Services, designed to ensure precision and efficiency for pharmaceutical and consumer goods packaging. Perfect for packaging tablets, capsules, and more. Get the best machines for accurate and fast blister packaging today, visit https://www.vmservices.co.in/ or call 9825513488.

#Blister Packing Machine#Blister Packing Machine Manufacturer#Blister Packing Machine Supplier#PVC Blister Pack Machine#Alu Alu Blister Pack Machine#Blister Pack Machine#Blister Packaging Machines#Pharmaceutical Packaging Machine#Blister Packing Machinery Manufacturers#Blister Packing Machinery Suppliers#Alu Alu Blister Packing Machine#Blister Packaging Equipment#Blister Packaging Machine Manufacturers#Blister Packaging

2 notes

·

View notes

Text

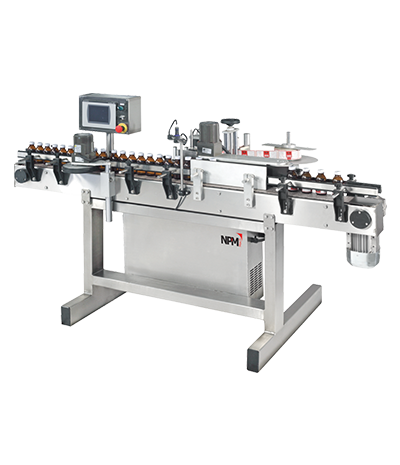

Revolutionizing Pharma Production: The Role of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Introduction

In the dynamic world of pharmaceuticals, precision, hygiene, speed, and compliance are non-negotiable. As the demand for high-quality medicines continues to rise globally, the pharmaceutical industry must meet rigorous standards in both production and packaging. This is where Pharma Packaging Machines come into play—ensuring products are safely, efficiently, and accurately packed before reaching the end-user.

At NPM Machinery Pvt. Ltd., we understand the critical importance of packaging in the pharma value chain. As a leading manufacturer of pharma packaging machines, our mission is to empower pharmaceutical companies with robust, automated, and intelligent machinery that supports regulatory compliance while improving productivity and product integrity.

In this blog, we will delve into the importance of pharma packaging machines, the types available, their benefits, and why NPM Machinery Pvt. Ltd. is your ideal partner in pharmaceutical automation.

Why Pharma Packaging Machines Matter

Pharmaceutical packaging is far more than just enclosing a product in a container. It is a protective barrier, a compliance requirement, a branding tool, and an enabler of global logistics. A well-packaged pharmaceutical product ensures:

Product integrity during transport and storage

Accurate dosage and ease of administration

Protection against contamination and tampering

Compliance with FDA and other global regulatory norms

Efficient serialization and tracking

Manual packaging simply cannot keep up with the high-volume, high-precision demands of modern pharmaceutical production. That’s where automated packaging solutions step in—offering speed, consistency, and compliance.

Core Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

At NPM Machinery Pvt. Ltd., we design and manufacture a full spectrum of advanced pharma packaging machines tailored to the needs of small-scale manufacturers as well as large pharmaceutical giants. Here are the most common types and their applications:

📦 1. Blister Packaging Machines

Ideal for packing tablets and capsules in pre-formed plastic blisters sealed with aluminum foil

Ensures tamper-proof packaging and extended shelf life

Used widely in retail and hospital pharmacy sectors

💊 2. Strip Packaging Machines

Designed to wrap tablets and capsules between aluminum or plastic strip foils

Compact, precise, and perfect for heat-sensitive medicines

Offers high output and minimal material wastage

🧪 3. Bottle Filling and Capping Machines

Automates filling of syrups, suspensions, and other liquids into bottles with accurate volume control

Integrates seamlessly with capping units for secure sealing

Customizable for different bottle sizes and materials

🏷️ 4. Labeling Machines

Applies labels accurately on bottles, ampoules, vials, or boxes

Supports serialization and barcoding for traceability

Compatible with multiple label shapes and sizes

🧼 5. Washing & Sterilizing Machines

Cleans vials, ampoules, and bottles before filling to ensure zero contamination

Uses air and water jets with complete automation

Essential for injectable and parenteral products

🧴 6. Cartoning Machines

Automates the packing of blister packs, bottles, or tubes into cartons

Integrates leaflet insertion and batch coding

Enhances product presentation and traceability

🎯 7. Inspection Machines

Detects broken tablets, missing capsules, misprinted labels, and other defects

Ensures every packaged product meets quality control standards

Reduces human error and improves customer trust

Benefits of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Choosing the right packaging solution is not just about machinery—it’s about performance, reliability, and long-term value. NPM Machinery's pharma packaging machines offer:

✅ 1. High-Speed Automation

Boost production rates with minimal human intervention

Ideal for mass manufacturing and 24/7 operations

✅ 2. Unmatched Accuracy

Delivers exact filling, sealing, and labeling

Reduces product loss and ensures dosage consistency

✅ 3. Compliance & Validation

Built with GMP, FDA, and CE compliance in mind

Supports 21 CFR Part 11 for electronic data integrity

✅ 4. Flexibility & Customization

Machines tailored to your product specifications

Modular designs allow for future scalability

✅ 5. Advanced Technology Integration

Equipped with PLC-based controls, SCADA systems, and IoT capabilities

Enables remote monitoring, real-time alerts, and preventive maintenance

✅ 6. Superior Build Quality

Made with stainless steel and corrosion-resistant materials

Long machine life, low maintenance, and robust performance

✅ 7. Global Support & Service

On-site training, remote diagnostics, and spare parts availability

Dedicated support teams for installation, validation, and upgrades

Industries We Serve

While our core strength lies in pharmaceutical packaging, our machines are versatile enough for other regulated industries such as:

Nutraceuticals

Ayurveda and Herbal

Cosmetics

Food & Beverage

Veterinary Medicine

Why Choose NPM Machinery Pvt. Ltd.?

With decades of experience, NPM Machinery Pvt. Ltd. has built a reputation for engineering excellence and customer-centric innovation. Here's what sets us apart:

✔️ 150+ skilled professionals including engineers, technologists, and validation experts

✔️ ISO-certified manufacturing with a focus on precision and safety

✔️ Custom turnkey packaging lines from design to commissioning

✔️ Strong domestic and global footprint with clients across Asia, Africa, Europe, and South America

✔️ Client-first approach—we adapt our solutions to your needs, not the other way around

Our goal is not just to sell machines—but to build long-term partnerships that add value to your production process, protect your brand, and ensure regulatory peace of mind.

Conclusion

The future of pharmaceutical manufacturing lies in smart, integrated, and efficient packaging systems. With increasing global demand, strict compliance requirements, and growing competition, investing in high-performance pharma packaging machines is no longer optional—it's essential.

At NPM Machinery Pvt. Ltd., we don’t just provide machines—we deliver confidence, quality, and peace of mind. Whether you're launching a new production line or upgrading your existing setup, we are here to guide you every step of the way with reliable, cutting-edge, and compliant solutions.

✅ Call to Action

Ready to upgrade your pharma packaging line? Partner with NPM Machinery Pvt. Ltd. and experience unmatched quality, service, and innovation. 📩 Contact us today for a free consultation or demo customized to your packaging needs! 🌐 Visit us at www.npmmachinery.com | 📞 +91-XXXXXXXXXX

0 notes