#Commercial water chiller system

Photo

ESEM International helps meet your building efficiency needs with the widest variety of water-cooled industrial and commercial chillers, Swimming Pool Heat Pumps, Water Coolers, Beverage Display Chillers, etc on the market. From reducing your facility’s carbon footprint to cutting operating costs, our energy-efficient products are tailored to fit almost any application. To know more information visit: https://www.eseminternational.com/swimming-pool-warmer.html

#Water chillers for hotels#Swimming pool heat pump#Industrial chiller suppliers#Commercial water chiller system

0 notes

Text

The AquaEdge 19MV Water-Cooled Centrifugal Chiller – Experience Unconditional Performance. It’s time to rethink what you know about chillers. In the past, more operating range often meant less efficiency at design conditions. Now Carrier has created a chiller that delivers both, unconditionally.

#hvac#air conditioning#chillers#commercial chillers#air cooled chillers#chiller plant#water cooled chillers#chiller system

0 notes

Text

Boilers And Chillers Erection Services In India

We have decades of experience servicing boilers and chillers for multiple commercial and industrial facilities as well as servicing other mechanical, electrical and plumbing systems.we provide Magnetic bearing chillers,Screw & scroll chillers,Reciprocating chillers,Steam & hot water boilers,Reciprocating chillers,Steam & hot water boilers,Chiller & boiler controls, System pumps and Cooling tower.

2 notes

·

View notes

Text

Chiller AC: Cooling Large Spaces Like a Pro.

While your trusty window AC might keep your apartment comfortable, it wouldn't stand a chance against cooling a giant office building or a sprawling hospital. That's where chiller AC systems come in. These industrial workhorses are the secret sauce behind large-scale air conditioning.

So, how do chiller ACs work?

Think of them as giant refrigerators for buildings. Instead of blowing cool air directly, they chill water. This ice-cold water then gets pumped throughout a building, where it cools the air through heat exchangers. There are two main types of chiller ACs:

Air-cooled: These operate similarly to your home AC, using outdoor fans to expel heat.

Water-cooled: These transfer heat to a separate cooling tower that uses water (often from a cooling pond or municipal source) to expel heat.

Where are chiller ACs used?

Chiller ACs are the go-to solution for large spaces that need precise temperature control. Here are some common applications:

Commercial buildings: Offices, hotels, and shopping malls all rely on chiller ACs for year-round comfort.

Industrial facilities: Factories and warehouses often use chillers to cool down machinery and processes that generate a lot of heat.

Healthcare facilities: Hospitals and clinics need to maintain cool temperatures for patient comfort and critical medical equipment.

Benefits of chiller ACs:

Efficient cooling: Chiller ACs can cool large areas very effectively, making them ideal for big spaces.

Zonal control: Different zones within a building can have their temperatures independently regulated.

Quiet operation: Chiller units are often located outdoors, keeping noise pollution down inside the building.

Chiller ACs vs. Regular ACs:

The key difference is scale. Regular ACs cool air directly, making them suitable for individual rooms or small buildings. Chiller ACs cool water that gets distributed throughout a building, making them perfect for large-scale applications.

So, next time you're enjoying the cool comfort of a large building, remember the hidden hero – the chiller AC system, quietly working away to keep things pleasant.

For any chiller AC needs, don't hesitate to contact Burak HVAC! Our team of experts is happy to answer your questions and help you find the perfect solution for your large-scale cooling requirements. Reach out to us via email at [email protected] or fill out our convenient contact form. We're here to ensure your commercial space stays comfortable and efficient.

#chiller plant#chiller ac#commercial hvac#hvac services#hvac solutions#hvac company#hvac systems#ac maintenance#ac repair#hvac repair

0 notes

Text

Chilled Water Systems: The Cool Backbone of Modern Infrastructure

Introduction

What Are Chilled Water Systems?

Chilled water systems are essential components in the heating, ventilation, and air conditioning (HVAC) industry. They provide a reliable method to cool large buildings and industrial processes by circulating chilled water throughout the system, effectively removing heat from the space.

Importance in Modern Infrastructure

In today's world, where energy efficiency and environmental impact are crucial considerations, chilled water systems play a vital role. They are used in various settings, from commercial buildings to industrial facilities, ensuring comfortable and safe environments while minimizing energy consumption.

How Chilled Water Systems Work

Basic Components

A typical chilled water system consists of chillers, cooling towers, pumps, and a network of pipes. The chiller is the core component, responsible for removing heat from the water, which is then circulated through the building or process.

The Cooling Cycle

The cooling cycle begins with the chiller, where refrigerant absorbs heat from the water. This chilled water is then distributed through the building via a network of pipes. As it flows through air handlers and fan coil units, it absorbs heat from the air, effectively cooling the space. The now-warmed water returns to the chiller to begin the cycle again.

Types of Chilled Water Systems

Air-Cooled Chillers

Air-cooled chillers use air to dissipate heat from the refrigerant. They are typically used in smaller installations or where water availability is limited. These systems are easier to install and maintain but can be less efficient in extreme temperatures.

Water-Cooled Chillers

Water-cooled chillers use water from a cooling tower to remove heat from the refrigerant. These systems are more efficient and suitable for larger installations but require more space and higher maintenance.

Applications of Chilled Water Systems

Commercial Buildings

In commercial buildings, chilled water systems are crucial for maintaining comfortable indoor temperatures. They are commonly used in office buildings, malls, and hotels.

Industrial Uses

Industries such as manufacturing, pharmaceuticals, and food processing rely on chilled water systems to maintain process temperatures and ensure product quality.

Data Centers

Data centers, which generate significant amounts of heat, use chilled water systems to keep servers cool and operational, preventing overheating and downtime.

Hospitals

Hospitals utilize chilled water systems to ensure a comfortable environment for patients and staff, as well as to maintain the proper functioning of medical equipment.

Benefits of Chilled Water Systems

Energy Efficiency

Chilled water systems are known for their energy efficiency, particularly water-cooled systems, which can significantly reduce energy consumption compared to traditional air conditioning systems.

Cost Savings

By reducing energy consumption, chilled water systems can lead to substantial cost savings over time. Additionally, their longer lifespan and lower maintenance costs contribute to overall savings.

Environmental Impact

These systems have a lower environmental impact due to their efficient use of energy and the ability to use eco-friendly refrigerants, reducing greenhouse gas emissions.

Challenges and Considerations

Installation Costs

While chilled water systems offer many benefits, the initial installation costs can be high, especially for water-cooled systems, which require extensive infrastructure.

Maintenance Requirements

Regular maintenance is crucial to ensure the efficiency and longevity of chilled water systems. This includes checking refrigerant levels, inspecting pumps and pipes, and ensuring the cooling tower is functioning correctly.

Space Considerations

Water-cooled systems require significant space for cooling towers and associated equipment, which can be a limitation in urban areas or buildings with limited space.

Choosing the Right Chilled Water System

Assessing Needs

Choosing the right system involves assessing the cooling needs of the building or process, including the required capacity and efficiency.

Budget Considerations

Budget plays a crucial role in the decision-making process. While water-cooled systems are more efficient, they come with higher upfront costs compared to air-cooled systems.

Long-Term Planning

Considering the long-term benefits, including energy savings and maintenance costs, is essential when choosing a chilled water system. Investing in a more efficient system upfront can lead to significant savings over time.

Advancements in Chilled Water Systems

Smart Technology Integration

Modern chilled water systems are incorporating smart technology, allowing for real-time monitoring and adjustments, which enhances efficiency and reliability.

Eco-Friendly Refrigerants

The use of eco-friendly refrigerants is becoming more common, reducing the environmental impact of chilled water systems and complying with stricter environmental regulations.

Improved Efficiency Designs

Advancements in design, such as variable speed drives and improved heat exchangers, are increasing the efficiency of chilled water systems, making them more effective and economical.

Case Studies

Successful Implementations

Numerous case studies highlight the successful implementation of chilled water systems in various settings, showcasing their benefits and efficiency.

Lessons Learned

These case studies also provide valuable lessons on the challenges faced during installation and operation, offering insights for future projects.

Future of Chilled Water Systems

Emerging Trends

The future of chilled water systems is bright, with trends such as increased automation, smarter controls, and more sustainable practices leading the way.

Sustainability Initiatives

Sustainability is a key focus, with efforts to reduce energy consumption and environmental impact driving innovation in the field of chilled water systems.

Conclusion

Recap of Key Points

Chilled water systems are essential for modern infrastructure, offering efficient and reliable cooling for various applications. Their benefits, including energy efficiency, cost savings, and environmental impact, make them a preferred choice in many settings.

Final Thoughts

Fabtech is technology advances and sustainability becomes a priority, chilled water systems will continue to evolve, providing even greater benefits and efficiencies. Investing in the right system today can lead to significant long-term gains.

FAQs

What is a chilled water system?

A chilled water system is an HVAC solution that uses chilled water to cool buildings or industrial processes by circulating the water through a network of pipes and heat exchangers.

How do chilled water systems save energy?

Chilled water systems save energy by efficiently removing heat from spaces using chilled water, which requires less energy than traditional air conditioning systems.

What are the main types of chilled water systems?

The main types are air-cooled chillers, which use air to dissipate heat, and water-cooled chillers, which use water from a cooling tower.

#bio pharma solutions#dedusting machine#chilled water systems#Tablet Coating Machine#Fabtech pharmaceutical

0 notes

Text

Commercial HVAC in Halifax, NS

Investing in a high-quality commercial HVAC system for your business establishment offers several benefits, including improved indoor air quality, enhanced comfort, energy efficiency, cost savings, reliability, and compliance with regulations.

Modern commercial HVAC systems are designed for quiet operation, minimizing noise disruptions in the workplace or commercial space. Quiet HVAC systems contribute to a more pleasant and productive environment for occupants.

Apollo Heating and Cooling service a wide variety of commercial HVAC equipment including package roof-top units, piped split systems, water source heat pumps, chillers, cooling towers, built-up air handlers, walk-in coolers/freezers, and reach-in coolers/freezers. Their Red Seal technicians are trained to monitor all aspects of commercial HVAC system’s performance to ensure optimum performance and efficiency. They know that the key to system longevity and efficiency is directly related to proper installation and scheduled maintenance.

Please visit their website: https://www.apollohvac.ca/heat-pumps-halifax to learn more about their commercial HVAC services in Halifax, NS.

0 notes

Text

Absorption Chillers Market Outlook Report 2024-2030: Trends, Strategic Insights, and Growth Opportunities | GQ Research

The Absorption Chillers Market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Absorption Chillers Market showcased a significant presence, boasting a valuation of US$ 1603.2 Million. This underscores the substantial demand for Acetophenone technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-absorption-chillers-market/

Projected Growth: Projections suggest that the Absorption Chillers Market will continue its upward trajectory, with a projected value of US$ 2196.39 Million by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 4.60%, reflecting a steady and robust growth rate for the Absorption Chillers Market over the coming years.

Technology Adoption:

In the Absorption Chillers market, technology adoption focuses on the utilization of thermally driven cooling systems that utilize heat energy for refrigeration purposes. These chillers use absorption cycles to transfer heat from a low-temperature heat source to a higher-temperature heat sink, typically using water and lithium bromide or ammonia as refrigerants. Advanced absorption chillers incorporate improvements in heat exchanger design, refrigerant absorption efficiency, and cycle optimization to enhance overall performance and energy efficiency.

Application Diversity:

The Absorption Chillers market serves various applications across industries such as commercial buildings, industrial processes, district cooling systems, and refrigeration. In commercial buildings, absorption chillers provide cooling solutions for air conditioning, space cooling, and comfort cooling in office buildings, hotels, hospitals, and shopping malls. In industrial processes, absorption chillers support cooling requirements for chemical processing, food and beverage production, and pharmaceutical manufacturing. Additionally, absorption chillers are used in district cooling systems to provide centralized cooling services to multiple buildings in urban areas.

Consumer Preferences:

Consumer preferences in the Absorption Chillers market are influenced by factors such as energy efficiency, reliability, maintenance requirements, and cost-effectiveness. End-users prioritize absorption chillers that offer high energy efficiency and low operating costs, helping to reduce electricity consumption and operational expenses. Additionally, consumers value reliable performance and minimal downtime, especially in critical applications where uninterrupted cooling is essential. Moreover, ease of maintenance, availability of spare parts, and compatibility with existing infrastructure are important considerations for consumers when selecting absorption chillers.

Technological Advancements:

Technological advancements in the Absorption Chillers market focus on improving efficiency, performance, and environmental sustainability through innovations in materials, heat transfer technology, and system design. Research efforts aim to develop advanced absorption materials and formulations with higher absorption capacity and stability, enabling chillers to operate more efficiently across a wider range of operating conditions. Additionally, advancements in heat exchanger design, such as microchannel and plate heat exchangers, enhance heat transfer efficiency and reduce pressure drop, leading to improved overall chiller performance. Moreover, integration with renewable energy sources and waste heat recovery systems further enhances energy efficiency and reduces environmental impact in absorption chiller applications.

Market Competition:

The Absorption Chillers market is characterized by competition among chiller manufacturers, HVAC system integrators, and energy service companies, driven by factors such as technology innovation, performance, reliability, and cost competitiveness. Major players leverage their expertise in absorption technology, research and development capabilities, and global distribution networks to maintain market leadership and gain competitive advantage. Meanwhile, smaller manufacturers and niche players differentiate themselves through specialized product offerings, customization capabilities, and targeted customer support services. Additionally, strategic partnerships, collaborations, and acquisitions are common strategies for companies to expand market presence and enhance product portfolios in the competitive Absorption Chillers market.

Environmental Considerations:

Environmental considerations are increasingly important in the Absorption Chillers market, with stakeholders focusing on reducing greenhouse gas emissions, minimizing refrigerant leakage, and promoting energy-efficient cooling solutions. Manufacturers strive to develop absorption chillers with low global warming potential (GWP) refrigerants, such as water and ammonia, to minimize environmental impact and comply with regulations on refrigerant usage. Additionally, efforts are made to improve energy efficiency and reduce electricity consumption in absorption chiller operations through system optimization, variable-speed control, and waste heat recovery. Moreover, initiatives such as life cycle assessment (LCA), eco-design principles, and environmental certifications contribute to promoting sustainable practices and responsible consumption in the Absorption Chillers market.

Top of Form

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

Thermax Limited

Carrier Corporation

Trane Technologies plc

Johnson Controls International plc

Broad Air Conditioning Co., Ltd.

Yazaki Corporation

Robur Corporation

Mitsubishi Heavy Industries Thermal Systems, Ltd.

Hitachi Appliances, Inc.

Shuangliang Eco-Energy Systems Co., Ltd.

EAW Energieanlagenbau GmbH

Century Corporation

The research report provides a comprehensive analysis of the Absorption Chillers Market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-absorption-chillers-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

#absorptionchillers#energyefficiency#sustainablecooling#infrastructuredevelopment#environmentalimpact

0 notes

Text

Enhance Your Cooling System with Water Tank Chillers

Are you tired of dealing with inadequate cooling systems that fail to meet your industrial or commercial needs? Look no further! Water tank chillers are here to revolutionize the way you handle cooling in your facility. Whether you're in the food processing industry, manufacturing sector, or any other field that requires precise temperature control, water tank chillers offer unmatched efficiency and reliability.

Understanding Water Tank Chillers

What are Water Tank Chillers?

Water tank chillers are robust cooling systems designed to maintain consistent temperatures in various industrial processes. They utilize a closed-loop refrigeration cycle to remove heat from water and maintain it at the desired temperature. These chillers come in various sizes and configurations to suit different applications, from small-scale operations to large industrial facilities.

How Do Water Tank Chillers Work?

At the heart of a water tank chiller lies a refrigeration system comprising compressors, condensers, evaporators, and expansion valves. The process begins with the compressor, which compresses refrigerant gas, raising its pressure and temperature. The hot, high-pressure gas then flows through the condenser, where it dissipates heat and condenses into a liquid.

Next, the liquid refrigerant passes through an expansion valve, where its pressure drops dramatically, causing it to evaporate and absorb heat from the water in the tank. This chilled water is then circulated through the process equipment, absorbing heat and maintaining optimal operating temperatures. Finally, the refrigerant returns to the compressor to restart the cycle.

Advantages of Water Tank Chillers

Precision Temperature Control

One of the most significant advantages of water tank chillers is their ability to provide precise temperature control. Whether you require sub-zero temperatures for food preservation or specific temperatures for industrial processes, these chillers can deliver consistent and reliable cooling performance.

Energy Efficiency

In today's energy-conscious world, efficiency is paramount. Water tank chillers excel in this aspect, offering high levels of energy efficiency compared to traditional cooling methods. By optimizing refrigeration cycles and utilizing advanced control systems, these chillers minimize energy consumption while maximizing cooling capacity.

Versatility

Water tank chillers are incredibly versatile, catering to a wide range of applications across various industries. Whether you're cooling equipment, maintaining temperatures in a production line, or ensuring product quality during storage, these chillers can adapt to your specific needs with ease.

Reliability and Durability

When it comes to industrial equipment, reliability is non-negotiable. Water tank chillers are renowned for their robust construction and dependable performance, ensuring uninterrupted operation even in demanding environments. With proper maintenance, these chillers can provide years of trouble-free service, minimizing downtime and maximizing productivity.

Applications of Water Tank Chillers

Food and Beverage Industry

In the food and beverage industry, maintaining optimal temperatures is crucial for preserving freshness and ensuring product quality. Water tank chillers play a vital role in this process, providing precise cooling for food processing, storage, and packaging operations. Whether it's chilling ingredients, freezing products, or controlling fermentation processes, these chillers offer unmatched reliability and efficiency.

Manufacturing and Industrial Processes

From plastics manufacturing to pharmaceutical production, temperature control is essential in various industrial processes. Water tank chillers are indispensable in these applications, providing cooling solutions for equipment, machinery, and production environments. Whether you're molding plastic components, extruding metal alloys, or conducting chemical reactions, these chillers can maintain the required temperatures with unparalleled accuracy.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on water tank chillers to provide chilled water for cooling buildings and commercial spaces. These chillers are integral components of central cooling plants, where they circulate chilled water through air handling units to maintain comfortable indoor temperatures. With their energy-efficient operation and precise temperature control, water tank chillers contribute to sustainable building practices and optimal comfort levels for occupants.

Conclusion

In conclusion, water tank chillers represent the pinnacle of cooling technology, offering unmatched efficiency, reliability, and versatility for various industrial and commercial applications. Whether you're in the food processing industry, manufacturing sector, or HVAC field, these chillers can enhance your cooling system and drive productivity to new heights. Invest in a water tank chiller today and experience the difference it can make in your operations.

1 note

·

View note

Text

Increasing Construction Activities Boosts MEA Chiller Market

The MEA chiller market is estimated to touch USD 1,227.6 million in 2023, which will reach USD 1,872.5 million, advancing at a 6.5% compound annual growth rate, by 2030.

The growth of this industry can be because of the increasing progression in the construction sector, the growing requirement for chillers for district cooling systems, and government support.

Moreover, the rising demand for chillers from the hospitality and transportation sectors is also fueling the industry. Additionally, the regional nations are concentrating on utilizing renewable energy for chillers and energy-efficient cooling and heating solutions.

Furthermore, the providers of district cooling are now emphasizing energy-efficient technologies to decrease their operational expenses and enhance the feasibility of their procedures. These strategies will further boost the progression of this industry during this decade.

The screw category, based on chiller type, is the largest contributor to the industry. This can be because of the increasing acceptance of screw chillers in industrial and commercial sectors.

Moreover, this category is further split into two parts: air-cooled and water-cooled, among these, water-cooled chillers account for a significant share. This can be because water-cooled chillers are extensively favored when the power consumption is more than 5 MW coupled with the arrival of developed water-cooled chillers.

The commercial category, based on end users, is leading the MEA chiller market. Moreover, this category comprises transportation, government, hospitality, offices and buildings, supermarket/hypermarket, healthcare, and other sectors, which together creates a high requirement for chillers.

Furthermore, between these, the transportation category will propel at a swift rate in the coming years. This will be because of the current as well as upcoming transportation developments in Nigeria, Egypt, Saudi Arabia, Qatar, Israel, and the U.A.E.

Whereas, the industrial category will advance at a remarkable rate during this decade. This is because of the increasing count of industrial projects, including oil & gas, in this region. The U.A.E., for instance, is witnessing huge funding for oil & gas plant expansion projects to increase the capacity of production.

Saudi Arabia is the largest contributor to the industry. This is because the nation is observing enlarged construction activities, which comprise metro and hotel projects, because of the enhancing tourism sector.

Moreover, the growth is also driven by government initiatives, including the National Transformation Programme (NTP) and Saudi Vision 2030.

Whereas, the U.A.E. will propel at a significant rate, of 6.7%, during this decade. This is because of the increasing count of construction projects in this nation, including hotels, because of the surging count of tourists.

With the continuous rise in construction activities, the MEA chiller industry will continue to progress in the coming years.

Source: P&S Intelligence

#MEA Chiller Market Share#MEA Chiller Market Size#MEA Chiller Market Growth#MEA Chiller Market Applications#MEA Chiller Market Trends

1 note

·

View note

Text

Installing district cooling |

District cooling for commercial buildings

Installing district cooling for commercial buildings involves strategically placing chillers and laying down underground pipes to efficiently distribute chilled water throughout the complex. By centralizing cooling production and distribution, businesses can enjoy cost-effective and environmentally friendly cooling solutions, ensuring optimal comfort for occupants. The installation process of district cooling systems for commercial buildings requires careful planning and coordination to maximize efficiency and minimize disruption to operations.

0 notes

Link

ESEM International helps meet your building efficiency needs with the widest variety of water-cooled industrial and commercial chillers, Swimming Pool Heat Pumps, Water Coolers, Beverage Display Chillers, etc. on the market. From reducing your facility’s carbon footprint to cutting operating costs, our energy-efficient products are tailored to fit almost any application. To know more information visit: https://www.eseminternational.com/water-chiller.html

#Swimming pool warmer#Water chiller Dubai#Heavy Industrial Water Chiller#Commercial water chiller system

0 notes

Text

Experience unconditional performance with the new Carrier AquaEdge®19MV. Click here to know more:

0 notes

Text

Boilers and chillers Erection manufacturer and supplier

We have decades of experience servicing boilers and chillers for multiple commercial and industrial facilities as well as servicing other mechanical, electrical and plumbing systems.we provide Magnetic bearing chillers,Screw & scroll chillers,Reciprocating chillers,Steam & hot water boilers,Reciprocating chillers,Steam & hot water boilers,Chiller & boiler controls, System pumps and Cooling tower.

For more details please visit our website -

#boiler#chiller#erection#manufacturer#supplier#steam boiler#hot water boiler#system pumps#cooling towers#boiler parts

0 notes

Text

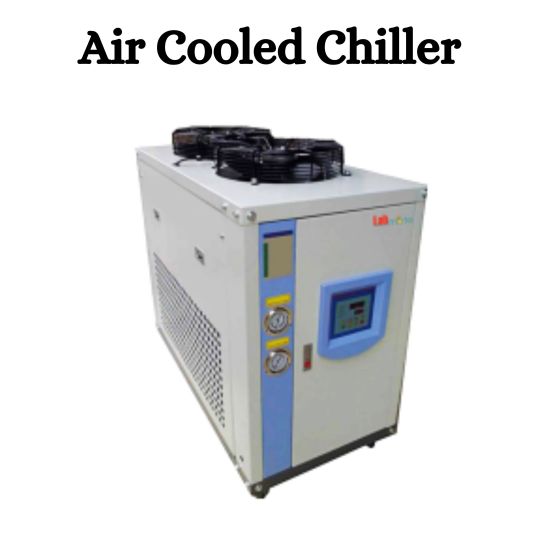

Air Cooled Chiller

An air-cooled chiller is a type of cooling system used to remove heat from a liquid, typically water, by transferring it to the air around the chiller unit. These chillers are commonly used in industrial and commercial settings for air conditioning, process cooling, and other applications where water-cooled systems are not practical or feasible. However, they can be less energy-efficient compared to water-cooled chillers, especially in hot climates where the ambient air temperature is high.

0 notes

Text

Reasons For Cooling Tower Maintenance in Columbia and Leesburg, VA

AA cooling tower can diffuse the heat perfectly and keep the commercial or industrial air conditioning functioning properly. As with other things, cooling tower maintenance in Columbia and Leesburg, VA, is integral to ensuring comfort and convenience for individuals residing or working in the concerned facilities/buildings.

Failure to maintain properly can pose a risk to all concerned. Therefore, it is essential to contact a maintenance expert with the know-how and experience of having the system function flawlessly. Maintenance is a complicated term that includes several steps, each of which is ensured. Some of the aspects of maintenance that require close consideration are:-

· Inspection- It pays to inspect the machinery at periodic intervals to know whether there are any flaws. Some issues may seem minuscule and inconsequential but aggravate over time and become serious. The first thing to check is the lubrication. The pump's operation will likely be compromised when there is insufficient lubrication. One may improve the pump's efficiency, which will move smoothly once the parts are lubricated. It is advisable to add some lubricant to the water seals and motor bearings. Checking the alignment of the individual components is essential, too.

· Airflow- The poor performance of a cooling tower is usually caused by restricted airflow. This may result in significant problems when not addressed appropriately. The cooling tower may ease functioning altogether as well. While multiple factors may cause such interruptions to unhindered airflow, it is important to identify the core problem and rectify it to have the system up and running again.

· Water Treatment- This is one of the most vital maintenance parts. The water treatment should be done to ensure both safety and efficiency of the tower. It is essential to know that the water in the tower may become a breeding ground for deadly bacteria that may adversely affect individuals' health. Moreover, unclean and contaminated water used by the tower may have an unbalanced pH or biofilm formation on its surface that may corrode the machinery, causing the tower to malfunction. Proper water treatment at regular intervals will not only add to the life of the tower but will also prevent health issues for the people nearby.

· Cleaning- Heat exchange between the condenser tubes inside the tower and the AC units/chillers is facilitated when the tower system performs perfectly. Improper or no maintenance can cause malfunction or improper cooling of the air. The slime, contaminants, and scales need to be cleaned from the condenser tubes regularly to avoid trouble during operation. Consistent cleaning is of paramount importance as build-ups are noticed in such towers that undergo water treatment frequently

The community or building residents may develop a plan for cooling tower maintenance in Columbia and Leesburg, VA. Obtaining assistance in such tasks is advisable so that there is no interruption in system maintenance.

0 notes

Text

Value Addition: Pioneering Sustainable Solutions in Dubai's Energy Sector

In the heart of Dubai's bustling energy landscape, Value Addition stands tall as a beacon of innovation and sustainability. Since its inception in 1997, with roots in both India and the UAE, Value Addition has emerged as a frontrunner in providing comprehensive solutions for a diverse array of industries, hospitality, hospitals, residences, institutions, malls, and leisure facilities. Specializing in system conceptual design, supply, installation, commissioning, and maintenance, Value Addition is synonymous with excellence and reliability.

At the core of Value Addition's offerings lie its expertise in hot water and steam boilers, thermal oil heaters, solar thermal, photovoltaic systems, oil/gas-fired condensing boilers, vapor absorption chillers, high-power LED lighting, piping, hydronic valves, commercial and industrial burners, and specialized services. With a deep reservoir of engineering knowledge and a wealth of experience, Value Addition excels in providing optimized and versatile solutions tailored to the unique requirements of various industries and applications.

Central to Value Addition's commitment to sustainability is its pioneering work in renewable energy solutions, particularly in the domain of solar technology. With a steadfast focus on innovation, Value Addition has spearheaded numerous projects in the UAE, including the installation of solar water heating systems and solar photovoltaic energy systems. This commitment to harnessing the power of the sun not only underscores Value Addition's dedication to environmental stewardship but also positions it as a trailblazer in the region's transition towards renewable energy sources.

One of Value Addition's flagship offerings is its centralized hot water heating systems, with a track record of successfully completing over 100 projects in the UAE alone. Leveraging its profound understanding of the intricacies of heating systems, Value Addition ensures seamless integration from generation to distribution, guaranteeing an uninterrupted supply of hot water to its clients. Whether it's for industrial, commercial, or residential applications, Value Addition's centralized hot water heating solutions are engineered to deliver unparalleled performance and efficiency.

Beyond the borders of the UAE, Value Addition's footprint extends across the Middle East, with over 800 turnkey projects under its belt. From Jordan to Oman, Value Addition has left an indelible mark with its installations, totaling over 500 MW+ of heating power. This extensive network of projects serves as a testament to Value Addition's unwavering commitment to excellence and customer satisfaction.

In addition to its prowess in heating solutions, Value Addition excels in the realm of industrial heating and cooling. With over 200 installations across the region, Value Addition has earned a reputation for delivering robust and reliable systems that cater to the diverse needs of industries. Whether it's maintaining optimal temperatures in manufacturing facilities or ensuring comfort in commercial spaces, Value Addition's solutions are engineered to perform under the most demanding conditions.

At the heart of Value Addition's success lies its unwavering dedication to adding value to its clients' operations. Through a comprehensive suite of products and services, backed by years of experience and expertise, Value Addition remains committed to driving innovation, sustainability, and efficiency in Dubai's energy sector. As the industry evolves and the demand for sustainable solutions continues to grow, Value Addition stands poised to lead the way, shaping the future of energy one project at a time.

#Solar water heating system in Dubai#Hot Water Boiler System in Dubai#Steam Boiler Suppliers in UAE#Solar Water Heaters Suppliers in UAE

0 notes