#Compact Data Center Server

Explore tagged Tumblr posts

Text

HD-H242-Z11 High-Density 4-Node Server | Edge & Data Center Ready

Upgrade your infrastructure with the HD-H242-Z11 Ver Gen001 – a compact 2U high-density server featuring 4 independent nodes with Intel® Xeon® D processors. Designed for edge computing, data centers, and mission-critical deployments, it offers high-performance computing, front-access storage bays, IPMI remote management, and optional 10G networking. Ideal for virtualization, analytics, and enterprise workloads in limited-space environments. for more details:: Hexadata HD-H242-Z11 Ver: Gen001 | High Density Server Page

#HD-H242-Z11 Server#High-Density Server#4-Node Server#2U Rack Server#Xeon D Server#Edge Computing Server#Rugged Server Solution#Twin Node Server#Compact Data Center Server#Gigabyte High-Density Server#Enterprise Server Solution#IPMI Remote Management Server#Front Access Storage Server#Edge Deployment Hardware#Modular Server System

0 notes

Text

Astronomers discover 2,674 dwarf galaxies using Euclid telescope

ESA's Euclid space telescope has been providing valuable data from the depths of space for almost two years. With its help, the largest and most accurate 3D map of the universe to date is to be created, with billions of stars and galaxies. The data from Euclid is analyzed by the international Euclid consortium, which also includes the research teams of Francine Marleau and Tim Schrabback at the University of Innsbruck.

From 25 Euclid images, astronomer Marleau and her team at the Department of Astro- and Particle Physics at the University of Innsbruck have now discovered a total of 2,674 dwarf galaxies and created a catalogue of dwarf galaxy candidates. Using a semi-automatic method, the scientists have identified candidates and analyzed and described them in detail.

"Of the galaxies identified, 58% are elliptical dwarf galaxies, 42% are irregular galaxies and a few are rich in globular clusters (1%), galactic nuclei (4%) and a noticeable fraction (6.9%) of dwarfs with blue compact centers," say Marlon Fügenschuh and Selin Sprenger from Marleau's team.

Testing cosmological models

The study, posted to the arXiv preprint server, provides insights into the morphology, distance, stellar mass, and environmental context of dwarf galaxies. As part of the Euclid project, Marleau is investigating the formation and development of galaxies, especially dwarf galaxies, the most numerous galaxies in the universe, whose abundance and distribution provide critical tests for cosmological models.

"We took advantage of the unprecedented depth, spatial resolution, and field of view of the Euclid Data. This work highlights Euclid's remarkable ability to detect and characterize dwarf galaxies, enabling a comprehensive view of galaxy formation and evolution across diverse mass scales, distances, and environments", emphasizes Marleau.

Deep look into the universe

The European Space Agency's (ESA) Euclid space telescope was launched on 1 July 2023. Scientists hope to learn more about the previously unexplored dark matter and dark energy that make up the universe. The international Euclid consortium analyzes the data. Over the next few years, the 1.2-meter-diameter space telescope will create the largest and most accurate 3D map of the universe and observe billions of galaxies.

Euclid can use this map to reveal how the universe expanded after the Big Bang and how the structures in the universe have developed. This gives scientists more clues to better understand the role of gravity and the nature of dark energy and dark matter.

More than 2,000 scientists from about 300 institutes and laboratories are jointly analyzing the mission data, which are also supplemented by ground-based telescopes.

IMAGE: Some of the dwarf galaxies discovered in the Euclid images. Credit: arXiv (2025). DOI: 10.48550/arxiv.2503.15335

13 notes

·

View notes

Text

>>You're busily scouring the halls of a veritable palace of corridors and cavernous spaces, the demi-plane of memory and data that represents the inner workings of your psionic powers. To so seamlessly blend the real, the digital, and the abstract, bends the mind into pretzels. So like most of the long-dead possessors of such a highly-personalized space, your mind forms a Partition Suite to navigate it in, in your own way. The entire place is at once compact and endless, a series of chambers and hallways, crammed with books and manila folders, with terminals and server towers, all containing detailed data; experiences, muscle memories, learned skills, schematics. It's all here.

>>You keep a Partition of yourself here full time, both as one of the regular functions of your power, and to act as a systems administrator. You can split your focus this way, without relinquishing control. Normally, you think to yourself, the SysAdmin just pings you via normal telepathy, but this time, you demanded that you come into the Suite and see what's going on for yourself. The corridor dumps you into the main chamber of the demi-plane. Sprawling over what looks like an endless city of towering buildings, the Hub is a floating island above the "Stacks Room." Every building is a server, the true representation of all those folders and books, all those skills.

>>You emerge from a gateway at the edge of the island, a portal exit from a real corridor somewhere else inside the Suite. The island itself is an inverted ziggurat, hosting a sprawling complex at the top. The widest level is consumed with what look to be bizarre crosses between functional buildings, and pieces of computer machinery, blown up to building sizes. All of it leads to a hole in the center of the island, broadly encircled by rings of platforms, climbing upwards until one stands eye-level with the Systems Administrator.

>>You look fondly on the image of yourself as you scramble up the platforms. All Partitions are direct reflection of your own visage, itself subject almost entirely to your whims these days, but the SysAdmin is always a little different. The SysAdmin is inhumanly large, and visible only from the waist up as she emerges from the hole, dressed in a pair of worker's coveralls. Just like you, the SysAdmin likes to show off what they got, and keeps the coveralls unzipped to the belly button. Unlike you, however, the SysAdmin sports six arms to your two, and uses them as naturally as she appears to breathe. The inside of the rings are lined with walls of projected screens, holographic data feeds, input fields, keyboards, everything goes through this Partition of you.

>>This time though, she's not working. The SysAdmin is doing that thing you do, where you vent stress by excessively rubbing your eyes, or by running your hands through your hair. Two of her arms are crossed, and sitting at their intersection is a woman. A woman with fiery red hair down to her tailbone, with features ominously close to your own. There's an energy in her eye that you feel has burned out of your own since the Time Loop was settled. She still has fire, and she's clearly of you. You feel like you've had time-enough to sort out the answer, and you're not sure how you feel about it. There hadn't really been enough time to sort out who she had ever been to you, in the past.

>>But that doesn't appear to matter anymore, because the drive to survive never left her, even as she reincorporated into you, seemingly swallowed up by Partition before you were sealed away. And yet, there she is, sitting mostly naked and draped in a coat she must've stolen from some stray memory in the Suite. There's barely a care on her face, as she stares back at you, you can tell there's a deep uncertainty in her eyes, but you've stared for too long. Unfortunately for you, you lack the words to say anything but her name.

>>"Blair?"

4 notes

·

View notes

Text

Efficient Cooling Solutions: Navigating Mumbai's Industrial Landscape with Water-Cooled Chillers

In the bustling industrial hub of Mumbai, where the relentless operation of machinery generates substantial heat, the need for effective cooling solutions has never been more critical. Among the diverse range of cooling technologies available, water-cooled chillers stand out as a reliable and efficient option. This article delves into the significance of water-cooled chillers in Mumbai's industrial context, highlighting their benefits, applications, and contributions to sustainable practices.

The Role of Water-Cooled Chillers: Water-cooled chillers play a pivotal role in maintaining optimal operating conditions for industrial processes by dissipating excess heat. In contrast to air-cooled alternatives, water-cooled chillers offer superior cooling efficiency, making them an ideal choice for the demanding requirements of Mumbai's industries. These chillers utilize water as a highly effective heat transfer medium, ensuring consistent and reliable cooling even in high-heat environments.

Advantages and Benefits:

Enhanced Efficiency: Water-cooled chillers boast higher efficiency compared to air-cooled systems, resulting in energy savings and reduced operating costs for industrial establishments.

Space Optimization: The compact design of water-cooled chillers allows for efficient space utilization within Mumbai's often limited industrial facilities.

Noise Reduction: Water-cooled systems are generally quieter than air-cooled counterparts, contributing to a more conducive working environment for employees.

Temperature Stability: With precise temperature control capabilities, water-cooled chillers ensure that critical processes are carried out consistently and efficiently.

Longevity: The use of water as a cooling medium helps extend the lifespan of equipment, reducing the frequency of maintenance and replacements.

Applications Across Industries: Water-cooled chillers find applications in various industries across Mumbai:

Manufacturing: Cooling machinery and equipment in industries such as textiles, chemicals, and automotive manufacturing ensures uninterrupted production and product quality.

Pharmaceuticals: Precise temperature control is crucial in pharmaceutical production, making water-cooled chillers indispensable for maintaining the integrity of sensitive substances.

Data Centers: As data centers proliferate, water-cooled chillers aid in preventing overheating of servers and ensuring reliable operations.

Food Processing: From refrigeration to maintaining hygiene during processing, water-cooled chillers contribute to safe and efficient food production.

Sustainability and Environmental Impact: In a time when sustainability is a global priority, water-cooled chillers offer significant environmental benefits. By reducing energy consumption and greenhouse gas emissions, these systems align with Mumbai's efforts towards a greener future. Additionally, water-cooled chillers can integrate with renewable energy sources, further enhancing their eco-friendly profile.

Conclusion: As Mumbai's industrial landscape continues to evolve, the role of water-cooled chillers remains paramount in ensuring efficient operations and sustainable practices. Their advantages in terms of efficiency, space optimization, and environmental impact make them a valuable asset across diverse industries. By embracing water-cooled chiller technology, Mumbai's industries can effectively navigate the challenges of heat management while contributing to a more sustainable and prosperous future.

2 notes

·

View notes

Text

Clean Energy Shift Sparks Massive Growth in Silicon Carbide MOSFETs Market

Silicon carbide (SiC) MOSFETs are revolutionizing power semiconductor applications with their superior efficiency, high-temperature tolerance, and compact design advantages over traditional silicon MOSFETs. SiC MOSFETs enable higher voltage capabilities, reduced switching losses, and smaller form factors—making them highly suitable for electric vehicles (EVs), renewable energy systems, and industrial applications.

As global energy infrastructure undergoes rapid electrification and decarbonization, SiC MOSFETs are becoming integral to this transformation, facilitating higher power density, better efficiency, and system miniaturization across sectors.

Market Drivers & Trends

The key factors fueling the growth of the silicon carbide MOSFETs market include:

Accelerated adoption of electric vehicles: EVs increasingly use SiC MOSFETs in on-board chargers (OBCs), inverters, and battery management systems to optimize energy efficiency and performance.

Rapid deployment of renewable energy systems: The demand for solar PV inverters and energy storage systems that utilize SiC MOSFETs continues to surge.

Increased focus on energy efficiency: SiC MOSFETs' ability to handle high frequencies and temperatures supports the miniaturization and optimization of power electronic systems.

Cost reduction due to scale and innovation: As production volumes rise and competition intensifies, the costs of SiC devices have declined significantly, further driving adoption.

Latest Market Trends

Recent market trends emphasize the growing importance of WBG semiconductors, particularly in the EV and power grid sectors:

Widespread use of 1200 V – 1700 V breakdown voltage SiC MOSFETs: These are gaining momentum for applications in solar PV, HVAC systems, motor drives, and charging infrastructure.

High-performance traction inverters: Automakers are adopting SiC-based inverters to extend driving range and improve energy efficiency.

Solar and energy storage integrations: Utility-scale installations are increasingly relying on SiC MOSFETs to enhance inverter efficiency and reduce system size.

Access important conclusions and data points from our Report in this sample – https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=81899

Key Players and Industry Leaders

The market is characterized by innovation-driven competition. Key players include:

STMicroelectronics N.V.

WOLFSPEED, INC.

Infineon Technologies AG

ROHM CO., LTD.

Toshiba Electronic Devices & Storage Corporation

Microchip Technology Inc.

Diodes Incorporated

Littelfuse, Inc.

SemiQ, Inc.

Sansha Electric Manufacturing Co., Ltd.

These companies are heavily investing in R&D, launching new product lines, and expanding their global footprint through strategic collaborations and acquisitions.

Recent Developments

September 2022: SemiQ launched a 1200V 40mΩ second-generation SiC MOSFET offering better switching efficiency for broad applications.

August 2022: Toshiba introduced its TWxxNxxxC SiC MOSFET series, with 650V and 1200V variants, targeting EVs, industrial equipment, and renewable energy solutions.

Wolfspeed and STMicroelectronics have announced expansion of their SiC production capacity to meet the rising global demand.

Market Opportunities

The expanding demand for efficient power electronics across sectors opens new avenues:

EV Infrastructure: Growing installation of EV fast-charging stations is boosting SiC MOSFET demand for high-power and reliable converters.

Data Centers: Increased use of SiC MOSFETs in UPS systems and server PSUs to reduce energy consumption and thermal footprint.

Industrial Automation: SiC MOSFETs are being adopted in motor drives and factory equipment for better operational control and efficiency.

Energy Storage: Integration of SiC in battery management and grid-level storage systems to enhance scalability and response time.

Future Outlook

The silicon carbide MOSFETs market is set to experience exponential growth over the next decade. Analysts expect advancements in 8-inch SiC wafer production and vertical integration strategies to bring further cost efficiencies. Increased collaboration between automotive OEMs and SiC component manufacturers is likely to catalyze mass adoption across electric mobility platforms.

By 2031, widespread electrification, renewable energy commitments, and stringent energy efficiency standards will solidify SiC MOSFETs' position as a cornerstone technology in global power electronics.

Market Segmentation

By Breakdown Voltage:

650 V – 900 V

900 V – 1200 V

1200 V – 1700 V (Largest segment)

Above 1700 V

By Application:

Inverters (Highest CAGR – 30.4%)

On Board Chargers (OBC)

Uninterruptible Power Supply (UPS)

Motor Drives

Energy Storage Systems

Others (Server, Switch Mode Power Supply)

By End-use Industry:

Automotive

Energy & Power

Industrial

Consumer Electronics

Others (Telecommunication, Healthcare)

Regional Insights

Asia Pacific held the largest market share in 2022 at 33.2%, led by China, India, Japan, and South Korea. Government incentives, booming EV sales, and rapid solar PV deployment are key growth factors.

North America emerged as the second-largest market, with strong contributions from the U.S. Renewable energy incentives, EV policy support, and increasing solar energy adoption are spurring demand.

Europe is also seeing significant adoption due to climate goals, automotive electrification, and innovation-led demand in industrial sectors.

Why Buy This Report?

In-depth Industry Analysis: Detailed segmentation by voltage, application, end-use, and geography.

Forecasts up to 2031: Market size, volume, and growth projections.

Competitive Intelligence: Profiles of leading players with insights into strategy and innovation.

Technology Trends: Analysis of emerging technologies, product developments, and market disruptors.

Regional Forecasts: Insights into major regional markets and country-level growth drivers.

This report serves as a comprehensive tool for decision-makers, investors, and businesses to understand market dynamics, identify opportunities, and stay ahead in the rapidly evolving SiC MOSFET landscape.

0 notes

Text

Glass Interposers Market 2025

The global glass interposers market was valued at US dollars two hundred thirty four point five million in two thousand twenty four and is forecasted to reach US dollars four hundred seventy eight point nine million by two thousand thirty reflecting a compound annual growth rate of twelve point six percent from two thousand twenty four to two thousand thirty. Glass interposers are innovative interconnection substrates used primarily in advanced semiconductor packaging. These components serve as a bridge connecting multiple integrated circuit dies in high density electronic packages. Unlike traditional interposers made from silicon or organic materials glass interposers utilize ultra thin sheets of specialized glass. Their key advantages include excellent electrical insulation minimal signal loss high thermal resistance and support for fine pitch interconnects. These features make them ideal for high performance computing systems fifth generation telecommunications optoelectronics and advanced consumer electronics.

Get free sample of this report at : https://www.intelmarketresearch.com/semiconductor-and-electronics/864/Glass-Interposers-Market

Glass interposers are essential for packaging technologies such as two point five dimensional and three dimensional integrated circuits where multiple chips are stacked or placed side by side. Their compatibility with through glass vias further enhances high speed data transmission with minimal latency and low power consumption. Glass interposers are well suited for use in artificial intelligence processors data centers and photonic devices because they offer superior electrical insulation thermal stability and higher interconnect density than conventional substrates. Adoption is driven by the push for advanced two point five dimensional and three dimensional packaging technologies and heterogeneous integration.

Market Size On a regional level the United States glass interposers market is also growing robustly. Valued at US dollars sixty one point five million in two thousand twenty four it is projected to reach US dollars one hundred twenty two point three million by two thousand thirty with a compound annual growth rate of twelve point one percent during the same period.

This growth trajectory is driven by the increasing adoption of high performance computing systems advancements in artificial intelligence and fifth generation technologies and the rising demand for miniaturized high density semiconductor packaging.

Market Dynamics Drivers Restraints Opportunities and Challenges Drivers Miniaturization of Electronic Components The trend toward smaller more powerful electronic devices necessitates compact yet high performance packaging. Glass interposers offer the density thermal management and fine line interconnection capabilities that enable this miniaturization.

High Performance Computing and Artificial Intelligence Artificial intelligence and high performance computing workloads require faster data transfer and better thermal management. Glass interposers provide low electrical resistance and superior thermal properties facilitating the performance required in servers graphics processing units and artificial intelligence processors.

Advancements in Semiconductor Packaging With the evolution of two point five dimensional and three dimensional integrated circuit packaging the role of interposers has become more significant. Glass interposers support high density interconnects better signal integrity and can be manufactured to thinner specifications than silicon.

Demand in Consumer Electronics Devices like smartphones wearables and smart home systems increasingly demand efficient space saving packaging. Glass interposers allow the integration of multiple functionalities into a single compact module.

Restraints High Manufacturing Costs The precision and specialized techniques required for producing glass interposers make them costlier compared to alternatives. The capital investment for equipment like laser drilling systems and plasma etching machines is significant.

Complexity in Mass Production Due to the need for ultra thin defect free glass and complex through glass via processing scaling up production remains a challenge.

Availability of Alternatives Silicon and organic interposers are well established in the market with mature production ecosystems and cost advantages. These pose a barrier to wider adoption of glass interposers especially in cost sensitive applications.

Opportunities Fifth Generation and Automotive Electronics Emerging applications in fifth generation infrastructure and automotive electronics require high speed reliable data transmission and thermal stability areas where glass interposers excel.

Material Innovation Integrating glass interposers with new semiconductors photonics and quantum computing components could enable cutting edge innovations in electronics.

Collaborative Development Partnerships between semiconductor manufacturers and glass substrate developers are fostering innovation improving yields and driving down costs.

Challenges Technical Limitations Despite their benefits glass interposers face technical hurdles in areas like ultra high density interconnects and extreme thermal environments.

Market Education and Adoption Shifting from traditional packaging methods requires significant investment and technical training. Convincing manufacturers to adopt glass interposers can be slow.

Supply Chain Bottlenecks The niche nature of the glass interposer market results in a less robust supply chain. Delays in sourcing raw materials or equipment can impact production timelines and costs.

Regional Analysis North America North America particularly the United States is a major player in the glass interposer market driven by high investments in semiconductor research and development and the presence of key technology firms. The strong demand for artificial intelligence cloud computing and fifth generation applications propels regional market growth.

Europe European countries such as Germany the United Kingdom and France are contributing through innovations in automotive electronics and smart industrial systems. Europe’s strong automotive and aerospace sectors also encourage the adoption of advanced interposer technologies.

Asia Pacific Asia Pacific led by China Japan and South Korea dominates the global market in volume. The region houses major semiconductor manufacturers and experiences rapid growth in electronics telecommunications and automotive sectors. Government support and technological advancement in manufacturing processes are also key enablers.

South America and the Middle East and Africa While relatively nascent South America and the Middle East and Africa regions are expected to grow due to increasing mobile and internet penetration smart city initiatives and investments in digital infrastructure.

Competitor Analysis Leading companies in the glass interposers market include

Kiso Micro Co Specializes in ultra thin glass and precision microfabrication Plan Optik AG Known for its high quality glass substrates and microstructured glass Ushio A key supplier of optical and semiconductor equipment Corning Offers specialty glass and ceramic materials with applications in semiconductor packaging Three D Glass Solutions Inc Focused on glass based RF and microwave interposer technology Triton Microtechnologies Inc Provides custom solutions in glass interposer design and manufacturing

These players are engaged in research and development activities strategic partnerships and capacity expansions to enhance their market presence.

Recent Developments In two thousand twenty four through the Packaging Applications Center of Excellence PACE Onto Innovation and LPKF Laser and Electronics SE partnered to expedite the mass manufacturing of glass core based panel level packages. The goal of this partnership is to satisfy the increasing need for cloud computing artificial intelligence and high performance computing applications. Between two thousand twenty five and two thousand twenty six AMD plans to use glass substrates in its high performance system in packages. Advanced system in packages in data center applications can benefit from glass substrates’ superior flatness mechanical strength and thermal characteristics over conventional organic substrates.

Global Glass Interposers Market Segmentation Analysis This report provides deep insight into the global glass interposers market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size competitive landscape development trend niche market key market drivers and challenges SWOT analysis value chain analysis and more.

The analysis helps the reader to shape competition within industries and to develop strategies for the competitive environment to enhance potential profit. Furthermore it provides a framework for evaluating and assessing the position of the business organization. The report structure also focuses on the competitive landscape of the global glass interposers market. It introduces in detail the market share market performance product situation operation situation and more of the main players which helps industry readers identify the main competitors and deeply understand the competition pattern of the market.

In a word this report is a must read for industry players investors researchers consultants business strategists and all those who have any kind of stake or plan to enter the glass interposers market in any manner.

Market Segmentation by Type Two Dimensional Two point Five Dimensional Three Dimensional

Market Segmentation by Manufacturing Process Laser Drilling and Etching Wafer Level Packaging Temporary Bonding and Debonding Others

Market Segmentation by Application Logic Imaging and Optoelectronics Memory MEMS and Sensors LED Others

Market Segmentation by End Use Industry Consumer Electronics Telecommunications Automotive Healthcare Military and Aerospace Others

Key Companies Kiso Micro Co Plan Optik AG Ushio Corning Three D Glass Solutions Inc Triton Microtechnologies Inc

Geographic Segmentation North America including USA Canada and Mexico Europe including Germany UK France Russia Italy and Rest of Europe Asia Pacific including China Japan South Korea India Southeast Asia and Rest of Asia Pacific South America including Brazil Argentina Colombia and Rest of South America The Middle East and Africa including Saudi Arabia UAE Egypt Nigeria South Africa and Rest of MEA

Frequently Asked Questions FAQs What is the current market size of the Glass Interposers Market As of two thousand twenty four the global glass interposers market is valued at US dollars two hundred thirty four point five million with projections to reach US dollars four hundred seventy eight point nine million by two thousand thirty.

Which are the key companies operating in the Glass Interposers Market Key players include Kiso Micro Co Plan Optik AG Ushio Corning Three D Glass Solutions Inc and Triton Microtechnologies Inc.

What are the key growth drivers in the Glass Interposers Market Growth is fueled by miniaturization of electronics demand for high performance computing advancements in semiconductor packaging and increasing use in consumer electronics.

Which regions dominate the Glass Interposers Market Asia Pacific leads the market in terms of volume while North America is a major player in innovation and adoption. Europe also shows strong growth in automotive and industrial electronics.

What are the emerging trends in the Glass Interposers Market Emerging trends include integration with fifth generation and automotive electronics development of glass photonic interposers and strategic partnerships aimed at cost reduction and innovation.

Get free sample of this report at : https://www.intelmarketresearch.com/semiconductor-and-electronics/864/Glass-Interposers-Market

0 notes

Text

GaN Power Device Market: Transforming Energy Efficiency and Power Solutions Across Automotive, Telecom, and Consumer Electronics

The global electronics and power systems landscape is undergoing a transformative shift with the increasing adoption of Gallium Nitride (GaN) power devices. GaN, a wide-bandgap semiconductor material, offers significant advantages over traditional silicon-based components. These benefits—such as higher efficiency, faster switching speed, smaller size, and lower energy consumption—are driving a surge in demand across a range of industries, from consumer electronics and automotive to renewable energy and telecom infrastructure.

Revolutionizing Power Efficiency

One of the most prominent drivers of the GaN power device market is the need for energy-efficient systems. As the world becomes more conscious of sustainability and environmental impact, industries are under pressure to design products that consume less power without compromising performance. GaN devices are inherently more efficient than their silicon counterparts. They can operate at higher voltages and temperatures, and their faster switching speeds reduce energy losses, making them ideal for modern power conversion systems.

These characteristics are particularly beneficial in applications like fast chargers, inverters, and electric vehicle (EV) systems. For instance, GaN-based chargers for smartphones and laptops are significantly smaller and faster than conventional chargers. They also run cooler and waste less energy during operation. This blend of convenience and efficiency is shaping a new consumer standard, further pushing manufacturers to adopt GaN technology.

Automotive Sector: Accelerated Integration

Electric vehicles and hybrid electric vehicles are at the forefront of the automotive transformation, and GaN power devices are playing a crucial role in this evolution. As car manufacturers strive to improve battery range, reduce weight, and enhance powertrain efficiency, GaN devices are emerging as a key enabler. They offer the ability to shrink the size of onboard chargers, DC-DC converters, and motor drive inverters—all essential components of EV architecture.

Furthermore, the automotive industry demands components that can withstand harsh environments while maintaining reliability. GaN’s capability to operate at high temperatures without degradation makes it well-suited for these challenges. As a result, major automotive players are investing in GaN-based technologies, not only to improve performance but also to meet increasingly strict environmental regulations.

5G and Data Centers: Powering the Future

The rollout of 5G networks and the exponential growth of data centers require highly efficient power delivery systems. GaN power devices, with their fast switching speed and high-frequency capabilities, are ideal for these applications. In base stations, GaN components help manage power more effectively, allowing telecom providers to build smaller, lighter, and more energy-efficient equipment.

In data centers, power management is critical due to the vast energy requirements of server farms. GaN devices enable more efficient voltage conversion and distribution, reducing power losses and improving thermal performance. With cloud computing, artificial intelligence, and IoT applications expanding rapidly, the need for robust and energy-efficient power infrastructure is greater than ever—and GaN technology is a strong solution to meet these needs.

Consumer Electronics: Compact and Capable

Consumer electronics is one of the most visibly impacted sectors by GaN adoption. From ultra-fast phone chargers to sleek, energy-efficient laptops and home entertainment systems, GaN devices are reshaping how electronic devices are powered. Users now demand fast-charging solutions that are compact enough to carry in a pocket but powerful enough to quickly recharge devices.

GaN-based adapters and power bricks are smaller and lighter because they require less heat dissipation and smaller passive components. This trend is encouraging major consumer electronics brands to redesign their power solutions with GaN, which in turn is fueling market growth at the consumer level.

Market Challenges and Developmental Hurdles

Despite the growing interest and adoption, the GaN power device market faces certain challenges. The technology is still relatively new compared to silicon, which benefits from decades of development and infrastructure. Manufacturing GaN devices involves complex processes and specialized substrates such as silicon carbide or sapphire, which can drive up costs.

Another hurdle is the availability of skilled engineers and designers who understand how to leverage GaN's capabilities fully. Traditional silicon design principles don’t always apply, and optimizing GaN’s performance requires a different engineering approach. However, as education around GaN technology improves and more design tools become available, these barriers are gradually diminishing.

Regional Market Dynamics

Geographically, Asia-Pacific leads the GaN power device market, driven by strong electronics manufacturing in countries like China, Japan, South Korea, and Taiwan. The region’s focus on EVs, consumer electronics, and telecom infrastructure provides a fertile ground for GaN growth.

North America and Europe are also key markets, with growing demand from automotive, aerospace, and defense sectors. The presence of major semiconductor firms and increasing R&D investments are helping accelerate GaN adoption in these regions. Government incentives for green energy and advanced transportation are further enhancing the market potential.

Looking Ahead

The future of the GaN power device market is bright. As the technology matures and manufacturing scales up, costs are expected to decline, paving the way for even broader adoption. With its superior efficiency, performance, and size advantages, GaN is well-positioned to become the new standard in power electronics.

Innovations in packaging, integration, and substrate materials will continue to evolve, expanding the range of GaN applications. From powering the next generation of electric vehicles to enabling ultra-efficient data centers and consumer devices, GaN technology is poised to play a pivotal role in the global shift toward smarter, cleaner energy solutions.

0 notes

Text

Understanding the Role of PDU Manufacturers and Rack Mount PDU Solutions

PDU manufacturers are critical in delivering dependable equipment when managing power in data centers and IT environments. A Power Distribution Unit (PDU) is essential for ensuring the right amount of power reaches your devices safely and efficiently. Rack Mount PDUs are especially important for organizations relying on rack-mounted equipment because we offer convenient, organized power management within server racks.

The Significance of PDU Producers

PDU manufacturers create and construct units customised explicitly to business environments' intricate power distribution requirements. High-quality producers' main concerns are durability, safety features, rack space, and equipment compatibility. Selecting the proper manufacturer can impact dependability and lower the likelihood of downtime.

At Hubnetix, we provide well-engineered PDUs designed for practical use in various environments. Our solutions include multiple socket configurations and easy installation features. This makes managing power a smoother task for IT teams.

Features of Rack Mount PDUs

Rack Mount PDUs are a simple and space-saving solution because they are made to fit straight into ordinary server racks. These PDUs are available in various sizes, including 6-way or 8-way UK sockets with standard cables and on/off controls.

Rack mount PDUs frequently have the following essential features:

Easy access to power sockets inside the rack

Compact design to save rack space

Durable construction for long-term use

On/off switches for individual control

Standardized cables for quick setup

These features help IT professionals maintain a clean and efficient power setup, vital in busy data centers or network rooms.

Choosing the Right Manufacturer

Choosing a reliable manufacturer is vital because not all PDUs are made equal. Reputable producers test their goods to fulfill stringent performance and safety requirements— our dedication to quality guarantees that the PDUs can withstand steady power demands without experiencing any issues.

We stand out by offering products that balance cost and quality. Our PDUs come with datasheets outlining specifications, helping buyers make informed decisions. The availability of support and warranty also adds value, providing peace of mind for customers.

How PDUs Support Your IT Infrastructure

Because we avoid overloads and provide consistent power, well-made PDUs from seasoned manufacturers keep your network operating smoothly. This lessens the possibility of hardware damage from erratic power supplies. Additionally, by keeping power cords accessible and organized, rack mount PDUs enhance cable management.

Businesses searching for power distribution solutions frequently discover that Hubnetix and other manufacturers provide a blend of high-quality goods and customer service, which facilitates the installation and upkeep of power systems.

Conclusion

Understanding the role of PDU manufacturers helps organizations make better choices when selecting power solutions. Rack mount PDUs are a practical and effective option for managing power in server racks, and choosing products from trusted manufacturers ensures safety and reliability. With a focus on quality and service, the proper PDU manufacturer supports the backbone of any IT environment.

We offer practical power distribution units that combine useful features and ease of use to meet the needs of modern data centers and network rooms. By selecting dependable PDUs, companies protect their investments and keep their operations running without interruption.

Read More: https://hubnetix.livepositively.com/understanding-the-role-of-pdu-manufacturers-and-rack-mount-pdu-solutions/new=1

0 notes

Text

Swissbit Storage Solutions for Data Centers, Enterprise and Edge Servers

06/05/2025 by Norman Schmidt

The evolution of servers and data centers has fundamentally changed the way businesses operate. As efficiency and data processing capabilities increase, the need for reliable and robust data storage solutions is also growing. In my new article, I discuss the challenges companies face and how Swissbit provides the ideal support with innovative storage solutions tailored for data centers, enterprise solutions and edge servers.

Introduction

Storage is an essential component in servers that affects performance and reliability. Well-thought-out component selection can enable systems to manage larger data loads, extend product lifespans and enhance power efficiency—ultimately helping lower operating costs. From large-scale data centers to smaller enterprise server rooms and remote edge locations, the lines between application-specific servers are fading and reshaping the balance of storage and computing resources. Navigating this shift is the essential challenge for many companies and a deep understanding of the applications and potential storage module is vital. As applications demand higher efficiency and greater data processing capabilities, Swissbit provides a range of storage solutions—from high-performance SSDs to sturdy and reliable SATA modules —engineered to meet the unique needs of server and edge environments.

Swissbit’s Data Center Storage Solutions Modern data center environments face growing challenges driven by explosive data growth, the rise of AI workloads, and the need for real-time responsiveness. These demands place intense pressure on storage modules to deliver not only high performance and low latency but also robust reliability, security, and energy efficiency. To meet these evolving requirements, Swissbit introduces the PCIe Gen5 D2200 series—a next-generation storage solution engineered for enterprise servers, data centers, and AI applications.

D2200 Series For enterprise and data center storage, as well as AI applications, the D2200 is the best choice. Launched last year, the PCIe Gen5 D2200 series offers exceptional 4K random read/write performance, a significant sequential read/write speed improvement to 14Gb/s and 10Gb/s and reduced read/write latency to ensure consistent QoS and smooth operation for latency-sensitive applications.

Comprehensive data protection features, including TCG Opal 2.0, ensure that data is securely encrypted and protected from unauthorized access, which is critical to maintaining data integrity and confidentiality. By supporting the latest NVMe 2.0 and OCP 2.0 standards, the D2200 Series ensures compatibility with future technologies and industry trends. Finally, the D2200 is energy efficient. It delivers high performance with reduced power consumption and runs up to 15-20°C cooler than competitive drives

Key Benefits ✔ Exceptional Performance – Delivers high-speed 4K random and sequential read/write (up to 14GB/s read, 10GB/s write) with low latency for consistent QoS in demanding applications. ✔ Robust Data Security – Features TCG Opal 2.0 encryption to protect data integrity and prevent unauthorized access. ✔ Future-Ready Standards – Supports NVMe 2.0 and OCP 2.0 for seamless compatibility with evolving enterprise and AI infrastructure. ✔ Energy Efficiency – Offers powerful performance with lower power usage, running 15–20°C cooler than competing solutions

💡Learn more about D2200 series.

Even in high-performance data centers, reliable boot drives are essential for initializing systems, managing firmware, and supporting critical OS functions. However, as rack space is at a premium, compact, space-saving storage modules are crucial to maximize density and maintain efficient infrastructure design.

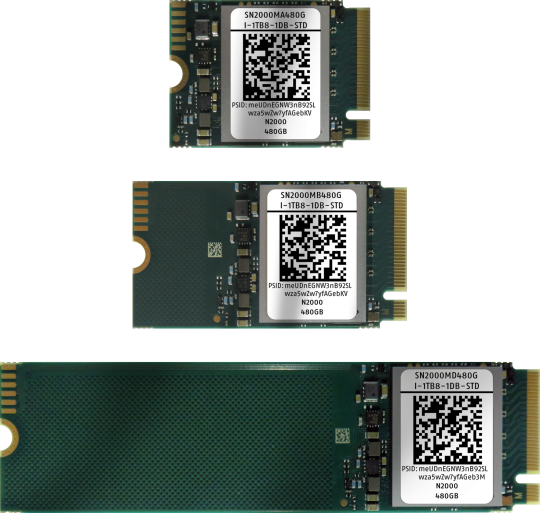

N2000 Series – Space saver for Boot Drives To optimize space in a high-density 1U server, a leading server manufacturer sought an ultra-compact boot drive solution - where every millimeter of board real estate was critical. The Swissbit N2000 M.2 2230 NVMe SSD met this requirement with its small footprint, enabling vertical mounting and freeing up valuable space for key components such as processors, memory modules, and thermal management systems.

Why did they choose Swissbit N2000? ✔ Smallest form factor ✔ Industrial grade reliability ✔ Sustaining high read & write performance ✔ Optimized power consumption ✔ Stable supply and longevity support

💡Learn more about the N2000 M.2 PCIe SSD for boot drives.

For boot drives in data centers, Swissbit's N3000 and A1200 series discussed below also offer compelling solutions.

Data Center vs. Enterprise While data centers require storage solutions that handle vast amounts of data at scale, emphasizing high capacity, low latency, fault tolerance, and continuous uptime, enterprise applications focus on performance, security, and data integrity, typically supporting specific business functions with more targeted, reliable storage needs in a contained environment.

Depending on the specific demands, Swissbit’s D2200 and A1200 are ideal modules to consider for enterprise applications. The D2200 excels in high-capacity, low-latency environments, making it perfect for data centers, AI applications, and scenarios requiring fast sequential speeds.

In contrast, the A1200 with its 8-channel PCIe architecture delivers top-tier sustained performance and ultra-low latency when supported by proper cooling making it an excellent choice for high-performance applications that require maximum throughput.

💡 Learn more about Swissbit storage solutions for Data Centers and Enterprise Solutions.

A1200 – Peak Performance

✔ M.2 form factor 2280 ✔ PCIe Gen4 / NVMe 1.4 / four lanes ✔ 3D NAND eTLC up to 1.92 TB ✔ Temperature range 0°C to 70°C (A1000: -25°C to 85°C) ✔ 1 DWPD Endurance ✔ AES256 Encryption / TCG Opal 2.0 ✔ Crypto erase / Secure Boot erase / Secure Boot

💡Learn more about the A1200.

Swissbit’s Storage Solutions for Edge Servers Edge servers require storage solutions that balance performance with low power consumption, as they often operate in remote or constrained environments. These servers must handle real-time data processing with low latency, while also supporting limited physical space and network bandwidth. As such, storage needs focus on compact, energy-efficient solutions with fast read/write speeds, reliability, and the ability to scale based on local data processing demands.

Swissbit’s N3000 and A1200 SSDs are both excellent choices for edge server deployments, each optimized for different performance and environmental demands. The N3000 is ideal for edge environments that require reliable OS boot functionality, low power consumption, and stable performance even under tight power constraints in high-temperature or airflow-limited conditions. With its 4-channel architecture, it offers consistent sustained performance and enhanced data protection features like secure boot, encryption, power-fail protection, and remote management, making it perfect for mission-critical systems in industrial and embedded applications.

On the other hand, the A1200, featuring an 8-channel PCIe architecture, is designed for edge use cases that demand maximum throughput and ultra-low latency. When supported by proper cooling measures such as adequate airflow or heatsinks, it delivers top tier sustained performance, making it the right choice for high-performance edge applications such as AI inference, real-time analytics, or video processing at the edge. Together, the N3000 and A1200 provide versatile options to meet the varying power, performance, and environmental needs of today’s edge computing landscape.

N3000 for Edge Servers and Boot Drives

A leading AMR manufacturer selected Swissbit N3000 M.2 2280 SSDs for seamless intralogistics automation. Why did they choose Swissbit N3000? ✔ Drive for OS boot purpose ✔ Reliable performance at higher temperatures ✔ Small, low power and low capacity, reliable, high retention. ✔ Secure boot, encryption, remote management, power fail protection

💡Learn more about M.2 PCIe SSD products like N3000.

Conclusion As modern server environments evolve—driven by increasing data loads, AI workloads, and efficiency demands—Swissbit delivers purpose-built storage solutions tailored to meet the distinct needs of data centers, enterprise systems, and edge computing. The D2200 PCIe Gen5 SSD leads the lineup with top-tier performance, low latency, and robust data protection for high-throughput environments like AI and enterprise storage. For space-constrained systems, the N2000 and N3000 offer compact, energy-efficient boot drive options with industrial-grade reliability. The A1200 bridges high performance and versatility with its 8-channel design, making it ideal for both enterprise and edge applications requiring sustained throughput and minimal latency—when properly cooled. Together, Swissbit’s storage portfolio delivers optimized solutions that balance power, performance, and reliability across all server tiers.

Why Swissbit?

Proven Expertise: 20+ years in industrial storage with "Made in Germany" quality.

Top-Tier Products: Maximum reliability, durability, and performance.

Exceptional Support: Expert engineers and strong supply chain advantages.

Swissbit original post : link

Swissbit website : link

Contac us :

Phone: +55 11 5507-2627

Email: [email protected]

0 notes

Text

Power Without Noise: The Elegant Intelligence Behind the DC-DC Converter

We live in a world powered by invisible rivers of energy. Whether it’s your phone charging on the desk, an EV gliding silently down the highway, or a satellite stabilizing its orbit above Earth, all of it depends on a quiet and tireless guardian: the DC-DC converter.

It doesn’t have a flashing screen or make mechanical sounds. But it’s doing something profound—transforming power with precision. If you’ve ever wondered how today’s electronics, vehicles, and machines stay so compact, efficient, and smart, the answer often lies in the humble DC-DC converter.

A Quiet Transformer in the Digital Age

Electricity isn’t always one-size-fits-all. Devices and systems require varying voltage levels, depending on the task. A processor might need 1.2V, a motor controller 12V, and a battery bank 48V. But if all you have is a 24V supply, how do you cater to such variety without loss?

This is where DC-DC converters come in. They regulate voltage from one DC level to another—efficiently and reliably.

But here’s the kicker: they’re not just voltage changers. They’re voltage sculptors. They take raw power and fine-tune it with intelligence, efficiency, and minimal heat loss.

DC to DC: What's the Real Deal?

To the non-engineer, a DC-DC converter may seem abstract. So let’s unpack it in simple terms:

Step-down converters (buck) lower the input voltage to power sensitive electronics.

Step-up converters (boost) raise low voltages—useful in things like portable solar power banks.

Buck-boost converters can do both, ideal in systems where voltage fluctuates unpredictably.

They’re made of inductors, capacitors, switches (often transistors), and controllers. The switching mechanism rapidly turns power on and off—so fast that your devices never feel the pulses. Instead, they receive a steady, safe, and clean voltage.

Think of it as a dance—precision, timing, and flow—except it happens millions of times per second.

The Real-World Importance

Let’s get practical. Say you're designing a drone. You’ve got a Li-ion battery that outputs 14.8V, but your motor controller needs 12V and your GPS module 5V. With space and weight at a premium, you need compact, efficient power conversion.

Enter a compact, multi-output DC-DC converter.

In the automotive world, DC-DC converters play a massive role. Modern electric vehicles often have high-voltage batteries (400–800V) but still require 12V to run legacy systems like lights, wipers, and infotainment. A DC-DC converter bridges that gap—quietly ensuring every component gets what it needs.

And in space tech? Satellites must operate efficiently with constrained solar energy. There's no room for waste. That’s why aerospace engineers obsess over high-efficiency DC-DC converters with radiation-hardened designs. They might not make headlines, but they keep the mission alive.

Efficiency Isn’t Optional—It’s Mission-Critical

Every watt lost in conversion equals:

Heat that needs to be dissipated

Power that must be generated (and paid for)

Batteries that deplete faster

Components that wear down sooner

Today’s converters boast efficiencies of 95% or more. That means less heat, longer life, and smaller form factors. And in battery-powered systems, that efficiency can directly translate into hours more runtime.

In data centers, for example, thousands of servers depend on high-density power supplies with integrated DC-DC converters. A 1% efficiency improvement could save hundreds of thousands of dollars annually in energy and cooling costs.

Innovation: From Bulky to Ultra-Compact

Just a decade ago, power supplies were bulky and heavy. But with advances in GaN (Gallium Nitride) and SiC (Silicon Carbide) semiconductor technologies, DC-DC converters are shrinking rapidly while delivering more power.

These new-age materials switch faster, generate less heat, and allow higher-frequency operation—meaning smaller inductors and capacitors. The result? A converter that fits in your smartwatch yet handles power like a champ.

And it’s not just about size. It’s also about control.

Modern converters come with digital interfaces—PMBus, I²C, or UART—so system designers can monitor voltage, temperature, and current in real time. Smart converters are no longer passive hardware—they’re programmable, adaptive, and data-rich.

Let’s Talk Human: Why Should You Care?

You might not be designing a rocket or an EV. But chances are, if you’re in product design, industrial automation, or even IT infrastructure, you’ve already faced the challenge of powering diverse systems cleanly and safely.

A poorly chosen or inefficient DC-DC converter might lead to:

Device overheating

Unexpected shutdowns

EMI issues that interfere with wireless signals

Reduced lifespan for expensive components

On the flip side, a thoughtfully integrated converter means:

Smaller PCBs

Cooler operations

Lower energy bills

Happier end-users

In essence, choosing the right DC-DC converter is a high-leverage engineering decision—quietly influencing performance, reliability, and customer satisfaction.

Application Spotlight: Solar + Storage

Let’s take a green energy example. A solar-powered off-grid system might generate power in DC—say 18V from panels—but store it in 12V batteries and run devices at 5V USB or 24V for a water pump.

Here, multiple DC-DC converters orchestrate this energy symphony:

MPPT charge controllers use buck or buck-boost converters

Inverters depend on steady DC input for efficient AC output

USB charging hubs rely on precision 5V outputs

And if these converters weren’t efficient, the whole premise of “green” would start to crack.

The Future Is Smart, Modular, and Even Smaller

Looking ahead, the world is moving toward distributed, modular power systems. Imagine every module—whether it’s a sensor, a display, or a motor—having its own mini converter that adapts to the central supply.

The result? Simplified system design, better energy use, and easier scaling.

This modular vision is being realized in 5G base stations, autonomous robots, and edge computing nodes. The unsung hero behind it all? You guessed it—the DC-DC converter.

Final Thought: Honor the Invisible Genius

In a world that celebrates sleek screens, shiny finishes, and user interfaces, it’s easy to forget the underlying intelligence that makes it all possible.

But engineers know. Designers know. And now—you know.

So the next time you see a high-performing, ultra-thin, cool-running device, think about what’s inside. Somewhere behind that flawless function is a compact, efficient DC-DC converter quietly doing its job, a guardian of clean power in a chaotic electrical world.

0 notes

Text

How Do Air Cooled Chillers Work? A Comprehensive Guide

In today's climate-conscious and efficiency-driven world, air cooled chillers have become a cornerstone of HVAC systems for commercial and industrial applications. These chillers offer an efficient way to cool spaces without requiring a constant water source, making them particularly suited for areas where water availability or infrastructure is limited. This article provides a comprehensive guide to understanding how air cooled chillers work, their components, and their advantages over other cooling technologies.

What Are Air Cooled Chillers?

Air cooled chillers are refrigeration systems used to remove heat from a liquid via a vapor-compression or absorption refrigeration cycle. They differ from water-cooled chillers in that they dissipate heat directly into the air rather than relying on a cooling tower and water supply. These systems are often used in medium to large buildings, manufacturing facilities, data centers, and hospitals.

Key Components of Air Cooled Chillers

To understand how air cooled chillers work, it’s essential to break down their core components:

Compressor: This is the heart of the chiller, compressing the refrigerant and increasing its pressure and temperature.

Condenser Coils and Fans: Located on the outside of the chiller, these coils and fans work together to release the absorbed heat into the ambient air.

Expansion Valve: It reduces the pressure of the refrigerant, cooling it down before it enters the evaporator.

Evaporator: This component absorbs heat from the chilled water or process fluid, transferring it to the refrigerant.

Each of these components plays a crucial role in the refrigeration cycle that air cooled chillers rely on.

How the Cooling Cycle Works

The operation of air cooled chillers is based on a four-step thermodynamic cycle:

Compression: The refrigerant enters the compressor as a low-pressure gas and is compressed into a high-pressure, high-temperature gas.

Condensation: The hot refrigerant gas flows through the condenser coils. Cooling fans blow ambient air across the coils, removing heat and condensing the gas into a high-pressure liquid.

Expansion: The high-pressure liquid then passes through an expansion valve where its pressure is reduced, cooling it further.

Evaporation: The cold refrigerant flows into the evaporator, where it absorbs heat from the water or fluid in the loop. This heat causes the refrigerant to evaporate into a gas again, and the cycle repeats.

This cycle allows air cooled chillers to efficiently extract heat from a space or process and release it into the surrounding air.

Advantages of Air Cooled Chillers

There are several benefits to choosing air cooled chillers for your facility:

Ease of Installation: No cooling tower or water supply system is needed, making installation quicker and less expensive.

Lower Maintenance: Without water pumps, towers, or plumbing, maintenance is simpler and less frequent.

Energy Efficiency: In mild to cool climates, these chillers can operate very efficiently with minimal auxiliary systems.

Space Saving: All components are typically packaged into a single outdoor unit, freeing up valuable indoor space.

Applications of Air Cooled Chillers

Thanks to their versatility and compact design, air cooled chillers are widely used in:

Commercial buildings (malls, offices)

Manufacturing facilities (plastics, food processing)

Medical environments (MRI machines, labs)

Data centers and server rooms

Final Thoughts

Understanding how air cooled chillers work is key to making informed decisions when planning or maintaining HVAC systems. Their air-based heat rejection method makes them especially useful in locations where water conservation is important or where plumbing infrastructure is limited. By leveraging the core principles of thermodynamics, air cooled chillers deliver reliable and energy-efficient cooling for a wide range of applications.

0 notes

Text

Hybrid Cooling Market For Data Centers | BIS Research

According to BIS Research, global hybrid cooling market for data centers is poised for significant growth as operators strive to meet escalating compute demands while improving energy efficiency. By 2024, a growing number of colocation and hyperscale facilities will be using hybrid cooling systems, which combine liquid and air-based techniques. These technologies comply with increasingly stringent environmental laws, efficiently handle increased rack densities, and use less water. In 2034, advancements in materials, sensors, and control systems will further improve hybrid cooling's scalability and efficiency. With capabilities like predictive maintenance and real-time load balancing, hybrid cooling is poised to emerge as a key technology for high-performance, environmentally friendly data center operations.

The global hybrid cooling market for data centers is on a growth trajectory as operators balance soaring compute demands with the urgent need for energy efficiency. By 2034, advancements in sensors, control algorithms, and materials will make hybrid cooling even more efficient and scalable.

Market Segmentation

By Application

1. Centralized Data Centers

Enterprise Data Centers: Individually owned and operated by organizations to support internal IT workloads, often requiring balanced and cost-effective cooling.

Hyperscale Data Centers: Operated by major cloud providers (e.g., Google, AWS), these massive server farms demand ultra-efficient hybrid cooling systems to manage extremely high power densities.

Colocation Data Centers: Multi-tenant facilities that lease out space, power, and cooling; they favor flexible hybrid cooling solutions to support varied client needs and equipment types.

2. Edge Data Centers

Smaller, decentralized facilities located closer to end users or data sources.

Require compact, modular, and efficient hybrid cooling systems capable of operating in constrained or remote environments to support latency-sensitive applications.

By Product

1. Liquid-to-Air Cooling Systems

Rear Door Heat Exchangers / Liquid-Assisted Air Cooling: Uses a liquid-cooled panel at the rear of the rack or integrates liquid circuits into air pathways to remove heat more efficiently than air cooling alone.

Closed Loop Liquid Cooling with Air Augmentation: Circulates liquid coolant within a closed system while supplementing with directed airflow to handle hotspots in high-density deployments.

2. Air-to-Liquid Cooling Systems

Direct-to-Chip / Cold Plate Cooling: Applies liquid coolant directly to heat-generating components (e.g., CPUs, GPUs) with residual air cooling used to manage ambient rack temperature.

Others (Chilled Beam, Immersion + Air Extraction): Encompasses innovative hybrid methods like chilled beams for overhead cooling or partial component immersion combined with air extraction to manage thermal loads.

Market Trend

A key emerging trend in the hybrid cooling market is the integration of AI-driven controls with cooling infrastructure. Thermal management is being revolutionized by real-time monitoring driven by machine learning as data centers, particularly hyperscale and edge facilities, grow in size and complexity. These clever devices dynamically modify the ratio of liquid to air cooling loops, forecast changes in workload, and examine thermal trends. By optimizing energy use and minimizing hot spots and equipment stress, this predictive technique dramatically lowers Power Usage Effectiveness (PUE). More independent, effective, and flexible data center operations are being made possible by the combination of AI and hybrid cooling.

Market Drivers

One of the primary drivers of the hybrid cooling market is the growing emphasis on sustainability and energy efficiency. Regulators, environmental organizations, and corporate ESG policies are putting more and more pressure on data centers to lower their carbon emissions, water consumption, and power usage effectiveness (PUE). By carefully combining liquid and air-based techniques, hybrid cooling systems offer a practical way to achieve these environmental objectives without sacrificing efficiency. Hybrid cooling is a desirable option in next-generation data center design because it lets operators balance operational efficiency and environmental responsibility by optimizing resource utilization and reacting to changing thermal loads.

Market Restrain

High Capital Expenditure: Small to mid-sized data centers may find hybrid cooling too expensive up front when compared to conventional air-based systems.

Complex Infrastructure Requirements: Installing extra parts like cold plates, rear-door heat exchangers, liquid distribution lines, and sophisticated control systems is part of the deployment process.

Integration Challenges: It can be technically challenging to retrofit existing facilities with hybrid cooling, particularly in legacy environments with constrained space or antiquated architecture.

Longer ROI Period: Although hybrid systems save money on energy and maintenance over the long run, the early costs of adoption may postpone ROI, which complicates financial justification.

Specialized Skillset Needed: Trained workers with knowledge of both liquid and air cooling systems are needed for operation and maintenance, which raises ongoing expenses and staffing issues.

Market Opportunity

Rising Rack Densities: Older facilities are struggling to manage modern workloads with existing air-based systems, creating demand for more efficient cooling upgrades.

Hybrid Integration Potential: Without requiring significant overhauls, solutions like rear-door heat exchangers and closed-loop liquid cooling can be easily included into current infrastructure to improve thermal performance.

Cost-Effective Modernization: Operators can extend the life of current sites and avoid relocation or expansion costs by retrofitting, which is a more affordable option than new building.

Revenue Growth for Providers: By utilizing a sizable installed base of older data centers, cooling solution suppliers and integrators can generate new revenue streams through retrofit services and maintenance.

Faster ROI for Operators: Retrofitting is an alluring low-cost solution because energy savings and increased operational efficiency allow for a quicker return on investment.

Key Market Players

Schneider Electric SE

Vertiv Holdings Co.

STULZ GmbH

Rittal GmbH & Co. KG

Mitsubishi Electric Corporation

Trane Technologies

Airedale International Air Conditioning Ltd

Take Action: Gain Valuable Insights into the Rising Investments and Market Growth of Hybrid Cooling Market For Data Centers!

Learn more about Energy and Power Vertical. Click Here!

Conclusion

The hybrid cooling market for data centers is rapidly evolving as operators seek to balance rising compute demands with sustainability and efficiency goals. By combining liquid and air-based cooling techniques, hybrid systems provide a versatile, energy-efficient solution that can manage high-density workloads while using less water and electricity. Hybrid cooling is positioned as a crucial technology for future data center architecture despite obstacles including high initial costs and complicated infrastructure, as well as prospects for retrofitting legacy facilities and advancements in AI-driven controls. Hybrid cooling will be essential to enable high-performance, sustainable data center operations globally as regulatory constraints and environmental concerns increase.

0 notes

Text

Rack Data Center Solutions in the US: Efficiency & Flexibility for Every Business

Rack-based data center solutions provide an organized and efficient way to house servers, enhancing flexibility across IT infrastructure for businesses of all sizes. Sophisticated rack designs improve cooling, scalability, and space optimization.

Rack-Based Infrastructure – Types, Cooling, and Scalability

Common types of rack setups include:

Open Frame Racks: Affordable and ideal for non-sensitive environments, allowing easy access and airflow with minimal physical security.

Enclosed Racks: Enhanced security and airflow management, often with integrated cooling or cable management.

Wall-Mount Racks: Compact solutions suitable for small-scale deployments.

Modular Rack Systems: Prefabricated, self-contained modules for easy transport and deployment.

Cooling is essential for rack infrastructure. Techniques such as rack and row-level cooling, rear door heat exchangers, and in-rack ACs help minimize hot spots and reduce energy waste, especially in high-density setups.

Scalability is another key advantage. Modular rack solutions allow businesses to scale IT resources on demand without extensive overhauls. With the rise of edge computing and AI workloads, companies increasingly adopt high density data center racks that support greater load capacity and future flexibility.

Why Rack Design Matters for Performance and Space Efficiency

A rack isn’t just a server shelf—it plays a critical role in performance, physical footprint, and energy use. Effective airflow management through hot and cold aisle containment lowers cooling costs and extends hardware life. Additionally, smart rack layouts improve cable management, reduce downtime, and simplify maintenance.

Space utilization is equally important. In urban data centers where real estate is costly, high density data center racks help maximize computing power while minimizing physical space.

Use Cases: From Small Businesses to Hyperscale Data Centers

Rack data centers in the US serve a range of customers:

Small to Medium Businesses (SMBs): Benefit from compact, pre-configured racks with plug-and-play simplicity and low overhead.

Large Enterprises and Hyperscalers: Use customized, high-capacity rack systems that support hybrid cloud, AI workloads, and extensive parallel processing. Hyperscalers increasingly rely on rack standardization for software-defined infrastructure and rapid provisioning.

Final Thoughts

As IT demands evolve, rack data centers in the US will play an increasingly vital role. Innovations in cooling, stability, and design are key to meeting future needs.

Choosing the right rack data center provider in the US is crucial. Whether you need server rack colocation services USA or are seeking high density data center racks, Data Center Mart can guide you with expert support and verified providers to ensure you stay ahead of data center trends. Up next: The Future of Data Center Solutions in the USA: Trends Every Business Must Know

0 notes

Text

Microserver Market Size, Share, Analysis, Forecast, and Growth Trends to 2032: Disruptive Technologies Set New Benchmarks

The Microserver Market Size was valued at USD 30.0 billion in 2023 and is expected to reach USD 108.9 billion by 2032 and grow at a CAGR of 15.4% over the forecast period 2024-2032.

The microserver market is rapidly gaining momentum as enterprises prioritize cost-efficiency, energy conservation, and scalability in IT infrastructure. These compact servers, designed for lightweight and specific workloads, are becoming essential in data centers and edge computing environments, especially with the exponential rise in IoT, AI, and big data applications. Key industry players are continuously investing in innovation to enhance microserver architecture, integrating advanced processors and improved connectivity.

The microserver market demand for microservers is surging across diverse sectors including telecommunications, BFSI, cloud services, and healthcare. Their modularity and low-power consumption make them an ideal choice for hyperscale data centers and decentralized network systems. With cloud-native applications growing at a rapid pace, microservers are poised to support distributed computing frameworks, offering a balance between performance and cost-efficiency that traditional servers cannot match.

Get Sample Copy of This Report: https://www.snsinsider.com/sample-request/4145

Market Keyplayers:

Acer Inc. (Acer Cloud Technology, Acer Microserver)

Advanced Micro Devices, Inc. (AMD EPYC Processors, AMD Ryzen Embedded Processors)

ARM Ltd. (ARM Cortex-A Processors, ARM Neoverse Platform)

Dell Inc. (Dell PowerEdge Microservers, Dell VxRail)

Fujitsu (Fujitsu PRIMERGY Microserver, Fujitsu SPARC M10 Server)

Hewlett Packard Co. (HPE ProLiant MicroServer Gen10 Plus, HPE Apollo)

IBM (IBM Power Systems, IBM BladeCenter)

Intel Corporation (Intel Xeon D Processors, Intel Atom C Processors)

Marvell Technology (Marvell ThunderX Processors, Marvell Octeon Processors)

MiTac International Corporation (MiTac Microserver Solutions, MiTac H-Series Microserver)

Penguin Computing, Inc. (Penguin Computing Altus Microservers, Penguin Computing Relion Servers)

Quanta QCT (Quanta Microserver, QuantaGrid D52G-1U)

Tilera Corporation (Tilera TILE-Gx Processors, Tilera iMesh Solutions)

Cavium, Inc. (Cavium ThunderX Processors, Cavium Octeon Processors)

Boston Limited (Boston Microserver Solutions, Boston Server Racks)

Super Micro Computer, Inc. (Supermicro SuperServer, Supermicro MicroBlade)

Lenovo Group Limited (Lenovo ThinkSystem Servers, Lenovo Flex System)

Huawei Technologies Co., Ltd. (Huawei FusionServer, Huawei TaiShan Servers)

Inspur Group (Inspur NF5280M5 Server, Inspur TS Microservers)

Nvidia Corporation (NVIDIA DGX Systems, NVIDIA RTX Servers)

Market Analysis The global microserver market is being driven by a confluence of technological advancements and evolving enterprise needs. The proliferation of data-intensive services, edge computing, and green IT solutions is pushing organizations to adopt microservers. These systems offer flexibility, reduced power consumption, and a smaller footprint—attributes crucial for modern data operations. Increasing reliance on real-time analytics and low-latency services has also accelerated adoption, as microservers offer optimized support for such use cases. Key industry leaders are diversifying their product lines and collaborating with chip manufacturers to cater to varied computing needs.

Market Trends

Surge in deployment of ARM-based and x86 microserver processors

Rising investment in edge computing infrastructure

Growing adoption in SMEs due to affordability and scalability

Integration of AI and ML applications with microserver ecosystems

Expansion of modular data centers driving microserver demand

Enhanced energy efficiency becoming a top priority for data centers

Movement toward open-source hardware and software platforms

Market Scope

Edge Computing Ready: Designed for low-latency environments and real-time processing

Eco-Friendly Technology: Prioritizes power efficiency and compact design for sustainability

Cost-Optimized Infrastructure: Ideal for startups and SMEs seeking scalable server solutions

Cloud-Native Compatibility: Supports containerization, microservices, and serverless computing

Versatile Applications: Enables use in telecom, healthcare, BFSI, government, and media

Microservers are no longer confined to niche applications. Their growing relevance across industries is expanding the market scope significantly, making them a cornerstone of next-gen IT environments. Enterprises are now leveraging microservers to enable flexible, resilient, and decentralized computing solutions.

Market Forecast The microserver market is on an accelerated growth trajectory, shaped by digital transformation and cloud migration trends. Industry players are forecasted to innovate aggressively, focusing on energy efficiency, processor diversity, and software optimization. The upcoming years will witness an upsurge in adoption from both large-scale enterprises and agile startups, as they seek reliable and compact computing frameworks. Government initiatives promoting green technologies and data localization will further bolster microserver deployments, especially in emerging economies.

Access Complete Report: https://www.snsinsider.com/reports/microserver-market-4145

Conclusion As digital workloads become increasingly diverse and decentralized, microservers are stepping up as the smart, sustainable solution for the future. Their ability to deliver high-performance computing with minimal environmental impact makes them a game-changer in today’s competitive landscape. With the momentum continuing to build, the microserver market promises not just evolution—but revolution—for modern computing infrastructures.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

0 notes

Text

Why the Integration of Embedded Edge Computing and IoT Is Critical for Industry 4.0