#Composite Insulators Industry News

Text

Composite Insulators Market 2022 | Global Business, Share, Trend and SWOT Analysis 2030 | By R&I

Reports & Insights has freshly issued a new report titled “Composite Insulators Market: Opportunity Analysis and Future Assessment 2022-2030” which speaks about the market size, market potential and comprehensive understanding of the statistics concerned with the development of the respective market. The market analysts estimate that the Composite Insulators Market size will elevate from XXX in 2022 to XXX by the year 2030, at an estimated CAGR of XX. The base year considered for the study is 2020, and the market size is projected from 2022 to 2030.

Request a Sample Copy of this Report @: https://reportsandinsights.com/sample-request/2534

Composite Insulators Introduction

Insulators basically serve its utility in electrical equipment with a view to sustain and differentiate electrical conductors without enabling current to percolate through the insulators. Silicone rubber is one of the most comprehensively utilized polymeric insulation materials for high tension products. Particularly, the composite insulators are a unique kind of insulation control that further holds a crucial role in overhead transmission lines.

Composite insulators are also known as non-porcelain insulators, synthetic insulators, rubber insulators, polymer insulators, among others. Notably, composite insulators are light in weight, minor in size, reliable to transport, light in structure, easy to maintain and easy to install. Such factors aid composite insulators to gain traction all across the markets. In addition to that, the composite insulator has excellent fouling resistance and robust fouling flash voltage resistance. Notably, the wet withstand voltage and fouling resistance voltage of composite insulators are 2 to 2.5 times that of porcelain insulators with the equal creepage distance.

Also, there is no need for cleansing and secure operation in severely polluted areas. Owing to such factors, the composite insulators are witnessing higher demand all around the world. Moreover, the soaring investments from governments and regulatory authorities to revamp the maturing grid networks across established nations together with the swift adoption of smart grid technology, worldwide, is further projected to boost the growth of the global composite insulators market in the coming years.

Wish to Know More About the Study? Click here to get a Report Description: https://reportsandinsights.com/report/composite-insulators-market

Composite Insulators Market Segmentation

The composite insulators market is segmented on the basis of voltage, application, product, rating, installation, end use, and region.

By Voltage

High Voltage

Medium Voltage

Low Voltage

By Application

Cables & Transmission Lines

Switchgears

Transformers

Bus Bars

Others

By Product

Pin Insulators

Suspension Insulators

Shackle Insulators

Other Insulators

By End Use

Residential

Commercial & Industrial

Utilities

By Rating

<11 KV

11 KV

22 KV

33 KV

5 KV

145 KV

220 KV

400 KV

800 KV

1200 KV

By Installation

Distribution

Transmission

Substation

Railways

Others

By Region

North America

Latin America

Europe

Asia Pacific

Middle East

Africa

Composite Insulators Market Key Players

Some of the key participating players in composite insulators market are:

Siemens Energy

ABB

GE

Toshiba

Aditya Birla

NGK Insulators

Hubbell

Bharat Heavy Electricals Limited

LAPP Insulators

Maclean-Fogg

Seves Group

TE Connectivity

To view Top Players, Segmentation and other Statistics of Composite Insulators Market Industry, Get Sample Report @: https://reportsandinsights.com/sample-request/2534

About Reports and Insights:

Reports and Insights is one of the leading market research companies which offers syndicate and consulting research around the globe. At Reports and Insights, we adhere to the client needs and regularly ponder to bring out more valuable and real outcomes for our customers. We are equipped with strategically enhanced group of researchers and analysts that redefines and stabilizes the business polarity in different categorical dimensions of the market.

Contact Us:

Neil Jonathan

1820 Avenue M, Brooklyn

NY 11230, United States

+1-(718) 312-8686

Find Us on LinkedIn: www.linkedin.com/company/report-and-insights/

View Latest Market Updates at: https://marketsresearchanalytics.com

#Composite Insulators Market Research#Composite Insulators Market Report#Composite Insulators Market Share 2021#Composite Insulators Market Size 2022#Composite Insulators Market Trends#Composite Insulators Market Key Players#Global Composite Insulators Market Analysis#Composite Insulators Industry News#Composite Insulators Industry Analysis#Composite Insulators Market Forecast#Composite Insulators Market CAGR#USA Composite Insulators Market#Japan Composite Insulators Market#Composite Insulators Market Demand#Argentina Composite Insulators Market#Australia Composite Insulators Market#Belgium Composite Insulators Market#Brazil Composite Insulators Market#Canada Composite Insulators Market#Chile Composite Insulators Market#China Composite Insulators Market#Columbia Composite Insulators Market#Egypt Composite Insulators Market#France Composite Insulators Market#Germany Composite Insulators Market#Global Composite Insulators Market#India Composite Insulators Market#Indonesia Composite Insulators Market#Composite Insulators Applications#Composite Insulators Industry

0 notes

Text

The Benefits Of Hempcrete

This is the house that Hemp built.

youtube

The benefits of using Hempcrete in every construction project.

Written by Casper Leitch

The benefits of Hempcrete is that it is a game-changer in the realm of Eco-friendly construction. If you're passionate about industrial hemp, hemp farming, or just want to see our planet thrive, you will be excited by the wonders of this revolutionary building material.

What is Hempcrete? It's a blend of industrial hemp, lime, and water coming together to form a supercharged building material. It's like nature's own recipe for sustainable construction, packed with benefits that go beyond your average brick and mortar.

An example is found in insulation uses. Hempcrete is like a cozy blanket for your home, but better. Its natural fibers create tiny air pockets, acting as a barrier against pesky temperature changes. Whether it's a scorching summer day or a chilly winter night, Hempcrete keeps things just right inside, saving you money on heating and cooling bills.

Hempcrete doesn't just keep you comfy, it keeps you safe too. Thanks to its fire-resistant properties, you can rest easy knowing your home is protected against potential disasters. No need to worry about flames spreading like wildfire, you are protected from fire in building built with Hempcrete.

While most building materials contribute to carbon emissions during production, Hempcrete does the opposite. As it cures, it actually sucks up carbon dioxide from the air, locking it away for good. It's like building your home while giving the planet a big hug.

Why aren't we seeing Hempcrete buildings popping up left and right? It all comes down to outdated regulations and misconceptions about industrial hemp. By spreading the word about the incredible potential of Hempcrete, we can push for policy changes that prioritize sustainability in construction. Imagine a world where every new building is a step towards a greener, cleaner future.

So whether you're into hemp farming, ending hemp prohibition, or just want to see our planet thrive, let's rally together and champion the widespread adoption of Hempcrete. Help educate business leaders and politicians in your community about the benefits, applications, and potential impact on the construction industry and the environment that the use of Hempcrete has.

The Insulation Powerhouse: Unraveling the Secrets of Hempcrete's Thermal Properties

youtube

Let's start by taking a closer look at Hempcrete's insulation capabilities – the cornerstone of its appeal as a sustainable building material. Traditional insulation materials often rely on synthetic fibers that are energy-intensive to produce and may contain harmful chemicals. In contrast, Hempcrete harnesses the natural properties of industrial hemp to create a highly efficient thermal barrier.

At the heart of Hempcrete's insulation prowess lies its unique composition. Made from a mixture of hemp hurds (the inner woody core of the hemp plant), lime binder, and water, Hempcrete forms a lightweight yet durable material with excellent insulating properties. The hemp fibers create a matrix of tiny air pockets within the material, effectively trapping heat during the winter months and repelling it during the summer – a phenomenon known as thermal inertia.

But what sets Hempcrete apart from traditional insulation materials is its ability to regulate humidity levels within a building. Unlike synthetic insulation materials, which can trap moisture and promote mold growth, Hempcrete acts as a natural moisture buffer, absorbing excess humidity when conditions are damp and releasing it when the air is dry. This not only helps to maintain a comfortable indoor environment but also contributes to improved air quality and reduced risk of mold-related health issues.

From an environmental standpoint, Hempcrete's insulation properties offer significant advantages over conventional materials. By reducing the need for artificial heating and cooling systems, Hempcrete helps to lower energy consumption and carbon emissions associated with building operations. Additionally, its natural composition makes it biodegradable at the end of its lifecycle, minimizing environmental impact and reducing reliance on finite resources.

Fire Resistance: Protecting Lives and Property with Hempcrete

In addition to its insulation properties, Hempcrete boasts impressive fire resistance – a critical feature for ensuring the safety and longevity of building structures. Unlike conventional building materials, which may combust or release toxic fumes when exposed to fire, Hempcrete exhibits a remarkable ability to withstand high temperatures without compromising its structural integrity.

The secret to Hempcrete's fire resistance lies in its mineral composition and low density. Lime, the primary binder used in Hempcrete, is inherently fire-resistant and acts as a natural flame retardant. When exposed to heat, the lime undergoes a process known as calcination, in which it releases water vapor and absorbs heat energy, effectively limiting the spread of flames and preventing the material from igniting.

Additionally, the low thermal conductivity of Hempcrete helps to slow the transfer of heat through the material, further reducing the risk of fire propagation. This combination of factors makes Hempcrete an ideal choice for fire-prone environments and high-risk applications where building safety is of utmost concern.

Beyond its immediate benefits for building occupants and stakeholders, Hempcrete's fire resistance has broader implications for public safety and disaster resilience. In regions prone to wildfires, hurricanes, or other natural disasters, buildings constructed with Hempcrete can serve as a protective barrier against external threats, providing invaluable peace of mind to residents and emergency responders alike.

Carbon Sequestration: Fighting Climate Change One Building at a Time

youtube

Perhaps the most compelling aspect of Hempcrete is its capacity for carbon sequestration – the process of capturing and storing carbon dioxide from the atmosphere. While traditional building materials often contribute to carbon emissions during production, Hempcrete operates in reverse, actively removing carbon dioxide from the air as it cures.

The key to Hempcrete's carbon sequestration potential lies in the carbon-negative nature of industrial hemp cultivation. Hemp plants absorb CO2 from the atmosphere during photosynthesis, converting it into biomass that can be used to produce a wide range of sustainable products, including building materials like Hempcrete. When hemp hurds are mixed with lime and water to create Hempcrete, the carbon stored within the plant material is effectively locked away for the lifespan of the building, reducing net carbon emissions associated with construction activities.

But the environmental benefits of Hempcrete don't stop there. In addition to sequestering carbon dioxide during its production, Hempcrete continues to contribute to carbon mitigation throughout its lifecycle. As a highly durable and long-lasting material, Hempcrete helps to minimize the need for frequent renovations or replacements, further reducing energy consumption and carbon emissions associated with building maintenance and disposal.

From an ecological standpoint, the cultivation of industrial hemp for Hempcrete production offers additional environmental benefits, including soil remediation, biodiversity preservation, and reduced reliance on fossil fuels and synthetic chemicals. By choosing Hempcrete over conventional building materials, builders and developers can play a significant role in combating climate change and building a more sustainable future for generations to come.

Overcoming Barriers to Adoption: Navigating Regulations and Changing Perceptions

Despite its numerous advantages, Hempcrete continues to face obstacles to widespread adoption, ranging from regulatory barriers to entrenched perceptions within the construction industry. In many countries, outdated regulations and misconceptions about industrial hemp have limited the use of Hempcrete in mainstream construction projects, relegating it to niche applications or experimental prototypes.

One of the primary challenges facing the widespread adoption of Hempcrete is the lack of standardized building codes and regulatory frameworks governing its use. Unlike traditional building materials, which have undergone rigorous testing and certification processes, Hempcrete is often subject to a patchwork of regulations that vary from region to region, making it difficult for builders and developers to navigate the permitting process and obtain approval for Hempcrete projects.

Additionally, misconceptions about industrial hemp and its association with psychoactive cannabis have contributed to stigma and resistance within the construction industry and regulatory agencies. Despite the fact that industrial hemp contains negligible levels of THC (the psychoactive compound found in cannabis) and is legally distinct from marijuana under most jurisdictions, lingering concerns about legality, safety, and performance have hampered acceptance of Hempcrete as a viable construction material.

However, as awareness of the environmental and economic benefits of industrial hemp continues to grow, momentum is building for policy changes that support the widespread adoption of Hempcrete in mainstream construction. In recent years, a growing number of countries have enacted legislation to legalize hemp cultivation and expand the use of hemp-based products, including building materials like Hempcrete. These regulatory developments, coupled with increasing demand for sustainable construction solutions, bode well for the future of Hempcrete and its potential to transform the built environment.

The Future of Hempcrete: Opportunities and Challenges in a Rapidly Evolving Landscape

youtube

Looking ahead, the future of Hempcrete appears bright, with ample opportunities for innovation and growth in the sustainable construction sector. As builders, architects, and developers continue to seek out Eco-friendly alternatives to conventional building materials, Hempcrete stands poised to capture a larger share of the market and emerge as a mainstream solution for sustainable building projects.

One of the key drivers of growth for the Hempcrete industry is the expanding market for green building materials and sustainable construction practices. With increasing awareness of the environmental and health impacts of traditional construction methods, consumers and industry professionals alike are turning to alternatives like Hempcrete to reduce their carbon footprint and create healthier indoor environments. This growing demand for sustainable building materials, coupled with advancements in hemp cultivation and processing technology, is fueling investment and innovation in the Hempcrete sector, driving down costs and expanding the range of applications for this versatile material.

However, despite its promise and potential, Hempcrete still faces a number of challenges that must be addressed in order to realize its full impact on the construction industry and the environment. Chief among these challenges is the need for continued research and development to optimize the performance, durability, and scalability of Hempcrete as a mainstream building material. While Hempcrete has demonstrated impressive properties in laboratory and small-scale applications, further testing and validation are needed to ensure its suitability for larger, more complex construction projects and diverse climatic conditions.

Additionally, efforts to overcome regulatory barriers and promote acceptance of Hempcrete within the construction industry will be crucial to its long-term success and viability. By advocating for standardized building codes, certification standards, and industry guidelines for Hempcrete construction, stakeholders can create a more supportive regulatory environment that encourages investment, innovation, and adoption of sustainable building practices.

In conclusion, Hempcrete represents a promising solution to the environmental and economic challenges facing the construction industry in the 21st century. With its exceptional insulation properties, fire resistance, and capacity for carbon sequestration, Hempcrete offers a compelling alternative to traditional building materials that is both sustainable and cost-effective. As advocates for industrial hemp, hemp farming, and sustainable development, we have a unique opportunity to champion the widespread adoption of Hempcrete and pave the way for a greener, more resilient built environment. By working together to overcome regulatory barriers, promote awareness, and drive innovation, we can harness the full potential of Hempcrete to create a brighter future for generations to come. Let's build a greener world, one Hempcrete block at a time.

Below is a FREE TO DOWNLOAD marijuana music MP3 by Muck Sticky.

One Day At A Time.

youtube

2 notes

·

View notes

Text

Copy of Can Fungal Biomass Make Construction More Sustainable?

The construction industry is an ever-growing problem when it comes down to sustainability. The population continues to grow and this requires more and more buildings to accommodate people's lives. More and more materials are required to construct buildings, and so naturally, more and more carbon is emitted into our atmosphere from these construction processes. But we can't just put a pause on population growth, or ban new buildings from being built, and we certainly can't just pretend this problem doesn't exist either.

How about focusing on improving the sustainability of the materials that are used in construction? What alternatives might there be to ensure more sustainable construction processes are used?

… that's where fungal biomass comes in.

Fungal Biomass... what is that exactly?

Biomass is a renewable material that's made from plants and animals. It can be used as energy or turned into useful materials. With fungal biomass, agricultural waste and other low-grade discarded materials (stalks, straw, sawdust, etc.) are used as substrates which are introduced to a fungus to create a material bound together by mycelium.

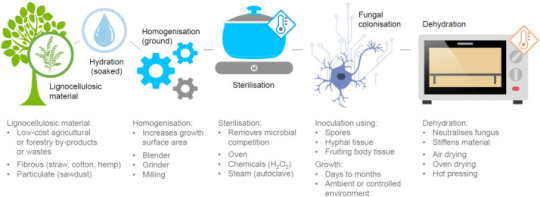

To create the mycelium material, a process must be followed to ensure good performance of the material.

For an explanation of this process check here, and refer to section 2.

Here are some important material properties of mycelium materials:

Handles tensile loading well

Has some compressive loading capabilities

Highly flame resistant

It has a very low thermal conductivity

Very high moisture uptake

Okay, sounds great! But what can the mycelium material be used for?

Structural application:

Mycelium has shown an ability to handle tensile loading well, however it has a low ability to withstand compressive loads, meaning the material is weak compared to traditional construction materials. Since structural materials are required to transfer heavy loads, this material wouldn't be effective and therefore is not being considered for structural use.

Thermal insulation:

Mycelium composite is a low-density material, which makes it an excellent insulator as low-density materials conduct heat slower. It performs similarly to other traditional insulators such as glass wool, extruded polystyrene, sheep wool etc.

Water absorption:

Moisture content will also have an impact on the thermal conduction. If mycelium insulation is exposed to moisture for more than a few hours, it can absorb it quickly and in large amounts. Luckily a large increase in moisture content results in just a small increase in heat conductivity. Check here for more(section 3.0).

Other risks resulting from moisture absorbency has delayed the journey of this type of insulation making it into people's homes, but hopefully solutions can be found as this type of insulation would make some amazing competition.

Fire safety:

Mycelium composite out-performs many conventional insulation materials. A mycelium composite can even perform so well under exposure to fire that its only competitor is phenolic formalhyde resin foams.

"Mycelium has been found to possess certain flame-retardant properties (e.g. high char residue and release of water vapour)"

More on that quote here.

Since the material would mainly char rather than burn, it would take longer for flames to travel through a cavity if it were filled with it. The material is also non-toxic therefore it is much safer than other insulators.

Read here for more information on thermal degradation and fire reaction properties of mycelium composites.

Why is this new material so important?

Mycelium material is completely biodegradable and renewable, it has a perfect life cycle and its cheap, what's more to love?

Discovering uses for fungal biomass and applying them is super important for the construction industry as it hopefully will kickstart a greater interest in building with sustainable materials. The current applications of this product are limited; however this material makes promise for the future of sustainability in construction.

Take a look at some videos and other helpful sources if you're still interested!

Engineered mycelium composite construction materials from fungal biorefineries: a critical review

Is Mycelium Fungus the Plastic of the Future?

Can Mycelium Fungus replace Concrete & Plastic?

Biohm

Ecovative

8 notes

·

View notes

Text

What is FRP Products and Its Uses?

Fiber-reinforced plastic (FRP) products are composite materials made from a combination of fibers and a resin matrix. The fibers provide the strength and stiffness, while the resin matrix holds the fibers together and protects them from environmental factors such as moisture, chemicals, and UV light.

FRP products are used in a variety of industries and applications, thanks to their unique properties, which include:

High strength-to-weight ratio: FRP products are significantly lighter than traditional materials such as steel, aluminum, and concrete, while still providing high strength and stiffness. This makes them ideal for applications where weight reduction is critical, such as aerospace, automotive, and marine industries.

Corrosion resistance: FRP products are highly resistant to corrosion, making them ideal for use in harsh environments such as chemical plants, wastewater treatment facilities, and offshore structures.

Electrical insulation: FRP products are non-conductive, meaning they do not conduct electricity. This makes them ideal for use in electrical and electronic applications where electrical insulation is required.

Design flexibility: FRP products can be easily molded into complex shapes, allowing for greater design flexibility and customization. This makes them ideal for applications where unique shapes and sizes are required.

Some common FRP products and their uses include:

FRP grating: Used in industrial, commercial, and recreational applications as an alternative to steel grating, due to its high strength, corrosion resistance, and low maintenance requirements.

FRP tanks and vessels: Used in chemical storage and processing, wastewater treatment, and oil and gas industries due to their corrosion resistance, high strength, and light weight.

FRP piping systems: Used in chemical processing, power generation, and water treatment industries due to their corrosion resistance, low maintenance requirements, and long service life.

FRP panels: Used in commercial and industrial buildings as wall and ceiling panels, due to their high strength, durability, and design flexibility.

In conclusion, FRP products are composite materials that offer high strength, low weight, and corrosion resistance, making them ideal for a wide range of applications in various industries. As technology advances and new materials are developed, FRP products are likely to continue to play an important role in the construction of products and structures in the future.

2 notes

·

View notes

Text

The Swedish pulp producer Renewcell has just opened the world's first commercial-scale, textile-to-textile chemical recycling pulp mill, after spending 10 years developing the technology.

While mechanical textiles-to-textiles recycling, which involves the manual shredding of clothes and pulling them apart into their fibres, has existed for centuries, Renewcell is the first commercial mill to use chemical recycling, allowing it to increase quality and scale production. With ambitions to recycle the equivalent of more than 1.4 billion T-shirts every year by 2030, the new plant marks the beginning of a significant shift in the fashion industry's ability to recycle used clothing at scale.

"The linear model of fashion consumption is not sustainable," says Renewcell chief executive Patrik Lundström. "We can't deplete Earth's natural resources by pumping oil to make polyester, cut down trees to make viscose or grow cotton, and then use these fibres just once in a linear value chain ending in oceans, landfills or incinerators. We need to make fashion circular." This means limiting fashion waste and pollution while also keeping garments in use and reuse for as long as possible by developing collection schemes or technologies to turn textiles into new raw materials.

Each year, more than 100 billion items of clothing are produced globally, according to some estimates, with 65% of these ending up in landfill within 12 months. Landfill sites release equal parts carbon dioxide and methane – the latter greenhouse gas being 28 times more potent than the former over a 100-year period. The fashion industry is estimated to be responsible for 8-10% of global carbon emissions, according to the UN.

Just 1% of recycled clothes are turned back into new garments. While charity shops, textiles banks and retailer "take-back" schemes help to keep those donated clothes in wearable condition in circulation, the capabilities of recycling clothes at end-of-life are currently limited. Many high street stores with take-back schemes, including Levi Strauss and H&M, operate a three-pronged system: resell (for example, to charity shops), re-use (convert into other products, such as cleaning cloths or mops) or recycle (into carpet underlay, insulation material or mattress filling – clothing is not listed as an option).

Much of the technical difficulty in recycling worn-out clothes back into new clothing comes down to their composition. The majority of clothes in our wardrobes are made from a blend of textiles, with polyester the most widely produced fibre, accounting for a 54% share of total global fibre production, according to the global non-profit Textile Exchange. Cotton is second, with a market share of approximately 22%. The reason for polyester's prevalence is the low cost of fossil-based synthetic fibres, making them a popular choice for fast fashion brands, which prioritise price above all else – polyester costs half as much per kg as cotton. While the plastics industry has been able to break down pure polyester (PET) for decades, the blended nature of textiles has made it challenging to recycle one fibre, without degrading the other. (Read more about why clothes are so hard to recycle.)

By using 100% textile waste – mainly old T-shirts and jeans – as its feedstock, the Renewcell mill makes a biodegradable cellulose pulp they call Circulose. The textiles are first shredded and have buttons, zips and colouring removed. They then undergo both mechanical and chemical processing that helps to gently separate the tightly tangled cotton fibres from each other. What remains is pure cellulose.

6 notes

·

View notes

Text

Soft-Touch Polyurethane Coatings Market: Exploring Growth Opportunities and Challenges

Introduction

Soft touch polyurethane coatings are a type of clear protective finish that provides a smooth, matte surface. These coatings are created through a chemical process that bonds polyurethane resin to the substrate material. They derive their soft feel from microscopic irregularities in the coating's surface structure that diffuse light and reduce shine.

Composition and Application

At the molecular level, soft touch polyurethane coatings consist of polyols and diisocyanates that crosslink during curing. This chemical reaction forms a tough, elastic polymer network bonded strongly to the underlying object. These coatings can be applied through various conventional methods such as spray painting, dip coating, flow coating and curtain coating.

Proper surface preparation including cleaning and priming is important for optimum adhesion. Multiple thin coats are usually needed, with enough time allowed between coats for proper curing. Curing speeds and properties can be modified by adjusting catalysts, temperature and humidity controls during application and drying.

Aesthetic and Tactile Benefits

Soft touch polyurethane coatings enhance the visual and tactile qualities of coated surfaces. Their matte, low-gloss finish provides an understated elegance as it diffuses reflections and minimizes fingerprint smudges. The coating's microscopic surface texture creates a smooth, silky feeling under the touch.

This improves handling comfort and ergonomics for devices that come into regular contact with human skin, such as automotive interior trim, medical and consumer electronics. The soft finish also provides an upscale, premium impression. A wide range of special effect pigments and modifiers can be incorporated into these coatings to impart additional visual characteristics.

Mechanical Properties

In addition to aesthetic attributes, soft touch polyurethane coatings offer robust mechanical performance. They form a hard, abrasion-resistant surface that protects the substrate from scuffs, scratches and wear. Coated components maintain their like-new appearance longer.

The coatings also impart some flexibility and impact resistance. Cured films withstand flexing and minor impacts without cracking or delaminating. This durability makes them well-suited for applications involving handling, assembly operations and occasional drops or bumps. Their chemical resistance protects coated surfaces from exposure to common liquids and environmental factors.

Additional Advantages

Soft touch polyurethane coatings provide certain functional advantages beyond appearance and handling characteristics. Their low-gloss finish makes surfaces less susceptible to fingerprints and smudges. This ease of cleanability is advantageous for sanitary applications.

Anti-microbial coatings can also be formulated by incorporating silver or other agents. The coating's lack of shine and pores hinders microbial habitation and growth. Coatings may offer benefits like static dissipation for electronic devices. In automotive uses, their insulating effect assists with thermal management and noise reduction.

Versatility in Many Industries

Thanks to their wide-ranging positive attributes, soft touch polyurethane coatings see application across diverse industries. In consumer electronics and medical devices, they enhance user experience and equipment longevity. For automotive interior and exterior trim components, the coatings boost tactile appeal and durability.

Their subtle elegance and easy maintenance make these finishes suitable for sanitary surfaces in food processing and other industrial settings. Other uses include coatings for recreational and sports equipment, cosmetic and perfume packaging, and specialty household items. Engineers and designers continue utilizing the technology in innovative new applications.

#Soft-Touch Polyurethane Coatings Growth#Soft-Touch Polyurethane Coatings Size#Soft-Touch Polyurethane Coatings Share

0 notes

Text

Energy-Efficient Building Techniques in Tarneit

In reaction to the global movement towards sustainability, the construction industry in Tarneit, an emerging suburb of Victoria, has been integrated. In particular, house builders Tarneit can incorporate sustainable and efficient methods, materials, and technologies in building construction.

These methods benefit the environment and are also financially sustainable for homeowners as they help cut down costs incurred in the provision of energy. This blog evaluates the various high-quality, energy-efficient building methods defining future housing in Tarneit.

Solar Power Integration

Integrating solar power systems is one of the most significant steps towards energy-efficient building. House builders in Tarneit increasingly embed solar panels and thermal systems in new constructions. Solar panels capture solar energy and directly convert it into electricity.

Solar thermal structures harness sun energy to warm water, which reduces the use of steam on non-renewable power assets. This cuts carbon emissions and hence supports the environment while lowering utility expenses.

Additionally, promoting incentives for solar power in Australia attracts new homeowners to embrace this power source.

Advanced Thermal Insulation

Proper insulation, therefore, plays a significant role in energy conservation, whereby temperatures within homes are well regulated, lowering the chances of using heaters or air conditioners frequently. House builders in Tarneit employ advanced insulation techniques, including foam insulation and high-quality batten insulation.

These materials are installed in the walls, roofs and floors as insulation and resist heat flow in cold and hot seasons. Insulation is crucial for making homes more comfortable by significantly reducing noise levels.

High-Efficiency Windows

Another strategy house builders in Tarneit use is installing energy-efficient windows to enhance home energy performance. Multiple-glazed or triple-glazed windows are made up of several glass panes separated by a gas with very low thermal conductivity.

These windows also play a part in controlling indoor temperatures, preventing the formation of condense and giving better soundproofing.

The frames employed in making these conservatories include fibreglass or composite frames, which are more energy-efficient and long-lasting.

Water-Saving Fixtures

Water performance in buildings is now considered one of the predominant additives of sustainable construction. In today's Tarneit homes, newer and more innovative houses feature energy and water-saving amenities such as low-flow toilets, showerheads, and faucets.

Experienced house builders in Tarneit prefer these fixtures to minimise water usage in daily life while maintaining functionality without achieving high levels of water usage.

By using significantly less water per minute compared to traditional fixtures, they help conserve a critical natural resource and lead to substantial savings on water bills.

The deliberate incorporation of water-efficient technology in homes demonstrates a commitment to environmental stewardship and economic efficiency.

Use of Sustainable Materials

The desire for building materials plays a vital function in the environmental effect of a construction undertaking. House builders in Tarneit use recycled building materials that are not obtained directly from the source and have been recycled first. Some sustainable materials used in construction include recycled steel, glass, re-use wood and bamboo.

Also, paints and adhesives are non-toxic, and sealants are used to reduce the emissions of VOCs, which harm the inhabitants of homes by providing them with good air quality.

Implementation of Smart Home Technology

Smart home technology is crucial today and significantly affects home energy management. Some of the features in houses in Tarneit include intelligent thermostats that control heating and cooling equipment depending on the number of people using the house and the climate.

For instance, LED lighting consumes less energy than traditional lighting; programmable appliances and water heaters also help save energy. These technologies allow owners to screen their power consumption behaviour in detail and, for this reason, be in a function to make rational selections.

Green Roofs and Living Walls

Some innovative house builders in Tarneit are incorporating green roofs and living walls into new constructions. These characteristics provide good thermal performance, minimise the speed and impact of water on buildings, contribute to air quality, and diversify the avian fauna within cities.

A green roof is a vegetative layer covered with vegetation and a growing medium or partially or fully developed plant layer on a waterproofing layer.

Similarly, living walls are part of the building's exterior or interior walls, covered with plants. They enhance a building’s insulation and add aesthetic value to the property.

Optimal Orientation and Layout

This is a fact because the position of a building and its architecture determine how much energy it will consume. Climatically responsive architecture is apparent, where house builders in Melton strategically place numerous windows and doors to maximise natural light and air circulation within the buildings.

Additionally, the structures are oriented in alignment with the direction of the winds and the sun. This approach minimises using artificial lights and mechanical air conditioners, thus saving power.

Such thoughtful placement enhances energy savings and ensures that living spaces maintain a natural comfort throughout the seasons, creating healthier and more sustainable living environments.

Final Takeaway

Thus, the residents of Melton who choose to live in a house constructed with the following features can have a relatively environmentally friendly way of life meeting the ecological requirements of the contemporary world. Various dedicated house builders in Melton are adopting these building practices, paving the way for a future where all newly constructed homes will be as energy-efficient as possible, reflecting a commitment to environmental responsibility and sustainability.

#House Builders Tarneit#Home Builders#home improvement#home improving project#home design#home decor#home#home & lifestyle#interior design

1 note

·

View note

Text

Go Recycle: Leaders in Car Batteries and Electrical Wire Recycling in Perth and Wangara

In an era where environmental preservation has become a paramount concern, recycling is no longer just an option but a necessity. Among the myriad of recyclable materials, car batteries and electrical wires hold significant importance due to their composition and potential environmental impact.

Go Recycle, a pioneering Perth-based company, has positioned itself as a frontrunner in the realm of car battery and electrical wire recycling services. At Go Recycle, we understand that the journey towards a more sustainable future begins with responsible disposal and recycling practices. Our aim is to facilitate these practices while providing convenient and efficient recycling services to individuals and businesses in Perth and Wangara.

The Imperative of Car Batteries Recycle in Perth

Car batteries, primarily lead-acid batteries, are a common yet hazardous component of automotive waste. They contain materials such as lead, acid, and plastic, which can be incredibly detrimental to the environment if not disposed of correctly. Perth, being a bustling city with a high number of vehicles, generates a considerable quantity of used car batteries annually, presenting a challenge and an opportunity for effective recycling practices.

Go Recycle rises to the challenge with its specialized Car Batteries Recycle Perth. By ensuring that these batteries do not end up in landfills, we prevent the harmful chemicals from contaminating the soil and water sources. Our advanced recycling process involves meticulously separating the battery components and safely extracting the acids, lead, and plastics. These materials are then processed and repurposed, effectively reducing the need for mining new materials and thereby lessening the carbon footprint associated with battery production.

The Significance of Electrical Wire Recycling in Wangara

Wangara, a vibrant industrial hub north of Perth, is home to numerous businesses that deal with electrical equipment. Consequently, there's a substantial stream of electrical wire waste generated regularly. Electrical wires consist of valuable metals like copper and aluminum, encased within plastic insulation. This combination of materials makes the recycling process more complex, but also highly beneficial both economically and environmentally.

Recognizing the need for a focused approach, Go Recycle offers Electrical Wire Recycling Wangara that cater specifically to the unique challenges posed by these materials. By employing state-of-the-art technology, we not only extract the precious metals for reuse but also ensure that the plastic insulation is adequately recycled, thus diverting a significant amount of waste from landfills.

The Go Recycle Advantage

What sets Go Recycle apart is our unwavering commitment to sustainability and customer satisfaction. Here are the key aspects of our service proposition that define the Go Recycle advantage:

Expertise and Efficiency

At Go Recycle, our team comprises recycling experts who possess a wealth of knowledge and experience in handling different types of materials. Our efficient collection and processing systems are designed to accommodate large volumes of recyclable materials, ensuring quick and hassle-free service for our clients.

Environmentally Responsible Methods

We incorporate eco-friendly techniques in every step of our recycling process. Our methods are compliant with the highest environmental standards, assuring our clients that their waste is being transformed in a manner that is safe for the planet.

Economic Incentives

Through our competitive pricing and incentive programs, we make it financially attractive for individuals and businesses to practice recycling. By offering monetary returns on recyclable materials like car batteries and electrical wires, we foster a culture where recycling is viewed as both a responsible and lucrative action.

Community Engagement

Go Recycle is not just a service; we are a community partner. We actively participate in educational and outreach programs to raise awareness about the importance of recycling. By engaging with the community, we aim to create a ripple effect that encourages widespread adoption of recycling practices.

Our Recycling Process

Go Recycle follows a systematic approach to car battery and electrical wire recycling. Here’s an overview of our process:

Collection: We provide convenient collection services from various locations throughout Perth and Wangara. Our clients can schedule pickups or drop off their recyclable materials at our facilities.

Sorting and Disassembly: Upon receiving the materials, we sort them based on type and composition. Car batteries are carefully disassembled to segregate lead, acid, and plastic.

Material Processing: The separated materials undergo processing. For car batteries, this means neutralizing the acid, purifying the lead, and preparing the plastic for remolding. Electrical wires are stripped of insulation, and the metals are recovered and purified.

Repurposing: Once the materials have been processed, they are ready to be repurposed and reintroduced into the manufacturing cycle. This leads to a reduction in the need for virgin materials and promotes the concept of a circular economy.

The Future of Recycling with Go Recycle

Sustainability is an evolving journey, and Go Recycle continues to innovate and improve upon our processes. Our research and development team is constantly exploring new methods to increase the efficiency and environmental benefits of our recycling programs.

The need for services such as car batteries recycle in Perth and electrical wire recycling in Wangara is more critical than ever before. As the call for environmental responsibility grows louder, Go Recycle remains dedicated to answering that call and leading by example in the recycling industry.

Conclusion

In conclusion, Go Recycle serves as a beacon of sustainability, driving forward the cause of responsible waste management in Perth, Wangara, and beyond. By focusing on the recycling of car batteries and electrical wires, we address a key area of concern within the realm of environmental preservation. Our mission is rooted in providing services that not only help protect the environment but also create value for our clients and the community.

For anyone seeking to dispose of their car batteries and electrical wires, partnering with Go Recycle means choosing a better future for our planet. Together, we can reduce waste, conserve resources, and pave the way towards a greener, more sustainable world. With Go Recycle, you're not just recycling; you're contributing to a movement that champions the health of our earth and the well-being of future generations.

1 note

·

View note

Text

Unveiling the Strength and Versatility of Resol Phenolic Resin: A Bond of Innovation

In the realm of materials science, resol phenolic resin emerges as a stalwart champion of strength, durability, and versatility. Born from the alchemy of chemical synthesis and human ingenuity, this remarkable substance has revolutionized industries ranging from automotive to construction. Let us embark on a journey to discover the extraordinary properties and myriad applications of resol phenolic resin, exploring the human intelligence and emotion that underpin its creation and utilization.

Exceptional Properties:

High Strength: Resol phenolic resin boasts exceptional mechanical strength, making it an ideal choice for applications where durability and reliability are paramount. Its ability to withstand extreme temperatures and harsh environmental conditions sets it apart as a material of choice in demanding engineering applications.

Fire Resistance: One of the hallmark properties of resol phenolic resin is its superior fire resistance. With a low flammability and high char yield, it serves as a critical component in fire-retardant materials for buildings, aircraft interiors, and other safety-critical applications.

Chemical Stability: Resol phenolic resin exhibits excellent resistance to a wide range of chemicals, acids, and solvents, making it suitable for use in corrosive environments such as chemical processing plants and offshore oil platforms.

Diverse Applications:

Composite Materials: Resol phenolic resin is widely used as a matrix material in the production of composite materials such as fiberglass reinforced plastics (FRP) and carbon fiber composites. Its ability to bond with reinforcing fibers creates lightweight yet strong structures for applications ranging from aerospace to sporting goods.

Insulation Products: The thermal and electrical insulation properties of resol phenolic resin make it a popular choice for manufacturing insulation products such as foam boards, pipe insulation, and electrical laminates. Its low thermal conductivity and high dielectric strength contribute to energy efficiency and safety in various industries.

Adhesives and Binders: As a versatile adhesive and binder, resol phenolic resin finds use in wood panels, plywood, particle boards, and foundry sand molds. Its strong bonding capabilities and heat resistance ensure the structural integrity and performance of bonded assemblies in diverse applications.

Innovative Manufacturing:

Precision Synthesis: The production of resol phenolic resin involves precise control over chemical reactions and process parameters to achieve desired properties such as molecular weight, viscosity, and curing characteristics. Advanced synthesis techniques and quality control measures ensure consistency and reliability in the final product.

Custom Formulations: Manufacturers tailor resol phenolic resin formulations to meet specific performance requirements for different applications. By adjusting resin composition, additives, and curing conditions, they optimize properties such as viscosity, tack, and flow behavior to suit diverse processing techniques and end-use conditions.

Human Ingenuity and Emotion:

Scientific Discovery: The development of resol phenolic resin is a testament to the curiosity, creativity, and perseverance of scientists and researchers who explore the frontiers of materials science. Their quest for innovation drives breakthroughs that unlock new possibilities and applications for this versatile material.

Engineering Excellence: Behind every application of resol phenolic resin lies the expertise and craftsmanship of engineers and technicians who harness its properties to solve real-world challenges. Their dedication to quality, safety, and performance ensures the integrity and reliability of structures and products made with this remarkable material.

Conclusion: Resol phenolic resin embodies the union of human intelligence and emotion in the pursuit of innovation and progress. From its exceptional properties to its diverse applications, it serves as a testament to the ingenuity and creativity of those who explore the boundaries of materials science. As we continue to unlock the potential of resol phenolic resin in various industries, let us celebrate the collaborative spirit and passion for discovery that drive its evolution and adoption.

In a world where challenges abound and solutions are sought, resol phenolic resin stands as a shining example of the transformative power of human ingenuity and emotion in shaping the materials that shape our world.

0 notes

Text

Aerospace Plastics Market: Innovations, Trends, and Future Growth

The aerospace industry is one of the most technologically advanced sectors, continuously evolving to meet stringent performance, safety, and efficiency standards. Within this landscape, aerospace plastics have emerged as critical materials, offering numerous advantages over traditional materials such as metals. These high-performance plastics are lightweight, durable, and resistant to corrosion, making them indispensable in modern aerospace engineering. This article delves into the current trends, key drivers, applications, and future prospects of the aerospace plastics market.

Market Overview

The global aerospace plastics market has witnessed significant growth over recent years. As of 2023, the market size was valued at USD X billion and is projected to reach USD Y billion by 2030, growing at a CAGR of Z% during the forecast period. The increasing demand for lightweight and fuel-efficient aircraft, coupled with advancements in plastic materials, is driving this growth.

Key Drivers

1. Weight Reduction: One of the primary benefits of aerospace plastics is their ability to significantly reduce the weight of aircraft. Reduced weight translates to lower fuel consumption, which is a critical factor for both commercial and military aviation. Plastics such as polyetheretherketone (PEEK), polyphenylene sulfide (PPS), and polyimides are increasingly used to replace heavier metal components.

2. Fuel Efficiency and Emissions: The aviation industry is under constant pressure to reduce carbon emissions and improve fuel efficiency. Aerospace plastics contribute to these goals by enabling the design of more aerodynamically efficient and lighter aircraft. This not only helps in reducing greenhouse gas emissions but also lowers operational costs.

3. Durability and Resistance: Aerospace plastics offer superior resistance to chemicals, heat, and corrosion compared to traditional materials. This enhances the longevity and performance of aircraft components, leading to lower maintenance costs and increased safety.

4. Technological Advancements: Continuous R&D in polymer science has led to the development of new high-performance plastics with enhanced properties. Innovations in composite materials, additive manufacturing (3D printing), and nanotechnology are expanding the application scope of aerospace plastics.

For a comprehensive analysis of the market drivers:- https://univdatos.com/report/aerospace-plastics-market/

Applications

Aerospace plastics are used in various applications within the industry, including:

-Structural Components: Plastics are increasingly being used in primary and secondary structural components of aircraft. These include fuselage parts, wing panels, and interior cabin structures. The use of composite materials like carbon fiber-reinforced plastics (CFRP) has revolutionized aircraft design.

- Interiors: The interior of an aircraft benefits greatly from the use of plastics. Lightweight plastics are used for seating, overhead compartments, wall panels, and flooring. These materials offer excellent fire resistance, durability, and ease of cleaning.

- Insulation and Wiring: Aerospace plastics provide excellent insulation properties, making them ideal for electrical wiring and cable insulation. They ensure safety and reliability in the aircraft’s electrical systems.

- Engine Components: High-performance plastics are used in various engine components such as housings, ducts, and seals. Their ability to withstand high temperatures and harsh chemical environments makes them suitable for use in and around the engine.

Regional Insights

The aerospace plastics market is geographically diverse, with key growth regions including North America, Europe, and Asia-Pacific.

- North America: This region holds a significant share of the market due to the presence of major aircraft manufacturers like Boeing and Lockheed Martin. The focus on fuel efficiency and emission reduction drives the demand for aerospace plastics.

- Europe: Europe is a major player in the aerospace industry, with companies like Airbus leading the market. Stringent environmental regulations and advancements in composite technologies are boosting the market for aerospace plastics.

- Asia-Pacific: The Asia-Pacific region is experiencing rapid growth in the aerospace sector, driven by increasing air travel and rising defense budgets. Countries like China, India, and Japan are investing heavily in new aircraft and aerospace technologies, fueling the demand for aerospace plastics.

For a sample report, visit:- https://univdatos.com/get-a-free-sample-form-php/?product_id=37117

Future Prospects

The future of the aerospace plastics market looks promising, with several trends expected to shape its trajectory:

- Sustainable Materials: There is a growing focus on the development of sustainable and recyclable plastics. Biodegradable polymers and bio-based composites are likely to gain traction in the aerospace industry.

- Advanced Manufacturing Techniques: Innovations in manufacturing processes, such as 3D printing and automated fiber placement, will enable more efficient production of complex plastic components, reducing costs and material wastage.

- Integration of Smart Materials: The integration of smart materials with self-healing and self-sensing capabilities is an emerging trend. These advanced materials can enhance the safety and performance of aircraft.

In conclusion, the aerospace plastics market is poised for robust growth, driven by the need for lightweight, durable, and fuel-efficient materials. As the aerospace industry continues to evolve, aerospace plastics will play a crucial role in shaping the future of aviation.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

#Aerospace Plastics Market#Aerospace Plastics Market Growth#Aerospace Plastics Market Share#Aerospace Plastics Market Forecast

0 notes

Text

Aluminium Composite Panels Market: Trends, Growth, and Future Prospects

Aluminium Composite Panels (ACPs) are gaining significant traction in the construction and renovation industries due to their versatile applications, aesthetic appeal, and functional benefits. These panels consist of two aluminium sheets bonded to a non-aluminium core, offering a combination of durability, lightweight properties, and resistance to weathering. The market for ACPs is expanding rapidly, driven by increasing urbanization, rising demand for sustainable building materials, and advancements in technology.

Market Overview

The global aluminium composite panels market has experienced substantial growth over the past decade. According to industry reports, the market size was valued at USD X billion in 2023 and is projected to reach USD Y billion by 2030, growing at a CAGR of Z% during the forecast period. This growth can be attributed to several factors, including the increasing construction activities in emerging economies, the rising focus on energy-efficient buildings, and the growing adoption of modern architectural designs.

Key Drivers

1. Urbanization and Infrastructure Development: Rapid urbanization, particularly in developing countries, is a major driver for the ACP market. As cities expand and new urban areas are developed, the demand for modern construction materials that offer both aesthetic and functional benefits is on the rise. ACPs are favored for their ability to provide a sleek, contemporary look while ensuring durability and cost-effectiveness.

2. Sustainable Building Materials: With growing environmental concerns, there is a heightened focus on sustainable building practices. Aluminium composite panels are increasingly preferred due to their recyclable nature and energy efficiency. They contribute to green building certifications and help in reducing the overall carbon footprint of structures.

3. Technological Advancements: Innovations in manufacturing processes and material technologies have significantly enhanced the performance characteristics of ACPs. Improved fire resistance, better insulation properties, and advanced surface coatings are some of the developments that have broadened the application scope of these panels.

For a comprehensive analysis of the market drivers:- https://univdatos.com/report/aluminium-composite-panels-market/

Applications

ACPs are used in a wide range of applications across various sectors:

- Exterior Cladding: One of the most common uses of ACPs is in exterior cladding or facades. They offer a modern and clean appearance, protect the building structure from weather elements, and provide insulation.

- Interior Decoration: ACPs are also popular for interior applications such as false ceilings, partitions, and wall panels. Their lightweight and flexible nature make them easy to install and maintain.

- Signage and Advertising: The durability and aesthetic appeal of ACPs make them suitable for outdoor signage and advertising boards. They can withstand harsh weather conditions and maintain their appearance over time.

- Transportation: In the transportation industry, ACPs are used for vehicle bodies and interiors, providing a lightweight yet strong solution that enhances fuel efficiency and durability.

For a sample report, visit:- https://univdatos.com/get-a-free-sample-form-php/?product_id=37129

Regional Insights

The ACP market is geographically diverse, with significant growth observed in Asia-Pacific, North America, and Europe.

- Asia-Pacific: This region dominates the market due to rapid urbanization, growing construction activities, and increasing investments in infrastructure development. Countries like China, India, and Japan are major contributors to the market growth.

- North America: The demand for ACPs in North America is driven by the need for energy-efficient buildings and the renovation of old structures. The presence of key manufacturers and technological advancements also contribute to market growth.

- Europe: In Europe, stringent regulations regarding building safety and energy efficiency are propelling the adoption of ACPs. The region's focus on sustainable construction practices further boosts market demand.

Future Prospects

The future of the aluminium composite panels market looks promising, with several trends likely to shape its trajectory:

- Green Buildings: The shift towards green building practices and sustainable construction materials will continue to drive the demand for ACPs. Manufacturers are likely to focus on developing more eco-friendly products to meet this demand.

- Innovative Designs: As architectural trends evolve, there will be a growing need for innovative and customizable ACP solutions. This will encourage manufacturers to invest in R&D and expand their product portfolios.

- Smart Cities: The development of smart cities, with their emphasis on advanced infrastructure and sustainable living, will create new opportunities for ACP applications.

In conclusion, the aluminium composite panels market is set for robust growth, driven by urbanization, sustainability trends, and technological advancements. As the construction industry continues to evolve, ACPs will play a crucial role in shaping modern architectural landscapes.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

#Aluminium Composite Panels Market#Aluminium Composite Panels Market Growth#Aluminium Composite Panels Market Share#Aluminium Composite Panels Market Forecast

0 notes

Text

Step Up Safety: Choosing the Right Safety Shoes for Ultimate Protection

Safety boots are an integral component of personal protective equipment (PPE) in a range of sectors and protect workers against various risks. In Singapore, a country that has placed great emphasis on occupational safety, there has been growing demand for top quality safety boots. KPR, the leading supplier of safety boots in Singapore, offers an extensive collection of safety footwear intended to satisfy rigorous safety regulations for different work settings. This article looks at why safety boots are important, the different varieties available and why KPR is the best choice for Singaporean businesses.

The importance of wearing safety shoes cannot be overstated in some industries such as construction, manufacturing and logistics. These industries frequently expose their employees to dangers like falling objects, heavy items or sharp things among others. Safety boots are designed to mitigate these threats so that they can do their duties with minimal risk of injury. The Minstry Of Menpower (MOM) stipulates that appropriate PPE such as Safety Boots must be used to reduce workplace accidents and improve security measures.

Safety boots have several functions in protecting users; firstly they protect the feet from impact injuries resulting from falling objects This is especially important in construction sites whereby heavy materials and equipment are constantly moved around The toe caps found in most types of safe shoes made from steel aluminum or composites prevent it from breaking therefore preventing fractures and other injuries KPR’s range of safety boots in Singapore includes those with reinforced toe caps conforming to international safety standards thus providing reliable protection for workers.

Another critical quality of Safety Boots is its ability to prevent puncture wounds due to sharp objects like nails or shards of metals by having puncture resistant plates on the sole. These plates usually made out steel or Kevlar will not let any sharp object pierce through into the foot sole thereby causing harm/any form of injury. To participants fearing this hazard if not prevented can greatly harm them hence requiring a good type shoes For instance, this feature can be found on KPR safety boots.

Chemical resistance is an additional important attribute of safety boots especially in industries where employees come into contact with hazardous substances. Chemical resistant shoes are made from materials that resist harmful chemicals preventing burns and other injuries. For instance, KPR offers some examples of chemical resistant safety boots in Singapore meant for use in chemical-intensive environments.

The importance of slip resistance cannot be overlooked when designing shoes to avoid slips, trips, and falls which are leading causes of accidents at workplaces. Safety boots with anti-slip soles allow workers to have a good hold on surfaces and minimize falls or slips. One example of this is the new range of sole designs featured by KPR’s safety boots which increases grip thus ensuring stability while walking and reducing chances of falling over whenever it rains or there is oil spillage.

Safety boots for electrical hazard protection are also very important particularly for individuals who work in electric power supply companies. Electrically insulated footwear used as safety boots prevent electric shocks due to its non-conductive nature. These hazards can be avoided by means of wearing electrical insulating footwear which is available among the range of products under this brand sold by KPR here in Singapore.

To ensure efficient work, people often neglect the fact that comfort is also a part of safety boots. If workers wear uncomfortable safety boots, they will get tired easily and their productivity will decrease leading to accidents increases. The design of KPR's safety boots is based on ergonomics thus provide enough padding making sure that it is comfortable for workers throughout the day while they enjoy arch support and breathability. These various aspects which make boots comfortable do not in any way affect its protective properties hence KPR’s products are suitable for tough working conditions.

Durability is another crucial factor when purchasing safety boots. They can be considered as high-quality shoes that go with time ensuring a maximum profit from them. As opposed to cheap knock-offs, KPR's safety boots are made from sturdy materials to withstand frequent use and provide lasting protection without having to buy new ones all the time. Therefore, this makes it economical for business users since it helps in cost cutting.

Additionally, KPR’s safety boots sold in Singapore have beautiful designs in mind apart from providing protection. Modern safety shoes no longer need to be bulky or even ugly looking like before. Consequently, there are different styles at KPR's disposal which combine elegance with functionality hence an employee can look good while remaining safe at work. In other words, these two elements blend well especially where such industries as retail and hospitality want images maintained.

Also necessary is ensuring proper maintenance of the footwear designed for maintaining foot safety. Conducting regular cleaning exercises and inspections on one’s shoes would help in prolonging their life span besides keeping them functioning optimally throughout their lifetime for maximum provision of security cover against workplace hazards. Thus safeguarding high standards of security within Singaporean firms by giving instructions on how to keep their product clean and intact is the whole idea behind the comprehensive maintenance guidelines by KPR for its customers in Singapore businesses. Besides, extra after sales services and supports are provided by KPR so as to enable customers who need expert advice to obtain it whenever they want.

When choosing safety boots, people should take into account both job-specific requirements and the workplace environment. Individuals may consult experts such as those at KPR in order for them to be advised on which type of shoes is appropriate for their needs. Therefore, KPR’s experienced and knowledgeable staff can give guidance by being aware of the industry standard requirements plus different risks that exist at a place of work thereby ensuring that workers are shoe protected accordingly.

Another important thing is training workers on how to use and maintain these safety shoes correctly. KPR has put in place various tools and programs which one might find handy towards teaching employees on how important safety boots are as well as proper ways in wearing them appropriately. In this way, it is possible to raise awareness about safety instead of just managing it at work places.

To sum up, there are no Singaporean companies concerned with working conditions that do not provide their personnel with necessary footwear for protection purposes. A number of hazards can be avoided by wearing safety boots since they have been designed specifically to meet the requirements of many tasks. Singapore has a variety of products supplied by KPR together protection, comfort and durability in boots thus they become most preferable among businesses that highly esteem their workers’ wellbeing. For this reason, investing in KPR’s safety boots will keep workforce safe increase productivity and help comply with regulations hence making a safer working environment where more job volumes can be achieved.

0 notes

Text

ACP Sheets : A Complete Guide by Alutechpanels

When it comes to modern architectural solutions, exterior ACP sheets have revolutionized the way buildings are designed and constructed. Alutechpanels, a leading name in the industry, offers top-quality ACP sheets that not only enhance the aesthetic appeal of your building but also provide unmatched durability and functionality. In this comprehensive guide, we will explore the various benefits and applications of exterior ACP sheets, along with the full form and features of ACP sheets.

What are ACP Sheets?

ACP stands for Aluminium Composite Panel. These panels are made by sandwiching a non-aluminium core between two aluminium sheets. The result is a lightweight, durable, and versatile material that is perfect for a variety of applications, particularly in building exteriors. Alutechpanels specializes in producing high-quality ACP sheets that meet the diverse needs of architects and builders.

Benefits of Exterior ACP Sheets

Aesthetic Appeal: Exterior ACP sheet from Alutechpanels come in a wide range of colors, textures, and finishes. Whether you prefer a sleek, modern look or a classic, traditional appearance, there is an ACP sheet to match your vision.

Durability: ACP sheets are highly resistant to weathering, corrosion, and impact. This makes them an ideal choice for exterior cladding, ensuring that your building remains beautiful and intact for years to come.

Insulation: ACP sheets offer excellent thermal and sound insulation properties, contributing to a comfortable and energy-efficient building environment.

Low Maintenance: Unlike traditional materials, ACP sheets require minimal maintenance. A simple cleaning routine is enough to keep them looking new and fresh.

Applications of Exterior ACP Sheets

Exterior ACP sheets from Alutechpanels are incredibly versatile and can be used in various applications, including:

Building Facades: Transform the look of your building with stylish and durable ACP sheets. They provide a modern and sophisticated finish that stands out.

Signage: ACP sheets are perfect for creating eye-catching signs and displays. Their smooth surface ensures excellent print quality and visibility.

Canopies and Awnings: Protect entrances and outdoor areas with ACP sheets that offer both functionality and aesthetic appeal.

Interior Applications: While primarily used for exteriors, ACP sheets can also enhance the interiors of commercial and residential spaces.

ACP Sheet Full Form Explained

Understanding the full form of ACP sheet is crucial for appreciating its composition and benefits. ACP, or Aluminium Composite Panel, is a combination of aluminium and a non-aluminium core, usually made of polyethylene or mineral-filled core. This unique construction provides the material with exceptional strength, flexibility, and durability, making it a preferred choice for various construction needs.

Why Choose Alutechpanels?

Alutechpanels stands out in the market for its commitment to quality, innovation, and customer satisfaction. Here are some reasons to choose Alutechpanels for your exterior ACP sheet needs:

Premium Quality: Alutechpanels uses high-grade raw materials and advanced manufacturing processes to produce ACP sheets that meet international standards.

Wide Range of Options: With a vast selection of colors, textures, and finishes, you can find the perfect ACP sheet to match your design requirements.

Expert Support: The team at Alutechpanels is dedicated to providing expert guidance and support throughout your project, ensuring a seamless experience from start to finish.

Sustainability: Alutechpanels is committed to sustainable practices, offering eco-friendly ACP sheets that contribute to a greener future.

Final Thoughts

Exterior ACP sheets by Alutechpanels are a game-changer in the world of architecture and construction. With their aesthetic versatility, durability, and low maintenance requirements, ACP sheets are the ideal solution for modern buildings. Understanding the ACP sheet full form and its applications further highlights the advantages of this innovative material. Choose Alutechpanels for your next project and experience the difference in quality and performance.

0 notes

Text

Polyimide Prices Trend, Database, Index, News, Chart, Forecast

Polyimide prices have been subject to fluctuations in recent years due to various factors impacting the supply chain and market dynamics. Polyimides are high-performance polymers known for their exceptional thermal stability, mechanical strength, and chemical resistance, making them indispensable in industries such as electronics, aerospace, automotive, and healthcare. The cost of polyimides is influenced by several key factors, including raw material prices, manufacturing processes, demand-supply dynamics, and technological advancements.

One significant factor affecting polyimide prices is the cost of raw materials. Polyimides are typically derived from aromatic dianhydrides and aromatic diamines, which are themselves derived from petroleum or other chemical feedstocks. Fluctuations in crude oil prices, geopolitical tensions, and supply chain disruptions can all impact the cost of these raw materials, thereby affecting the overall price of polyimides. Additionally, the availability of raw materials can be influenced by factors such as natural disasters, regulatory changes, and shifts in global trade patterns, further contributing to price volatility.

Get Real Time Prices of Polyimide: https://www.chemanalyst.com/Pricing-data/polyimide-1579

Manufacturing processes also play a crucial role in determining polyimide prices. The production of polyimides involves several complex steps, including polymerization, curing, and post-treatment processes. Energy costs, labor expenses, and capital investments required for equipment and infrastructure all factor into the manufacturing cost of polyimides. Innovations in process efficiency, automation, and recycling technologies can help manufacturers optimize their operations and reduce production costs, ultimately influencing the market price of polyimides.

Demand-supply dynamics significantly impact polyimide prices, as these polymers are used in a wide range of high-performance applications. Rapid industrialization, urbanization, and technological advancements drive demand for polyimides in sectors such as electronics (e.g., flexible printed circuits, display films), aerospace (e.g., lightweight composites, thermal insulation), automotive (e.g., engine components, electrical insulation), and healthcare (e.g., medical devices, implants). Fluctuations in end-user demand, market trends, and competitive dynamics can lead to shifts in supply and demand equilibrium, thereby affecting polyimide prices.