#Compressed Air Line Filter

Explore tagged Tumblr posts

Text

Ensure clean, dry air with a high-quality compressed air line filter. Designed to remove oil, moisture, and particulates, it protects tools and improves efficiency. Ideal for industrial, automotive, and workshop applications. Reliable and easy to maintain.

1 note

·

View note

Text

Extend Filter Life & Reduce Costs: High-Performance SS Filter Cartridges

Looking for superior SS filter cartridges that deliver extended life and reliable filtration? Look no further! We are a leading manufacturer of SS filter cartridges, designed for optimal performance in various applications. Our cartridges offer unmatched durability, high-temperature resistance, and excellent cleanability. Upgrade your filtration system today and experience the difference!

0 notes

Text

#Line Filter for Air Compressor#Air Compressor Filter#Air Compressor Air-Line Filters#Compressed Air Filters

1 note

·

View note

Text

#Refrigeration Screw Compressors#Air Compressor on Rent#Compressed Air Pipe in India#Air Compressor on Rent in Delhi#Line Filter Manufacturers

0 notes

Text

Overflow

✦ Part 7 < Part 8

Reader x Choso Kamo | 18+ MDNI

cw: soft smut, emotional intimacy, overstimulation, accidental repeated orgasms, technique malfunction, creampie x multiple, passing out of overstimulation, reader in control, whimpery sub!Choso, praise kink, oral (f + m), very gentle dom!reader, shower aftercare

⸻

Part 6

The late afternoon sun filters through Choso’s living room, painting everything in gold. Two months of stability—of real, unshakable calm—have given you something rare: peace. He’s relaxed on the couch with you curled beside him, Netflix murmuring in the background, popcorn spilled across the coffee table.

Your fingers drift through his damp hair as he leans in for a kiss. It’s slow, soft, and entirely tender—the sort of touch that’s mirrored in his hold around you.

“Trust me?” he murmurs.

“Always,” comes your quiet reply.

A smile stretches across his face, one you know is real.

They kiss again—this time deeper—and you melt under the warmth of it. He claims your lips with steady gentleness, hands trailing from your waist to your back. It feels perfect—safe.

Moments like this have become a beautiful pattern: predictably sweet affection, anchored trust, the kind of intimacy you thought only existed in dreams.

His lips curve against yours. “I missed you.”

Your heart aches. “Me too.”

He leans in again. In the stretch of silence between breaths, everything feels perfectly balanced—until it’s not.

Without warning, his hand tightens.

It’s quick. A flash. Enough to make you flinch—but he doesn’t release.

You pull away slightly. “Choso?”

He doesn’t respond.

The air between you shivers. He kisses you again, but his press is hard now—too hard. The sweetness turns edgy. The hand that was gentle on your back grips your hip like steel.

It tears at the trust you’ve built.

You press your palm to his wrist. His bones press through his skin. “That hurts,” you whisper.

Still, he doesn’t break away.

You break the kiss. Fear blooms in your chest.

“Choso—please.”

He pulls you tight, one arm clamping you to the couch. The other drags a line of kisses back up to your ear, rough and urgent.

Your breath comes fast.

He’s not smiling anymore. His eyes flicker in and out like faulty floodlights. His face marks blaze outward—lines branching across his cheeks, over his temples again.

“It’s… okay,” he breathes, voice strained.

You don’t believe him. Your heart hammers.

“I don’t… I don’t think this is okay,” you say.

He stares past you, into something you can’t see.

Then—

In an instant, his arm unclasps, and he yanks you upright. Without a word, he storms toward the bedroom, your breath caught between cries.

He yanks the bedroom door open and shoves you onto the bed. Not gentle. Wild.

You land back-first, knocking the wind out of you.

“Choso—what are you doing?” you say, voice quivering.

He stands over you—breath ragged, eyes white-hot. His face is streaked with blood from his nose and temple. His mark-lines are spread again, but not glowing—like scars crackling with electricity beneath the skin.

He comes toward you, lips parted, almost feral—hungry.

He kisses you hard, teeth brushing your lower lip. It stings. The kisses break apart, jagged and sharp.

You push at his chest. “Choso, slow down!”

But he only tightens the kiss.

It’s not that he didn’t hear you—he’s deliberately ignoring you. Because he wants more. He needs more.

You clamp your eyes shut. Fear twists inside your chest.

You push again at his shoulders, tearful and frantic. “Stop—please!”

Suddenly, he breaks away. He looks at you. Something fluid passes over his eyes—rage, remorse, fear. For a moment, he looks like himself again. But–

His eyelids flutter closed. Blood seeps from his tear ducts and nose. His knees go weak, and he collapses beside you, face-first onto the blanket.

You scream. Your heart stops.

You sit frozen, hands shaking. He’s unconscious—blood streaked across the side of his face.

Your chest compresses. The aftershocks of fear ripple through you.

You yank your phone off the table and call Shoko’s number, fingers trembling.

“Shoko! Please—Choso just… bled. From his eyes. I… I don’t know.”

Her voice is calm, immediate: “Is he responsive?”

You shake, though she can’t see. “No. He’s out cold. I think he’s bleeding from the eyes.”

“Stay with him. I’m on my way, i‘ll get Suguru.” Shoko cuts the call.

You drop the phone. Your breath shakes. You can’t think.

Two minutes later, you hold his cheek—face pale, pulse faint. It keeps beating.

You stroke his hair, your tears wet on his neck.

“I’m here,” you whisper. “I’m so sorry.”

Footsteps pound in the quiet hallway. The door bursts open. Shoko appears with Geto and a small bag, voice clipped.

“Let me see.” She checks his vitals carefully as you step away.

Shoko tiptoes between him and you, working quickly: wipes, cuff, glass vial.

She shakes her head. “Consciousness is low. Internal bleeding. We need to move him.”

“Do it,” you say, voice brittle.

Geto lifts Choso gently like he weighs nothing. You carry a blanket, leading the way to her car. You put Choso in the back shuffled between you both. Shoko wraps tube ice to his temple as you hold his hand, silent tears dripping across his palm.

-

At the clinic, Shoko rushes in, phone to lips. “He’s bleeding from ocular vessels—suspected cursed blood overstrain. Get ready for transfusion support and cleansing seals.”

Nurses swarm. You stand back as they gently place Choso on a table.

They ask you to wait in a separate room. You pace. It’s pitch dark and cold.

Minutes stretch. You clutch your hands to stop yourself from shaking. You felt his fear earlier. You heard him. But this feels… worse.

Shoko pulls you in. “He’s stable. Eye hemorrhaging stopped. Consciousness low, but okay.”

You stumble into her arms, relief flooding. You shake again.

“He’ll… be okay?” you whisper.

Shoko nods. “Under sedation through the night. I’ll stay.”

You breathe, tears flooding.

You sit by his bedside. Shoko is dozing off, eyes heavy with exhaustion. Monitors beep steady; Choso’s breathing is quiet and even.

You take his hand again. Press your forehead to it.

“Please don’t leave me,” you whisper.

The blood markers on his pillow stain, but don’t run. His cheek is cold.

You curl against him, silent tears slipping down.

A pale glow appears behind the curtains. You leave Shoko’s side to stand at the window.

The sun is gentle. Warm. Forgiving.

You whisper a promise: “We’re going to fix this.”

A whisper of breeze brushes the curtains — and your heart steadies.

to be continued

໒꒰ྀི ˶• ༝ •˶ ꒱ྀི১ hope you like it!!

be sure to check out my other stuff too <3

taglist: @queenshu

#jjk#jjk smut#jjk x reader#jjk fanfic#smut#choso kamo#jjk choso#choso x reader#choso smut#jujutsu kaisen choso#choso x you#choso smau#choso x y/n#choso fluff

27 notes

·

View notes

Note

you're the last one to receive the gift i hope you know......... 🪨🪨🪨💥💥💥

------

It is just another boring Tuesday. T-Mart, the only convenience store in the whole two-mile radius, is empty at this time of the day where the sun is at its highest and almost everyone is at work. There are no customers, only the three workers loitering in boredom, waiting for the shift to finish. Murder is flipping through a tabloid magazine, Horror is manning the register, and Killer is doing her nails – all of them periodically glancing at the clock to see when they will be released from this hell.

“huh, have you heard the new scandal of dream yet?” Murder asks out of the blue, breaking the stale silence among them.

“dream… like our ceo’s brother? that dream?” Horror perks up.

“yeah,” Murder says, her mouth curved into a devious smirk. “apparently she got caught sneaking out of the hotel with ink. you know… the famous musician.”

“wait, isn’t ink married? to that wwe performer – crux or something?”

“cross, yeah. here, look at this.” Murder flips the magazine to show Horror the salacious photo: Dream in a trench coat and Ink in an oversize hoodie, both looking like deers caught in the headlights.

Killer snorts from across Horror, which is as close to a laughter as she gets. “that is the least stealthy thing i’ve ever seen. trench coat and sunglasses? that’s one face mask away from announcing to the world that you’re doing something you shouldn’t be doing.”

Murder smirks back. “apparently her publicist is saying this is a business meeting.”

“at 2 am?” Killer grins, propping her chin on her hand. “they should’ve met in broad daylight. no one suspects shady business at brunch time.”

“they’d get caught anyway,” Horror muses. “the universe really loves to create chaos.”

Yep, just another regular Tuesday.

Until the wall explodes.

“oh, come on,” Horror groans, ducking under the register as chunks of drywall fly all over the place.

Through the dust strides a figure in a long black coat, slightly floating off the ground. A web of strings shoots from the figure, quickly covering the whole area with glitching patterns and noises of a dying Wi-Fi modem. The air hums with electricity as the apparent villain points at the three unfortunate minimum wage workers.

“fear me, you abominations – for i am error the destroyer! surrender your worthless lives to me, or face your deletion off this world!” The villain proclaims, her voice crackling like a compressed MP3 file.

The trio exchange unimpressed glances.

“seriously?” Horror raises an eye ridge at Error. “that’s your line? that’s so corny. where did you get that from? straight-to-dvd trash bin?”

Error’s fingers glow ominously. “do not dare to underestimate me, you-”

Murder interrupts whatever is about to come out of the villain’s mouth. “oh, we’re shaking in our boots,” she deadpans, glaring at the destroyed wall with a twitch in her eye. “every week there’s a new evil overlord wannabe around these parts. blah blah world domination blah blah you’re gonna be my minions – we get it already. take the cash. or burn the place down. we’re not getting paid enough for this.”

“keys are under the fire alarm box,” Killer chimes in. “just don’t take the slushie machine though – it’s the only thing keeping us alive here.”

Error’s face glitches. She clearly doesn’t expect this level of apathy from her soon-to-be hostages. “insolent worms! you will submit!” she screeches.

“big words for someone who looks like a tiktok filter,” Killer quips, now holding a boxcutter and spinning it in her hands. “also, that’s just a horrendous costume. Where did you get it? The bargain bin?”

“how dare you- this is a custom design!”

“yeah, it shows.” Killer tilts her head, grinning. “and not in a good way.”

“well,” Horror says to the side, squinting at her phone. “according to chirper updates, the starlights should be here in three minutes. so if you’re gonna finish your monologue, you should probably do it now before they haul your ass to who-knows-where.”

Error splutters, her glitches spreading to the rest of her body as she’s incandescent with rage. “you- all of you insolent freaks! you will regret this!”

“not more than this job, i wager,” Murder says, her voice bored. “you know, if you want to be an evil nuisance, you can just go to business school. like our blood-sucking ceo.”

Error looks like she might implode on the spot. “you can’t just- you can’t-”

“aww, what’s the matter, glitchy?” Killer drawls. “the school of evil didn’t teach you how to deal with a little bit of criticism?”

Before Error can say anything in response, another wall explodes, showering people with even more debris.

“STOP RIGHT THERE, ERROR!!” a chorus of voices exclaim. The local magical girl squad – the Starlights – have arrived in all the pastel and frilly glory, posing dramatically in the rubble. There’s Solar, the leader of the group holding a bow in her hands. Prism, who brandishes a giant calligraphy brush. And Aqua, who wields two billy clubs. Any villain would hate to cross their paths, and Error isn’t an exception.

The customer service trio quickly hides somewhere when the fight starts, but still peeks in to see what’s happening. The Starlights launch into their usual spiel about love, righteousness, and protecting the innocent, while Error’s glitching presence seems to falter even more. Murder leans toward Killer.

“10g saying that villain will break in five minutes because of the speeches instead of the fighting.”

“pfft, should be three minutes max.” Killer counters.

Three minutes later, Error is wrapped in sparkly ribbons, courtesy of the Starlights, and hauled away as the squad strikes yet another triumphant pose. The day is saved, but the store is probably not. The workers exchange another look with each other.

“thanks for cleaning up the mess,” Horror calls out sarcastically as the magical girls prance out of the store through the hole they created. “urgh, can we go home now?” she asks, slumping even further onto the counter.

“nope. still got four hours left,” Murder replies, uncaring as she picks up the discarded magazine and continues reading it.

Killer sighs, flipping the boxcutter back into her pocket. “i’m gonna break the slushie machine.”

“do it,” Horror says, completely deadpan, her eye staring straight at Killer. “i dare you.”

Just another Tuesday.

YAYAYAYAYA I BREEEZED OVER IT I GOTTA REALLY READ IT BUT ITS SO FUNNY. The way they're so nonchalant is the funniest thing ever, they're just trying to survive their shift bruh 💔

23 notes

·

View notes

Text

Line - The Ink Demonth 2024 (Day 8)

In which someone stumbles over their words.

ao3 link

— — — — —

"In the end, all those years ago, Joey Drew finally succeeded! He created life." The memory of Joey Drew said, staring down the teeth-filled maw of the giant Beast Bendy. "But Audrey," he continued, his voice ringing firm with passion. "you're so much more than that. You were his family, his daughter. My daughter. And I love you so very much."

The beast rose up on its fists, stalking closer to Joey until it towered inches away from his face. "Be quiet!" the voice of the Ink Demon hissed, gurgling with growing fury. "The wretch is mine!"

"Remember who you are, Audrey," Joey begged. "Remember!"

"Your words are wasted!" the demon growled, and the beast snatched Joey tight in one of its claws. The sickening sound of cracking bones filled the air. "The failure of Joey Drew dies here." He squeezed harder, sharp talons compressing around Joey's torso.

Joey gasped as his ribs strained against the force. "I know you're in there," he said, wheezing as he forced his words out. He held the End Reel in his shaking hands, his face screwed in pain and desperation. "You don't have to do this anymore." He swallowed, gathering his strength. "It's— you— hold on." He paused, eyebrows drawn together, and the pain abruptly dropped from his expression. "You don't have to be this anymore. Ugh, damn it."

Joey dropped his forehead onto the inky skin of the beast's claw, which ceased its movement, now rigid and unalive. "Cut!" he shouted, voice muffled in the synthetic substance.

"Forgot your line again, Joey?" Henry called from the ground, amid a flurry of groans and sighs.

"It's not my fault this part of the script is so dialogue heavy!" Joey retorted, spreading his arms as the animatronic hand slowly lowered him to the ground. "And so passionate! It takes a lot of effort to pull it all together into something believable!"

"You don't have to tell me that," Henry chuckled, coming forward to help Joey readjust his outfit. "You're preaching to the choir, here."

"How was my line?" Audrey asked from her spot off-screen, microphone in front of her and the script in her hands. "Was it alright? I've never done a voice-over before."

"Maybe ease off on the sobbing," Ben said, the echoing filter now turned off on his mic. He leaned back in his chair across from her, crossing his legs. "At least while speaking. The pause in between the two sentences would be a better spot."

"You were great, Audrey," Henry assured her, straightening Joey's tie. "Besides, you'll have plenty of time to practice since Joey keeps stumbling."

"You can only say that because you have only one big speech. I have three!" Joey grumbled.

"And he was also the main character of the last movie," Ben snarked, grinning. "Give it a rest, Joey. Say your lines right."

"Says the person who doesn't have to give any expressions," Joey retorted. "You just say stuff and Bill or Mike does all the acting!"

Ben's expression darkened. "Uh-huh. So you're saying you'd be perfectly fit to be the voice for the Ink Demon?"

"I bet it'd be easier than Mr. Drew, by all means!" Joey huffed, crossing his arms.

"Guys, c'mon," Audrey cut in before Ben could stand up. "We all have our strengths. Let's all chill out, okay?"

"How about you nail your lines before you start going after Ben's, eh?" Henry added, patting Joey on the back.

"Places!" the director yelled, and Henry walked off set as Joey reassumed his position and the animatronic handlers moved Beast Bendy back to its mark.

"You sure you don't want to head out until you're needed?" Audrey asked—not for the first time—as Henry settled into a chair beside her and Ben. "Must be boring, watching all the action instead of being part of it."

"Are you kidding?" Henry said, grinning at her. "There's nowhere else I'd rather be."

"Sentimental old man," Ben remarked, startling a laugh out of Audrey.

Henry sighed with a smile. "I suppose you're not far off the mark." He turned back to the set as the second assistant camera came forward with the clapper.

"And… action!"

#the ink demonth#batim#bendy and the ink machine#batdr#bendy and the dark revival#bendy#the ink demon#beast bendy#joey drew#henry stein#audrey drew#doodle dump#drawing prompt#batdr actor au anyone?#this one’s short and simple but i like it enough

26 notes

·

View notes

Text

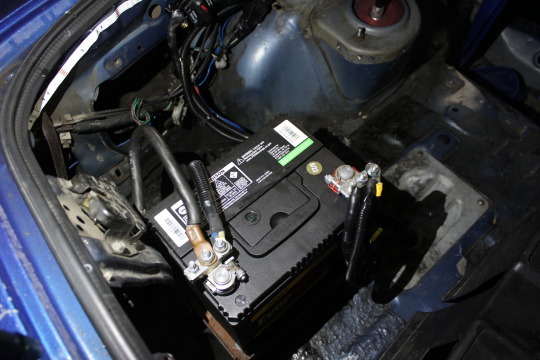

Little FC update: I deleted and removed some clutter from the engine bay. Starting with the leaking and complicated swirl pot setup. Then I purchased the greddy compression tube along with new charge pipes. The old setup w/ stock throttle body tube made it so the charge pipe had to do a 180 and to be removed to service oil filter. That is no longer the case! And it looks a bit more sleek. I also got an oversized air filter to replace the teeny cone filter. This changed the turbo flutter noise. Next up I had redone alot of the chassis wiring, IT WAS A MESS before, been cleaning it up as I go. Fixed a few drive-ability issues along the way. Then finally the parts table.. I got some new coilovers to replace the mismatched set. It had 10k front springs and 10k rear springs on dampers with zero adjustment. Now sitting on 8k front, and 6k rear - 32 way adjustable. I got powered by MAX rear links for camber and toe adjustment. I plan to raise the car a little to fix geometry and get clearance for the 245 square setup. It had a few other minor things I got to address as well. I added stock sway bars back on, with adjustable end links to eliminate preload. Power steering lines leaking- replaced with new. Also got some new steering rack bellow boots. Upgraded to an FD Alternator, fixed tps wiring, and got a front lip for the S5 front bumper.

#clubt#rx7#mazda#90s#cars#rotary#driftcar#drifting#dreams#jdm#initiald#racecar#motorsports#carculture#build

13 notes

·

View notes

Text

Improve air quality and protect equipment with a high-performance air compressor line filter. Remove moisture, oil, and contaminants for efficient operation. Ideal for industrial and commercial use. Ensure clean, dry air for optimal performance and longevity.

1 note

·

View note

Text

Breathe Easy with Clean Air Industrial Dust Filter Cartridges - GTS Filter India System

GTS Filter India System is play a crucial role in maintaining clean air quality in various Industrial Dust Filter Cartridges settings. These cartridges are designed to capture and remove dust particles and other contaminants from air streams, ensuring a safe and healthy working environment. Understanding the types, functions, and applications of these filter cartridges is essential for optimizing their performance and ensuring efficient air filtration processes.

Types of Industrial Dust Filter Cartridges

Pleated Cartridges

It is feature a pleated filter media, which provides a large surface area for efficient dust capture. These cartridges are commonly made from materials such as polyester, cellulose, or synthetic fibers. We are offer high dust holding capacity and are suitable for a wide range of industrial applications.

Cartridge Dust Collectors

It is utilize cylindrical filter cartridges to capture dust particles from the air stream. These collectors typically consist of multiple cartridges arranged in a housing, allowing for effective dust filtration. We are used in various industries, including metalworking, woodworking, pharmaceuticals, and food processing.

Cartridge Filters with Nanofiber Technology

It is nanofiber technology feature a layer of nanofibers coated onto the filter media. Nanofibers enhance filtration efficiency by capturing smaller particles and extending the service life of the cartridge. These filters are ideal for applications where fine particulate matter needs to be removed from the air stream, such as in cleanrooms and electronics.

Functions of Industrial Dust Filter Cartridges

Dust Removal

The primary function is to remove dust particles and other airborne contaminants from industrial processes. By capturing dust at the source, these cartridges help maintain clean air quality and prevent respiratory issues among workers.

Air Purification

It is contribute to air purification by trapping particulate matter and preventing it from being released into the atmosphere. This ensures compliance with environmental regulations and minimizes the impact of industrial activities on surrounding communities.

Equipment Protection

It is such as machinery and HVAC systems, can suffer from damage and efficiency loss due to the accumulation of dust and debris. Dust filter cartridges help protect equipment by preventing the ingress of contaminants and maintaining optimal operating conditions.

Applications of Industrial Dust Filter Cartridges

Welding and Metal Fabrication

In welding and metal fabrication processes, dust filter cartridges are used to capture welding fumes, metal particles, and other airborne contaminants. This helps create a safer working environment for welders and reduces the risk of respiratory illnesses.

Pharmaceutical

It is facilities rely on dust filter cartridges to maintain cleanroom environments and prevent contamination of drugs and medical devices. These cartridges remove airborne particles, bacteria, and other contaminants that could compromise product quality.

Woodworking and Furniture Production

Industrial Dust Filter Cartridges Manufacturers play a vital role in woodworking and furniture production facilities by capturing wood dust, sawdust, and other airborne particles. By controlling dust emissions, these cartridges help improve air quality and minimize the risk of fire hazards in woodworking shops.

Address : Wing A, Fourth Floor FOF 10 & 11, Signet Plaza, Kunal Char Rasta, Samta Gotri Road, Gotri, Vadodara - 390 021, Gujarat, INDIA

Email Id : [email protected]

Phone No : +91-9328433915

Url : https://www.filterselementsstrainers.com/industrial-dust-filter-cartridges/

#INDUSTRIAL DUPLEX FILTER#COMPRESSED AIR LINE FILTER#NATURAL GAS FILTER#NITROGEN GAS FILTER#NATURAL GAS AIR FILTER#PLEATED FILTER CARTRIDGE#DUPLEX WATER FILTER#COMPRESSED AIR GAS FILTER

0 notes

Text

#Line Filter for Air Compressor#Air Compressor Filter#Air Compressor Air-Line Filters#Compressed Air Filters

1 note

·

View note

Text

Why Water Cooled Air Compressors Are Ideal for Hot Climates

Compressors that dissipate heat into the surrounding water are more efficient than their air-only counterparts. This reduces the workload on the compressor and hence lowers energy costs. Water Chillers compressors are also highly recommended for use in hot environments. Since water cools particularly efficiently, the engine may maintain a higher horsepower output while using less oil, thanks to this cooling mechanism.

Air-cooled compressors are quieter than water-cooled compressors but still make some noise when operating. Although this is a potential issue, it can be fixed. There are several air cooler varieties that, until recently, were little known and infrequently utilised but which will reduce noise considerably. Coolers that use water or oil as their medium are the market leaders. Both types transfer heat from the refrigerant and its surroundings to the liquid phase of your cooling system using a sealed heat exchanger.

How Water Cooled Air Compressors Work

Because air is a gas, water-cooled air compressors can compress it efficiently. Its molecules are composed of atoms, and when these atoms hit one another, they generate heat. These impacts provide friction and a mechanical force proportional to the piston head's area and mass.

The motor shaft in Water Cooled Compressors is encased in a water jacket to remove excess heat. In most cases, water is injected into the motor. This keeps the engine from getting too hot to function properly.

The benefits of water-cooled air compressors compared to the more conventional type of air compressor

There is a lot of moisture in the air during the summer, and the air compressor industry is very competitive. This can lead to problems with the compressor's ability to cool the air and provide the high pressure you require for your business. Water Cooled Compressors are suitable for firms operating in hot regions and will assist in ensuring that your business continues to be successful in these conditions.

Compressors that use air cooling are sometimes called centrifugal or reciprocating water-cooled compressors because they continuously use a pump to circulate water through a casing surrounding an impeller.

Water cooled air compressors are more efficient for your business

When the temperature outside soars, your business's offices and production facilities must remain as cool as possible. While big, industrialised hot houses are possible, they also have a substantial energy footprint. Extreme heat makes it hard to cool down or even maintain. Still, a well-designed water cooling system will ensure that your company operates at peak performance, no matter the temperature outside.

There is a lot of moisture in the air during the summer, and the air compressor industry is very competitive. Because of this, the compressor may have trouble reducing the air's temperature and producing sufficient pressure. Water Cooled Compressors are suitable for firms operating in hot regions and will assist in ensuring that your business continues to be successful in these conditions. Providing the high pressure, you require for work.

Conclusion

Colt Equipment's (p) Ltd offers its bandit series of low-priced machines with all the compressor parts needed for the best process in many industrial settings. In addition to reciprocating compressors, also called mobile compressors and field portable compressors, our organisation offers a high-quality Water Cooled Compressors for mechanical equipment.

#Line Filter Manufacturers#Oil Free Air Compressor Manufacturers in India#Compressed air solutions#Evaporative Condensors in India#Water Chillers Suppliers

0 notes

Text

I've been obsessed with translating asmr vibes into music for a decade and so far I've managed to think of three main principles and they are compression, phase alignment, and frequency modulation.

Compression is more about time than it is about loudness. You can apply compression as an effect to a sound and it will change the attack/onset and decay of the sound. It can change whether a sound feels close or far, light or heavy, in ways that constant volume can't. Compression can be a way to get that very tingly and satisfying tap or thwap or tonk or squish to a transient in a mix.

Phase alignment is hard to hear, but you can always feel it when it changes. I don't understand the whole thing, but it describes the period of a sound waveform when it crosses the centerpoint of its amplitude and how that relates to other waveforms in the same medium. Phase changes when a sound source gets closer or further from the listener (exhale into your hand while bringing it closer to and farther from your face and you'll hear it too). If a couple of similar waveforms line up with each other in that time domain, particularly when comparing stereo panned audio, they're considered to be coherent, and if they don't line up exactly or if they contradict each other then they're incoherent. Abstractly speaking when more than one waveform containing stereo right and left info are more coherent they sound more monophonic and centered and when they're more incoherent they sound wider and less centered. This can make sounds feel boring or annoying in isolation but the tingly parts of my brain love when this changes rapidly through a song and a rhythm.

Frequency is a massive part of making music tingly, or making it anything else, since it has a lot to do with what our ears and brains do and don't like to hear. On the surface it's the simplest part to explain, even though it's intimately connected with phase interference in practice — basically the volume of certain frequencies can completely change the perceived distance, direction, timbre and loudness of a sound. It can also suggest what the medium is that it's being heard through. It makes things underwater sound like they're underwater, it makes thin air sound thin and humid air sound humid, and of course it makes lofi lofi. Our ears are most tuned in to frequencies above 100Hz and below 7000Hz, with the sweet spots imo being around 220, 500, 800, 2400 and 6000, so focusing on that makes a good place for very satisfying asmr sounds. Adding frequencies below our above the ones in the middle of our range can bring more weight and more detail to it as well. Emphasizing different frequencies for the coherent sounds and the incoherent sounds can bring even more dimensionality to the feel of it. And finally, changing the frequency over time, like with a filter, can make that sound move even more.

So then the tingly music recipe seems to be using all three of these things together. Time effects like delays and reverbs help too. Keeping things right on the line between boring and distracting. There's a huge range of styles and sounds this can apply to. I will continue to experiment with this

5 notes

·

View notes

Text

The morning light filtered through the sheer curtains, casting a soft glow across the bathroom. Bryan, a 18-year-old boy with soft features and a lean, wiry physique, was already awake, though the first bell hadn't yet rung. He stretched languidly, his muscles still warm from sleep, and padded across the cool tile floor to the bathtub.

Bryan had a peculiar habit - he always bathed in his clothes, usually his sports jersey and compression shorts. There was something about the way the fabric clung to his skin, growing heavy and translucent as it soaked up the water, that never failed to stir something deep inside him. With a mischievous grin, he climbed into the empty tub and turned the faucet.

The first splash of warm water against his bare legs sent a shiver up his spine. He shimmied out of his soaked pajama shorts and kicked them aside, leaving him in just his snug Lycra boxers. As the bath filled, Bryan slipped his sports jersey over his head, the familiar scent of sweat and fresh detergent enveloping him like an old friend.

He lowered himself into the rising water, the warm liquid seeping into the fabric and turning it a darker shade of blue. The material clung to his flat chest and narrow waist as he leaned back against the porcelain, knees poking out above the surface. With a contented sigh, Bryan let his eyes flutter shut.

His hands drifted down his body, fingertips tracing the outlines of his muscles through the thin, waterlogged jersey. The fabric clung to him everywhere, outlining his slim frame and revealing the lines of his ribcage, his hipbones, the definition of his thighs. Bryan couldn't resist touching himself like this, when the clothes were heavy and shiny, turning him into a 3D puzzle he loved to solve.

One hand slipped beneath the waistband of his tight boxers to wrap around his cock, which was already starting to stiffen. He rubbed slow, teasing circles around the head, watching the way the fabric moved with him, clinging to every curve and ridge. The other hand roamed his body, mapping out the wet polyester stretched taut over his chest, the jut of his collarbones, the dip of his navel.

Bryan's breath quickened as his arousal grew, his pulse pounding in his ears. He hooked a leg over the side of the tub and let his boxers ride down, fully exposing himself. The cool air kissed his overheated skin, making him gasp. Water droplets glistened on his hairless chest and abs, and his rigid cock jutted up from a thatch of dark blond curls.

With his shorts around his thighs, Bryan stroked himself harder, fingers dipping into the clinging wet fabric to caress his balls. His other hand slid up under his jersey to pinch a pert nipple. He groaned at the dual stimulation, hips rocking up into his fist. The bath sloshed around him as he writhed in pleasure.

He could feel the pressure building at the base of his spine, his thighs starting to tremble. Bryan bit his lip hard, muffling his moans as he fucked his hand. The jersey and boxers clung to his body like a second skin, the sensation almost too much to bear. He was so close, teetering right on the edge...

Bryan came with a strangled gasp, his whole body going rigid. Thick ropes of pearly white ejaculate painted his quivering abs and heaving chest, splattering against the jersey. He shuddered through the aftershocks, muscles twitching, before finally slumping back against the tub.

For a long moment he just lay there, panting, sweat cooling on his skin. Then he reached for the washcloth, hissing as the rough fabric scraped against his sensitive, spent cock. Bryan cleaned himself up and wrung out his clothes as best he could. The water had turned a cloudy blue and he felt languid and boneless.

With a groan, he hauled himself out of the tub and padded to the mirror. He looked like he'd been for a swim, his jersey translucent and clinging to his every curve, shorts dark and dripping. Rivulets of water traced down his legs. Bryan plucked at the damp fabric, watching it stretch and cling to his fingers.

He thought he probably looked pretty ridiculous, but Bryan didn't care. This was his secret ritual, a stolen moment just for himself before the chaos of school and friends and family intruded. For now, he was content to just enjoy the way his clothes felt against his skin, the intimacy of his own company.

Bryan took his time getting dressed in fresh clothes, letting his damp uniform air dry. He knew he'd be squirming and adjusting all day, hyperaware of the fabric rubbing against his skin. It was a pleasant ache, a reminder of his private pleasure.

Humming to himself, Bryan grabbed his backpack and headed out to catch the bus, the phantom sensation of his sports jersey and compression boxers still clinging to his skin. He couldn't wait to get home and do it all again tomorrow.

0 notes

Text

The Unseen Workhorse: How Compressor Felt Drives Efficiency and Longevity

In the industrial world, air and gas compressors are indispensable machines, powering everything from manufacturing lines and pneumatic tools to refrigeration systems and medical equipment. They are the lungs of many operations, converting power into compressed air or gas. But lurking within these robust machines, often unnoticed, is a critical component that ensures their smooth, efficient, and long-lasting operation: Compressor Felt.

Far from being a mere piece of fabric, compressor felt is a highly engineered nonwoven material, specifically designed to perform vital functions such as filtration, sealing, sound dampening, and absorption. Its quality directly impacts the performance, lifespan, and maintenance costs of your valuable compressor systems.

At PARKNONWOVEN, with our state-of-the-art manufacturing facilities in Gurugram, Haryana, India, we are a leading producer of high-quality nonwoven felts, precisely engineered to meet the demanding requirements of various compressor applications.

The Unsung Workhorse: What is Compressor Felt?

Compressor felt refers to specialized nonwoven felt materials that are integrated into various parts of air and gas compressors. Unlike woven fabrics, felt is produced by mechanically or thermally interlocking fibers into a dense, matted structure. This unique construction provides specific properties essential for compressor functionality.

These felts are not a one-size-fits-all solution; they are meticulously designed based on their intended role within the compressor system, serving as:

Filtration Media: Capturing airborne particulates, oil mist, or moisture.

Sealing Elements: Creating tight seals between components to prevent leaks.

Acoustic Dampeners: Absorbing noise and vibration.

Absorption Pads: Wicking or holding lubricants, or absorbing contaminants.

Beyond the Machine: Why Compressor Felt is Indispensable for Performance

The precise function of compressor felt is critical for several reasons:

Protecting Internal Components: High-quality filtration felt prevents abrasive particles from entering and damaging sensitive moving parts like pistons, rotors, and valves.

Ensuring Clean Air/Gas Output: For applications requiring pure, uncontaminated air (e.g., medical, food processing, electronics manufacturing), the felt filter ensures that the output is free from dust, oil mist, and other impurities.

Noise Reduction: Compressors can be noisy machines. Felt materials serve as effective acoustic insulation, dampening vibrations and reducing operational noise levels, contributing to a better working environment.

Enhancing Efficiency & Longevity: Proper filtration reduces wear and tear, leading to less friction, lower energy consumption, and significantly extending the overall service life of the compressor.

Preventing Leaks: As gasket material, felt provides a reliable seal under various pressures and temperatures, preventing expensive air or gas loss and maintaining system integrity.

Engineered for Demanding Environments: Key Properties of Effective Compressor Felt

The performance requirements for compressor felt are rigorous, demanding specific material properties:

High Filtration Efficiency: The ability to consistently capture a wide range of particle sizes without excessive pressure drop.

Oil/Moisture Absorption & Retention: For oil mist separation or lubrication wicking, the felt must effectively absorb and hold liquids without degradation.

Excellent Acoustic Dampening: A porous, dense structure that can effectively absorb sound waves and vibrations.

Superior Sealing & Gasketing: The ability to conform to surfaces, withstand compression, and maintain a tight seal under varying temperatures and pressures.

Temperature Resistance: Capable of operating consistently within the compressor's specific temperature range, from ambient intake air to high-temperature compressed gas.

Chemical Compatibility: Resistance to various compressor oils, refrigerants, and atmospheric contaminants encountered during operation.

Durability & Resilience: Withstanding continuous mechanical stress, compression, and airflow without degradation, tearing, or shedding fibers.

Consistent Thickness & Density: Uniformity across the material ensures predictable and reliable performance in critical applications.

The Fabric of Functionality: Materials and Types of Compressor Felt

The choice of fibers and the manufacturing process are crucial for tailoring compressor felt to its specific role. Common materials used include:

Polyester (PET) Felt: A versatile and widely used synthetic fiber known for its strength, durability, good temperature resistance, and chemical compatibility with many compressor oils. It's often needlepunched to achieve desired density and porosity for filtration and dampening.

Polypropylene (PP) Felt: Offers excellent chemical resistance, especially to acids and alkalis, and is often used where moisture absorption is critical or for lower temperature applications.

Blends and Specialty Fibers: For highly specific requirements, blends of synthetic fibers or even natural fibers like wool (known for excellent oil absorption and acoustic properties in certain traditional applications) might be considered, though modern compressors heavily favor engineered synthetics.

The needlepunching process is particularly effective for creating compressor felts, as it allows for precise control over the felt's density, thickness, and porosity, enabling customization for specific filtration or acoustic dampening performance.

Where Felt Makes a Difference: Key Applications within Compressors

Compressor felt finds diverse applications within various types of compressors:

Air Intake Filters: Essential for capturing dust, dirt, and other airborne particulates before they enter the compressor's delicate internal mechanisms.

Oil Separator Elements: In oil-lubricated compressors, felt layers are crucial for separating oil mist from the compressed air/gas stream, ensuring cleaner output.

Gaskets and Seals: Used around flanges, covers, and other mating surfaces to prevent air/gas leaks and maintain system pressure.

Acoustic Insulation & Liners: Applied within compressor enclosures or around noisy components to absorb sound and reduce operational noise levels.

Vibration Dampening Pads: Placed under mounting points or between vibrating components to absorb mechanical vibrations and prevent their transmission.

Lubrication Wicks: In some smaller compressors, felt can be used to wick and distribute lubricants to bearing surfaces.

The Hidden Benefits: Investing in High-Quality Compressor Felt

Choosing the right, high-quality compressor felt offers a cascade of advantages:

Improved Air/Gas Purity: Ensures the compressed medium meets stringent quality standards for various industrial and sensitive applications.

Extended Compressor Lifespan: Reduces wear and tear on expensive internal components, delaying costly repairs and replacements.

Reduced Maintenance Costs: Fewer breakdowns, less frequent filter changes, and longer component life lead to significant savings.

Quieter Operation: Creates a more comfortable and compliant working environment by effectively dampening noise.

Enhanced Energy Efficiency: Clean components and proper sealing mean the compressor doesn't have to work harder than necessary, leading to lower energy consumption.

PARKNONWOVEN: Precision-Engineered Nonwoven Felts for Compressor Excellence

At PARKNONWOVEN, we understand that the performance of your compressor systems hinges on the quality of every component, no matter how small. As a leading manufacturer of high-quality nonwoven felts in Gurugram, Haryana, India, we are uniquely equipped to meet the precise demands of compressor applications.

Our capabilities in compressor felt manufacturing include:

Customized Material Solutions: We produce nonwoven felts from a variety of synthetic fibers (e.g., polyester, polypropylene) in various densities, thicknesses, and GSMs (Grams per Square Meter) to match specific filtration, sealing, or acoustic requirements.

Engineered Performance: Our felts are designed with controlled porosity, compressibility, and resilience to ensure optimal airflow, effective sealing, and superior acoustic dampening under operational conditions.

Robust Durability & Compatibility: We ensure our felts exhibit excellent resistance to oils, chemicals, and temperature fluctuations, providing long-lasting performance in demanding compressor environments.

Consistent Quality: Through stringent manufacturing processes and quality control, we guarantee uniform felt products that deliver reliable and predictable performance.

By partnering with PARKNONWOVEN, you secure a foundation of excellence for your compressor systems, ensuring cleaner air, longer lifespan, and more efficient operation.

Conclusion: Small Component, Big Impact

Compressor felt may be a relatively small and often overlooked component, but its role in the efficiency, longevity, and safety of air and gas compressors is undeniable. Investing in high-quality, engineered compressor felt is a proactive step towards optimizing your industrial operations, reducing costs, and ensuring reliable performance.

Optimize Your Compressor Performance. Partner with PARKNONWOVEN for Advanced Nonwoven Felt Solutions!

Don't let subpar components compromise your valuable compressor systems. For robust filtration, reliable sealing, and effective noise reduction, the right compressor felt makes all the difference. PARKNONWOVEN is your trusted expert in manufacturing precision-engineered nonwoven felts tailored for the demanding world of compressors.

Choose the expertise, cutting-edge technology, and unwavering quality that define PARKNONWOVEN.

Contact our dedicated team of nonwoven specialists NOW! Let's discuss your specific compressor felt requirements and explore how our advanced nonwoven solutions can enhance the efficiency, longevity, and operational excellence of your compressed air and gas systems. Your path to superior performance starts here, in Gurugram, Haryana.

#CompressorFelt#NonwovenFelt#FiltrationMedia#IndustrialMachinery#PARKNONWOVEN#AirCompressor#GasCompressor#IndustrialFelt

0 notes

Text

Air Compressor Parts and Accessories

Evergreen Compressed Air and Vacuum offers reliable and genuine OEM parts & accessories for all major brands of Air Compressors, Vacuum Pumps and Air Dryers at reasonable cost. We offer services in the state of Washington — Seattle, Tacoma, Everett, Kent, Mount Vernon, Olympia, Auburn. We also serve the Oregon market in Portland, Tigard, Salem, Clackamas & Eugene. Our air compressor parts such as lubricants, valves, separators, belts, couplings, drains and filters are designed to keep your compressor and vacuum systems running at peak performance and reduce the cost of ownership of your compressed air system. Getting air compressor accessories you need is as easy as contacting our team of dedicated service engineers. They are trained to solve problems quickly and efficiently.

Brands we offer

ELGi

Sullivan-Palatek

Sullair

Gardner Denver

Quincy

CP

Rogers

FS-Curtis

Ingersoll Rand

Atlas Copco

Vac-u-lok

DV

Saylor-Beall

Champion

Airtech

Beacon Medaes

Busch

Why do you need to buy air compressor spare parts from OEMs?

Every component within an air compressor has a designated service life and undergoes wear and tear over time, necessitating regular maintenance to ensure optimal performance and longevity. While aftermarket replacement parts may be enticing due to lower costs, it’s essential to prioritize sourcing from Original Equipment Manufacturers (OEMs). OEM air compressor parts ensure proper performance levels and minimize equipment failure risk .

Comparison of OEM vs. Aftermarket Air Compressor Parts

Durability Designed and tested specifically for the equipment, OEM parts offer superior durability, extending the lifespan of the air compressor . While less expensive, aftermarket air compressor parts may not meet durability standards, leading to quicker wear and tear.

Efficiency Optimized for efficiency, OEM parts help the system run at peak performance with minimal energy waste. Aftermarket parts may reduce efficiency due to slight differences in design, leading to higher energy consumption.

Warranty Using OEM air compressor parts preserves the manufacturer’s warranty, ensuring ongoing support and coverage. Installing aftermarket parts can void the equipment’s warranty, leaving you unprotected in case of failures.

Safety OEM parts adhere to strict industry safety standards, minimizing risks associated with part failures.Safety standards for aftermarket air compressor parts vary, and non-compliant parts may pose safety hazards and operational risks.

Maintenance Intervals OEM parts are designed for consistent performance and usually require less frequent maintenance, helping reduce downtime.Due to potential compatibility issues, aftermarket parts often need more frequent replacements and maintenance checks.

Improved Safety OEMs adhere to industry safety standards, providing enhanced protection for users and minimizing occupational hazards. Third party air compressor spare parts may compromise safety and pose risks to health and the environment.

Stringent Quality Standards OEM parts undergo rigorous endurance tests and quality inspections to ensure consistent performance and reliability. Choosing OEM air compressor parts guarantees adherence to quality standards and reliable operation.

Air compressor parts that need replacement include

Dust filters and oil separators These components are crucial in safeguarding the compressor against damage and performance degradation caused by internal contaminants. Dust particles from inlet pose a significant threat to compressor rotors, leading to reduced efficiency and premature wear.

Air filter Swapping your air compressor’s line filter cartridge with counterfeit alternatives compromises filtration efficiency, resulting in pressure drops and compromised air quality. Genuine airline filters ensure optimal filtration, reducing the need for frequent replacements and minimizing lifecycle costs. Proper condensate management, combined with genuine airline filters, ensures efficient removal of moisture and contaminants, protecting your equipment from corrosion and performance degradation.

Why Evergreen for Your Air Compressor Parts?

Wide Range of Trusted Brands: We offer parts for top air compressor brands, including ELGi, Sullair, Quincy, Ingersoll Rand, Atlas Copco, and more.

Expert Service: Our team of specialists is ready to assist you in finding the right parts quickly and efficiently, ensuring minimal downtime for your equipment.

Genuine Parts Guarantee: We only supply genuine air compressor parts, ensuring you receive the highest quality and reliability.

It’s essential to procure spare parts and air compressor accessories exclusively from OEMs and reputable suppliers and maintain a service kit containing essential tools for safe part replacement. Talk to our parts specialist today.

Other Products:

Air compressor parts

Air compressor service

Air compressor Dealer

0 notes