#Compressed Bio Gas

Text

Nexgen Energia is providing CNG/CBG Pump dealership in India

What is Bio CBG (Compressed Biogas)? What are its benefits?

Biogas is an environment-friendly renewable energy source. The gas is produced naturally through a process that breaks organic matter like municipal solid waste, animal waste, sugarcane press mud, industrial bio-waste, and agricultural biomass and converts it into Biogas, which can be used as an automobile fuel, industry gas, and electricity in the market.

With the aim to reduce greenhouse gas emissions and making more our nation environment-friendly, Government of India has introduced many key government programs like SATAT scheme, Waste to energy program, National policy of Bio-fuel, Biogas scheme to have a green planet, developing rural economy while enhancing farmer’s income, Reduction in Crude and LNG imports thereby huge savings in forex, utilisation of domestic feedstock to produce biofuels, climate change mitigation, introducing upgrading technology to generate biofuels, and enabling India to create more employment and business opportunities.

Is CNG pump profitable in India?

The Compressed Biogas (CBG) market is expected to grow from USD 1.47 billion in 2022 to USD 2.25 Billion in 2029 at a CAGR of 6.3% in the 2022- 2029 period, in India. As per Oil and Natural resources minister, India will receive Rs 2 Lakh in investment to develop 5000 biogas plants by 2023-24.

Why to invest in Bio CBG plants of NGE?

Nexgen Energia has created a future roadmap for converting waste to energy India and making our planet energy independent by introducing a concept of CBG (Compressed Bio Gas).

The company has already been acknowledged for providing best entrepreneurial opportunities in clean fuel energy, world-class team to assist startups, extensive branding and marketing, committed to the partner's growth along with a successful business module.

NexGen Energia is India’s fastest growing integrated clean fuel energy company with its vision to redefine the manufacturing & distribution of alternate future energy sectors. The company has its major presence in almost all the streams including license for CNG/CBG production, green diesel production & its retail outlet distribution, Bio coal, EV charging station, Lubricants, etc. a high caliber team, state- of- the- art technologies, and cutting-edge R&D, quality consciousness, and transparency; creating an ecosystem where all energy in all its forms is tapped most responsibly and delivered to the consumers/stakeholders most affordably. The company lines up with a massive expansion plan to launch 40,000 production plants & retail outlets on CBG on the DODO Model by 2027 which is aligned with the SATAT (Sustainable Alternative towards Affordable Transportation) scheme initiated by the Government of India.

1 note

·

View note

Text

Five Stages of Mamma Mia

Fandom: Batfam, DC Comics

Summary: AU where Catherine Johnson is Jason's bio mom and Jason doesn't know who his father is. (Jason Todd is Jason Johnson for fic reasons).

Chapters: 16/?

Characters: Jason Todd, Jason Blood, Catherine Todd Mention, Bruce Wayne, Willis Todd Mention

Relationship(s): Past Catherine Todd/Jason Blood, Past Catherine Todd/Bruce Wayne, Past Catherine Todd/Willis Todd

Additional Tags: Canon Divergent AU, Mamma Mia-inspired AU, Angst, Hurt/Comfort, Long Lost/Secret Relatives, Father-Son Relationship(s), Jason Todd Experiences the Five Stages of Grief

Chapter Sixteen: Thank You For The Music

The next three nights, Bruce had to go out on patrol, which meant they missed the baseball game. Jason wasn't upset about it. Unbeknownst to Dick and Bruce, Jason hatched a plan to follow them to the site. He snagged a domino mask from the cave and put skates on. Jason thought it'd be best to ride behind the Batmobile the whole way, concealing himself with a cloaking spell. He tied a thick cord around the fender and said a prayer when the Batmobile started.

He managed to hold on until they stopped at a warehouse, and he rolled into the fender. Jason fell on his back.

Bruce hopped out of the Batmobile and picked Jason up. "What are you doing here? No, you cannot–."

"I followed you guys here with nothing but a cloaking spell... Let me come with you," Jason pleaded.

Dick glanced at Bruce. "He has a point. How did we not notice him?" Dick replied. Jason grinned proudly.

"Don't encourage him," Bruce whispered, "I would leave you in the car but in Gotham... I don't think that'd be safe."

"So, I could come with you?" Jason asked.

Bruce sighed and nodded. "Stay close to your brother," Bruce replied without thinking, and Jason nodded.

"What? I'm not babysitting–."

"You're the one who said he has a point," Bruce replied as he rushed into the building. Dick showed Jason how to get into the building without making a noise, and Jason used a cloaking spell for both of them.

Dick scanned the warehouse for signs of life, but no one was in the building. "Bats, no one's–."

"Get him out of here now!" Bruce interrupted.

Before Dick could turn to get them out of the building, they heard popping noises followed by hissing sounds, and the room filled with gas. Jason chuckled involuntarily, and he covered his mouth. Dick cursed before starting to laugh and carried Jason out of the building under his arm and practically threw Jason in the Batmobile. Jason writhed in pain as he hollered with involuntary laughter. Tears streamed down his face as he tried to regain control of himself. Dick had seen the gas effects on children before, but it'd never been that severe that fast. Dick injected Jason and then himself while he waited for the laughter to wear off.

Dick caught his breath, but Jason took longer to regain his calm. Dick climbed into the backseat with him and checked his breathing. Jason's eyes rolled back, and his breathing stopped. "No, no, no no... Jason, stay with me," Dick whispered as he started compressions. Shortly after Dick heard the crack of Jason's ribs, Jason's eyes opened, and he grabbed Dick's wrist.

"You're hurting me," Jason mumbled breathlessly.

"Well, I thought you were dying," Dick replied as he leaned into the front seat and pressed two buttons.

"What's up?" a woman's voice answered. "Who's the kid?"

"Watch him... He's B's kid, and he almost died, so I want you to keep him alert while I go back–."

"Go, I've got him... I'm on my way there," she interrupted. Dick left Jason in the Batmobile, and Jason lay on his back, staring at the dash. "Do you wanna do codenames, or are you familiar with who everyone is?"

"I'm Jason, and I'm not Batman's kid... At least I'm not sure," Jason whispered as he tried to take short breaths.

"Well, I'm Barbara. How old are you, Jason?" Barbara asked.

"Twelve... But I'll be thirteen... In August," Jason replied.

"The big one-three. Are you excited?" Barbara questioned. Jason started crying. "What's the matter?"

"He's gonna be mad at me," Jason whimpered.

"He's probably worried sick about you... Okay, Jason, I'm here. I'm gonna let myself in," Barbara warned him. The call hung up, and the night air hit his face as Batgirl joined him in the backseat of the Batmobile.

When the doors shut, Jason stared at her. "You didn't say you were Batgirl," Jason mumbled. She checked his vitals, and Jason grinned drowsily.

"What's the goofy grin for?" Barbara asked.

"Nothin'... You're just pretty," Jason whispered.

"Poor kid's delirious," Barbara chuckled.

Jason frowned. "Sorry, I shouldn't have–."

"It's fine," Barbara replied, "But I find it sweet that you thought to apologize... Also, I don't think the ribs are broken. They're bruised, but Alfred'll check." Jason nodded, and she took off her cape, draping it over him.

"I don't want to be a burden... Do you think he'll–."

"You're not a burden to anyone. You're just a child," Barbara interrupted.

"Would he teach me how to protect myself if I asked him to?" Jason questioned.

Barbara blinked hard. "I'm not sure, Jason... I know you don't think he should have to protect you, but he does. It's his job to protect you as your father," Barbara explained. She was stern, but it didn't shake Jason.

"I don't know if he's my dad," Jason replied.

"But you think he might be, and I'm sure–."

Dick and Bruce came to the car and got in. Bruce immediately looked at Jason lying in the backseat and asked if he was alright. Jason nodded. "Good," Bruce whispered before turning the car's autopilot on. The ride to the cave was mostly silent, save for the few times Barbara prompted Jason to take deep breaths and cough.

Bruce insisted on being the one to carry Jason to the infirmary when he fell asleep. He went upstairs and changed clothes, leaving Jason with Alfred. Dick took Barbara to get her bike, and Jason slept. He only slept through a few tests Alfred ran, but it was enough for him to feel like himself again.

Bruce joined him shortly afterward, and he rustled a hand through Jason's hair. "Feeling better?" Bruce asked. Jason nodded.

They sat in silence, and Bruce handed Jason Catherine's diary. Bruce knew how important the diary was to Jason, and he hoped it would comfort Jason in ways he couldn't.

November 1, 1997

Willis is back. I have no idea where he's been, but he promised me things would be different. Willis took me on a ride on his motorcycle, then we went to get some fries and a malt. It felt nice to do something normal for once, but I knew he was hiding something.

When we got to his apartment, it was a mess, and I cleaned up. He didn't ask me to. I just wanted to help... That's when it happened. I fell right back in. It was familiar.

There was no flair, no fanfare. It was just him and me. Willis and Catherine... Bonnie and Clyde. And before you say it, yeah. I know they died in the end. Isn't that what we all do, though?

It was nice until he ruined it. He turned towards me and started talking about his next job and how he'd be head honcho someday, and I'd be his number one dame. His dame? Who the hell does he think I am? I know I'm no Mother Teresa, but I always thought someday some man would want me to be his only. I wanted to be Willis's only one. I know he's no Bruce or Jason, but I thought he'd get how it feels to be a nobody. Two nobodies together making a somebody, you know?

With Bruce, I'm his mystery girlfriend. With Jason, I'm his muse. I thought that I had a better chance with Willis. I thought we'd be something. So, I made a big deal out of everything. I made him mad. I made him so angry...

It was my fault. I know Willis didn't mean it. God... I wish I knew what to do. Why is it that love only hurts this bad when I'm involved?

I forgive him, though. He told me all the big guys in the business had multiple women and that it was more of a status thing. It is the 90's. It's not like they'd mean anything to him. Besides, he told me he loved me for the first time tonight. I think I love him too.

Jason set the diary aside and held his wrist over his eyes. "Are you okay?" Bruce asked.

"Why'd so many people hurt my mom?" Jason asked. His voice was broken as tears streamed down the side of his face.

"I don't know, Jason... I do know she didn't deserve any of it," Bruce whispered, "And neither did you... I would go back and change it all if I could." Jason sat up and hugged Bruce in tears. Without thinking, Bruce kissed the top of his head.

"It wouldn't be so bad... I mean... It wouldn't be so bad if you were my dad," Jason mumbled as he pressed his face into Bruce's sweatshirt. Bruce let out a small breath.

#fic#5somm fic#batfam#Jason Todd#Jason Blood#Catherine Todd Mention#Bruce Wayne#Willis Todd Mention#Past Catherine Todd/Jason Blood#Past Catherine Todd/Bruce Wayne#Past Catherine Todd/Willis Todd#Canon Divergent AU#Mamma Mia-inspired AU#Angst#Hurt/Comfort#Long Lost/Secret Relatives#Father-Son Relationship(s)#Jason Todd Experiences the Five Stages of Grief

4 notes

·

View notes

Text

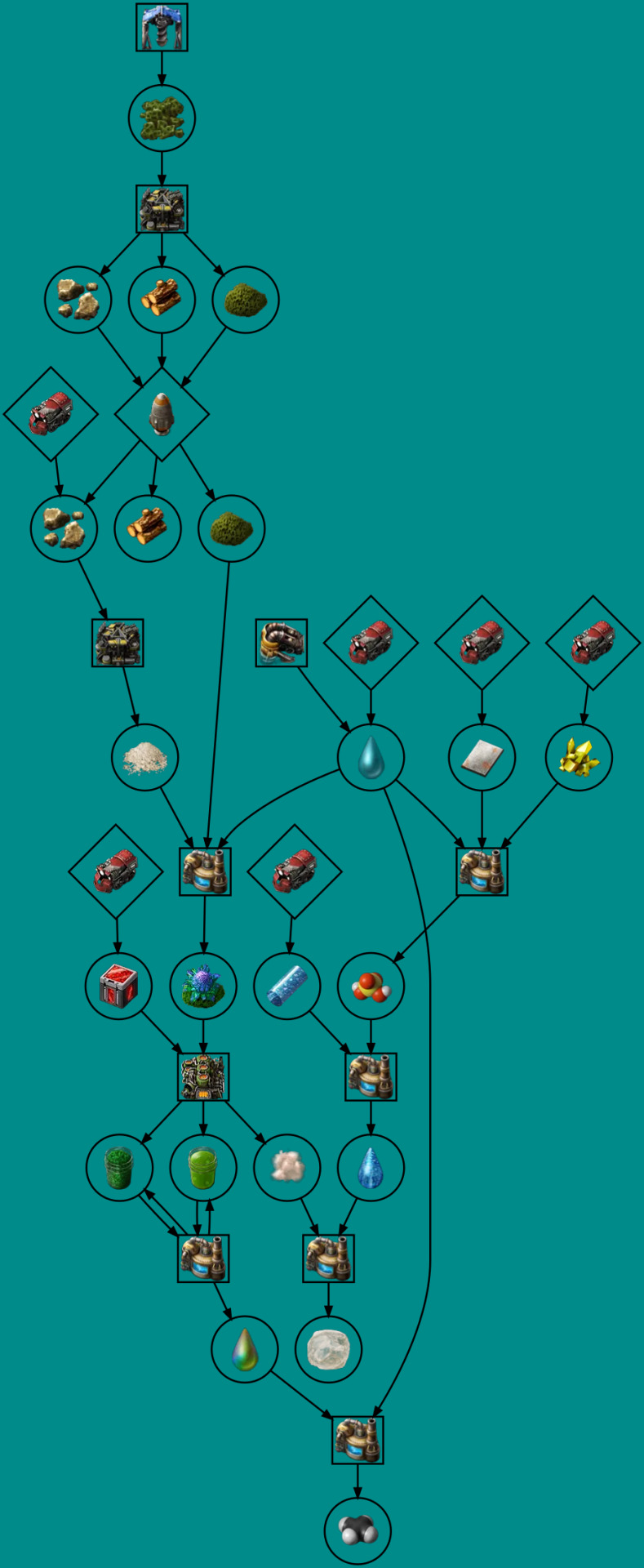

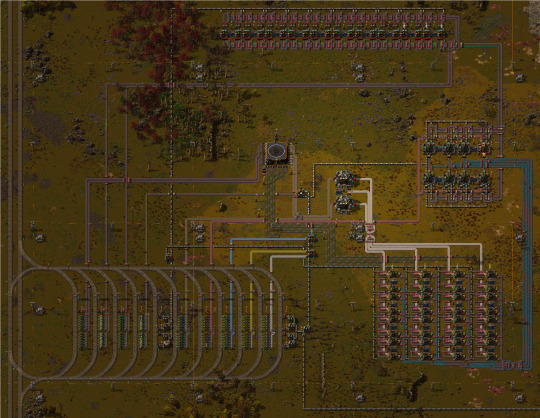

In today's stream, we began by setting up Material Science only to find that there were many bio-related byproducts. In response to this, we put together Vitamelange processing as it's a key ingredient in handling said byproducts.

Compared to Iridium processing, Vitamelange was a bit simpler. For the most part it's just a feed-forward system, with one machine producing an ingredient going into the next machine, though with a couple byproducts.

The main flow was Vitamelange (mined on the moon Arislan) ==> Vitamelange Nugget ==> Vitamelange Bloom ==> Vitamelange Spice & Vitamelange Extract. Raw Vitamelange is crushed on Arislan and shipped via rocket to Nauvis for further processing.

Spice and Extract are our main products, but the Bloom processing step produces 40 Spice with a 10% chance of producing 1 Extract. We will need much more Extract than Spice, so we have a Chemical Plant taking both, and using them to convert a bit of Spice into Extract, similar to Kovarex Enrichment for Uranium. This produces a loop, of which only excess amounts of Spice and Extract can move on to the rest of the factory.

I mentioned byproducts earlier. Crushing Vitamelange can produce a bit of Wood and Stone, which we feed back into our factory and as an ingredient for Vitamelange Bloom. Processing Vitamelange Bloom produces Methane Gas, which we compress into Methane ice for later usage. Finally, the Spice/Extract loop produces a wee bit of Light Oil, which is cracked down into Petroleum Gas and also fed back into the factory.

There's a bit of extra factory to produce some intermediates, primarily Sulfuric Acid and Cryonite Slush for processing the Methane. Stone is also crushed into Sand.

On the next stream we will return to Material Science, and simultaneously set up Bio Science and Biosludge processing.

#factorio#arislan turned out really tiny#conquered the entire place in the first few minutes#diagram

3 notes

·

View notes

Text

Air Diy Equipment - Why Air Equipment Are Popular

Older diesel engines likely have rubber seals and hoses. There are Diesel mining piston air compressor in bio-diesel that eat rubber. Modern engines use artificial silicone rubber meaning that this is not a quandary. If yours can be an older model however changing the rubber components for you to switch is advisable.

This label of the clients are regarded to be one of your bests ever produced. It comes with a complete kit several useful spares. It even offers 18 gauge band nailer. It is fast and efficient in its performance and uses limited power produce. The oil free compressor which can attached on the machine could be easily fixed and taken off if considered necessary. This oil free compressor assures an incredible performance. This model is specifically produced for industrial as well as agricultural use. It runs in the super associated with 90 per second with large gallon and offers 2.8 CFM.

Though Sunrita were good, they might only produce so much energy. Around 3000 B.C. people started melting metals, such as, gold, copper and lead, and also they needed a device that could produce more pressure in comparison to human lung area. The Egyptian and Sumerians up and running by when using the wind, after that blowpipes involving their work. The first mechanical compressor, the hand-operated bellows was created, and very quickly after that, the foot bellows arrived to use. The bellows, a lot more than 2,000 years proved as being a very reliable compressor.

Air compressors, both new and used, come within shapes and sizes. Some are portable and some stationary, and you'll have to know precisely what wants you have are in this scenario. If you're an DIYer and intend screw to utilize it around the house for performing some light finishing work, it makes sense for which get an inferior machine because of this very handheld. There are small compressors that could be carried manually , from a built-in be in charge of. There are also ones that are portable, but you're quite slightly bigger basically a involving wheels.

The diesel car nearly disappeared for a while there. While diesel trucks were common, the viability of diesel cars begin to really drop off to the stage where even the diesel stalwart Mercedes moved away their own store for probably the most part. This trend has swung 180 degrees. And also the difference? The viability of diesel models that get tremendous gas mileage.

The tank size, measured in US gallons, tell you how much air is compressed and you something of notion of how long you can operate your air tool for having a time. Diesel portable air compressor that affect how long you can run your tool for are the PSI and HP on the engine itself as elements determine how quick your compressed air supply is rejuvenated.

Moisture can build up in several different parts on the compressor anyone need understand how to house it. The tanks on the machine always be places place most moisture will collect. To get rid of the moisture it is advisable to drain it using the valves the particular machine.

Replacing the AC compressor on a GM 350 engine isn't nearly as hard due to the fact looks. The compressor is held to the engine by an aluminum cradle. The cradle doesn't need to be removed to switch the air compressor. There are simply three bolts that hold the compressor towards the cradle that have to be removed.

#screw compressor#Air Compressor#rotary screw compressor#Portable air compressor#rotary air compressor

3 notes

·

View notes

Text

How Sustainable is Napier Grass Bio-CNG Compared to Traditional Fossil Fuels

Introduction

In the quest for sustainable energy solutions, Napier grass bio-CNG (Compressed Natural Gas) presents a compelling alternative to traditional fossil fuels. As the world pivots towards greener energy sources, Gruner Renewable, a leader in renewable energy technology, explores the sustainability of using Napier grass as a bio-CNG source, underscoring its environmental and economic benefits compared to conventional fuels.

The Sustainability of napier grass bio cng plant

Bio-CNG derived from Napier grass represents a significant advancement in renewable energy technology. This section delves into why Napier grass bio-CNG is a more sustainable option than traditional fossil fuels, focusing on its environmental impact, cost-effectiveness, and energy efficiency.

1. Renewable and Abundant Resource

Napier grass is a fast-growing perennial that can be harvested multiple times a year, making it an abundant and renewable biomass source. Unlike fossil fuels, which are finite and emit significant greenhouse gases, Napier grass absorbs CO2 from the atmosphere during its growth, contributing to a lower net carbon footprint when used as a fuel source.

2. Reduced Greenhouse Gas Emissions

The process of converting Napier grass into bio-CNG captures methane, a potent greenhouse gas, preventing it from escaping into the atmosphere. When burned, bio-CNG releases significantly fewer pollutants, such as nitrogen oxides and sulfur dioxide, compared to fossil fuels. This results in cleaner air and a lower overall impact on global warming.

3. Energy Security and Local Development

Napier grass can be grown in a variety of climates and soil types, reducing dependence on imported fuels and promoting energy security. The development of local bio-CNG plants creates jobs and stimulates local economies, particularly in rural areas where economic opportunities may be limited. Gruner Renewable supports these initiatives by providing expertise and technology to maximize the efficiency and output of napier grass bio cng plant.

Economic Considerations

While the environmental benefits of Napier grass bio-CNG are clear, its economic viability is also a significant factor in its sustainability. This section examines the cost-related aspects of producing and using Napier grass bio-CNG.

4. Cost of Production and Maintenance

Initially, setting up a bio-CNG plant requires a substantial investment in technology and infrastructure. However, the recurring costs of growing Napier grass and producing bio-CNG are generally lower than extracting and refining fossil fuels. Additionally, government incentives for renewable energy projects can further enhance the economic feasibility of bio-CNG plants.

5. Price Stability

The cost of fossil fuels can fluctuate widely based on geopolitical events and market dynamics, whereas the price of bio-CNG tends to be more stable. Napier grass can be locally sourced, reducing transportation costs and shielding users from global oil price volatility.

Challenges and Future Prospects

Despite its advantages, there are challenges to the widespread adoption of Napier grass bio-CNG. Addressing these can determine the scale and speed at which it can replace traditional fossil fuels.

6. Scalability and Technological Challenges

Scaling up Napier grass bio-CNG production to meet large-scale energy demands involves overcoming technological and logistical challenges. Continuous research and development are needed to improve the efficiency of bio-CNG production processes and to enhance the storage and distribution infrastructure.

7. Regulatory and Market Adoption

The transition to bio-CNG requires supportive regulatory frameworks and market readiness. Policies that incentivize renewable energy adoption and consumer awareness campaigns can drive the uptake of bio-CNG as a mainstream energy source.

Conclusion

Napier grass bio-CNG offers a sustainable and economically viable alternative to traditional fossil fuels, providing a pathway to reduce environmental impact and enhance energy security. Gruner Renewable is at the forefront of this transition, leveraging cutting-edge technology and sustainable practices to harness the power of Napier grass in the energy sector.

Call to Action

Join Gruner Renewable in transforming the energy landscape with sustainable bio-CNG solutions. Visit our website to learn more about our projects and how we are making renewable energy accessible and beneficial for all.

0 notes

Text

Ethylene Acrylic Elastomer (AEM) Market Report: Trends, Analysis, and Projections

Ethylene Acrylic Elastomer (AEM) is a versatile synthetic rubber known for its excellent heat resistance, oil resistance, and mechanical properties, making it a valuable material in various industries. This blog delves into the dynamics of the global AEM market, analyzing key drivers, applications across sectors, emerging trends, and future growth prospects.

Understanding the AEM Market:

Ethylene Acrylic Elastomer (AEM) Also known as Ethylene Acrylate Rubber (EAM), is a copolymer of ethylene and acrylic monomers, offering a unique balance of properties such as heat resistance, chemical resistance, flexibility, and durability. It finds applications in automotive, industrial, oil and gas, and consumer goods industries.

Market Dynamics:

Automotive Sealing Systems: AEM rubber is widely used in automotive sealing systems, gaskets, O-rings, and hoses due to its excellent heat resistance, oil resistance, and sealing performance in engine compartments and transmission systems.

Oil and Gas Industry: In the oil and gas sector, AEM compounds are employed in seals, gaskets, and components for equipment exposed to oil, fuels, and harsh operating conditions, maintaining performance and reliability over a wide temperature range.

Industrial Applications: AEM elastomers find applications in industrial machinery, pumps, seals for hydraulic systems, conveyor belts, and vibration damping components due to their resistance to chemicals, ozone, and weathering.

Consumer Goods and Electronics: AEM's properties make it suitable for consumer goods such as appliance seals, gaskets, and electrical insulation, providing reliability and longevity in demanding environments.

Applications Across Industries:

Automotive: Seals, gaskets, O-rings, hoses.

Oil and Gas: Seals, gaskets, components for harsh environments.

Industrial Machinery: Seals, belts, vibration damping components.

Consumer Goods: Appliance seals, gaskets, electrical insulation.

Market Trends:

Demand for High-Performance Elastomers: Increasing demand for elastomers with superior heat resistance, oil resistance, and durability drives adoption of AEM in automotive, oil and gas, and industrial applications, replacing traditional elastomers in demanding environments.

Customized Formulations: Manufacturers focus on developing customized AEM compounds with specific properties such as low-temperature flexibility, compression set resistance, and chemical compatibility to meet diverse application requirements across industries.

Sustainability Initiatives: Development of bio-based AEM formulations, recycling initiatives for elastomer waste, and green manufacturing practices align with sustainability goals and regulatory requirements, driving market innovation.

Future Prospects:

The global AEM market is poised for steady growth, propelled by increasing demand from key industries, technological advancements in polymer science, and sustainability initiatives. Investments in R&D, collaboration for material innovations, and expanding application areas will shape market evolution and competitiveness.

Conclusion:

Ethylene Acrylic Elastomer (AEM) stands out as a high-performance elastomer offering durability, heat resistance, and chemical compatibility crucial for demanding applications across industries. Understanding market trends, technological innovations, and customer needs is vital for stakeholders in the AEM market to capitalize on growth opportunities and address evolving industry requirements effectively. With a focus on performance, customization, and sustainability, the AEM market presents promising avenues for continued innovation and market expansion globally.

0 notes

Text

Navigating Regulatory Frameworks in the Renewable Methanol Market

Renewable Methanol: A Promising Alternative Fuel for the Future

Production of Renewable Methanol

Renewable methanol can be produced from a variety of renewable resources such as biomass, biogas or directly from carbon dioxide and hydrogen. The most common production process starts with the conversion of biomass feedstocks like agricultural waste or organic municipal waste into syngas using a gasification process. The syngas obtained mainly contains carbon monoxide and hydrogen which are then converted into methanol through catalytic synthesis. Methanol synthesis from syngas is a well established industrial process. Similarly, biogas from the anaerobic digestion of organic waste can also be converted into syngas and then methanol. An emerging approach is to produce methanol directly from captured carbon dioxide and hydrogen. Electrolyzers powered by renewable electricity can produce hydrogen which is then combined with CO2 to synthesize methanol using specialized catalysts. Overall, these processes allow the production of liquid renewable methanol without consuming fossil fuels.

Applications and Uses of Renewable Methanol

Renewable methanol holds promising applications as a green alternative fuel and chemical feedstock if produced on a large scale commercially. Here are some of its key uses:

One of the major applications of renewable methanol is in the transportation sector as an alternative vehicle fuel or fuel additive. It can be used directly in methanol-fueled vehicles or blended with gasoline or diesel. It allows vehicles to run cleaner with much fewer emissions. Renewable methanol can also replace fossil-based methanol used in manufacturing formaldehyde, acetic acid, methyl tert-butyl ether (MTBE), and other chemical products. As a chemical building block, it avoids the use of raw materials derived from non-renewable resources. Renewable methanol produced directly from captured CO2 also provides opportunities for carbon utilization at industrial scale.

Advantages of Renewable Methanol Over Other Alternative Fuels

Renewable methanol scores over other alternative fuels due to several advantages. Unlike hydrogen, it is a liquid at ambient conditions making it much easier to store and transport through the existing infrastructure. It has a higher energy density than other biofuels like ethanol, which means more energy can be packed into the same storage space. Methanol vehicles also do not require expensive new technologies and can use the existing internal combustion engines. Moreover, methanol produces less smog-causing emissions in tailpipes compared to gasoline, has lower toxicity than ethanol and is safer to handle than compressed natural gas.

Barriers and Challenges

Despite advantages, there are some barriers challenging large-scale production and use of renewable methanol. The production costs using biomass or captured carbon need to be reduced significantly for methanol to compete with gasoline and other petroleum fuels on price. Methanol vehicles also have limited infrastructure currently for fueling compared to gasoline vehicles limiting their adoption.

Conclusion

In conclusion, renewable methanol holds big promise as a future transportation and industrial fuel as well as chemical feedstock due to its various advantages over other substitutes. With further technological advancements aimed at reducing costs and expanding supporting infrastructure and vehicles, it could emerge as an important pillar helping achieve global decarbonization goals across multiple sectors of the economy. Many pilots and demonstration projects are already underway to validate deployment of renewable methanol on a wider scale. Overall, it presents exciting opportunities for establishing a truly sustainable bio-based methanol industry.

0 notes

Text

Building a Sustainable Future with Bio Briquettes Manufacturers - Shubh Shree Bricks

We are offer a sustainable and eco-friendly alternative to traditional fossil fuels, and at the forefront of this innovative industry are Bio Briquettes Manufacturers. These play a crucial role in producing high-quality of contributing to global efforts towards environmental conservation and renewable energy adoption.

We are made from organic materials such as agricultural residues, forestry waste, and other renewable resources. It is employ advanced technology and sustainable practices to efficiently convert these raw materials into compact, energy-dense briquettes. Through processes like compression, heating, and binding, they ensure that the briquettes maintain their structural integrity and high calorific value.

One of the key benefits is their renewable nature, as they utilize organic waste materials that would otherwise contribute to environmental pollution. By recycling these materials into help reduce greenhouse gas emissions and mitigate the impact of deforestation, thus contributing to a cleaner and healthier environment.

Furthermore, offer a cost-effective and efficient energy solution for various applications, including heating, cooking, and industrial processes. They burn cleanly with minimal smoke and ash, making them ideal for both household and commercial use. Additionally, can serve as a sustainable alternative to traditional charcoal and firewood, helping to conserve natural resources and reduce dependence on finite fossil fuels.

We are dedicated to promoting the widespread adoption by producing reliable and high-quality products. They continuously invest in research and development to improve processes, enhance product performance, and explore new sources. By collaborating with stakeholders across sectors, including governments, NGOs, and communities, they strive to raise awareness about the environmental benefits of Bio Briquettes Suppliers and create a more sustainable energy future for generations to come.

Address : Jaipur:- Pn. 8, Ganesh Vihar-b, T.n. Mishra Marg, Nirman Nagar, Jaipur, 302019

Phone No : +91 9799998880

Email Id : [email protected]

Url : https://www.biomass.co.in/manufacturers/bio-briquettes.html

#Mustard Briquettes Manufacturers#Sawdust Briquettes Manufacturers#Sawdust Pellet Manufacturers#6mm Pellet Manufacturers#Pellet Burner Manufacturers#Non Torrefied Pellets Manufacturers#Biomass Briquettes Manufacturers#Biomass Pellet Manufacturers#Biomass Wood Pellets Manufacturers

0 notes

Text

🌇🔥 Gas It Up: Navigating the Urban Energy Landscape 2024-2033 🚀🏙️

Hey Urban Pioneers! 💡✨ Let's turn the city lights into gas lights as we dive into the forecast for the City Gas Distribution Market from 2024 to 2033! 📆🌐 Get ready for a decade of transformative trends in urban energy delivery! ⛽💨

🔥 City Gas Symphony Forecast: From bustling metropolises to cozy neighborhoods, the next decade is set to redefine how cities fuel their energy needs. The City Gas Distribution Market is in for a revolutionary spin! 🌆🔄

⚙️ Urban Gas Gadgets:

Smart Meters, Smarter Cities: Bid farewell to manual readings! Smart meters are taking center stage, offering real-time data for efficient gas consumption and billing. 📊🔍

Hydrogen Hubs: The rise of the green gas! Hydrogen is making its mark in city distribution, paving the way for cleaner, more sustainable energy solutions. 💚🌱

Virtual Pipelines: Think beyond the traditional grid! Virtual pipelines ensure flexibility in delivering gas to areas not connected to the main infrastructure. 🌐🛤️

🌱 Sustainable Urban Fuel Revolution:

Bio-Methane Magic: Turning waste into wonder! Bio-methane is gaining traction, creating a circular economy by converting organic waste into a clean energy source. 🔄🍃

CNG for Urban Mobility: Greening up the streets! Compressed Natural Gas (CNG) is becoming the go-to fuel for urban transportation, reducing emissions and improving air quality. 🚗🌿

Community Gas Networks: Connecting communities! Decentralized gas distribution networks are fostering community resilience and energy security. 🤝🏡

📈 Market Metropolis: Analysts predict a surge in demand for city gas distribution solutions, driven by a global push towards cleaner, more sustainable urban living. Are you ready to fuel the future? ⛽🌎

Drop your favorite city emoji below and let's ignite a conversation about the urban energy revolution! 🔥🏢 #CityGasChic #UrbanEnergyRevolution #GasLightsGlowing

0 notes

Text

How to Start Bio CNG Business with an Industry Overview

The Bio CNG industry revolves around generating renewable natural gas, and its significant impact on waste reduction cannot be understated. Comprising approximately 92-98% methane and only 2-8% carbon dioxide, Bio CNG is primarily derived from agricultural waste, kitchen waste, napier grass, and municipal solid waste. The strategic roadmap outlined in the Bio CNG business plan ensures efficient production, with benefits such as the utilization of renewable biomass resources and a reduced carbon footprint.

The Bio CNG manufacturing process involves multiple stages, including raw material drying, shredding, anaerobic digestion, purification, compression, and the utilization of by-products.

Additional details indicate that Bio CNG production in India is expected to increase from USD 1.47 billion in 2022 to USD 2.25 billion in 2029. Given India's heavy reliance on imports for 79% of its crude oil and about 50% of its natural gas needs, the government is actively promoting the inclusion of gas, particularly through ventures in the bio CNG production sector, in the country's energy portfolio. The goal is to elevate the current gas contribution of 6.5% to 15%.

IID offers crucial support to entrepreneurs in establishing their ventures in the industry, providing both handholding assistance and a comprehensive bio CNG plant project report. Additionally, guidance from industry experts is available to ensure the success of these endeavors.

Presented here is an in-depth Project Report focusing on Bio CNG (Compressed Natural Bio Gas), encompassing its processes, market positioning, demands, investment prospects, and financial projections. The document offers a thorough analysis of the industry, covering aspects such as plant capacity, land and building requirements, raw material specifications with a supplier list, plant and machinery details, flow sheet diagrams, total capital investment, and a meticulous calculation of the rate of return, break-even analysis, and profitability assessment.

In light of global efforts to adopt renewable energy across various sectors, there is a collective push towards green alternatives for conventional fuels. The imperative to reduce carbon footprint is paramount, necessitating innovative solutions before our planet faces severe environmental consequences. Governments worldwide are actively endorsing initiatives such as Electric Vehicles, Nuclear Power Plants, Solar Energy, among others, as part of the broader strategy to transition to sustainable energy sources. Within this context, Bio CNG emerges as a noteworthy green energy option.

https://www.iid.org.in/industrial-solution/mega-industry/bio-cng-business

0 notes

Text

Bihar Biofuel Production Promotion Policy, 2023

(Effective from 10.07.2023 to 31.03.2028)

Eligibility

Only standalone distilleries (single feed or dual feed) producing 100% fuel grade Ethanol which will be developed as a Greenfield project shall be eligible

Units producing Compressed Bio Gas (CBG)/Bio-CNG shall be eligible

Read More:- Bihar Biofuel Production Promotion Policy, 2023 Hebe

#biharbiofuel#biharpolicy2023#newpolicy2023#newgovermentpolicy2023#biofuelpolicy2023#hebeconsultancy

0 notes

Text

Best CNG (CBG) Franchise/Agency Company in India

Nexgen Energia is giving opportunity to open CNG/CBG Pump franchise/Agency Bio CNG retail outlets pan India. NexGen Energeia’s business projects are diversified to CNG/CBG production, CBG retail outlets, green diesel production, green diesel retail outlets, bio-coal, EV charging, etc. The business project Based on Government’s SATAT scheme.

#CNG Pump & Filling Station#cng pump dealership#Is CNG dealership profitable?#Compressed Bio Gas#Waste to Energy#cng agency#cng pump franchise#cng/cbg pump dealership

0 notes

Text

From Waste to Power: The Biogas Plant Journey

In the quest for sustainable and renewable energy sources, biogas plants stand out as a beacon of innovation. This article embarks on a journey through the transformative process of converting waste into power, exploring the mechanics of biogas production and its role in the broader landscape of renewable energy.

Unveiling the Biogas Production Process

1. Microbial Alchemy: Anaerobic Digestion

Key Operational Aspect:

Biological Transformation: Anaerobic bacteria break down organic matter in the absence of oxygen.

Methane Generation: Biogas, primarily composed of methane, is produced as a byproduct.

At the heart of biogas production lies the microbial alchemy of anaerobic digestion. In this biological process, specialized bacteria break down organic matter in the absence of oxygen, initiating a transformation that leads to the generation of biogas. The primary component of biogas is methane, a potent and clean-burning fuel.

2. Versatility in Feedstock

Key Operational Aspect:

Diverse Organic Inputs: Biogas plants can process various organic materials, including agricultural residues, food waste, and sewage sludge.

Adaptability to Local Resources: The flexibility of feedstock supports the utilization of region-specific organic materials.

Biogas plants exhibit versatility in the types of feedstock they can process. From agricultural residues and food waste to sewage sludge, these plants can efficiently convert diverse organic inputs into valuable biogas. This adaptability allows for the utilization of locally available resources, making biogas a promising solution for regions with different organic waste streams.

Advantages Propelling Biogas into the Renewable Energy Sphere

1. Green Energy Generation

Key Advantage:

Low Carbon Footprint: Biogas production minimizes greenhouse gas emissions, contributing to a cleaner environment.

Renewable and Sustainable: The organic nature of feedstock ensures a continuous and renewable source of energy.

Biogas production holds a significant advantage in contributing to green energy generation. The process minimizes the carbon footprint by capturing methane, a potent greenhouse gas that would otherwise be released during the natural decomposition of organic matter. The renewable and sustainable nature of biogas feedstock ensures a continuous source of clean energy.

2. Waste Management and Resource Recovery

Key Advantage:

Effective Waste Treatment: Biogas plants offer a solution for the efficient treatment of organic waste, reducing the burden on landfills.

Nutrient-Rich Byproducts: The residue from anaerobic digestion, known as digestate, serves as a valuable organic fertilizer.

Beyond energy generation, biogas plants play a crucial role in waste management and resource recovery. These plants provide an effective solution for treating organic waste, diverting it from landfills and mitigating environmental impact. Additionally, the nutrient-rich digestate produced as a byproduct serves as a valuable organic fertilizer, closing the loop on resource utilization.

Biogas Applications Across Sectors

1. Powering Homes and Industries

Key Application Areas:

Electricity Generation: Biogas can be used to produce electricity through combustion in gas engines or turbines.

Industrial Heat Production: The heat generated from burning biogas can be utilized for industrial processes.

Biogas finds applications in powering both homes and industries. Through combustion in gas engines or turbines, biogas can generate electricity to meet the energy needs of households and industrial facilities. The heat produced during this process can further be harnessed for various industrial applications.

2. Transportation Fuel

Key Application Area:

Bio-CNG Production: Biogas can be processed into compressed natural gas (CNG) for use as a clean and sustainable transportation fuel.

Reducing Carbon Emissions: Bio-CNG derived from biogas contributes to lower carbon emissions in the transportation sector.

Biogas extends its influence into the transportation sector through the production of bio-compressed natural gas (CNG). This clean and sustainable fuel offers an alternative to traditional fossil fuels, contributing to efforts to reduce carbon emissions in the transportation industry.

Future Prospects: Scaling Up Biogas for Global Impact

1. Integrated Systems for Circular Economy

Key Development Prospect:

Integration with Agriculture: Biogas plants can be integrated with agricultural practices, creating a circular economy loop.

Enhanced Sustainability: The symbiotic relationship between biogas production and agriculture fosters a sustainable and closed-loop system.

Looking ahead, the integration of biogas plants with agriculture holds the promise of creating integrated systems within a circular economy. By utilizing organic waste from agricultural activities as feedstock for biogas production and returning the nutrient-rich digestate to the fields as fertilizer, a symbiotic relationship can be established, enhancing overall sustainability.

2. Community-Based Biogas Initiatives

Key Development Prospect:

Localized Energy Production: Community-based biogas initiatives empower local communities to produce their own clean energy.

Addressing Energy Poverty: These initiatives have the potential to address energy poverty by providing reliable and decentralized power sources.

The future of biogas involves community-based initiatives that empower localities to produce their own clean energy. By establishing localized biogas plants, communities can address energy poverty by ensuring reliable and decentralized power sources, fostering energy independence.

Conclusion

The journey from waste to power unfolds through the remarkable process of biogas production. With its roots in microbial alchemy and a commitment to sustainability, biogas stands as a transformative force in the realm of renewable energy. From effective waste management to versatile applications across sectors, biogas plants have the potential to reshape our energy landscape. As we look towards a future that demands cleaner, more sustainable energy solutions, the biogas plant journey becomes a beacon of innovation and a testament to the possibilities of turning organic waste into a valuable resource for powering our world.

0 notes

Text

"Fueling the Future: Emerging Technologies in Hydrogen Storage Systems"

According to a new report published by Allied Market Research, titled, “Hydrogen Storage Market," The hydrogen storage market was valued at $2.8 billion in 2022, and is estimated to reach $8.6 billion by 2032, growing at a CAGR of 12.7% from 2023 to 2032.

Request Sample PDF of this report : https://www.alliedmarketresearch.com/request-sample/123264

Hydrogen storage is a key enabling technology for the advancement of hydrogen and fuel cell technologies in applications including stationary power, portable power, and transportation. Hydrogen has the highest energy per mass of any fuel; however, its low ambient temperature density results in a low energy per unit volume, therefore requiring the development of advanced storage methods that have potential for higher energy density.

Hydrogen storage system refers to the industry involved in the development, manufacture, and distribution of technologies and infrastructure required for the safe and efficient storage of hydrogen. Hydrogen storage systems play a critical role in enabling the utilization of hydrogen as an energy carrier for various applications. Hydrogen energy storage encompasses a range of storage technologies and solutions such as compresses gas storage, liquid storage, metal and chemical hydride storage, and solid-state storage.

Increase in rate of adoption of hydrogen as a clean energy carrier and the need for efficient and reliable storage solutions are positively impacting the hydrogen storage system market development. The hydrogen storage system business includes various stakeholders, including technology providers, equipment manufacturers, infrastructure developers, research institutions, and government entities.

Request for Customization of This Report at: https://www.alliedmarketresearch.com/request-for-customization/123264

Hydrogen is a promising alternative for fossil fuels in numerous applications. Some of these applications are in the domain of hydrogen energy, and no other alternatives can compete with hydrogen, such as heavy and long-distance transport (e.g., heavy-duty trucks, ships, and planes), as well as energy-intensive manufacturing sectors (e.g., ferrous, and nonferrous metals, petroleum refining, chemicals, and cement).

These sectors are difficult to electrify, and other alternatives (for instance bio energy) that cannot cater to the demand with the current technology. Therefore, various industries have adopted hydrogen as a replacement for fossil fuels to decarbonize and meet the need for energy. This is estimated to offer significant hydrogen storage system market opportunities for vendors during the forecast period. Hydrogen energy is important for supporting energy security and renewable energy, zero emission pathway, and economic growth.

Hydrogen is an ideal option for an energy-intensive manufacturing sector, grid electrical supply, heavy and long-distance transport, and gas networks. Moreover, it is a key ingredient for producing chemicals. Usage of fossil fuels leads to carbon emissions; therefore, several industries are adopting hydrogen as an alternative for fossil fuels.

The transportation sector is a significant contributor to greenhouse gas emissions. Hydrogen fuel cells have gained attention as a zero-emission alternative for various modes of transportation, including cars, buses, trucks, and trains. Hydrogen storage systems enable the safe storage and efficient delivery of hydrogen to fuel cell vehicles, thereby boosting the adoption of this clean transportation solution. Analysis of the latest hydrogen storage system industry research report reveals that hydrogen fuel cell powered electric vehicles have been gaining traction among automakers for the last few years. Advances in hydrogen fuel cell technology are expected to drive the development of hydrogen energy storage and expansion of hydrogen storage infrastructure.

Enquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/123264

The hydrogen storage market is segmented into type, storage form, end-use industry, and region. On the basis of type, the market is categorized into cylinder, merchant, on-site, and on-board. On the basis of storage, the market is bifurcated into material-based hydrogen storage and physical hydrogen storage. On the basis of end-use industry, the market is classified into chemical, oil refineries, automotive & transportation, metalworking, and others. On the basis of region, it is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Major players operating in the hydrogen storage market are Air Liquide, Linde Plc, Worthington Industries Inc, Luxfer Holdings PLC, Hexagon Composites ASA, Chart Industries, Inc., INOXCVA, Hbank Technologies Inc., PRAGMA INDUSTRIES and Steelhead Composites.

Key Findings Of The Study

By type, the cylinder segment is estimated to display the highest growth rate, in terms of revenue, from 2023 to 2032.

By storage, the physical segment is estimated to display the highest growth rate, in terms of revenue, registering a CAGR of 13.4% from 2023 to 2032.

By end-use industry, the chemical segment is estimated to display the highest growth rate, in terms of revenue, from 2023 to 2032.

By region, Asia-Pacific garnered the highest share of more than 40% in 2022, in terms of revenue.

0 notes

Text

Biogas Compression Market: Global Demand Analysis & Opportunity Outlook 2036

Research Nester’s recent market research analysis on “Biogas Compression Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitors analysis and a detailed overview of the global Biogas Compression Market in terms of market segmentation by feedstock, application, and region.

Growing Focus Due to Its Usage in Dynamic Sectors and Eco-Friendly Benefits

The global biogas market is the source of various biofuel and biogas and thus has a large-scale scope to uplift in the predicted year. Generated through anaerobic digestion or germination of natural component, Biogas gives several energy sources that mainly comprises 50-70% methane, 30-50% carbon dioxide, and small amounts of other gases. Various reasons have contributed to the surge of the global biogas compression market, including rising ecological issues, renewable energy demands, government back-up with advantageous policies and inducement, and possible economic advantages of generating Biogas.

Request Report Sample@

Because biogas is a more protected manner to do away with waste and keep the atmosphere clean, an increasing population and a boost in the production of dry garbage are assisting this product's market growth. Developing desire for garbage treatment processes in agriculture, industry, and municipalities is another primary reason the Biogas Compression Market will have this projected growth.

Some of the primary growth factors and challenges that are associated with the growth of the global biogas market are:

Growth Drivers:

Rising production and demand for Biogas

Comparatively cheap manufacturing cost of biogas compression than fossil fuel.

Challenges:

Biogas is being gathered and utilized to produce electricity or steam at various landfills, wastewater plants, and breweries. However, various scopes for biogas generation are yet to be used. Until recent times, the low cost of fossil fuels has stopped the usage of biogas production. There is a scarcity of concern about the possibilities and benefits of biogas production by citizens, government authorities, and the business sector, which has restricted interest in biogas production. Another primary reason often projected is the need for high investment capital. But the real reason behind facing challenges in biogas production was the impractically high desires of possible users. Biogas technology cannot resolve each issue of a farm, a village, or a big animal production unit. Basically, more knowledge, presentation, and investment in biogas technology would assist in conquering these challenges in the forecast timeline.

By feedstock, the global biogas compression market is segmented into bio-municipal waste, agriculture remains, energy crops. The bio-municipal waste segment will be the highest share in the market as it will earn the top-most profit by the end of 2036 by booming at a substantial CAGR over the anticipated period. Mainly, bio-municipal garbage is the waste accumulated daily from the different locality of different countries, which involve newspapers, clothing, furniture, bottles, cans, food, and appliances which further used for fermentation and produce bigas compression.

By region, the North American biogas compression market will profit significantly by 2036. The possibility for the growth of the U.S. biogas compression industry is massive. They count more than 15,000 new sites advanced for expansion recently: 8,600 dairy, poultry, and swine farms; 2,000 food scrap-only systems; and implementing the gas at 470 landfills that are splaying their gas. If wholly understood, these new biogas systems could generate 103 trillion kilowatt hours of electricity annually and limit the discharges comparable to eliminating 117 million passenger transports from the road.

Access our detailed report at:

0 notes

Text

Key Considerations for Setting Up a Bio CNG Plant

As businesses and governments worldwide seek renewable energy solutions, bio Compressed Natural Gas (bio CNG) emerges as a compelling alternative due to its environmental and economic benefits. Gruner Renewable, a leader in sustainable energy technologies, explores the economic feasibility and return on investment (ROI) considerations vital for anyone looking to set up a bio C0NG plant. Understanding these financial metrics is crucial for making informed decisions and ensuring the long-term success of such ventures.

Economic Feasibility of Bio CNG Plants

setup a bio cng plant convert organic waste into renewable energy, offering a sustainable way to manage waste while producing energy. The economic feasibility of these plants depends on several factors that potential investors must consider:

Initial Capital Investment

The setup a bio cng plant can vary widely depending on the scale of the operation and the technology used. Initial expenses typically include land acquisition, construction of the plant, purchasing anaerobic digesters, and installing gas purification and compression systems. Gruner Renewable provides clients with customized solutions that balance technology needs with budget constraints, optimizing initial investments.

Operational Costs

Running a bio CNG plant involves ongoing expenses such as maintenance of equipment, labor, feedstock procurement, and energy consumption for plant operations. To minimize these costs, Gruner Renewable implements high-efficiency systems and automates processes where possible, reducing labor costs and increasing operational efficiency.

Return on Investment Considerations

Feedstock Availability and Cost

The availability and cost of organic waste material play a crucial role in determining the ROI of a bio CNG plant. Locating the plant near abundant, low-cost or even free feedstock sources can significantly reduce input costs and improve profitability. Gruner Renewable assists clients in establishing strong supply chains for organic waste, which is critical for ensuring a steady and economical feedstock supply.

Revenue Streams

setup a bio cng plant generate income primarily through the sale of bio CNG, which can be used as a fuel in vehicles or for heating purposes. Additionally, by-products such as digestate can be sold as organic fertilizers, adding another revenue stream. Understanding market demands and pricing strategies for bio CNG and by-products is essential for projecting potential income and calculating ROI.

Government Incentives and Subsidies

Many governments offer incentives for renewable energy projects, including tax breaks, grants, and subsidies, which can significantly enhance the economic viability of bio CNG plants. These incentives not only reduce the effective cost of the project but also accelerate the breakeven point, improving overall ROI. Gruner Renewable stays abreast of relevant incentives and helps clients navigate the application processes to maximize financial benefits.

Long-term Profitability and Market Trends

Market Demand for Renewable Energy

The growing demand for renewable energy sources is driving up the value of bio CNG, making investments in bio CNG plants increasingly profitable. Gruner Renewable conducts market analysis to help clients understand current trends and future demand in the renewable energy market, ensuring that their projects are aligned with market needs.

Technological Advances

Investing in the latest technology can improve the efficiency and output of bio CNG plants, directly impacting ROI. Gruner Renewable is committed to innovation, continually updating plant designs with the latest advancements in anaerobic digestion and gas purification technologies to maximize energy output and reduce waste.

Conclusion

Setting up a bio CNG plant involves considerable financial planning and strategic decision-making. By carefully evaluating the economic feasibility and potential ROI, businesses can ensure that their investment in bio CNG technology is both sustainable and profitable. Gruner Renewable is dedicated to supporting its clients through every step of this process, from initial feasibility studies to operational optimization, driving forward the global transition to renewable energy.

Call to Action

Are you considering investing in a bio CNG plant? Contact Gruner Renewable today to explore how we can help you achieve a successful and profitable bio CNG operation. Visit our website to learn more about our services and how we can assist you in making your renewable energy project a reality.

0 notes