#Concrete Brick Making Machine manufacturers

Text

Brick vs Block: Which Construction Material Is Right for You?

Introduction

Choosing the right construction material is a crucial decision for builders and contractors. Concrete bricks and blocks are two popular choices, each with its own set of advantages and applications.

In this blog, we will compare these two construction materials to help builders make informed decisions that align with their project requirements. Additionally, we'll explore the importance of selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers.

Concrete Bricks:

Concrete bricks are widely used in construction due to their versatility and aesthetic appeal. Here are some key benefits and applications of concrete bricks:

1. Aesthetics: Concrete bricks come in a variety of colors and textures, making them an excellent choice for projects that prioritize aesthetics. They can be used to create visually appealing facades, accent walls, and even decorative elements within a structure.

2. Precision: Concrete bricks are manufactured to precise dimensions, ensuring uniformity and ease of installation. This precision makes them ideal for intricate brickwork patterns and designs.

3. Durability: Concrete bricks are known for their strength and durability, making them suitable for load-bearing applications. They can withstand harsh weather conditions, which is essential for structures exposed to the elements.

4. Thermal Insulation: Concrete bricks offer good thermal insulation properties, helping to regulate indoor temperature and reduce energy consumption. This makes them a popular choice for residential construction.

5. Soundproofing: Due to their density, concrete bricks also provide effective soundproofing, which is valuable in reducing noise transfer between rooms or from the outside.

Applications of Concrete Bricks:

Residential homes

Commercial buildings

Retaining walls

Fireplaces

Garden walls

Decorative features

Concrete Blocks:

Concrete blocks, often referred to as cinder blocks or concrete masonry units (CMUs), have their own unique advantages and applications:

1. Structural Strength: Concrete blocks are favored for their structural strength and load-bearing capacity. They are commonly used in the construction of foundations, retaining walls, and other structural elements.

2. Cost-Efficiency: Concrete blocks are generally more cost-effective than bricks. Their larger size means fewer blocks are needed to cover a given area, reducing material and labor costs.

3. Speed of Construction: Due to their size, concrete blocks can be laid quickly, speeding up the construction process. This efficiency is particularly beneficial for large-scale projects.

4. Fire Resistance: Concrete blocks offer excellent fire resistance, which is a critical factor in building safety. They can withstand high temperatures and provide valuable fire protection.

5. Minimal Maintenance: Concrete blocks require minimal maintenance over the years, making them a low-maintenance option for long-lasting structures.

Applications of Concrete Blocks:

Foundations

Basement walls

Retaining walls

Commercial buildings

Industrial facilities

Warehouses

Selecting Reliable Concrete Brick and Block Making Machine Manufacturers

In addition to choosing the right construction material, it's essential to consider the machinery and equipment used in the manufacturing process. High-quality concrete bricks and blocks depend on the reliability of the production equipment. Here's why selecting trustworthy Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is crucial

1. Product Quality: Reliable manufacturers produce machines that meet industry standards, ensuring the consistent production of top-quality bricks and blocks.

2. Efficiency: Modern brick and block making machines offer improved efficiency and output. Investing in machinery from reputable manufacturers can lead to increased productivity and reduced production costs.

3. Support and Service: Established manufacturers often provide comprehensive support and maintenance services for their equipment, minimizing downtime and optimizing machine performance.

4. Innovation: Leading manufacturers invest in research and development, resulting in innovative features and technologies that can enhance the quality and efficiency of brick and block production.

5. Compliance: Ensure that the machinery you purchase complies with safety and environmental regulations in your region.

Conclusion

Both materials have their strengths and applications. Concrete bricks offer versatility and aesthetics, while concrete blocks provide structural strength and cost-efficiency. The choice between these two construction materials depends on your project's specific needs.

Additionally, selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is essential to ensure the consistent production of high-quality building materials. By carefully considering both the construction material and the machinery used in production, builders and contractors can make informed decisions that lead to successful and durable construction projects. Whether it's the material or the machinery, quality, and reliability are key to building a solid foundation for any construction venture.

Benny Enterprises is the best option for your best brick-making machine and block-making machine manufacturers we are also well known for being the best Fly ash brick making machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more.

Contact us for further…

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes

Text

https://forceaacplant.com/Force aac plant provide the best aac plant, AAC Block Plant, CLC Plant, CLC Block Plant Making Machine at best cost. It is the best aac plant manufacturers, AAC Block Plant, CLC Plant, CLC Block Plant Making Machine Supplier, Manufacturer company in Pune, Mumbai, Nashik, Kolhapur, Satara, sangli, Bangalore, Chennai, Gujrat, Ahmedabad, India

#aac plant#aac plant machinery#aac brick making machine#aac block plant Manufacturers#aac block plant Supplier#aac blocks manufacturing plant cost#aac block plant machinery#aac block machinery manufacturers#foaming agent and raw material for clc plant#horizontal wire cutting machine for aac block#Semi-automatic clc plant manufacturers#clc plant machinery#clc bricks machinery cost#clc plant manufacturers#clc plant suppliers#clc block plant manufacturers#clc block plant suppliers#clc block making machine#cellular light weight (clc) concrete block making machines#clc brick making machine#clc brick making machine manufacturers#concrete foaming agent manufacturers#concrete foaming agent suppliers#foaming agent for concrete#foaming agent for clc blocks#reversible concrete mixer machine manufacturers#reversible concrete mixer machine suppliers#reversible drum concrete mixer machine#reversible concrete mixer with feeder#reversible concrete mixer with inline feeder

0 notes

Text

Revolutionizing Construction with Semi-Automatic Brick Making Machines

Semi-automatic brick making machines are revolutionizing the construction landscape by offering an efficient, cost-effective, and quality-driven solution. To harness the full potential of these machines, it's imperative to partner with a reliable concrete block machine manufacturer. By making an informed decision, construction companies can propel their projects forward, meeting timelines and quality standards with ease.

0 notes

Text

Ultra Tile Machine is a one of the leading manufacturer and exporter of PVC Rubber Mould from past decades. We are a Noida situated machinery manufacturing company providing cost effective and innovative solutions to serve all your needs. PVC Rubber Mould - Manufacturers, Suppliers in India.

#PVC Rubber Mould Manufacturers#Cement Brick Making Machine Manufacturers#Concrete Block Making Machine Manufacturers

1 note

·

View note

Text

Concrete Blocks - Manufacturing, Classification & Uses

Concrete blocks are nowadays replacing bricks in masonry construction, notably in many multi-storeyed buildings. They are available in three types namely solid, hollow and cellular, widely used for the construction of filler walls and boundary walls in RC framework.

Concrete blocks are usually made in large sizes to make blockwork faster and consume less cement in joints than the brickwork. If the percentage of the voids is more than 25%, then they are hollow blocks and blocks with voids less than 25% are only perforated blocks.

The cellular concrete blocks are generally referred to as lightweight aerated concrete blocks. All these blocks are extensively used for compound walls and non-loadbearing walls.

Hollow blocks are specially made for loadbearing walls, which are useful in reducing a dead load of masonry in buildings. Blocks can also be with cement and sand called cement-sand blocks or with cement and soil called soil-cement blocks which are of low strength and use for low-cost construction.

Manufacturing of Concrete Blocks

BIS recommends a fineness modulus of the combined aggregate between 3.6 to 4 and coarse aggregates used are of size 6 to 12 mm. Lean mixes up to 1:8 are generally used. Concrete mix for concrete blocks should not be richer than one part of the cement to six parts of the volume of combined aggregate.

Concrete blocks can be handmade and also machine-made. The cast block is then cured in a water tank or yard for at least 14 days (water need to be changed at least every 4 days).

After curing, the blocks are dried for 4 weeks before being used in masonry construction. They should be stacked with voids in the horizontal direction to facilitate easy drying, or they should be steam cured and dried.

The whole process allows the complete shrinkage of the block to take place they are laid on the wall, which is very important for strong walls.

Classification of Concrete Blocks

Hollow concrete blocks

Open and Closed cavity-type hollow concrete blocks are classified into three grades:

Grade A - They possess a minimum density of 1500 kg/m³ and are used for load-bearing walls.

Grade B - They have a density below 1500 kg/m¬³ and used for load-bearing walls.

Grade C - These blocks are used for non-load bearing walls and have density more than 1000 kg/m³.

All these blocks are available in decorative facings like fluted facing to provide artistic effects.

Solid concrete blocks

They should be manufactured for specific concrete strength of 4.0 and 5.0 N/mm² in 28 days. These blocks are used as load-bearing walls and have a density of not less than 1800 kg/m³.

Paver blocks

These blocks are solid concrete blocks of different shapes specially made for exterior ground paving on sidewalks, parking lots, driveways, petrol pumps, industrial floors, etc.

AAC Blocks

AAC blocks refer as Autoclaved Aerated Concrete Blocks. These blocks are also termed as light-weight hollow blocks.

They are prepared as solid blocks from cement, water and materials like ground sand, pulverized fly ash together with additives to aerate and stabilize the air bubbles.

The final result is a mixture of thick liquid which is then poured into steel moulds to form large cakes. After some time, the mixture sets and ready to cut into a serious of individual blocks of required size using taut steel wires.

Very light blocks for partition and moderate-weight blocks for light loadbearing walls can be obtained from aac blocks. These blocks do not shrink on drying as the material is obtained by autoclaving.

The autoclaved cement product is crystalline, which is different from the product obtained by normal wet curing or by ordinary steam curing.

Sizes and Tolerances

The nominal dimensions of concrete block as per BIS are as follows:

Length - 600, 500, 450 or 400 mm

Height - 100 or 200 mm

Width - 50, 75, 100, 150, 200, 250 or 300 mm

Actual sizes will be less than 10 mm of mortar thickness. For Concrete and Hollow concrete blocks nominal length 390 mm and height 190 mm. The thickness for loadbearing walls is 190 mm, compound walls 140 mm and for filler walls 90 mm.

These dimensions can easily be achieved in machine-made blocks than handmade blocks. The width of blocks use for load-bearing walls is 200 mm and for parapet or filler walls is 100 mm.

Points to Remember:

The mortar strength should not be more than the strength of the blocks. With high mortar strength, cracks will be less and very large, but with low mortar strength, cracks will be small and distributed.

We should use only blocks that are cured properly for at least 14 days and dried for 4 weeks to avoid shrinkage during construction.

We should not wet the blocks while placing in masonry construction.

Freshly-made and uncured concrete blocks should never be allowed on the work.

Blockwork, particularly ordinary cement sand blocks and soil-cement blocks should not be used as loadbearing walls for concrete slab roof which favours to expand and contract with temperature.

The maximum difference in sizes allowed is ±5 mm in length and ±3 mm in height and width.

They should be protected from rains while being stored as they absorb moisture by wetting and shrinking on drying.

The main disadvantage of concrete blocks is shrinkage due to the movement of moisture content which is not present in bricks. As these blocks are much larger than bricks, any foundation movement will cause blockwork to crack more than the brickwork.

Cement blocks, Concrete blocks, Hollow concrete blocks, solid concrete blocks, Paver blocks, AAC blocks Concrete blocks in Hyderabad

#aac Blocks#aac blocks online#aac block size#Cement blocks#Concrete blocks#Hollow concrete blocks#solid concrete blocks#Paver blocks#AAC blocks

2 notes

·

View notes

Text

Fixings and Fasteners: Essential Components for Secure and Durable Installations

In construction, manufacturing, and DIY projects, Fixings And Fasteners are essential components that ensure materials are securely attached, stable, and capable of withstanding stress over time. From securing heavy structural elements to holding smaller parts in place, the right choice of fixings and fasteners can make a significant difference in the safety, strength, and durability of an installation.

This guide will explore the different types of fixings and fasteners, their uses, and how to select the right ones for various applications.

What Are Fixings and Fasteners?

Fixings and fasteners are hardware devices used to join or secure materials together. They come in various forms, including screws, bolts, nails, rivets, anchors, and clips, each designed for specific tasks. These components can be used for permanent or temporary connections and are critical in ensuring that structures and assemblies hold up under mechanical forces such as tension, compression, and shear.

Types of Fixings and Fasteners

Screws

Screws are one of the most commonly used fasteners. They are designed to be driven into materials like wood, metal, or plastic with a twisting motion. Screws come in a wide range of types, such as wood screws, machine screws, and self-tapping screws, each suited to different materials and applications.

Common Applications: Furniture assembly, decking, and general construction.

Bolts and Nuts

Bolts are threaded fasteners typically used with nuts to secure two or more parts together. They are ideal for applications where high strength and durability are required. Bolts and nuts come in different sizes, grades, and materials, including steel, stainless steel, and brass.

Common Applications: Heavy machinery, automotive, structural steelwork, and construction.

Nails

Nails are used to fasten materials by driving them through one or more layers using a hammer or nail gun. Unlike screws or bolts, nails do not have threads, making them suitable for applications where high shear strength is needed.

Common Applications: Framing, roofing, and carpentry.

Anchors

Anchors are used to secure fasteners to surfaces like concrete, brick, or drywall, where screws or bolts alone would not be effective. There are several types of anchors, including wall plugs (also known as rawl plugs), toggle bolts, and concrete anchors.

Common Applications: Hanging heavy objects like shelves, fixtures, and cabinets on walls.

Rivets

Rivets are permanent fasteners used to join two or more materials by deforming the head after insertion. They are commonly used in applications where access to both sides of the material is limited.

Common Applications: Aircraft assembly, shipbuilding, and metalworking.

Washers

Washers are thin plates with a hole in the middle, used to distribute the load of a threaded fastener, like a screw or bolt. They help prevent the fastener from loosening and can protect the material surface from damage.

Common Applications: With screws and bolts in mechanical and structural installations.

Clips and Clamps

Clips and clamps are fasteners that hold objects together or secure cables and pipes in place. They are often used in scenarios where frequent disassembly or adjustment is necessary.

Common Applications: Cable management, piping systems, and automotive assembly.

Staples

Staples are U-shaped fasteners driven into materials using a staple gun or hammer. They are commonly used for attaching thin materials like fabric, paper, or insulation to wood or other surfaces.

Common Applications: Upholstery, packaging, and light construction.

Choosing the Right Fixings and Fasteners

Selecting the appropriate fixing or fastener for a project depends on several factors:

Material Type: Different materials require specific types of fasteners. For example, wood screws are designed for timber, while machine screws are suitable for metal or plastic.

Load Requirements: The strength and load-bearing capacity of the fastener should match the weight and mechanical forces it will need to withstand. Bolts and anchors are often used in high-load applications, while screws and nails are better for lighter tasks.

Environmental Conditions: In outdoor or corrosive environments, such as marine or chemical industries, materials like stainless steel or galvanized fasteners are preferred for their resistance to rust and wear.

Installation Method: Consider how the fastener will be installed. Some fasteners, like nails and staples, are hammered in, while others, like screws and bolts, require tools like screwdrivers or wrenches.

Permanent vs. Temporary: If the assembly needs to be frequently disassembled and reassembled, choose fasteners like screws, bolts, or clamps. For permanent installations, rivets or nails might be more appropriate.

Common Applications of Fixings and Fasteners

Construction: Fasteners such as screws, bolts, and nails are used to assemble structures, secure frameworks, and attach components like doors and windows.

Manufacturing: In industries such as automotive and aerospace, fasteners like bolts, rivets, and clips ensure the secure attachment of parts that undergo mechanical stress.

Home Improvement: From hanging shelves to assembling furniture, various fixings and fasteners are used in everyday home projects.

Electrical Installations: Fasteners like anchors, clips, and clamps are essential for securing wiring and electrical components in place.

Conclusion

Fixings and fasteners are fundamental to nearly every construction, manufacturing, and DIY project. Selecting the right type based on material, load, and environmental factors ensures that your installation is secure, durable, and safe. With the vast range of options available, understanding the specific requirements of your project will guide you in choosing the most appropriate fixing or fastener for the job.

0 notes

Text

Affordable and High-Quality Interlocking Tiles Making Machines

In today's fast-paced construction industry, efficiency and quality are paramount. At BTM Product, we understand the challenges faced by builders, contractors, and manufacturers in delivering top-notch results while managing costs. That's why we're proud to offer our state-of-the-art interlocking tiles making machines, designed to revolutionize your production process and elevate the standard of your projects.

Our interlocking tiles making machine are the result of years of research, development, and industry experience. We've combined cutting-edge technology with robust engineering to create a solution that not only meets but exceeds the expectations of our clients. Whether you're a small-scale contractor or a large construction firm, our machines are tailored to suit your specific needs and scale of operations.

Why Choose BTM Product's Interlocking Tiles Making Machines?

1. Unmatched Affordability

We believe that high-quality equipment shouldn't break the bank. Our interlocking tiles making machines are priced competitively, offering you the best value for your investment. By choosing BTM Product, you're not just buying a machine; you're making a smart financial decision that will pay dividends in the long run.

2. Superior Quality Output

Quality is at the heart of everything we do. Our machines are engineered to produce interlocking tiles of the highest standard, ensuring consistency, durability, and aesthetic appeal. The precision of our equipment means you can rely on uniform results, batch after batch.

3. Versatility and Adaptability

Our interlocking tiles making machines are designed to handle a wide range of materials, including concrete, cement, and even fly ash. This versatility allows you to experiment with different compositions and create unique products tailored to your clients' needs.

4. Energy Efficiency

In an era where sustainability is crucial, our machines are designed with energy efficiency in mind. By optimizing power consumption, we help you reduce operational costs and minimize your environmental footprint.

5. User-Friendly Operation

We understand that not all operators have extensive technical knowledge. That's why our interlocking tiles making machines feature intuitive controls and user-friendly interfaces, making them accessible to workers of all skill levels.

6. Durability and Low Maintenance

Built to last, our machines are constructed using high-grade materials that withstand the rigors of daily use. This durability translates to less downtime and lower maintenance costs, ensuring your production remains uninterrupted.

7. Customization Options

We recognize that every project is unique. Our interlocking tiles making machines can be customized to meet your specific requirements, whether it's adjusting production capacity or incorporating special features.

8. Comprehensive Support

When you choose BTM Product, you're not just buying a machine; you're gaining a partner. Our team of experts is always ready to provide technical support, maintenance advice, and operational guidance to ensure you get the most out of your investment.

Our Other Machines

paver block making machine

fly ash brick making machine

The Versatility of Our Interlocking Tiles Making Machines

Our interlocking tiles making machines are not limited to a single application. Their versatility extends to various construction materials and products, including:

1. Standard Interlocking Tiles

Perfect for pathways, driveways, and outdoor spaces, our machines produce interlocking tiles that combine strength with aesthetic appeal.

2. Paver Blocks

Create stunning paver blocks for landscaping projects, pedestrian walkways, and commercial spaces.

3. Kerb Stones

Manufacture precise kerb stones for road construction and landscaping applications.

4. Fly Ash Bricks

Our machines are also capable of producing high-quality fly ash bricks, offering an eco-friendly alternative to traditional clay bricks.

The Fly Ash Brick Making Machine: A Game-Changer in Sustainable Construction

As part of our commitment to innovation and sustainability, BTM Product offers a specialized fly ash brick making machine. This cutting-edge equipment allows you to tap into the growing market for eco-friendly construction materials.

Fly ash bricks are gaining popularity due to their numerous advantages:

1. Environmental Benefits: By utilizing fly ash, a byproduct of coal combustion, these bricks help reduce waste and lower the carbon footprint of construction projects.

2. Cost-Effective: The production of fly ash bricks is often more economical than traditional clay bricks, offering savings for both manufacturers and end-users.

3. Superior Properties: Fly ash bricks boast excellent compressive strength, low water absorption, and uniform shape, making them ideal for various construction applications.

4. Versatility: These bricks can be used in both load-bearing and non-load-bearing structures, offering flexibility in design and application.

5. Reduced Energy Consumption: The production process of fly ash bricks requires less energy compared to conventional bricks, further enhancing their eco-friendly profile.

Our fly ash brick making machine is designed to maximize efficiency and quality in the production of these innovative building materials. With precise control over the mixing and molding processes, you can consistently produce fly ash bricks that meet or exceed industry standards.

Streamlining Your Production Process

At BTM Product, we understand that efficiency is key to your success. That's why our interlocking tiles making machines and fly ash brick making machine are designed to streamline your production process:

1. Rapid Production: Our machines boast impressive production rates, allowing you to meet tight deadlines and increase your output.

2. Minimal Waste: Precise material control and efficient molding processes minimize waste, saving you money on raw materials.

3. Quick Setup and Changeover: Easily switch between different product types or sizes with minimal downtime.

4. Automated Features: Many of our machines include automated functions that reduce the need for manual intervention, improving consistency and reducing labor costs.

5. Quality Control Integration: Built-in quality control measures ensure that every tile or brick meets your exacting standards.

Training and Support: Empowering Your Team

When you invest in a BTM Product machine, whether it's our interlocking tiles making machine or fly ash brick making machine, you're not just getting equipment – you're gaining a partner in success. We offer comprehensive training and support to ensure your team can operate the machinery effectively and efficiently:

1. On-Site Training: Our experts provide hands-on training at your facility, ensuring your operators are comfortable with all aspects of the machine's operation.

2. Ongoing Technical Support: Our dedicated support team is always available to answer questions and troubleshoot any issues you may encounter.

3. Maintenance Guidance: We provide detailed maintenance schedules and guides to help you keep your machine in top condition, maximizing its lifespan and performance.

4. Upgrades and Updates: As technology evolves, we offer upgrades and updates to keep your equipment at the cutting edge of efficiency and quality.

Some Blogs

Automatic Fly Ash Brick Making Machine at the Best Price

Get the Best Fly Ash Brick Making Machine in India

Conclusion

In an industry where quality, efficiency, and sustainability are paramount, BTM Product's interlocking tiles making machines and fly ash brick making machine stand out as the clear choice for forward-thinking businesses. By investing in our technology, you're not just purchasing equipment – you're investing in the future of your company and the construction industry as a whole.

Our commitment to affordability doesn't come at the cost of quality. Instead, it's a reflection of our dedication to making advanced technology accessible to businesses of all sizes. With BTM Product's machines, you can compete at the highest level, delivering superior products while maintaining a healthy bottom line.

Whether you're looking to expand your product line, increase your production capacity, or transition to more sustainable building materials, our interlocking tiles making machines and fly ash brick making machine are the tools you need to succeed. Join the ranks of satisfied BTM Product customers who have transformed their operations and elevated their standing in the competitive construction market.

Take the first step towards revolutionizing your production process. Contact BTM Product today to learn more about our affordable and high-quality interlocking tiles making machines and fly ash brick making machine. Let's build a stronger, more efficient, and sustainable future together.

0 notes

Text

The Evolution of Block Machines and Their Role in Modern Construction

In the ever-evolving world of construction, technology continues to revolutionize the way we work. One such technological advancement that has significantly transformed the construction industry is the block-making machine. These mechanical devices are designed to produce concrete blocks in various sizes and shapes with remarkable precision and accuracy, meeting the diverse demands of construction projects worldwide.

What Are Block Machines?

Block machines are specialized equipment developed to manufacture concrete blocks in large quantities. These machines have largely replaced the traditional manual methods of block making, significantly increasing production efficiency while ensuring consistency in the quality of the blocks produced. Block machines are environmentally friendly and utilize removable gang mold technology, allowing them to produce multiple blocks simultaneously during each casting cycle. This innovation not only speeds up the construction process but also reduces labor costs and minimizes material waste.

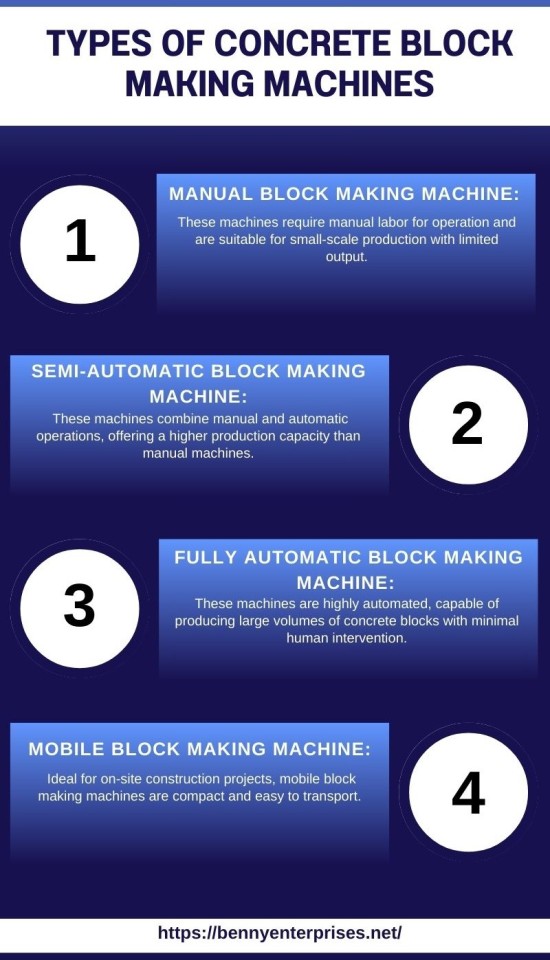

Types of Block Machines Offered by OTC Power

At OTC Power, we are committed to delivering high-quality block-making solutions to our customers. We offer a wide range of block machines designed to meet different production needs. Here are some of the types of block machines available:

Automatic Hydraulic Block and Paver Machine: This machine is fully automated, utilizing hydraulic pressure to produce blocks and pavers of various sizes. Its high efficiency and low maintenance make it an excellent choice for large-scale construction projects.

Automatic Concrete Block Machine: Designed for versatility, this machine automates the entire block-making process, from mixing to molding. It can produce a wide range of blocks, including hollow, solid, and interlocking blocks, making it ideal for projects requiring different block types.

Semi-Automatic Hydraulic Concrete Block Machine: For those looking for a balance between automation and manual control, this semi-automatic machine provides flexibility. It uses hydraulic pressure to mold blocks and allows operators to have more control over the production process.

Egg-Laying Concrete Block Making Machine: This machine is known for its mobility and ability to produce blocks directly on the construction site. It’s perfect for projects with limited space or where permanent installation of machinery is not feasible. It is capable of producing both hollow and solid bricks, offering versatility to meet different construction needs.

Meeting Global Demand

OTC Power is proud to serve customers across various regions, including Sharjah, Congo, Angola, Uganda, Rwanda, and South Africa. Our machines are designed to cater to the specific needs of each market, ensuring customer satisfaction through reliable performance and high-quality block production.

Why Choose OTC Power?

At OTC Power, we understand the importance of quality and efficiency in construction projects. Our block machines are built with durable materials and advanced technology to ensure long-lasting performance and low maintenance costs. Whether you are looking to expand your production capacity or streamline your block-making process, OTC Power has the right solution for you.

https://otcglobal.net/products/block-machine/

#diesel generator in sharjah#diesel generator supplier in dubai#perkins diesel generator in uae#diesel generator company in congo#diesel generator in congo#youtube#diesel generator supplier in sharjah#diesel generator in dubai#diesel generator in uae#perkins diesel generator supplier in dubai#constructioniteminuae#constructioniteminsharjah#constructionitemindubai#constructionmachineinuae#constructionmachineinsharjah#constructionmachineindubai#blockmachineinuae#blockmachineinsharjah#blockmachineindubai#Waterdrillingmachineinuae#Waterdrillingmachineinsharjah#Waterdrillingmachineindubai#drillingmachineinuae#drillingmachineinsharjah#drillingmachineindubai#generatorindubai#generatorinafrica#solarpowerinuae#generatorsparepartsinuae#cumminsgenerator

0 notes

Text

Hydraulic Paver Block Making Machine

Robexo Industries is a Manufacturer, and Supplier of Hydraulic Paver Block Making Machine in India.

Robexo Industries is a Manufacturer, Exporter, and Supplier of Automatic Fly Ash Brick Making Machine, Concrete Block Making Machine, Paving Block Making Machine, Brick Making Machine, Fly Ash Brick Making Machine, etc.

The Hydraulic Paver Block Making Machine is a state-of-the-art, high-efficiency machine designed to produce high-quality paver blocks for various construction projects.

This machine leverages hydraulic technology to ensure precise and consistent block formation, making it an ideal choice for manufacturers and construction companies aiming to meet high production demands with superior quality.

Features:

Hydraulic system: Uses hydraulic pressure to compact and mold the concrete mixture into blocks.

Molds: Interchangeable molds allow for different block designs and sizes.

Vibration system: Helps to remove air pockets and ensure uniform density.

Control panel: Allows for easy operation and adjustment of settings.

High-pressure pump: Enables high-density blocks with minimal effort.

Applications:

Road construction

Pavement construction

Walkway and sidewalk construction

Patio and driveway construction

Landscaping projects

Robexo Industries is a Manufacturer, and Supplier of Hydraulic Paver Block Making Machine in India Including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal.

For more information and inquiries, feel free to contact us.

View Product: Click Here

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chhattisgarh#Exporter#ExporterofHydraulicPaverBlockMakingMachine#Goa#Gujarat#Haryana#HimachalPradesh#HydraulicPaverBlockMakingMachine#HydraulicPaverBlockMakingMachineinAhmedabad#HydraulicPaverBlockMakingMachineinIndia#India#Jharkhand#Karnataka#Kerala#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#ManufacturerofHydraulicPaverBlockMakingMachine#Meghalaya#Mizoram#Nagaland#Odisha#Punjab#Rajasthan

0 notes

Text

Components, Parts & working of fly ash brick making machine

Fly ash bricks have gradually gained importance in the construction market as a green solution compared to the red clay bricks. These bricks are produced from industrial waste thus playing a massive role in sustainable construction. The fly ash brick making machine is useful in the process as it helps in the production of quality bricks. These machines have become essentials in the brick making industry due to the increased demand of sustainable and efficient solutions.

A Fly Ash Brick Making Machine is a sophisticated manufacturing tool used to create strong and durable fly ash bricks from fly ash, cement, sand and water. A fly ash brick making machine is a type of machinery that will help in the making of bricks with the right quality, efficiency and uniformity. The machine mixes the fly ash with other materials, presses the mixture into a mold and produces concrete bricks.

Components and Parts

Feeding System: This component is the core of accuracy in feeding the raw materials into the machine.

Mixing System: This helps in ensuring that fly ash, cement, sand, and water are well blended to form a uniform mixture.

Molding System: Brick making material is poured into molds to give the specific shape to the products. This is because it is possible to use molds of different sizes and shapes to make a variety of bricks.

Compaction and Vibration System: Brings together the mixture and expels air to create voluminous and strong bricks.

Curing System: Bricks are made to undergo a process of Curing in order to improve their strength and dame.

Maintenance and Operational Tips for Fly Ash Brick Making Machine

It is important to perform proper maintenance of your Fly Ash Brick Making Machine to guarantee maximum efficiency as well as service durability.

Routine Inspections: To perform a daily check on the extent of wear and tear of different parts of the machine. Make sure that all the bolts and screws are properly tightened so that there are no loose parts that would lead to failure in their operations.

Lubrication: Another technique is to apply oil or grease on the moving parts so as to reduce friction and wear of the equipment. It is important to use recommended lubricants to maintain compatibility and performance.

Cleanliness: Clean the machine after every use to prevent accumulation of the residue or any other debris within the fixture. They should also see to it that there are no deposits in the molds and the area used for mixing the bricks.

Revolutionize your brick manufacturing process

Flying principles of the fly ash brick making machine incorporate aspects such as feeding, mixing, molding, compacting, and curing of bricks. Therefore, adopting a fly ash brick making machine has a number of advantages that make it a worthy investment. It also focuses on sustainability through the reuse of industrial waste and effective and affordable method of brick production. It increases efficiency and also plays a key role in the protection of the environment. Please click on the following link to visit our website to explore brick machinery’s fly ash brick making machine.

#fly ash brick making machine#brick making machine#brickmakingmachine#fly ash brick making machine in gujarat#fly ash brick plant#brickmachine#brick making machine in india

0 notes

Text

Selecting the right concrete block making machine for your construction business is a significant decision that can impact your productivity, profitability, and overall success. Benny Enterprises is the best choice for all your needs, we are the finest Concrete Brick Making Machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes

Text

[ad_1]

Fasteners play a vital function in development, manufacturing, and on a regular basis tasks. They maintain objects collectively and make sure the integrity of assemblies and buildings. Understanding the varied sorts of fasteners is important for choosing the correct one to your wants, whether or not constructing furnishings, assembling equipment, or finishing a DIY undertaking. This text will present a complete overview of ten various kinds of fasteners, detailing their distinctive traits, makes use of, and advantages.

Selecting the right fastener can considerably influence your undertaking's energy, sturdiness, and security. With so many choices out there, it is important to grasp the variations between them. We'll discover nails, screws, bolts, nuts, washers, rivets, pins, clips and clamps, anchors, and adhesives and tapes. Every sort of fastener has its options and is appropriate for particular purposes.

Nails

Nails are amongst development and woodworking's most important and broadly used fasteners. They're sometimes fabricated from metal however may also be present in different metals like copper, aluminum, and brass. Nails are pushed into supplies utilizing a hammer or nail gun, making a friction-based maintain that retains parts collectively.

There are numerous sorts of nails, every designed for particular functions. Widespread nails are used for normal development and framing. Ending nails, which have smaller heads, are perfect for trim work the place a easy end is desired. Roofing nails have massive, flat heads to carry down shingles and different roofing supplies. Different specialised nails embody masonry nails for attaching wooden to brick or concrete and brad nails, that are skinny and infrequently utilized in detailed woodworking tasks.

The primary benefit of nails is their simplicity and ease of use. They're cheap and available in varied sizes and lengths. Nonetheless, nails can loosen over time below sure circumstances, corresponding to with wooden motion, on account of modifications in humidity. To handle this, some nails are coated or designed with rings or spirals to extend their holding energy.

Screws.

Screws are versatile fasteners that present a strong and sturdy maintain. In contrast to nails, screws have threads that reduce into the fabric as they're pushed in, making a mechanical lock that's extra proof against pulling out. This makes screws very best for purposes the place a safe, long-lasting connection is required.

Screws are available a variety of sorts and sizes. Wooden screws are designed particularly for wooden, with a pointy level and coarse threads to grip the wooden fibers. Machine screws, then again, are used with nuts or tapped holes in steel and plastic. Sheet steel screws have sharp threads for connecting steel sheets, whereas self-tapping screws can create their threads in softer supplies.

One of many most important advantages of screws is their removability. They are often simply unscrewed and reinserted with out damaging the fabric, making them very best for tasks needing changes or disassembly. Screws are pushed utilizing a screwdriver or energy drill, and their heads are available varied shapes, corresponding to flat, Phillips, and hex, to accommodate completely different instruments and purposes.

Bolts.

Bolts are much like screws however are usually used with nuts to create a powerful, safe connection. They're generally utilized in development, equipment, and automotive purposes requiring a high-strength fastener. Bolts are normally fabricated from metal and can be found in varied grades to swimsuit completely different energy necessities.

There are a number of sorts of bolts, every designed for particular functions. Hex bolts, with their hexagonal heads, are probably the most frequent sorts utilized in many purposes. Carriage bolts have a rounded head and a sq. neck, stopping them from turning when the nut is tightened.

Lag bolts, or lag screws, are heavy-duty fasteners with a hex head and coarse threads, typically utilized in wooden development.

Bolts are sometimes inserted by means of pre-drilled holes and secured with a nut on the other aspect. This creates a clamping drive that holds the supplies collectively. Washers are sometimes used with bolts to distribute the load and forestall injury to the fabric. Bolts may be tightened utilizing wrenches or socket instruments, and their energy makes them very best for purposes the place security and sturdiness are important.

Nuts.

Nuts are important parts used along with bolts to safe supplies collectively. They arrive in varied sizes and styles, every designed to satisfy particular wants. The most typical sort is the hex nut, which has six sides and is simple to grip with a wrench. Different sorts embody wing nuts, which may be tightened by hand, and lock nuts, which have options to stop them from loosening over time.

Nuts are internally threaded to match the threads of a bolt. When the bolt is inserted by means of supplies, and the nut is tightened, it creates a powerful, safe connection. That is significantly helpful in purposes the place the fastener might have to be eliminated and reinstalled a number of instances, corresponding to in equipment and automotive assemblies.

The fabric of the nut can also be an necessary consideration. Metal nuts are frequent, however chrome steel, brass, or different specialised supplies could also be used for purposes requiring resistance to corrosion or excessive temperatures. As well as, some nuts have coatings or finishes to boost their efficiency and longevity in particular environments.

Washers.

Washers are skinny, flat discs with a gap within the heart that distributes a fastener's load. They're sometimes positioned between the nut and the mounted materials or between the bolt head and the fabric. Washers assist forestall injury to the fabric, cut back friction, and supply a extra even distribution of the fastener's load.

There are a number of sorts of washers, every designed for particular purposes. Flat washers are the commonest and supply a easy, even floor for the nut or bolt head to relaxation in opposition to. Lock washers have a break up or toothed design that stops the fastener from loosening on account of vibration or motion. Fender washers have a bigger diameter and unfold the load over a bigger space, making them very best for skinny or comfortable supplies.

The washer's materials can differ relying on the appliance. Metal washers are frequent, however plastic, rubber, or different specialised supplies could also be utilized in corrosive environments or the place electrical insulation is required. Washers are a small however important element in lots of fastening purposes, making certain the longevity and reliability of the connection.

Rivets

Rivets are everlasting fasteners used to hitch supplies, sometimes in purposes the place welding is just not possible. They include a cylindrical shaft with a head on one finish. When put in, the shaft is deformed to carry the rivet in place, creating a strong and dependable connection. Rivets are generally utilized in development, aerospace, and automotive industries.

There are completely different sorts of rivets, every suited to particular purposes. Stable rivets are probably the most primary sort and require entry to each side of the fabric for set up. Blind rivets, also referred to as pop rivets, may be put in from one aspect, making them very best for conditions the place just one aspect is accessible. Structural rivets, corresponding to bridges and plane, are utilized in purposes requiring excessive energy and sturdiness.

Rivets provide a number of benefits, together with their energy and resistance to vibration. As soon as put in, they supply a everlasting connection that may probably keep robust. Nonetheless, rivets will not be detachable with out

damaging the fabric, so they're finest suited to purposes the place a everlasting connection is desired.

Pins.

Pins are versatile fasteners that maintain parts collectively or align them throughout meeting. They arrive in varied kinds, together with straight, dowel, and cotter pins. Pins are sometimes cylindrical and may be comprised of steel, plastic, or different supplies, relying on the appliance.

Straight or dowel pins are generally used to align parts in woodworking and metalworking. They're inserted into pre-drilled holes to make sure exact positioning and alignment. Cotter pins safe different fasteners, corresponding to bolts or clevis pins. Their break up design permits them to be simply inserted and eliminated, making them very best for non permanent connections.

The primary benefit of pins is their simplicity and ease of use. They supply a fast and efficient technique to maintain parts collectively or align them throughout meeting. Pins can be found in varied sizes and supplies, making them appropriate for a number of purposes.

Clips and Clamps.

Clips and clamps are fasteners that maintain objects collectively or quickly safe them. They arrive in varied kinds, together with spring clips, hose clamps, and cable clips. Clips and clamps are generally utilized in automotive, plumbing, and electrical purposes.

Spring clips, also referred to as retaining clips, maintain parts collectively or in place. They're sometimes fabricated from steel and use spring rigidity to safe objects. Hose clamps safe hoses onto fittings, making certain a good, leak-free connection. Cable clips arrange and safe electrical cables, stopping them from turning into tangled or broken.

Clips and clamps provide a number of benefits, together with ease of use and flexibility. They supply a fast and efficient technique to safe objects quickly or completely, relying on the appliance. Clips and clamps can be found in varied sizes and supplies, making them appropriate for a number of makes use of.

Anchors.

Anchors are fasteners that connect objects to supplies which might be in any other case tough to safe, corresponding to concrete, brick, or drywall. They supply a powerful, dependable connection by increasing throughout the materials because the fastener is put in. Anchors are generally utilized in development, plumbing, and electrical purposes.

There are a number of anchors, every designed for particular supplies and purposes. Plastic anchors are utilized in drywall and different light-weight supplies, increasing because the screw is pushed in to offer a safe maintain. Metallic anchors, corresponding to toggle bolts and wedge anchors, are utilized in heavier supplies like concrete and brick, offering a strong and sturdy connection.

Anchors' most important benefit is their potential to offer a safe connection in supplies which might be in any other case tough to lock. They're simple to put in and out there in varied sizes and supplies, making them appropriate for a variety of purposes.

Adhesives and Tapes.

Adhesives and tapes are fasteners used to bond objects collectively with out the necessity for mechanical fasteners like nails or screws. They supply a strong and sturdy maintain and are generally utilized in development, automotive, and manufacturing purposes.

There are numerous sorts of adhesives, together with epoxy, cyanoacrylate (tremendous glue), and polyurethane. Every sort has its properties and is suited to particular purposes. Epoxy is thought for its energy and resistance to chemical substances, making it very best for heavy-duty purposes. Cyanoacrylate gives a fast, robust bond and is usually used for small, exact purposes.

Tapes like duct, electrical, and double-sided tape are generally used as fasteners. Relying on the appliance, they supply a fast and simple technique to bond objects collectively quickly or completely. Tapes can be found in varied supplies and strengths, making them appropriate for a number of makes use of.

Adhesives and tapes have the principle benefits of versatility and ease of use. They supply a powerful, sturdy bond with out mechanical fasteners, making them very best for varied purposes.

Conclusion

Understanding the various kinds of fasteners and their particular makes use of is important for any development, manufacturing, or DIY undertaking. Nails, screws, bolts, nuts, washers, rivets, pins, clips and clamps, anchors, adhesives, and tapes every have their distinctive traits and benefits.

Whether or not constructing furnishings, assembling equipment, or finishing a easy house restore, understanding which fastener to make use of could make all of the distinction. Every sort of fastener has its strengths and is suited to particular purposes. Their significance can't be overstated, as they make sure the integrity and longevity of assemblies and buildings.

[ad_2]

Supply hyperlink

0 notes

Text

Revolutionizing Construction with Semi-Automatic Brick Making Machines

In the dynamic world of construction, innovative technologies are reshaping the way we build. One such groundbreaking advancement is the semi-automatic brick making machine. As the demand for efficient and cost-effective construction solutions continues to rise, these machines have become a game-changer in the industry. In this article, we’ll explore the benefits and features of semi-automatic brick making machines, and we’ll also shed light on the importance of choosing the right concrete block machine manufacturer.

Understanding Semi-Automatic Brick Making Machines:

Semi-automatic brick making machines have gained popularity for their ability to streamline the brick production process. These machines strike a perfect balance between manual and fully automatic systems, allowing for increased efficiency without compromising on control. With features like auto-material feeding and hydraulic pressing, these machines ensure consistent brick quality while minimizing labor requirements.

Key Features of Semi-Automatic Brick Making Machines:

a. Auto-material Feeding: The automated material feeding system reduces the need for manual intervention, enhancing overall efficiency.

b. Hydraulic Pressing: The hydraulic pressing mechanism ensures uniform and high-quality brick production, meeting industry standards.

c. User-Friendly Interface: Most semi-automatic brick making machines come equipped with user-friendly interfaces, making operation and maintenance hassle-free.

Benefits of Semi-Automatic Brick Making Machines:

a. Cost-Effective: These machines offer a cost-effective solution by reducing labor costs and increasing production rates.

b. Consistent Quality: The automation features ensure consistent brick quality, meeting the stringent requirements of construction projects.

Choosing the Right Concrete Block Machine Manufacturer:

When investing in a semi-automatic brick making machine, the choice of manufacturer plays a crucial role. Consider the following factors:

a. Experience and Reputation: Opt for a manufacturer with a proven track record and positive reviews in the industry.

b. Technology and Innovation: Choose a manufacturer that incorporates the latest technology and innovation into their machines.

c. After-Sales Support: Ensure the manufacturer provides comprehensive after-sales support, including maintenance and troubleshooting assistance.

Conclusion:

Semi-automatic brick making machines are revolutionizing the construction landscape by offering an efficient, cost-effective, and quality-driven solution. To harness the full potential of these machines, it’s imperative to partner with a reliable concrete block machine manufacturer. By making an informed decision, construction companies can propel their projects forward, meeting timelines and quality standards with ease.

View Source: https://medium.com/@raytoneblockm/revolutionizing-construction-with-semi-automatic-brick-making-machines-e8c57ff299f2

0 notes

Text

Ultra tile machines are widely known as Fly Ash Brick Making Machine Manufacturers. Deals in manufacturing and exporting a affordable price range of Fly Ash Brick Manufacturing Machines using basic raw materials and electric components. Our offered by Ultra Tile hold some special attributes like low maintenance, precise in performance and a longer functional life.

#Fly Ash Brick Making Machine Manufacturers#Concrete Block Making Machine Manufacturers#PVC Rubber Mould Manufacturers

0 notes

Text

Homeowner’s Guide to Industrial Bricks & Durability

If you are wondering why historical buildings have remained sturdy over the years, it's due to the unique materials used in their construction, specifically industrial bricks. These prove that industrial bricks are worth the investment because of their lasting effect. Due to their extensive production process, these materials garnered a reputation for durability. To learn why these are wise investments for homeowners, read the full article.

The Manufacturing Process of Industrial Bricks

Clay, shale, and concrete are the popular raw materials used to produce these construction materials. In addition to these elements, bricks are solid because of their firing process, which makes them hard and long-lasting. That said, brick manufacturers follow extensive control measures during production to maintain their quality.

Structural Integrity

A brick’s compressive strength defines its carrying capacity under compression. Manufacturers measure this by using a compression testing machine. This is an important step since these materials are usually used to build load-bearing structures. In doing so, sellers can determine what kind of structures these materials could support. Here are the different compressive resistances of bricks:

First-class: 105 kg/cm2

Second-class: 70 kg/cm2

Common bricks: 35 kg/cm2

Sun-dried: 15 to 25 kg/cm2

These building materials are so durable that there are minimal signs of wear and tear, even a hundred years later. They can withstand different weather conditions, from strong wind and rain to extremely high or low temperatures. This serves as an added perk to homeowners since it requires little maintenance.

Well, here’s a fun fact. Did you know that multiple historic Australian brick houses across the country have stood the test of time? Yes, that’s right. Even during the mid-18th century, many homeowners used industrial bricks to build their homes. At this time, bricks were one of the most affordable materials and served different functional and decorative purposes in homes.

Industrial Bricks Resistance to Environmental Factors

Australia experiences extreme weather conditions all year round, so it's important that homes remain safe despite the harsh temperatures. Bricks can handle extreme temperatures, moisture, and UV exposure. Thanks to their manufacturing process, these materials are resistant to fires and can prevent them from spreading.

Another common problem of homeowners are termites, especially in wooden houses. Fortunately, industrial bricks are pest-resistant and repellent.

Low Maintenance Requirements

If you’re considering using bricks for your home, several brick suppliers are ready to give you tips on maintaining them. While it may seem like a time-consuming process, bricks are actually very easy to maintain. Inspections for these materials are recommended annually, especially on older buildings. One sign of damage owners must watch out for is spotting. Thus, it should be addressed immediately.

Other important things to watch out for are holes, which may allow external elements to enter the home. This is why it's important to have them sealed. Compared to other construction materials like wood and vinyl siding, these are much less difficult to maintain.

Well, choosing bricks for your home will result in long-term cost savings. This is due to minimised repairs and maintenance needs over the years.

Sustainability and Environmental Benefits

The process of creating bricks is far more environmentally friendly than that of other construction materials. Its natural materials make it more sustainable for the environment. Well, this is due to its components commonly being clay, sand, and shale.

Moreover, excess bricks can be recycled and reused for other projects. Homeowners could repurpose these bricks for other building parts, such as landscaping or making these decorative items.

Due to its resistance to numerous natural factors, industrial bricks help boost a home’s energy efficiency. These materials help moderate internal temperatures. They can maintain a building’s warmth during cold temperatures and vice versa in warmer weather.

In addition, bricks can withstand extreme weather conditions with barely any damage. This factor makes them more cost-efficient for homeowners since fewer repair expenses exist. Some suppliers also have carbon offsetting programs that help the environment. They do this by helping fund projects that reduce carbon emissions, such as reforestation.

Aesthetic and Market Value

Brickworks in Australia provide different finishes and colours. This variation allows individuals building a home to choose the aesthetic that fits their vision. For those who want a more trendy look, the Brick of the Year for 2024 has been declared the San Selmo Classico Limewash. It has a strong European heritage and is manufactured in Italy inspired by recycled bricks.

Bricks' timelessness makes them aesthetically pleasing and an ideal option for most homeowners. Aside from this factor, bricks offer a wide range of options. With aesthetics and functionality, bricks can significantly contribute to property value and curb appeal.

Its requirement for skilled labour and specialised building techniques contribute to its overall value and integrity. On the other hand, its style contributes to curb appeal, creating the perfect facade.

Find Brick Suppliers in Australia

While industrial bricks may cost more upfront than other construction materials, they last much longer and require fewer repairs. While building a home is tedious and expensive, builders should consider durability and sustainability. So, whether it’s your forever home or not, finding a reputable supplier is essential for seamless collaboration during construction.

Find the best design and colour of brick for your home with Austral Bricks. Book a free consultation today!

1 note

·

View note

Text

Types of Fasteners: A Comprehensive Guide

Bhansali Fasteners is a well-known Fasteners Manufacturers in India. We manufacture, stock, and provide all types of stainless steel fasteners in various sizes at the greatest prices. Our fastener section is known as We, as a fastener manufacturer, supply a variety of fasteners such as bolts, nuts, screws, washers, and more.

1. Screws

Screws are one of the most versatile and widely used fasteners. They have a threaded shaft that provides strong holding power and are primarily used to join materials such as wood, metal, and plastic.

Wood Screws: These have a coarse thread and a tapered point designed to penetrate wood easily. They are commonly used in carpentry and woodworking projects.

Machine Screws: These have a uniform thread and are used with nuts or threaded holes in metal and plastic parts. They are prevalent in machinery and electronic assemblies.

Self-Tapping Screws: These create their own threads as they are driven into a material, making them ideal for attaching materials without pre-drilling.

Deck Screws: Designed for outdoor use, these screws are coated to resist corrosion and have a sharp point for penetrating decking materials.

2. Bolts

Bolts are similar to screws but differ in their use. They typically require a nut to secure them and are used in applications where high strength is needed.

Hex Bolts: These are characterized by their hexagonal heads and are used in construction and machinery. They come in various grades, indicating their strength.

Carriage Bolts: These have a rounded head and a square neck that prevents them from turning once installed. They are often used in wood-to-wood or wood-to-metal applications.

Lag Bolts: Also known as lag screws, these are large, heavy-duty fasteners used to secure heavy materials like wood and metal. They are commonly used in construction and landscaping.

3. Nuts

Nuts are paired with bolts to fasten materials together. They come in various shapes and sizes to suit different applications.

Hex Nuts: These are the most common type and are used with hex bolts. They come in various materials and finishes.

Lock Nuts: These have a special design to prevent them from loosening under vibration. They include nylon insert lock nuts, jam nuts, and metal lock nuts.

Wing Nuts: These have two large "wings" that allow for easy hand tightening. They are used where frequent adjustments are needed.

4. Washers

Washers are used with screws and bolts to distribute the load and prevent damage to the surface being fastened.

Flat Washers: These provide a larger bearing surface and distribute the load evenly. They are used in most fastening applications.

Lock Washers: These prevent nuts and bolts from turning, slipping, or coming loose due to vibration and torque. They include split lock washers and toothed lock washers.

Fender Washers: These have a larger outer diameter than standard flat washers, providing extra support and load distribution.

5. Rivets

Rivets are permanent fasteners used to join two or more materials together. They are commonly used in construction, automotive, and aerospace industries.

Solid Rivets: These are the most common type and are used in high-stress applications where strength is critical.

Blind Rivets: Also known as pop rivets, these can be installed from one side of the workpiece, making them ideal for applications where access is limited.

Drive Rivets: These are hammered into place and are used in light-duty applications.

6. Anchors

Anchors are used to secure fasteners in materials that are brittle or unable to support the weight of the fastener alone, such as drywall or masonry.

Plastic Anchors: These expand as the screw is driven in, providing a secure hold in drywall and plaster.

Masonry Anchors: These are used in concrete, brick, and stone. Examples include wedge anchors and sleeve anchors.

Toggle Bolts: These have a spring-loaded wing that expands behind the wall, providing strong holding power for heavy loads.

We are also one of the leading Fasteners Supplier in Russia and Fasteners Supplier in Saudi Arabia. We take care of their clients' needs and ensure that all steel bolts, nuts, washers, screws, and fasteners are in order before shipping. Bhansali Fasteners is one of the major Bolt Suppliers in India. Bolts Suppliers in India.low-maintenance, sustainability benefits, and adaptability for fluid transportation in industries such as oil and gas, chemical, food, pharmaceuticals, and construction. They provide reliability and safety. Bolt Suppliers in India is known for its industrial fasteners, which include high-quality bolts, nuts, screws, and washers.

Website: bhansalibolt.com

Source: Fasteners Manufacturers

#Fasteners Manufacturers in India#Fasteners Manufacturers#Bolt Manufacturers in India#Bolt Manufacturers

0 notes