#Concrete block making machine manufacturers

Text

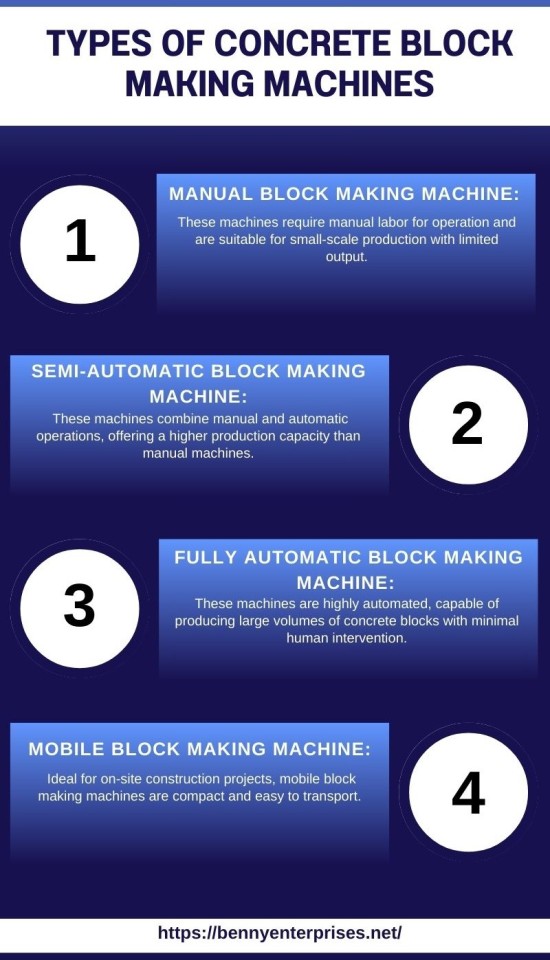

Brick vs Block: Which Construction Material Is Right for You?

Introduction

Choosing the right construction material is a crucial decision for builders and contractors. Concrete bricks and blocks are two popular choices, each with its own set of advantages and applications.

In this blog, we will compare these two construction materials to help builders make informed decisions that align with their project requirements. Additionally, we'll explore the importance of selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers.

Concrete Bricks:

Concrete bricks are widely used in construction due to their versatility and aesthetic appeal. Here are some key benefits and applications of concrete bricks:

1. Aesthetics: Concrete bricks come in a variety of colors and textures, making them an excellent choice for projects that prioritize aesthetics. They can be used to create visually appealing facades, accent walls, and even decorative elements within a structure.

2. Precision: Concrete bricks are manufactured to precise dimensions, ensuring uniformity and ease of installation. This precision makes them ideal for intricate brickwork patterns and designs.

3. Durability: Concrete bricks are known for their strength and durability, making them suitable for load-bearing applications. They can withstand harsh weather conditions, which is essential for structures exposed to the elements.

4. Thermal Insulation: Concrete bricks offer good thermal insulation properties, helping to regulate indoor temperature and reduce energy consumption. This makes them a popular choice for residential construction.

5. Soundproofing: Due to their density, concrete bricks also provide effective soundproofing, which is valuable in reducing noise transfer between rooms or from the outside.

Applications of Concrete Bricks:

Residential homes

Commercial buildings

Retaining walls

Fireplaces

Garden walls

Decorative features

Concrete Blocks:

Concrete blocks, often referred to as cinder blocks or concrete masonry units (CMUs), have their own unique advantages and applications:

1. Structural Strength: Concrete blocks are favored for their structural strength and load-bearing capacity. They are commonly used in the construction of foundations, retaining walls, and other structural elements.

2. Cost-Efficiency: Concrete blocks are generally more cost-effective than bricks. Their larger size means fewer blocks are needed to cover a given area, reducing material and labor costs.

3. Speed of Construction: Due to their size, concrete blocks can be laid quickly, speeding up the construction process. This efficiency is particularly beneficial for large-scale projects.

4. Fire Resistance: Concrete blocks offer excellent fire resistance, which is a critical factor in building safety. They can withstand high temperatures and provide valuable fire protection.

5. Minimal Maintenance: Concrete blocks require minimal maintenance over the years, making them a low-maintenance option for long-lasting structures.

Applications of Concrete Blocks:

Foundations

Basement walls

Retaining walls

Commercial buildings

Industrial facilities

Warehouses

Selecting Reliable Concrete Brick and Block Making Machine Manufacturers

In addition to choosing the right construction material, it's essential to consider the machinery and equipment used in the manufacturing process. High-quality concrete bricks and blocks depend on the reliability of the production equipment. Here's why selecting trustworthy Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is crucial

1. Product Quality: Reliable manufacturers produce machines that meet industry standards, ensuring the consistent production of top-quality bricks and blocks.

2. Efficiency: Modern brick and block making machines offer improved efficiency and output. Investing in machinery from reputable manufacturers can lead to increased productivity and reduced production costs.

3. Support and Service: Established manufacturers often provide comprehensive support and maintenance services for their equipment, minimizing downtime and optimizing machine performance.

4. Innovation: Leading manufacturers invest in research and development, resulting in innovative features and technologies that can enhance the quality and efficiency of brick and block production.

5. Compliance: Ensure that the machinery you purchase complies with safety and environmental regulations in your region.

Conclusion

Both materials have their strengths and applications. Concrete bricks offer versatility and aesthetics, while concrete blocks provide structural strength and cost-efficiency. The choice between these two construction materials depends on your project's specific needs.

Additionally, selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is essential to ensure the consistent production of high-quality building materials. By carefully considering both the construction material and the machinery used in production, builders and contractors can make informed decisions that lead to successful and durable construction projects. Whether it's the material or the machinery, quality, and reliability are key to building a solid foundation for any construction venture.

Benny Enterprises is the best option for your best brick-making machine and block-making machine manufacturers we are also well known for being the best Fly ash brick making machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more.

Contact us for further…

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes

Text

Are You Looking For Concrete Block Making Machine Manufacturers In India

Ultra tile machines Concrete Block Making Machine Manufacturers. These machines have evolved significantly, with modern technology pushing the boundaries of efficiency and versatility. Among these advancements. The invention of the concrete block making machine revolutionized construction by automating the production of concrete blocks. These machines, initially simple and manually operated, evolved into complex These machines are designed to manufacture high-quality concrete tiles with precision, speed, Concrete Block Making Machine Manufacturers.

Visit us for more info.- https://www.paverblockmachine.co/concrete-block-making-machine-manufacturers.html

Contact information

For any kind of query, contact us with the details below.

+91-8766215878, 7272890786

Vill Sorkha Jahidabad, Sector-115, Greater Noida uttar pradesh 201301

Opening : 24×7 Hour

0 notes

Text

Ultra Tile Machine is a one of the leading manufacturer and exporter of PVC Rubber Mould from past decades. We are a Noida situated machinery manufacturing company providing cost effective and innovative solutions to serve all your needs. PVC Rubber Mould - Manufacturers, Suppliers in India.

#PVC Rubber Mould Manufacturers#Cement Brick Making Machine Manufacturers#Concrete Block Making Machine Manufacturers

1 note

·

View note

Text

https://forceaacplant.com/Force aac plant provide the best aac plant, AAC Block Plant, CLC Plant, CLC Block Plant Making Machine at best cost. It is the best aac plant manufacturers, AAC Block Plant, CLC Plant, CLC Block Plant Making Machine Supplier, Manufacturer company in Pune, Mumbai, Nashik, Kolhapur, Satara, sangli, Bangalore, Chennai, Gujrat, Ahmedabad, India

#aac plant#aac plant machinery#aac brick making machine#aac block plant Manufacturers#aac block plant Supplier#aac blocks manufacturing plant cost#aac block plant machinery#aac block machinery manufacturers#foaming agent and raw material for clc plant#horizontal wire cutting machine for aac block#Semi-automatic clc plant manufacturers#clc plant machinery#clc bricks machinery cost#clc plant manufacturers#clc plant suppliers#clc block plant manufacturers#clc block plant suppliers#clc block making machine#cellular light weight (clc) concrete block making machines#clc brick making machine#clc brick making machine manufacturers#concrete foaming agent manufacturers#concrete foaming agent suppliers#foaming agent for concrete#foaming agent for clc blocks#reversible concrete mixer machine manufacturers#reversible concrete mixer machine suppliers#reversible drum concrete mixer machine#reversible concrete mixer with feeder#reversible concrete mixer with inline feeder

0 notes

Text

Revolutionizing Construction with Semi-Automatic Brick Making Machines

Semi-automatic brick making machines are revolutionizing the construction landscape by offering an efficient, cost-effective, and quality-driven solution. To harness the full potential of these machines, it's imperative to partner with a reliable concrete block machine manufacturer. By making an informed decision, construction companies can propel their projects forward, meeting timelines and quality standards with ease.

0 notes

Text

Concrete Blocks - Manufacturing, Classification & Uses

Concrete blocks are nowadays replacing bricks in masonry construction, notably in many multi-storeyed buildings. They are available in three types namely solid, hollow and cellular, widely used for the construction of filler walls and boundary walls in RC framework.

Concrete blocks are usually made in large sizes to make blockwork faster and consume less cement in joints than the brickwork. If the percentage of the voids is more than 25%, then they are hollow blocks and blocks with voids less than 25% are only perforated blocks.

The cellular concrete blocks are generally referred to as lightweight aerated concrete blocks. All these blocks are extensively used for compound walls and non-loadbearing walls.

Hollow blocks are specially made for loadbearing walls, which are useful in reducing a dead load of masonry in buildings. Blocks can also be with cement and sand called cement-sand blocks or with cement and soil called soil-cement blocks which are of low strength and use for low-cost construction.

Manufacturing of Concrete Blocks

BIS recommends a fineness modulus of the combined aggregate between 3.6 to 4 and coarse aggregates used are of size 6 to 12 mm. Lean mixes up to 1:8 are generally used. Concrete mix for concrete blocks should not be richer than one part of the cement to six parts of the volume of combined aggregate.

Concrete blocks can be handmade and also machine-made. The cast block is then cured in a water tank or yard for at least 14 days (water need to be changed at least every 4 days).

After curing, the blocks are dried for 4 weeks before being used in masonry construction. They should be stacked with voids in the horizontal direction to facilitate easy drying, or they should be steam cured and dried.

The whole process allows the complete shrinkage of the block to take place they are laid on the wall, which is very important for strong walls.

Classification of Concrete Blocks

Hollow concrete blocks

Open and Closed cavity-type hollow concrete blocks are classified into three grades:

Grade A - They possess a minimum density of 1500 kg/m³ and are used for load-bearing walls.

Grade B - They have a density below 1500 kg/m¬³ and used for load-bearing walls.

Grade C - These blocks are used for non-load bearing walls and have density more than 1000 kg/m³.

All these blocks are available in decorative facings like fluted facing to provide artistic effects.

Solid concrete blocks

They should be manufactured for specific concrete strength of 4.0 and 5.0 N/mm² in 28 days. These blocks are used as load-bearing walls and have a density of not less than 1800 kg/m³.

Paver blocks

These blocks are solid concrete blocks of different shapes specially made for exterior ground paving on sidewalks, parking lots, driveways, petrol pumps, industrial floors, etc.

AAC Blocks

AAC blocks refer as Autoclaved Aerated Concrete Blocks. These blocks are also termed as light-weight hollow blocks.

They are prepared as solid blocks from cement, water and materials like ground sand, pulverized fly ash together with additives to aerate and stabilize the air bubbles.

The final result is a mixture of thick liquid which is then poured into steel moulds to form large cakes. After some time, the mixture sets and ready to cut into a serious of individual blocks of required size using taut steel wires.

Very light blocks for partition and moderate-weight blocks for light loadbearing walls can be obtained from aac blocks. These blocks do not shrink on drying as the material is obtained by autoclaving.

The autoclaved cement product is crystalline, which is different from the product obtained by normal wet curing or by ordinary steam curing.

Sizes and Tolerances

The nominal dimensions of concrete block as per BIS are as follows:

Length - 600, 500, 450 or 400 mm

Height - 100 or 200 mm

Width - 50, 75, 100, 150, 200, 250 or 300 mm

Actual sizes will be less than 10 mm of mortar thickness. For Concrete and Hollow concrete blocks nominal length 390 mm and height 190 mm. The thickness for loadbearing walls is 190 mm, compound walls 140 mm and for filler walls 90 mm.

These dimensions can easily be achieved in machine-made blocks than handmade blocks. The width of blocks use for load-bearing walls is 200 mm and for parapet or filler walls is 100 mm.

Points to Remember:

The mortar strength should not be more than the strength of the blocks. With high mortar strength, cracks will be less and very large, but with low mortar strength, cracks will be small and distributed.

We should use only blocks that are cured properly for at least 14 days and dried for 4 weeks to avoid shrinkage during construction.

We should not wet the blocks while placing in masonry construction.

Freshly-made and uncured concrete blocks should never be allowed on the work.

Blockwork, particularly ordinary cement sand blocks and soil-cement blocks should not be used as loadbearing walls for concrete slab roof which favours to expand and contract with temperature.

The maximum difference in sizes allowed is ±5 mm in length and ±3 mm in height and width.

They should be protected from rains while being stored as they absorb moisture by wetting and shrinking on drying.

The main disadvantage of concrete blocks is shrinkage due to the movement of moisture content which is not present in bricks. As these blocks are much larger than bricks, any foundation movement will cause blockwork to crack more than the brickwork.

Cement blocks, Concrete blocks, Hollow concrete blocks, solid concrete blocks, Paver blocks, AAC blocks Concrete blocks in Hyderabad

#aac Blocks#aac blocks online#aac block size#Cement blocks#Concrete blocks#Hollow concrete blocks#solid concrete blocks#Paver blocks#AAC blocks

2 notes

·

View notes

Text

A Comprehensive Guide to Hydraulic Paver Block Making Machine

Welcome to "A Comprehensive Guide to Hydraulic Paver Block Making Machine." In the ever-evolving world of construction and infrastructure development, the significance of efficient and eco-friendly building materials cannot be overstated. Paver blocks have emerged as a popular choice due to their durability, versatility, and aesthetic appeal. At the heart of this revolution lies the Hydraulic Paver Block Making Machine – a game-changing technology that has transformed the production of paver blocks.

This article aims to delve into the intricacies of Hydraulic Paver Block Making Machine, providing a detailed exploration of their working principles, key components, and various types available in the market. We will uncover tips and some troubleshooting steps.

Moreover,we will highlight essential considerations for selecting the right machine that aligns with specific project requirements. Whether you are an industry professional seeking to optimize production processes or an enthusiast eager to grasp the mechanics behind paver block manufacturing, this guide will equip you with invaluable insights.

Understanding Hydraulic Paver Block Machine Specifications

When it comes to hydraulic paver block machines, understanding their specifications is crucial for making informed decisions. These machines are essential for producing high-quality, durable, and aesthetically pleasing paver blocks used in various construction projects.

Hydraulic paver block machine specifications encompass a range of key features. The capacity, which determines the number of blocks produced per hour, directly impacts productivity. The molding area size affects the dimensions and shapes of the blocks. Additionally, the power and pressure rating influence the machine's efficiency and performance.

Moreover, it's essential to consider the automation level and control system, as advanced automation ensures precision and ease of operation. The type of molds compatible with the machine allows for versatility in block design. Understanding these specifications empowers buyers to select the ideal hydraulic paver block machine that aligns with their specific project requirements, resulting in cost-effective and successful paving solutions.

Choosing the Right Paver Type: Interlocking vs. Non-interlocking

When it comes to selecting the right paver type for your project, the choice between interlocking and non-interlocking pavers plays a crucial role in determining the overall outcome. Here are some key points to consider for each option:

Interlocking Pavers:

Interlocking pavers are designed to fit tightly together, creating a durable and stable surface.

They offer excellent load-bearing capabilities, making them ideal for driveways, walkways, and high-traffic areas.

The interlocking design provides flexibility, allowing them to withstand ground movement without cracking.

These pavers come in various shapes, colors, and patterns, enabling versatile and visually appealing designs.

Installation is relatively easier due to the interlocking system, reducing labor time and costs.

Repairs are simple, as individual pavers can be replaced without affecting the entire surface.

Non-Interlocking Pavers:

Non-interlocking pavers are more affordable compared to their interlocking counterparts.

They are suitable for light to moderate traffic areas like patios, garden pathways, and decorative landscape elements.

Installation may require more precision and skill as they do not have the interlocking mechanism.

Although repairs are possible, they might be more labor-intensive and could involve replacing larger sections.

Pro Tips for Maintaining Your Paver Block Making Machine

Regular Cleaning: Clean the machine daily to remove any residual concrete and debris that can cause blockages or malfunctions.

Lubrication: Keep all moving parts well-lubricated to reduce friction and prevent wear and tear.

Inspection: Conduct routine inspections to identify and address any signs of wear, damage, or misalignment promptly.

Tighten Bolts: Check and tighten all bolts and nuts regularly to maintain stability and prevent vibrations.

Replace Worn Parts: Replace worn-out parts immediately to prevent further damage and ensure optimal performance.

Calibration: Calibrate the machine regularly to ensure accurate and consistent block dimensions.

Electrical Connections: Inspect and secure electrical connections to prevent electrical issues.

Professional Maintenance: Schedule periodic maintenance by qualified technicians to address complex servicing and extend the machine's lifespan.

Operating Guidelines: Train operators on proper machine operation and safety protocols to prevent mishandling or accidents.

Store in Shelter: Store the machine in a sheltered area to protect it from weather conditions and extend its longevity.

Troubleshooting Hydraulic Paver Block Making Machine

Low Block Quality: Adjust the hydraulic pressure and ensure proper alignment of molds to improve block quality.

Block Disintegration: Check the mix proportions of raw materials and the curing process for better block strength.

Oil Leaks: Inspect hydraulic hoses and connections, repair or replace damaged parts, and refill hydraulic oil as needed.

Excessive Noise/Vibrations: Tighten loose components and bolts, and ensure proper leveling of the machine.

Uneven Block Height: Verify uniform material distribution in the mold and calibrate the machine for consistent block height.

Machine Not Starting: Check power supply, fuses, and safety switches; repair or replace faulty electrical components.

Insufficient Block Production: Clean and maintain the machine regularly, and optimize the production process for efficiency.

Irregular Block Shapes: Inspect mold condition, ensure proper vibration, and adjust mold settings to achieve uniform shapes.

Safety Hazards: Implement strict safety protocols, provide training to operators, and display safety guidelines prominently.

Seek Professional Help: If issues persist, consult experienced technicians or manufacturers for advanced troubleshooting and repairs.

Conclusion

A Comprehensive Guide to Hydraulic Paver Block Making Machine highlights the indispensable role of perfect hydraulic machines in revolutionizing paver block production. The detailed exploration of working principles, types, and maintenance underscores their efficiency and eco-friendly advantages. By embracing these cutting-edge technologies, the construction industry gains a competitive edge in creating durable and visually appealing infrastructure. As Perfect Hydraulic Machines continue to shape the future of paver block manufacturing, their impact on sustainable construction practices remains unparalleled.

#Hydraulic Paver Block Making Machine#perfect hydraulic machines#hydraulic machines#Fly Ash Brick Machine

2 notes

·

View notes

Text

Bolt Manufacturers: Crafting the Backbone of Modern Industry

In the world of construction, automotive, aerospace, and manufacturing industries, bolts may seem small, but their role is anything but insignificant. These humble fasteners hold together the structures that define our daily lives. But what makes a great bolt, and how do bolt manufacturers ensure they meet the rigorous demands of modern engineering?

What Are Bolts, and Why Are They So Essential?

Bolts are more than just pieces of metal. They are the building blocks of infrastructure, machinery, and countless other applications. Without reliable bolts, our bridges would crumble, vehicles would fall apart, and manufacturing processes would grind to a halt.

At their core, bolts serve a simple purpose: they fasten two or more objects together. But not all bolts are created equal. From materials to design, the factors that go into producing a high-quality bolt are numerous and complex.

The Bolt Manufacturing Process: Precision in Every Step

Bolt manufacturing involves a highly intricate process designed to ensure durability, strength, and reliability. Each bolt undergoes several critical stages to meet industry standards.

Material Selection: The first step in creating a top-tier bolt is selecting the right material. Typically, bolts are made from high-strength steel alloys, but stainless steel, titanium, and other metals can also be used depending on the application. The choice of material determines the bolt's strength, corrosion resistance, and durability.

Forging: Once the material is selected, the bolt is forged. This process involves heating the metal to a high temperature and shaping it using specialized machines. Forging gives the bolt its basic shape and enhances its structural integrity.

Threading: After forging, the bolt is threaded. This step is crucial because the threading ensures that the bolt can be fastened securely. Precision is vital here, as even the slightest deviation in the threading process can compromise the bolt's functionality.

Heat Treatment: To further enhance strength, bolts often undergo heat treatment. This involves heating the bolt to specific temperatures and then cooling it rapidly, altering its internal structure to increase hardness and durability.

Surface Coating: Finally, bolts are coated to protect them from corrosion and wear. Depending on the application, coatings such as zinc plating or galvanization may be applied.

Different Types of Bolts and Their Applications

The variety of bolts produced by manufacturers is staggering. Each type is designed for a specific purpose, and selecting the right bolt for the job is crucial to ensure the integrity of the structure or machinery.

Hex Bolts: One of the most common types, hex bolts are used in a wide range of applications, from construction to machinery. Their six-sided head allows for easy tightening and loosening with a wrench.

Carriage Bolts: With a rounded head and a square section beneath it, carriage bolts are often used in wood construction. The square section locks the bolt in place, preventing it from spinning as the nut is tightened.

Anchor Bolts: These are designed to secure objects to concrete. They are commonly used in construction to anchor structural elements to foundations.

Lag Bolts: Known for their large size and strength, lag bolts are used to fasten heavy materials like wood and metal. They are commonly used in construction and deck building.

Eye Bolts: Featuring a loop at one end, eye bolts are used for lifting or attaching cables and chains. They are often found in rigging and lifting applications.

The Future of Bolt Manufacturing: Innovation and Sustainability

As industries evolve, so too does the demand for better, stronger, and more sustainable bolts. Manufacturers are continuously innovating to meet these demands.

Advanced Materials: New materials, such as carbon fiber composites and advanced alloys, are being developed to create bolts that are lighter yet stronger than ever before.

Automation and Precision Engineering: The rise of automation in manufacturing is enabling greater precision in bolt production. Robotic systems and computer-aided design (CAD) ensure bolts are produced with minimal deviation, improving both efficiency and quality.

Sustainable Manufacturing: With increasing emphasis on environmental responsibility, bolt manufacturers are adopting greener production methods. This includes using recycled materials, reducing energy consumption, and minimizing waste in the manufacturing process.

Superb Quality Bolt Manufacturer in India

Bhansali Fasteners is one of the biggest bolt manufacturers in India. Bolts are an excellent choice for fluid transfer in a variety of sectors, including as food, chemicals, oil & gas, pharmaceuticals, and construction. They also provide advantages for sustainability and cheap maintenance costs. They offer dependability and security.

We provide low-cost, high-quality bolts to ensure efficient and effective work. Our bolts meet numerous standards, including ASTM, ASME, ANSI, UNS, and DIN. Our collection, which includes various sizes, thicknesses, bars, and grades, meets a diverse variety of requirements. In addition, we are a major screw manufacturer in India.

One of the top bolt manufacturers in India is Bhansali Fasteners. Bolts are polished in compliance with the dimensions and thickness of the wall specified by the client. An additional choice for situations with greater requirements is heat treatment. We manufacture, provide, and stock a wide variety of bolts in different sizes at competitive prices. Additionally, look at the bolt weight chart.

We are also a Bolt Manufacturers in UAE, Bolt Manufacturer in Bangladesh.

For More Detail

Website: bhansalibolt.com

Product: SS Bolt Manufacturer

Other Product: Fasteners Manufacturers In Saudi Arabia.

#Bolt Manufacturers In India#Bolt Manufacturers#SS Bolt Manufacturer#Bolt Suppliers#Fasteners Manufacturers In Saudi Arabia

0 notes

Text

A Complete Guide to Paver Block Making Machines: Benefits and Applications

Paver blocks have become an essential component in modern construction and landscaping projects. Their versatility, durability, and aesthetic appeal make them a popular choice for driveways, walkways, patios, and various other outdoor surfaces. At the heart of paver block production lies the paver block making machine, a crucial piece of equipment that has revolutionized the manufacturing process. In this comprehensive guide, we'll explore the world of paver block making machines, their benefits, applications, and how BTM Product is leading the way in this innovative industry.

Understanding Paver Block Making Machines

A paver block making machine is a specialized piece of equipment designed to produce interlocking concrete pavers efficiently and consistently. These machines utilize a combination of hydraulic pressure, vibration, and precise mold designs to create high-quality paver blocks in various shapes, sizes, and patterns. The production process involves mixing concrete, filling molds, compacting the mixture, and curing the finished blocks.

Benefits of Using Paver Block Making Machines

1. Increased Productivity

Paver block making machines significantly boost production rates compared to manual methods. With the ability to produce thousands of blocks per day, these machines help manufacturers meet high demand and tight project deadlines.

2. Consistent Quality

The automated nature of paver block making machines ensures uniform compression and vibration, resulting in consistently high-quality blocks. This consistency leads to better structural integrity and a more polished final appearance in paving projects.

3. Cost-Effective Production

By streamlining the manufacturing process and reducing labor requirements, paver block making machines help lower production costs. This cost-effectiveness allows manufacturers to offer competitive pricing while maintaining profitability.

4. Versatility in Design

Modern paver block making machines can produce a wide range of shapes, sizes, and patterns. This versatility allows for creative designs and customization options to suit various architectural and landscaping requirements.

5. Reduced Material Waste

The precise control offered by paver block making machines minimizes material waste during production. This not only reduces costs but also contributes to more sustainable manufacturing practices.

6. Improved Working Conditions

Automating the paver block production process reduces the physical strain on workers, leading to improved safety and working conditions in manufacturing facilities.

Applications of Paver Blocks

The versatility of paver blocks produced by paver block making machines makes them suitable for a wide range of applications:

1. Residential Driveways and Walkways

Paver blocks offer an attractive and durable solution for residential driveways and walkways. Their interlocking design provides excellent load-bearing capacity and resistance to surface cracking.

2. Commercial Parking Lots

The strength and durability of paver blocks make them ideal for high-traffic commercial parking areas. They can withstand heavy vehicle loads while offering excellent drainage properties.

3. Public Sidewalks and Plazas

Many municipalities choose paver blocks for public spaces due to their aesthetic appeal, ease of maintenance, and ability to create visually interesting patterns.

4. Pool Decks and Patios

Paver blocks are a popular choice for pool surrounds and patios, offering slip-resistant surfaces and design flexibility to complement outdoor living spaces.

5. Industrial Flooring

In warehouses and manufacturing facilities, paver blocks provide a durable and easily repairable flooring solution that can withstand heavy machinery and frequent traffic.

6. Erosion Control

Permeable paver blocks are increasingly used in erosion control applications, helping to manage stormwater runoff and prevent soil erosion in vulnerable areas.

7. Landscaping and Gardening

Paver blocks are versatile elements in landscape design, used to create garden paths, retaining walls, and decorative borders.

Our Other Machines

interlocking tiles making machine

fly ash brick making machine

Pioneering Paver Block Making Machine Technology

As a leader in the industry, BTM Product has been at the forefront of paver block making machine technology. Our commitment to innovation and quality has resulted in a range of machines that set new standards in efficiency, versatility, and reliability.

Key Features of BTM Product Paver Block Making Machines:

1. Advanced Hydraulic Systems

Our machines incorporate state-of-the-art hydraulic systems that ensure precise control over compression and vibration, resulting in consistently high-quality paver blocks.

2. User-Friendly Controls

Intuitive control panels and automated features make our paver block making machines easy to operate, reducing the learning curve for operators and minimizing human error.

3. Quick Mold Change System

BTM Product machines are designed with rapid mold change capabilities, allowing manufacturers to switch between different paver block designs quickly and efficiently.

4. Energy-Efficient Operation

We prioritize energy efficiency in our designs, incorporating features that optimize power consumption without compromising on performance.

5. Robust Construction

Built to withstand the demands of continuous operation, BTM Product paver block making machines are known for their durability and low maintenance requirements.

6. Customization Options

We offer customizable solutions to meet specific production needs, allowing manufacturers to tailor their equipment to their unique requirements.

Choosing the Right Paver Block Making Machine

Selecting the appropriate paver block making machine is crucial for maximizing productivity and ensuring high-quality output. Consider the following factors when making your decision:

1. Production Capacity

Assess your current and future production needs to choose a machine with the right capacity. BTM Product offers a range of models to suit various production scales.

2. Block Varieties

Consider the types of paver blocks you plan to produce. Ensure the machine can accommodate the desired shapes, sizes, and patterns.

3. Space Requirements

Evaluate the available space in your production facility and choose a machine that fits comfortably within your layout.

4. Budget Considerations

While initial cost is important, also consider long-term factors such as energy efficiency, maintenance requirements, and potential for scalability.

5. After-Sales Support

Look for a manufacturer like BTM Product that offers comprehensive after-sales support, including training, maintenance services, and readily available spare parts.

Maintenance and Care

Proper maintenance is essential for ensuring the longevity and optimal performance of your paver block making machine. Regular cleaning, lubrication, and inspection of critical components will help prevent downtime and extend the life of your equipment. BTM Product provides detailed maintenance guidelines and offers service contracts to keep your machine running at peak efficiency.

Future Trends in Paver Block Making Machine Technology

The paver block industry continues to evolve, driven by advances in technology and changing market demands. Some emerging trends to watch include:

1. Increased Automation

Future paver block making machines are likely to incorporate more automated features, further reducing the need for manual intervention and improving efficiency.

2. Sustainable Production

As environmental concerns grow, we can expect to see machines designed to produce more eco-friendly paver blocks using recycled materials and energy-efficient processes.

3. Smart Manufacturing

Integration with IoT (Internet of Things) technology will allow for real-time monitoring and optimization of the production process.

4. Enhanced Customization

Advancements in mold design and production techniques will enable even greater customization options for paver blocks, meeting the growing demand for unique and personalized designs.

Some Blogs

Automatic Fly Ash Brick Making Machine at the Best Price

Get the Best Fly Ash Brick Making Machine in India

Conclusion

Paver block making machines have transformed the construction and landscaping industries, offering a efficient and versatile solution for producing high-quality interlocking pavers. The benefits of increased productivity, consistent quality, and design flexibility make these machines an invaluable asset for manufacturers and contractors alike.

As a pioneer in this field, BTM Product continues to push the boundaries of what's possible with paver block making machine technology. Our commitment to innovation, quality, and customer satisfaction ensures that we remain at the forefront of this dynamic industry.

Whether you're a seasoned manufacturer looking to upgrade your equipment or a newcomer to the paver block industry, understanding the capabilities and benefits of paver block making machines is crucial for success. By choosing the right machine and implementing best practices in production and maintenance, you can unlock new levels of efficiency and quality in your paver block manufacturing process.

As we look to the future, the paver block industry is poised for continued growth and innovation. With advancements in technology and a growing emphasis on sustainable construction practices, paver block making machines will play an increasingly important role in shaping our built environment. By staying informed about the latest developments and partnering with industry leaders like BTM Product, you can position your business for long-term success in this exciting and evolving field.

0 notes

Text

Selecting the right concrete block making machine for your construction business is a significant decision that can impact your productivity, profitability, and overall success. Benny Enterprises is the best choice for all your needs, we are the finest Concrete Brick Making Machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes

Text

Silicone Plastic Mold Manufacturers | Silicone Plastic Mold - Ultra Tile Machine

As distinguished Silicone Plastic Mold Manufacturers, Ultra Tile Machine precision-engineered molds exhibit excellence in design and functionality, meeting the diverse needs of clients across various sectors Ultra Tile Machine delivers molds that enable efficient and precise production processes. ultra Tile Machine Meeting the diverse needs of clients across various sectors. Utilizing cutting-edge technology and a commitment to superior craftsmanship is a trusted name in the industry. With a proven track record of innovation and quality, silicone plastic mold manufacturing, serving industries worldwide.

visit us for more info.- https://www.paverblockmachine.co/silicone-plastic-mould.html

Contact Us

Contact information

For any kind of query, contact us with the details below.

+91-8766215878, 7272890786

Vill Sorkha Jahidabad, Sector-115, Greater Noida uttar pradesh 201301

Opening : 24×7 Hour

0 notes

Text

Ultra tile machines are widely known as Fly Ash Brick Making Machine Manufacturers. Deals in manufacturing and exporting a affordable price range of Fly Ash Brick Manufacturing Machines using basic raw materials and electric components. Our offered by Ultra Tile hold some special attributes like low maintenance, precise in performance and a longer functional life.

#Fly Ash Brick Making Machine Manufacturers#Concrete Block Making Machine Manufacturers#PVC Rubber Mould Manufacturers

0 notes

Text

Advancements in Smart Materials for the Next Generation of Mechanical Engineering

Arya College of Engineering & I.T. is revolutionizing the field of mechanical engineering, enabling the creation of innovative systems and devices that can adapt to their environment. As research and development continue to push the boundaries of material science, the potential applications of smart materials in mechanical engineering are vast and transformative. Here's a glimpse into the future of smart materials in this field.

Intelligent Robotics

Smart materials are poised to revolutionize the world of robotics, paving the way for machines that can adapt, regenerate, and change shape. Soft robots composed of smart materials will soon move with the grace of living creatures, while microrobots made from smart materials will deliver targeted medicine to diseased cells. The development of lifelike prosthetic limbs with artificial muscles and tendons is also a promising application of smart materials in robotics.

Self-Healing and Adaptive Structures

Smart materials have the potential to transform the construction industry by enabling self-healing and adaptive structures. Buildings made with smart materials can adjust their windows to block sunlight, self-repair cracks in concrete, and even withstand extreme weather events like earthquakes and hurricanes. These materials can dissipate energy, making them ideal for enhancing the resilience and longevity of civil structures.

Energy Harvesting and Storage

Smart materials are revolutionizing the field of energy harvesting and storage. For example, piezoelectric materials can convert mechanical vibrations into electrical energy, while thermoelectric materials can generate power from temperature differences. These materials have the potential to power a wide range of devices, from wearable electronics to remote sensors, without the need for batteries.

Biomedical Applications

The unique properties of smart materials make them highly suitable for biomedical applications. Shape memory alloys can be used in minimally invasive surgeries, as they can be easily inserted into the body and then triggered to change shape, allowing for the deployment of stents or other medical devices. Smart materials can also be used to create drug delivery systems that release medication in response to specific stimuli, such as changes in pH or temperature.

Wearable Technology

Smart materials are at the heart of wearable technology, enabling devices that can respond to bodily fluids like sweat and detect foreign invaders like viruses. These materials must be comfortable enough for people to wear regularly, making the engineering behind them crucial. Smart sensors that detect blood sugar levels and deliver insulin are just one example of how smart materials are transforming wearable technology.

Challenges and Future Outlook

While the potential of smart materials in mechanical engineering is immense, there are still challenges to overcome. These include cost, scalability, integration with existing technologies, and durability. However, significant progress has been made in recent years, driven by advancements in nanotechnology, material science, and manufacturing techniques. Continued research and collaboration across disciplines are essential for further unlocking the potential of smart materials and accelerating their widespread adoption.As the field of smart materials continues to evolve, it is clear that they will play a crucial role in shaping the future of mechanical engineering. By harnessing the unique properties and adaptive behavior of these materials, engineers can develop innovative technologies and systems that enhance efficiency, sustainability, and quality of life. From intelligent robotics to self-healing structures and biomedical devices, the applications of smart materials are vast and transformative, promising to revolutionize the way we approach mechanical engineering challenges.

0 notes

Text

OTC Power's Advanced Block Machines, Revolutionizing Construction Across Africa and the UAE

In today's rapidly evolving construction industry, the demand for durable, sustainable, and cost-effective building solutions has never been higher. OTC Power, a leading manufacturer and supplier of block machines, is paving the way for modern construction by providing cutting-edge machinery designed to meet the unique needs of diverse markets. From the UAE to Angola, Congo, Uganda, Rwanda, and South Africa, OTC Power’s block machines are playing a crucial role in transforming the landscape of urban and rural infrastructure.

The Importance of Block Machines in Modern Construction: Block machines have become an essential tool in the construction industry, offering an efficient and reliable way to produce high-quality concrete blocks for a wide variety of projects. Whether for residential buildings, commercial spaces, or infrastructure projects, block machines ensure precision, strength, and cost savings compared to traditional methods. OTC Power’s block machines are designed to meet the demands of both large-scale and small-scale construction, making them ideal for use in growing economies like those of Africa and the UAE.

#dieselgeneratorinuae#dieselgeneratorinsharjah#dieselgeneratorindubai#dieselgeneratorinuganda#dieselgeneratorincongo#dieselgeneratorinangola#dieselgeneratorinrwanda#dieselpowergeneratorinuae#dubaigeneratorcompany#dubaigeneratorcompanyinsharjah#generatorfactoryinuae#generatorsupplierinuae#generatorinuae#generatorindubai#generatorinafrica#solarpowerinuae#generatorsparepartsinuae#cumminsgenerator#towerlightinuae#perkinsgenerator#perkinsdieselgeneratorinuae#perkinsgeneratorinuae#perkinsgeneratorindubai#perkinsinuae#perkinsindubai#constructioniteminuae#constructioniteminsharjah#constructionitemindubai#constructionmachineinuae#constructionmachineinsharjah

0 notes

Text

Revolutionizing Construction with Semi-Automatic Brick Making Machines

In the dynamic world of construction, innovative technologies are reshaping the way we build. One such groundbreaking advancement is the semi-automatic brick making machine. As the demand for efficient and cost-effective construction solutions continues to rise, these machines have become a game-changer in the industry. In this article, we’ll explore the benefits and features of semi-automatic brick making machines, and we’ll also shed light on the importance of choosing the right concrete block machine manufacturer.

Understanding Semi-Automatic Brick Making Machines:

Semi-automatic brick making machines have gained popularity for their ability to streamline the brick production process. These machines strike a perfect balance between manual and fully automatic systems, allowing for increased efficiency without compromising on control. With features like auto-material feeding and hydraulic pressing, these machines ensure consistent brick quality while minimizing labor requirements.

Key Features of Semi-Automatic Brick Making Machines:

a. Auto-material Feeding: The automated material feeding system reduces the need for manual intervention, enhancing overall efficiency.

b. Hydraulic Pressing: The hydraulic pressing mechanism ensures uniform and high-quality brick production, meeting industry standards.

c. User-Friendly Interface: Most semi-automatic brick making machines come equipped with user-friendly interfaces, making operation and maintenance hassle-free.

Benefits of Semi-Automatic Brick Making Machines:

a. Cost-Effective: These machines offer a cost-effective solution by reducing labor costs and increasing production rates.

b. Consistent Quality: The automation features ensure consistent brick quality, meeting the stringent requirements of construction projects.

Choosing the Right Concrete Block Machine Manufacturer:

When investing in a semi-automatic brick making machine, the choice of manufacturer plays a crucial role. Consider the following factors:

a. Experience and Reputation: Opt for a manufacturer with a proven track record and positive reviews in the industry.

b. Technology and Innovation: Choose a manufacturer that incorporates the latest technology and innovation into their machines.

c. After-Sales Support: Ensure the manufacturer provides comprehensive after-sales support, including maintenance and troubleshooting assistance.

Conclusion:

Semi-automatic brick making machines are revolutionizing the construction landscape by offering an efficient, cost-effective, and quality-driven solution. To harness the full potential of these machines, it’s imperative to partner with a reliable concrete block machine manufacturer. By making an informed decision, construction companies can propel their projects forward, meeting timelines and quality standards with ease.

View Source: https://medium.com/@raytoneblockm/revolutionizing-construction-with-semi-automatic-brick-making-machines-e8c57ff299f2

0 notes

Text

What is AAC Block Manufacturing Process?

In recent years, Autoclaved Aerated Concrete (AAC) blocks have revolutionized the construction industry. These lightweight, precast foam concrete blocks offer excellent thermal insulation, soundproofing, and fire-resistant properties, making them a preferred choice for modern construction. At Essarcon, we take pride in manufacturing high-quality AAC block Machines that adhere to the highest standards. Here’s an in-depth look at our AAC block manufacturing process.

1. Raw Material Preparation

The foundation of any great product lies in the quality of its raw materials. For AAC blocks, the essential ingredients are:

Cement: Acts as a binder and gives the blocks their structural integrity.

Lime: Works as a major constituent that reacts with the aluminum powder to create the desired aeration.

Sand or Fly Ash: Provides the siliceous component, contributing to the strength of the blocks.

Gypsum: Enhances the properties of the mixture and helps in the setting process.

Aluminum Powder: This is the key to creating the aeration process, forming tiny bubbles within the mix.

All raw materials are thoroughly inspected for quality before they enter the manufacturing process.

2. Mixing and Dosing

The carefully measured raw materials are then fed into a large mixer. Water is added to the dry mix to create a slurry. This slurry is mixed at a high speed to ensure a uniform consistency. The aluminum powder is added at this stage, triggering a chemical reaction that releases hydrogen gas. This gas forms tiny bubbles within the slurry, giving the AAC blocks their characteristic lightweight and porous structure.

3. Pouring and Rising

Once the mixing is complete, the slurry is poured into large molds. The molds are designed to accommodate the expansion of the slurry as it rises. Over the next few hours, the hydrogen gas continues to be released, causing the slurry to expand to about twice its original volume. This rising process forms millions of tiny air pockets within the material, which are crucial for the AAC block’s insulation properties.

4. Pre-Curing

After the slurry has risen and solidified, the resulting mass, known as a “green cake,” is ready for pre-curing. The molds are transferred to a pre-curing chamber where they are allowed to set for a few hours. During this stage, the green cake gains enough strength to be cut into blocks without losing its shape.

5. Cutting

Once the pre-curing process is complete, the green cake is demolded and transferred to a cutting machine. This machine precisely cuts the cake into blocks of the desired dimensions. The blocks can be customized to different sizes depending on the construction requirements. Essarcon’s cutting-edge technology ensures minimal waste and maximum precision during this stage.

6. Autoclaving

The most critical phase in the AAC block manufacturing process is autoclaving. The freshly cut blocks are placed in an autoclave, a large pressure chamber, where they are subjected to high temperature and pressure. The blocks are steamed at approximately 180°C (356°F) under a pressure of around 12 bars. This autoclaving process takes about 10 to 12 hours.

During autoclaving, the lime reacts with the silica in the sand or fly ash to form calcium silicate hydrates. This reaction gives the AAC blocks their strength and durability. The process also locks in the tiny air bubbles within the blocks, ensuring their lightweight and insulating properties.

7. Quality Control and Packaging

Once the autoclaving process is complete, the blocks are left to cool. They undergo a rigorous quality control process to ensure they meet the required standards for strength, density, and dimensions. Any blocks that do not meet these standards are recycled back into the production process.

Finally, the blocks are packaged and prepared for shipment to construction sites. At Essarcon, we ensure that our AAC blocks are carefully handled to prevent damage during transportation, guaranteeing that they arrive at your site in perfect condition.

8. Environmental Benefits

In addition to their construction benefits, AAC blocks are also environmentally friendly. The manufacturing process uses fly ash, a byproduct of thermal power plants, which helps in reducing industrial waste. The lightweight nature of AAC blocks reduces the overall structural load, leading to savings in steel and concrete usage. Moreover, the superior insulation properties of AAC blocks contribute to energy savings in buildings.

Conclusion

AAC blocks manufacturing process is simple and easy. Whether one is building a residential, commercial, or industrial project, AAC blocks offer the strength, durability, and energy efficiency needed to create long-lasting structures.

For more information on AAC Block Manufacturing Process contact Essarcon 8600 210 200

0 notes