#Conducting Polymers Report

Explore tagged Tumblr posts

Text

The conducting polymers market is projected to be valued at $7.35 billion in 2024, with an expected expansion at a CAGR of 7.97% to reach $15.82 billion by 2034.

#Conducting Polymers Market#Conducting Polymers Report#Conducting Polymers Industry#Advanced Materials#BISResearch

0 notes

Text

Rising Demand in Flexible Electronics Fuels Conductive Polymers Market Growth

Rising Demand for Lightweight, Flexible, and Efficient Electronics Fuels Growth in the Conductive Polymers Market.

The Conductive Polymers MarketSize was valued at USD 5.92 Billion in 2023 and is expected to reach USD 11.88 Billion by 2032 and grow at a CAGR of 8.07% over the forecast period 2024-2032.

The Conductive Polymers Market is witnessing robust growth due to increasing demand for lightweight, flexible, and efficient electronic components across industries. Conductive polymers are organic polymers that conduct electricity, combining the mechanical properties of plastics with the electrical conductivity of metals or semiconductors. Their applications span displays, batteries, sensors, actuators, antistatic coatings, and solar cells. With the rapid development of wearable technology, EVs, and IoT devices, the market is poised for sustained expansion.

Key Players:

3M

Solvay

SABIC

PolyOne Corporation

Lehmann & Voss & Co.

Advanced Polymer Materials Inc.

Agfa-Gevaert Group

Celanese Corporation

Eeonyx

Heraeus Holding

Future Scope & Emerging Trends:

The conductive polymers market is evolving rapidly, fueled by innovation in flexible electronics, organic solar cells, and high-performance batteries. As industries push toward lightweight and sustainable materials, conductive polymers offer an eco-friendly alternative to traditional conductive metals. Key trends include the development of highly conductive nanocomposites, polyaniline (PANI) and polypyrrole (PPy) blends, and bio-compatible polymers for medical applications. The rise of 5G networks, smart fabrics, and printed electronics further amplifies the scope for conductive polymers. Additionally, growing interest in energy storage and supercapacitors is propelling R&D investments worldwide.

Key Points:

Conductive polymers combine electrical conductivity with flexibility and lightweight properties.

Widely used in electronics, energy, automotive, and biomedical industries.

Prominent materials include polythiophene, polyaniline, and polypyrrole.

Increasing use in OLED displays, solar panels, and smart textiles.

Asia-Pacific remains the largest market, driven by electronics and EV growth.

Conclusion:

The Conductive Polymers Market is on a strong upward trajectory, supported by technological innovation and the growing adoption of smart and sustainable materials. As demand increases for next-gen electronics, renewable energy systems, and advanced medical devices, conductive polymers will play an integral role in shaping the future of multiple high-growth industries. With continued R&D and market expansion, this sector holds exciting potential for investors and innovators alike.

Read Full Report: https://www.snsinsider.com/reports/conductive-polymers-market-4742

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Conductive Polymers Market#Conductive Polymers Market Size#Conductive Polymers Market Share#Conductive Polymers Market Report#Conductive Polymers Market Forecast

0 notes

Text

0 notes

Text

Successful synthesis of helical conductive polymers with circular polarization activity in response to magnetic fields

Researchers at University of Tsukuba have synthesized a helical, magnetically active conductive polymer with exceptionally high optical activity using cyclosporine A as a helix-inducing agent. This polymer exhibits distinct absorption of circularly polarized light, corresponding to the orientation of an applied magnetic field. In the realm of semiconductors, spintronics—a technology that manipulates electronic devices by controlling electron spin within magnetic fields—has gained considerable attention for its potential application in communication technologies. Traditionally, research in this area has predominantly focused on inorganic magnetic materials; only a few studies have investigated organic electronics, particularly conductive polymers. Drawing on extensive experience in topological magnetism dating back to the late 1990s, the University of Tsukuba research team has reported several innovative organic magnetic materials in the spintronics domain.

Read more.

11 notes

·

View notes

Text

Achieving High-Precision Material Testing with Star EMBSYS Servo Tensile Testing Machines

In modern material science and quality assurance, precision testing is critical for ensuring product reliability, safety, and compliance. Tensile strength—the ability of a material to withstand pulling forces—is a fundamental property that influences product design across industries such as automotive, aerospace, construction, electronics, and packaging. A servo tensile testing machine is an essential tool for conducting such tests with high accuracy and repeatability. Among the leading providers in this domain, Star EMBSYS has earned a reputation for delivering advanced, durable, and efficient tensile testing systems that meet international standards and industrial demands.

Precision Engineering with Intelligent Servo Control

Star EMBSYS's servo tensile testing machines are built with high-end servo motors and closed-loop control systems that provide exceptional accuracy in force application and displacement measurement. These systems are ideal for testing a wide range of materials including metals, polymers, composites, textiles, and rubber. Whether for R&D or routine quality checks, Star EMBSYS machines offer controlled testing environments with programmable test parameters, user-defined speed settings, and automatic data logging.

Equipped with load cells of varying capacities, high-resolution extensometers, and digital controllers, Star EMBSYS machines provide accurate stress-strain curves and real-time feedback on material behavior under tensile loads. Their advanced software suite allows operators to analyze mechanical properties such as yield strength, ultimate tensile strength, elongation, and modulus of elasticity with ease. Results are displayed in graphical and tabular formats, enabling quick interpretation and reliable decision-making.

What truly differentiates Star EMBSYS is the seamless integration of mechanical precision with software intelligence—enabling automated test cycles, data export, and report generation to reduce human intervention and enhance efficiency.

Tailored Solutions with Industry-Focused Features

Understanding that different industries have varying testing requirements, Star EMBSYS offers custom-built servo tensile testing machines tailored to specific applications. From compact benchtop models for academic institutions to high-capacity floor-standing units for industrial testing labs, the company provides scalable solutions without compromising on performance.

Star EMBSYS machines support a wide range of grips and fixtures to accommodate samples of different shapes, sizes, and materials. This flexibility allows manufacturers and quality control labs to conduct a full range of tests, including tensile, compression, flexural, and peel tests. Moreover, the machines are designed with operator safety in mind, featuring protective enclosures, overload protection, and emergency stop systems.

In addition to manufacturing top-tier equipment, Star EMBSYS offers robust after-sales support, calibration services, operator training, and remote diagnostics. Their commitment to customer satisfaction and technical excellence makes them a preferred partner across sectors including automotive OEMs, aerospace manufacturers, research labs, and educational institutions.

Conclusion

In today’s competitive industrial landscape, investing in a servo tensile testing machine is crucial for maintaining material integrity and meeting quality standards. Star EMBSYS delivers state-of-the-art solutions that combine accuracy, flexibility, and reliability—backed by superior service and customization options. For businesses that prioritize precision testing and product performance, Star EMBSYS stands out as a trusted and forward-thinking provider in the tensile testing segment.

Visit:- https://www.starembsys.com/servo-tensile-testing-machine.html

0 notes

Text

Maintaining Your HVAC System with AC Pro-Tech Aerosol: The Ultimate AC Coil Cleaning Solution

Keeping your HVAC system operating smoothly and for a long time is very important, especially where there are lots of high humidity and corrosive substances. Cleaning your system’s AC coils with a good cleaner is very effective in protecting your system. One of the main products here is the AC Pro-Tech Aerosol which is the best from AC Products USA.

Understanding the Importance of AC Coil Maintenance

Jacobs (2023) reports that it is critical to service your HVAC regularly to ensure that it continues to operate efficiently, reliably and safely. So don't let maintenance go if you want to lose the slow and take on the low, low energy bills, that is. It also reduces dust and debris in the home, which is better for your lungs and can also increase system life and reduce your carbon footprint, helping out several good causes. Particularly, the AC cooling coils one section of your HVAC that is responsible for transferring heat. Eventually, these coils might attract all manner of garbage and dirt that will weigh them down and bust the thing loose. The machines will run well and last long, if you clean the AC coils frequently and use a good cleaner spray.

Introducing AC Pro-Tech Aerosol

The AC Pro-Tech Aerosol is a specially formulated AC coil cleaning spray designed to provide a protective coating to your HVAC system. This product not only cleans but also offers long-lasting protection against corrosion, UV rays, and other environmental factors.

Key Features:

Modified Acrylic Polymer Base: Provides a hard, clear coating that allows heat transfer while preventing corrosion.

UV Stable: Protects against material degradation due to ultraviolet rays.

Non-Conductive: Safe for use on electronic components within the HVAC system.

Flexible Barrier: Creates an oxygen barrier that remains flexible over time.

For more details and to purchase, visit the AC Pro-Tech Aerosol product page.

Why Choose AC Pro-Tech Aerosol?

When it comes to maintaining your AC Pro air conditioning system, the AC Pro-Tech Aerosol stands out for several reasons:

Comprehensive Protection: It shields the PCB, cabinet, and coils with a single application.

Ease of Use: Found in a simple spray, one can put it on easily.

Tested and Trusted: It went through a test that was very fast, but very hard, so we know it will last.

Versatility: It can work on new and old machines, making them last longer.

Application Guidelines

To achieve the best results with the AC Pro-Tech Aerosol, follow these steps:

Preparation: Ensure the HVAC system is turned off and clean the surface thoroughly.

Application: Shake the can well and spray evenly over the areas that you want, also on coils, cabinets, and PCBs.

Drying: Let the coat dry fully before you turn the system back on.

Maintenance: Check the system often and put it back on if you need to keep the best cover.

Complementary Products

For a comprehensive maintenance routine, consider using the AC Pro-Clean No Rinse Foaming HVAC Coil Cleaner in conjunction with the AC Pro-Tech Aerosol. This product is made especially to work well with machine parts with a cover on the outside. It can clean a part of the machine that makes heat and a part that gets rid of heat without taking away the cover.

Conclusion

It is important to maintain your HVAC system to guarantee it lasts and performs well. Taking on the AC Pro-Tech Aerosol is a good way to maintain your car because it cleans and protects at the same time. Because of its distinctive way of being made, it is chosen by professionals and homeowners.

More details and a range of other products are available at AC Products USA.

FAQs

1. How is AC Pro-Tech Aerosol distinguished from other coil cleaners?

While normal cleaners only clean, AC Pro-Tech Aerosol offers defense against corrosion and ultraviolet rays, which helps your HVAC equipment last longer.

2. Am I allowed to use AC Pro-Tech Aerosol on any type of HVAC system?

Yes, it is built to fit well with most HVAC systems, both in homes and commercial spaces, as well as those made by Protech AC.

3. Does AC Pro-Tech Aerosol need to be applied often?

Regularly check your system and respray it with aerosol, annually or as required by the current conditions.

4. Can the HVAC electronic parts be safely exposed to the aerosol?

Absolutely. Because it’s non-conductive, it is safe to apply to PCBs and other electronic parts.

5. Where do I find AC Pro-Tech Aerosol?

You can get the product from AC Products USA.

1 note

·

View note

Text

Is Activated Bleaching Earth the Key to Sustainable Oil Processing?

The activated bleaching earth market has traditionally revolved around its role in the refining of edible oils and fats, lubricants, and waxes. Known for its adsorptive properties and wide surface area, this naturally occurring clay—usually processed from bentonite—is widely used to remove color, impurities, and oxidation products. While the broader applications of bleaching earth are well-documented, one emerging area that has not garnered enough mainstream attention is the increasing relevance of regenerable activated bleaching earth (R-ABE) in tandem with the growth of bio-based oils.

This shift is not merely technical; it represents a strategic evolution aligned with global trends in sustainability, circular economy principles, and cost-efficient refining. As plant-derived oils—especially used cooking oils (UCO), algal oils, and bio-lubricants—gain traction as feedstocks for biodiesel and specialty chemicals, the demand for more sustainable and reusable filtration media like R-ABE is rising rapidly.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/rep-gb-15287

Activated Bleaching Earth in Context: From Conventional to Circular

Historically, the bleaching process in oil refining has been linear: activated bleaching earth is used once and then discarded, often in landfills or as a filler in construction materials. This approach, while economically viable in the past, is facing growing scrutiny due to both environmental regulations and the rising costs of raw materials. Countries with limited access to high-quality bentonite deposits, such as Indonesia, Brazil, and parts of Europe, are especially affected by increasing import dependency and price volatility.

At the same time, the global market for bio-based oils is expanding significantly. According to a 2035 report by Future Market Insights, the activated bleaching earth sales are projected to grow from a valuation of USD 2,938.4 million in 2024 to USD 5,132 million by 2035, showcasing a steady 5.2% CAGR over the forecast period. This shift calls for more efficient, cost-effective, and environmentally responsible refining processes, making regenerable bleaching clays an attractive proposition.

What Makes Regenerable Activated Bleaching Earth Different?

Unlike conventional variants, R-ABE is engineered to retain structural integrity and adsorption capacity over multiple cycles. This is achieved through thermal or chemical regeneration processes that restore its surface properties without significantly degrading performance. Manufacturers like Clariant and AMC (Ashapura Minechem Ltd.) are already piloting R-ABE technologies that enable up to five reuse cycles, reducing total material consumption by nearly 70%.

The ability to regenerate bleaching earth directly reduces the carbon footprint associated with mining, processing, and disposal. In lifecycle assessments conducted by the Indian Institute of Chemical Technology (IICT), the use of R-ABE in vegetable oil refining showed a 46% decrease in total environmental impact compared to single-use alternatives. Moreover, the economic savings from reduced clay usage and lower waste disposal costs have attracted mid-sized refiners and biodiesel producers looking to improve operational efficiency.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 ��𝐨𝐰: https://www.futuremarketinsights.com/reports/activated-bleaching-earth-market

Application Synergy: R-ABE in Bio-Lubricants and Used Cooking Oil Processing

One of the fastest-growing applications of regenerable activated bleaching earth is in the treatment of used cooking oils, which are commonly repurposed as feedstock for renewable diesel and hydrotreated vegetable oil (HVO). These oils typically contain high levels of polymers, free fatty acids, and pigments—compounds that can severely hinder downstream processing if not properly removed.

R-ABE's high affinity for polar compounds and its ability to maintain porosity after multiple regeneration cycles make it ideal for this application. In a pilot study conducted by the BioEnergy Research Center in Malaysia, R-ABE was used to treat UCO over three regeneration cycles, maintaining 88% of its original bleaching efficiency while reducing the overall refining cost by 27%.

In the domain of bio-lubricants—where high oxidative stability and purity are critical—R-ABE helps remove metal contaminants and trace peroxides, extending shelf life and improving product performance. The use of R-ABE in this context also aligns with the stringent quality standards of REACH and USDA BioPreferred certifications.

Challenges to Adoption: Supply Chain, Technology, and Market Awareness

Despite its benefits, the widespread adoption of regenerable activated bleaching earth is not without challenges. One major hurdle is the lack of standardization in regeneration processes. Thermal regeneration, while effective, requires significant energy input and can damage clay structure if not properly controlled. Chemical regeneration, on the other hand, involves solvent recovery systems that may not be economically viable for smaller facilities.

Another concern is the limited availability of commercially proven R-ABE products. While some large-scale players in Asia and Europe are investing in this space, market awareness among small-to-medium oil refiners remains low. Policy support may eventually tilt the balance. With tightening EU directives on industrial waste and the growing global emphasis on carbon accounting, the ability to regenerate filter media could soon become a regulatory requirement rather than an option.

Minerals & Ores Industry Analysis: https://www.futuremarketinsights.com/industry-analysis/minerals-and-ores

Conclusion: A Sustainable Pivot for the Activated Bleaching Earth Market

The evolution of the activated bleaching earth market is quietly entering a new phase. Driven by the rising use of bio-based oils and the pressing need for circular industrial practices, regenerable activated bleaching earth is emerging as both a technical and strategic solution. It bridges the gap between high-performance oil purification and sustainable resource management, offering long-term cost savings and environmental benefits.

Though not yet a mainstream topic in market analysis, the potential of R-ABE to redefine oil purification processes is undeniable. As bio-oil refining expands and sustainability becomes central to procurement decisions, regenerable bleaching clays could transform from a niche innovation into an industry standard—ushering in a new era for an otherwise traditional material.

Top Segments Studied in the Activated Bleaching Earth Market Research Report

By Material Type:

In terms of Material Type, the industry is divided into Natural Bleaching Earth and Acid-activated Bleaching Earth.

By End-Use Industry:

In terms of End-Use, the industry is divided into Food and Beverage, Oil and Gas, Cosmetics and Personal Care, Chemical Processing, Pharmaceuticals, and Others.

By Region:

The report covers key regions, including North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia, and the Middle East and Africa (MEA).

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

0 notes

Text

Europe Flooring Market Global Trends, Statistics, Size, Share, Regional Analysis by Key Players (2022-2028)

The Europe flooring market is expected to grow from US$ 75.48 million in 2022 to US$ 108.52 million by 2028; it is estimated to grow at a CAGR of 6.2% from 2022 to 2028.

Europe Flooring Market Introduction

Expect significant expansion in the European flooring market, driven by two key factors: the growing popularity of loose lay flooring and the integration of aqua+ technology in laminate options. Top manufacturers like Aqua Flooring, Kronotex, Senhong, and Egger are supplying laminate flooring, adhesives, and plasticizers that feature advanced waterproofing. This makes their products an excellent choice for environments susceptible to moisture, including kitchens, bathrooms, hallways, and commercial properties. These firms have also developed a patented waterproof acoustic flooring adhesive that sets a new industry benchmark for moisture resistance. Moreover, the market will be buoyed by the increasing adoption of flooring solutions with interlocking mechanisms for easy installation and self-adhesive applications, offering convenient do-it-yourself solutions. These innovations are poised to attract new customers and enable vendors to extend their reach into burgeoning markets, thereby strongly fueling the Europe flooring market's growth throughout the forecast period.

Download our Sample PDF Report

@ https://www.businessmarketinsights.com/sample/BMIRE00025823

Europe Flooring Strategic Insights

Strategic insights for the Europe Flooring market offer a comprehensive, data-driven analysis of the industry landscape. This includes a close examination of current trends, key players, and important regional specificities. These insights provide practical recommendations, enabling readers to distinguish themselves from competitors by identifying unexplored market segments or crafting unique value propositions. Through data analytics, these insights assist industry participants—be they investors, manufacturers, or other stakeholders—in anticipating future market shifts. A forward-looking perspective is crucial, helping stakeholders foresee market changes and prepare for sustained success in this evolving region. Ultimately, sound strategic insights empower readers to make well-informed decisions that lead to profitability and help them achieve their business goals within the market.

Europe Flooring Regional Insights

The geographic scope of the Europe Flooring market outlines the specific areas where a company conducts its operations and competes. Grasping local distinctions—like varied consumer preferences (e.g., demand for certain plug types or battery backup durations), diverse economic landscapes, and differing regulatory frameworks—is crucial for adapting strategies to individual markets. Businesses can expand their reach by identifying regions with unmet needs or by customizing their product offerings to cater to local demands. A focused market approach allows for more efficient resource allocation, targeted marketing efforts, and better positioning against local competitors, ultimately fostering growth in those specific areas.

Europe Flooring Market Segmentation

Europe Flooring Market

By Product Type

Polymer Matrix

Ceramic Matrix

Metal Matrix

Europe Flooring Market

By Testing Method

Destructive

Non-Destructive

Europe Flooring Market

By Application

Aerospace and Defense

Transportation

Wind Energy

Building and Construction

Electrical and Electronics

Europe Flooring Market

Regions and Countries Covered

Europe

UK

Germany

France

Russia

Italy

Rest of Europe

Europe Flooring Market

Market leaders and key company profiles

Mohawk Flooring

Shaw Industries Group, Inc.

Tarkett

Forbo International SA

Gerflor

Interface, Inc.

Beaulieu International Group

Toil Corporation

Milliken

About Us:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

0 notes

Text

Defective Chinese Imports in India? Urgent Legal Remedies to Sue Suppliers, Recover Payments & Resolve Contract Disputes (2025 Guide)-4| Online Dispute Resolution Platforms for Cross-Border Claims | Documentation and Evidence Preservation Strategies | Due-Diligence Protocol | Enforcement of Judgments | Post-Judgment Enforcement

Online Dispute Resolution Platforms for Cross-Border Claims Some specialised ODR platforms are now focusing on claims relating to India-China trading disputes, thus saving costs and time. Therefore, in the Tata Motors case, the settlements from accredited ODR platforms were made binding under Indian law. ODR Selection Criteria: ● Track record of the platform’s enforcement in both countries’ jurisdictions ● Technical expertise of available mediators ● Translation and linguistic assistance ● Handling protocols of documentary evidence

Documentation and Evidence Preservation Strategies: Required Legal Documents Applicable to Imports from China Evidence Collection for Used Parts and Substandard Materials Beyond standard records like emails and contracts, cases involving used or inferior components call for more technical forms of proof:

Documentation Regarding the Dating of the Component: Prepare expert reports on date codes and wear marks, along with instructions on how to distinguish new from used components.

Material Composition Tests: Performing XRF tests for metals, to identify polymers for plastics, and chemical examination for textiles, to be performed in accredited laboratories meeting ISO 17025 compliance standards.

Statistical Sampling Protocol: For shipments comprising a large number of identical components, conduct sampling by ISO 2859 for statistical relevance and validity in a court of law.

Software Version Authentication: Credible Findings That Will Stand Legal Scrutiny. Case Study Success: In a 2024 case, we secured a favourable judgment after metallurgical evidence was presented demonstrating that the bearings in the so-called “new” machinery had already undergone stress cycles that would not have been consistent with factory-standard testing. Supply Chain Protection Framework: A must read for Indian Businesses and Companies before they import from Chinese Manufacturers And Suppliers.

0 notes

Text

Global Electrostatic Discharge (ESD) Tray Industry Trends: Key Developments and Forecast Insights Through 2031

Global Electrostatic Discharge (ESD) Tray Market demonstrates robust expansion, valued at USD 404 million in 2024. Recent projections indicate the market will accelerate at a 9.6% CAGR, surpassing USD 738 million by 2031. This trajectory is propelled by escalating demand from semiconductor manufacturing, automotive electronics, and consumer electronics sectors, where component protection during handling and transport is critical.

ESD Trays serve as indispensable protective solutions for static-sensitive components across industries. Their conductive or dissipative polymer construction (typically PP, PE, or PS) prevents electrostatic damage during logistics operations. The shift toward Industry 4.0 and smart manufacturing has intensified quality control requirements, making ESD-safe handling materials fundamental rather than optional.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/294114/global-esd-tray-forecast-market-2025-2031-537

Market Overview & Regional Analysis

Asia-Pacific commands over 58% of global ESD tray production, with China, South Korea, and Taiwan serving as manufacturing epicenters. The region benefits from concentrated semiconductor fabrication plants and electronics assembly hubs. Japan leads in high-precision tray solutions for automotive-grade components, while Southeast Asia emerges as a cost-competitive alternative for standardized designs.

North America emphasizes premium customized solutions, particularly for aerospace and military applications requiring stringent ESD compliance. Europe shows strong adoption of reusable tray systems aligned with circular economy directives. Both regions invest heavily in smart trays with embedded RFID technology for component tracking.

Key Market Drivers and Opportunities

The market thrives on three primary catalysts: semiconductor industry expansion (particularly 5G and IoT chips), EV revolution driving automotive electronics demand, and reshoring of electronics manufacturing in Western markets. Semiconductor applications account for 42% of tray usage, followed by consumer electronics (31%) and automotive (18%). Emerging opportunities include:

Development of anti-microbial ESD trays for medical electronics

Lightweight composite materials for aerospace applications

Smart trays with IoT-enabled condition monitoring

Furthermore, the push toward sustainable manufacturing creates demand for recycled polymer trays meeting ESD standards without compromising performance.

Challenges & Restraints

Volatility in polymer prices (especially PP and PE) creates margin pressures for tray manufacturers. Technical constraints include balancing static dissipation with mechanical durability in thin-wall designs. The market also faces:

Intellectual property disputes over proprietary polymer formulations

Logistical complexities in closed-loop reusable systems

Stringent certification requirements for high-reliability applications

Smaller manufacturers struggle with the capital intensity of IATF 16949 and VDA 6.3 certifications required for automotive supply chains.

Market Segmentation by Type

Polypropylene (PP) Trays

Polyethylene (PE) Trays

Polystyrene (PS) Trays

Composite Material Trays

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/294114/global-esd-tray-forecast-market-2025-2031-537

Market Segmentation by Application

Semiconductor Manufacturing

Consumer Electronics Assembly

Automotive Electronics

Medical Device Manufacturing

Aerospace Components

Market Segmentation and Key Players

Daewon

Peak International

ASE Group

Mishima Kosan

SHINON

TOMOE Engineering

HWA SHU

ESDEMC Technology

TIP Corporation

GWP Group

Report Scope

This comprehensive analysis covers the global ESD tray market from 2024 through 2031, providing detailed segmentation and regional breakdowns. The report delivers actionable intelligence on:

Volume and revenue forecasts by material type and end-use industry

Competitive benchmarking of major manufacturers

Supply chain analysis including raw material sourcing trends

Technology roadmap for smart and sustainable tray solutions

Our research methodology combined primary interviews with 120+ industry stakeholders and exhaustive analysis of production capacity data across key regions. The report enables stakeholders to:

Identify high-growth application segments

Evaluate emerging material technologies

Assess competitive positioning

Navigate regulatory requirements

Get Full Report Here: https://www.24chemicalresearch.com/reports/294114/global-esd-tray-forecast-market-2025-2031-537

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

0 notes

Text

Integration of Phase Change Materials in Renewable Energy Systems: Future Outlook

The Phase Change Materials Market mainly focuses on allowing energy optimization, decreasing energy usage, and boosting the temperature comfort in industries such as construction, HVAC, textiles, automotive, electronics, and packaging.

When Phase Change Materials (PCM) logs or solidify, they can take up or release substantial thermal energy at certain temperatures. These are commonly found in thermal energy storage solutions, temperature regulation, and are used for energy-efficient construction. The demand for building materials that reduce energy use and are environmentally sustainable is driving fast growth in the global Phase Change Materials market. Carbon reduction and the use of renewable energy are now important, so PCMs are being added more often to both green materials and thermal storage systems. Because of this, the market stands to grow a lot in the following years, supported by policies and advancements in technology.

Request a FREE frameworkof the report "Phase Change Materials Market" at: https://www.metatechinsights.com/request-sample/1249

Market Drivers

1. There is a Growing Demand for Buildings That Save Energy

The rising importance of reducing energy use in the construction sector is one of the main factors propelling the growth of Phase Change Materials. International Energy Agency (IEA) reports show that buildings account for about 30% of world energy use, which has resulted in more governments putting strict energy codes and green certifications in place. Used in building envelopes, PCMs support a comfortable indoor temperature with lower usage of heaters and air conditioners. Because of this, more people are interested in thermal energy storage with Phase Change Materials, which has fueled the market’s growth.

2. Developments in the Technology of Material Science

Programmable and composite technologies have made a big impact on the way PCM is used. With the help of micro- and nano-encapsulation, PCMs have a strong ability to work well and be used reliably for a long time. Markets predict that the encapsulated PCM market will increase at a CAGR of more than 17% up to 2030. Because of these developments, industries that require precise heat control, such as textiles, pharmaceuticals, and packaging, can use them. This makes these materials useful in more places, which contributes to the expansion of the global Phase Change Materials market.

Type Segment Analysis: Organic PCMs

People are using paraffin and fatty acids because they are chemically stable, do not cause corrosion, and can be broken down easily. They give reliable heat conductivity, with only a small risk of supercooling and phase separation. Organic PCMs are important in the building & construction industry, used widely for thermal insulation on walls, ceilings, and HVAC. Besides, the ability to be used in micro-encapsulation opens their use for items in textiles and electronics. The move toward eco-friendly heating options and new regulations is also pushing more people to use bio-based organic Phase Change Materials worldwide.

Encapsulation Technology Segment Analysis: Micro-Encapsulation

By enclosing PCMs in a polymer shield, micro-encapsulation permits PCMs to remain stable, resist leaking, and blend better with the host substances. As a result, PCMs can now work in dynamic uses such as smart clothing, seat systems in vehicles, batteries, and packing materials. Because it helps with temperature swings in processors and makes their features safer, this segment is thriving. Using micro-encapsulation, PCMs can now be produced as powders or slurries, which creates new markets. Rapid growth for the micro-encapsulated Phase Change Materials segment in smart textiles and wearable technology can be expected because of their increasing use.

Browse "Phase Change Materials Market Report" with in-depth TOC: https://www.metatechinsights.com/industry-insights/phase-change-materials-market-1249.

Regional Analysis: North America and Europe

In North America, the market for Phase Change Materials (PCM) is growing fast, thanks to efforts to conserve energy, protect the environment, and smart building systems. More green building materials with phase change technology are being used in the U.S. as people are concerned about the environment and attracted by economic advantages. The U.S. Green Building Council says that over the past decade, the share of LEED-certified buildings has gone up, and many have used PCMs in walls, ceilings, and HVAC systems to help insulate the building and decrease peak energy use.

In Europe, adoption, innovation, and support from regulators in PCM are currently strongest in. It has demonstrated leadership in sustainable building, using the circular economy, and producing clean energy. The Energy Performance of Buildings Directive from the European Union (EPBD) makes it mandatory for all new and renovated buildings to be more efficient. The rules promote the use of Phase Change Materials to store thermal energy, which results in a lower need for heating and cooling and helps buildings reach a zero-energy status. Both residential and commercial projects in Germany, France, the Netherlands, and the United Kingdom are quickly being built using PCMs. Through “Energiewende,” Germany supports the use of renewable energy and aims to make existing structures more energy-efficient, which has led to the use of PCM-enhanced wallboards and roofs in many places. Actions by both federal and state governments are having a major influence. The Better Buildings Initiative, along with incentives from the Inflation Reduction Act, helps to use energy-efficient construction materials, among them are bio-based Phase Change Materials.

Competitive Landscape and Industry Players

The Global Phase Change Materials Market is moderately fragmented and competitive, with several key players focusing on technological innovation, strategic partnerships, and geographical expansion to strengthen their market positions.

Major players include:

Henkel AG & Co. KGaA

BASF SE

Phase Change Energy Solutions Inc.

Cryopak

Outlast Technologies LLC

Rubitherm Technologies GmbH

Entropy Solutions Inc.

Advansa B.V.

Firms are devoting a lot of resources to developing new technology for PCMs, and they are also increasing their production in fast-changing regions such as Asia-Pacific and the Middle East. Product diversification, mergers & acquisitions, and working with construction and textile businesses fall under competitive strategies. Still at the heart of their expansion is thermal energy storage through phase change and micro-encapsulation in materials for HVAC and fabrics.

Purchase the Phase Change Materials Market Report at: https://www.metatechinsights.com/checkout/1249.

About Us:

Metatech Insights stands as a leader in market research companies that provides clear and concise reports about regional and global markets, extending to pharmaceuticals and medical devices, as well as consumer goods markets, and others. Market analysis combined with trends and competition reports also includes growth opportunities and forecasts in research materials provided by their organization. Metatech Insights creates remarkable value by transforming deep market research into structured, precise data insights that drive businesses to make better decisions for sustainable growth while obtaining market superiority.

Contact:

50 MacAleese Lane #24, Moncton, New Brunswick,

E1A3L9, Canada

Tel: +15064048481

Email: [email protected]

Website: https://www.metatechinsights.com

0 notes

Text

0 notes

Text

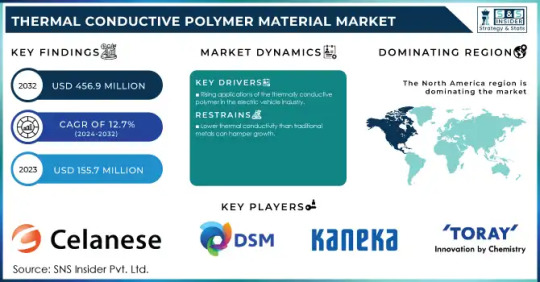

Global Thermal Conductive Polymer Material Market: Key Drivers, Challenges, and Opportunities

Increasing Demand for Heat Management in Electronics and Automotive Applications Fuels Growth in the Thermal Conductive Polymer Material Market.

The Thermal Conductive Polymer Material Market size was USD 155.7 Million in 2023 and is expected to Reach USD 456.9 Million by 2032 and grow at a CAGR of 12.7% over the forecast period of 2024-2032.

The Thermal Conductive Polymer Material Market is driven by the increasing need for efficient heat dissipation solutions in high-performance applications such as electronics, automotive, aerospace, and LED lighting. These polymers offer a combination of thermal conductivity, lightweight properties, electrical insulation, and design flexibility, making them a preferred alternative to traditional metal-based thermal management materials. As industries move toward miniaturization and energy efficiency, the demand for advanced thermal conductive materials continues to rise.

Key Players:

Celanese Corporation

DSM

KANEKA CORPORATION

TORAY INDUSTRIES, INC.

SABIC

HELLA GmbH & Co.

MERCK KGaA

Saint-Gobain

Arkema

RTP Company

Future Scope & Emerging Trends:

Looking ahead, the market for thermal conductive polymer materials is set to grow rapidly, with a strong push from the electric vehicle (EV) industry, smart electronics, and 5G infrastructure. These sectors demand materials that not only manage heat effectively but also contribute to lightweight design and energy efficiency. An emerging trend is the integration of nanomaterials to enhance thermal conductivity while maintaining electrical insulation. Additionally, increasing environmental regulations are encouraging the development of recyclable and sustainable thermal polymers. As R&D efforts intensify, new product formulations with higher thermal performance and greater durability are expected to enter the market, opening new applications and use cases.

Key Points:

Rising demand for heat dissipation in compact, high-power devices.

Shift toward lightweight and electrically insulating materials in EVs and electronics.

Asia-Pacific leading the market due to rapid industrialization and electronics manufacturing.

Innovations in nanotechnology driving improved material performance.

Focus on eco-friendly, recyclable polymer solutions aligned with global sustainability goals.

Market expected to register a strong CAGR through 2030.

Conclusion:

The thermal conductive polymer material market is on a high-growth trajectory, driven by technological innovations, environmental considerations, and the evolving needs of high-performance industries. With rising applications in EVs, electronics, and renewable energy systems, the market presents vast opportunities for manufacturers, researchers, and investors. Strategic partnerships, product diversification, and sustainability-focused innovation will be key to long-term success in this dynamic market.

Read Full Report: https://www.snsinsider.com/reports/thermal-conductive-polymer-material-market-3243

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Thermal Conductive Polymer Material Market#Thermal Conductive Polymer Material Market Size#Thermal Conductive Polymer Material Market Share#Thermal Conductive Polymer Material Market Report#Thermal Conductive Polymer Material Market Forecast

0 notes

Text

#Conductive Polymer Coating Market report#Conductive Polymer Coating Market Analysis#Conductive Polymer Coating Market Growth

0 notes

Text

Silicone-Based Conductive Adhesives: Game-Changer for EMI Shielding and Thermal Management

Global Silicone Based Electrically Conductive Adhesives Market is experiencing robust growth, with a valuation reaching USD 890 million in 2024. According to comprehensive market analysis, the sector is projected to expand at a CAGR of 6.3%, reaching approximately USD 1.45 billion by 2032. This substantial growth is primarily driven by increasing demand from electronics manufacturing, particularly in consumer electronics and automotive applications where reliable conductive bonding solutions are essential for next-generation technologies.

Silicone based conductive adhesives represent a specialized class of materials combining silicone polymers with conductive fillers, offering unique advantages over traditional soldering methods. These adhesives provide excellent thermal stability, mechanical flexibility, and electrical conductivity - making them indispensable for applications requiring durable connections under thermal cycling or mechanical stress conditions.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/293998/silicone-based-electrically-conductive-adhesives-forecast-market

Market Overview & Regional Analysis

Asia-Pacific currently dominates the global market, accounting for over 40% of total consumption, with China, Japan, and South Korea as primary demand centers. The region's leadership stems from its vast electronics manufacturing base and expanding automotive production, particularly in electric vehicles. China alone contributes nearly 30% of global PCB production, creating sustained demand for reliable conductive adhesives in electronic assembly applications.

North America maintains strong market presence with approximately 30% market share, supported by advanced electronics development and strict regulatory standards that favor high-performance adhesive solutions. Europe follows closely, where environmental regulations like RoHS and REACH are accelerating the transition from traditional soldering to conductive adhesives in electronics manufacturing.

Key Market Drivers and Opportunities

The market is primarily driven by three key factors: the relentless miniaturization of electronic components, rapid growth in electric vehicle production, and increasing adoption in medical electronics. Smartphone manufacturers shipped over 1.2 billion units globally in 2023, each requiring dozens of conductive adhesive applications for component assembly. This trend toward smaller, more complex devices continues to create demand for advanced bonding solutions that can maintain reliability in compact form factors.

Emerging opportunities exist in the healthcare sector, where silicone-based conductive adhesives are finding growing application in wearable medical devices and implantable electronics. The medical electronics market is projected to grow at 7.5% annually through 2030, creating significant demand for biocompatible conductive adhesives that can withstand sterilization processes and long-term bodily contact.

Challenges & Restraints

The market faces several challenges including material cost volatility and competition from alternative technologies. Silver, a primary conductive filler material, has experienced price fluctuations of 15-20% in recent years, impacting adhesive pricing stability. Additionally, traditional soldering methods continue to dominate many applications, particularly where ultimate conductivity is prioritized over flexibility and thermal performance.

Technical limitations present another challenge, as silicone-based adhesives typically offer lower conductivity than metallic solders, restricting use in high-current applications. Processing requirements also add complexity, with many formulations requiring precise curing conditions that demand specialized equipment and operator training.

Market Segmentation by Type

High Conductivity Silicon Based Conductive Adhesive

Medium and Low Conductivity Silicon Based Conductive Adhesive

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/293998/silicone-based-electrically-conductive-adhesives-forecast-market

Market Segmentation by Application

Consumer Electronics

Automotive

Aerospace

Medical Devices

Industrial Electronics

Others

Competitive Landscape

The market features strong competition between global chemical giants and specialized adhesive manufacturers. Henkel AG & Co. KGaA and 3M Company collectively account for approximately 35% of the market share, leveraging their extensive R&D capabilities and global distribution networks. These leaders continue to innovate with advanced formulations incorporating novel conductive fillers like graphene and carbon nanotubes to enhance performance characteristics.

Emerging players are gaining traction by focusing on niche applications, particularly in the medical and aerospace sectors where specialized performance requirements create opportunities for differentiation. Regional manufacturers in Asia are increasingly competitive, offering cost-effective alternatives while steadily improving product quality to challenge established brands.

Key Market Players:

Henkel AG & Co. KGaA

3M Company

DOW Corning

H.B. Fuller

Master Bond Inc.

Creative Materials Inc.

MG Chemicals

Polytec PT GmbH

Lord Corporation

Permabond Engineering Adhesives

Report Scope

This comprehensive market analysis covers the global silicone based electrically conductive adhesives industry from 2024 to 2032, providing detailed insights into:

Current market size and future growth projections

In-depth segmentation by product type and application

Regional market dynamics and growth opportunities

Competitive landscape and market share analysis

Key technological trends and innovation areas

The report also includes detailed profiles of leading market participants, analyzing their product portfolios, manufacturing capabilities, strategic initiatives, and financial performance. Market challenges, emerging opportunities, and investment potential are thoroughly evaluated to provide stakeholders with actionable business intelligence.

Get Full Report Here: https://www.24chemicalresearch.com/reports/293998/silicone-based-electrically-conductive-adhesives-forecast-market

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

Other Related Reports:

0 notes

Text

Flexible Printed Circuit Boards Market Driven by Consumer Electronics Demand

Flexible Printed Circuit Boards (FPCBs) are thin, bendable interconnect solutions that enable complex circuit designs in compact form factors. These boards consist of a flexible polymer substrate, conductive copper traces, and protective coverlays, offering significant advantages such as reduced weight, enhanced heat dissipation, and higher reliability compared to rigid PCBs. FPCBs are increasingly adopted in smartphones, wearable devices, automotive sensors, medical equipment, and aerospace systems, responding to the industry’s push for miniaturization, flexibility, and rugged performance.

The flexibility of these circuits not only simplifies assembly but also opens up new market opportunities in three-dimensional packaging and foldable gadgets. Continuous advancements in material science and manufacturing processes are driving down production costs while improving signal integrity and durability. Market research suggests that rapid innovation in consumer electronics, coupled with the rising demand for lightweight and high-performance components, is fueling Flexible Printed Circuit Boards Market growth. In addition, stringent space and weight constraints in automotive and aerospace applications further underscore the need for flexible interconnect solutions.

The flexible printed circuit boards market is estimated to be valued at USD 27.02 Bn in 2025 and is expected to reach USD 57.53 Bn by 2032. It is projected to grow at a compound annual growth rate (CAGR) of 11.4% from 2025 to 2032. Key Takeaways

Key players operating in the Flexible Printed Circuit Boards Market are:

-Samsung Electro-Mechanics

-NOK Corporation

-Flex Ltd.

-Jabil Inc.

-Fujikura Ltd.

These market leaders leverage strong R&D capabilities and strategic partnerships to maintain competitive market share. Samsung Electro-Mechanics invests heavily in advanced material research to deliver high-density interconnect solutions, while NOK Corporation focuses on automotive-grade FPCBs that meet stringent quality standards. Flex Ltd. utilizes its global footprint and contract manufacturing expertise to serve diverse industry segments, driving overall market revenue. Jabil Inc. offers integrated design-to-production services, enhancing supply chain efficiency and reducing time-to-market. Fujikura Ltd. emphasizes continuous innovation in multilayer flexible circuits, targeting next-generation foldable displays and wearable devices. Collectively, these market companies shape market dynamics through collaborative product launches, mergers, and acquisitions, as outlined in leading market reports.

‣ Get More Insights On: Flexible Printed Circuit Boards Market

‣ Get this Report in Japanese Language: フレキシブルプリント基板市場

‣ Get this Report in Korean Language: 유연인쇄회로기판시장

‣ Read More Related Articles- South Korea Emerging as Printed Electronics Leader

0 notes