#ContaminationControl

Explore tagged Tumblr posts

Text

Why Cleanroom Finger Cots Are a Game Changer in High-Tech Industries

In today’s world of precision work, whether it’s electronics, pharmaceuticals, or scientific research, keeping everything clean and free from contaminants is crucial. That’s where cleanroom finger cots come in—small but mighty protectors in some of the most sensitive environments.

Here’s why they matter:

✨ Anti-Static Properties: Cleanroom finger cots keep static in check, protecting delicate electronics and components from the hidden danger of electrical discharge. No more damaging sensitive tech while you work!

🦠 Reduces Contamination Risks: These little gloves act as a barrier, minimizing contact between your skin and surfaces that could carry bacteria, viruses, or harmful particles. A cleaner workspace and healthier you!

🌱 Class 100 Cleanliness Standard: Designed to meet strict cleanliness guidelines, these finger cots ensure that you’re working in an environment free from excess particles—perfect for those ultra-clean conditions in labs or manufacturing.

🖐️ Convenient & Comfortable: They’re lightweight, portable, and easy to wear. So you can stay protected and focused, without the hassle of bulky gloves or equipment.

If you work in an industry where cleanliness and safety are non-negotiable, cleanroom finger cots are a must-have. Protect your work, your equipment, and yourself. 🙌

#Cleanroom#AntiStatic#ContaminationControl#LabProtection#SafetyFirst#IndustrialInnovation#CleanTech#YOUSUTO

2 notes

·

View notes

Text

Unveiling the Advancements and Challenges in Mycoplasma Diagnostics

Mycoplasma, a genus of small, self-replicating bacteria, has gained significant attention in the medical and scientific communities due to its impact on human health and its role in various diseases. The accurate diagnosis of mycoplasma infections is crucial for effective treatment and prevention. Mycoplasma Diagnostics is a unique group of bacteria that lacks a cell wall, making it resistant to many common antibiotics. These bacteria are known to cause a wide range of infections, including respiratory illnesses, urogenital infections, and even systemic diseases. Mycoplasma pneumoniae, for example, is a leading cause of community-acquired pneumonia, while Mycoplasma genitalium is associated with urethritis and cervicitis. The ability of mycoplasma to evade the immune system and its resistance to antibiotics make it a challenging pathogen to diagnose and treat effectively. Get more insights on,Mycoplasma Diagnostics

0 notes

Text

✨ What Are Clean Room Systems & Why Are They a Big Deal? (A Simple Guide!) ✨

Hey there, science enthusiasts, healthcare pros, and curious minds! 🧪🏥 Ever wondered how ultra-clean spaces in pharma labs, hospitals, or electronics factories stay that clean? The secret? Clean Room Systems!

Let’s break it down in a fun, easy way—because even the tiniest speck of dust can mess up life-saving meds or microchips. 🤯

🌪️ What’s a Clean Room?

A clean room is a super-controlled space where dust, microbes, and even your sneeze particles (😷) are filtered out. Think of it like a VIP zone for precision—where air is literally cleaner than an operating room!

Where are they used? ✔ Pharma & Biotech ✔ Hospitals (ICUs, OTs, IVF labs) ✔ Electronics (Microchips, Nanotech) ✔ Food Production & Aerospace

🔬 How Do Clean Rooms Work?

1️⃣ HEPA/ULPA Filters: Trap 99.97%+ particles (even ones smaller than a human hair!). 2️⃣ Positive Pressure: Keeps dirty air out by pumping in ultra-clean air. 3️⃣ Laminar Airflow: Air moves in smooth streams to sweep away contaminants. 4️⃣ Sealed Construction: Special walls, floors, and doors to prevent leaks.

🏷️ Clean Room Classes (Because Not All Clean Rooms Are Equal!)

Clean rooms are graded by ISO standards (ISO 1 = ultra-clean to ISO 9 = least clean). Fun fact: A Class 100 room means ≤100 particles per cubic foot—way cleaner than your bedroom! 😉

💰 Cost in India?

Prices vary, but modular clean rooms start around ₹2,000–5,000/sq. ft. (Custom setups? Let’s chat!).

🚨 Common Mistakes to Avoid

❌ Skipping HVAC design checks ❌ Using non-cleanroom materials (bye, duct tape!) ❌ Ignoring staff training (even a fingerprint can ruin experiments!)

💡 Why Should You Care?

Ensures safe medicines, sterile surgeries & flawless tech.

Mandatory for GMP, ISO, WHO compliance.

Saves costs by preventing contamination disasters.

🤝 Need a Clean Room? We’ve Got You!

At AUM Industries, we design custom clean rooms for pharma, hospitals, labs & more! From modular OTs to HVAC solutions, we make clean air easy.

📩 DM or Email: [email protected] 🌐 Website: www.aumindustriesmfg.com

🚀 Loved this? Share the knowledge!

#CleanRoomTech#PharmaInnovation#HospitalDesign#ContaminationFree#STEM#ScienceMadeSimple#AUMIndustries#CleanRoomTechnology#ModularCleanrooms#PharmaManufacturing#HealthcareInnovation#GMPCompliance#ContaminationControl#HVACSystems#MadeInIndia#ISOStandards

0 notes

Text

Ensure precise microbial air sampling with the BioCapt Single-Use Microbial Impactor. Designed for contamination control, it provides highly accurate detection of airborne microorganisms in cleanrooms and critical environments. Aseptic, easy to use, and compliant with industry standards.

0 notes

Text

As leading Pharmaceutical Clean Room Manufacturers, EPACK Prefab delivers high-performance, custom-engineered clean rooms designed to meet the stringent requirements of the pharmaceutical industry. Our prefabricated clean rooms ensure a controlled, contamination-free environment, essential for maintaining product quality and regulatory compliance.

With advanced manufacturing capabilities and years of expertise, we offer tailored solutions that are durable, efficient, and quick to install. Trust EPACK Prefab for clean rooms that prioritize safety, precision, and reliability.

Contact us today to learn more about our innovative clean room solutions!

#PharmaceuticalCleanRoom#CleanRoomManufacturers#EPACKPrefab#CleanRoomSolutions#PrefabricatedCleanRooms#PharmaIndustry#ContaminationControl#CustomCleanRooms#CleanRoomInstallation#PharmaInfrastructure

0 notes

Text

Anaerobic Jar 7L

Labmate Anaerobic Jar creates an oxygen-free atmosphere for cultivating anaerobic microorganisms. With a 2.5L capacity and space for 6 dishes, it features air-tight seals and a high-quality O-ring to prevent contamination. Made of PMMA, it takes 2-4 hours to attain anaerobic conditions.

#AirborneParticleCounter#CleanroomTechnology#AirQuality#ParticleDetection#ContaminationControl#Cleanroom

0 notes

Text

"High-Quality Cleanroom Wipers by Lahari Enterprises"

Lahari Enterprises offers high-quality cleanroom wipers for pristine cleaning in controlled environments. Our wipers ensure contamination-free surfaces, meeting strict standards for cleanliness and efficiency. Trust us for reliable and effective cleanroom solutions.

0 notes

Text

If your answer is yes, take a look at our range of gamma irradiated dry cleanroom wipes that strongly prevent the risk of contamination in your cleanrooms. https://cleaningcard.net/product-category/cleanroom-wipes/

#cleanrooms#pharmaceutical#medicaldevice#cleanroomwipes#drycleanroomwipes#ApexProtect#sterile#contaminationcontrol#wetwipes

1 note

·

View note

Text

Air shower is a self-contained chamber designed to be seamlessly integrated into clean rooms and similar controlled environments, typically placed at entrances. Its primary purpose is to significantly reduce particulate contaminants, preventing them from entering the clean room and aiding in their removal when individuals exit. This is accomplished through a robust air velocity of 25 meters per second.

The air shower features an intuitive audio and visual display system that allows for flexible showering times, adjustable from 0 to 99 seconds, to meet specific requirements. To enhance contamination control, it employs airflow nozzles configured in sets of 6, 12, and 24, effectively capturing and expelling contaminants.

0 notes

Text

youtube

Modular Cleanroom Manufacturers in India | Experts in PUF Panel And Sandwich Partition Solutions

Did you know a single particle can cost a pharmaceutical company millions in product recalls?

That’s why industries across India trust modular cleanrooms—custom-built for hygiene, flexibility, and excellence. 💼✨

From pharmaceutical manufacturing to modular hospital theatres, electronics, food processing, cosmetics, and research labs—cleanrooms are transforming the future of precision industries. 🏭🔬

Discover why Polyurethane Foam panels, sandwich panels, air handling units, and laminar airflow systems are revolutionizing contamination control. 🌬️

Looking to upgrade your facility with a world-class modular cleanroom solution?

✅ Designed for speed, hygiene, and scalability ✅ Built with advanced, contamination-proof materials ✅ Ideal for industries where purity and compliance matter most

🔗 Visit www.aumindustriesmfg.com 📧 Email us: [email protected] 📞 Call: +91-9664808777 | +91-9722549868 | +91-9978629339

Let's build a cleaner, smarter, and safer tomorrow together! 🚀

#modularcleanrooms#cleanroommanufacturers#pufpanelsolutions#sandwichpanelexperts#pharmacleanroom#hospitalcleanroom#electronicsmanufacturing#foodprocessingindia#cosmeticsmanufacturing#contaminationcontrol#airhandlingunits#laminarairflow#cleanroomsolutions#industrialcleanrooms#madeinindia#futureready#aumindustries#cleanroomtechnology#healthcareinfrastructure#turnkeysolutions#precisionengineering#cleanenvironment#cleanroomdesign#cleanroomsetup#Youtube

0 notes

Text

Cargo Air Shower

Cargo air shower is an automated system used in clean rooms that includes a photoelectric sensor and an automated door. PLC-controlled blowing ensures air purity and avoids the recirculation of microscopic pollutants. The electronic door locking technology ensures a clean seal, preventing contaminant seepage. The four-door electrical interlock generates a gas chamber effect, preventing contamination.

0 notes

Text

Advanced Particle Measurement Systems for Precision Monitoring

Discover cutting-edge Particle Measurement Systems from Particle Measuring Systems, designed to deliver accurate monitoring solutions for cleanrooms and controlled environments. Ideal for industries requiring stringent contamination control, these systems ensure superior performance and reliability.

0 notes

Text

Efficiently control contamination: Pass Box, PCR Work Station, and Sanitizing Tunnel, your laboratory's guardians of purity.

Visit Here for More:- https://bit.ly/3O5HggL

#PassBox#SafeTransfer#SecurePassage#ContaminationControl#PCRWorkStation#LabSafety#DNAAnalysis#ResearchTools#SanitizingTunnel#HygieneStation#DisinfectionGateway#GermFreePassage#CleanAndSafe

0 notes

Text

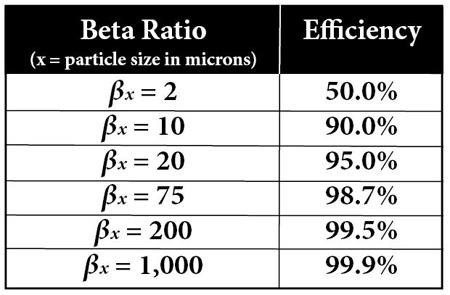

Understanding of the BETA factor

What is the Beta Ratio?

The beta ratio refers to the efficiency in which a given filter element removes the particle of a given size. The Beta Ratio is calculated using the ISO multi-pass test standard 16889:1999.

How is it measured?

Get your filter check today, Call +91 7030901266

So, to purchase a filter with a beta ratio of 2-10 is considered poor, it is advised to use filters with at least a Beta factor of 75 and 98.7% effectiveness. High quality, efficient filter assemblies can achieve 200 to 2000 Beta Ratio for given particle size and should be ideal to achieve a low level of contamination.

Also read: https://www.linkedin.com/pulse/you-buying-right-oil-filter-anshuman-agrawal-mlt-1-/

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that helps you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#hydraulic oil filter#contamination#oil purification system#oil purification machine#oil contamination#oil purification#oil testing#oil filter machine#oil filter systems#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#wind turbines#gas turbine#steam turbine#steel#metal#mining#oil dehydration systems

2 notes

·

View notes

Text

Anaerobic Jar 2.5L

Labmate Anaerobic Jar creates an oxygen-free atmosphere for cultivating anaerobic microorganisms. With a 2.5L capacity and space for 6 dishes, it features air-tight seals and a high-quality O-ring to prevent contamination. Made of PMMA, it takes 2-4 hours to attain anaerobic conditions.

#AirborneParticleCounter#CleanroomTechnology#AirQuality#ParticleDetection#ContaminationControl#Cleanroom

0 notes

Text

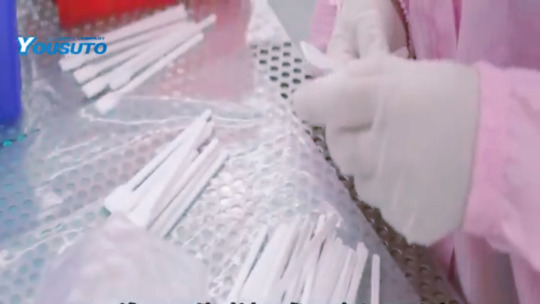

New Cleanroom & Electronics Cleaning Solutions: The Future of Precision and Contamination Control

At YOUSUTO, we’re always looking for ways to elevate cleanliness standards in the industries that rely on precision and purity. That’s why we’re thrilled to announce our expanded product line of cleaning swabs, designed specifically for the unique needs of electronics and cleanroom environments. Whether you're working in semiconductor manufacturing, healthcare, or electronics, our cotton, foam, and fabric swabs are engineered to meet the highest standards of performance and contamination control.

✨ Why Choose Our Cleaning Swabs?

Foam Swabs for Precision Cleaning: Ideal for electronics and sensitive components, our foam swabs eliminate the risk of lint and debris. Their open-cell foam structure makes them highly absorbent, perfect for picking up solvents and thoroughly cleaning surfaces without leaving any residue behind.

Fabric Swabs for Cleanroom Environments: Our fabric swabs, made from high-performance materials like polyester and microfiber, are the go-to choice for environments with the strictest cleanliness requirements. They offer superior durability and are engineered to reduce particle generation, making them perfect for cleanrooms, medical facilities, and high-tech industries.

Cotton Swabs for Everyday Use: While they might not be suitable for the most delicate electronics, our cotton swabs still play a key role in routine cleaning tasks. Soft, absorbent, and versatile, they’re perfect for general cleaning needs in both personal and professional settings.

🔧 Tailored Solutions for Every Need

No matter the task, we have a swab solution for you. Our swabs come in a wide range of sizes and tip shapes, providing the flexibility to clean everything from intricate circuits to large-scale equipment. Whether you need to remove oil, dust, or other contaminants, our cleaning swabs are designed to deliver the efficiency and cleanliness you expect.

💡 Innovation Meets Reliability

At yousuto company, our commitment to innovation drives us to continuously improve our products. Our cleaning swabs undergo rigorous testing to ensure reliability, high performance, and minimal contamination risk. With customizable options available, we provide the right tools for every job.

🌍 The Future of Cleaning Technology

As industries evolve and technology advances, so too must the tools we use to maintain them. We’re proud to be at the forefront of cleaning innovation, and we’re excited to continue delivering solutions that help our clients stay ahead of the curve. Cleanliness is more than just a priority—it’s a necessity for success in high-tech environments.

🔗 Explore our new cleaning swab collection today! https://yousutoswab.com/2024/12/26/foam-swabs-manufacturer/

#Cleanroom #ElectronicsCleaning #ContaminationControl #Innovation #PrecisionCleaning #FoamSwabs #FabricSwabs #CottonSwabs #CleaningSolutions #TechIndustry #CleanTech #Medical #Electronics

2 notes

·

View notes