#Control System using MATLAB help

Explore tagged Tumblr posts

Note

are you doing a systems and controls course where you are using matlab?

not currently, but i took that one last year. it was a doozy and it was like aaaallll matlab. my uni is obsessed with matlab though, so almost every class uses it at this point in upper division. if you ever need help i gotchu (maybe, no promises, i am no expert but ive used it a fucking lot lmao)

3 notes

·

View notes

Text

How BTech Mechanical Can Lead to Careers in Robotics

When most students think of Mechanical Engineering, they picture machines, engines, or automobiles. But here’s something exciting—Mechanical Engineering is one of the strongest foundations for a career in Robotics. Yes, you read that right. If you’re someone who dreams of working on intelligent machines, drones, or automation systems, a BTech in Mechanical can be your perfect Launchpad.

Let’s break it down so you see the big picture.

What’s the Link Between Mechanical Engineering and Robotics?

Robotics is not a single-subject field. It combines mechanical engineering, electronics, computer science, and control systems. A robot, after all, is a physical system—made up of gears, motors, joints, and frames. And who better than a mechanical engineer to design and build those parts?

In fact, many leading robotics engineers started with a mechanical background. That’s because mechanical engineering gives you:

A strong understanding of kinematics and dynamics (how things move)

Skills in mechanical design and CAD

Knowledge of materials and manufacturing

Basics of control systems and automation

In simpler words, mechanical engineers are the architects of the robot’s body. They ensure that what’s imagined can be built, function, and perform in the real world.

What You Learn in BTech Mechanical That Helps in Robotics

Here are a few key subjects and skills taught in BTech Mechanical that directly contribute to robotics:

Engineering Mechanics & Dynamics: These help you understand how forces act in machines.

Machine Design & CAD: You’ll learn to design robotic arms, gear systems, and mobile robots.

Thermodynamics & Fluid Mechanics: Useful if you're designing robots for extreme environments.

Automation and Control Engineering: Many colleges include mechatronics and automation, laying the base for robotic control systems.

In institutes that focus on real-world learning, you’ll also work on mini projects and hands-on labs—and that’s where true robotics interest gets sparked.

Where Do Robotics Engineers Work?

You might be surprised at how widespread robotics is. Industries hiring robotics professionals include:

Automotive & Aerospace: Building robots for manufacturing and assembly lines.

Healthcare: Designing robotic surgical tools and prosthetics.

Agriculture: Drones and autonomous farming equipment.

Logistics & Warehousing: Robotics in Amazon-like fulfillment centers.

Defense & Space: Autonomous vehicles, drones, and exploration bots.

So yes, it’s no longer just “rocket science”—robotics is now applied science, and mechanical engineers are at the heart of it.

Top Skills You Need to Add Alongside Your Degree

While your BTech in Mechanical gives you the base, to truly excel in robotics, you should explore:

Programming Skills (Python, C++, MATLAB)

Microcontrollers & Sensors (Arduino, Raspberry Pi)

Robotics Simulation Tools (ROS, Gazebo)

Machine Learning Basics (for intelligent robot behavior)

These can be learned via online courses, robotics clubs, or elective subjects in college.

Choosing the Right College Makes a Difference

Now here’s something important—not all mechanical programs are the same. The best engineering colleges in Odisha are those that go beyond textbooks. Look for places that encourage interdisciplinary projects, have modern labs, and foster industry connections.

For example, NM Institute of Engineering and Technology (NMIET) in Bhubaneswar, though known primarily for its strong mechanical and technical base, also supports hands-on learning, industry collaboration, and practical workshops—exactly the environment where robotics thrives. Institutes like NMIET, affiliated with BPUT and accredited by AICTE, offer a strong academic foundation paired with exposure to real-world applications.

Interestingly, NMIET also maintains industry tie-ups with companies like IBM, Cognizant, and Capgemini—which often explore robotics and automation in their operations. A setup like this can open doors to internships or projects that align with robotics, even if your core branch is mechanical.

Final Thoughts

If you’ve been wondering whether a BTech in Mechanical can lead you into the world of robotics, the answer is: Absolutely, yes. Mechanical engineers are not just part of the robotics field—they are essential to it.

So, if your interest lies in building things that move, think, and react, consider mechanical engineering as your foundation. And when choosing where to study, keep in mind that the best engineering colleges in Odisha are those that integrate practical learning, tech-savvy faculty, and an open environment for innovation.

Remember, the robots of tomorrow need bright minds today—and your journey can begin with a single decision.

#bhubaneswar b tech colleges#college of engineering bhubaneswar#best engineering colleges in orissa#best engineering colleges in bhubaneswar#best private engineering colleges in odisha#best engineering colleges in odisha

0 notes

Text

Model-Based Design Tools: Revolutionizing Engineering Development

Model-Based Design (MBD) tools are transforming how engineers and developers approach system design, especially for complex embedded systems in industries like automotive, aerospace, industrial automation, and consumer electronics. These tools provide a structured and highly visual development methodology that allows teams to simulate, test, and validate system behavior long before physical prototypes are built. The result is faster development cycles, reduced errors, and a more efficient path from concept to deployment.

What Is Model-Based Design?

Model-Based Design is a design methodology that uses models to represent system behavior and functionality. These models are often built using tools like MATLAB® and Simulink®, where engineers can graphically design algorithms and simulate how systems will behave under various conditions. Unlike traditional code-first approaches, MBD starts with system modeling and then automatically generates production-quality code from those models.

At the core of MBD is the simulation-based approach, which means engineers can analyze and optimize system performance early in the design process. This approach is especially beneficial in industries where safety, reliability, and performance are critical.

Key Components of Model-Based Design Tools

Model-Based Design tools typically include several integrated components that work together to provide a full development workflow:

System Modeling: Visual blocks and diagrams are used to represent system logic, dynamics, and control behavior. This makes it easier to conceptualize the system as a whole and ensure different subsystems interact correctly.

Simulation and Analysis: Engineers can simulate system performance under real-world conditions. This includes testing various input conditions, disturbances, and failure scenarios without physical hardware.

Automatic Code Generation: Once the model is validated, the tool can generate optimized C/C++ code for embedded deployment. This saves time and ensures that the code reflects the verified model exactly.

Verification and Validation: Formal testing, including Hardware-in-the-Loop (HIL) and Software-in-the-Loop (SIL), can be done within the model environment to catch errors early. Requirements tracing and test case generation also become more structured.

Integration with Hardware: MBD tools support integration with real-time hardware platforms, enabling rapid prototyping, testing, and eventual system deployment.

Benefits of Model-Based Design Tools

The use of Model-Based Design tools offers several distinct advantages across the product development life cycle:

1. Reduced Development Time

Because MBD allows for early testing, design iterations happen faster. Changes can be made in the model and immediately validated, without the need to rewrite code or rebuild hardware.

2. Improved Design Quality

Simulation and early validation help detect design errors and inconsistencies before they escalate. This reduces the risk of failure in real-world scenarios and improves the overall quality of the final product.

3. Cost Efficiency

By catching issues early and reducing the need for physical prototypes, MBD significantly reduces development costs. Automatic code generation further minimizes the effort and time required for coding.

4. Team Collaboration

Model-Based Design tools offer a common visual language for system engineers, control engineers, and software developers. This shared platform improves collaboration and reduces misunderstandings in multi-disciplinary teams.

5. Easier Compliance and Documentation

Many industries require rigorous documentation and compliance with standards such as ISO 26262 (automotive) or DO-178C (aerospace). MBD tools help with automated report generation, model traceability, and structured testing, all of which support regulatory requirements.

Applications Across Industries

Automotive

Model-Based Design is extensively used in the automotive sector for developing advanced driver assistance systems (ADAS), powertrain control, and electric vehicle (EV) management systems. Real-time simulation and automatic code generation help meet safety and performance benchmarks.

Aerospace

In aerospace, MBD is used for flight control systems, navigation, and avionics. The ability to simulate conditions like turbulence or sensor failure in a virtual environment is invaluable.

Industrial Automation

Industrial control systems such as robotic arms, conveyor systems, and CNC machines benefit from the rapid prototyping and optimization that MBD offers.

Medical Devices

Medical equipment such as infusion pumps and diagnostic machines can be modeled to ensure accuracy, reliability, and regulatory compliance before real-world testing.

Popular Model-Based Design Tools

Some of the most widely used tools in the MBD ecosystem include:

MATLAB®/Simulink®: Industry-standard tools for modeling, simulation, and automatic code generation.

Stateflow®: Used for modeling and simulating decision logic based on state machines and flow charts.

dSPACE® and NI VeriStand: Platforms for Hardware-in-the-Loop simulation and rapid control prototyping.

LabVIEW: Offers graphical programming and dataflow-based design for engineering systems.

Challenges and Considerations

While Model-Based Design tools offer substantial advantages, they also come with a learning curve. Teams must be trained in how to use the tools effectively and understand modeling principles. Also, highly complex systems can result in large, difficult-to-maintain models if not properly managed.

Another consideration is model fidelity—ensuring that the simulated model accurately represents real-world behavior. This often requires detailed system knowledge and careful calibration of the model parameters.

The Future of Model-Based Design

As systems become more complex and interdisciplinary, Model-Based Design will play an even more central role. Integration with AI and machine learning, cloud-based simulation environments, and enhanced real-time collaboration tools are likely to shape the next generation of MBD platforms.

Furthermore, the rise of digital twins—virtual replicas of physical systems—relies heavily on model-based methodologies. As industries continue to move toward intelligent automation and cyber-physical systems, the use of Model-Based Design tools will only increase.

Conclusion

Model-Based Design tools by Servotechinc are a game-changer for modern engineering. They streamline development, enhance collaboration, reduce costs, and ensure a higher quality of products across various industries. By embracing MBD, companies position themselves at the forefront of innovation, equipped to tackle the challenges of complex systems with confidence and efficiency.

0 notes

Text

What Sets Apart a Great Electronics Design Engineer and a Top-Tier PCB Designer

Developing cutting-edge products requires more than just a basic understanding of electronics—it demands specialized expertise at multiple levels of the design process. While the roles of an electronics design engineer and a PCB designer often overlap, each discipline has its own set of core skills, priorities, and best practices. Understanding these differences can help companies build stronger teams and ensure both functionality and manufacturability from concept to production.

1: Foundations: Concept vs. Layout

Electronics Design Engineer

System-level thinking: Architects circuits that meet performance, power, and cost targets.

Component selection: An electronics design engineer chooses processors, sensors, power supplies, and other parts based on specifications and availability.

Simulation and validation: Uses SPICE, MATLAB, or custom scripts to verify that circuits behave as intended under various conditions.

PCB Designer

Physical realization: Translates schematic diagrams into board layouts, deciding component placement, routing, and layer stacks.

Signal integrity: Manages trace lengths, impedance control, and differential pairs to prevent timing mismatches and noise.

Thermal management: Integrates heat sinks, copper pours, and thermal vias to maintain reliable operating temperatures.

2: Technical Skills: Breadth vs. Depth

Breadth of Knowledge (Engineer)

A great electronics engineer understands analog and digital domains, power management, RF techniques, and often systems integration. Their toolkit includes:

Circuit simulation tools (e.g., Cadence, LTspice)

Firmware debugging (e.g., JTAG, SWD)

Test equipment (oscilloscopes, spectrum analyzers)

Depth of Expertise (PCB Designer)

A top-tier PCB designer goes deep into board stack-up design, advanced routing strategies, and material characteristics:

PCB CAD software mastery (e.g., Altium Designer, Mentor Xpedition)

High-speed design considerations (e.g., controlled impedance, crosstalk analysis)

3: Collaboration and Workflow

Communication Styles

Electronics engineers often work in cross-functional teams—mechanical, software, and compliance—to validate overall design requirements. Their deliverables include schematics, block diagrams, and simulation reports.

PCB designers interact heavily with manufacturing partners. They must document fabrication drawings, assembly notes, and BOM details clearly to avoid production delays.

By recognizing the strengths each role brings—and fostering close collaboration between them—teams can bring innovative, reliable products to market faster and more efficiently.

Source: https://extrondesignservice.blogspot.com/2025/05/what-sets-apart-great-electronics.html

0 notes

Text

Struggling with MATLAB simulink? Hire experts from PhD assistants and stop worrying

In the rapidly changing landscape of academic and engineering research, MATLAB and Simulink have become fundamental software programs. In many engineering domains, like control systems, signal processing, power electronics, robotics, and machine learning, MATLAB and Simulink are synonomous with simulation and model-based design. For research scholars, understanding MATLAB Simulink is often a requisite, if not always an easy feat. That is where PhD Assistants comes into play, offering premier MATLAB Simulink assistance, online training, and custom project progression, so you can better focus on your research.

Specialized MATLAB Simulink Support for PhD and MTech Scholars

PhD Assistants provides peer-to-peer MATLAB Simulink support, to help MTech and PhD scholars to frame a project in relation to their specific needs in the engineering, science, and technology domain. The team not only understand their particular area but also have many years of practical experience in creating simulation models and technical projects using MATLAB and Simulink.

Support is available from simple simulation arrangement right through to complex and detailed real-time modeling, including:

Model Design & Simulation

Code Generation & Testing

Real-Time Systems Implemented

Toolbox-specific support (Simscape, Stateflow, DSP System Toolbox)

PhD Assistants practitioners are interested in ensuring we provide more than just technical support, but support with understanding and academic value, enabling the scholar to freely build, represent and disseminate their MATLAB Simulink project.

Comprehensive MATLAB Simulink Online Guidance – Learn from Anywhere

PhD Assistants is aware of the expectations of digital learners today. That is why a structured learning environment providing MATLAB Simulink online training sessions. PhD Assistants echoes flexibility and convenience while never losing the depth.

The online sessions include:

One on one live tutorial

Step by step Project Explanation

Building actual models

Custom learning paths, depending on research topics

These sessions have great value for researchers wishing to build their conceptual understanding and hands-on practical skills at the same time.

Why Choose PhD Assistants for MATLAB Simulink Services?

Subject Matter Experts: Work with highly professional MATLAB and Simulink experts with extensive academic and industrial experience.

100% Customization: Get support custom to your research title, domain, and university style/format.

Online and Offline Delivery: Get real-time online sessions or ready to deliver project packages.

On-time completion and support: Projects and support are given on time, with regular updates, and open communication.

Get Started Today

Whether you’re encountering difficulties with a Simulink model, putting together a journal publication, or developing a sophisticated simulation project, PhD Assistants is your academic collaborator. Boost your research output with professional MATLAB Simulink services that save time, elevate quality, and assure academic success.

0 notes

Text

Exploring B.Tech in Mechanical Engineering: Scope, Career Paths, and Why It’s Still a Top Choice in 2025

In an era of rapid technological change, where AI and data science often dominate the headlines, Mechanical Engineering remains the timeless backbone of the modern industrial world. If you're a student wondering which engineering branch offers the perfect blend of traditional strength and future adaptability, then B.Tech in Mechanical Engineering should be at the top of your list.

This comprehensive program continues to be a cornerstone of India’s engineering education, producing professionals who power everything from manufacturing and automotive industries to space research and robotics.

So what exactly does a B.Tech in Mechanical Engineering entail? What career opportunities does it open up in today’s evolving job market? And why do thousands of students still choose this field every year?

Here’s your detailed guide, inspired by insights from Edunet Educare’s expert breakdown.

What is B.Tech in Mechanical Engineering?

A Bachelor of Technology (B.Tech) in Mechanical Engineering is a 4-year undergraduate program that delves into the design, development, manufacturing, and maintenance of mechanical systems. From engines and turbines to robotics and advanced materials, this program offers a holistic education in the principles of mechanics, thermodynamics, fluid dynamics, and material science.

Unlike many modern engineering streams that are confined to the digital space, mechanical engineering bridges physical systems with emerging technologies like automation, 3D printing, and artificial intelligence.

Core Subjects Covered in B.Tech Mechanical Engineering

The course curriculum is comprehensive and includes both theoretical and hands-on training. Some of the major subjects you will encounter include:

Engineering Mechanics

Thermodynamics

Fluid Mechanics

Heat and Mass Transfer

Machine Design

Manufacturing Technology

Mechatronics

CAD/CAM (Computer-Aided Design & Manufacturing)

Industrial Engineering

Robotics and Automation

In addition to lab sessions, students often take part in industrial training, internships, and final-year projects, which help in applying theoretical concepts to real-world scenarios.

Skills You’ll Gain

Mechanical engineers are problem-solvers. This course helps students build:

Strong analytical and mathematical skills

Creative design thinking

Technical drawing and modeling

Use of engineering software like AutoCAD, SolidWorks, ANSYS, MATLAB

Project management and teamwork

Knowledge of safety standards and industry practices

These skills make mechanical engineers versatile across industries.

Top Colleges for B.Tech in Mechanical Engineering in India

If you are serious about pursuing this program, selecting the right institution is key. Some of the most reputed colleges for Mechanical Engineering include:

IITs (Indian Institutes of Technology) – like IIT Bombay, IIT Madras, IIT Delhi

NITs (National Institutes of Technology)

BITS Pilani

Delhi Technological University (DTU)

Vellore Institute of Technology (VIT)

MIT Manipal

College of Engineering Pune (COEP)

For a curated list of top-performing colleges and personalized counseling, students can refer to: 👉 Edunet Educare – Mechanical Engineering Program Guide

Career Opportunities After B.Tech Mechanical Engineering

Graduates from this stream are highly employable across core industries and emerging tech sectors. Here's a breakdown of some major career paths:

1. Core Mechanical Roles

Design Engineer

Production Engineer

Maintenance Engineer

Quality Control Engineer

CAD/CAM Specialist

2. Advanced Tech Roles

Robotics Engineer

Mechatronics Engineer

Automation Specialist

Thermal System Designer

3. Management and Consultancy

Supply Chain Analyst

Operations Manager

Project Engineer

Technical Consultant

4. Higher Education and Research

Many students pursue M.Tech, MBA, or even MS abroad to specialize further or shift to managerial roles.

Government and Public Sector Jobs

Mechanical Engineers are regularly recruited into:

PSUs like BHEL, ONGC, GAIL, SAIL, IOCL

DRDO, ISRO, HAL for aerospace and defense research

Indian Railways and Public Works Departments

UPSC & State-level Engineering Services

With a good GATE score, opportunities in government sectors are abundant and secure.

Entrepreneurship and Startups

The rise in startup culture and Make in India initiatives has also opened doors for mechanical engineers in product design, manufacturing, automation systems, and more. From 3D printing startups to custom EV parts manufacturing—innovation is thriving in this space.

Emerging Fields for Mechanical Engineers

Mechanical Engineering is constantly evolving. Here are some exciting future-focused areas:

Green Energy and Sustainable Engineering

Electric Vehicle (EV) Technology

Aerospace and UAV Systems

Nanotechnology and Smart Materials

AI-Driven Manufacturing (Industry 4.0)

With multidisciplinary collaboration becoming the norm, mechanical engineers with digital skills are in high demand.

Salary Expectations

The average starting salary for mechanical engineering graduates in India ranges between ₹3.5 – ₹6 LPA, depending on the college, location, and company. With experience and specialization, this can easily grow into ₹10–20 LPA in managerial or overseas roles.

PSUs offer salaries as per the 7th Pay Commission, along with job stability and government perks.

Why Choose Mechanical Engineering in 2025?

Despite the rise of software-centric courses, mechanical engineering continues to be one of the most evergreen and versatile fields. Here’s why:

✅ Demand in Core & Non-Core Sectors ✅ Strong Foundation for Interdisciplinary Roles ✅ Global Career Opportunities ✅ Innovation-Friendly – Especially in renewable energy and automation ✅ Balanced mix of theory and application

Mechanical engineers are the builders of civilization—from bridges and automobiles to Mars Rovers and next-gen cooling systems. If you love solving real-world problems and creating tangible solutions, this course is for you.

Final Word

Choosing a career path is a major decision, and it should align with both your interests and the demands of the market. B.Tech in Mechanical Engineering provides a perfect balance between tradition and innovation, with endless opportunities across industries.

To explore top colleges, entrance exam guidance, and personalized mentoring for your engineering journey, visit: 🔗 Edunet Educare – Mechanical Engineering Course Guide

#B.Tech Mechanical Engineering#Mechanical Engineering Courses#Career in Mechanical Engineering#Engineering in India#Mechanical Engineering Scope#Top Engineering Colleges#STEM Careers India#Future of Mechanical Engineering#Edunet Educare

0 notes

Text

Why Robotics and AI are the Future of Engineering Education

In a world rapidly shaped by automation, smart machines, and intelligent systems, engineering education is undergoing a major transformation. Traditional streams like mechanical, electrical, and computer science remain foundational—but the spotlight is now firmly on emerging interdisciplinary domains like robotics and artificial intelligence (AI).

Understanding how these two disciplines are revolutionizing industries is essential for students entering the engineering field. More importantly, opting for robotics and artificial intelligence courses can open up a wide range of career opportunities that are not only future-proof but also globally relevant.

Technology Is Redefining How We Work

From self-driving cars and intelligent healthcare systems to automated factories and virtual assistants, AI and robotics are already embedded in everyday life. These technologies are no longer optional—they are essential components in solving modern problems.

As industries evolve, there is a growing demand for professionals who understand how to design, develop, and manage intelligent machines and systems. This demand is changing what engineering students need to learn, and how they prepare for their careers.

Robotics and AI: A Perfect Match

While robotics focuses on building physical machines that can move, interact, and perform tasks, AI gives these machines the intelligence to make decisions, learn from data, and improve over time. Together, they create systems that can work autonomously, adapt to new situations, and predict outcomes.

This integration has applications across fields like:

Manufacturing and automation

Healthcare and surgery

Agriculture and precision farming

Defense and security

Smart cities and infrastructure

The skills gained through robotics and AI education enable students to work across these varied sectors, making their career options more diverse and future-focused.

An Interdisciplinary Learning Experience

What makes robotics and artificial intelligence courses especially unique is their interdisciplinary nature. Students don’t just learn programming or mechanical design—they combine knowledge from:

Electronics and sensors

Computer science and machine learning

Mechanical systems and automation

Control theory and embedded systems

Data analysis and cognitive computing

This holistic learning approach produces engineers who are better equipped to solve complex, real-world problems using intelligent technology.

Skills That Matter in 2025 and Beyond

Today’s employers look for more than technical expertise. They want professionals who can:

Code in Python, C++, or MATLAB

Work with microcontrollers and robotic platforms

Apply AI tools like TensorFlow or OpenCV

Design systems using simulation and modeling software

Think critically and collaborate across disciplines

Robotics and AI programs nurture these abilities by blending classroom instruction with project-based learning, labs, and internships. This real-world exposure helps students transition smoothly into industry or advanced research.

Why Students Are Choosing This Path

For many students, the appeal of robotics and AI lies not just in the technology—but in its impact. These fields allow you to work on meaningful innovations like assistive robots, disaster-response systems, clean energy automation, or medical diagnostics powered by AI.

In short, students can use their skills to solve urgent global challenges—while also building strong, rewarding careers.

A Smart Choice for the Future

For aspiring engineers, now is the right time to explore programs that specialize in robotics and AI. Institutions that offer a future-focused curriculum, strong lab infrastructure, and industry partnerships give students the edge they need in a competitive global market.

One such institution is the NMAM Institute of Technology (NMAMIT), under NITTE University. The college offers a dedicated program in robotics and artificial intelligence that blends engineering fundamentals with hands-on training, research exposure, and career development support. With access to modern labs, experienced faculty, and real-world projects, students are prepared not just for their first job—but for the technologies of tomorrow.

Conclusion

Robotics and AI are reshaping the way we live, work, and learn. As the demand for intelligent systems grows, so does the need for skilled professionals who can create and manage them. By choosing the right robotics and artificial intelligence courses, students can position themselves at the heart of innovation.

For those seeking to build future-ready skills in an academically strong and industry-connected environment, NMAMIT at NITTE University offers a path worth considering.

1 note

·

View note

Text

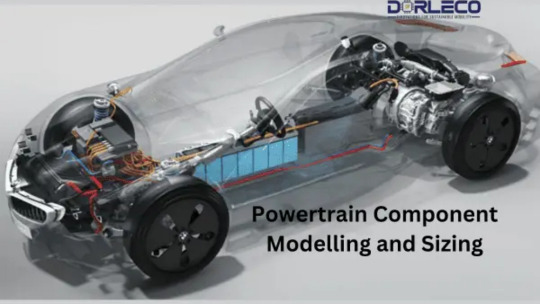

Powertrain Component Modelling and Sizing

Introduction

The dynamic automotive sector is depending more and more on virtual engineering and digital simulations to satisfy strict performance, efficiency, and regulatory requirements. The core of a vehicle’s design is the powertrain, which is the collection of elements that are accountable for generating and distributing power to the wheels. In order to achieve the best possible balance between performance, fuel efficiency, cost, and emissions, powertrain component modelling and size are crucial, regardless of the powertrain’s configuration — internal combustion engine (ICE), hybrid, or entirely electric. The systematic technique, advantages, difficulties, and prospects for powertrain component modelling and sizing in the automotive engineering process are all examined in this blog.

1. Understanding the Powertrain Component

Determining the vehicle’s intended use and performance goals is the first step in any powertrain development cycle. This fundamental stage lays the groundwork for component-level specifications and architectural choices.

Vehicle Type: EV, hybrid, commercial vehicle, sports car, or passenger car.

Performance metrics: include top speed, gradeability, towing capacity, and desired acceleration (0–100 km/h).

Compliance goals include safety regulations, fuel economy requirements, pollution regulations, and sustainability goals.

A thorough comprehension of these factors guarantees that the finished powertrain design complies with regulatory standards and market expectations.

2. Powertrain Architecture Selection

The type of vehicle and its intended use have an impact on the strategic choice of powerplant layout. Among the primary categories are:

Engine Internal Combustion (ICE)

Powertrain Hybrid (PHEV, HEV)

Electric Vehicles with Batteries (BEV)

Electric Vehicles using Fuel Cells (FCEV)

Core elements such the engine, electric motor, battery, gearbox, and control units must interact differently in each architecture. For downstream modelling, it is crucial to map the component interaction and energy flow paths at this point.

3. Modelling at the Component Level

Modelling engines

Modelling for ICE-based systems includes:

Creation of torque-speed curves

Mapping of fuel consumption

Emissions modelling and thermal behaviour

To model operating circumstances, assess combustion efficiency, and investigate transient responses, advanced programs such as GT-Power, AVL Cruise, or MATLAB/Simulink are used.

1.Modelling Transmissions

In this context, the gearbox connects wheel torque and engine power, while modelling helps determine:

Ideal gear ratios

Timing and logic for gear changing

Losses brought caused by inertia and friction

Reactivity and driveability

Single-speed gearboxes are frequently used in electric vehicles; nonetheless, efficiency and thermal considerations are still crucial.

2. Modelling Electric Motors and Batteries

In systems that are electrified:

Electric Motor: Efficiency mapping, torque-speed characteristics, inverter management, and the possibility of regenerative braking are all included in the simulations.

State of charge (SOC), voltage-current profiles, thermal performance, capacity decline, and charging/discharging behaviour are all included in the models of batteries.

Consequently, these components play a vital role in enabling accurate range estimation and supporting effective hybrid control schemes.

3. Control System Modelling

To that end, modern cars use intelligent control algorithms to regulate the flow of torque and energy. Key elements include:

Distribution of power in hybrid automobiles

Energy management systems for batteries (BMS)

Control of traction and stability

Regenerative braking and torque vectoring

Furthermore, control system modelling optimises real-time responses by ensuring smooth interaction between physical components.

4. Component sizing and optimisation

Each component is guaranteed to be neither overdesigned nor underutilised with proper dimensions. Engineers optimise variables like

Engine displacement and output torque

Maximum power and continuous motor rating

C-rate and battery capacity

Gear ratios for transmissions

The proper trade-offs between performance, efficiency, cost, and packing can be achieved with the aid of optimisation technologies (such as genetic algorithms and experiment design).

5. Compatibility and System Integration

The powertrain must function as a cohesive system in addition to its individual performance. Important integration factors consist of:

Thermal control of the battery, inverter, and engine.

Packaging and weight distribution to maintain vehicle dynamics

Features of NVH (Noise, Vibration, Harshness)

Compatibility of mechanical and electrical interfaces

Therefore, ignoring these elements may lead to inefficiencies, reliability issues, or dissatisfied clients.

6. Performance Validation Through Simulation

Subsequently, once components are designed and scaled, system-level simulations are conducted to validate the full powertrain component across real-world scenarios.

Urban driving cycles, such as the FTP-75 and WLTP

Profiles of highway loads

Simulations of hill climbing or towing

Conditions for idle-stop and regenerative braking

Engineers can create control methods and identify bottlenecks early in the process with the help of simulation technologies (such as MATLAB, dSPACE, and IPG Carmaker).

7. Physical Testing and Prototyping

Although simulation offers a theoretical starting point, physical testing is still necessary:

Prototype vehicle builds

Engine test beds and dynamometers for the chassis

Tests of endurance and durability

Prior to mass production, these tests ensure system robustness by validating predictions and identifying unforeseen mechanical, thermal, or ergonomic concerns.

8. Cost Analysis and Compromises

Additionally, a high-performance Powertrain Component needs to be profitable. Cost modelling includes:

Complexity of manufacturing and material selection

Tooling expenses and supplier availability

Implications for warranty and maintenance

In addition, simulations help identify cost-effective solutions without sacrificing critical performance parameters.

9. Iterative Refinement

In practice, the development process is rarely linear; instead, several design iterations are driven by insights gained from simulation, testing, and consumer feedback.

Modifying component specifications

Control logic revision

Power split or thermal load rebalancing

Consequently, this iterative loop ensures that the end product is optimised on all fronts — performance, cost, durability, and regulatory compliance.

10. Records and Adherence

As a result, this iterative loop not only streamlines development but also ensures that the end product is optimised on all fronts — performance, cost, durability, and regulatory compliance.

Logs from simulations and technical reports

Design specifications and the bill of materials

Safety requirements and emissions certifications

Design decision traceability

Proof of due diligence throughout the development process is necessary to comply with international rules (such as those set forth by the EPA, CARB, and UNECE).

Benefits of Powertrain Component Modelling and Sizing:

✔ Performance Enhancement

Fine-tuning for certain objectives, such as high torque, quick acceleration, or fuel economy, is possible through simulation.

✔Enhanced Productivity

Appropriate size improves energy efficiency on both ICE and EV platforms by preventing overdesign and lowering internal losses.

✔ Saving Money

Furthermore, by avoiding needless overspecification, manufacturers can effectively reduce manufacturing and material costs without compromising quality.

✔ Emissions Management

As a result of precise engine mapping and electric system optimisation, CO₂ and NOₓ emissions are significantly reduced.

✔ Predictive Knowledge

Prior to costly tooling and prototyping, simulations identify possible failure areas or inefficiencies.

✔ Personalisation

The architecture and Powertrain Component flexibility made possible by early modelling is advantageous for a variety of vehicle types, including haul trucks and two-wheelers.

✔ Superior Energy Organisation

Reliability and range are directly impacted by efficient battery and power management systems, particularly in EVs and hybrids.

✔ Reduced Market Time

Virtual iterations make faster development cycles possible as opposed to conventional build-and-test loops.

✔ Dependability

Moreover, stress analysis and thermal modelling ensure durability, which in turn lowers warranty claims and enhances brand recognition.

✔ Attention to Regulations

By ensuring early compliance with international safety and emissions standards, manufacturers can significantly reduce the need for costly redesigns later in the development cycle.

Difficulties with Powertrain Component Sizing and Modelling

Despite its strength, this strategy has drawbacks: Model Complexity: It takes knowledge and computing power to accurately simulate multi physics systems. Data Reliability: Reliable input data is necessary for model accuracy, which frequently necessitates rigorous physical testing for calibration. Integration Difficulties: Maintaining balance between electrical, mechanical, and control systems is difficult. Dynamic Operation Limits: Unexpected real-world circumstances are not always taken into account by models. Cost of Software Tools: Smaller businesses cannot afford the sophisticated simulation suites. Rapid Technological Changes: As EVs advance quickly, current models may become outdated. Real-World Parameter Uncertainty: It is challenging to accurately forecast traffic, temperature, and driver behaviour.

Conclusion

At the forefront of contemporary vehicle engineering is the modelling and sizing of powertrain components. In a cutthroat market, they enable automakers and suppliers to create vehicles that are effective, legal, and perform well. Engineers may unlock better ideas while cutting down on time, expense, and environmental effect by combining virtual simulations with actual testing. Modelling techniques will only become more crucial as the sector continues its transition to electrification and autonomous systems. Experts anticipate that future developments in digital twins, AI-driven simulations, and cloud-based co-simulation platforms will further push the limits of accuracy and effectiveness. Powertrain modelling and sizing are essentially strategic enablers of innovation, performance, and sustainability in mobility when used with insight and rigour.

#Dorleco#EVEngineering#PowertrainModelling#AutomotiveInnovation#VCU#CANDisplay#BatteryManagement#SimulationDrivenDesign#ElectricVehicles#MobilitySolutions#FutureOfTransport#EngineeringExcellence#DigitalEngineering

0 notes

Text

From Cars to Wearables: The Stealthy Power of Embedded Systems

Embedded systems are the invisible backbone of modern technology. These compact, task-specific computing units are embedded into larger systems to perform dedicated functions. From your car's braking system to the smartwatch on your wrist, embedded systems quietly power our daily lives. At Silicon Signals, we bring these innovations to life through expert embedded systems development services.

What Are Embedded Systems?

Embedded systems blend hardware and software, designed for a specific application within a broader system. Unlike general-purpose computers, they prioritize efficiency, speed, and reliability. For example, an anti-lock braking system (ABS) in vehicles prevents wheel lock-up during sudden stops—this is a primary embedded system. Meanwhile, a mobile dashboard app showing vehicle diagnostics can be seen as a secondary embedded system.

Real-World Applications of Embedded Systems

1. Automotive: Driving the Future

Cars today are filled with embedded systems. These systems manage engine performance, fuel economy, safety features, and even autonomous driving.

Engine Control Units (ECUs): Ensure optimal engine performance and emission control.

ADAS (Advanced Driver Assistance Systems): Handle functions like adaptive cruise control, lane assistance, and collision avoidance.

Example: Tesla's Autopilot is powered by sophisticated embedded systems that combine real-time processing, AI, and sensor fusion.

2. Wearables: Technology You Can Wear

Wearables like smartwatches and fitness bands use embedded systems to provide health monitoring and real-time feedback.

Example: The Apple Watch uses embedded software for ECG monitoring, heart rate tracking, and fitness tracking—demonstrating how embedded systems enable personal health management.

3. Smart Homes and Consumer Electronics

From smart refrigerators to voice-activated assistants, embedded systems enhance user experience and functionality in consumer devices.

Smart TVs: Enable AI-driven content recommendations, app integrations, and voice control.

Home Automation: Devices like Amazon Alexa and Google Nest rely on embedded systems to manage everything from lighting to security.

Example: Samsung SmartThings platform unifies home automation by integrating multiple embedded systems into a single control hub.

The Role of Embedded Systems Development Services

At Silicon Signals, our embedded development services help businesses innovate efficiently. Our offerings include:

Hardware Design & Optimization: Creating compact, reliable, and power-efficient solutions.

Firmware Development: Building responsive, scalable software for embedded hardware.

Testing & Validation: Ensuring compliance and safety through rigorous testing.

IoT & Edge Integration: Enabling real-time, low-latency data processing and connectivity.

Whether you're in automotive, healthcare, industrial automation, or consumer tech, we provide tailor-made solutions to meet your embedded system needs.

Leading Tools in Embedded Systems Development

1. MATLAB & Simulink

Used extensively for modeling, simulation, and testing, particularly in automotive and aerospace industries.

Ideal for hardware-in-the-loop (HIL) testing

Rich libraries for control and signal processing

Example: Aerospace developers simulate flight control systems using Simulink to reduce development time and ensure safety.

2. Keil µVision

A go-to IDE for ARM microcontrollers, commonly used in medical and industrial devices.

Offers intuitive debugging and RTOS support

Example: Used in the development of precision medical devices like insulin pumps for safe and reliable dosage control.

Key Development Tips

Clear Design Objectives: Align your embedded system with operational goals and constraints.

Rigorous Testing: Ensure functionality and reliability at every stage.

Modular Design: Build scalable, easy-to-update components.

Security First: Implement encryption, secure boot, and regular firmware updates.

Emerging Trends in Embedded Systems

AI Integration: Smart systems for predictive analytics and automation.

Low-Power Design: Energy-efficient systems to support sustainability.

Edge Computing: Real-time local processing for applications like autonomous vehicles.

Overcoming Development Challenges

Scalability: Design systems that evolve with tech advances.

Integration: Ensure seamless operation with existing systems.

Security: Combat cyber threats with robust protections.

Speed-to-Market: Maintain innovation without sacrificing quality.

Conclusion: Embedded Systems at the Heart of Innovation

Embedded systems are revolutionizing how we live and work. From self-driving cars to smart homes and wearable health monitors, their presence is growing—and so is their impact. Companies that embrace embedded development will shape the future of connected technology.

Partner with Silicon Signals to develop next-gen embedded systems that are efficient, secure, and scalable.

Ready to turn your idea into reality? Let's build smarter systems together.

Contact Silicon Signals today for embedded development solutions that power innovation.

Mail us on: [email protected]

0 notes

Text

Understanding Mechatronics: A Beginner’s Guide for Freshers

If you’ve just stepped into the world of engineering or are considering which specialization to pursue, you might have come across the term Mechatronics. It sounds futuristic—and honestly, it is. But what exactly is it? Is it mechanical? Is it electronics? Or is it something else altogether?

Let’s break it down and make it simple for you.

What Is Mechatronics?

Mechatronics is an interdisciplinary field that blends mechanical engineering, electronics, computer science, and control engineering. It’s all about designing and creating smarter machines—systems that not only move or perform tasks but also think and respond intelligently.

Think of things like self-driving cars, robotic arms in factories, automated coffee machines, or even drones that maintain stability mid-air. All of these rely on the principles of mechatronics.

This discipline is becoming essential in today’s automation-driven world, especially with the rise of Industry 4.0, where machines communicate with each other to optimize performance without human input.

Why Should You Care as a Fresher?

In the early stages of your engineering journey, it's important to understand where the future is headed. Mechatronics is one of those areas that’s not just growing—it’s exploding.

As a fresher, you might still be figuring out what excites you most. But if you're someone who enjoys blending creativity with technology—imagine coding a program and then watching it control a real robot—this field will likely click with you.

Also, if you eventually want to work in automation, AI-driven systems, or robotics, mechatronics offers you the foundation and flexibility to go in multiple directions.

What Will You Learn in Mechatronics?

Typically, if you pursue mechatronics as a core subject or even as an elective, you’ll dive into areas like:

Sensors and Actuators: Devices that help machines sense their environment and act accordingly.

Microcontrollers and Embedded Systems: The brains of most modern electronic machines.

Mechanical Design: Basics of gears, motors, and structures that move.

Control Systems: How to ensure a robot does what it’s supposed to—no more, no less.

Programming: Often in C/C++ or Python to control the devices.

You may also get your hands on software like MATLAB, Simulink, or Arduino IDE early on.

How to Get Started in College

You don't have to wait till the third year to explore mechatronics. In fact, some colleges start offering related workshops and certifications right from the first year. If you're studying in a place where the labs are well-equipped and faculty are research-active, you'll probably get the chance to work on actual robots or automation systems before you graduate.

During a visit to a lab at NMIET Bhubaneswar, I noticed students working on automated vehicle prototypes that used sensors for obstacle detection. It struck me how mechatronics isn’t just a theoretical subject in such institutions—it’s hands-on and real.

Career Scope: Where Can Mechatronics Take You?

Mechatronics engineers are highly valued in sectors like:

Robotics and Automation

Aerospace

Automobile Manufacturing

Medical Equipment Development

Home Automation and Smart Devices

With increasing reliance on smart systems and AI-driven hardware, companies are actively seeking engineers who can work across domains. This is where mechatronics gives you a massive edge.

Even core mechanical or electrical engineers are now advised to pick up basic knowledge of microcontrollers or coding. So, if you're already in a college that encourages learning beyond your core, you're in the right place.

What Makes a Good College for Mechatronics Learning?

Let’s be honest—your learning environment plays a big role. Access to automation labs, exposure to industry tools, faculty who encourage innovation, and the chance to work on real-world projects—these are the things that matter most.

Some of the top engineering colleges in Odisha are already introducing mechatronics modules in mechanical and electronics streams. The goal is to create engineers who can build, code, and innovate.

It’s always a good idea to look into whether the institute collaborates with industries for internships and whether they have tie-ups for campus placements with companies involved in automation or robotics.

Final Thoughts: A Future-Proof Path

Mechatronics is not just another subject—it’s a mindset. It teaches you to look at machines not just as static components, but as intelligent systems that interact with the world.

As a fresher, you don’t need to master it all at once. Start with basic projects—maybe build a line-follower robot or an automatic light system. Join clubs, take up online certifications, and most importantly, stay curious.

If you’re in an environment where creativity and cross-disciplinary learning are encouraged—like the one I saw at NMIET—you’re already ahead of the curve.

So, if you’re dreaming of working on robots, smart devices, or even futuristic innovations we haven’t seen yet—mechatronics might just be the path you’ve been looking for.

#bhubaneswar b tech colleges#college of engineering bhubaneswar#best engineering colleges in orissa#best engineering colleges in bhubaneswar#best private engineering colleges in odisha#best engineering colleges in odisha

0 notes

Text

Electrical Engineering Assignment Help

-Power Systems: Power generation, distribution, and renewable energy solutions.

-Telecommunication: Designing and analyzing communication systems, including wireless and optical communications.

-Signal Processing: Techniques like Fourier and Laplace transforms, digital filters, and signal transmission.

-Control Systems: System analysis, stability, feedback control, and automated systems.

2.Key Tools We Use

Our team leverages powerful software tools to tackle intricate electrical engineering challenges:

-LabVIEW: For creating virtual instruments and simulation of electrical systems.

-PSpice/Multisim: For circuit simulation and analysis of electrical circuits.

- AutoCAD/ANSYS: For designing electrical systems and layouts.

3.Why Electrical Engineering is So Demanding

-Complexity of Topics: Electrical engineering combines complex mathematical equations, theoretical concepts, and practical applications. Mastery over the core subjects, from circuit theory to digital electronics, requires constant practice

4.Our Process for Assisting Students

-Step 1: Request Your Assignment Help: Share the details of your assignment or project through email or our website.

-Step 2: Customized Solutions**: Our experts study the problem and create a custom solution tailored to your requirements.

5.Advanced Topics and Research Support

- Advanced Circuit Design: Focused on intricate designs and simulations for complex circuits.

-Power System Optimization: Helping students work on advanced power system analysis and optimization techniques

6. Student Testimonials

-All Assignment Experts really helped me understand power systems better. Their clear explanations made complex concepts easier to grasp. – Ryan, Electrical Engineering Student

- I was struggling with MATLAB assignments, but the team here guided me through every step. They helped me improve my grades significantly.” – Jessica, Undergraduate Student

- I got my renewable energy project done with the help of experts. The team was quick, and my professor was impressed by the quality. – Mark, Senior Student

Kickstart Your Path to Academic Success Today!

0 notes

Text

Model-Based Design with Simulink: Revolutionizing Engineering Development

In today’s fast-paced and increasingly complex engineering landscape, traditional development methods are being replaced by more efficient and integrated solutions. One such groundbreaking approach is Model-Based Design (MBD), particularly through Simulink, a powerful simulation and model-based environment from MathWorks. MBD with Simulink streamlines the design, testing, and implementation of dynamic systems, providing engineers with a comprehensive framework that enhances innovation, collaboration, and product quality.

What is Model-Based Design?

Model-Based Design is a systematic approach to engineering that uses models as an integral part of the development process. Instead of writing code or building prototypes early on, engineers create system-level models to simulate, analyze, and validate behavior. These models serve as executable specifications and help bridge the gap between theoretical design and practical implementation.

The core advantages of MBD include:

Accelerated development cycles

Improved accuracy and reliability

Seamless verification and validation

Enhanced communication between multidisciplinary teams

Why Simulink?

Simulink, a product of MathWorks, is a visual programming environment that enables engineers to model, simulate, and analyze multidomain dynamic systems. It’s integrated tightly with MATLAB and provides libraries of predefined blocks for continuous and discrete systems, signal processing, controls, communication, and more.

With Simulink, users can design complex systems using block diagrams instead of traditional code. This makes it easier to visualize system behavior and quickly iterate designs through simulation.

Key Features of Simulink in Model-Based Design

1. Graphical Modeling

Simulink allows you to build models using intuitive block diagrams, enabling engineers to visually assemble system components and logic. This approach improves collaboration, especially in multidisciplinary teams, by offering a clear view of system behavior.

2. Simulation and Analysis

One of Simulink’s most powerful features is its ability to simulate system dynamics. Engineers can test various conditions, input signals, and fault scenarios without building physical prototypes, reducing development time and costs.

3. Automatic Code Generation

With Simulink Coder, Embedded Coder, and HDL Coder, engineers can automatically generate production-quality C, C++, and HDL code directly from their models. This ensures that the final implementation is aligned with the tested model, reducing integration errors.

4. Verification and Validation

Simulink includes tools for formal verification, testing, and validation such as Simulink Test, Simulink Coverage, and Simulink Design Verifier. These tools help ensure the system meets specifications and regulatory requirements throughout development.

5. Integration with Hardware

Simulink models can be deployed to hardware for real-time simulation and testing. It supports hardware-in-the-loop (HIL) and processor-in-the-loop (PIL) testing, allowing for seamless transition from design to deployment.

Applications of Model-Based Design with Simulink

Model-Based Design using Simulink is widely applied across industries:

Automotive

In the automotive sector, MBD is used for developing control systems such as powertrain, braking, steering, and advanced driver-assistance systems (ADAS). Simulink allows engineers to simulate vehicle dynamics, test control algorithms, and generate production-ready embedded code.

Aerospace and Defense

Simulink supports the design of flight control systems, navigation, and communication systems. It ensures safety and reliability through rigorous simulation, code verification, and compliance with industry standards like DO-178C.

Industrial Automation

Engineers in industrial automation use Simulink to develop and validate control strategies for manufacturing processes, robotics, and instrumentation. It integrates with PLCs and other industrial hardware to streamline deployment.

Medical Devices

In medical technology, Simulink enables the design and testing of life-critical systems such as infusion pumps, ventilators, and diagnostic devices. The visual modeling approach supports compliance with regulatory standards like ISO 13485 and IEC 62304.

Benefits of Using Simulink for Model-Based Design

1. Reduced Development Time

Simulink enables rapid prototyping and iterative testing through simulation, allowing teams to identify and resolve issues early in the development cycle.

2. Improved Design Quality

Modeling and simulating complex systems ensure that designs are thoroughly analyzed and optimized before deployment, leading to higher performance and reliability.

3. Cost Efficiency

By minimizing physical prototyping and reducing time-to-market, MBD with Simulink helps companies save on development costs and resource allocation.

4. Cross-Functional Collaboration

The visual nature of Simulink models makes it easier for engineers from different domains (mechanical, electrical, software) to collaborate and contribute to a unified system design.

5. Traceability and Documentation

Simulink supports documentation and traceability throughout the development process, which is essential for safety-critical industries and compliance with standards.

Challenges and Considerations

While Simulink and MBD offer numerous advantages, successful implementation requires:

Proper training and expertise in Simulink and MBD principles

Well-defined modeling guidelines and version control

Integration with existing workflows and tools

Clear communication across engineering teams

Organizations must also ensure that they have the necessary infrastructure and toolchain to fully benefit from model-based practices.

Conclusion

Model-Based Design servotechinc with Simulink is transforming the way engineering teams develop complex systems. By emphasizing modeling, simulation, and automated code generation, Simulink enables faster development, higher quality, and a smoother path from concept to deployment.

Whether you're working in automotive, aerospace, medical devices, or industrial automation, leveraging Simulink for MBD offers a robust, scalable, and future-ready approach to engineering innovation. As industries continue to demand smarter and safer systems, Model-Based Design with Simulink stands out as a vital tool in the modern engineer’s toolkit.

0 notes

Text

Best Machine Learning Jobs for 2025

Machine learning (ML) is transforming industries, and demand for skilled professionals is higher than ever. If you’re considering a career in ML, here are some of the top roles you should explore in 2025.

1. Machine Learning Engineer

Machine Learning Engineers build and optimize ML models for real-world applications. They collaborate with data scientists and software developers to deploy AI-powered solutions. This role is one of the best machine learning jobs for 2025, offering high demand and competitive salaries.

Key Skills:

Proficiency in Python, TensorFlow, and PyTorch

Strong understanding of data structures and algorithms

Experience with cloud computing and deployment frameworks

2. Data Scientist

Data Scientists extract insights from large datasets using statistical methods and ML models. Their expertise helps businesses make data-driven decisions.

Key Skills:

Strong background in statistics and data analytics

Proficiency in Python, R, and SQL

Experience with data visualization and machine learning frameworks

3. AI Research Scientist

AI Research Scientists work on cutting-edge AI innovations, improving existing ML techniques and developing new algorithms for various applications.

Key Skills:

Advanced knowledge of deep learning and neural networks

Strong mathematical and statistical background

Proficiency in Python, MATLAB, or Julia

4. Computer Vision Engineer

Computer Vision Engineers specialize in AI systems that process and analyze visual data, such as facial recognition and autonomous vehicles.

Key Skills:

Expertise in OpenCV, TensorFlow, and PyTorch

Experience with image processing and pattern recognition

Knowledge of 3D vision and augmented reality applications

5. NLP Engineer

Natural Language Processing (NLP) Engineers design models that allow machines to understand and generate human language, powering chatbots, virtual assistants, and more. This profession is expected to remain one of the top machine learning careers in 2025, with continued advancements in AI-driven communication.

Key Skills:

Proficiency in NLP frameworks like spaCy and Hugging Face

Experience with speech recognition and sentiment analysis

Strong programming skills in Python and deep learning

6. Deep Learning Engineer

Deep Learning Engineers develop advanced neural networks for applications like medical imaging, autonomous systems, and voice recognition.

Key Skills:

Expertise in TensorFlow and PyTorch

Strong understanding of neural networks and optimization techniques

Experience with large-scale data processing

7. ML Ops Engineer

ML Ops Engineers ensure the seamless deployment, automation, and scalability of ML models in production environments.

Key Skills:

Experience with CI/CD pipelines and model deployment

Proficiency in Kubernetes, Docker, and cloud computing

Knowledge of monitoring and performance optimization for ML systems

8. Robotics Engineer

Robotics Engineers integrate ML models into robotic systems for industries like healthcare, manufacturing, and logistics.

Key Skills:

Experience with robotic simulation and real-time control systems

Proficiency in ROS (Robot Operating System) and C++

Understanding of reinforcement learning and sensor fusion

9. AI Product Manager

AI Product Managers oversee the development of AI-powered products, bridging the gap between business needs and technical teams.

Key Skills:

Strong understanding of AI and ML technologies

Experience in product lifecycle management

Ability to communicate between technical and non-technical stakeholders

10. Reinforcement Learning Engineer

Reinforcement Learning Engineers specialize in training AI agents to learn through trial and error, improving automation and decision-making systems.

Key Skills:

Expertise in reinforcement learning frameworks like OpenAI Gym

Strong knowledge of deep learning and optimization techniques

Proficiency in Python and simulation environments

Conclusion

The demand for machine learning professionals continues to rise, offering exciting opportunities in various domains. Whether you specialize in data science, NLP, or robotics, gaining expertise in the latest ML tools and technologies will help you stay ahead in this dynamic industry. Leveraging AI recruitment Agency can streamline your job search, helping you connect with top employers looking for ML talent. If you're looking for your next ML job, start preparing now to land a high-paying and rewarding role in 2025.

Read More Blogs

0 notes

Text

Interactive Basic Computer Course Online

Basic Computer Course - Aapka Pehla Kadam Digital Duniya Mein

Computers ab har zindagi ka hissa hain. A basic computer course helps you start your digital journey. Yeh article aapko batayega why these skills matter today.

Digital duniya mein aage badhne ke liye, basic computer knowledge zaroori hai. Whether you’re a student ya professional, yeh course opportunities kholta hai. Chalo, iske baare mein detail mein jaante hain!

What is a Basic Computer Course?

Basic computer course ek shuruaati training hai. Yeh aapko fundamental skills aur knowledge deta hai. Topics jaise hardware, software, aur applications cover hote hain.

Iska Hindi naam hai "मूल कंप्यूटर कोर्स". Agar aapne kabhi computer nahi chalaya, yeh perfect hai. Course khatam hone tak, aap daily tasks easily kar sakoge.

Why Should You Take a Basic Computer Course?

Aaj digital zamane mein computer skills bahut important hain. So, yeh course kyun lena chahiye? Here are some wajah:

• Jobs: Har job mein basic computer skills maange jaate hain. Yeh aapko employable banata hai.

• Kaam Fast: Computers tasks ko tez aur aasaan karte hain. Documents likhne se lekar budgeting tak, sab easy ho jata hai.

• Baatcheet: Email aur social media se duniya se judna zaroori hai. Yeh course inka use sikhata hai.

Plus, students ke liye online resources ka fayda hota hai. Personal growth bhi hoti hai jab aap naya seekhte ho. Confidence badhta hai aur mind active rahta hai.

Course Content - Kya Sikhega Aap?

Basic computer course mein kaafi kuch shamil hota hai. Let’s dekhte hain kya-kya seekh sakte hain aap:

Hardware aur Software Basics

Hardware matlab computer ke physical parts hote hain. Jaise monitor, keyboard, aur CPU. Software woh programs hain jo computer chalate hain.

Isme aap hardware pehchanoge. Software kaise kaam karta hai, yeh bhi samajh aayega. Yeh basic step har beginner ke liye zaroori hai.

Operating Systems - Windows, Mac, Linux

Operating system (OS) computer ka dimaag hota hai. Yeh hardware aur software ko control karta hai. Common OS hain Windows, Mac, aur Linux.

Course mein inka basic use sikhaya jata hai. File manage karna aur software install karna bhi aata hai. Yeh knowledge daily kaam mein helpful hai.

Internet aur Email

Internet ek bada jankaari ka jaal hai. Email communication ka zariya hai. Is section mein aap seekhoge:

• Web safe browsing kaise karni hai.

• Email account banane aur chalane ka tarika.

• Online safety aur manners.

Yeh skills aaj har kisi ke liye must hain.

Microsoft Office Suite

Microsoft Office tools ka ek set hai. Isme Word, Excel, aur PowerPoint shamil hain. Yeh kaam ke liye bahut useful hain:

• Word: Documents likhne ke liye.

• Excel: Data manage karne aur spreadsheets banane ke liye.

• PowerPoint: Presentations tayyar karne ke liye.

Course mein inka basic use sikhaya jata hai. Files create, edit, aur save karna aasan ho jata hai.

How to Choose the Right Course?

Bahut saare courses hain, toh sahi chunna mushkil ho sakta hai. Here are kuch tips jo madad karenge:

• Syllabus Dekho: Course mein zaroori topics hone chahiye.

• Teacher ka Experience: Achhe instructors se quality training milti hai.

• Time Flexibility: Apne schedule ke hisaab se course chuno.

Reviews padhna bhi helpful hai. Certificate dene wala course resume ke liye acha hota hai. So, wisely decide karo!

Personal Experience - Mera Safar

Mujhe yaad hai jab maine computer seekhna shuru kiya. Bahut nervousness thi shuruaat mein. Lekin har class ke saath confidence badha.

Ek baar mujhe office ke liye presentation banani thi. Course mein seekhe skills se maine PowerPoint banaya. Sabne tareef ki aur mujhe khushi hui.

Yeh tajurba batata hai ki basic skills kitne powerful hote hain. Yeh aapki personal aur professional life badal sakte hain.

Conclusion - Aapka Agla Kadam

Basic computer course sirf technology seekhna nahi hai. Yeh aapko digital duniya mein strong banata hai. Sahi skills se aap zyada achieve kar sakte ho.

Ab wait mat karo. Aaj hi shuruaat karo. Ek basic computer course join karo aur apna digital safar shuru karo.

Har expert kabhi beginner tha. Aapka time ab hai. Happy learning aur aage badho!

Accountant course ,

Taxation Course

courses after 12th Commerce ,

after b com which course is best ,

Diploma in financial accounting ,

SAP fico course ,

BAT Course ,

GST Course ,

Basic Computer Course fee ,

Payroll Management Course,

Tally training institute,

One year course ,

Advanced Excel Course ,

Computer ADCA Course in Delhi

Data Entry Operator Course fee,

diploma in banking finance ,

Stock market Delhi,

six months diploma course in accounting

Income Tax

Accounting

Tally

Career

#business accounting and taxation (bat) course#diploma in taxation#sap fico course#finance#gst course

0 notes

Text

Mastering MATLAB and Simulink: From Modelling to Digital Communication Applications

In the dynamic world of engineering and technology, MATLAB and Simulink have become indispensable tools for professionals involved in modeling, simulation, and digital communication systems. As the demand for advanced analytical capabilities continues to grow, mastering these platforms is essential for anyone looking to excel in this field. This guide will take you through the fundamentals of MATLAB and Simulink, their applications in digital communication, and how TechSource Asia can help you become proficient in these powerful tools.

Introduction to MATLAB and Simulink for Modelling and Simulation

MATLAB and Simulink are two of the most widely used software platforms for modeling and simulation across various engineering disciplines. MATLAB provides a high-level programming environment for numerical computation, visualization, and application development, while Simulink offers a block diagram environment for multi-domain simulation and model-based design.

These platforms are essential for engineers and scientists who need to design, simulate, and analyze complex systems. Whether you are working on control systems, signal processing, or digital communication, MATLAB and Simulink provide the flexibility and power needed to bring your ideas to life.

Understanding Simulink’s Capabilities

Simulink is a versatile tool that enables users to create detailed models of systems and processes. Its drag-and-drop interface allows you to build complex models using pre-built blocks, making it easier to visualize and simulate the behavior of systems in real time. Simulink is particularly useful for simulating dynamic systems, where understanding the temporal evolution of signals and states is crucial.

With Simulink online, you can easily access this powerful tool from anywhere, ensuring that your projects remain on track no matter where you are.

Seamless Integration with MATLAB

One of the key strengths of Simulink is its seamless integration with MATLAB. This integration allows users to leverage MATLAB’s computational capabilities directly within Simulink models. You can write custom scripts in MATLAB, use them to drive simulations in Simulink, and analyze the results—all within a unified environment. This synergy between MATLAB and Simulink enhances your ability to develop, test, and refine models more efficiently.

Advantages of Model-based Design

Model-based design (MBD) is a methodology that uses models as the primary means of design and verification. Simulink’s support for MBD enables engineers to move from concept to deployment faster and with greater accuracy. By simulating and testing models before implementation, you can identify and address potential issues early in the design process, reducing development time and costs.

At TechSource Asia, we provide tools and training that empower you to fully utilize model-based design, ensuring that your projects meet the highest standards of performance and reliability.

Exploring Simulink Features

Simulink offers a wide range of features designed to enhance your modeling and simulation experience. Some of the key features include:

Simulation Manager: Manage and run multiple simulations in parallel, optimizing your workflow and reducing simulation time.

Stateflow: Model and simulate decision logic using state machines and flow charts.

Data Import/Export: Easily import data from external sources and export simulation results for further analysis.

Code Generation: Automatically generate C, C++, and HDL code from your models, facilitating deployment in real-time systems.

These features make Simulink a powerful tool for tackling complex engineering challenges, whether in academia, industry, or research.

Top 5 Applications of MATLAB and Simulink in Digital Communication Systems

MATLAB and Simulink are extensively used in the field of digital communication systems. Here are five top applications where these tools shine:

Signal Processing and Modulation

Signal processing is at the heart of digital communication. MATLAB and Simulink provide tools for designing and simulating modulation schemes, filtering, and signal analysis, ensuring optimal performance of communication systems.

Channel Modeling and Equalization

Accurate channel modeling is crucial for understanding how signals propagate in different environments. Simulink’s simulation capabilities allow for the modeling of various channel conditions, helping engineers design robust equalization techniques to mitigate signal degradation.

Error Correction Coding

Error correction is essential for reliable communication over noisy channels. MATLAB and Simulink support the design and simulation of various error correction codes, such as Reed-Solomon and Turbo codes, which are critical for maintaining data integrity in digital communication systems.

Synchronization and Timing Recovery

Synchronization and timing recovery are vital for ensuring that transmitted signals are correctly received and interpreted. Simulink provides tools for simulating and testing synchronization algorithms, helping engineers fine-tune their systems for optimal performance.

Network Simulation

Simulink enables the simulation of entire communication networks, from the physical layer to the application layer. This capability is particularly valuable for testing and validating the performance of communication protocols and network architectures before deployment.

Master MATLAB and Simulink Through TechSource Asia’s In-person and Online Training Courses

To fully leverage the power of MATLAB and Simulink, it’s essential to have a solid understanding of their capabilities and applications. TechSource Asia offers comprehensive MATLAB training courses designed to help you master these tools, whether you’re a beginner or an experienced user.

Comprehensive Learning Opportunities

Our training courses cover everything from the basics of MATLAB and Simulink to advanced techniques for digital communication systems. We offer both in-person and Simulink online courses to accommodate your learning preferences.

Hands-on Experience with Cutting Edge Tools

TechSource Asia’s training programs emphasize practical, hands-on experience. You’ll work with real-world data and industry-standard tools, gaining the skills you need to apply MATLAB and Simulink to your projects confidently.

Practical Application and Industry Relevance