#Copper Lugs Manufacturers In India

Text

Choosing the right ATEX cable glands is a critical decision that affects the safety, efficiency, and compliance of industrial operations in hazardous areas. By understanding the ATEX directives, industries can ensure their electrical installations are safe and reliable.

#Cable Tie Manufacturer In India#Brass Components Manufacturer In Jamnagar#Cable Gland Manufacturers In India#Cable Lugs Manufacturers In India#Lugs Manufacturers In India#Copper Lugs Manufacturers In India#Cable Gland Manufacturers In Jamnagar#Brass Conduit Fittings In India#Brass Pipe Fittings Suppliers#Pipe Fittings Manufacturers In India#Brass Pipe Manufacturers In Jamnagar#Brass Fitting Manufacturers In India#Brass Fittings Manufacturers In Jamnagar#Cable Cleats Manufacturer In Jamnagar India#Brass Manufacturers In India

0 notes

Text

Cable Ties Supplier in Ahmedabad | Control Panel Accessories Supplier in Ahmedabad - Samir Trading

Cable Ties Supplier in Ahmedabad | Control Panel Accessories Supplier in Ahmedabad - Samir Trading

About Samir Trading Corporation

Since 1982 in the Electrical Industry and in the Cable Tie industry since year 1986, with such a long experience we have the determination and the foresight to offer a wide range of high quality electrical products to Control panels manufacturers, Machine manufacturers, Electrical contractors, etc.

KSS is an ISO 9001 & ISO 14001 & OHSAS 18001 certificated company and has been approved by UL, CSA, VDE, DNV, GL, LLOYD, CE, ABS, IP68.

Customer Satisfaction with Best Quality at Reasonable Prices

OUR PRODUCTS

1.Cable Ties:

2. Control Panel Accessories:

3. Cooling Solution:

4.Copper lugs:

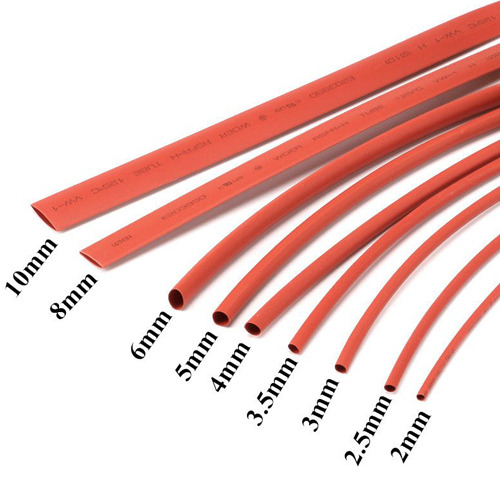

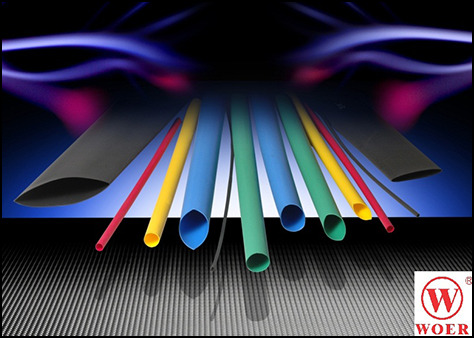

5.Heat Shrinkable sleeves:

6.Wiring accessories :

OUR BLOGS

1.KSS Cable Ties Supplier In Ahmedabad:

2.Locks & Hinges Suppliers In Ahmedabad:

3.Spirals Suppliers In Ahmedabad:

4.Printable Sleeves Suppliers In Ahmedabad:

5.Cable Tie Gun/Tool Suppliers In Ahmedabad:

6.Polyolefin Heat shrink Tubing Suppliers In Ahmedabad:

7.Cable Tie Mount Suppliers In Ahmedabad:

Quick Link

Home

About Us

Blogs

Contact Us

Products

Cable Ties

Heat Shrinkable Sleeves

Wiring Accessories

Control Panel Accessories

Cooling Solutions

Copper Lugs

Get in Touch

1451, Mamunayak Ni Pole, Nr. Jagat Agencies, Gandhi Road, Ahmedabad, Gujarat - 380001.

+91 97253 99929

+91 90168 13316

#Cable Ties Supplier in Ahmedabad#Wiring Accessories Supplier in Ahmedabad#Control Panel Accessories Supplier in Ahmedabad#Cooling Fan Supplier in Ahmedabad#Heat shrinkable sleeves Supplier in Ahmedabad#Copper Lugs suppliers In Ahmedabad.

0 notes

Text

Tubular cable lugs

At bewl we offers high quality tubular cable lugs with DIN 48 201 dimensions and DIN 46 235 tube dimensions. We are tabular lugs manufacturer, exporter, supplier in India. These lugs are made of metal, copper or aluminium and come in various shapes and sizes.

1 note

·

View note

Text

Exploring Lightning Arresters and Their Applications

A lightning strike is an awe-inspiring display of nature's power, but it can also wreak havoc on buildings and electrical systems in its path. Lightning arresters play a pivotal role in safeguarding against the destructive force of lightning. In addition to lightning arresters, other essential components of a comprehensive Lightning Protection System include cable glands and lugs. For top-notch quality and performance, consider renowned lug manufacturers in India, ensuring every aspect of your lightning protection setup meets the highest standards.

What are lightning arrestors?

Lightning Arresters are integral components of Lightning Protection Systems. They are designed to divert the immense energy of a lightning strike away from structures and electrical equipment.

Welcome to the realm of Lightning Arresters—a crucial component in the defense against nature's most electrifying force. In this article, we'll uncover the inner workings of these devices and explore their diverse applications, from shielding buildings to preserving the integrity of electrical systems. Let's journey through the fascinating world of Lightning Arresters and their indispensable role in safeguarding infrastructure.

These devices ensure that the electrical systems remain unharmed by providing a low-resistance path to the ground.

Two main types of lightning arresters are commonly used:

Conventional Lightning Arresters (Franklin rods)

These are simple yet effective devices consisting of long metallic rods, typically made of copper.

Installed at the highest points of structures, they intercept lightning strikes and channel the electric charge safely to the ground.

Suitable for smaller structures like residential buildings, they require additional components such as metallic conductors and earthing designs.

Early Streamer Emission (ESE) Lightning Arresters

ESE lightning arresters offer a more advanced solution for lightning protection.

Emitting charged particles provides a faster conductive point of discharge for lightning bolts, covering larger areas with greater efficiency.

These devices harness ambient electromagnetic energy during lightning events, offering a swift and effective means of grounding fault currents.

Let’s dive into the applications:

Lightning Arresters serve as the first line of defense against the formidable force of lightning, safeguarding structures and electrical systems from potential damage. Whether a conventional Franklin rod or an innovative ESE arrester, investing in robust lightning protection measures is essential for mitigating risks and ensuring infrastructure resilience against nature's fury.

Lightning arrestors are commonly installed on buildings, towers, and other structures to intercept lightning strikes and safely redirect the electrical charge to the ground. By providing a path of least resistance, they prevent damage to the structure and mitigate the risk of fire or structural failure.

Lightning arrestors are installed within electrical systems to safeguard sensitive equipment and components from the damaging effects of lightning-induced surges. By diverting excess electrical energy away from the system, they help prevent equipment malfunction, data loss, and downtime.

Final Thoughts

Partnering with reputable lightning arrestor manufacturers and suppliers is imperative for quality lightning arrester solutions. Look for trusted names in the industry, such as Axis, who offer reliable products and expert guidance on lightning protection strategies.

With robust lightning protection measures, structures can confidently weather the storm, keeping occupants safe and infrastructure secure against nature's unpredictable forces.

Axis India stands at the forefront as a premier cable gland manufacturer in India and supplier of lightning arrestors and a wide array of Electrical Components, serving clients across 80+ countries worldwide. Whether you're seeking a quote or expert consultation, our dedicated team is ready to assist you.

Visit our https://axis-india.com/contact-us/ section to connect with an industry expert today.

0 notes

Text

Enhancing Electrical Connections: Chetna Engg (CECO), Leading Copper Cable Lug and Bonded Earth Rods

In the realm of electrical engineering, the significance of quality connections cannot be overstated. Whether it's in industrial setups, commercial buildings, or residential spaces, the integrity of electrical connections is paramount for safety, efficiency, and reliability. At Chetna Engg (CECO) , we recognize this crucial aspect and specialize in providing top-notch solutions for electrical connections through our premium range of copper cable lugs and bonded earth rods.

As one of the leading manufacturers in India, Chetna Engg (CECO) takes pride in offering a diverse array of products engineered to meet the highest standards of quality and performance. Let's delve into the key offerings that set us apart in the industry:

Copper Cable Lugs: Our copper cable lugs stand as a testament to precision engineering and superior craftsmanship. Designed to facilitate secure and efficient connections, our cable lugs ensure minimal resistance, thereby optimizing electrical conductivity. Whether it's for power distribution, control panels, or machinery, our comprehensive range caters to diverse application requirements with ease.

As prominent copper lug manufacturers in India, we adhere to stringent quality control measures at every stage of production. From sourcing high-grade copper materials to employing advanced manufacturing techniques, we prioritize excellence to deliver products that exceed expectations. Moreover, our copper cable lugs are available in various sizes, configurations, and finishes to accommodate specific project needs effectively.

Copper Bonded Earth Rods: Grounding systems play a pivotal role in ensuring electrical safety by dissipating fault currents and preventing hazardous voltage buildup. Our copper bonded earth rods offer a robust solution for establishing reliable grounding connections in diverse environments. Crafted from high-quality materials, these rods feature a copper coating that enhances corrosion resistance while maintaining exceptional conductivity.

At Chetna Engg (CECO), we understand the critical role of grounding in electrical installations, which is why our copper bonded earth rods undergo rigorous testing to ensure optimal performance and longevity. Whether it's for lightning protection systems, substations, or telecommunications infrastructure, our earth rods provide a dependable grounding solution that instills confidence in every project.

Why Choose Chetna Engg (CECO)?

1. Uncompromising Quality: We prioritize quality in every aspect of our operations, from raw material selection to final product inspection, ensuring that our customers receive nothing but the best.

2. Customization Options: With our flexible manufacturing capabilities, we can tailor our products to meet specific requirements, accommodating diverse applications and project specifications.

3. Technical Expertise: Backed by a team of skilled engineers and technicians, we offer comprehensive technical support and guidance to assist our customers throughout their project lifecycle.

4. Timely Delivery: We understand the importance of timelines in project execution, which is why we strive to maintain efficient production schedules and prompt delivery timelines.

In conclusion, Chetna Engg (CECO) stands as a trusted partner for all your copper cable lug and bonded earth rod requirements in India. With a commitment to quality, innovation, and customer satisfaction, we continue to set new benchmarks in the electrical engineering industry. Get in touch with us today to experience the excellence firsthand!

0 notes

Text

BIMetallic Lugs and BIMetallic Connectors: Revolutionizing Electrical Connections

In the field of electrical connections, the significance of BIMetallic Lugs and BIMetallic Connectors cannot be overstated. These innovative components play a vital role in ensuring efficient and reliable electrical conductivity, especially in scenarios involving divergent metals.

Importance of BIMetallic Lugs

Preventing Disparate Contact

One of the primary reasons for using Aluminum Bimetallic Lugs is to prevent disparate contact between the terminal lug and copper transport bar. This strategic use of divergent metals helps avoid potential issues arising from incompatible materials.

Avoiding Galvanic Action

To further enhance the longevity of electrical connections, BIMetallic Lugs are employed to steer clear of galvanic action. This proactive measure ensures the stability and durability of the connections over time.

BIMetallic Lugs and Connectors Dealers in India

Pioneer Powers Internationals

As a leading manufacturer, supplier, and exporter based in Mumbai, Maharashtra, India, Pioneer Powers Internationals has established itself as a reliable source for high-quality BIMetallic Connectors and BIMetallic Lugs.

Product Specifications and Features

The bimetallic connectors and lugs offered by Pioneer Powers Internationals are available in various specifications to meet the diverse requirements of clients. Their products are precisely engineered, feature rugged construction, and exhibit the ability to withstand adverse conditions.

Competitive Pricing of BIMetallic Lugs

Composition and Design

Pioneer Powers Internationals adopts a unique design approach, creatively combining two different metals in the fabrication of BIMetallic Connectors and Lugs. The palm of the connectors is made from electrolytic copper, ensuring optimal conductivity, while the rest is crafted from aluminum.

Emphasis on Quality and Durability

Quality is paramount for Pioneer Powers Internationals, with a focus on durability and reliability. The company is committed to addressing customer concerns, especially those related to the fatigue of threads.

Unique Design of BIMetallic Connectors

Creative Use of Two Different Metals

The innovative use of two different metals in the design of BIMetallic Connectors sets them apart in terms of performance and longevity. This creative approach ensures optimal conductivity and minimizes the risk of wear and tear.

Electrolytic Copper and Aluminum Composition

The use of electrolytic copper in the palm of the connectors, combined with aluminum for the remaining parts, showcases a commitment to delivering products of exceptional quality.

Quality Assurance in BIMetallic Connectors

Emphasis on Durability and Reliability

Pioneer Powers Internationals places a strong emphasis on the durability and reliability of its BIMetallic Connectors and Lugs. Understanding that customer satisfaction hinges on product performance, the company ensures that its offerings meet the highest standards.

Addressing Customer Concerns

Acknowledging that customer complaints often revolve around thread fatigue, Pioneer Powers Internationals takes proactive measures to address these concerns. The company prioritizes quality control to mitigate issues and build a strong reputation.

Lightning Protection and Earthing

Additional Offerings by Pioneer Powers Internationals

Apart from BIMetallic Lugs and Connectors, Pioneer Powers Internationals is renowned for being prominent dealers in all types of Earthing and Lightning Protection solutions. This comprehensive approach positions them as a one-stop solution for various electrical needs.

Prominent Dealers in the Market

With a reputation for excellence and a commitment to quality, Pioneer Powers Internationals has solidified its position as a prominent dealer in the market, offering a wide range of solutions for lightning protection and earthing.

Conclusion

BIMetallic Lugs and BIMetallic Connectors stand out as essential components in the electrical industry. Pioneer Powers Internationals, with its commitment to quality, innovative design, and customer satisfaction, has emerged as a reliable source for these critical elements.

For More Info Visit their Website:

0 notes

Text

Advantages of Using Cable Lugs from Top Cable Lugs Manufacturer and Supplier in India

What are cable lugs, and why are they important?

Cable lugs act as unsung heroes in this intricate web of electrical connections to ensure reliable cable-to-electrical device bonding. Let’s try to understand the significance of cable lugs & why we should use premium-quality cable lugs. Cable Lugs are crucial because they ensure a strong connection between a cable and a cable outlet.

Cable lugs are a commonly overlooked element at the heart of robust electrical systems. These are very important connectors that provide safe links between cables and electrical equipment for a smooth supply of electricity. However, what is required is a solution that will provide both stability and reliability.

A cable lug, also referred to as an electrical connector or wire terminal, is a vital component that ensures a reliable and safe bond between the cables to different electrical apparatus. There are many variations, such as copper lugs, aluminium lugs, crimping lugs, and other cable lug types.

Why should I choose a top cable lugs manufacturer and supplier in India?

In India, a good reason to go for the best cable lugs manufacturer and supplier is explained here.

It is imperative in a vast cable lug market to ensure reliability. This implies poor quality of connections may lead to overheating and electrical hazards. One must then select the best manufacturer in India to navigate the sea of options to have long-lasting electrical connections.

Elcon Global, as a Cable Lugs Supplier in India, knows the challenges associated with poor-quality cable lugs. Poor-quality connectors lead to inefficiency, safety risks, and high maintenance costs. The question then arises: What is the best way to distinguish mediocre cable lugs from higher-quality lugs?

What Are the Benefits of Using High-Quality Cable Lugs?

Poorly made cable lugs can be said to have numerous consequences, including poor conductivity, susceptibility to corrosion, and compromised lifespan. These problems not only hamper your electrical systems but could later lead to unexpected complications and expenses.

High-quality cable lugs, such as those provided by Elcon Global, offer several advantages:

Excellent Conductivity: Copper lugs of Elcon Global ensure optimal conductivity, thus no loose or faulty connections to disrupt the flow of flow.

Durability: Elcon Global makes cable lugs from the finest materials and engineering technology. These connections last long and require little replacement.

Versatility: We have a variety of cable lugs, among these are copper lugs and aluminium lugs for different electrical needs. They have crimping lugs and a variety of other cable lug types to cater to different applications.

Easy Installation: Our cable lugs, whether crimping lugs or others, are designed for ease of installation. This enables electricians and technicians to easily connect and disconnect cables saving them time and effort.

Is it possible to use cable lugs for high and low-voltage applications?

Amidst the challenges, there exists a solution: Elcon Global. As one of the leading cable lugs manufacturer in India, Elcon Global offers a comprehensive range of cable lugs that are fit for high- and low-voltage applications.

Precision Engineering: Elcon Global, as a Cable Lugs Manufacturer and Supplier in India, assures high performance in various applications.

Top-Grade Materials: Elcon Global manufactures only the highest purity of materials, making Cable Lugs the best conductor and immune from corrosion suppliers in India.

Adherence to Standards: This assures your electrical connections are in the right hands and are of international standard, Elcon Global.

Diverse Range: Elcon Global, a leading Electrical Connectors and Wire Terminals provider, has a wide range of cable lugs for different applications.

Elcon Global: The Leading Cable Lugs Supplier in India.

Why choose Elcon Global as a leading cable lugs manufacturer and supplier in India?

When it comes to the efficiency and reliability of your electrical systems, there is no better option than Elcon Global.

Cutting-Edge Technology: As a top cable lugs supplier and manufacturer in India, Elcon Global adopts advanced technology in manufacturing its products to guarantee the best possible outcomes.

Unwavering Commitment: Elcon Global, therefore, has made its quality commitment uncompromising, making it a dependable solution for your electrical connections.

Finally, cable lugs from Elcon Global should not be seen as an option, but a strategic decision for the effectiveness and durability of your electrical systems. We are renowned Cable Lugs Supplier in India.

Your electrical projects deserve the best, you should get the best from Elcon Global for Cable Lugs exceeding expectations, a premier Cable Lugs Manufacturer in India. Contact us now.

#cable lugs manufacturer in india#cable lugs supplier in india#cable lugs manufacturer#cable lugs supplier

0 notes

Text

Alloy 20 Valve Manufacturer in India

Specialityvalve is the prime Alloy 20 Valve Manufacturer in India. We supply to Andhra Pradesh, Kerala and Bihar. Alloy 20 valve, also known as Carpenter 20 valve, is a specialized type of industrial valve made from a specific alloy known as Alloy 20. This alloy is a highly corrosion-resistant material designed to withstand a wide range of corrosive environments, including sulfuric acid, chloride solutions, and various other aggressive chemicals. Alloy 20 valves are widely used in industries such as chemical processing, petrochemicals, pharmaceuticals, and food processing, where exposure to corrosive substances is common. We manufacture Alloy 20 valve which is made from a nickel-iron-chromium-based alloy with additions of copper and molybdenum. Its chemical composition typically includes around 24% nickel, 20% chromium, 3-4% copper, and 2-3% molybdenum, along with small amounts of other elements such as iron, manganese, and niobium. The presence of these elements imparts exceptional corrosion resistance and mechanical strength to the alloy.

Types:

Alloy 20 Ball Valves

Alloy 20 Gate Valves

Alloy 20 Globe Valves

Alloy 20 Check Valves

Alloy 20 Butterfly Valves

Alloy 20 Diaphragm Valves

Alloy 20 Plug Valves

Alloy 20 Needle Valves

Alloy 20 Pressure Relief Valves

Alloy 20 Control Valves

Advantages:

Corrosion Resistance

Wide Chemical Compatibility

High Temperature Resistance

Mechanical Strength

Ease of Fabrication

Low Risk of Contamination

Reduced Maintenance Costs

Long Service Life

Flexibility

Versatility

Industries:

Chemical Processing Industry

Petrochemical Industry

Pulp and Paper Industry

Oil and Gas Industry

Water Treatment Industry

Desalination Plants

Marine Industry

Power Generation Industry

Mining Industry

Semiconductor Industry

Textile Industry

Description:

Available material: Alloy20 (N08020)

Size: 1/2” to 12”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Ends: Socket Weld, Flanged, Wafer, Lug, Threaded, Buttweld

Operations: Lever Operated, Handwheel, Electric Actuated and Pneumatic Actuated, Gear Operated

Visit us: https://www.specialityvalve.com/product-category/alloy-20-valves/

0 notes

Text

5 Ways in Which Retaining Rings Help Your Machinery - Circlips India

Mechanical fasteners called retaining rings provide rigid shoulders to hold parts in place. The rings are deformed while being put on or taken off, but they quickly return to their natural form. Retaining rings can be employed in a broad range of applications due to their spherical ring features.

Several considerations must be made to guarantee that a heavy duty retaining ring will perform as intended and cause no issues once the design enters production.

Step 1 – Find out what kind of ring you'll need.

Different types of retaining rings can be used for axial or radial installations in a housing or on a shaft. Shaft rings are fitted on the outside diameter of pins, studs, and shafts, while internal rings are built into grooves or recesses in bores and housings. Therefore, always choose the right type according to the application.

Step 2 – Choosing between axial and radial ring assembly.

The lugs and holes on an axial retaining ring allow it to be inserted into a shaft or bore groove at a specific location along the axis. Once in place, they make complete contact with the groove. They can bear high thrust loads because loads are transmitted into the groove wall throughout much of the groove's circle.

Along the rim of a circle, a ring is built radially and then set in place. When compared to their axial counterpart, these rings lack lugs and lug holes and don't wrap around the groove quite as far. They tolerate less thrust stresses to the groove wall because of the gap section.

Step 3 – Choosing the right ring size.

The housing or shaft diameter is the determining factor in the ring size. When manufacturing retaining rings, many international standards are adhered to.

Step 4 – Choose the metal and polish for your retaining ring.

There are three main kinds of material used to make retaining rings. The most common material is carbon spring steel (SAE 1060-1090). It is very durable, can be bent without breaking, and has a great surface for plating, making it resistant to corrosion. Stainless steel (PH 15-7Mo) is the second most popular material. The steel of this quality is resistant to air oxidation at temperatures as high as 900 degrees Fahrenheit, making it both robust and durable. Beryllium copper, the third substance, is nonmagnetic, electrically conductive, and very resistant to corrosion from sea air and saltwater.

To avoid corrosion, a retaining ring's polish is just as crucial as the material it's made of. A phosphate finish is the norm since it prevents rusting over time. Zinc plating applied mechanically is still another option. It may last up to 96 hours in salt spray, making it ideal for use in applications that are constantly exposed to the elements. In addition, zinc dichromate lacquer can withstand salt spray for up to 240 hours before corrosion sets in. Stainless steel and other expensive noncorrosive materials can be replaced with this low-cost alternative.

Step 5 – Choosing tools for installation.

The next step, after settling on a retaining ring, is picking out the appropriate equipment. Pliers and pneumatic equipment are used to install axial retaining rings, whereas applicators and dispensers are used to place radial retaining rings. Fingers, hammers, and other improvised instruments can cause harm as well as damage components, thus they should be avoided. Automatic assembly equipment is often used for high-volume installations.

Step 6 – Choose packaging.

The packing is the last factor to think about. There are two sources for retaining rings. One option is bulk packing in boxes or bags of varied sizes, which is useful if the item will be installed with a hand tool. The alternative packaging technique uses automated equipment to stack the rings on top of one another before sealing the stack with tape. The resultant cartridges can be used with automated assembly machinery, speeding up the process of installing the rings.

Contact reliable retaining ring suppliers and get the best material!

0 notes

Text

Stainless steel pipes' fundamental applications and advantages.

offsets, couplings, nipples, as well as unions. Copper lugs manufacturers in India offer high-quality materials.

0 notes

Text

Selecting ATEX Cable Gland for Industry Safety | Atlas Metal

Discover how to select the right ATEX cable glands with Atlas Metal for your industry, ensuring safety and compliance with international standards. We, at Atlas Metal, are committed to providing quality custom metal solutions, including ATEX cable glands, that meet the highest standards of safety and performance.

#Cable Tie Manufacturer In India#Brass Components Manufacturer In Jamnagar#Cable Gland Manufacturers In India#Cable Lugs Manufacturers In India#Lugs Manufacturers In India#Copper Lugs Manufacturers In India#Cable Gland Manufacturers In Jamnagar#Brass Conduit Fittings In India#Brass Pipe Fittings Suppliers#Pipe Fittings Manufacturers In India#Brass Pipe Manufacturers In Jamnagar#Brass Fitting Manufacturers In India#Brass Fittings Manufacturers In Jamnagar#Cable Cleats Manufacturer In Jamnagar India#Brass Manufacturers In India

0 notes

Text

Copper Lugs: Empowering Connections with Unrivaled Conductivity and Durability

At Pioneer Power International, we take immense pride in being a leading manufacturer in India, delivering exceptional electrical components that fuel industries with reliable solutions. In this article, we delve into the world of copper lugs, an integral element in establishing robust and efficient connections for various applications.

Unleashing the Potential of Copper Lugs: Copper lugs, meticulously crafted at Pioneer Power International, stand as the epitome of excellence when it comes to electrical connectors. These lugs, designed to provide unparalleled conductivity and durability, ensure optimal power transmission while withstanding the test of time in diverse industrial environments.

The Power of Copper: Copper, renowned for its exceptional electrical conductivity, forms the core of these lugs. At Pioneer Power International, we utilize the highest quality copper material, allowing for efficient and reliable current flow, thereby minimizing energy loss and maximizing performance. With copper lugs, businesses can experience enhanced productivity and improved operational efficiency.

Durability that Endures: In demanding industrial settings, durability is paramount. Copper lugs from Pioneer Power International are engineered to withstand extreme conditions, including temperature fluctuations, moisture, and corrosion. This durability ensures a long-lasting and dependable connection, reducing maintenance requirements and minimizing downtime.

Versatility for Various Applications: With a diverse collection of copper lugs available at Pioneer Power International, businesses across industries can find the perfect fit for their specific needs. Whether it’s power distribution, telecommunications, automotive, or renewable energy systems, our comprehensive range of copper lugs offers versatile solutions for a wide array of applications.

Ease of Installation: We understand the value of time and efficiency. Our copper lugs are designed with user-friendly features, allowing for easy and hassle-free installation. With streamlined assembly processes, businesses can save valuable time and resources while ensuring secure connections.

Collections That Cater: At Pioneer Power International, our copper lugs are available in a wide range of sizes and configurations, catering to diverse wire gauges and connection requirements. We offer collections that encompass a variety of copper lug types, ensuring that our customers find the perfect match for their specific applications.

Pioneer Power International: Delivering Excellence: As a reputable manufacturer, Pioneer Power International has set the benchmark for quality and reliability. Our copper lugs embody our commitment to excellence, providing customers with top-of-the-line electrical components that surpass industry standards.

Copper lugs from Pioneer Power International empower businesses with unmatched conductivity, durability, and versatility. With their exceptional electrical performance, these lugs ensure optimal power transmission while withstanding the rigors of industrial environments. Experience the power of copper and elevate your electrical connections with Pioneer Power International’s comprehensive range of copper lugs. Trust in our commitment to excellence and join the ranks of satisfied customers who have harnessed the true potential of copper for their business success.

#CopperLugs#OptimalPowerTransmission#ConductivityandDurability#PioneerPowerInternational#ManufacturingExcellence#IndustrialSolutions#VersatileApplications#StreamlinedInstallation#WideRangeofSizes#UnmatchedPerformance#ReliableConnections#EfficiencyandProductivity#HighQualityElectricalComponents

1 note

·

View note

Text

How do Copper Cable Lugs Work? Here is what you need to know

One of the electrical industry's challenging responsibilities is creating a robust terminal or a junction between a cable and an electrical system. These junction points maintain the integrity and operability of an electrical system. A minor fault in them can cause tremendous damage. Hence, cable lugs get used to create proper connectivity even if the cables are in tension indoors and outdoors.

Design features of copper cable lugs

Made of copper and aluminium, the design features of the cable lugs ensure the connectivity and safety of the cable terminals and the electrical system. In most cases, copper cable lugs are chosen for better connectivity, strength and durability in the terminal junctions.

A cable lug design has a barrel and a palm. The entire structure is properly shaped using copper, the best metal conductor within the price range. The barrel section has a perfect lumen size that matches the specific diameter of the copper cables (size ranges from 1.5 to 1000 sq. mm in diameter) used in the modern electrical industry. It means the barrel part is made hollow to easily accommodate the end point or terminal of a copper cable.

The palm section is a flat semicircular or square projection above the barrel with a hole. This hole connects with a junction in an electrical system. When a cable terminal is inserted and crimped, the barrel will not leave space inside. Similarly, the palm section will provide ample strength to hold the junction in its place.

How does a copper cable lug work?

Now that we know the design and structure of a copper cable lug, we can easily understand how it works. A copper cable lug gets chosen according to the specifications, such as the cable diameter and the features of the junction of an electrical system.

A cable is then inserted into the barrel section of a cable lug. It is then crimped without leaving space inside to avoid electrical malfunctions. Once the terminal is ready, the palm is attached to the electrical system junction as per suitability or the directions given in the product specifications. Generally, the palm of a cable lug is screwed tightly with the electrical system. A spring clip or bolt is also used to connect a cable lug to an electrical system.

Based on the design specifications, there can be more than one palm hole in each copper cable lug. Match an electrical system's termination or connection features to get a vital junction.

Things to consider

Generally, copper is the prime choice for cable lugs to create a vital junction due to its exceptional strength and malleable properties. Based on the cable properties and electrical system junction features, a cable lug is chosen to create a better connection that will stand the test of time.

Axis is a leading manufacturer and supplier of Electrical Components to over 80+ Countries. To get a quote or to talk to our industry expert visit our contact us section.

About The Author:

Axis is India’s leading Manufacturer- Exporter of wide range of components used in electrical installations & Equipment building industries. In a short span Axis has gained tremendous popularity amongst the quality conscious customers worldwide. The brand Axis has become synonymous with quality.

0 notes

Text

Triple Eccentric Butterfly Valve Manufacturer in India

Specialityvalve is famous for its Triple Eccentric Butterfly Valve Manufacturer in India. A Butterfly Valve is a mechanism that regulated the flow of materials within a large pipe diameter by the quarter-turn of the disc. It is a motion like a butterfly that has wings that move up and down at 90 degrees. The butterfly valve is a metal disc framed on a rod. It is operated when the valve completely blocks the passageway and when it is open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened gradually to compress the flow.

Triple eccentric butterfly valve are industrial valves that are designed to fully open or close a passage of the working medium flowing through a pipeline. They can also use for flow control purposes. They are bubble-tight shut off which cannot be accomplished by utilizing twofold counterbalanced butterfly valves.

The valve has 3 balances in contrast with the concentric butterfly valve. This triple counterbalance has one extra counterbalance which is a funnel-shaped seat. The tapered shape seat will match the plate that was created to match the seat. This plan will make the seat has no grating or rubbing while shutting or opening. This design will additionally make the triple eccentric butterfly valve from an air pocket, tight in high-weight applications.

Industries of Triple Eccentric Butterfly Valve

Oil and gas

Pulp and paper

HVAC

Chemical Plants

Shipbuilding

Advantages of Triple Eccentric Butterfly Valve

Small fluid resistance

Lightweight

It is open and close

Simple structure

Disadvantages of Triple Eccentric Butterfly Valve

It is not suitable for small diameter pipelines below DN200

The sealing performance can affect the valve

Material: Cast iron, Ductile iron, Stainless steel (SS304, SS316, F304, F316, CF8, CF8M, SS316L, SS409L), Carbon steel, Duplex steel.

Class: PN10 to PN100

ANSI 150 to 600

End Connection: Wafer, Lug, Flanged

Size: 2" to 72"

Operations: Lever, Gear Operated, Electric Actuated, Pneumatic Actuated

https://www.specialityvalve.com/product-category/triple-eccentric-butterfly-valve/

Monel Valve Manufacturer in India:

Specialityvalve is one of the best Monel Valve Manufacturer in India. Monel valves refer to industrial valves assembled from monel alloys which are nickel-copper-based corrosion-resistant solid solution alloys. Monel is a solid-solution binary alloy. It needs to be revolved and worked at slow speeds and low feed rates.

It is resistant to corrosion and acids and some alloys can withstand a fire in pure oxygen. Monel is much more expensive than stainless steel. Monel alloy 400 has a specific gravity of 8.80 at a melting range of 1300-1350 °C, an electrical conductivity of approx. 34% and a hardness of 65 Rockwell B. It is significant for its toughness which is maintained over a considerable range of temperatures.

Monel valve uses in aircraft construction especially in making the frames and skins of experimental rocket planes. It is also used for safety wiring in aircraft maintenance to ensure that fasteners cannot come undone which is usually in high temperatures and stainless wire is used in other areas for economy.

Advantages of monel valve

Ability to hold up in high-temperature situations as well as low temperatures.

It has high mechanical strength

It is easy to shape and form

Resistance to alkalis

Ease of welding and brazing

Disadvantages of monel valve

Poor machinability

Exposure to pitting corrosion in a saltwater environment

Galvanic corrosion can be created in the presence of monel

Types of monel valve

Monel ball valve

Monel gate valve

Monel checks the valve

Monel globe valve

Monel butterfly valve

Body material- Monel400(UNS N04400), Monel 403, Monel 404(UNS N04404), Monel R-45(UNS N04405), Monel 406, Monel 411

Size-1/2’’-24’’

Class- 150 to 800

Nominal Pressure- PN25 to PN100

Medium: LNG, cryogenic application, water, air, steam

Ends- Flanged, lug, wafer, Buttweld, threaded

Operation- pneumatic actuated, electric actuated, gear operated, lever operated, and Handwheel operated

Specialityvalve is the leading Monel Valve Manufacturer in India which provides the latest technology and well-equipped machinery. It helps in achieving new heights with the help of in-house capabilities to produce one of the best quality Monel valves.

https://www,specialityvalve.com/product-category/monel-valve/

0 notes

Text

The 2-Minute Rule For Outdoor termination kits

Self Amalgamating Tape The adhesive coating to the lug sealing tubes, the breakout system and fingers gives a very good environmental seal, while the cores are guarded with slender or medium wall tubing.

To the fixation / software / insulation / mounting and protection of cables, Together with cable ties, heat shrink tubing and spiral wrapping band, a person also can elect to use tape.

Now we have put cookies on your own Laptop that will help make this Site improved. In the event you keep on to work with This page We are going to believe you will be satisfied with this

Because of this, they will not be a hundred% precise for a selected gadget. Remember to Speak to our product sales support for information on precise equipment. Sample & Obtain

Enter your email tackle to enroll in our e-newsletter detailing the most recent and finest on the earth of cable jointing products and services:

Email: * You should critique our Privateness Assertion that describes how we course of action your profile details and how to assert your individual data safety rights Go on x Thanks! Your e-newsletter subscription is submitted

Suitable for both indoor and outdoor use in all local weather circumstances, the Uniterm range covers applications for polymeric cables as much as 33kV. The elements combine to provide the critical features including electrical functionality, pressure Regulate and humidity sealing, demanded for all medium voltage merchandise

The products and solutions have a great acceptance & brand name recall throughout India & various marketplaces overseas. The solutions are bought all over India through a longtime chain of sellers and distributors supported by Regional Advertising and marketing workplaces of the business.

Tinned Copper Braid to shield conductive wiring from interference and dealing with substantial existing and lower voltage.

Pressure Grading Mastic, a drinking water-resistant adhesive utilized on connectors and cable components, Utilized in MV joints to provide worry aid of the electric industry.

Believed delivery dates - opens in a new window or tab consist of vendor's dealing with time, origin ZIP Code, vacation spot ZIP Code and time of acceptance and may rely upon shipping assistance selected and receipt of cleared paymentcleared payment - opens in a brand new window or tab. Supply moments might vary, In particular through peak intervals.

Don’t see this option? The vendor may well continue to be capable to personalize your merchandise. Test contacting them via Messages to determine!

It is possible to choose based on the genuine software, then taking ideal steps to help make the electric area distribution and electric powered field strength in the best point out can improve the trustworthiness of cable operation. About ZMS Cable Extras Manufacturer & Wholesaler

foundation screened connector system RSTI suitable for 42kV. RSTI Screened, Separable Relationship Technique 800A approximately 42kV RSTI screened separable connectors are created to link one and three-core polymeric cables to mediumvoltage gas insulated switchgear along with other equipment. Outdoor termination kits

0 notes

Text

Benefits of Using CRS TMT Bars in India

Earthquake, floods, tropical storms, and other natural disasters are daily news in India. To build safe and strong structures in a diverse and geographically challenging country like ours, you need to ensure that the backbone of your RCC structures is STEEL that is tough and resilient.

The gold standard for steel in RCC construction is CRS TMT bars which accounts for 80% of the market in India and 60% of the global market share.

Here are some of the main benefits of using CRS TMT bar (Sariya)

Higher Ductility – The special Themerx quenching & self-tempering process results in a hard outer marten site core while leaving the inner core of ferrite, pearlite

What does this mean for construction and structures?

The ductile core of the CRS TMT bar gives it enhanced elongation and bendability.

During the construction process, this helps the crew to bend the TMT sariya in desired shapes and makes the construction process more manageable.

For the structures, this flexibility results in an enhanced ability to weather earthquakes without losing structural integrity. A structure made from flexible TMT steel is better able to remain intact and standing even during the sideways movement of a seismic event.

2. Anti-Corrosive properties – The CRS manufacturing process also imparts rust-resistant properties to the TMT steel bar. At Moira Sariya, for example, we add copper, nickel, and chrome to the raw materials, which gives the Moira TMT sariyas higher corrosion resistance as compared to ordinary steel bars made from sponge iron.

This makes CRS TMT bars the perfect choice for construction in regions such as coastal areas or for underground facilities, where groundwater salinity, acid particles, or excess moisture in the air is a problem.

3.Cross ribbed pattern for better bonding – All CRS TMT bars come with ribbed patterns which are added to enhance bonding between the concrete and the steel.

Ordinary sariyas without these ribs and lugs can result in a weakened structure as there is a great chance that during a critical event such as an earthquake the concrete material might lose its grip and slip off.

4.Cost-effective – CRS TMT sariyas offer greater tensile strength and yield strength as compared to ordinary sariya. This means that less steel is required for the construction process – leading to significant savings in the cost of material, storage, and transport.

CRS TMT steel bars are the default choice for almost all large construction projects and rightly so! In fact, the government has made it mandatory for builders and contractors to use TMT bars for all large projects as these bars are inherently earthquake resistant (it should be noted that 60% of the country falls into various seismic zones).

If you want your structure to last till its expected life cycle and beyond, then using the best steel is obligatory, and there is no doubt that CRS TMT bars are the best available in the market!

#moira sariya price in indore#thermex tmt bar#tmt bar manufacturer in mp#tmt bar manufacturer#tmt sariya

0 notes