#Copper Parts Manufacturers in India

Text

Top 8 Copper Parts Manufacturers in India

This Comprehensive Blog Delves Into the Crucial Role of Copper Parts Within India’s Industrial Sector, Showcasing Their Importance Across Various Industries Thanks to Their Exceptional Properties Like Conductivity and Corrosion Resistance. Highlighting the Top Manufacturers in India Such as Meck Industries, Hindustan Copper Limited, Bhagyanagar India Limited, Madhav Copper, Rajnandini Metal, Sterlite Copper, Gujarat Copper Alloy Ltd., and Kavya Metal, It Emphasizes Their Dedication to Precision Manufacturing and Superior Quality. With Insights Into Sustainability and Customization Options, This Guide Provides Valuable Information for Businesses Seeking Top-Notch Copper Components. Dive Deeper Into the Article for A Thorough Analysis and To Learn, How These Leading Manufacturers Are Shaping India’s Copper Industry.

Read More: Top 8 Copper Parts Manufacturers in India

#Copper Parts Manufacturers in India#Copper Components Manufacturers in India#Top Copper Parts Manufacturers in India#Best Copper Parts Manufacturers in India#Top Copper Components Manufacturers in India#Best Copper Components Manufacturers in India

0 notes

Text

Top Brass Components Manufacturer in India

In today’s fast-evolving industrial landscape, innovation is key to staying ahead. One material that continues to play a crucial role in various sectors is brass. Known for its remarkable adaptability, durability, and resistance to corrosion, brass components are integral to modern industrial systems. From automotive and electrical to plumbing and machinery, brass is at the heart of many innovations. Among the leading manufacturers in this domain, Atlas Metal, based in Jamnagar, stands out as a pioneer in providing top-quality brass parts.

The Unique Properties of Brass

Brass, an alloy primarily composed of copper and zinc, is renowned for its versatility and performance. One of its most notable properties is its resistance to corrosion, making it ideal for use in environments exposed to moisture or chemicals. This characteristic is crucial for components used in plumbing, marine applications, and outdoor machinery, where exposure to elements is inevitable.

Additionally, brass possesses excellent thermal and electrical conductivity, making it a preferred material in the electrical and electronics industries. Its malleability allows for easy machining into precise components, while its inherent durability ensures longevity, even in demanding applications.

The ability of brass to withstand extreme temperatures without losing structural integrity further enhances its use in industries that rely on heavy-duty machinery and equipment. These unique properties have positioned brass as a key driver in numerous industrial innovations.

Brass Components Across Industries

Brass components find wide applications in several key industries:

Automotive Industry: Brass is commonly used in the production of engine parts, gears, and fuel connectors. Its resistance to heat and corrosion makes it ideal for ensuring the durability of these critical components.

Electrical and Electronics: Brass is widely used in earthing accessories, electrical connectors, terminals, and switchgear due to its superior conductivity and malleability, ensuring precision and reliability in complex electrical systems.

Plumbing and Sanitary Applications: Brass fittings, valves, and pipes are the backbone of modern plumbing systems. Its corrosion resistance ensures that brass parts last longer in both residential and industrial water systems.

Machinery and Heavy Equipment: Brass bushings, bearings, and fasteners are integral to many mechanical systems due to their durability and resistance to wear and tear.

Atlas Metal: A Leader in Brass Manufacturing

In Jamnagar, a city widely known as the brass manufacturing hub of India, Atlas Metal has carved a niche for itself as a leader in the production of high-quality brass components. With a focus on precision engineering, Atlas Metal offers a wide range of brass parts tailored to the specific needs of various industries.

The company’s commitment to innovation and quality is reflected in its use of advanced technology and stringent quality control processes. Atlas Metal produces everything from brass nuts, bolts, and fasteners to specialized fittings, terminals, and connectors that meet the demands of today’s high-performance industries.

What sets Atlas Metal apart is its emphasis on customization. Understanding that different industries require unique specifications, Atlas Metal works closely with its clients to deliver components that perfectly match their requirements, ensuring optimal performance and efficiency.

Why Choose Atlas Metal?

Quality Assurance: Atlas Metal places a high priority on quality control, ensuring that every component meets international standards.

Expertise and Experience: With years of experience in the brass manufacturing industry, Atlas Metal brings expertise and innovation to every project.

Advanced Manufacturing Techniques: The company uses cutting-edge technology to deliver precision-engineered parts.

Global Reach: Atlas Metal exports its products to clients worldwide, reflecting its reliability and reputation in the global market.

Conclusion

Brass components are indispensable to many industries, driving innovation with their versatility and durability. Atlas Metal, a leading brass parts manufacturer in Jamnagar, has been at the forefront of providing high-quality, precision-engineered components for global markets. With a commitment to quality, innovation, and customer satisfaction, Atlas Metal continues to be a trusted partner for industries seeking reliable brass solutions.

#brass parts manufacturer in Jamnagar#brass fitting manufacturers in india#pipe fittings manufacturers in india#brass conduit fittings in india#cable tie manufacturer in india#cable gland manufacturers in india#lugs manufacturers in india#cable lugs manufacturers in india#copper lugs manufacturers in india

1 note

·

View note

Text

where are 2 feet Narmadeshwar Shivling Found?

Narmadeshwar Shivling refers to a particular type of Shivling, a sacred symbol representing the Hindu deity Lord Shiva, sourced from the Narmada River in India. The Narmada River, considered one of the seven holy rivers in Hinduism, flows through the central part of India. The stones used to make these Shivlings are naturally occurring and typically found in the riverbed. Devotees believe that these Shivlings possess special spiritual significance and are considered highly auspicious for worship. They are often used in temples and homes for rituals and prayers dedicated to Lord Shiva.

In Hinduism, Shivling can be classified into various types based on their materials, shapes, and locations. Here are some common types:

Spatalinga: These are naturally occurring Shivlings found in the riverbeds, particularly in the Narmada River. Spatalingas are shaped by the flow of water and are considered highly propitious.

Parthiv Linga: Parthiv Lingas are made of clay or mud. They are often used in rituals and ceremonies, especially during festivals or when a temporary representation of Lord Shiva is needed.

Narmadeshwar Linga: Narmadeshwar Lingas are specifically sourced from the Narmada River. They are believed to possess special spiritual significance and are highly revered by devotees.

Sphatika Linga: Sphatika Lingas are made of quartz crystal. They are considered highly propitious and are believed to radiate positive energy. Sphatika Linga is often used in meditation and healing practices.

Banalinga: Banalingas are made of stone, typically carved from a single stone. They come in various shapes and sizes and are worshipped in temples and homes.

Ashtadhatu Linga: Ashtadhatu Lingas are made of eight metals, including gold, silver, copper, zinc, lead, tin, iron, and mercury. They are believed to possess unique spiritual properties.

Panchaloha Linga: Panchaloha Lingas are made of a blend of five metals, typically gold, silver, copper, iron, and zinc. They are considered auspicious and are used for worship and rituals.

Jyotirlinga: Jyotirlingas are a set of twelve sacred Linga spread across India, each representing a different manifestation of Lord Shiva. They are considered highly auspicious pilgrimage sites and are worshipped fervently by devotees.

The most famous size of Shivling is: 2 Feet Narmadeshwar Shivling

A 2 feet Narmadeshwar Shivling refers to a Shivling sourced from the Narmada River in India that measures approximately two feet (24 inches) in height. Narmadeshwar Shivlings are naturally occurring stones found in the riverbed of the Narmada River and are considered highly sacred in Hinduism.

A Shivling of this size, made from Narmadeshwar stone, would be quite substantial and would be likely to be used as a central object of worship in temples or sacred spaces. Devotees believe that Narmadeshwar Shivlings possess special spiritual significance and are revered for their connection to Lord Shiva.

Such large Narmadeshwar Shivlings are often the focus of elaborate rituals, prayers, and ceremonies, where devotees offer various sacred items such as water, milk, honey, and flowers as offerings. They are symbols of divine presence and are believed to radiate positive energy and strengthen the spiritual growth and well-being of those who worship them.

Manufacturer Websites:

Local spiritual or religious stores may carry Narmadeshwar Shivlings of various sizes. Visit them to inspect the stones in person and inquire about pricing. Some manufacturers or distributors sell 2 feet Narmadeshwar Shivlings directly to consumers through their websites. Check for pricing and shipping information on their platforms.

#narmada shivling#narmadeshwar shivling original#narmadeshwar shivling for home#narmadeshwar shivling online

2 notes

·

View notes

Text

Excellence in Non-Ferrous Forging & Casting in India

Non-ferrous forging and casting have emerged as critical processes in the manufacturing landscape, contributing significantly to India's industrial prowess. With a focus on metals like aluminum, copper, brass, and bronze, the country's expertise in non-ferrous forging and casting has reached new heights. Let's explore the excellence that India brings to these essential metallurgical processes.

Non-ferrous forging in India is marked by precision and skill, as manufacturers leverage advanced techniques to shape metals into components with superior mechanical properties. The forging process involves applying heat and pressure to mold metals into desired forms, enhancing their strength and durability. Indian forging facilities are equipped with state-of-the-art technology, ensuring the production of high-quality components that meet international standards.

Casting, another integral part of non-ferrous metal processing, is equally impressive in India. Foundries across the country use advanced casting methods to create intricate and complex shapes from molten non-ferrous metals. The attention to detail in the casting process is evident in the precision components that are vital to various industries.

Industries such as automotive, aerospace, and electronics in India benefit significantly from the excellence in non-ferrous forging and casting. The automotive sector, for instance, relies on these processes for manufacturing engine components, transmission parts, and lightweight structural elements. The use of non-ferrous metals contributes to fuel efficiency and sustainability, aligning with global trends.

In the aerospace industry, where precision and reliability are paramount, non-ferrous forging and casting play a crucial role. Components like aircraft engine parts and structural elements are crafted with meticulous attention to detail, ensuring the highest standards of performance and safety.

The electronics industry in India also reaps the rewards of non-ferrous forging and casting. The superior thermal conductivity of non-ferrous metals makes them ideal for applications such as heat sinks and connectors. The corrosion resistance of these metals ensures the longevity of electronic components in various environments.

As India continues to position itself as a global manufacturing hub, the excellence in non-ferrous forging and casting becomes a cornerstone of its industrial success. The commitment to quality, technological advancement, and sustainability places India at the forefront of non-ferrous metallurgy, contributing to the growth and competitiveness of its industries on the world stage. The journey of excellence in non-ferrous forging and casting in India is undoubtedly a testament to the nation's capabilities in shaping the future of manufacturing.

2 notes

·

View notes

Text

HOW NEHRU CAN TRULY BE CALLED 'THE ARCHITECT OF INDIA'S BIMARU ECONOMIC STRUCTURE'. ................................................................................. - HOW NEHRU INCOMPETENTLY, & PER MANY HISTORIANS, MALICIOUSLY, RUINED EASTERN INDIAN ECONOMIES, LIKE BENGAL, BIHAR, JHARKHAND, MADHYA PRADESH, CHHATTISGARH, & ORISSA, BY HIS ONE SIDED (SUBSIDIZED/EQUALIZED FREIGHT COST OF RAW MATERIAL ONLY & NOT FOR FINISHED GOODS) FREIGHT EQUALIZATION POLICY. - HOW NEHRU IN THE GARB OF A SOCIALIST INDIA, MANAGED TO CREATED A REGRESSIVELY CAPITALISTIC INDIA INSTEAD.

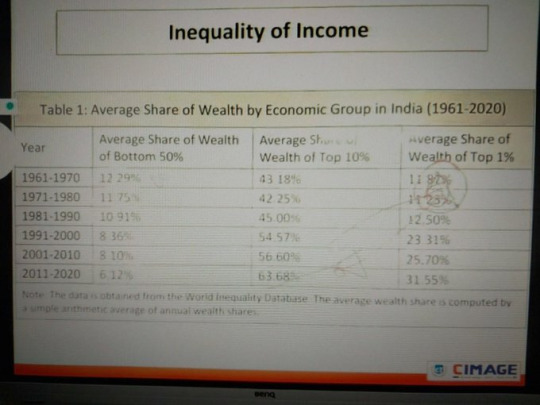

Here are India's 60 yr Share of Wealth stats, from 1961-2020, taken from the 'World Inequality Database'.

Looking at which, most would be forced to ask, why is it that in a wholly socialized state like India (& heavily publicized so at that for 60 yrs)....that our Top 1% 's share in wealth goes up 3 times, Top 10%'s share goes up 1.5 times, BUT SHARE OF THE BOTTOM 50% IS LITERALLY HALVED?

The answer to this lies largely in one man, Nehru, & his policies, either incompetently unintentional or maliciously intentional, policies directly responsible for creating a deeply disparate & heavily lopsided yet overall non-flourishing economic structure, for the entire first half century of the 'Dominion (of Britain) India'.

And the biggest mishap-causing misadventure, being 1951's infamous FREIGHT EQUALIZATION POLICY.

👇

https://en.wikipedia.org/wiki/Freight_equalisation_policy#:~:text=Freight%20equalisation%20policy%20was%20adopted,subsidised%20by%20the%20central%20government.

☝

Above is the Russian Govt+military reaction, to Indian 'independence' in mid 1947. This article was published in the Russian central military newspaper 'Red Star' on July 31, 1947, just 2 weeks before the official date of India's so-called Independence.

"Chief economic positions still remain in British hands–railways,marine transport,port economy,irrigation systems,finance,basic part of jute,industry,almost whole mining industry etc"

“The defence of economic positions and interests is not possible without political power. That power will be secured in the person of the capitalists, landowners and businessmen who are dependent upon British capital.”

“The partition, does not affect the feudal power of the Princes who have always supported British domination.”

"The British Govt plans to artificially separate industrial from agricultural areas,turning it to a agrarian & raw material appendage of Britain."

Exactly what Nehru's Freight Equalization Policy achieved 4 yrs later!

And to add to what y'all I assume would already have read from above, as to it's evil designs & effects, it created a reverse-reward scenario, whereby all the resource-rich states were essentially penalized for their natural advantages, by taking away all incentive for processing-industries & final transportation industries, that are a logical next step from the extraction industries, to germinate & set base in these places. Thereby creating a scenario where the South-western & western coastal states like Maharashtra, Gujarat & Tamil Nadu, & parts of Punjab in North India, were able to find logical easy base for all the processing & transportation industries in their states, for industries like steel, cement, heavy manufacturing, & power, all enabled via raw materials from the other far-off states, like iron ore, coal, limestone, bauxite, copper etc, even w/o any personal natural resources to rely on themselves, merely by virtue of being easy locations to set up ports in for exports, & w/o industries having to compromise on higher transportation & value-added processing costs, that cost aspect equalized & protected for all distances from the resource point. All this, with resource states not finding even some respite in terms of return benefits from any possibly subsidized finished product costs, finished goods not covered by this policy!

These 4-5 states effectively thus became the parasites, for atleast 7 of the traditionally god-gifted states of today like Bihar, Jharkhand, Madhya Pradesh, Chhattisgarh, Orissa, Bengal & Uttar Pradesh, killing all their hope at industrial development & economic progress, & where there is economic (or lotsa times attached) spiritual hopelessness, springs leftism in all it's devious forms, giving birth to intense communism & it's shameful offsprings of caste-divide & gang-culture, literally turning these states HOUSING HALF OF INDIA'S POPULATION, into the pot-holes of the Indian Union -the BIMARU (for Bihar, Madhya Pradesh, Rajasthan, Uttar Pradesh) states of India.

Now in all of this, it's not as if the above-mentioned coastal states were turning themselves into heavens of prosperity either, merely relatively well-off & with a hopeful disposition of the future, that in itself enough to attract large-scale migration from the above BIMARU states, particularly Maharashtra with a more traditionally Hindi-friendly ambience, but also in TN, creating a new urban housing problem, giving birth anew to Mumbai's infamously gargantuan chawl (dingy hutment) lifestyle.

And the reasons for these states, given all these special privileges, not able to take off well enough, aren't directly visible, yet that we can now, on basis of our analysis of Nehru & his so-called Independent India, over innumerable blogs prior, safely interpret, to be an India yet functioning in 1950s & till mid-1960s as some sort of a vassal state of Britain. Only natural then for a supreme state in such a relationship, to not be assumed to desire nations other than itself any sorta economic or strategic base in it's territory, thus curtailing more robust foreign economic to-and-fro.

A utterly class-subservient bent, not seen just for the British race, but per historians, eg Kanchan Gupta, in his hateful sense of complex & hatred of dark-skinned & skinny Bengali community, even worse passionate Hindu Durga-lovers, & per many, all largely borne of his hatred for Bose.

And thus ends yet another inglorious chapter from the life of the self-confessed Last British Ruler of India.

The Tale of the Internal Destruction of India, & it's Premier at it.

2 notes

·

View notes

Text

What is African wax print fabric?

African wax print fabric is a 100% cotton fabric most popular in West African countries, including. Nigeria, Ghana, Senegal, Gambia, Kenya and Tanzania.

History

African wax print fabric has its roots in Indonesian batik, which was brought to Africa by Dutch traders in the 19th century. The designs were initially produced in Holland and exported to the Dutch colonies in Indonesia, but were eventually brought to West Africa where they became popular.

In the early 20th century, European textile manufacturers began producing the fabric in Europe and exporting it to Africa. However, the fabric was not widely accepted by Africans until it was adapted to suit local tastes and needs. African entrepreneurs, particularly in Ghana and Nigeria, began producing their own versions of the fabric, incorporating local designs and motifs.

Today, the fabric is produced and worn throughout Africa, and has become an important part of African fashion. It is used to make traditional clothing such as dresses, skirts, and head wraps, as well as modern clothing such as shirts, pants, and even shoes.

BASIC STEPS IN AFRICAN WAX PRINT FABRIC PRODUCTION

1. Preparation

2. Raw cotton fibres

3. Spinning the cotton to make yarn

4. Using the yarn to produce grey cloth

- Design

- Wax Printing

- Indigo Dyeing

- Crackling Effect

- Colouration

- Washing

- Finishing

Production

African wax print fabric is produced through a process called wax-resist dyeing. The fabric is first washed and bleached, then a wax design is stamped or printed onto the fabric using a copper stamp or roller. The fabric is then dyed, and the wax is removed, leaving a design that is resistant to the dye. This process can be repeated multiple times to create intricate and colorful designs.

Symbolism

African wax print fabric has a rich symbolic meaning in African culture. The patterns and colors used in the fabric often have specific meanings related to cultural traditions, spirituality, and social status. For example, some patterns may be associated with specific tribes or regions, while others may be worn for special occasions such as weddings or funerals.

The fabric has also become a symbol of African identity and resistance, particularly during the colonial era. It was often worn as a symbol of African pride and cultural independence, and was even used as a form of protest against colonial rule.

Conclusion

African wax print fabric is a beautiful and important part of African culture and fashion. Its complex history and rich symbolism make it a fascinating subject of study, and its vibrant colors and designs make it a popular choice for clothing and accessories. Whether worn as a traditional garment or incorporated into modern styles, African wax print fabric in Rajkot, Gujarat will continue to be a symbol of African culture and identity for generations to come.

For more:

Where Can I Get Authentic African Fabric Supplier In India?

Why You Should Pay Attention To African Printed Fabric?

African Fabric Supplier In Zambia

1 note

·

View note

Text

Sunex India

We are manufacturer of CNC Turned Components, CNC Machined Parts, Brass Components, CNC Stainless Steel Components, Dowel Pins, Taper Pins, Stainless Steel Turned Parts, Brass Inserts, Threaded Rods, Brass Unions, Threaded Bars, Sheet Metal Components, Sheet Metal Fabrication, Dowel Pins, Copper Components, Fabrication, Welding, Stainless Steel Turned Parts, Stamped Parts, Metal Stamped Parts, Taper Pins, Threaded Rods, Junction Box, Metal Fabrication, Sheet Metal Brackets, to the Building and Construction Industries, Automobile and Furniture Industries.

0 notes

Text

CNC Laser Cutting Machine Manufacturers in India: Driving Innovation in Metal Fabrication

The ascent of CNC laser cutting technology has reformed the metal fabrication industry. Offering unrivaled accuracy, proficiency, and speed, CNC Fiber laser cutting machines have turned into the foundation of current assembling processes across the globe. In India, this industry is quickly advancing, with a few manufacturers driving the manner in which in giving cutting-edge answers for different areas. Whether it's CNC laser cutting machine manufacturers in Gujarat, Ahmedabad, or across India, these organizations have become central participants in worldwide assembling.

What is CNC Laser Cutting?

CNC laser cutting is a technology that utilizes a powerful laser pillar to cut, dissolve, or etch materials like metals, plastics, and composites. CNC (Computer Numerical Control) technology permits the laser to adhere to exact advanced guidelines to make definite cuts. The most widely recognized sorts of CNC lasers incorporate CO2 lasers and fiber lasers, the last option being profoundly productive and acquiring ubiquity for its high level abilities.

CNC laser cutting machines are particularly famous for their capacity to make multifaceted cuts with unbelievable precision. Whether working with hardened steel, aluminum, or different metals, these machines offer great outcomes that far surpass conventional strategies. The accuracy and speed of CNC laser cutting make it ideal for enterprises like auto, aviation, hardware, and development.

Why CNC Fiber Laser Cutting Machines Are Well known in India

In India, CNC fiber laser cutting machine manufacturers have been at the front line of this mechanical unrest. Fiber lasers utilize an alternate medium to create the laser shaft contrasted with CO2 lasers, making them more energy-proficient, quicker, and requiring less support. These elements have added to the fast ascent in prevalence of fiber laser cutting machines in India.

A few benefits of CNC fiber laser cutting machines include:

High Cutting Pace: Fiber lasers are known for their quick cutting velocities, which can altogether decrease creation time, expanding generally speaking proficiency.

Energy Productivity: These machines consume less power than customary CO2 lasers, making them all the more harmless to the ecosystem and cost-effective.

Accuracy: The little, concentrated laser bar considers very exact cutting, bringing about clean edges with insignificant material wastage.

Flexibility: Fiber lasers can cut different metals, including gentle steel, aluminum, metal, and copper.

CNC Laser Cutting Machine Manufacturers in Gujarat

Gujarat has turned into a center for CNC laser cutting technology. The state is home to various manufacturers that represent considerable authority in CNC laser cutting machines, especially CNC fiber laser cutting machines. These organizations have earned respect for their capacity to deliver solid, elite execution machines that take special care of both neighborhood and global business sectors.

The manufacturers in Gujarat center around coordinating high level elements like computerized stacking and dumping frameworks, multi-hub cutting abilities, and simple to-utilize interfaces that upgrade the general efficiency of the machine. Their machines are ordinarily utilized in businesses that require high accuracy and speed, for example, car and aviation producing. These manufacturers are committed to conveying machines that satisfy worldwide guidelines while residual cost-effective, making them a solid player in the serious scene of metal fabrication technology.

CNC Laser Cutting Machine Manufacturers in Ahmedabad

As the biggest city in Gujarat, Ahmedabad assumes an essential part in India's assembling area. The city is home to probably the most imaginative CNC laser cutting machine manufacturers in India. These manufacturers center around creating best in class machinery that consolidates superior execution with low working costs.

In Ahmedabad, CNC laser cutting machine manufacturers offer machines with a large number of capacities, from cutting thick steel plates to etching multifaceted plans on meager metals. These machines are utilized by different businesses, including farming, protection, and customer hardware. Ahmedabad-based manufacturers are likewise known for giving amazing after-deals support, guaranteeing that their machines stay functional with insignificant free time.

CNC Laser Cutting Machine Manufacturers in India: Industry-Driving Arrangements

India is quickly turning into a forerunner in the worldwide assembling industry, because of its developing organization of CNC laser cutting machine manufacturers. These organizations not just proposition progressed answers for enterprises in India yet additionally trade their machines to worldwide business sectors. The machines fabricated in India are known for their strength, accuracy, and proficiency, going with them a favored decision for organizations hoping to put resources into long haul arrangements.

The interest for CNC fiber laser cutting machines in India keeps on rising, especially in enterprises that require complex and excellent metal cutting. Indian manufacturers have made critical headways in creating machines that are custom-made to address the issues of assorted ventures. These machines are intended to deal with different metals and are furnished with highlights that further develop creation times, lessen material wastage, and proposition more noteworthy adaptability in cutting complex shapes and examples.

Key Elements of CNC Laser Cutting Machines

Accuracy and Precision: CNC laser cutting machines give unrivaled exactness, guaranteeing that even the most intricate plans are sliced flawlessly.

Energy Productivity: With the utilization of fiber lasers, these machines offer more energy effectiveness than more established advancements like CO2 lasers. This outcomes in lower functional costs and a more modest carbon impression.

Low Support: CNC fiber laser cutting machines require insignificant upkeep because of less moving parts, adding to their long life expectancy and diminished margin time.

Speed: These machines are known for their speed in cutting metal, which essentially diminishes creation times and works on generally speaking productivity.

Flexibility: CNC laser cutting machines can work with different sorts of metals, including tempered steel, aluminum, and copper. They are reasonable for many businesses, from auto to hardware.

End

India's CNC laser cutting machine manufacturers are at the bleeding edge of the metal fabrication industry, offering elite arrangements that are assisting organizations across various areas with expanding their proficiency and efficiency. With manufacturers in Gujarat and Ahmedabad driving the way, the Indian market is ready to turn into a worldwide center point for CNC laser cutting technology.

For organizations hoping to put resources into high-accuracy, cost-effective, and energy-proficient cutting arrangements, India offers a wide exhibit of choices from top manufacturers. The blend of cutting-edge technology, gifted labor force, and a guarantee to development guarantees that CNC laser cutting machines made in India fulfill the most elevated global guidelines.

As businesses keep on developing, CNC laser cutting technology will stay a basic part in driving efficiency and advancement. Indian manufacturers are prepared to satisfy the developing need, guaranteeing that their machines stay at the very front of present day fabricating. Whether you are in auto, aviation, or development, the interest in CNC laser cutting machines is a stage toward guaranteeing higher efficiency, better quality, and an upper hand in the worldwide market.

#fiberlasercuttingmachine#fiberlasercuttingmachinemanufacturer#metweld#cncfiberlasercuttingmachine#industrialcncfiberlasercutter#manufacturer#fiberlasercutter

0 notes

Text

Geotextiles and Geogrids Market Analysis: Future Outlook and Key Applications

The recycled copper market plays a vital role in the global economy due to its contribution to sustainability and resource conservation. Copper is a highly recyclable material, and recycled copper holds the same properties as freshly mined copper. This has driven its increasing adoption across various industries, especially in light of the global push toward sustainability and green practices. Recycling copper significantly reduces energy consumption, minimizes carbon emissions, and helps in preserving natural resources.

The recycled copper industry was valued at US$ 27.0 billion in 2022. It is projected to grow at a CAGR of 5.3% from 2023 to 2031, reaching an estimated US$ 43.0 billion by the end of 2031.

The demand for copper is continually rising, especially in sectors like electronics, construction, and renewable energy, and recycled copper offers a cost-effective alternative to newly mined copper. The increasing emphasis on reducing environmental impact and adopting circular economy models further accelerates the market’s growth.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/recycled-copper-market.html

Market Segmentation

The recycled copper market can be segmented based on service type, sourcing type, application, industry vertical, and region.

By Service Type

Collection

Sorting

Shredding

Melting and Refining

By Sourcing Type

Post-consumer Scrap

Industrial Scrap

By Application

Electrical and Electronics

Construction

Automotive

Industrial Machinery

Others

By Industry Vertical

Power Generation

Transportation

Electronics and Electrical Equipment

Building and Construction

Others

By Region

North America

Europe

Asia-Pacific

Latin America

Middle East and Africa

Regional Analysis

North America: The North American recycled copper market is witnessing growth, with the U.S. being a key contributor due to its developed recycling infrastructure and strong industrial base. Increased environmental regulations are also promoting the use of recycled copper in the region.

Europe: Europe is one of the leading regions in the recycled copper market, driven by stringent environmental policies and initiatives such as the European Green Deal. Germany, the U.K., and France are major markets within the region.

Asia-Pacific: The Asia-Pacific region holds the largest share of the recycled copper market, with countries like China, India, and Japan leading the demand. China, being a significant consumer of copper for its manufacturing and electronics industries, plays a crucial role in driving market growth.

Latin America and the Middle East & Africa: These regions are also expected to experience moderate growth, with the increasing adoption of recycling practices and the growing construction and automotive industries.

Market Drivers and Challenges

Market Drivers:

Sustainability Initiatives: Growing awareness about environmental sustainability is encouraging industries to adopt recycled copper to reduce carbon footprints.

Cost-Effectiveness: Recycled copper is cheaper to produce compared to mining and processing virgin copper, making it an attractive option for various industries.

Government Regulations: Governments across the globe are enforcing regulations and policies promoting recycling, which is fostering the growth of the recycled copper market.

Market Challenges:

Collection and Sorting Complexity: One of the primary challenges is the difficulty in collecting and sorting scrap copper, which affects the efficiency of recycling processes.

Quality Concerns: Maintaining the quality of recycled copper compared to virgin copper can be a challenge for manufacturers, particularly in high-end applications like electronics.

Market Trends

Circular Economy: The concept of a circular economy, focusing on the reuse and recycling of materials, is gaining momentum. This is driving industries to adopt recycled copper as part of their sustainable practices.

Technological Advancements: Innovations in recycling technology are enhancing the efficiency and quality of recycled copper, making it more appealing for a broader range of applications.

Increased Usage in Renewable Energy: With the global shift toward renewable energy, recycled copper is increasingly being used in wind turbines, solar panels, and electric vehicles.

Future Outlook

The future of the recycled copper market appears promising, with continued growth expected over the next decade. The increasing emphasis on sustainable development, paired with advancements in recycling technology, will drive further expansion. By 2031, the market is projected to exceed USD 60 billion, bolstered by industrial demand and global environmental initiatives. Emerging regions, particularly in Asia and Africa, will see significant growth as they develop their recycling infrastructure.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=76591<ype=S

Key Market Study Points

Detailed analysis of regional growth and opportunities in North America, Europe, and Asia-Pacific.

Insights into technological innovations driving the efficiency of recycled copper processes.

Evaluation of environmental policies and their impact on market dynamics.

Competitive Landscape

The recycled copper market is highly fragmented, with key players focusing on expanding their recycling capacities, improving collection processes, and investing in innovative technologies. Leading companies in the market include:

Aurubis AG: One of Europe’s largest copper recyclers, Aurubis continues to invest in recycling technology.

Umicore N.V.: A global leader in materials technology, Umicore focuses on sustainable recycling solutions.

Sims Metal Management: A leading global recycler of copper, with significant operations in North America and Europe.

Kuusakoski Recycling: Specializes in industrial recycling, providing copper recycling services to a variety of industries.

Recent Developments

Aurubis AG announced the expansion of its recycling facility in Germany, enhancing its ability to process post-consumer and industrial scrap.

Umicore has introduced a new technology to improve the purity of recycled copper for use in high-end electronics.

Sims Metal Management has expanded its collection services in North America, allowing for increased processing of copper scrap.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Bandsaw Machine Suppliers

Dipti Bandsaw is a bandsaw machine suppliers and manufacturer of top-quality bandsaw machines that can be used for cutting and processing various materials like stainless steel, alloy steel, mild steel, brass, aluminum, copper, plastic and wood. We have been developing cutting edge bandsaw machines for our clients in India and abroad for quite some time now, and we can provide with products like horizontal bandsaw machines and vertical bandsaw machines. At Dipti Bandsaw, we make sure that our products deliver the finest performance and many years of durability. If you are thinking of getting the best bandsaw machines, you can get them from us at Dipti Bandsaw.

Easy to use and manage, our bandsaw machines can certainly deliver smooth cutting results each and every time. As one of the best bandsaw machine suppliers, our band saw machines are characterized by sturdy and stable design. The continuous cutting features help to make sure that the power consumption is always maintained low. The parts of the machine can last for a long time. Even when something happens with these parts, they can be easily replaced and repaired. The heavy duty features of these machines can enable users to manage large production requirements.

0 notes

Text

Carbon Steel ASTM A350 LF2 Flanges Suppliers In India

Carbon Steel ASTM A350 LF2 Flanges Manufacturers In India,Supplier In India,Stocklist In India,Exporter In India

Introduction:- Carbon Steel ASTM A350 LF2 Flanges Manufacturers In India

Carbon Steel ASTM A350 LF2 flanges are crucial components used in various industrial sectors, particularly for applications requiring durability and performance at low temperatures. In India, several manufacturers specialize in producing these high-quality flanges, catering to both domestic and international markets. Here’s an overview of the landscape of Carbon Steel ASTM A350 LF2 flange manufacturing in India

India has a robust industrial manufacturing sector, and the production of Carbon Steel ASTM A350 LF2 flanges is a significant part of this landscape. The country’s manufacturing capabilities are well-developed, with numerous companies specializing in flanges and other piping components. Indian manufacturers adhere to stringent quality standards to produce flanges that meet international specifications

Product Overview:-

Product Overview:-

ASTM A350 LF2 flanges are available in welded or bolted designs. Flanges are bolted or welded to pipes to create connections between pipes. Shasan Piping Solution is a leading manufacturer and supplier of a variety of ASME SA 350 GR LF2 Weld Neck Flange dimensions and types. Material composition includes carbon, silicon, manganese, phosphorus, sulfur, molybdenum, copper, chromium, nickel, vanadium, and niobium.

A350 LF2 Class 1 flanges are most commonly used, but Class 2 is used in certain applications. You can also heat treat the flange to harden it. Heat treatment methods include normalizing and tempering. A350 LF2 blind flange is a type of flange that is installed on the end of a pipe to completely close the pipeline. These can be screwed or permanently welded and can be easily removed during maintenance operations. A350 LF2 Carbon Steel ASTM slip-on flanges are used on seamless pipes and are easy to install in the correct position as the pipe can be slid onto the flange and moved into position before welding or bolting. Astm A350 grade LF2 Class 2 pipe flanges are also used in similar capacity. Please contact us for product details and prices.

Specifications:-

Specification List of ASME SA 350 GR LF2 Weld Neck Flange

Size

1/2" TO 4"

Range

15 NB TO 100 NB IN 3000 LBS, 6000 LBS, 9000 LBS

Grade

ASTM / ASME A105/ A105N/ A694 F42/46/52/56/60/65/70 / A350 LF3/ A350 LF2

Pressure Rating

2000#, 3000#, 6000#, 9000#

Class

150#, 300#, 400#, 600#, 900#, 1500# & 2500#.

Type

Socketweld Fittings, Screwed-Threaded Fittings

Form

Tee, Union, Full Coupling, Half Coupling,Elbow 45 Deg & 90 Deg, Swage Nipple, Cross, Cap, Plug Bush

Benefits:-

LF2 flanges are specifically designed to maintain their toughness and impact resistance at very low temperatures, down to -50°F (-46°C). This makes them ideal for cryogenic applications and environments where other materials might become brittle.

Carbon Steel ASTM A350 LF2 flanges offer numerous advantages, including excellent low-temperature performance, durability, versatility, and cost-effectiveness. These benefits make them a valuable choice for a wide range of industrial applications where reliability and safety are paramount.

Conclusions:-

LF2 flanges are specifically engineered to perform reliably in low-temperature environments, making them essential for applications involving cryogenic fluids or operations in cold climates.

Carbon Steel ASTM A350 LF2 flanges are a reliable and versatile choice for piping systems, particularly in low-temperature environments. Their combination of durability, compliance with industry standards, cost-effectiveness, and ease of use makes them a valuable component in many industrial applications.

Email Id :- [email protected] Contact No:- 88879709191

0 notes

Text

The Importance and Benefits of Copper Earthing Electrodes in Electrical Systems

Veraizen Earthing is a major copper earthing electrode manufacturer in India. Copper Earthing Electrodes are also made from Hot Dip Galvanized Pipes, with a copper termination and a 20 mm copper interior. Copper Earthing Electrodes Suppliers offers a diverse selection of Copper Earthing Electrode products, including the electrogrip 60mm 3 metre, electrogrip 40mm 3 metre, electrogrip 50mm 3 metre, electrogrip 80mm 3 metre, electrogrip 90mm 3 metre, and electrogrip 40mm 2 metre pure copper earthing electrode.

Understanding Earthing Systems

Earthing, also known as grounding, is the process of connecting the non-current-carrying parts of electrical equipment to the earth. This connection ensures that in case of a fault, such as a short circuit or surge, the excess electricity is safely discharged into the ground, preventing damage to equipment and reducing the risk of electric shock to individuals.

An earthing electrode is a vital part of this system. It is a conductive rod or plate buried in the ground, which provides a low-resistance path for fault currents to dissipate into the earth. Among the various materials used for earthing electrodes, copper stands out due to its superior electrical and mechanical properties.

Why Copper?

Copper is highly regarded for its excellent conductivity, durability, and resistance to corrosion. These properties make it the ideal material for earthing electrodes. Let’s delve into the specific advantages of copper in earthing systems:

Superior Electrical Conductivity

Copper has one of the highest electrical conductivities among metals, second only to silver. This high conductivity ensures that fault currents are efficiently conducted into the ground, minimizing the risk of electrical hazards. In comparison to other materials like galvanized steel, copper provides a much lower resistance path, which is critical in achieving an effective earthing system.

Corrosion Resistance

One of the most significant challenges with earthing electrodes is their exposure to soil and environmental conditions, which can lead to corrosion over time. Copper’s natural resistance to corrosion makes it highly durable, even in harsh environments. This ensures that the electrode remains effective for a long period, reducing the need for frequent replacements and maintenance.

Longevity and Reliability

Copper earthing electrodes are known for their longevity. Once installed, they can function effectively for decades without significant degradation. This reliability is crucial for safety, as a compromised earthing system can lead to severe electrical failures and safety hazards.

Versatility in Applications

Copper earthing electrodes are versatile and can be used in a wide range of applications, including residential, commercial, and industrial settings. Whether it’s grounding the electrical system of a home, a high-rise building, or a large industrial facility, copper electrodes are suitable due to their consistent performance.

Ease of Installation

Another advantage of copper electrodes is their ease of installation. They can be easily driven into the ground without the risk of damage, thanks to their strength and flexibility. This not only saves time during installation but also reduces labor costs.

Types of Copper Earthing Electrodes

There are several types of copper earthing electrodes available, each designed to meet specific requirements:

Solid Copper Rods: These are pure copper rods that offer excellent conductivity and durability. They are often used in areas with high soil resistivity.

Copper Bonded Rods: These rods have a steel core that is coated with copper. They combine the strength of steel with the conductivity and corrosion resistance of copper, making them cost-effective and efficient.

Copper Earthing Plates: These are flat plates made of copper, buried in the ground. They provide a large surface area for fault currents to dissipate and are typically used in earthing systems where deep burial is not feasible.

Copper Earthing Electrodes Manufacturers in India

The top copper earthing electrode supplier in India is Veraizen Earthing.We are also a top provider of pure copper electrodes, copper-bonded electrodes, and copper plates.We have established a solid reputation in the local and global sectors via strong business ethics and high-quality products such as Copper Earthing Electrode. We ship our stuff all around the world. They are popular among our regular clientele because of their long lifespan and affordable cost.We also produce and market copper-bonded solid electrodes, earth rods, solar earthing, and chemical earthing. We Supply Lightning Arrester Manufacturers in Mumbai and Lightning Arrester Manufacturers in Kolkata.

#Copper Earthing Electrodes manufacturers in india#Copper Earthing Electrodes Supplier in india#Copper Earthing Electrodes Suppliers#Lightning Arrester Manufacturers in Mumbai#Lightning Arrester Manufacturers in Kolkata

0 notes

Text

Tandoor Exporters: Bringing the Flavors of India to the World

Tandoors have been an integral part of Indian cuisine for centuries, used to create iconic dishes like tandoori chicken, naan, and kebabs. As the popularity of Indian food has grown globally, tandoor exporters have played a crucial role in introducing these unique cooking methods and flavors to international markets.

Tandoor manufacturing in India has seen significant growth, with companies like Parshadi Lal and Sons leading the way. However, the role of Tandoor Exporters In Jaipur in the evolution of tandoor products cannot be understated. These exporters have been instrumental in bringing these innovative tandoor products to global markets. By showcasing the benefits of modern tandoors, they have helped to expand their reach beyond traditional Indian and Pakistani cuisine. This has led to increased demand for tandoor-cooked food, benefiting restaurants, food trucks, and home cooks worldwide.

While adapting to global trends, tandoor exporters remain committed to preserving the traditional methods and flavors of Indian cuisine. With the utmost care and attention to detail, these skilled craftsmen and experienced professionals manufacture each tandoor.

Modern Tandoor Exporters In Chandigarh have embraced innovation to create attractive and user-friendly designs. They utilize durable materials such as copper and aluminum to craft tandoors that not only perform well but also have an eye-catching appearance. These exporters ensure that their tandoors meet international standards and undergo rigorous quality checks before being exported.

The innovation of tandoor products has opened up new possibilities for this traditional cooking method. Parshadi Lal and Sons is one of the best tandoor manufacturers, who introduce modern designs, improving efficiency, and ensuring safety. We have been instrumental in bridging the gap between traditional Indian cooking methods and global culinary trends.

By combining innovation with a commitment to tradition, they have successfully introduced the flavors of the tandoor to the world, making Indian cuisine more accessible and appreciated than ever before.

Visit us at www.tandoorsindia.in for more information!

0 notes

Text

Best CNC Bending Services India By Sawant Group

In the competitive manufacturing landscape of India, precision and efficiency are paramount. For any company looking to produce high-quality metal parts, choosing the right bending service provider is crucial. Sawant Group, a name synonymous with quality and innovation in the metal fabrication industry, stands out as a leading provider of CNC bending services across India.

What makes Sawant Group the preferred choice?

1. State-of-the-Art Technology and Expertise:

Sawant Group boasts a cutting-edge fleet of CNC bending machines, equipped with the latest technology and software. This ensures superior precision and repeatability in bending operations, even for complex and intricate designs. Their team of experienced engineers and technicians possesses in-depth knowledge of CNC bending processes, allowing them to deliver exceptional results.

2. Wide Range of Bending Capabilities:

From simple bends to intricate shapes, Sawant Group can handle a diverse range of bending projects. They cater to various industries, including automotive, aerospace, construction, and more, meeting the specific requirements of each. Their capabilities include:

Sheet Metal Bending: Precision bending of various metal sheets, including stainless steel, aluminum, brass, and copper.

Tube Bending: Efficient and accurate bending of tubes and pipes in different materials and dimensions.

Profile Bending: Specialized bending of complex shapes using advanced software and machinery.

3. Unmatched Quality Control:

Sawant Group prioritizes quality control at every stage of the bending process. They utilize rigorous quality assurance systems and implement strict inspection procedures to ensure that every part meets the highest standards. This commitment to quality has earned them the trust of numerous leading companies across India.

4. End-to-End Solutions:

Sawant Group understands the importance of a seamless experience. They offer end-to-end solutions, from initial design consultation to final delivery. This includes:

Assistance: Their team of experienced engineers assists clients in optimizing designs for efficient bending and maximizing material utilization.

Material Sourcing: They offer a wide range of materials to choose from, ensuring access to the best options for specific applications.

Prototyping and Testing: They provide rapid prototyping services to ensure client satisfaction before full-scale production.

Delivery and Logistics: They offer flexible delivery options, ensuring timely and secure delivery of finished products.

5. Competitive Pricing and Timely Delivery:

Sawant Group is committed to delivering competitive pricing without compromising on quality. They utilize efficient production processes and streamlined operations to ensure cost-effectiveness. Their dedicated team prioritizes timely delivery, ensuring projects are completed within deadlines.

6. Customer-Centric Approach:

Sawant Group prides itself on its customer-centric approach. They believe in open communication and collaboration, working closely with clients to understand their specific needs and requirements. Their team is always available to answer questions and provide expert guidance throughout the entire project lifecycle.

Benefits of Choosing Sawant Group for CNC Bending Services:

Improved Product Quality: Achieving superior precision and consistency in bending operations results in enhanced product quality and performance.

Reduced Production Costs: Efficient CNC bending processes reduce material waste and minimize production time, leading to significant cost savings.

Increased Efficiency: Streamlined operations and timely deliveries enhance overall production efficiency.

Enhanced Innovation: Access to advanced technology and experienced engineers opens doors to explore innovative bending solutions and optimize designs.

Strong Customer Relationships: Sawant Group’s dedication to customer satisfaction fosters long-lasting relationships built on trust and mutual respect.

Conclusion:

When it comes to CNC bending services in India, Sawant Group stands out as a reliable and trusted partner. Their commitment to quality, technology, and customer satisfaction makes them the preferred choice for companies seeking exceptional bending solutions. By choosing Sawant Group, you can be confident in delivering superior products and achieving your manufacturing goals with confidence.

For More Info Visit Us At :- Sawant Group

Email :- [email protected]

Mob No :- +91 98810 66175

0 notes

Text

Flanges | Platinex Piping Solution LLP

About Flanges

The type of flanges is regulated based on different country norms or connection types, and the flanges are produced in different sizes according to reasons of using. This material is chosen due to its ability to withstand the highest heat and pressure levels that will apply the area to be used, the rate at which the pipe may get corroded and the area where the flange will be used.

Similarly besides flanges which the widest photo figurative facet of joining today, they are mostly used in the systems, they provide various benefits. Regarding the place of use, materials have to be completely different like brass, copper and irons or those usual metals. The second of all is that it is quite convenient as it enables you save time in pipe system maintenance. We so called create each type of flange and pipe range on demand according to your individual needs.

Pipe flanges

Pipe flanges manufacturer are a very important element for connecting different types of pipes, valves, pumps and other similar sewage equipment together. They are a kind of protective systems installing to join the piping with various types of equipment.

Grades in Flanges

Stainless Steel Flanges

Carbon Steel Flanges

Alloy Steel Flanges

Monel Flanges

Inconel Flanges

Hastelloy Flanges

Nickel Alloy Flanges

Enabling the two substances to be coupled by means of inner and outer sides clamp parts is fluency connection. Along the slopes, then, put decking which will be useful for eliminating troubles that might occur. The next will be, for ensuring the firmly holding of these bolts among the flanges. Sealing elements are used for the purposes of prevention of leak but this is done after the process of tightening those flanges. In order to have a healthy seal, care should be paid to flanges to be matched and bolts to be tightened with the recommended torque.

Stainless Steel Flanges and Fittings Pros.

The stainless steel flanges is second to none on the resistance to corrosion as a result of chromium addition, which creates an oxide film at the surface. This protective layer serves as a barrier against the harmful elements however; corrosion and rust would still take place if the protective layer is degraded. Stainless steel is long lasting, robust and easy to care for, and it is self-healing. The chromium barrier found on material surface can be re-formed to heal the limited damage to the surface.

Correct flange and fitting maintenance is key advice to prevent rust and wear surface of the equipment. There is a possibility for corrosion to take place if the suit is in contact with salt, including the seaside air and road salt. For high-quality stainless steel components, make sure that the appropriate grade of stainless steel for your application is chosen and corrosive substances and rust are subsequently removed using suitable solvents as part of regular maintenance.

Flexibility is also one of the advantages of this choice. All stainless steel components can be expatiated upon or fabricated to your specific specs for custom made fittings or flanges.

0 notes

Text

Activating Excellence: The Role of Bleaching Earth in Oil Purification

Oil purification is essential in the chemical and food industries. It ensures the oil we consume is of high quality and safe. Activated bleaching earth is the key material that is used in the process of oil purification.

What is Bleaching Earth?

Bleaching earth is commonly called bleaching clay. It is a fine and powdery substance that is made from natural minerals like attapulgite and bentonite. These natural minerals contain montmorillonite. Montmorillonite is a type of clay that has high absorbent properties, which makes bleaching earth a great component for removing impurities from oil.

Bleaching earth can be found in many parts of the world including the USA, China, Brazil and India. Before using it for oil purification, it is processed and treated with acid to boost its ability to absorb the impurities.

How Does Bleaching Earth Work?

The role of activated bleaching earth is to remove the impurities that can affect the colour, taste and stability of oil. The impurities present in the oil include pigments such as carotenoids and chlorophyll, phospholipids, trace metals and oxidation products.

Role of Activated Bleaching Earth in Oil Purification

The following are the points that explain the role of activated bleaching earth in oil purification:

Absorption: During the process of absorption, the activated bleaching earth absorbs pigments and colour bodies like chlorophyll and carotenoids. It gives crude oil its dark colour. This product makes the oil clearer and lighter. Bleaching earth also removes metals like copper and iron that can cause oil to go rancid. This helps the oil stay fresh for a longer time.

Degumming: It is a process where bleaching earth removes phospholipids and clarifies the oil. The gum-like substance can make oil unstable and cloudy.

Neutralization: This process helps the bleaching earth neutralize components like fatty acids and oxidation products. Neutralization is done because these products can degrade the quality of oil during oil processing.

Benefits of Using Bleaching Earth

There are several benefits of using activated bleaching earth in oil purification. Some of them are:

It helps in giving improved oil quality by removing impurities. This helps in increasing the shelf life of the oil.

Using bleaching earth from a leading activated bleaching earth manufacturer in India can improve the smell and taste of edible oils. It helps in making the oil look more appealing to its consumers.

By eliminating trace metals and other pro-oxidants, bleaching earth can help in the prevention of rancidity. This helps in keeping oils fresh for a long time.

Purified oils can be used as vegetable oils, animal fats and even for biodiesel purification.

Process of Oil PurificationThere are several steps included in the process of oil purification. Some of them are:

Degumming: It is a process where water or an acid is added to crude oil for the removal of phospholipids and hydration. It is done by using a centrifuge which helps in separating the hydrated gums from the oil.

Neutralization: During this process, the oil is treated with sodium hydroxide. It helps in freeing the oil from fatty acids by forming a soap stock.

Bleaching: For bleaching, the mixture is heated and stirred continuously to ensure the absorption of impurities. Using the filtration process, the oil and bleaching earth are separated.

Deodorization: The final step involves the removal of any remaining volatile compounds that can majorly affect the smell and taste of the oil. For the process of deodorization, the oil is heated under vacuum conditions to achieve the best quality oil.

Use Natural Active Clay LLP’s Activated Bleaching Earth Natural Active Clay LLP is a leading activated bleaching earth manufacturer in India. Our facility allows us to procure premium raw materials essential for producing the best quality activated bleaching earth.

We are on a mission to provide the best and pure quality products to our consumers. We aim to set new standards of eco-friendliness and efficiency by using cutting-edge technology and research and development for manufacturing our products.

Connect with us for further assistance at Natural Active Clay LLP’s website.

0 notes