#Top Copper Parts Manufacturers in India

Text

Top 8 Copper Parts Manufacturers in India

This Comprehensive Blog Delves Into the Crucial Role of Copper Parts Within India’s Industrial Sector, Showcasing Their Importance Across Various Industries Thanks to Their Exceptional Properties Like Conductivity and Corrosion Resistance. Highlighting the Top Manufacturers in India Such as Meck Industries, Hindustan Copper Limited, Bhagyanagar India Limited, Madhav Copper, Rajnandini Metal, Sterlite Copper, Gujarat Copper Alloy Ltd., and Kavya Metal, It Emphasizes Their Dedication to Precision Manufacturing and Superior Quality. With Insights Into Sustainability and Customization Options, This Guide Provides Valuable Information for Businesses Seeking Top-Notch Copper Components. Dive Deeper Into the Article for A Thorough Analysis and To Learn, How These Leading Manufacturers Are Shaping India’s Copper Industry.

Read More: Top 8 Copper Parts Manufacturers in India

#Copper Parts Manufacturers in India#Copper Components Manufacturers in India#Top Copper Parts Manufacturers in India#Best Copper Parts Manufacturers in India#Top Copper Components Manufacturers in India#Best Copper Components Manufacturers in India

0 notes

Text

HOW NEHRU CAN TRULY BE CALLED 'THE ARCHITECT OF INDIA'S BIMARU ECONOMIC STRUCTURE'. ................................................................................. - HOW NEHRU INCOMPETENTLY, & PER MANY HISTORIANS, MALICIOUSLY, RUINED EASTERN INDIAN ECONOMIES, LIKE BENGAL, BIHAR, JHARKHAND, MADHYA PRADESH, CHHATTISGARH, & ORISSA, BY HIS ONE SIDED (SUBSIDIZED/EQUALIZED FREIGHT COST OF RAW MATERIAL ONLY & NOT FOR FINISHED GOODS) FREIGHT EQUALIZATION POLICY. - HOW NEHRU IN THE GARB OF A SOCIALIST INDIA, MANAGED TO CREATED A REGRESSIVELY CAPITALISTIC INDIA INSTEAD.

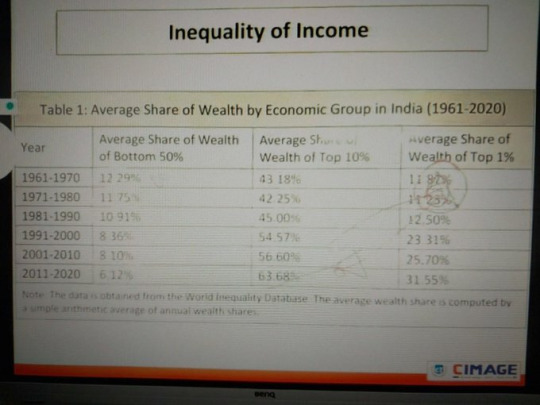

Here are India's 60 yr Share of Wealth stats, from 1961-2020, taken from the 'World Inequality Database'.

Looking at which, most would be forced to ask, why is it that in a wholly socialized state like India (& heavily publicized so at that for 60 yrs)....that our Top 1% 's share in wealth goes up 3 times, Top 10%'s share goes up 1.5 times, BUT SHARE OF THE BOTTOM 50% IS LITERALLY HALVED?

The answer to this lies largely in one man, Nehru, & his policies, either incompetently unintentional or maliciously intentional, policies directly responsible for creating a deeply disparate & heavily lopsided yet overall non-flourishing economic structure, for the entire first half century of the 'Dominion (of Britain) India'.

And the biggest mishap-causing misadventure, being 1951's infamous FREIGHT EQUALIZATION POLICY.

👇

https://en.wikipedia.org/wiki/Freight_equalisation_policy#:~:text=Freight%20equalisation%20policy%20was%20adopted,subsidised%20by%20the%20central%20government.

☝

Above is the Russian Govt+military reaction, to Indian 'independence' in mid 1947. This article was published in the Russian central military newspaper 'Red Star' on July 31, 1947, just 2 weeks before the official date of India's so-called Independence.

"Chief economic positions still remain in British hands–railways,marine transport,port economy,irrigation systems,finance,basic part of jute,industry,almost whole mining industry etc"

“The defence of economic positions and interests is not possible without political power. That power will be secured in the person of the capitalists, landowners and businessmen who are dependent upon British capital.”

“The partition, does not affect the feudal power of the Princes who have always supported British domination.”

"The British Govt plans to artificially separate industrial from agricultural areas,turning it to a agrarian & raw material appendage of Britain."

Exactly what Nehru's Freight Equalization Policy achieved 4 yrs later!

And to add to what y'all I assume would already have read from above, as to it's evil designs & effects, it created a reverse-reward scenario, whereby all the resource-rich states were essentially penalized for their natural advantages, by taking away all incentive for processing-industries & final transportation industries, that are a logical next step from the extraction industries, to germinate & set base in these places. Thereby creating a scenario where the South-western & western coastal states like Maharashtra, Gujarat & Tamil Nadu, & parts of Punjab in North India, were able to find logical easy base for all the processing & transportation industries in their states, for industries like steel, cement, heavy manufacturing, & power, all enabled via raw materials from the other far-off states, like iron ore, coal, limestone, bauxite, copper etc, even w/o any personal natural resources to rely on themselves, merely by virtue of being easy locations to set up ports in for exports, & w/o industries having to compromise on higher transportation & value-added processing costs, that cost aspect equalized & protected for all distances from the resource point. All this, with resource states not finding even some respite in terms of return benefits from any possibly subsidized finished product costs, finished goods not covered by this policy!

These 4-5 states effectively thus became the parasites, for atleast 7 of the traditionally god-gifted states of today like Bihar, Jharkhand, Madhya Pradesh, Chhattisgarh, Orissa, Bengal & Uttar Pradesh, killing all their hope at industrial development & economic progress, & where there is economic (or lotsa times attached) spiritual hopelessness, springs leftism in all it's devious forms, giving birth to intense communism & it's shameful offsprings of caste-divide & gang-culture, literally turning these states HOUSING HALF OF INDIA'S POPULATION, into the pot-holes of the Indian Union -the BIMARU (for Bihar, Madhya Pradesh, Rajasthan, Uttar Pradesh) states of India.

Now in all of this, it's not as if the above-mentioned coastal states were turning themselves into heavens of prosperity either, merely relatively well-off & with a hopeful disposition of the future, that in itself enough to attract large-scale migration from the above BIMARU states, particularly Maharashtra with a more traditionally Hindi-friendly ambience, but also in TN, creating a new urban housing problem, giving birth anew to Mumbai's infamously gargantuan chawl (dingy hutment) lifestyle.

And the reasons for these states, given all these special privileges, not able to take off well enough, aren't directly visible, yet that we can now, on basis of our analysis of Nehru & his so-called Independent India, over innumerable blogs prior, safely interpret, to be an India yet functioning in 1950s & till mid-1960s as some sort of a vassal state of Britain. Only natural then for a supreme state in such a relationship, to not be assumed to desire nations other than itself any sorta economic or strategic base in it's territory, thus curtailing more robust foreign economic to-and-fro.

A utterly class-subservient bent, not seen just for the British race, but per historians, eg Kanchan Gupta, in his hateful sense of complex & hatred of dark-skinned & skinny Bengali community, even worse passionate Hindu Durga-lovers, & per many, all largely borne of his hatred for Bose.

And thus ends yet another inglorious chapter from the life of the self-confessed Last British Ruler of India.

The Tale of the Internal Destruction of India, & it's Premier at it.

2 notes

·

View notes

Text

Bandsaw Machine Suppliers

Dipti Bandsaw is a bandsaw machine suppliers and manufacturer of top-quality bandsaw machines that can be used for cutting and processing various materials like stainless steel, alloy steel, mild steel, brass, aluminum, copper, plastic and wood. We have been developing cutting edge bandsaw machines for our clients in India and abroad for quite some time now, and we can provide with products like horizontal bandsaw machines and vertical bandsaw machines. At Dipti Bandsaw, we make sure that our products deliver the finest performance and many years of durability. If you are thinking of getting the best bandsaw machines, you can get them from us at Dipti Bandsaw.

Easy to use and manage, our bandsaw machines can certainly deliver smooth cutting results each and every time. As one of the best bandsaw machine suppliers, our band saw machines are characterized by sturdy and stable design. The continuous cutting features help to make sure that the power consumption is always maintained low. The parts of the machine can last for a long time. Even when something happens with these parts, they can be easily replaced and repaired. The heavy duty features of these machines can enable users to manage large production requirements.

0 notes

Text

Top Brass Components Manufacturer in India

In today’s fast-evolving industrial landscape, innovation is key to staying ahead. One material that continues to play a crucial role in various sectors is brass. Known for its remarkable adaptability, durability, and resistance to corrosion, brass components are integral to modern industrial systems. From automotive and electrical to plumbing and machinery, brass is at the heart of many innovations. Among the leading manufacturers in this domain, Atlas Metal, based in Jamnagar, stands out as a pioneer in providing top-quality brass parts.

The Unique Properties of Brass

Brass, an alloy primarily composed of copper and zinc, is renowned for its versatility and performance. One of its most notable properties is its resistance to corrosion, making it ideal for use in environments exposed to moisture or chemicals. This characteristic is crucial for components used in plumbing, marine applications, and outdoor machinery, where exposure to elements is inevitable.

Additionally, brass possesses excellent thermal and electrical conductivity, making it a preferred material in the electrical and electronics industries. Its malleability allows for easy machining into precise components, while its inherent durability ensures longevity, even in demanding applications.

The ability of brass to withstand extreme temperatures without losing structural integrity further enhances its use in industries that rely on heavy-duty machinery and equipment. These unique properties have positioned brass as a key driver in numerous industrial innovations.

Brass Components Across Industries

Brass components find wide applications in several key industries:

Automotive Industry: Brass is commonly used in the production of engine parts, gears, and fuel connectors. Its resistance to heat and corrosion makes it ideal for ensuring the durability of these critical components.

Electrical and Electronics: Brass is widely used in earthing accessories, electrical connectors, terminals, and switchgear due to its superior conductivity and malleability, ensuring precision and reliability in complex electrical systems.

Plumbing and Sanitary Applications: Brass fittings, valves, and pipes are the backbone of modern plumbing systems. Its corrosion resistance ensures that brass parts last longer in both residential and industrial water systems.

Machinery and Heavy Equipment: Brass bushings, bearings, and fasteners are integral to many mechanical systems due to their durability and resistance to wear and tear.

Atlas Metal: A Leader in Brass Manufacturing

In Jamnagar, a city widely known as the brass manufacturing hub of India, Atlas Metal has carved a niche for itself as a leader in the production of high-quality brass components. With a focus on precision engineering, Atlas Metal offers a wide range of brass parts tailored to the specific needs of various industries.

The company’s commitment to innovation and quality is reflected in its use of advanced technology and stringent quality control processes. Atlas Metal produces everything from brass nuts, bolts, and fasteners to specialized fittings, terminals, and connectors that meet the demands of today’s high-performance industries.

What sets Atlas Metal apart is its emphasis on customization. Understanding that different industries require unique specifications, Atlas Metal works closely with its clients to deliver components that perfectly match their requirements, ensuring optimal performance and efficiency.

Why Choose Atlas Metal?

Quality Assurance: Atlas Metal places a high priority on quality control, ensuring that every component meets international standards.

Expertise and Experience: With years of experience in the brass manufacturing industry, Atlas Metal brings expertise and innovation to every project.

Advanced Manufacturing Techniques: The company uses cutting-edge technology to deliver precision-engineered parts.

Global Reach: Atlas Metal exports its products to clients worldwide, reflecting its reliability and reputation in the global market.

Conclusion

Brass components are indispensable to many industries, driving innovation with their versatility and durability. Atlas Metal, a leading brass parts manufacturer in Jamnagar, has been at the forefront of providing high-quality, precision-engineered components for global markets. With a commitment to quality, innovation, and customer satisfaction, Atlas Metal continues to be a trusted partner for industries seeking reliable brass solutions.

#brass parts manufacturer in Jamnagar#brass fitting manufacturers in india#pipe fittings manufacturers in india#brass conduit fittings in india#cable tie manufacturer in india#cable gland manufacturers in india#lugs manufacturers in india#cable lugs manufacturers in india#copper lugs manufacturers in india

1 note

·

View note

Text

A manufacturing line that includes a variety of equipment for cleaning, filling, capping, and labeling syrup bottles is known as a pharmaceutical syrup filling line. It’s interesting that it also has an automated syrup production facility. We are a well-known manufacturer of syrup filling lines with uses in the culinary, pharmaceutical, nutraceutical, and herbal industries. Our syrup suspension filling line, which has an elegant appearance, is furnished with state-of-the-art components for production, cleaning, filling, capping, and labeling tasks. The entire suspension fill line functions as a single, integrated system, streamlining the production process.

As one of the top exporters of oral suspension filling lines from India, Adinath has developed both fully automatic and semi-automated oral liquid filling lines. The manufacturing capacity of our filling lines ranges from 500 to 50,000 liters per day.

Let’s have a look on some of the key equipments of our syrup filling line:

Syrup Manufacturing Plant

The pharmaceutical business uses oral liquid manufacturing plants as the best instruments for producing oral liquids. It is specifically made to address two important issues that have a direct impact on the liquids’ quality. Minimal liquid handling by hand and efficient cleanliness throughout production.

youtube

Automatic Bottle Washing Machine

Our bottle washing machine, sometimes called a linear bottle washer, is widely utilized in the pharmaceutical business. It has an all-automatic setup that guarantees hassle-free vial loading on the stainless steel wire mesh conveyor. You can also push them manually from the feed table if you’re comfortable doing things that way. Use this automated machine to save a lot of labor, and you can even opt to have an automatic emptying mechanism when needed. The latter is not required.

youtube

Automatic Bottle Filling Machine

The pharmaceutical business frequently uses bottle filling machines, also referred to as bottle fillers, to pack various liquids into various bottle types. This adaptable device can be used to fill bottles, jars, and containers made of glass, plastic, aluminum, steel, copper, and PET, among other materials. It can also fill aqueous solutions, foamy liquid, and semi-viscous solutions. The machine’s essential components include feeding needles, a piston pump, a quality stainless steel slat conveyor belt, and a robust foundation structure.

youtube

Automatic Bottle Capping Machine

We provide bottle stoppers that are used to cap bottles in a variety of industries, including the manufacturing of chemicals, pharmaceuticals, food and beverage products, pesticides, and alcoholic beverages. Our bottle capping machine is constructed with an M.S. frame and stainless steel enclosures or cladding. An orientation-style cap feeder is included with our ROPP bottle cap sealing machine to ensure smooth cap feeding.

youtube

Bottle Visual Inspection Machine

Adinath International produces and exports a cGMP certified bottle inspection machine with a three track conveyor and hooded lighting configuration. Aside from an inspection table with an SS construction, there is a background that alternates between black and white for a perfect visual inspection. A slat chain made of stainless steel is also a part of it. This machine will last for many years because of its sturdy adjustable bolt support and stainless steel square pipes.

youtube

Automatic Bottle Sticker Labeling Machine

This machine is widely used for labeling PET, aluminum, glass, plastic, and copper bottles, cans, jars, and other containers. With the most advanced microprocessor control label dispensing mechanism available, this linear design machine can detect labels and items with maximum efficiency. Additionally, it features a specially created mechanical and electronic technology that is useful for quickly applying transparent labels on bottles. For the labeling of different bottle types, there are no sections that need to be changed.

youtube

#syrup suspension filling line#oral suspension filling lines#semi-automated oral liquid filling lines#oral liquid manufacturing plants#Automatic Bottle Washing Machine#Automatic Bottle Filling Machine#Automatic Bottle Capping Machine#Bottle Visual Inspection Machine#Automatic Bottle Sticker Labeling Machine#Youtube

0 notes

Text

List of Top 10 Iron Syrup in India

Iron syrup, the most vital part of all anaemia patients and people with a little low iron level, is now coming with so many varieties in the market. Even one iron syrup supplier in India is supplying a huge variety of iron syrups from different brands, so think how many more syrups are available in the entire pharma market! And among this plethora of options, it would be really a daunting task for anyone to find the best syrup which is perfect for all aspects. That’s why we have searched and listed out top 10 iron syrup in India for your ease. Scroll down to know their names.

Which Are the Best Iron Syrup in India?

Earlier, there was only a few options available in iron syrups. But these days, Iron syrup manufacturer manufacturs iron syrup in various formulations. So, it’s necessary to check the formulation, ingredients, other nutrition availability, and the probable side effects before buying one from an iron syrup supplier. Now you can find best iron syrup for adults, and best iron syrup for child also. Here are the names of top 10 iron syrups in India that are bets from every aspect.

1. Dexotone Iron Tonic

Dexotone iron tonic is a very nutritious iron syrup in India for both adults and children. ferric ammonium citrate, a bioavailable form of iron, vitamin B12, B9, C and zinc. Along with treating iron deficiency, it increases the production of red blood cells, improves brain functioning and boost up energy levels.

2. Hapro Bloodo Vita Syrup

Hapro Bloodo Vita syrup is best for adults and it contains iron, folic acid, magnesium phosphate, Ferrum phosphate and more nutrients. It helps create healthy red blood cells, better blood circulation all-over the body, and manage weight loss.

3. Livogen Syrup

Livogen syrup treats iron deficiency in pregnant women and made of folic acid, iron etc.

4. Dexorange Hematinic Syrup

Dexorange Hematinic Syrup comes with folic acid, vitamin b12 and iron. It addresses and treats iron deficiency in pregnant ladies.

5. Hemfer Syrup

Hemfer Syrup is rich in ferrous glycine sulphate, folic acid, vitamin b12, D-biotin, and zinc sulphate. It is effective for managing anaemia and also improves hair growth.

6. Sangobion Syrup

Sangobion syrup contains so many ingredients like Vitamin C , Copper sulfate and manganese sulfate, Folic acid and Vitamin B12. It elevates the low red blood cells level. It is available in delicious vanilla and strawberry-scented flavours, especially for kids. However, pregnant women and people with more serious illnesses can also take it if they lack iron.

7. Ferrous Iron Syrup

8. Ferium XT Syrup

9. Orofer XT Iron Tonic

10. Wilsoplex Herbal Syrup

Conclusion

We have made this list after lots of searching and checking people’s opinions about these syrups to give you just a basic information. There are more iron syrups available in India that might have the best ingredients and work very efficiently for iron deficiency. It’s totally up to you which brand and which syrup you will choose.

If you are looking for a leading iron syrup manufacturer in India to collect most effective and good quality iron syrups, then come to Sapphire HealthCare. This is a well-reputed iron syrup manufacturer and supplier in this country selling iron syrups made of best and genuine ingredients only. Get low-price but highest-quality iron syup from Sapphire healthcare.

0 notes

Text

Types of Round Bars: Materials and Their Uses

Rajkrupa Metal Industries is one of the Premium Quality Aluminium Bronze Round Bar Manufacturer In India. We are now the industry leader in Aluminium Bronze Round Bar. We have consciously positioned itself as a top-tier manufacturer and retailer in the worldwide Aluminium Bronze Round Bar market due to its excellent corporate and technical people skills.

Our company, which manufactures with ISO 9001:2015 certification. We are one of the top Aluminium Bronze Round Bar Manufacturer who complies with the International Quality Standard (IQS).

1. Steel Round Bars

Steel round bars are the most commonly used type due to their strength, durability, and versatility. Steel bars are available in several grades, each with distinct properties suited to different applications.

Carbon Steel Round Bars: These are used in applications requiring high strength and hardness. Commonly used in the construction industry for building frameworks, shafts, and in the manufacturing of machinery parts.

Alloy Steel Round Bars: These bars include additional alloying elements like chromium, manganese, and nickel to enhance specific properties. They are used in automotive parts, power generation, and heavy equipment.

Stainless Steel Round Bars: Known for their excellent corrosion resistance and aesthetic appeal, these bars are used in food processing equipment, medical instruments, and architectural structures. We are also the leading Round bars manufacturer in India.

2. Aluminum Round Bars

Aluminium round bars are lightweight, corrosion-resistant, and easy to machine, making them ideal for various applications where weight and corrosion are critical factors.We are also a Premium Quality Aluminium Bronze Round Bar Manufacturer In India.

6061 Aluminum Round Bars: This grade is known for its excellent mechanical properties and is commonly used in aerospace components, marine fittings, and structural applications.

7075 Aluminum Round Bars: Featuring high strength and good fatigue resistance, these bars are used in high-stress applications such as aircraft structures and military equipment.

3. Brass Round Bars

Brass round bars are an alloy of copper and zinc, offering good corrosion resistance, electrical conductivity, and an attractive appearance. They are widely used in applications requiring both functionality and aesthetics.

CZ121 Brass Round Bars: Known for their excellent machinability, these bars are used in manufacturing precision components, gears, and fittings.

CZ114 Brass Round Bars: Featuring good strength and corrosion resistance, these are used in the production of valves, pump components, and marine hardware.

4. Copper Round Bars

Copper round bars offer excellent electrical and thermal conductivity, making them essential in electrical and electronic applications.

C101 Copper Round Bars: These are used in electrical conductors, connectors, and switchgear due to their high electrical conductivity.

C110 Copper Round Bars: Known for their excellent ductility and corrosion resistance, these bars are used in plumbing, heating systems, and in the manufacturing of electrical components.

5. Titanium Round Bars

Titanium round bars are valued for their high strength-to-weight ratio, corrosion resistance, and biocompatibility. These properties make them suitable for high-performance applications.

Grade 2 Titanium Round Bars: Used in chemical processing, desalination plants, and in medical devices due to their corrosion resistance and biocompatibility.

Grade 5 (Ti-6Al-4V) Titanium Round Bars: Known for their high strength and lightweight, these bars are used in aerospace, military, and automotive applications.

Aluminium Bronze Round Bar Suppliers are well-known for their excellent strength, corrosion resistance, thermal and electrical conductivity, and other properties. We are now the industry leader in Aluminium Bronze Round Bar. We have consciously positioned itself as a top-tier manufacturer and retailer in the worldwide Aluminium Bronze Round Bar market due to its excellent corporate and technical people skills.

#RoundBarsManufacturersinIndia#RoundBarsManufacturers#RoundBars#AluminiumBronzeRoundBarManufacturerInIndia#AluminiumBronzeRoundBarManufacturer#AluminiumBronzeRoundBar

0 notes

Text

Monel 400 Scrap Manufacturers in India

Omkar Metal is proud to introduce Monel 400, a top-tier alloy renowned for its remarkable corrosion resistance and longevity. Composed primarily of nickel and copper, Monel 400 stands as a testament to high performance in various industrial applications. As industries progress towards sustainable practices, the demand for eco-friendly solutions continues to surge. In this context, the recycling of Monel 400 scrap emerges as a pivotal opportunity to foster a circular economy.

In the ever-evolving landscape of industrial processes, the importance of sustainability cannot be overstated. Monel 400, with its exceptional properties, offers a sustainable alternative that aligns with modern environmental objectives. By embracing the recycling of Monel 400 scrap, industries can not only reduce their environmental footprint but also promote resource efficiency and minimize waste generation.

Omkar Metal recognizes the significance of contributing to a circular economy by promoting the recycling of Monel 400 scrap. Through our commitment to sustainability, we aim to facilitate the transition towards greener practices within the industry. By advocating for the reuse and recycling of valuable materials like Monel 400, we strive to play our part in building a more sustainable future.

Furthermore, the recycling of Monel 400 scrap presents numerous benefits beyond environmental conservation. It offers a cost-effective solution for industries, reducing the need for raw material extraction and lowering production costs. Additionally, recycled Monel 400 retains its superior properties, ensuring that quality and performance are never compromised.

Omkar Metal is dedicated to promoting sustainable practices and contributing to a circular economy through initiatives like the recycling of Monel 400 scrap. Together, let us embrace this opportunity to create a more environmentally conscious and resource-efficient industrial landscape.

We Buy and sell Scrap From cities such as Mumbai, Bengaluru, Chennai, New Delhi, Pimpri-Chinchwad, Hyderabad, Pune, Kolkata, Gurgaon, Navi Mumbai, Ahmedabad, Noida, Riyadh, Vadodara, Visakhapatnam, Ludhiana, Haryana, ranchi, uttarpradesh, uttershiv, mirzapur, aligarh, coimbatore, goa, kohlapur, solapur, navi mumbai, midc, gidc, sangli, pune, ankleshwar, chennai, alang, bhavnagar, alwar.

We Buy and sell All Types of Scrap to Saudi Arabia, UAE, Bahrain, China, Peru, Nigeria, Jordan, Muscat, Kuwait, Dubai, Thailand (Bangkok), Venezuela, Germany, Canada, Russia, Australia, Vietnam, Kazaksthan, Jiddah, Libya, Yemen, Algeria, Qatar, Oman, Iran, United States Of America, United Kingdom, Australia, South Africa, Mexico, Turkey, France, European Union, New Zealand, Angola, Congo, Kenya, Lebanon, Spain, Indonesia, Malaysia, Lebanon, Iraq, Iran, Egypt, Madagascar, Sri Lanka, Denmark, Poland, Italy, Brazil, Sudan, Singapore And Netherlands.

0 notes

Text

Prominent Pipes and Tubes Manufacturers in India

Nova Steel Corporation is one of the prominent Pipes and Tubes Manufacturers in India. Pipes and tubes are typically made from a range of materials, including metals such as steel, stainless steel, copper, and aluminum, as well as nonmetals such as PVC, CPVC, polyethylene, and fiberglass. Each material has distinct features such as strength, corrosion resistance, flexibility, and cost-effectiveness, making it ideal for a variety of applications in industries such as construction, plumbing, oil and gas, and automotive.

We are a significant pipes and tubes manufacturers in India. We provide all types of pipes and tubes in various grades and materials. Pipes and Tubes are created utilizing high-quality raw materials and cutting-edge technology to meet the needs of our valued customers, and they are available in a variety of diameters, wall thicknesses, and sizes at reasonable prices.

Pipe is mostly utilized in pipeline and piping systems for the purpose of transporting gases or fluids as a vessel. The tube serves as a structural component. We are also a leading Large Diameter Pipe Manufacturers in India. Pipes & Tubes are used in various parts of India. We have supplied Pipes & Tubes in various cities and in different industries in India. We are therefore known as one of the top-rated Pipes & Tubes Suppliers in India.

For More Details:

Website: novasteelcorporation.com

Product: Pipes & Tubes Suppliers

Oher Product: Round Bar Manufacturer in India

0 notes

Text

Monel 400 Flanges: Top Manufacturer & Exporters | Metalforgeindia

In the economic global, where sturdiness and resistance to harsh environments are vital, Monel 400 flanges stand out as a advanced desire. A leading producer and exporter, is famend for turning in brilliant Monel 400 flanges that meet stringent industry standards. This weblog will delve into the characteristics, applications, and blessings of Monel 400 flanges, and why it is the cross-to dealer for many industries.

Understanding Monel 400

Composition and Properties

Monel 400 is a nickel-copper alloy, comprising about 67% nickel and 23% copper, with small amounts of iron, manganese, carbon, and silicon. This particular composition imparts numerous effective homes:

- Corrosion Resistance: Monel 400 offers extraordinary resistance to a wide variety of corrosive environments, which includes seawater, hydrofluoric acid, sulfuric acid, and alkalis.

- High Strength: The alloy continues its energy and sturdiness over a huge temperature range, from sub-0 temperatures to 1000°F (538°C).

- Thermal Conductivity: Monel 400 well-knownshows right thermal conductivity, making it appropriate for heat switch applications.

- Ductility and Toughness: The alloy is thought for its exquisite mechanical residences, consisting of high ductility and sturdiness.

Key Features

- Nickel Content: Provides exceptional corrosion resistance and high-temperature overall performance.

- Copper Content: Enhances resistance to corrosion by using acids and different aggressive chemicals.

- Versatility: Suitable for numerous packages due to its first-rate mechanical residences and resistance to environmental elements.

Applications of Monel 400 Flanges

Monel 400 flanges are used throughout numerous industries due to their robust homes. Some of the key programs encompass:

Marine Industry

- Seawater Equipment: Monel 400 flanges are perfect for marine applications, which includes shipbuilding and offshore oil platforms, due to their resistance to seawater corrosion.

- Desalination Plants: The alloy’s durability in saline environments makes it best for use in desalination flora.

Chemical Processing

- Chemical Plants: Monel 400 flanges are utilized in chemical processing system, inclusive of reactors, warmth exchangers, and piping structures, wherein resistance to corrosive chemical compounds is critical.

- Petroleum Refining: The alloy’s resistance to bitter fuel environments and natural acids makes it appropriate to be used in petroleum refining procedures.

Power Generation

- Nuclear Plants: Monel 400 is utilized in nuclear strength flowers for additives like steam generators and reactor manage rods because of its resistance to high-temperature corrosion.

- Thermal Power Plants: The alloy’s potential to withstand excessive temperatures and corrosive environments makes it ideal for use in boilers and warmth exchangers.

Aerospace

- Aircraft Components: Monel 400 flanges are used inside the aerospace enterprise for additives that require high strength and corrosion resistance at accelerated temperatures.

- Engine Parts: The alloy’s longevity and thermal conductivity make it suitable for engine parts uncovered to extreme situations.

Leading Manufacturer and Exporter

MetalForge India has established itself as a leading producer and exporter of Monel 400 flanges. Here’s why it is the desired desire for many industries:

Commitment to Quality

Quality is the cornerstone of operations. The corporation adheres to the very best standards of nice control to ensure that its Monel 400 flanges meet or exceed industry specs. Every product undergoes rigorous checking out and inspection to assure its performance in stressful programs.

Advanced Manufacturing Facilities

Modern-day manufacturing facilities are equipped with modern technology and equipment. This allows the employer to provide Monel 400 flanges with precision and consistency. The centers are staffed with the aid of experienced professionals committed to delivering pinnacle-satisfactory products.

Custom Solutions

Is familiar with that exclusive industries have unique necessities. The corporation offers custom answers to satisfy the unique wishes of its clients. Whether you need flanges in a particular length or with precise mechanical houses, can tailor its merchandise to suit your utility.

Global Reach

The leading exporter has a strong global presence. Its Monel 400 flanges are relied on through customers around the arena for his or her best and reliability. The corporation guarantees timely transport and tremendous customer support, regardless of your place.

Sustainable Practices

Is dedicated to sustainable manufacturing practices. The company strives to reduce its environmental effect by means of imposing electricity-green techniques and decreasing waste. This commitment to sustainability extends to its products, which are designed for durability and durability, decreasing the want for frequent replacements.

Why Choose Monel 400 Flanges?

Versatility

Monel 400 flanges are flexible and can be utilized in an extensive range of applications throughout different industries. Their specific houses make them suitable for environments that call for high performance and reliability.

Long-term Performance

The sturdiness and resistance to harsh conditions ensure that Monel 400 flanges offer long-term performance. This makes them a cost-powerful answer for industries where aspect failure can cause great downtime and price.

Safety and Reliability

In important programs including marine, chemical processing, and energy era, protection and reliability are paramount. Monel 400 flanges provide the necessary energy and resistance to ensure secure and reliable operation.

Conclusion

Monel 400 flanges are an essential factor in lots of high-performance applications. Their exquisite houses, together with high strength, corrosion resistance, and first-rate mechanical houses, make them the material of desire for industries ranging from marine to aerospace. MetalForge India, a main producer and exporter of Monel 400 flanges, is dedicated to supplying incredible merchandise that meet the annoying requirements of current industries. With a focal point on quality, advanced production facilities, custom answers, and sustainable practices, MetalForge India is your trusted accomplice for Monel 400 flanges.

0 notes

Text

Aluminium Alloy 2014 Sheets & Plates Suppliers In India

Aluminium Alloy 2014 is renowned for its high strength and excellent machinability, making it a prime choice for various industrial applications. At SIDDHGIRI TUBES, we offer top-quality Aluminium Alloy 2014 sheets and plates, catering to the diverse needs of our clients.

Understanding Aluminium Alloy 2014

Aluminium Alloy 2014 is a high-strength alloy primarily composed of aluminium, with copper as the principal alloying element. This alloy is known for its high strength-to-weight ratio and good machinability, making it ideal for structural applications where durability and performance are critical. It is often used in aerospace, military, and transportation sectors due to its superior mechanical properties.

Key Features of Aluminium Alloy 2014 Sheets & Plates

1. High Strength

Aluminium Alloy 2014 is one of the strongest aluminium alloys available. Its high strength makes it suitable for heavy-duty applications where durability is paramount.

2. Excellent Machinability

This alloy is highly machinable, allowing for precise and complex shapes to be easily manufactured. Its machinability is a significant advantage in producing components that require tight tolerances.

3. Good Weldability

While Aluminium Alloy 2014 has good weldability, it requires special care due to its copper content. With proper techniques, it can be effectively welded for various applications.

4. High Fatigue Resistance

The alloy's excellent fatigue resistance ensures longevity and reliability, particularly in applications subject to repeated stress and strain.

Applications of Aluminium Alloy 2014 Sheets & Plates

Given its exceptional properties, Aluminium Alloy 2014 finds use in a wide range of applications, including:

1. Aerospace Industry

The high strength and lightweight nature of Aluminium Alloy 2014 make it ideal for aerospace applications, including aircraft structures, fuselage frames, and wing panels.

2. Military Applications

Due to its excellent mechanical properties, this alloy is used in military equipment and components that require high strength and durability under extreme conditions.

3. Automotive Industry

Aluminium Alloy 2014 is used in automotive components such as engine parts and chassis, where high strength and fatigue resistance are crucial.

4. Transportation

The transportation sector utilizes this alloy for manufacturing high-strength, lightweight components that enhance fuel efficiency and performance.

Why Choose SIDDHGIRI TUBES?

At SIDDHGIRI TUBES, we are dedicated to providing superior Aluminium Alloy 2014 sheets and plates that meet the stringent requirements of various industries. Here’s why we are a trusted supplier:

Quality Assurance

We source our Aluminium Alloy 2014 sheets and plates from reputable manufacturers, ensuring they meet international standards and specifications. Each product undergoes rigorous quality checks to guarantee performance and reliability.

Customer-Centric Service

Our customer-first approach ensures that we understand and meet your specific needs. Our knowledgeable team is always available to provide technical support and guidance, helping you choose the right material for your application.

Comprehensive Range

We offer a wide range of Aluminium Alloy 2014 sheets and plates in various sizes and thicknesses, catering to different industrial requirements. Whether you need standard or custom dimensions, we have the right solution for you.

Competitive Pricing

At SIDDHGIRI TUBES, we offer high-quality products at competitive prices, ensuring you get the best value for your investment. Our cost-effective solutions help you achieve your project goals without compromising on quality.

Conclusion

Aluminium Alloy 2014 sheets and plates from SIDDHGIRI TUBES are an excellent choice for applications demanding high strength, excellent machinability, and good fatigue resistance. Our commitment to quality, customer satisfaction, and competitive pricing makes us your ideal partner for all your aluminium alloy needs. Contact us today to learn more about our products and how we can support your next project.

0 notes

Text

Crafting Precision: Exploring the World of Stainless Steel Round Bars

Introduction to Stainless Steel Round Bars

Among the numerous kinds of industrial materials currently in the market, stainless steel round bars are particularly outstanding due to their versatility and capacity for strength and corrosion. Hans Metal India these characteristics make them important in a wide range of industries, including construction, automotive, medical, and maritime applications. An investigation of the characterstics of crafting process shall involve stainless steel bar. carfting is one the best method in which its work very smoothly. concreting process is commonly seen in construction works. Stainless Steel Round Bar Manufacturer in India and Stainless Steel Plate Manufacturer in India.This article mainly go to the detectable way and help to work in easy way and quick.

Uses of Stainless Steel Round Bars

Construction and Architecture

Because of its strength, beauty, and ability to withstand weathering, stainless steel round bars are widely utilised in the construction sector. By using Architecture methods it can be easy to analyze the product. Stainless Steel Sheet Manufacturer in India and Round Bar Suppliers in UAE .Their contribution is vital, in constructing buildings, bridges and various infrastructure projects.

Automotive Industry

It is a automated machinery instruments which work in machinery way. SS Round Bar Manufacturer in India and Copper Sheet Manufacturers in India.In the sector various parts, like axles, bolts and engine components are crafted from stainless steel bars. These materials excel in applications that demand reliability and top notch performance due, to their durability and resistance to wear.

Medical Devices

In the field of medicine surgical instruments orthopedic implants and various medical devices are crafted from stainless steel bars. These materials are well suited for critical healthcare uses because of their ability to be sterilized without losing their quality and their compatibility, with the body.

The Crafting Process:

1. Choice of Raw Materials:

In the stage of the process one should opt for quality stainless steel. The specific application will dictate the choice of steel alloy with popular options being 304, 316 and 410 grades. common grades include 304, 316, and 410. Specific qualities like stronger corrosion resistance, better machinability, or higher strength are offered by each grade.

2. Pouring and Pouring Melt:

In an electric arc furnace, the chosen raw materials are melted at extremely high temperatures. This method ensures that the alloy composition remains consistent. The process involves melting steel and shaping it into finished forms, like slabs, billets or blooms.

3. Hot Rolling: The cast steel is put through rolling mills and heated above its recrystallization temperature during the hot rolling process. In this process, the steel is shaped into a rough cylindrical shape and its thickness is decreased.

4.Heat Treatment Process; The rolled bars undergo annealing to enhance their flexibility and reduce their toughness. In this procedure the steel is heated to a temperature. Then slowly cooled down. Moreover annealing helps in relieving stresses in the material.

5. Precision Rolling: To obtain the required diameter and surface finish, the bars are subjected to precision rolling or drawing after annealing. By taking this process, the round bars are guaranteed to meet strict criteria for surface quality and dimensional tolerances.

6. Cutting and Finishing: Depending on the needs of the ultimate use, the lengthy steel rods are cut into predetermined lengths and go through a variety of finishing procedures, including grinding, polishing, or coating. The circular bars get their distinctive glossy, smooth look from this process.

Conclusion

Round stainless steel bars are proof of the strength of expert engineering and fine craftsmanship. From raw material to essential industrial component, they go through a number of carefully regulated procedures, each of which adds to their remarkable qualities. The use of stainless steel round bars in aerospace, automotive, medical, and construction applications is still essential to the advancement of contemporary industry. These extraordinary materials will become even more important and versatile as production methods and technology advance.

0 notes

Text

Pipes and Tubes: The Backbone of Modern Infrastructure

Sagar Steel Corporation is a top Pipes and Tubes Manufacturers in India. Pipes and tubes are essential to the efficient functioning of many industries, from building to transportation and beyond. These cylindrical parts are the foundation of many systems, carrying fluids, gasses, and even data while guaranteeing effectiveness, dependability, and safety in a wide range of applications.

Pipes and tubes are sometimes used interchangeably, although they have important distinctions that require elucidation. Pipes are primarily hollow cylinders used to transport fluids or gasses under pressure, whereas tubes provide a wider range of uses, including structural and transportation. Tubes can vary in thickness, diameter, and material composition to meet the precise needs of their intended application.

The materials that are used to make pipes and tubes are as varied as the uses for which they are intended. Steel, copper, plastic, and alloys are common materials that are selected for their special qualities including durability, heat conductivity, and resistance to corrosion. Extrusion, welding, and seamless processing are examples of advanced manufacturing processes that guarantee the pipes and tubes manufacturers adhere to strict quality requirements.

Their universality highlights their crucial role in forming the world we live in, from energy and utilities to building and transportation. Future developments in this field should bring forth even higher levels of resilience, sustainability, and efficiency in our built environment. We are also a Pipes and Tubes Suppliers.

As an industry pioneer, we think that our unique products should benefit our consumers completely, like Corten Steel Pipes Manufacturers & Alloy Steel Seamless Pipes in India.

For More Detail

Website: sagarsteel.net

Product: Pipes and Tubes Suppliers in India

Other Product: Carbon Steel Seamless Pipes Manufacturer in India.

0 notes

Text

Fluxing Magic: Lime’s Impact on Slag Formation in Copper Smelting

Lime is an integral element in copper smelting, directly contributing to slag formation. This article delves into this fascinating relationship and investigates its profound effects on efficiency and quality in this critical industrial process.

Understanding Slag Formation

Lime plays an essential part of copper smelting, where its creation forms an essential aspect. Molten copper undergoes the smelting process in which impurities are extracted and removed in order to produce purified copper products. Lime is strategically added during this step in order to react with acidic impurities like silica (SiO2) to form stable compounds known as slag that float on top of molten copper for removal purposes.

Lime and Slag Formation

Lime (calcium oxide, CaO) serves an integral function in copper smelting as a flux agent, reacting with silica impurities present in molten copper to neutralize and promote its formation into slag. This chemical reaction leads to calcium silicate (CaSiO3) production that aids effective impurity separation processes.

Acidic Impurity Neutralization: Lime is an excellent way of neutralizing acidic impurities like silica, creating stable slag compounds which are easy to separate from the molten copper.

Lime Enhances Copper Recovery: By aiding efficient slag formation, lime can improve copper recovery rates during the smelting process.

Lime's addition helps regulate heat management within the smelting furnace, providing ideal temperatures for efficient copper extraction and impurity removal. Benefits of Lime in Copper Smelting mes Utilizing Copper industry lime products india smelting offers several distinct advantages:

Lime promotes faster and more thorough removal of impurities from molten copper, leading to improved process efficiency and productivity. Reduced Energy Consumption: Lime helps optimize smelting conditions to reduce energy use and operational costs while improving process efficiencies and productivity.

Environment Sustainability: Lime-based slag formation can reduce waste generation and the environmental impact of copper smelting through cleaner, more efficient processes.

Importance of Quality Lime Supply

For optimal copper smelting results, obtaining top-quality lime from reliable suppliers is crucial to achieve optimal results. High-grade lime ensures uniform chemical composition and purity levels to provide reliable performance throughout the smelting process.

Conclusion

Lime's role in slag formation is integral to copper smelting, impacting efficiency, energy use and environmental sustainability. By taking advantage of lime's fluxing properties to optimize operations and foster sustainable growth and innovation.

Reputable lime manufacturers in Jodhpur, Rajasthan play an invaluable role in providing high-quality lime products that meet the stringent requirements of the Copper mining lime solutions Rajasthan industry.

#Copper mining lime solutions Rajasthan#Best lime manufacturers for copper in Jodhpur#Copper industry lime products india

0 notes

Text

Top Fiber Laser Cutting Machine in India | Indian Trade Bird

Indian Trade Bird offers a comprehensive selection of state-of-the-art Fiber Laser Cutting Machines, empowering you with unparalleled cutting precision, speed, and efficiency for your metal fabrication needs. A fiber laser cutting machine is extremely useful in cutting sheet metal including carbon steel, stainless steel, copper, brass, aluminum and titanium. They achieve exceptional cutting speeds and thicknesses, maximizing your production output. These machines are ideal for intricate designs and complex shapes, making them suitable for a diverse range of metal cutting applications. From sheet metal fabrication and automotive parts to electronics and medical devices, Fiber Laser Cutting Machines offer unmatched versatility.

For more details clicks here - https://www.indiantradebird.com/product/fiber-laser-cutting-machine

0 notes

Text

Electronics Recycling Market Analysis , Dynamics, Players, Type, Applications, Trends, Regional Segmented, Outlook & Forecast till 2033

The Global Electronics Recycling market is worth USD 35 billion in 2023 and anticipated to reach USD 120 billion by 2033, expanding at a high-value 13.1% CAGR from 2024 to 2033.

The competitive analysis of the Electronics Recycling Market offers a comprehensive examination of key market players. It encompasses detailed company profiles, insights into revenue distribution, innovations within their product portfolios, regional market presence, strategic development plans, pricing strategies, identified target markets, and immediate future initiatives of industry leaders. This section serves as a valuable resource for readers to understand the driving forces behind competition and what strategies can set them apart in capturing new target markets.

Market projections and forecasts are underpinned by extensive primary research, further validated through precise secondary research specific to the Electronics Recycling Market. Our research analysts have dedicated substantial time and effort to curate essential industry insights from key industry participants, including Original Equipment Manufacturers (OEMs), top-tier suppliers, distributors, and relevant government entities.

Receive the FREE Sample Report of Electronics Recycling Market Research Insights @ https://stringentdatalytics.com/sample-request/electronics-recycling-market/12548/

Market Segmentations:

Global Electronics Recycling Market: By Company

• Eco-Tech Environmental Services Inc.

• American Retroworks Inc.

• AERC Recycling Solutions

• Dlubak Glass Company

• MBA Polymers Inc.

• Universal Recyclers Technologies

• CRT Recycling Ltd.

• Fortune Plastic & Metal Inc.

• Sims Metal Management Limited

• A2Z Group

Global Electronics Recycling Market: By Type

• Steel

• Tin

• Nickel

• Aluminum

• Copper

• Zinc

• Gold

• Silver

• Plastic Resins

Global Electronics Recycling Market: By Application

• Computers

• Mobile Phones

• Other

Regional Analysis of Global Electronics Recycling Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Electronics Recycling market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Electronics Recycling Market Research Report @ https://stringentdatalytics.com/purchase/electronics-recycling-market/12548/

Key Report Highlights:

Key Market Participants: The report delves into the major stakeholders in the market, encompassing market players, suppliers of raw materials and equipment, end-users, traders, distributors, and more.

Comprehensive Company Profiles: Detailed company profiles are provided, offering insights into various aspects including production capacity, pricing, revenue, costs, gross margin, sales volume, sales revenue, consumption patterns, growth rates, import-export dynamics, supply chains, future strategic plans, and technological advancements. This comprehensive analysis draws from a dataset spanning 12 years and includes forecasts.

Market Growth Drivers: The report extensively examines the factors contributing to market growth, with a specific focus on elucidating the diverse categories of end-users within the market.

Data Segmentation: The data and information are presented in a structured manner, allowing for easy access by market player, geographical region, product type, application, and more. Furthermore, the report can be tailored to accommodate specific research requirements.

SWOT Analysis: A SWOT analysis of the market is included, offering an insightful evaluation of its Strengths, Weaknesses, Opportunities, and Threats.

Expert Insights: Concluding the report, it features insights and opinions from industry experts, providing valuable perspectives on the market landscape.

Report includes Competitor's Landscape:

➊ Major trends and growth projections by region and country

➋ Key winning strategies followed by the competitors

➌ Who are the key competitors in this industry?

➍ What shall be the potential of this industry over the forecast tenure?

➎ What are the factors propelling the demand for the Electronics Recycling?

➏ What are the opportunities that shall aid in significant proliferation of the market growth?

➐ What are the regional and country wise regulations that shall either hamper or boost the demand for Electronics Recycling?

➑ How has the covid-19 impacted the growth of the market?

➒ Has the supply chain disruption caused changes in the entire value chain?

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected]), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes