#Top Copper Components Manufacturers in India

Text

Top 8 Copper Parts Manufacturers in India

This Comprehensive Blog Delves Into the Crucial Role of Copper Parts Within India’s Industrial Sector, Showcasing Their Importance Across Various Industries Thanks to Their Exceptional Properties Like Conductivity and Corrosion Resistance. Highlighting the Top Manufacturers in India Such as Meck Industries, Hindustan Copper Limited, Bhagyanagar India Limited, Madhav Copper, Rajnandini Metal, Sterlite Copper, Gujarat Copper Alloy Ltd., and Kavya Metal, It Emphasizes Their Dedication to Precision Manufacturing and Superior Quality. With Insights Into Sustainability and Customization Options, This Guide Provides Valuable Information for Businesses Seeking Top-Notch Copper Components. Dive Deeper Into the Article for A Thorough Analysis and To Learn, How These Leading Manufacturers Are Shaping India’s Copper Industry.

Read More: Top 8 Copper Parts Manufacturers in India

#Copper Parts Manufacturers in India#Copper Components Manufacturers in India#Top Copper Parts Manufacturers in India#Best Copper Parts Manufacturers in India#Top Copper Components Manufacturers in India#Best Copper Components Manufacturers in India

0 notes

Text

Wire Harness Manufacturers in India: Bhagyadeep Cables

In today's fast-evolving industries, efficient and reliable electrical connections are crucial for ensuring smooth operations across various applications. Wire harnesses play an integral role in this, providing a streamlined and organized way to bundle wires and cables that transmit electrical power and signals. Among the leading players in this domain is Bhagyadeep Cables, a prominent wire harness manufacturer in India known for its high-quality products and innovative solutions tailored to meet diverse industry needs.

The Importance of Wire Harnesses

Wire harnesses are essential components in many industries, including automotive, aerospace, electronics, telecommunications, healthcare, and more. They offer several advantages, such as:

Space Optimization: Wire harnesses bundle multiple wires into a single unit, reducing clutter and saving space.

Enhanced Safety: By securing and organizing wires, harnesses help prevent short circuits, electrical fires, and other hazards.

Improved Performance: Wire harnesses ensure stable and efficient electrical connections, minimizing signal interference and power loss.

Simplified Installation and Maintenance: Pre-assembled wire harnesses make installation and maintenance quicker and more straightforward, reducing downtime.

Bhagyadeep Cables: Leading the Way in Wire Harness Manufacturing

Bhagyadeep Cables has established itself as a leader in wire harness manufacturing by delivering superior quality products that adhere to global standards. The company provides a comprehensive range of wire harness solutions designed to cater to various applications and industries.

Key Features of Bhagyadeep Cables' Wire Harnesses

Customization to Meet Unique Requirements: Bhagyadeep Cables understands that each industry has unique demands. Therefore, the company offers fully customized wire harness solutions, engineered to specific dimensions, configurations, and material requirements to match client needs precisely.

Top-Quality Materials and Components: The company uses high-grade materials, such as copper, aluminum, and specialized insulating materials, to ensure optimal conductivity, durability, and resistance to environmental factors like heat, moisture, and chemicals.

Advanced Manufacturing Processes: Bhagyadeep Cables employs cutting-edge manufacturing technologies and automated processes to produce wire harnesses that meet the highest standards of precision, consistency, and reliability.

Stringent Quality Control: Quality is paramount at Bhagyadeep Cables. Every wire harness undergoes rigorous quality checks, including continuity testing, insulation resistance testing, and pull force testing, to ensure flawless performance and safety.

Compliance with International Standards: The wire harnesses manufactured by Bhagyadeep Cables comply with global standards, such as ISO, UL, and RoHS, guaranteeing quality, safety, and environmental responsibility.

Industries Served by Bhagyadeep Cables

Bhagyadeep Cables caters to a wide range of industries that rely on reliable and efficient wire harness solutions:

Automotive Industry: Wire harnesses are essential in vehicles for transmitting signals and power to various components, such as engines, lighting systems, infotainment systems, and safety features. Bhagyadeep Cables provides robust and durable automotive wire harnesses that withstand the rigors of on-road and off-road conditions.

Industrial Equipment: For machinery and industrial automation, wire harnesses are crucial for connecting various control units, sensors, and actuators. Bhagyadeep Cables designs harnesses that support seamless communication and power flow, enhancing equipment efficiency and reliability.

Telecommunications and Data Centers: In telecommunications and data centers, wire harnesses are used to manage data and power cables efficiently, ensuring optimal performance and minimizing interference. Bhagyadeep Cables offers custom wire harness solutions that meet the specific requirements of high-speed data transmission.

Consumer Electronics: For devices like household appliances, audio systems, and personal gadgets, wire harnesses provide the necessary connections for internal circuitry, enhancing product performance and longevity.

Medical Devices: Wire harnesses play a critical role in medical equipment, where reliability and safety are paramount. Bhagyadeep Cables manufactures specialized wire harnesses that meet the stringent quality and safety standards required in the healthcare sector.

Why Choose Bhagyadeep Cables for Wire Harness Solutions?

Expertise and Experience: With years of experience in the cable and wire harness industry, Bhagyadeep Cables brings a wealth of knowledge and expertise to every project, ensuring reliable and efficient solutions.

Innovation-Driven Approach: Bhagyadeep Cables invests in continuous research and development to stay at the forefront of technological advancements and offer innovative wire harness solutions that cater to emerging industry trends.

Customer-Centric Focus: The company prides itself on its customer-centric approach, working closely with clients to understand their specific needs and deliver solutions that exceed expectations.

Competitive Pricing and On-Time Delivery: By optimizing its manufacturing processes, Bhagyadeep Cables offers high-quality wire harnesses at competitive prices while ensuring timely delivery.

Conclusion

As one of the leading wire harness manufacturers in India, Bhagyadeep Cables is committed to providing top-notch, reliable, and customized solutions for various industries. With a focus on quality, innovation, and customer satisfaction, the company continues to set new benchmarks in the wire harness manufacturing sector. For businesses looking for a trusted partner in wire harness solutions, Bhagyadeep Cables stands as a reliable choice, ensuring excellence in every connection.

0 notes

Text

Top Brass Components Manufacturer in India

In today’s fast-evolving industrial landscape, innovation is key to staying ahead. One material that continues to play a crucial role in various sectors is brass. Known for its remarkable adaptability, durability, and resistance to corrosion, brass components are integral to modern industrial systems. From automotive and electrical to plumbing and machinery, brass is at the heart of many innovations. Among the leading manufacturers in this domain, Atlas Metal, based in Jamnagar, stands out as a pioneer in providing top-quality brass parts.

The Unique Properties of Brass

Brass, an alloy primarily composed of copper and zinc, is renowned for its versatility and performance. One of its most notable properties is its resistance to corrosion, making it ideal for use in environments exposed to moisture or chemicals. This characteristic is crucial for components used in plumbing, marine applications, and outdoor machinery, where exposure to elements is inevitable.

Additionally, brass possesses excellent thermal and electrical conductivity, making it a preferred material in the electrical and electronics industries. Its malleability allows for easy machining into precise components, while its inherent durability ensures longevity, even in demanding applications.

The ability of brass to withstand extreme temperatures without losing structural integrity further enhances its use in industries that rely on heavy-duty machinery and equipment. These unique properties have positioned brass as a key driver in numerous industrial innovations.

Brass Components Across Industries

Brass components find wide applications in several key industries:

Automotive Industry: Brass is commonly used in the production of engine parts, gears, and fuel connectors. Its resistance to heat and corrosion makes it ideal for ensuring the durability of these critical components.

Electrical and Electronics: Brass is widely used in earthing accessories, electrical connectors, terminals, and switchgear due to its superior conductivity and malleability, ensuring precision and reliability in complex electrical systems.

Plumbing and Sanitary Applications: Brass fittings, valves, and pipes are the backbone of modern plumbing systems. Its corrosion resistance ensures that brass parts last longer in both residential and industrial water systems.

Machinery and Heavy Equipment: Brass bushings, bearings, and fasteners are integral to many mechanical systems due to their durability and resistance to wear and tear.

Atlas Metal: A Leader in Brass Manufacturing

In Jamnagar, a city widely known as the brass manufacturing hub of India, Atlas Metal has carved a niche for itself as a leader in the production of high-quality brass components. With a focus on precision engineering, Atlas Metal offers a wide range of brass parts tailored to the specific needs of various industries.

The company’s commitment to innovation and quality is reflected in its use of advanced technology and stringent quality control processes. Atlas Metal produces everything from brass nuts, bolts, and fasteners to specialized fittings, terminals, and connectors that meet the demands of today’s high-performance industries.

What sets Atlas Metal apart is its emphasis on customization. Understanding that different industries require unique specifications, Atlas Metal works closely with its clients to deliver components that perfectly match their requirements, ensuring optimal performance and efficiency.

Why Choose Atlas Metal?

Quality Assurance: Atlas Metal places a high priority on quality control, ensuring that every component meets international standards.

Expertise and Experience: With years of experience in the brass manufacturing industry, Atlas Metal brings expertise and innovation to every project.

Advanced Manufacturing Techniques: The company uses cutting-edge technology to deliver precision-engineered parts.

Global Reach: Atlas Metal exports its products to clients worldwide, reflecting its reliability and reputation in the global market.

Conclusion

Brass components are indispensable to many industries, driving innovation with their versatility and durability. Atlas Metal, a leading brass parts manufacturer in Jamnagar, has been at the forefront of providing high-quality, precision-engineered components for global markets. With a commitment to quality, innovation, and customer satisfaction, Atlas Metal continues to be a trusted partner for industries seeking reliable brass solutions.

#brass parts manufacturer in Jamnagar#brass fitting manufacturers in india#pipe fittings manufacturers in india#brass conduit fittings in india#cable tie manufacturer in india#cable gland manufacturers in india#lugs manufacturers in india#cable lugs manufacturers in india#copper lugs manufacturers in india

1 note

·

View note

Text

A manufacturing line that includes a variety of equipment for cleaning, filling, capping, and labeling syrup bottles is known as a pharmaceutical syrup filling line. It’s interesting that it also has an automated syrup production facility. We are a well-known manufacturer of syrup filling lines with uses in the culinary, pharmaceutical, nutraceutical, and herbal industries. Our syrup suspension filling line, which has an elegant appearance, is furnished with state-of-the-art components for production, cleaning, filling, capping, and labeling tasks. The entire suspension fill line functions as a single, integrated system, streamlining the production process.

As one of the top exporters of oral suspension filling lines from India, Adinath has developed both fully automatic and semi-automated oral liquid filling lines. The manufacturing capacity of our filling lines ranges from 500 to 50,000 liters per day.

Let’s have a look on some of the key equipments of our syrup filling line:

Syrup Manufacturing Plant

The pharmaceutical business uses oral liquid manufacturing plants as the best instruments for producing oral liquids. It is specifically made to address two important issues that have a direct impact on the liquids’ quality. Minimal liquid handling by hand and efficient cleanliness throughout production.

youtube

Automatic Bottle Washing Machine

Our bottle washing machine, sometimes called a linear bottle washer, is widely utilized in the pharmaceutical business. It has an all-automatic setup that guarantees hassle-free vial loading on the stainless steel wire mesh conveyor. You can also push them manually from the feed table if you’re comfortable doing things that way. Use this automated machine to save a lot of labor, and you can even opt to have an automatic emptying mechanism when needed. The latter is not required.

youtube

Automatic Bottle Filling Machine

The pharmaceutical business frequently uses bottle filling machines, also referred to as bottle fillers, to pack various liquids into various bottle types. This adaptable device can be used to fill bottles, jars, and containers made of glass, plastic, aluminum, steel, copper, and PET, among other materials. It can also fill aqueous solutions, foamy liquid, and semi-viscous solutions. The machine’s essential components include feeding needles, a piston pump, a quality stainless steel slat conveyor belt, and a robust foundation structure.

youtube

Automatic Bottle Capping Machine

We provide bottle stoppers that are used to cap bottles in a variety of industries, including the manufacturing of chemicals, pharmaceuticals, food and beverage products, pesticides, and alcoholic beverages. Our bottle capping machine is constructed with an M.S. frame and stainless steel enclosures or cladding. An orientation-style cap feeder is included with our ROPP bottle cap sealing machine to ensure smooth cap feeding.

youtube

Bottle Visual Inspection Machine

Adinath International produces and exports a cGMP certified bottle inspection machine with a three track conveyor and hooded lighting configuration. Aside from an inspection table with an SS construction, there is a background that alternates between black and white for a perfect visual inspection. A slat chain made of stainless steel is also a part of it. This machine will last for many years because of its sturdy adjustable bolt support and stainless steel square pipes.

youtube

Automatic Bottle Sticker Labeling Machine

This machine is widely used for labeling PET, aluminum, glass, plastic, and copper bottles, cans, jars, and other containers. With the most advanced microprocessor control label dispensing mechanism available, this linear design machine can detect labels and items with maximum efficiency. Additionally, it features a specially created mechanical and electronic technology that is useful for quickly applying transparent labels on bottles. For the labeling of different bottle types, there are no sections that need to be changed.

youtube

#syrup suspension filling line#oral suspension filling lines#semi-automated oral liquid filling lines#oral liquid manufacturing plants#Automatic Bottle Washing Machine#Automatic Bottle Filling Machine#Automatic Bottle Capping Machine#Bottle Visual Inspection Machine#Automatic Bottle Sticker Labeling Machine#Youtube

0 notes

Text

Best Fiber Laser Cutting Machine Manufacturer in Faridabad

Faridabad, a major industrial hub in India, is home to some of the leading fiber laser-cutting machine manufacturers. The city’s strategic location and industrial ecosystem make it an ideal location for companies specializing in advanced cutting and welding technologies. Among these companies, Weldarc India stands out as the best fiber laser cutting machine manufacturer in Faridabad, known for its innovative solutions, superior quality, and exceptional customer service.

The Rise of Fiber Laser Cutting Technology

Fiber laser cutting technology has revolutionized the metal fabrication industry, offering unparalleled precision, speed, and efficiency. Unlike traditional cutting methods, fiber lasers use high-intensity laser beams to cut metals with high precision, minimizing waste and ensuring smooth edges. This technology is especially beneficial for industries that require complex designs and high-quality finishes, such as automotive, aerospace, and electronics.

Why Weldarc India?

1. Advanced Technology and Innovation

Weldarc India has always been at the forefront of innovation in fiber laser cutting technology. The company invests heavily in research and development to ensure that its machines incorporate the latest advances. This commitment to innovation ensures that Weldarc India’s fiber laser cutting machines are equipped with advanced features such as automatic control, real-time monitoring, and energy-saving systems.

2. Superior Quality and Durability

Quality is the hallmark of Weldarc India’s fiber laser cutting machines. The company uses high-quality materials and components to manufacture the machines, ensuring durability and long-lasting performance. Each machine undergoes rigorous quality testing and inspection to meet international standards, providing customers with reliable and robust solutions.

3. Customization and Flexibility

Weldarc India understands that different industries have their requirements. Therefore, the company offers customized solutions to suit specific needs. Whether it is a small-scale manufacturing plant or a large manufacturing unit, Weldarc India offers flexible options to meet different operational requirements. Their machines are designed to handle a wide range of materials and thicknesses, making them versatile tools for a variety of applications.

4. Exceptional Customer Support

Customer satisfaction is a top priority at Weldarc India. The company offers comprehensive support services, including installation, training, maintenance, and troubleshooting. A team of experienced technicians and engineers is always available to support customers, ensuring flawless operations and minimal downtime. This dedication to customer service has earned Weldarc India a reputation for reliability and trust.

Advantages of fiber laser cutting machines

1. Precision and accuracy

One of the main advantages of fiber laser cutting machines is their precision. The high-intensity laser beam allows for extremely precise cutting, even on complex designs. This level of precision is important for industries that require tight tolerances and high-quality finishes.

2. Speed and efficiency

Compared to conventional cutting techniques, fiber laser cutting machines are much faster. The speed of the laser beam, combined with automated control, ensures rapid material processing. This increased efficiency translates into increased productivity and cost savings for businesses.

3. Versatility

Fiber laser cutters can cut a wide range of materials, including stainless steel, aluminum, copper, and brass. This versatility makes them ideal for a wide range of applications, from industrial manufacturing to artistic projects. Additionally, the ability to handle varying thicknesses allows for greater flexibility in production.

4. Low Maintenance

Fiber laser cutters are known for their low maintenance requirements. Unlike other cutting methods that involve wear and tear on mechanical components, fiber lasers have minimal moving parts, reducing the need for frequent repairs and replacements. This results in lower maintenance costs and longer machine life.

Read more: Tig welding machine manufacturers

Weldarc India’s Commitment to Excellence

As a leading fiber laser cutting machine manufacturer in Faridabad, Weldarc India is committed to providing top-notch products and services. The company’s focus on quality, innovation, and customer satisfaction sets it apart from other manufacturers. By continuously improving its technology and processes, Weldarc India ensures that its customers receive the best possible solutions for their cutting and welding needs.

Conclusion

When it comes to choosing the best fiber laser cutting machine manufacturer in Faridabad, Weldarc India emerges as the undisputed leader. With cutting-edge technology, superior quality, customization options, and exceptional customer support, Weldarc India delivers unmatched value to its customers. As the industry continues to evolve, Weldarc India remains committed to driving innovation and excellence in fiber laser cutting technology.

For companies looking for reliable, efficient, and highly accurate cutting solutions, Weldarc India is the ideal choice. Their commitment to excellence and customer-centric approach makes them the preferred partner for industries in India and beyond. Experience the difference in fiber laser cutting from Weldarc India can help your business and explore the future of metal fabrication today.

#welding products manufacturer in India#Fiber Laser Cutting Machine manufacturers#Welding and cutting machine manufacturers#Welding Machine manufacturer in India#welding products#welding technology#welding industry#welding solutions#fiber laser cutting#welding innovation#welding equipment#industrial welding machines#custom welding machines#advanced welding technology#welding machine suppliers#welding automation#welding products India#welding support services#welding machine quality#welding manufacturer selection

0 notes

Text

Reliable Brass Castings Manufacturers in India

Saxeo is a leading name among Brass Castings Manufacturers in India. Our expertise and commitment to quality ensure that each casting is crafted with precision and durability. We understand the importance of reliable components in various industrial applications, and our brass castings are designed to meet these demands. With advanced manufacturing processes and a team of skilled professionals, we deliver castings that stand the test of time.

Precision Copper Castings Suppliers

As prominent Copper Castings Suppliers, Saxeo provides high-quality castings tailored to your specific needs. Our copper castings are known for their superior performance and longevity, making them ideal for a wide range of applications. We use the finest materials and techniques to produce castings that meet the highest industry standards. Whether you need intricate designs or large-scale productions, Saxeo has the expertise to deliver.

Quality Assurance and Custom Solutions

At Saxeo, quality assurance is a top priority. We follow stringent quality control measures to ensure that each casting meets the required specifications and standards. Our team works closely with clients to understand their unique requirements, providing custom solutions that cater to their specific needs. From initial consultation to final delivery, Saxeo is dedicated to offering exceptional service and products.

Why Choose Saxeo for Your Casting Needs?

Choosing Saxeo for your Brass and Copper castings needs means opting for quality, reliability, and excellence. Our commitment to customer satisfaction, combined with our extensive experience, makes us the preferred partner for many industries. We are proud to offer castings that not only meet but exceed expectations, ensuring optimal performance and durability.

Contact Us

For more information about our brass and copper castings, visit Saxeo. Let us help you with your next project by providing top-quality castings that deliver results.

0 notes

Text

Are You Looking For The Best Commercial RO Plant Manufacturer In India?

Intentions were in vain or worthless as they weren't even trying, yet Netsol Water helps its customers in the same manner. The greatest production facilities provide you with the best commercial RO plant manufacturer along with their advanced operational machinery systems & services or amenities at a very affordable costs, so it is always available at ease to you & will always be in demand.

But first, let's have a quick look at this RO Plant & its sophisticated or enchanting RO Technical Process.

Reverse Osmosis & RO Plant

A RO water treatment or RO filtration plant is essentially a facility that efficiently removes organic matter, & harmful heavy (toxic) chemical compounds, including a wide range of contaminants or impurities from raw feed water. The final result is clean, safe, fresh water that has been filtered to a desired degree & is appropriate for almost all applications in industry as well as a small number of commercial ones.

Netsol Water, the industry leader in manufacturing industrial plus commercial RO plants, offers you the best tools & an ISO-approved (accredited) RO plant system or facility.

We can suitably alter the water plant systems & facilities we manufacture to satisfy the unique requirements of our clients. We offer fully & partially automated solutions to meet the demands of our clients.

The water plant system will last longer since our RO plant is constructed of chrome steel along with other premium strong components including metals (i.e., Lifespan, & Durability).

The firm now manufactures RO plant systems equipment suitable for employment in various industrial settings or enterprises. These systems can produce or create water at 100 to 500 Litres per Hour (LPH).

Top commercial RO Plant Manufacturers can be listed as:

Following is a directory list of the finest commercial RO plant manufacturers in our nation, we will be guiding you with them as:

NETSOL WATER: One of the top producers of equipments, apparatuses & water & Wastewater Treatment Plant systems or facilities is Netsol Water. With its own production facility, it began its journey & started its working operations in the year 2012.

It provides water treatment, wastewater treatment, & organic green waste management for several significant corporations, such as Vedanta, NTPC, as well as Sleep Well, including several other start-ups, as well as hospitals, universities, schools, & various educational institutions.

2. COMMERCIAL RO PLANT: Due to the firm or company's lacking in providing with much more innovative & pleasing design, the Commercial RO Plant’s RO water purifier has fallen from in ranking of being the finest water purifying plant facilities integrated with gadget or devices & systems that can recover & recycle water upto 75-80 % percent are accessible.

3. COMPACT STP PLANT: The Compact STP Plant is one of a kind RO system firm or company subsidized under Netsol Water. Commercial RO System offered by Compact STP is of the smart grade with a simple water purifying plant system that costs less. According to USEPA regulations & standards, its silver nano-technology along with copper additives effectively destroys viruses & bacteria.

4. URBAN STP Plant: According to the facts we gained while researching numerous companies & organizations, the worldwide brand known as Urban STP is one of the finest & greatest water-purifying plant facilities.

Urban STP's system or facility is combined or compiled with a sophisticated (smart-sensing) alert system & purifying technologies (Reverse Osmosis + UltraViolet + MicroFiltration) & has an outstanding water recovery rate.

5. SEWAGE TREATMENT PLANTS: Because of its multi-stage filtration mechanism, it provides 100% clean, safe, & tasteful drinking water. It combines the most effective purifying processes known, including Reverse Osmosis +UV+MTDS.

#netsolwater#commercial ro plant manufacturer#commercial ro plant manufacturer in india#netsol water#water is life

0 notes

Text

Aluminium Alloy 2024 Round Bars Manufacturers In India

Siddhgiri Tubes is a renowned Manufacturer, Supplier, Stockist, and Exporter of Aluminium Alloy 2024 Round Bars. We specialize in crafting and delivering a diverse range of Aluminium Alloy 2024 Round Bars to our valued clientele. Our round bars are meticulously manufactured using top-grade alloys and other alloying elements, ensuring superior quality and performance. These round bars exhibit a range of appearances, from a dull grey to a rough surface texture.

Understanding Aluminum Alloy 2024

Aluminium Alloy 2024 is an aluminium-copper alloy, primarily composed of aluminium (90.7-94.7%), copper (3.8-4.9%), manganese (0.3-0.9%), and magnesium (1.2-1.8%). This specific composition lends the alloy its remarkable strength and machinability. It is often used in applications where high strength-to-weight ratios are crucial.

Key Properties of 2024 Aluminium Alloy Round Bars

High Strength: One of the standout features of Aluminium Alloy 2024 is its high strength. This makes it ideal for structural components in the aerospace and automotive industries.

Excellent Fatigue Resistance: The alloy's ability to withstand repeated stress cycles without significant degradation makes it perfect for use in aircraft structures and other high-stress environments.

Good Machinability: Aluminium 2024 round bars are easy to machine, allowing for the creation of complex shapes and components with precision.

Corrosion Resistance: While not as corrosion-resistant as some other aluminium alloys, 2024 offers adequate protection in most environments, especially when treated with anodization or protective coatings.

Benefits of Choosing Aluminium Alloy 2024 Round Bars

Siddhgiritubes are a trusted provider of Aluminium Alloy 2024 round bars, offering high-quality products that meet industry standards. Here are some benefits of choosing Siddhgiritubes:

Quality Assurance: Siddhgiritubes ensures that their products undergo rigorous quality checks to meet the required specifications and standards.

Wide Range of Sizes: They offer a variety of sizes to cater to different industrial needs, ensuring you find the right fit for your project.

Custom Solutions: Siddhgiritubes provides customized solutions to meet specific project requirements, ensuring optimal performance and efficiency.

Specification Chart of Aluminium Alloy 2024 Round Bars

Hardness 8 HW

Grade and Specification 6000 Series, ASTM B 211 ASME SB 211 / ASTM B 619 ASME SB 619

Temper T3 - T8

Size Ranges 15- 150" NB IN

Al (Min) 98%

ASME B36.10M Schedule Chart SCH5, SCH10, SCH40, STD, SCH80, SCH120, SCH160

Alloy Or Not is Alloy

Surface Treatment Anodized, Powder Coated, Mill Finished

Most popular types Seamless / ERW / Welded / Fabricated

Forms / Shapes Square, Round

Pipe End Forming Treaded Both Ends, Plain One End, Treaded One End, Bevel both ends, Bevel large end, Bevel one end, Beveled end, Plain Both Ends, Bevel small end, Beveled One end

Technique Extruded or seamless

Conclusion

These round bars find extensive applications across numerous industries. Our Aluminium Alloy 2024 Round Bars are available in various types, including AMS 4121 round bars, hexagonal bars, hot-rolled bars, bars and rods, cold-rolled round bars, cold-drawn bars, round rods, hot finish bars, half-round bars, cold finish round bars, and pump shaft quality bars.

0 notes

Text

Types of Round Bars: Materials and Their Uses

Rajkrupa Metal Industries is one of the Premium Quality Aluminium Bronze Round Bar Manufacturer In India. We are now the industry leader in Aluminium Bronze Round Bar. We have consciously positioned itself as a top-tier manufacturer and retailer in the worldwide Aluminium Bronze Round Bar market due to its excellent corporate and technical people skills.

Our company, which manufactures with ISO 9001:2015 certification. We are one of the top Aluminium Bronze Round Bar Manufacturer who complies with the International Quality Standard (IQS).

1. Steel Round Bars

Steel round bars are the most commonly used type due to their strength, durability, and versatility. Steel bars are available in several grades, each with distinct properties suited to different applications.

Carbon Steel Round Bars: These are used in applications requiring high strength and hardness. Commonly used in the construction industry for building frameworks, shafts, and in the manufacturing of machinery parts.

Alloy Steel Round Bars: These bars include additional alloying elements like chromium, manganese, and nickel to enhance specific properties. They are used in automotive parts, power generation, and heavy equipment.

Stainless Steel Round Bars: Known for their excellent corrosion resistance and aesthetic appeal, these bars are used in food processing equipment, medical instruments, and architectural structures. We are also the leading Round bars manufacturer in India.

2. Aluminum Round Bars

Aluminium round bars are lightweight, corrosion-resistant, and easy to machine, making them ideal for various applications where weight and corrosion are critical factors.We are also a Premium Quality Aluminium Bronze Round Bar Manufacturer In India.

6061 Aluminum Round Bars: This grade is known for its excellent mechanical properties and is commonly used in aerospace components, marine fittings, and structural applications.

7075 Aluminum Round Bars: Featuring high strength and good fatigue resistance, these bars are used in high-stress applications such as aircraft structures and military equipment.

3. Brass Round Bars

Brass round bars are an alloy of copper and zinc, offering good corrosion resistance, electrical conductivity, and an attractive appearance. They are widely used in applications requiring both functionality and aesthetics.

CZ121 Brass Round Bars: Known for their excellent machinability, these bars are used in manufacturing precision components, gears, and fittings.

CZ114 Brass Round Bars: Featuring good strength and corrosion resistance, these are used in the production of valves, pump components, and marine hardware.

4. Copper Round Bars

Copper round bars offer excellent electrical and thermal conductivity, making them essential in electrical and electronic applications.

C101 Copper Round Bars: These are used in electrical conductors, connectors, and switchgear due to their high electrical conductivity.

C110 Copper Round Bars: Known for their excellent ductility and corrosion resistance, these bars are used in plumbing, heating systems, and in the manufacturing of electrical components.

5. Titanium Round Bars

Titanium round bars are valued for their high strength-to-weight ratio, corrosion resistance, and biocompatibility. These properties make them suitable for high-performance applications.

Grade 2 Titanium Round Bars: Used in chemical processing, desalination plants, and in medical devices due to their corrosion resistance and biocompatibility.

Grade 5 (Ti-6Al-4V) Titanium Round Bars: Known for their high strength and lightweight, these bars are used in aerospace, military, and automotive applications.

Aluminium Bronze Round Bar Suppliers are well-known for their excellent strength, corrosion resistance, thermal and electrical conductivity, and other properties. We are now the industry leader in Aluminium Bronze Round Bar. We have consciously positioned itself as a top-tier manufacturer and retailer in the worldwide Aluminium Bronze Round Bar market due to its excellent corporate and technical people skills.

#RoundBarsManufacturersinIndia#RoundBarsManufacturers#RoundBars#AluminiumBronzeRoundBarManufacturerInIndia#AluminiumBronzeRoundBarManufacturer#AluminiumBronzeRoundBar

0 notes

Text

Prominent Pipes and Tubes Manufacturers in India

Nova Steel Corporation is one of the prominent Pipes and Tubes Manufacturers in India. Pipes and tubes are typically made from a range of materials, including metals such as steel, stainless steel, copper, and aluminum, as well as nonmetals such as PVC, CPVC, polyethylene, and fiberglass. Each material has distinct features such as strength, corrosion resistance, flexibility, and cost-effectiveness, making it ideal for a variety of applications in industries such as construction, plumbing, oil and gas, and automotive.

We are a significant pipes and tubes manufacturers in India. We provide all types of pipes and tubes in various grades and materials. Pipes and Tubes are created utilizing high-quality raw materials and cutting-edge technology to meet the needs of our valued customers, and they are available in a variety of diameters, wall thicknesses, and sizes at reasonable prices.

Pipe is mostly utilized in pipeline and piping systems for the purpose of transporting gases or fluids as a vessel. The tube serves as a structural component. We are also a leading Large Diameter Pipe Manufacturers in India. Pipes & Tubes are used in various parts of India. We have supplied Pipes & Tubes in various cities and in different industries in India. We are therefore known as one of the top-rated Pipes & Tubes Suppliers in India.

For More Details:

Website: novasteelcorporation.com

Product: Pipes & Tubes Suppliers

Oher Product: Round Bar Manufacturer in India

0 notes

Text

Double Sided PCB Manufacturers in India at Shree Ram Electronics

When it comes to double sided PCB manufacturers in India, we stand out as a leading name in the industry. With a strong commitment to the Make in India initiative, we led by a visionary woman entrepreneur, has grown into a prominent organization known for its high-quality products and innovative solutions.

Double sided PCBs, or printed circuit boards, are crucial components in a wide range of electronic devices. Unlike single-sided PCBs, double sided PCBs have conductive copper layers on both sides of the board. This allows for more complex and dense circuit designs, making we ideal for advanced electronics that require higher functionality within a compact space. As a result, the demand for double sided PCBs has been steadily increasing across various sectors, including telecommunications, automotive, medical devices, and consumer electronics.

We excel in meeting this demand by producing top-notch double sided PCBs that adhere to stringent quality standards. The company leverages advanced manufacturing techniques and state-of-the-art equipment to ensure that every PCB we produce is reliable and efficient. Our commitment to quality is evident in every step of the manufacturing process, from the selection of raw materials to the final inspection of finished products.

One of the key advantages of choosing us among the double sided PCB manufacturers in India is our dedication to innovation and customer satisfaction. We understand that each client has unique requirements and are committed to providing customized solutions that meet specific needs. Whether it's a small batch for prototyping or a large order for mass production, Shree Ram Electronics has the capability and expertise to deliver.

Shree Ram Electronics is deeply rooted in the Make in India ideology, which emphasizes self-reliance and boosting domestic manufacturing capabilities. This approach not only supports the local economy but also ensures that customers receive high-quality products that are competitively priced and delivered on time. The company’s leadership by a dynamic woman entrepreneur further showcases our commitment to diversity and empowerment in the workplace.

In conclusion, if you are looking for reliable and innovative double sided PCB manufacturers in India, Shree Ram Electronics is the ideal choice. Our combination of high-quality manufacturing, commitment to customer satisfaction, and support for the Make in India initiative make we a standout player in the industry. With us, you can be assured of getting the best PCBs that meet your exact specifications and enhance the performance of your electronic devices.

0 notes

Text

Monel 400 Flanges: Top Manufacturer & Exporters | Metalforgeindia

In the economic global, where sturdiness and resistance to harsh environments are vital, Monel 400 flanges stand out as a advanced desire. A leading producer and exporter, is famend for turning in brilliant Monel 400 flanges that meet stringent industry standards. This weblog will delve into the characteristics, applications, and blessings of Monel 400 flanges, and why it is the cross-to dealer for many industries.

Understanding Monel 400

Composition and Properties

Monel 400 is a nickel-copper alloy, comprising about 67% nickel and 23% copper, with small amounts of iron, manganese, carbon, and silicon. This particular composition imparts numerous effective homes:

- Corrosion Resistance: Monel 400 offers extraordinary resistance to a wide variety of corrosive environments, which includes seawater, hydrofluoric acid, sulfuric acid, and alkalis.

- High Strength: The alloy continues its energy and sturdiness over a huge temperature range, from sub-0 temperatures to 1000°F (538°C).

- Thermal Conductivity: Monel 400 well-knownshows right thermal conductivity, making it appropriate for heat switch applications.

- Ductility and Toughness: The alloy is thought for its exquisite mechanical residences, consisting of high ductility and sturdiness.

Key Features

- Nickel Content: Provides exceptional corrosion resistance and high-temperature overall performance.

- Copper Content: Enhances resistance to corrosion by using acids and different aggressive chemicals.

- Versatility: Suitable for numerous packages due to its first-rate mechanical residences and resistance to environmental elements.

Applications of Monel 400 Flanges

Monel 400 flanges are used throughout numerous industries due to their robust homes. Some of the key programs encompass:

Marine Industry

- Seawater Equipment: Monel 400 flanges are perfect for marine applications, which includes shipbuilding and offshore oil platforms, due to their resistance to seawater corrosion.

- Desalination Plants: The alloy’s durability in saline environments makes it best for use in desalination flora.

Chemical Processing

- Chemical Plants: Monel 400 flanges are utilized in chemical processing system, inclusive of reactors, warmth exchangers, and piping structures, wherein resistance to corrosive chemical compounds is critical.

- Petroleum Refining: The alloy’s resistance to bitter fuel environments and natural acids makes it appropriate to be used in petroleum refining procedures.

Power Generation

- Nuclear Plants: Monel 400 is utilized in nuclear strength flowers for additives like steam generators and reactor manage rods because of its resistance to high-temperature corrosion.

- Thermal Power Plants: The alloy’s potential to withstand excessive temperatures and corrosive environments makes it ideal for use in boilers and warmth exchangers.

Aerospace

- Aircraft Components: Monel 400 flanges are used inside the aerospace enterprise for additives that require high strength and corrosion resistance at accelerated temperatures.

- Engine Parts: The alloy’s longevity and thermal conductivity make it suitable for engine parts uncovered to extreme situations.

Leading Manufacturer and Exporter

MetalForge India has established itself as a leading producer and exporter of Monel 400 flanges. Here’s why it is the desired desire for many industries:

Commitment to Quality

Quality is the cornerstone of operations. The corporation adheres to the very best standards of nice control to ensure that its Monel 400 flanges meet or exceed industry specs. Every product undergoes rigorous checking out and inspection to assure its performance in stressful programs.

Advanced Manufacturing Facilities

Modern-day manufacturing facilities are equipped with modern technology and equipment. This allows the employer to provide Monel 400 flanges with precision and consistency. The centers are staffed with the aid of experienced professionals committed to delivering pinnacle-satisfactory products.

Custom Solutions

Is familiar with that exclusive industries have unique necessities. The corporation offers custom answers to satisfy the unique wishes of its clients. Whether you need flanges in a particular length or with precise mechanical houses, can tailor its merchandise to suit your utility.

Global Reach

The leading exporter has a strong global presence. Its Monel 400 flanges are relied on through customers around the arena for his or her best and reliability. The corporation guarantees timely transport and tremendous customer support, regardless of your place.

Sustainable Practices

Is dedicated to sustainable manufacturing practices. The company strives to reduce its environmental effect by means of imposing electricity-green techniques and decreasing waste. This commitment to sustainability extends to its products, which are designed for durability and durability, decreasing the want for frequent replacements.

Why Choose Monel 400 Flanges?

Versatility

Monel 400 flanges are flexible and can be utilized in an extensive range of applications throughout different industries. Their specific houses make them suitable for environments that call for high performance and reliability.

Long-term Performance

The sturdiness and resistance to harsh conditions ensure that Monel 400 flanges offer long-term performance. This makes them a cost-powerful answer for industries where aspect failure can cause great downtime and price.

Safety and Reliability

In important programs including marine, chemical processing, and energy era, protection and reliability are paramount. Monel 400 flanges provide the necessary energy and resistance to ensure secure and reliable operation.

Conclusion

Monel 400 flanges are an essential factor in lots of high-performance applications. Their exquisite houses, together with high strength, corrosion resistance, and first-rate mechanical houses, make them the material of desire for industries ranging from marine to aerospace. MetalForge India, a main producer and exporter of Monel 400 flanges, is dedicated to supplying incredible merchandise that meet the annoying requirements of current industries. With a focal point on quality, advanced production facilities, custom answers, and sustainable practices, MetalForge India is your trusted accomplice for Monel 400 flanges.

0 notes

Text

Crafting Precision: Exploring the World of Stainless Steel Round Bars

Introduction to Stainless Steel Round Bars

Among the numerous kinds of industrial materials currently in the market, stainless steel round bars are particularly outstanding due to their versatility and capacity for strength and corrosion. Hans Metal India these characteristics make them important in a wide range of industries, including construction, automotive, medical, and maritime applications. An investigation of the characterstics of crafting process shall involve stainless steel bar. carfting is one the best method in which its work very smoothly. concreting process is commonly seen in construction works. Stainless Steel Round Bar Manufacturer in India and Stainless Steel Plate Manufacturer in India.This article mainly go to the detectable way and help to work in easy way and quick.

Uses of Stainless Steel Round Bars

Construction and Architecture

Because of its strength, beauty, and ability to withstand weathering, stainless steel round bars are widely utilised in the construction sector. By using Architecture methods it can be easy to analyze the product. Stainless Steel Sheet Manufacturer in India and Round Bar Suppliers in UAE .Their contribution is vital, in constructing buildings, bridges and various infrastructure projects.

Automotive Industry

It is a automated machinery instruments which work in machinery way. SS Round Bar Manufacturer in India and Copper Sheet Manufacturers in India.In the sector various parts, like axles, bolts and engine components are crafted from stainless steel bars. These materials excel in applications that demand reliability and top notch performance due, to their durability and resistance to wear.

Medical Devices

In the field of medicine surgical instruments orthopedic implants and various medical devices are crafted from stainless steel bars. These materials are well suited for critical healthcare uses because of their ability to be sterilized without losing their quality and their compatibility, with the body.

The Crafting Process:

1. Choice of Raw Materials:

In the stage of the process one should opt for quality stainless steel. The specific application will dictate the choice of steel alloy with popular options being 304, 316 and 410 grades. common grades include 304, 316, and 410. Specific qualities like stronger corrosion resistance, better machinability, or higher strength are offered by each grade.

2. Pouring and Pouring Melt:

In an electric arc furnace, the chosen raw materials are melted at extremely high temperatures. This method ensures that the alloy composition remains consistent. The process involves melting steel and shaping it into finished forms, like slabs, billets or blooms.

3. Hot Rolling: The cast steel is put through rolling mills and heated above its recrystallization temperature during the hot rolling process. In this process, the steel is shaped into a rough cylindrical shape and its thickness is decreased.

4.Heat Treatment Process; The rolled bars undergo annealing to enhance their flexibility and reduce their toughness. In this procedure the steel is heated to a temperature. Then slowly cooled down. Moreover annealing helps in relieving stresses in the material.

5. Precision Rolling: To obtain the required diameter and surface finish, the bars are subjected to precision rolling or drawing after annealing. By taking this process, the round bars are guaranteed to meet strict criteria for surface quality and dimensional tolerances.

6. Cutting and Finishing: Depending on the needs of the ultimate use, the lengthy steel rods are cut into predetermined lengths and go through a variety of finishing procedures, including grinding, polishing, or coating. The circular bars get their distinctive glossy, smooth look from this process.

Conclusion

Round stainless steel bars are proof of the strength of expert engineering and fine craftsmanship. From raw material to essential industrial component, they go through a number of carefully regulated procedures, each of which adds to their remarkable qualities. The use of stainless steel round bars in aerospace, automotive, medical, and construction applications is still essential to the advancement of contemporary industry. These extraordinary materials will become even more important and versatile as production methods and technology advance.

0 notes

Text

Double Core Cable Market Analysis, Dynamics, Players, Type, Applications, Trends, Regional Segmented, Growth Opportunities, Supply and Demand, Outlook & Forecast till 2033

The competitive analysis of the Double Core Cable Market offers a comprehensive examination of key market players. It encompasses detailed company profiles, insights into revenue distribution, innovations within their product portfolios, regional market presence, strategic development plans, pricing strategies, identified target markets, and immediate future initiatives of industry leaders. This section serves as a valuable resource for readers to understand the driving forces behind competition and what strategies can set them apart in capturing new target markets.

Market projections and forecasts are underpinned by extensive primary research, further validated through precise secondary research specific to the Double Core Cable Market. Our research analysts have dedicated substantial time and effort to curate essential industry insights from key industry participants, including Original Equipment Manufacturers (OEMs), top-tier suppliers, distributors, and relevant government entities.

Here are some reasons why purchasing a market research report can be valuable:

Informed Decision-Making: Market research reports offer detailed and comprehensive insights into specific markets, industries, or sectors. This information allows businesses to make well-informed decisions, minimizing risks and maximizing opportunities.

Competitive Analysis: Market research reports often include detailed analysis of key competitors, their market share, strategies, and performance. This information helps businesses understand their competitive landscape and devise effective strategies to gain a competitive advantage.

Market Trends and Forecasting: Reports provide information on current market trends, emerging technologies, and future forecasts. This foresight helps businesses anticipate changes in the market and adapt their strategies accordingly.

Customer Behavior and Preferences: Understanding customer behavior is crucial for developing products or services that meet their needs. Market research reports often include data on consumer preferences, buying patterns, and demographics, aiding in targeted marketing efforts.

Regulatory Compliance: Reports may include information on regulatory frameworks, compliance requirements, and industry standards. This is particularly important for businesses operating in regulated industries to ensure legal compliance.

Investment Decisions: Investors can use market research reports to assess the potential of different industries or companies before making investment decisions. These reports provide a comprehensive overview of market conditions and growth prospects.

Receive the FREE Sample Report of Double Core Cable Market Research Insights @ https://stringentdatalytics.com/sample-request/double-core-cable-market/7699/

Market Segmentations:

Global Double Core Cable Market: By Company

• Fast Cables Limited

• Jenuincable

• RS Components

• Eurocable

• Finolex

• Olex

• NARVA

• Dongguan Slocable Photovoltaic Technology Co.,Ltd.

• Dynamic Cables

• LAPP

• Tycab Australia

• RR Global

Global Double Core Cable Market: By Type

• Pure Copper Core Cable

• Tinned Copper Core Cable

• Others

Global Double Core Cable Market: By Application

• Consumer Electronics

• Marine Industry

• Automotive Industry

• Others

Regional Analysis of Global Double Core Cable Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Double Core Cable market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Double Core Cable Market Research Report @ https://stringentdatalytics.com/purchase/double-core-cable-market/7699/

Demand for Market Research:

Business Decision-Making: Businesses across industries rely on market research to make informed decisions. The demand is driven by the need for insights into market trends, customer behavior, competitive landscapes, and potential opportunities or threats.

Globalization: As businesses expand globally, there is an increasing demand for market research to understand diverse markets, cultural nuances, and regulatory environments.

Technological Advancements: The rapid pace of technological advancements creates a demand for market research to assess the impact of new technologies, understand consumer preferences for tech products, and identify opportunities for innovation.

Changing Consumer Preferences: Businesses need to stay updated on evolving consumer preferences and buying behaviors. Market research helps companies tailor their products and services to meet changing customer demands.

Investment and Finance: Investors and financial institutions rely on market research to assess the viability of potential investments, understand market trends, and evaluate the performance of companies.

Regulatory Compliance: Industries with strict regulatory frameworks, such as healthcare and finance, require market research to stay compliant with laws and regulations.

Product Development: Companies investing in research and development often use market research to identify gaps in the market, assess product feasibility, and understand consumer needs.

Supply of Market Research:

Market Research Agencies: Specialized market research agencies and firms are significant suppliers of market research. These organizations conduct comprehensive studies, surveys, and analyses for clients across various industries.

Technology Platforms: Online platforms and software tools provide businesses with access to self-service market research solutions. These platforms often offer data analytics, survey tools, and industry reports.

Independent Consultants: Independent consultants or freelancers in the field of market research contribute to the supply side by offering specialized expertise to businesses seeking customized research solutions.

Educational Institutions: Research conducted by academic institutions often contributes to the supply of market research. However, this type of research is typically more focused on theoretical aspects and may not always align with immediate business needs.

Government Agencies: Government bodies may conduct market research to inform policy decisions, and some of this information may be available to businesses. However, government agencies are not typically direct suppliers to the private sector.

Data Providers: Companies that collect and aggregate data, such as social media platforms, e-commerce websites, and data analytics firms, contribute to the supply of market research data.

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected] ), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

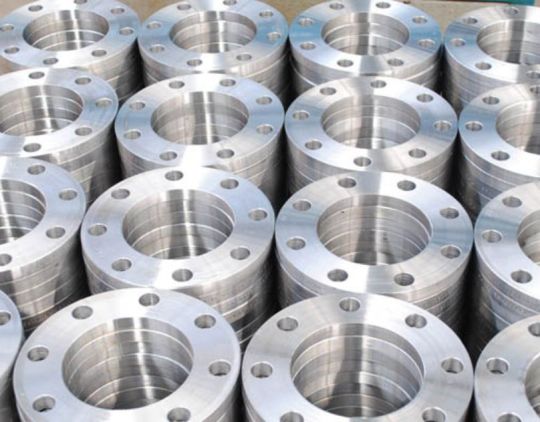

Unveiling the Secret: How to Select the Best Flange for Your Project

Metalica Forging Inc. is a leading Flanges Manufacturer in India. A flange is a projecting rim or edge that is commonly utilized for strength, alignment, or connection in engineering and building applications. Flanges are widely utilised in pipeline systems to help with the assembly and disassembly of pipes, valves, and other components.

Flange Supplier in India may seem like simple components in the grand scheme of engineering projects, but their importance cannot be overstated. They serve as crucial connectors, joining pipes, valves, and other equipment in a wide array of industries, from oil and gas to manufacturing and construction. However, choosing the right Flange Suppliers for your project is not always a straightforward task. With numerous types, materials, and specifications available, the selection process can be daunting. But fear not, for in this blog post, we will unveil the secrets to selecting the perfect flange for your specific needs.

Understanding Flanges:

Before diving into the selection process, it's essential to have a basic understanding of what flanges are and how they function. Essentially, a flange is a protruding rim or edge that is used to connect two objects, often by bolting them together. In the context of piping systems, flanges are used to join pipes, valves, fittings, and other components, allowing for easy assembly, disassembly, and maintenance.

Types of Flanges:

Flanges come in various types, each designed for specific applications and requirements. Some common types of flanges include:

Plate Flanges: are flat, circular flanges with bolt holes drilled directly into the flat surface, commonly used in low-pressure applications for connecting pipes, valves, and fittings. They offer a simple and cost-effective solution for joining components in systems where high pressure and temperature are not critical factors.

Slip-On Flanges: These flanges slide over the pipe and are then welded in place. They are relatively easy to install and are suitable for low-pressure applications.

Blind Flanges: As the name suggests, blind flanges are used to seal the end of a pipe or vessel. They are commonly used for pressure testing or when the end of the pipe needs to be closed off.

Socket Weld Flanges: Similar to slip-on flanges, socket weld flanges are welded to the pipe. However, they feature a recessed area (socket) into which the pipe fits, providing additional strength and stability.

Threaded Flanges: These flanges have threaded holes, allowing them to be screwed onto the pipe without the need for welding. They are commonly used in low-pressure, non-critical applications.

Hub Flanges: Hub Flanges can be customised to meet specific customer requirements and come in an assortment of sizes, dimensions, and forms. Being a top manufacturer of hub flanges, we supply them to a broad range of industries, including transportation, paper & pulp, plumbing, food processing and others. We are renowned for the outstanding quality, dependability, and durability of our goods. There are several different kinds of hub flanges that we offer, such as carbon steel, copper nickel, stainless steel, monel, inconel, and more. The International Quality Standards (IQS) are followed in the design and development of hub flanges. In accordance with the needs of the customer, we also provide customised Hub Flanges.

Factors to Consider:

When choosing the perfect flange for your project, several factors should be taken into consideration:

Pressure and Temperature: One of the most critical factors is the pressure and temperature conditions the flange will be subjected to. Different flange materials and designs have varying pressure and temperature ratings, so it's essential to select a flange that can withstand the operating conditions of your system.

Material Compatibility: Flanges are available in a wide range of materials, including carbon steel, stainless steel, and various alloys. The material chosen should be compatible with the fluid being transported and resistant to corrosion, erosion, and other forms of degradation.

Flange Facing and Gasket Material: The flange facing and gasket material play a crucial role in ensuring a reliable seal between flange joints. Factors such as the type of fluid, operating temperature, and pressure should be considered when selecting the appropriate facing and gasket material.

Size and Dimensions: Flanges come in various sizes and dimensions to accommodate different pipe sizes and pressure ratings. It's essential to select a flange that matches the size and specifications of your piping system to ensure proper alignment and functionality.

Consultation and Expertise:

While understanding the basics of flanges is essential, choosing the perfect flange for your project may require consultation with experts in the field. Engineers, manufacturers, and suppliers with experience in flange selection can provide valuable insights and recommendations based on your specific requirements and constraints.

We produce flanges in several Indian cities.

Flanges Manufacturer In Rajkot

Flanges Manufacturer In Ahmedabad

Flange Manufacturer In Surat

Flange Manufacturer In Bhavnagar

Flange Manufacturer In Pune

For More Detail

Website: metalicaforginginc.com

Other Product: JIS Flanges Manufacturer in India.

0 notes

Text

Exploring Lightning Arresters and Their Applications

A lightning strike is an awe-inspiring display of nature's power, but it can also wreak havoc on buildings and electrical systems in its path. Lightning arresters play a pivotal role in safeguarding against the destructive force of lightning. In addition to lightning arresters, other essential components of a comprehensive Lightning Protection System include cable glands and lugs. For top-notch quality and performance, consider renowned lug manufacturers in India, ensuring every aspect of your lightning protection setup meets the highest standards.

What are lightning arrestors?

Lightning Arresters are integral components of Lightning Protection Systems. They are designed to divert the immense energy of a lightning strike away from structures and electrical equipment.

Welcome to the realm of Lightning Arresters—a crucial component in the defense against nature's most electrifying force. In this article, we'll uncover the inner workings of these devices and explore their diverse applications, from shielding buildings to preserving the integrity of electrical systems. Let's journey through the fascinating world of Lightning Arresters and their indispensable role in safeguarding infrastructure.

These devices ensure that the electrical systems remain unharmed by providing a low-resistance path to the ground.

Two main types of lightning arresters are commonly used:

Conventional Lightning Arresters (Franklin rods)

These are simple yet effective devices consisting of long metallic rods, typically made of copper.

Installed at the highest points of structures, they intercept lightning strikes and channel the electric charge safely to the ground.

Suitable for smaller structures like residential buildings, they require additional components such as metallic conductors and earthing designs.

Early Streamer Emission (ESE) Lightning Arresters

ESE lightning arresters offer a more advanced solution for lightning protection.

Emitting charged particles provides a faster conductive point of discharge for lightning bolts, covering larger areas with greater efficiency.

These devices harness ambient electromagnetic energy during lightning events, offering a swift and effective means of grounding fault currents.

Let’s dive into the applications:

Lightning Arresters serve as the first line of defense against the formidable force of lightning, safeguarding structures and electrical systems from potential damage. Whether a conventional Franklin rod or an innovative ESE arrester, investing in robust lightning protection measures is essential for mitigating risks and ensuring infrastructure resilience against nature's fury.

Lightning arrestors are commonly installed on buildings, towers, and other structures to intercept lightning strikes and safely redirect the electrical charge to the ground. By providing a path of least resistance, they prevent damage to the structure and mitigate the risk of fire or structural failure.

Lightning arrestors are installed within electrical systems to safeguard sensitive equipment and components from the damaging effects of lightning-induced surges. By diverting excess electrical energy away from the system, they help prevent equipment malfunction, data loss, and downtime.

Final Thoughts

Partnering with reputable lightning arrestor manufacturers and suppliers is imperative for quality lightning arrester solutions. Look for trusted names in the industry, such as Axis, who offer reliable products and expert guidance on lightning protection strategies.

With robust lightning protection measures, structures can confidently weather the storm, keeping occupants safe and infrastructure secure against nature's unpredictable forces.

Axis India stands at the forefront as a premier cable gland manufacturer in India and supplier of lightning arrestors and a wide array of Electrical Components, serving clients across 80+ countries worldwide. Whether you're seeking a quote or expert consultation, our dedicated team is ready to assist you.

Visit our https://axis-india.com/contact-us/ section to connect with an industry expert today.

0 notes