#Corrugated Sheet Roll Forming Machine

Explore tagged Tumblr posts

Text

Best Quality Metro sheet manufacturers in India

Metro Sheet Manufacturers in India: Powering the Growth of PEB Construction

India’s construction industry is experiencing rapid evolution, driven by the increasing demand for fast, durable, and cost-effective building solutions. One of the key innovations shaping this transformation is the rise of Pre-Engineered Buildings (PEBs)—steel structures that are pre-designed, factory-fabricated, and assembled on-site. As the backbone of PEB cladding and roofing systems, Metro sheet manufacturers in India are playing a pivotal role in enabling this shift toward modern infrastructure development.

What Are Metro Sheets?

Metro sheets refer to high-quality, profiled metal sheets commonly used for roofing and wall cladding in industrial, commercial, and residential buildings. These sheets are typically made from galvanized steel, Galvalume, or aluminum, and often come with protective coatings and attractive color finishes. Their durability, light weight, and corrosion resistance make them ideal for a wide range of construction applications—particularly in pre-engineered steel structures.

Metro sheets are available in various profiles, including trapezoidal, corrugated, and standing seam, offering versatility in design while ensuring strength and weather protection. These sheets serve as both functional and aesthetic elements in PEB construction.

Role of Metro Sheet Manufacturers in the PEB Industry

In the context of PEBs, metro sheets act as the external skin of the building, providing structural protection, insulation, and visual appeal. PEB manufacturers rely on metro sheet suppliers to provide high-precision, quality-controlled materials that align with the specific dimensions and performance requirements of their projects.

Key contributions of metro sheet manufacturers to the PEB sector include:

Customization: Sheets are produced to exact sizes, thicknesses, and finishes as per PEB design requirements.

High Production Standards: Use of advanced roll-forming machines and automated production lines ensures consistent quality and precision.

Durability and Protection: Coated sheets protect steel frames from weather elements, enhancing the lifespan of the building.

Speed of Construction: Pre-fabricated sheets enable quick installation, reducing project timelines and labor costs.

By offering reliable supply chains and consistent quality, metro sheet manufacturers support the seamless execution of PEB projects across India.

Market Demand and Industrial Applications

The Indian PEB market is growing rapidly due to increased demand in sectors like logistics, warehousing, manufacturing, agriculture, aviation, and commercial development. With this growth, the demand for superior roofing and cladding materials has also surged—placing metro sheet manufacturers in a critical position.

Some common applications of metro sheets in PEBs include:

Warehouses and distribution centers

Cold storage and agro-processing units

Airports and hangars

Manufacturing plants and workshops

Commercial and institutional buildings

Residential roofing and farm structures

The ability of metro sheets to withstand harsh environments, including heat, rain, and wind, makes them especially suitable for diverse Indian climatic conditions.

Conclusion

Metro sheet manufacturers in India are integral to the success of the growing PEB industry. By delivering high-quality, customizable, and durable roofing and cladding solutions, they empower PEB manufacturers to construct modern, efficient, and sustainable buildings across the country. As demand for rapid and resilient infrastructure continues to grow, the collaboration between metro sheet and PEB manufacturers will remain a cornerstone of India’s construction future.

Visit:- https://www.pebmanufacturers.in/metro-sheet.html

0 notes

Text

Roofing Sheets A Comprehensive Guide by Hi-Tech Pipes

Roofing sheets, also known as corrugated metal sheets, are a versatile and durable roofing material used in various residential, commercial, and industrial buildings. They are available in a wide range of colors and profiles to suit different architectural styles and functional requirements.

Hi-Tech Pipes: A Leading Manufacturer of Roofing Sheets

Hi-Tech Pipes is a renowned manufacturer of roofing sheets in India. The company is known for its commitment to quality, innovation, and sustainability. Hi-Tech Pipes’ roofing sheets are manufactured using high-grade steel and undergo rigorous quality control checks to ensure they meet the highest standards.

Types of Roofing Sheets

There are two main types of roofing sheets:

Galvanized steel roofing sheets: These sheets are coated with a zinc layer to protect them from corrosion. Galvanized steel roofing sheets are the most common type of roofing sheet due to their affordability and durability.

Color coated roofing sheets: These sheets are galvanized steel sheets that have been painted with a layer of color coating. Color coated roofing sheets offer a wider range of aesthetic options and enhanced UV protection.

Manufacturing Process of Roofing Sheets

The manufacturing process of roofing sheets involves several steps:

Selection of raw materials: High-quality steel coils are selected as the base material for roofing sheets.

Coil slitting: The steel coils are slit into strips of the desired width.

Cold roll forming: The steel strips are cold-rolled into the desired profile using specialized forming machines.

Galvanizing: The roofing sheets are galvanized in a molten zinc bath to provide corrosion protection.

Color coating: For color coated roofing sheets, an additional step of applying a color coating is done using a paint application system.

Quality inspection: The roofing sheets undergo rigorous quality inspection to ensure they meet the required specifications, including thickness, coating uniformity, and surface finish.

Applications of Roofing Sheets

Roofing sheets are widely used in various applications, including:

Residential roofing: Roofing sheets are a popular choice for residential roofing due to their affordability, durability, and ease of installation.

Commercial roofing: Roofing sheets are also frequently used in commercial buildings, such as warehouses, factories, and shopping complexes.

Industrial roofing: Roofing sheets are a common choice for industrial roofing applications due to their ability to withstand harsh weather conditions and chemical exposure.

Benefits of Roofing Sheets

Roofing sheets offer several advantages over other roofing materials:

Durability: Roofing sheets can withstand harsh weather conditions, including wind, rain, and snow.

Corrosion resistance: Galvanized roofing sheets are highly resistant to corrosion, ensuring a long lifespan.

Low maintenance: Roofing sheets require minimal maintenance compared to other roofing materials.

Affordability: Roofing sheets are a relatively affordable roofing material.

Lightweight: Roofing sheets are lightweight and easy to install.

Versatility: Roofing sheets are available in a wide range of colors and profiles to suit different architectural styles.

Sustainability: Roofing sheets can be recycled, making them an environmentally friendly roofing option.

Hi-Tech Pipes: A Commitment to Quality and Sustainability

Hi-Tech Pipes is committed to providing high-quality roofing sheets that meet international standards. The company employs advanced manufacturing techniques and stringent quality control measures to ensure the consistency and reliability of its products.

Hi-Tech Pipes is also committed to sustainability practices. The company has implemented eco-friendly manufacturing processes and utilizes recycled materials whenever possible to minimize its environmental impact.

Conclusion

Roofing sheets��are a versatile, durable, and affordable roofing material suitable for various applications. Hi-Tech Pipes, with its commitment to quality, innovation, and sustainability, stands as a leading manufacturer of roofing sheets, catering to the needs of diverse industries and projects across India.

0 notes

Text

Comprehensive Guide to Packaging Supplies in Melbourne: Essential Products for Every Industry

Packaging supplies in Melbourne are vital for the majority of enterprises, whether they be manufacturing facilities, warehouses, godowns, food facilities, or any other kind of commercial or industrial institution. The top suppliers of packaging items are aware of the particular requirements of the sector and provide a wide range of goods, from vacuum sealers to various kinds of sticky tapes.

Examining the Varieties of Packaging Products and Their Characteristics

There are many different types of packaging items, each created to satisfy certain industry standards. Pallet pads are quite an important product when sending important items on pallets as some splinters, dust, etc may damage the products. Sheets of corrugated cardboard are used to create protective layers between goods. Secure packing options for goods of all forms are provided by cartons and boxes, which come in a variety of sizes and strengths. For products’ organisation and storage, corrugated trays and folders are perfect, especially in retail and warehouse settings.

Leading packaging product providers serve not just the industrial sector but also the service industry, including the food and hotel sectors. Biodegradable wrap, plates and bowls, mugs of various kinds, and cutlery such as knives, spoons, forks, etc. are some of the items used to package and deliver food to customers in an appropriate manner. Dispensing cartons, retail rolls, bags, sheets, tubes, wraps, and takeout bowls are examples of eco-friendly sustainable packaging that has become increasingly popular in recent years as people's awareness of environmental issues has grown.

The top providers of packaging materials also address janitorial demands, providing a wide variety of items to preserve safety and cleanliness in commercial and industrial settings. Workplace hygiene requires supplies including roll-up hand towels, toilet tissue dispensers, and face tissues. The room or restroom is kept fresh and clean using products like odour control dispensers and antibacterial hand cleaners.

In recent decades, the e-commerce business has expanded rapidly, and as a result, packing machines and dispensers have become crucial for suppliers of goods sold online. Stretch wrap machines, vacuum sealers, and automatic tape dispensers are all made to handle large quantities of goods, increasing output and lowering labour expenses.

Look through the products area of the websites of top packaging product providers and purchase what you need or what businesses need.

Source: https://paramount-packaging.blogspot.com/2024/11/comprehensive-guide-to-packaging.html

0 notes

Text

R Panel Roll Formers

Zyforming offers a full line of roof and wall panel roll forming machines, one-stop custom solutions, on-site support and warranties. Learn more about our automatic/easy-operate corrugated sheet forming machines. Get a quote for roof and wall roll forming machine now! R Panel Roll Formers

0 notes

Text

The structure of the roller extrusion granulator

There are different classifications of organic fertilizer granulator: disc granulator, rotary drum granulator, and roller extrusion pelletizer; Because the organic fertilizer particles produced by different organic fertilizer ingredients are different, and different soils require different fertilizer particle sizes, the granulator solves this problem, and can produce organic fertilizers of different particle sizes and shapes with different granulation machines according to different needs. Today we mainly introduce the double roller press granulator. The extrusion structure of the extrusion granulator mainly has two forms of roll extrusion and wheel grinding extrusion. The roller extruding pelletizer consists of a feeding device and two parallel rolls that rotate relative. The axis line of one roll is fixed, and the axis line of the other roll is parallel to move, so that there is an accurate small gap between the two rolls. The size of the gap is adjusted by two or four hydraulic cylinders of the push rod to move the roller axis line to maintain a constant extrusion pressure. The arrangement of charging system and roll of extrusion granulator has many forms; Screw pusher can be vertical or horizontal; Its speed is adjustable; The hopper position is adjustable and kept constant; The surface of the circumference of the roll is spherical or corrugated to form a shaped cavity. The powder is continuously and evenly added from the hopper to the top of the two rolls, and under the continuous rotation of the extrusion roll, the powder is bitten into the two rolls and extruded into sheet material.

0 notes

Text

Профнастил С-8 материал C-8 Такой профнастил имеет трапециевидную форму гофры. russian model c8 roofing machine c8 metal roofing roll forming machine Machine de formage de rouleau de toiture en métal C8

【Whatsapp���+86 13505403010 【Email】 [email protected] 【Web】www.steelmama.com www.tilemakingmachinery.com 【Youtube】https://bit.ly/3R2Mcmn

c8aluminiumroofingsheetmakingmachine

c8doublelayerrollformingmachinerussian

C8roofandwallsheetrollformingmachine

C8metalsheetmachine

c8roofpanel

C8roofsheetrollformingmachine

C8roofingpanelrollformingmachine

C8trapezoidalformingmachinefromChinasupplier

c8c10c21c44rollformingmachine

C80Cprofilerollformingmachine

CorrugatedboardforroofC8

GlazedSteelTileRollFormingMachineC8

popularrussiantypec18roofformingmachine

RussiaC-8profilesheetmachine

RussiaTypeWallPanelSheetRollFormingMachine

russianglazedtilerollformingmachine

russianmodelc8roofingmachine

russianmodelc8

RussianStyleC8RoofPanelRollFormingMachine

c8 aluminium roofing sheet making machine

c8 double layer roll forming machine russian

C8 roof and wall sheet roll forming machine

C8 metal sheet machine

c8 roof panel

C8 roof sheet roll forming machine

C8 roofing panel roll forming machine

C8 trapezoidal forming machine from China supplier

c8 c10 c21 c44 roll forming machine

C80 C profile roll forming machine

Corrugated board for roof C8

Glazed Steel Tile Roll Forming Machine C8

popular russian type c18 roof forming machine

Russia C-8 profile sheet machine

Russia Type Wall Panel Sheet Roll Forming Machine

russian glazed tile roll forming machine

russian model c8 roofing machine

russian model c8

Russian Style C8 Roof Panel Roll Forming Machine

1 note

·

View note

Text

The Role of Custom Corrugated Box Packaging Making Machines

Packaging plays a critical role in protecting and promoting products during storage, transit, and retail display. Among the most versatile and widely used packaging materials is corrugated cardboard. To meet the diverse packaging needs of various industries, custom corrugated box packaging making machines have emerged as an invaluable solution. These machines are designed to efficiently produce tailor-made corrugated boxes, providing businesses with the flexibility to create packaging that perfectly suits their products and brand. In this article, we will explore the significance, functionalities, and advantages of custom box making machine in today's dynamic packaging landscape.

1. Understanding Custom Corrugated Box Packaging Making Machines

What are Custom Corrugated Box Packaging Making Machines?

Custom corrugated box packaging making machines are automated devices designed to manufacture corrugated cardboard boxes tailored to the specific requirements of a business. These machines can produce boxes of various shapes, sizes, and styles, accommodating the diverse needs of different industries, including e-commerce, food and beverage, pharmaceuticals, electronics, and more.

Working Principle

The working principle of custom corrugated box packaging making machines involves a series of precise steps:

Corrugated Cardboard Feeding: The corrugated cardboard, typically supplied in rolls or sheets, is fed into the machine.

Printing (Optional): Some advanced custom box making machines may include a printing module to add branding, product information, or barcodes on the boxes.

Die Cutting and Creasing: The machine uses a die cutting tool to cut the cardboard into the desired shape and create creases for easy folding.

Gluing and Folding: The machine applies adhesive to the necessary areas, and the cardboard is folded and pressed to form the box's structure.

Finishing and Ejection: The finished custom corrugated box is ejected from the machine, ready for use in packaging products.

Advantages of Custom Corrugated Box Packaging Making Machines

Flexibility in Design: Custom corrugated box packaging making machines enable businesses to create boxes tailored to their products, optimizing space and providing an excellent fit.

Efficient Production: These machines can produce boxes at high speeds, reducing production time and increasing overall efficiency.

Cost-Effectiveness: By eliminating the need for outsourcing packaging production, businesses can save on costs and maintain better control over their packaging supply chain.

Consistency in Quality: Automated production ensures consistent box quality, minimizing variations and potential defects.

Sustainable Packaging: Corrugated cardboard is a recyclable and biodegradable material, making custom corrugated boxes an eco-friendly packaging solution.

Branding Opportunities: Custom printing options allow businesses to incorporate their brand elements and enhance brand visibility.

2. Types of Custom Corrugated Box Packaging Making Machines

Custom corrugated box packaging making machines come in different types to suit various production needs:

Manual Machines: These machines require some manual intervention, such as feeding the cardboard or adjusting settings. They are suitable for smaller production volumes.

Semi-Automatic Machines: Semi-automatic machines combine manual and automated processes, striking a balance between production volume and labor requirements.

Fully Automatic Machines: These machines are highly automated, requiring minimal human intervention. They are capable of handling large-scale production with high precision and efficiency.

Digital Printing Machines: Some custom box making machines offer digital printing capabilities, allowing for on-demand customization and short print runs.

3. Applications of Custom Corrugated Box Packaging Making Machines

Custom corrugated box packaging making machines find extensive applications in various industries, including:

E-Commerce and Shipping: Custom boxes are essential for e-commerce businesses to package and ship products safely and efficiently.

Food and Beverage: The food industry utilizes custom boxes for packaging perishables, ready-to-eat meals, and beverages.

Pharmaceuticals: Custom boxes are used to package and protect pharmaceutical products, ensuring safety and compliance with regulations.

Electronics: Electronics manufacturers rely on custom boxes to package delicate and valuable electronic devices securely.

Retail and Display: Custom boxes play a crucial role in retail displays, creating an attractive and branded packaging presentation.

4. Future Developments and Advancements

As technology continues to evolve, custom corrugated box packaging making machines are likely to witness the following advancements:

Increased Automation: Manufacturers may focus on further automating the entire production process, reducing human intervention and increasing efficiency.

Advanced Customization Options: Machines may incorporate advanced digital printing and cutting technologies to offer even more intricate and personalized box designs.

Integration with Software Systems: Custom box making machines could be integrated with enterprise resource planning (ERP) and supply chain management systems for seamless production and inventory management.

Sustainability Features: Machines may incorporate eco-friendly adhesives and recycled cardboard options to further enhance the sustainability of custom corrugated boxes.

Conclusion

Custom corrugated box packaging making machines have revolutionized the packaging industry by providing businesses with the ability to create tailor-made packaging solutions that perfectly suit their products and brand. The efficiency, versatility, and cost-effectiveness of these machines have made them indispensable tools for a wide range of industries.

As technology continues to advance, custom corrugated box packaging making machines will likely see further developments, contributing to more sustainable packaging solutions and enhancing the overall efficiency of the packaging process. By embracing these cutting-edge machines, businesses can elevate their packaging game, delighting customers with personalized and well-protected products while streamlining their production processes.

0 notes

Text

Review – Double deck roll forming machines

Review – Double deck roll forming machines

Double deck roll forming machine is a type of machine can create a variety of forming profiles to provide to the sheet metal market a diversity of utility choices and good options to constructions. Vietsteel Ltd will detail some information about some most common double deck roll forming machines available on the market.Get more news about double deck compression forming machine,you can vist our website!

At present, Vietsteel can provide 4 series lines of double deck roll forming machines as the result of combinations of the two roll forming decks within the machine: both roofing roll forming decks (DR), a roofing roll forming deck and a corrugated roll forming deck (DC), a roofing roll forming deck and a Step tile roll forming deck (DS), a Step tile roll forming deck and a corrugated roll forming deck (SC). Each line includes two models with different forming speeds. Our customers have a diversity of options.

The Advantages of Double Deck Roll Forming Machine

The machine has excellent forming speed, high production efficiency, output sheeting are at great quality. The double deck roll forming machines by Vietsteel help businesses save time, resources and operating costs. Costs and prices are reasonable. The machine produces products with almost absolute accuracy, with minimum tolerance figures in shape and size. Machines work steadily for 15 years with 1 year warranty. Double deck roll forming machines can produce sheeting for many different thicknesses, colors, materials upon customers’ orders. The origins of machines and components are clearly verified. For our clients, Vietsteel’s team will advise the right model that is suitable with the business situation.

0 notes

Text

Meet the MTC team: Best Yet Affordable Cold Roll Former!

Shanghai MTC Industrial Co. LTD is focused in manufacturing shape steel cold roll forming machines, slitting line and whole group international trade business. We have a hi-tech environment, advanced production equipment, strict check, developed after-sales work and solicitous service. We could design different types of roll forming machine according to clients’ requirements.

Along each length, features such as holes, slots, or embosses can easily be added, making the roll forming process a very cost effective method of achieving a strong, multi-functional shape. Roll forming is used instead of extrusion, where the metal required cannot easily be extruded, or where the features along the length of the part are uneconomic to add to an extrusion, or where an extrusion is not accurate enough.

Here, at MTC, we are a roll forming machine manufacturer in Shanghai China providing turn-key solutions for Roll forming equipment, such as, corrugated sheet roll forming machine and Highway guardrail roll forming machine along with insulated sandwich panel production lines! We fabricate Highway guardrail roll forming machine that is a cold roll forming product shaping out of steel coil into the shape of two waves guardrail or three waves guardrail.

Plus, crash barrier highway guardrails have demonstrated highly valuable in falling the extent and power of accidents. Because all scientific supplies about the machinery have been greatly satisfied, our metal roll forming equipment and insulated sandwich panel production line would manufacture exquisite final products as per industry standard in the worldwide markets.

As well, we at MTC have gainfully realized the name of reliable unit to offer a most profitable quality range of Corrugated Sheet Roll Forming Machine adhering to the industry standards and norms for qualitative production. This machine is available in various technical specifications as per the requirements of our valuable clients. The provided machine is widely acknowledged by our esteemed clients owing to its long functional life and smooth operations. Furthermore, we provide this machine to our clients’ at the best price.

Our core values are quality, competence, trustworthiness & honesty, which can definitely and stably maintain us to go far. For more details please visit our website.

0 notes

Video

tumblr

Corrugated Sheet Roll Forming Machine

0 notes

Text

Boost Efficiency with Melbourne Packaging Supplies: A Comprehensive Overview

In Melbourne packaging supplies are quintessential for most types of industries be it a warehouse, godown, manufacturing facility, food facility or any other commercial or industrial establishment. The leading packaging products suppliers understand the unique needs of the industry and hence offer a number of different products ranging from adhesive tapes of different types to vacuum sealers and more.

A Look at The Diverse Nature of Packaging Products and Their Features

Packaging products come in various forms, each designed to meet specific industry requirements corrugated cardboard box made from sheets are used for providing protective layering between products. Cartons and boxes, available in multiple sizes and strengths, offer secure packaging solutions for items of all shapes. Corrugated trays and folders are ideal for organising and storing products, particularly in warehouses and retail environments.

Not just the industrial sector but the leading suppliers of packaging products also serve the service sector like the hospitality and catering industries. Some of the products for packaging and properly presenting food for consumers include biodegradable cling wrap, plates and bowls, cling wrap, cups of various types, and cutlery like knives, spoons, forks, etc of various types. Nowadays, people are becoming more environmentally conscious hence the rise of eco-friendly sustainable packaging like dispensing cartons, retail rolls, bags, sheets, tubing, wraps, and takeaway bowls.

Janitorial needs are another area that is catered by the leading suppliers of packaging products, offering a diverse range of products to maintain cleanliness and safety in industrial and commercial environments. Items like facial tissues, toilet tissue dispensers, and roll hand towels are essential for maintaining hygiene in workplaces. Products such as antibacterial hand cleansers and odour control dispensers keep the room or washroom clean and fresh.

When it comes to the e-commerce industry, has grown by leaps and bounds in recent decades and due to this packaging machines and dispensers are becoming quintessential for sellers selling products through e-commerce. Automatic tape dispensers, vacuum sealers, or stretch wrap machines, all these tools are designed to handle high volumes of products, improving productivity and reducing labour costs.

Check out the products section of the website of leading suppliers of packaging products and buy what is required for businesses or as per your needs.

Source: https://paramount-packaging.blogspot.com/2024/09/boost-efficiency-with-melbourne.html

0 notes

Text

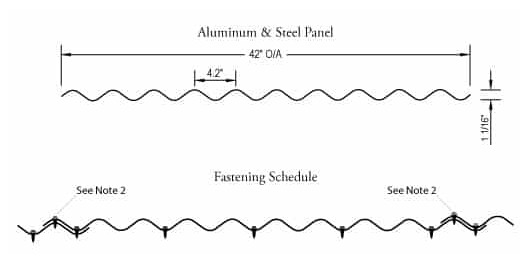

4.2 inch corrugated sheet roll forming machine

Corrugated sheet roll forming machine can do the production of 4.2 inch corrugated roof sheet automatically with high speed. As a popular building material, 4.2 inch corrugated roof sheet has so many characters, there are some details about the products and machine in the followings.

Here is the profile for your reference:

Description of Roll-Formed 4.2’’ Corrugated Sheets

4.2 Corrugated panels are often used to replace transite roofing and siding. The larger pattern of 4.2 corrugated looks very similar to the old cement-asbestos panels that were used in construction projects up until the material was phased out in the 80’s due to its toxic health effects. Today, builders and developers looking to replace transite with a similarly shaped alternative find our 4.2 corrugated to be the ideal solution.

We are proud to be one of the few facilities in the country to roll form 4.2” (Four and Two Tenths Inch) corrugated panels. This incredibly popular style is versatile and strong, and our ability to create custom orders has allowed us to work for a number of industries in need of the specialty product. These panels feature corrugations 1 1/16 inches tall and 4.2 inches apart (From crest to crest). These dimensions make it a sturdy and attractive option for projects of all sizes.

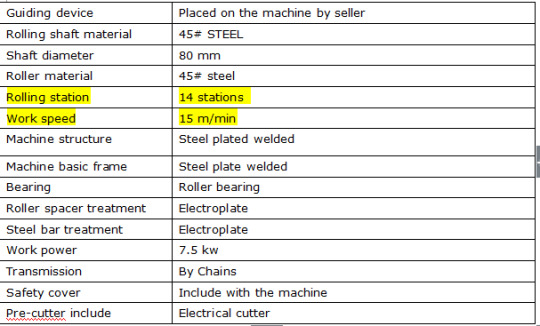

Here I will show some parameters of corrugated sheet roll forming machine:

Applications of 4.2 Inch Corrugated roof sheet

4.2 Inch corrugated roof sheet have become a popular look for roofing, siding, and decorative applications. The pronounced look provides a more distinct aesthetic than smaller patterns, while the understated nature of sheet metal keeps it from being too bold.

Our purpose-built machinery can roll form the exact size of 4.2’’ panels you need in a variety of gauges and substrates. If you’ve shopped around and found other shops that offer 4.2’’, chances are they get their stock from us.

Here is a video of corrugated sheet roll forming machine for your reference

youtube

If you want to know more details about the machine, please feel free to contact with us at any time.

Email: [email protected]

Whatsapp: +8615127755788 and +8613733275488

0 notes

Link

A) De coiler 2 ton cap.

B) Entry Gate with

C) Roll Forming Line with 9 stations, 1 Gear Boxes & 5 H.P. electrical.

D) Control Panel semi auto

E) Cutting Unit

TECHNICAL SPECIFICATIONS:-

Maximum sheet width that can be formed

1250 mm

Maximum sheet thickness in CRCA Strips that can be formed

1.2 mm

Horizontal distance between shafts

500mm

Number of forming stations

16 nos.

Total HP for Line

8

Speed of the machine

10 -14 mt / mint

Size of machine

9500 x 1700 x 1100 MM

MANDREL UNCOILER

Coil weight

5 MT Max

Coil width

1250 MM

Coil bore

450 MM min, 510 MM max dia.

Mandrel movement

Manually adjusted

Back Tension

Manually adjusted

#Corrugated Roll Forming Machine#Corrugated Roll Forming#Corrugated Roll Forming Line#Corrugated Sheet Roll Forming Machine#Corrugated Roll Former

0 notes

Link

Details of Corrugated Roll Forming Machine

A) De coiler 2 ton cap. B) Entry Gate with C) Roll Forming with 9 stations, 1 Gear Boxes & 5 H.P. electrical. D) Control Panel semi auto E) Cutting Unit

TECHNICAL SPECIFICATIONS

Maximum sheet width that can be formed

1250 mm

Maximum sheet thickness in CRCA Strips that can be formed

1.2 mm

Horizontal distance between shafts

500mm

Number of forming stations

16 nos.

Total HP for Line

8

Speed of the machine

10 -14 mt / mint

Size of machine

9500 x 1700 x 1100 MM

MANDREL UNCOILER

Coil weight

5 MT Max

Coil width

1250 MM

Coil bore

450 MM min, 510 MM max dia.

Mandrel movement

Manually adjusted

Back Tension

Manually adjusted

Motor - ABB Gear box – Elecon Bearing - SKF

#Corrugated Roll Forming Machine#Corrugated Sheet Roll Forming Machine#Corrugated Roll Former#Roll Forming Machine#Custom Roll Forming Machine

0 notes

Link

We are indulged in the manufacturing and exporting of Corrugated Sheet Roll Forming Machine. These products are designed to reduce man power and stable steel base design. These machines are used in industrial sectors and are available in market at Compititive Rates. These products equipped with various features including en31 material hafts, elecon gear box , abb motors and more. This forming line has no limit on processing length; you can set a program on the computer control according to your requirement

D coiler 5 ton cap.

Entry Gate with

Roll Forming Line with 18 stations, 10 H.P. electrical.

Control Panel semi auto

Cutting Unit (Hydro.)

Technical Specifications

Maximum sheet width that can be formed : 1250 mm

Maximum sheet thickness in CRCA Strips that can be formed : 1.2 mm

Horizontal distance between shafts : 500mm

Number of forming stations : 16 nos.

Total HP for Line : 8

Speed of the machine : 10 -14 mt / mint

Size of machine : 9500 x 1700 x 1100 mm

Mandrel Uncoiler

Coil weight : 5 MT Max

Coil width : 1250 MM

Coil bore : 450 MM min, 510 MM max dia.

Mandrel movement : Manually adjusted

Back Tension : Manually adjusted

#Corrugated Roll Forming Machine#Corrugated Sheet Roll Forming Machine#Corrugated Roll Former#Corrugated Sheet Roll Former

0 notes

Text

Corrugated Sheet Roll Forming Machine

Corrugated Sheet Roll Forming Machine

Corrugated Sheet Roll Forming Machine can manufacture different profile of stainless steel roofing sheet and wall sheets as per customer’s requirement drawing and necessity. This profile is new structure equipment with different width. It’s make many reward like low product capacity, easy installation, high strength.

D coiler 5 ton cap.

Entry Gate with

Roll Forming Machinewith 18 stations, 10…

View On WordPress

#Corrugated Roll Forming machine#Corrugated Sheet Roll Forming#Corrugated Sheet Roll Forming Line#Corrugated Sheet Roll Forming Machine#Corrugated Sheet Roll Forming Machine Exporter#Corrugated Sheet Roll Forming Machine In India#Sheet Roll Forming#Sheet Roll Forming Line#Sheet Roll Forming Machine

0 notes