#Ignition SCADA

Explore tagged Tumblr posts

Text

Integrators Speak: What Makes Ignition Their SCADA Platform of Choice

SCADA Isn't Just a System—It’s a Strategic Decision

When your plant's efficiency, uptime, and scalability hinge on your SCADA system, choosing the right platform isn’t just a tech decision—it’s a business-critical one. And for more and more integrators and manufacturers, Ignition by Inductive Automation is the name that keeps rising to the top.

But why?

Let’s hear from those who work in the trenches—industrial integrators who implement, optimize, and rely on SCADA systems every day.

The SCADA Wish List: What Today’s Integrators Value Most

When evaluating the best SCADA software in 2025, experienced integrators say the same things matter:

Flexibility to fit diverse architectures.

Rapid development and deployment.

Ease of integration with MES, ERP, and IoT layers.

Licensing models that scale with the business, not against it.

Modern UI/UX for operators and stakeholders alike.

Ignition doesn’t just check these boxes—it redefines them.

Why Ignition SCADA Stands Out

Unlimited Licensing

One integrator put it best: “We’re not paying more just because a facility is growing.” Ignition’s licensing model allows for unlimited tags, screens, and clients—ideal for evolving operations.

Modular Architecture

With components like Perspective, Vision, MQTT Transmission, and Edge, integrators can build exactly what a plant needs—without bloat.

Web-Based Deployment

Forget clunky installs and patchwork updates. Launch from any browser, on any device.

Speed and Simplicity

From drag-and-drop design to streamlined SCADA system integration, Ignition helps integrators get systems up faster—with fewer headaches for their clients.

Beyond Features: A Platform That Powers Partnership

SCADA isn’t just about code—it’s about collaboration. And that’s where Ignition really shines.

Active Community & Support Inductive Automation’s forums, documentation, and user groups make it easy for integrators to solve problems fast—and innovate faster.

Inductive University Whether onboarding new talent or upskilling veterans, Ignition Inductive Automation offers robust training and certifications to keep teams sharp.

Scalable for Startups and Enterprises Alike From single-machine interfaces to enterprise-wide dashboards, integrators praise Ignition’s ability to grow with the customer—without forcing rework.

How It Stacks Up: Ignition vs. Other SCADA Platforms

Unlike traditional SCADA vendors that lock you into proprietary ecosystems, Ignition thrives on interoperability and openness. Whether integrating with SQL databases, MQTT brokers, or third-party APIs, it’s engineered to play well with others.

In fact, many integrators report migrating from legacy systems not just because of features—but because of frustration with outdated architectures and restrictive vendor policies.

Real Talk from the Field

“We’ve built systems for food processors, chemical plants, and packaging lines. Ignition let us design fast, customize deeply, and deliver value that made clients go ‘wow.’ It’s not just software—it’s a competitive advantage.” — SCADA Integrator, Midwest U.S.

INS3’s Take: The Platform You Can Build a Future On

At INS3, we work closely with integrators and manufacturers to solve real-world automation challenges. And time and again, Ignition emerges as the platform that meets today’s demands—and tomorrow’s dreams.

Whether you’re exploring your first SCADA deployment or replacing a legacy setup, we’re here to help you:

Evaluate your current tech stack.

Identify high-impact opportunities.

Build smarter, faster, and more connected systems.

SCADA That Supports Innovation, Not Limits It

If you're looking for a SCADA platform that empowers your integrators, delights your operators, and supports your business goals—Ignition SCADA by Ignition Inductive Automation is the answer.

Let’s build something scalable, intuitive, and future-ready—together.

0 notes

Text

Did you know there are free SCADA tools that are still “professionally capable”?

Options like VTScadaLight, Ignition Free, and Rapid SCADA offer real‑time monitoring, control, and data logging – all without licensing fees

Want to try but don’t know where to start?

Discover the list and how‑to here:

0 notes

Text

Hydrogen Leak Detection: Sensors, Systems, and Prevention

Hydrogen, as a clean energy carrier, is gaining momentum across industries ranging from fuel cell technology to chemical processing and aerospace. However, its unique properties, low ignition energy, high diffusivity, and wide flammability range also make it a challenging substance to manage safely. A hydrogen leak, if undetected, can pose significant risks, including fire, explosion, and environmental impact. This article explores modern hydrogen leak detection technologies, integrated systems, and proactive prevention strategies. It also outlines how safety methodologies like HAZOP (Hazard and Operability Study), HAZID (Hazard Identification), and principles of Process Safety Management (PSM) and risk management are vital to minimizing the likelihood and impact of hydrogen leaks.

Hydrogen Leak Detection Technologies

Sensor-Based Detection

The cornerstone of hydrogen leak detection lies in sensors. These devices come in various types, including:

Catalytic bead sensors: These detect hydrogen through oxidation, offering fast response times but are less suitable in oxygen-deficient environments.

Electrochemical sensors: Functional for low concentration detection, these provide high sensitivity and are ideal for confined spaces.

Thermal conductivity sensors: To measure changes in thermal conductivity caused by hydrogen's presence, offering long service life and low maintenance.

Optical sensors: Utilizing laser or infrared spectroscopy, these provide highly accurate and fast remote detection, making them ideal for large facilities.

MEMS-based sensors: Miniaturized sensors using micro-electromechanical systems provide low-cost, low-power solutions for distributed sensing networks.

Proper sensor placement, calibration, and integration into automated systems are crucial for reliable leak detection and immediate response.

Leak Detection Systems and Integration

Beyond individual sensors, integrated hydrogen leak detection systems form the backbone of modern safety architecture. These systems often include:

Distributed control systems (DCS) and SCADA systems to collect, monitor, and analyze sensor data in real time.

Alarm systems to alert operators or trigger automatic shutdowns.

Ventilation and purging mechanisms to disperse hydrogen accumulations.

Fire suppression systems are tailored for hydrogen flames, nearly invisible to the naked eye.

Advanced analytics and AI-driven pattern recognition are also being deployed to predict potential failure points, improving early intervention capabilities.

Prevention and Risk Management Strategies

Detecting a leak is only part of the safety equation—preventing one is equally important. This is where systematic safety methodologies like HAZOP and HAZID come into play.

HAZOP involves a structured review of process designs to identify deviations that could lead to hazardous situations.

HAZID is often used during the early stages of a project to identify potential hazards, including leak-prone areas or material compatibility issues.

This includes quantitative and qualitative evaluations of leak probabilities, consequence modeling, and risk scoring to prioritize mitigation efforts.

Process Safety Management (PSM) ensures that safety is embedded throughout the hydrogen system lifecycle—from design and installation to operation and decommissioning. Key PSM elements include:

Mechanical integrity programs to ensure components can withstand hydrogen’s unique properties.

Employee training on hydrogen-specific hazards and emergency procedures.

Management of change (MOC) protocols to assess risks from modifications.

Incident investigation to learn from past leaks and improve future systems.

All these elements contribute to a cohesive risk management approach, where detection, response, and prevention work together seamlessly.

Conclusion

Hydrogen's promise as a sustainable energy solution must be balanced by an equally strong commitment to safety. Structured methodologies like HAZOP and HAZID, underpinned by rigorous risk assessment and Process Safety Management, provide a comprehensive framework for prevention and control.

By leveraging technology and proactive planning, industries can mitigate the risks associated with hydrogen leaks, ensuring operational continuity and the safety of workers and communities. As hydrogen becomes more central to the global energy mix, these measures are not optional they are imperative.

1 note

·

View note

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

ARMxy RK3588 Embedded System Ignition Edge for SCADA Applications

BL450 Series ARM Embedded Computer is an industrial-grade ARM controller with flexible I/O configuration, based on the Rockchip RK3588J/RK3588 processor, featuring a quad-core ARM Cortex-A76 + quad-core ARM Cortex-A55 + triple-core ARM Cortex-M0 architecture, witha clock speed of up to 2.0G/2.4GHz. It is equipped with 32GB/64GB/128GB eMMC and 4GB/8GB/16GB LPDDR4X RAM and ROM configurations. Supporting a rich set of I/O interfaces, it also integrates a 6TOPS NPU, enabling deep learning capabilities. The BL450 series iswidely used in industrial control, edge computing, AIoT, artificial intelligence, communication management, AGV robots, machine vision inspection, robotics, industrial IoT gateways, energy storage systems, automation control, and transportation infrastructure.

BL450 Series ARM Embedded Computer offers 1 to 3 optional RJ-45 network ports, including two 10/100/1000M ports and one 10/100M adaptive port, along with 2×USB 3.1, one optional HDMI 2.1, and optional X-series and Y-series I/O boards for communication, PWM output, pulse counting, and other data acquisition and control functions. It supports 8K@30fps H.264 video encoding and 8K@60fps H.265 video decoding. Built-in Mini PCIe interface allows support for Bluetooth, WiFi, 4G, and 5G communication modules.

BL450 Series supports multiple operating systems, including Linux-5.10.209, Linux-RT-5.10.209, Ubuntu 20.04, Debian 11, and Android 13. It is also compatible with Docker containers, Node-Red, and Qt-5.15.10 for graphical development. The BLIoTLink industrial protocol conversion software enables fast industrial data acquisition and conversion, facilitating seamless integration with mainstream IoT cloud platforms and industrial SCADA software. Additionally, the BLRAT remote access tool provides remote access and maintenance, while Node-Red allows for rapid IoT application development.

Designed with professional electrical performance and high/low-temperature testing, the BL450 series operates reliably under harsh electromagnetic interference and extreme temperatures ranging from -40°C to 85°C. With DIN35 rail mounting, it is suitable for various industrial applications.

0 notes

Text

Ignition is a leading SCADA solution provider based in India. With a strong focus on innovation and cutting-edge technology, Ignition offers comprehensive solutions for industrial automation, including real-time data monitoring, control, and visualization. Their robust and customizable software platform is designed to meet the unique needs of various industries, helping businesses optimize their operations and improve their bottom line. Trust Ignition to power your automation needs and drive your success forward.

0 notes

Text

Low-Code Revolution: Building Rapid Industrial Applications with Ignition Perspective

Coding Fatigue Is Real — and It’s Slowing Down Innovation

Think about your last software project on the plant floor. Did it stall due to scarce dev resources? Did it take months to go from concept to screen?

You're not alone.

Many manufacturing teams feel stuck between complex custom code and one-size-fits-all SCADA systems. But there’s a better way now — one that brings speed, flexibility, and control back to your team:

Welcome to the low-code industrial automation movement.

What Is Low-Code—and Why Does It Matter for SCADA?

Low-code platforms let your team design and deploy industrial apps with minimal hand-coded logic. Instead of building everything from scratch, you use intuitive drag-and-drop tools and reusable components to get from prototype to production — fast.

In a world where operational agility is gold, this means:

· Less reliance on rare developer skills

· Shorter turnaround for new interfaces

· More ownership at the plant level

When paired with a powerful SCADA app builder like Ignition Perspective, low-code goes from a buzzword to a breakthrough.

Why Industrial Teams Are Embracing Low-Code SCADA Platforms

1. Speed Without Sacrifice Build mobile-responsive HMIs, dashboards, and control views in hours — not weeks. With Perspective’s web-based design, updates roll out in real time across devices.

2. Flexibility to Fit Your Flow Need a maintenance dashboard that works on a tablet? Or a KPI tracker that updates in real time from your MES? You can build exactly what you need — and tweak it as you go.

3. Collaboration Without Silos Your engineering, IT, and operations teams can work together in one visual environment. No more passing code between departments or waiting for dev bandwidth.

4. Rapid SCADA Deployment Across Plants Low-code tools make it easier to scale — and standardize — apps across multiple facilities, reducing complexity and improving visibility from top floor to shop floor.

Real-World Wins: When Custom Meets Quick

One operations head at a packaging manufacturer recently shared their experience:

“We rolled out a downtime tracker built in Perspective — no external developers, no long wait. Just a clean interface our team actually uses, deployed across three sites in two weeks.”

That's the promise of industrial application development powered by low-code: solutions that feel tailored, yet deploy like off-the-shelf tools.

Technology Is Just the Start — People Make It Work

Behind every dashboard and alert is a team trying to solve real challenges. That's why great low-code tools don’t just empower faster builds — they empower your people to lead digital transformation on the ground.

Whether you’re an engineer tired of waiting on IT or a plant manager with a dozen apps on your wishlist, the right low-code SCADA platform helps you move from idea to impact faster.

Your Plant, Your Pace, Your Platform

This isn’t about replacing your existing systems overnight. It’s about augmenting them with agile tools that make everyday work easier — from operator screens to executive insights.

Low-code in industrial automation isn’t a trend. It’s a response to a clear need: speed, flexibility, and control — without sacrificing stability.

Ready to Explore What You Could Build in a Week?

Let’s talk about your SCADA goals and explore how Ignition software SCADA combined with low-code development can help you bring them to life faster and smarter.

0 notes

Text

Automation Systems Texas | Ignition Software | SCADA System | IIoT

Kymera Systems Inc is an organization specializing in delivering proven, scalable IIoT (Industrial Internet of Things) solutions, as well as the design, installation, and maintenance of automation systems. We provide innovative, stable and secure solutions to a wide range of customers in fields such as Oil & Gas, Water/Wastewater, Power Generation, Food and Beverage, Manufacturing and Industrial processes with the help of our team of qualified experts in electrical, automation, and information systems. In fact, our approach to our client's desire to get the best out of their automation assets can be applied to any industry. Our world-class employees focus their energy on helping businesses meet the challenges of today's new economic realities, such as globalization, competitiveness and ever-changing commodity and energy prices. With an emphasis on cybersecurity, we can either work with your current control and data system to optimize it’s performance or design a new, faster, lower-cost solution to maximize the effectiveness and increase not only the usability and functionality of your control system, but we can also increase your bottom line in the process.

1 note

·

View note

Text

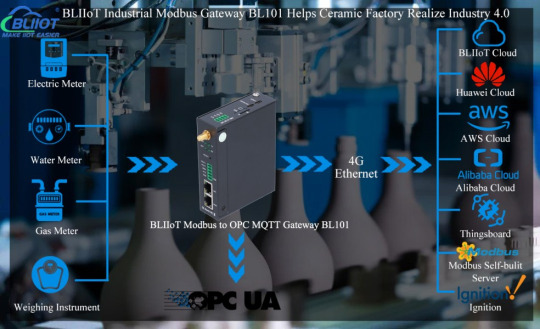

BLIIoT Industrial Modbus to MQTT OPC UA Gateway BL101 Helps Ceramic Factory Realize Industry 4.0

1. Industry 4.0 background

Today, as production lines become increasingly automated, industrial production capacity is rising sharply, and global overcapacity is no longer a new topic. Whoever can fundamentally solve the problem of overcapacity will occupy an important position in the future industry. Putting aside technical appearances such as "digital economy", "Internet of Things" and "cloud computing", you will find that the fundamental purpose of Industry 4.0 lies here - demand guides production, further enhances value creation, and minimizes costs and losses.

2. How does a ceramic factory realize the production process of Industry 4.0?

In order to realize Industry 4.0, the ceramic factory uses BLIIoT Modbus to MQTT OPC UA Gateway BL101 to collect data such as electric meters, water meters, gas meters, and weighing instruments in the ceramic factory, and uploads the data to the cloud through the MQTT protocol. In this way, real-time online monitoring and statistics of energy consumption can be facilitated, and equipment abnormalities can be found in time.

3. What is BLIIoT Modbus to MQTT OPC UA Gateway BL101 ?

Modbus Gateway BL101 is an industrial IoT gateway that converts Modbus RTU and Modbus TCP into Modbus TCP, OPC UA, MQTT, Huawei Cloud IoT, AWS Cloud, ThingsBoard Cloud, Alibaba Cloud, BLIIoT Cloud and other protocols.

BLIIoT Modbus Gateway BL101 adopts embedded Linux system, supports TSL, SSL encryption, provides 1 RS232/RS485 optional serial input, 1 power output, 2 Ethernet ports and 2 USB ports, and supports SIM card and SD card. The built-in 4G network or Ethernet access to the Internet has the characteristics of fast speed and low latency. It supports OpenVPN for secure data transmission.

4. Advantages of using BLIIoT Modbus to MQTT OPC UA Gateway BL101

Data Collection

BLIIoT Modbus to MQTT OPC UA Gateway BL101 collects data such as electric meters, water meters, gas meters, and weighing instruments in ceramic factories. BL101 can connect to instrumentation equipment and collect data through RS232/RS485, Modbus RTU/Modbus TCP protocols, and upload data to the cloud or OPC through MQTT protocol UA and so on. In this way, real-time online monitoring of data and statistics of energy consumption can be realized, and abnormalities can be found in time.

Cloud Monitoring

The BL101 gateway can support BLIIoT Cloud, AWSCloud, Huawei Cloud, Alibaba Cloud, Thingsboard, Modbus self-bulit Server, Ignition SCADA and third-party cloud platforms, and upload data to the cloud platform. Through cloud monitoring, ceramic factories can monitor energy in real time In order to achieve the purpose of energy saving and emission reduction, we can detect abnormalities in time and take measures to adjust them.

Statistical energy consumption

By collecting data such as electricity meters, water meters, gas meters, and weighing instruments, and uploading them to the cloud using the MQTT protocol, energy consumption statistics can be realized to understand usage conditions in real time. In this way, it is convenient for ceramic factories to understand the usage of various energy sources, find problems in time, and take measures to adjust them.

Government Subsidies

In order to promote the development of Industry 4.0, the government provides corresponding subsidies to enterprises that realize Industry 4.0 reform. Ceramic factories can also obtain government subsidies through reforms to reduce the cost of realizing Industry 4.0 and achieve benefits such as energy saving and emission reduction. Get great help for the development of the factory.

5.Conclusion

The BLIIoT Modbus to MQTT OPC UA Gateway BL101 can help ceramic factories realize Industry 4.0. Ceramic factories can monitor and count energy consumption in real time online, detect abnormalities in time, and take measures to adjust to achieve the goal of energy conservation and emission reduction. At the same time, government subsidies can be obtained to reduce the cost of realizing Industry 4.0.

More information about BLIIoT Modbus to MQTT OPC UA Gateway BL101: https://www.bliiot.com/modbus-gateways-p00305p1.html

0 notes

Text

Industrial Automation

In the past, automation was done to save costs connected with human operators and to boost productivity because automated systems can operate around-the-clock (i.e. wages & benefits). Automation's current emphasis is on improving the quality and flexibility of the production process. When pistons were manually installed into engines in the automotive industry, there was a 1–1.5% error rate. Currently, automated equipment with a 0.00001% error rate performs this task.

Industries use automation to boost output, lower labour costs, employee benefits costs, and other related costs while improving precision and flexibility.

A SCADA system gives users additional visibility so they can decide more wisely. For instance, a plant supervisor at a facility that bottles soft drinks would like to have access to information on all of the production lines so that they may increase uptime and decrease downtime. They require tags from all of the manufacturing stations in order to do this

To combine hardware and software in one package, OnLogic has teamed with Inductive Automation. Ignition, a platform provided by Inductive Automation's SCADA system, links all the equipment on your plant floor. Since it is independent of hardware, you may use whatever mix of PLCs, databases, and PCs as you see fit. Decision-makers can make the best choice at the appropriate moment with the help of the robust visualisation and reporting features that are already incorporated into Ignition SCADA software. Additionally, Inductive Automation offers an integrator programme, which gives you the chance to collaborate with certified integration experts in your area to design a comprehensive solution that is ideal for you without having to engage an internal specialist.

We frequently hear from clients who are thinking about purchasing industrial hardware that they can't withstand the downtime brought on by unreliable IT equipment. For instance, American Woodmark chose OnLogic's industrial PCs to replace their outdated desktop towers due to the time wasted sweeping out scrap from CNC equipment. When they switched to a fanless system designed to work in a production setting, downtime decreased to less than 1%. In this customer story, you can read more about the project and the advantages of fanless computing.

For SCADA programmes, the deployment settings vary as much as the sectors they support. Ignition Edge products from OnLogic are designed for deployments in a variety of SCADA applications. We provide products that can withstand dust, heat, shock, vibration, and varying input power. Systems are customised for your project and produced to order. All of our hardware platforms come with choices including an inbuilt 4G LTE modem for remote communication, PoE+ ports for a camera, and a variety of additional features. Use our hardware in conjunction with Ignition Edge to further raise uptime, lower downtime, and boost operational effectiveness.

SCADA consists of both software and hardware elements and enables both local and remote factory supervision and control. Additionally, they gather data in real-time, enabling businesses to manage their industrial operations.

Software for supervisory control and data acquisition (SCADA) is developing quickly. Some clients, however, are unaware of the possible advantages and cost reductions. For instance, improved HMI designs and event processors for things like conveyor stops, pump operating, and generator starts. As a consequence, they give customers a tool to feel secure even while they are away from the business. Therefore, we have only discussed a few of the technological advancements that assist clients in maximising the ROI of their SCADA systems.

On-site and linked to the network's communication infrastructure, the SCADA system is in use. Then, they link remotely to the communication infrastructure and provide data to the cloud or the SCADA system within the cloud network. The operator may then make the appropriate modifications after being able to see any error or aberration in the manufacturing process. As a result, the SCADA system makes it simple to automate these processes, eliminating the need for manual labour.

SCADA software may gather data for analysis, troubleshoot issues before they arise, and find improvements. As a result, the PLCs transmit the data collected from the devices and distribute it to the HMI, operator computers, and servers. Then, the operator may interact with equipment by operating pumps or opening valves,

A detailed understanding of the engineering process being monitored and/or controlled as well as the programming language and related standards is necessary for a SCADA system to operate effectively and safely.

Programming for SCADA may be done in a variety of forms, and the majority of contemporary SCADA packages contain built-in libraries of icons and other tools for visual displays.

The complexity of SCADA programming necessitates knowledge and expertise to grasp. If installed properly, the system will work without a hitch for many years. If put badly, however, the system will probably become unstable and may even result in fatalities.

IPCS

0 notes

Text

ARMxy RK3588 Embedded System Ignition Edge for SCADA Applications

BL450 Series ARM Embedded Computer is an industrial-grade ARM controller with flexible I/O configuration, based on the Rockchip RK3588J/RK3588 processor, featuring a quad-core ARM Cortex-A76 + quad-core ARM Cortex-A55 + triple-core ARM Cortex-M0 architecture, witha clock speed of up to 2.0G/2.4GHz. It is equipped with 32GB/64GB/128GB eMMC and 4GB/8GB/16GB LPDDR4X RAM and ROM configurations. Supporting a rich set of I/O interfaces, it also integrates a 6TOPS NPU, enabling deep learning capabilities. The BL450 series iswidely used in industrial control, edge computing, AIoT, artificial intelligence, communication management, AGV robots, machine vision inspection, robotics, industrial IoT gateways, energy storage systems, automation control, and transportation infrastructure.

BL450 Series ARM Embedded Computer offers 1 to 3 optional RJ-45 network ports, including two 10/100/1000M ports and one 10/100M adaptive port, along with 2×USB 3.1, one optional HDMI 2.1, and optional X-series and Y-series I/O boards for communication, PWM output, pulse counting, and other data acquisition and control functions. It supports 8K@30fps H.264 video encoding and 8K@60fps H.265 video decoding. Built-in Mini PCIe interface allows support for Bluetooth, WiFi, 4G, and 5G communication modules.

BL450 Series supports multiple operating systems, including Linux-5.10.209, Linux-RT-5.10.209, Ubuntu 20.04, Debian 11, and Android 13. It is also compatible with Docker containers, Node-Red, and Qt-5.15.10 for graphical development. The BLIoTLink industrial protocol conversion software enables fast industrial data acquisition and conversion, facilitating seamless integration with mainstream IoT cloud platforms and industrial SCADA software. Additionally, the BLRAT remote access tool provides remote access and maintenance, while Node-Red allows for rapid IoT application development.

Designed with professional electrical performance and high/low-temperature testing, the BL450 series operates reliably under harsh electromagnetic interference and extreme temperatures ranging from -40°C to 85°C. With DIN35 rail mounting, it is suitable for various industrial applications.

0 notes

Text

Ignition is a leading SCADA solution provider based in India. With a strong focus on innovation and cutting-edge technology, Ignition offers comprehensive solutions for industrial automation, including real-time data monitoring, control, and visualization. Their robust and customizable software platform is designed to meet the unique needs of various industries, helping businesses optimize their operations and improve their bottom line. Trust Ignition to power your automation needs and drive your success forward.

0 notes

Text

Why Unified Namespace Architecture Is the Backbone of Industry 4.0 Integration

How to Simplify Data Flow, Empower Teams, and Future-Proof Your Plant

Drowning in Data, Starving for Insight?

You’ve invested in sensors, PLCs, SCADA, MES, and maybe even a few shiny new IIoT platforms. But when your team needs a clear, real-time view of operations across the plant floor… it still feels like you’re piecing together a puzzle with missing pieces.

Each system speaks its own language. Your data is locked in silos. And just trying to answer a simple question like “What’s happening on Line 2?” means logging into three different platforms.

Sound familiar?

That’s where unified namespace architecture comes in — and why more manufacturing leaders are calling it the cornerstone of true Industry 4.0 integration.

What Is a Unified Namespace (UNS)? And Why Does It Matter?

In simple terms, UNS is a single source of truth — a structured, real-time data layer where every device, system, and application publishes and subscribes to live, contextual data.

No more point-to-point integrations. No more fragile data pipelines. Just one cohesive layer of real-time data visibility.

✅ Why It Matters: Instead of building (and constantly maintaining) dozens of connections, you build once — to the UNS. Everything talks through it. It’s cleaner, faster, and infinitely more scalable.

Turning Complexity into Clarity

Without UNS: Your automation engineer is chasing down OPC tags. Your MES vendor wants another custom connector. Your SCADA and ERP are still passing notes via CSV.

With UNS: Everyone — from machines to dashboards to predictive analytics tools — gets their data from one place, in one format, in real time.

✅ The Result? Your plant becomes a data-driven ecosystem, where decision-making is faster, smarter, and aligned.

How It Powers Industry 4.0 Integration

Unified namespace architecture isn’t just an IT convenience — it’s an operational game-changer.

🔹 Connects SCADA and MES systems effortlessly 🔹 Supports modern IIoT architecture with tools like MQTT and Sparkplug B 🔹 Bridges legacy equipment with future-ready applications 🔹 Enables autonomous operations, predictive maintenance, and AI-driven insights

And since it's architected for interoperability, your investments in cloud, automation, and analytics now all work in harmony — not at odds.

Real Impact. Real Results.

We worked with a mid-sized food processing facility recently. They had five systems across two sites, each managed by a different team. Data was delayed, downtime was misdiagnosed, and scaling new lines felt impossible.

INS3 implemented a UNS framework using modern protocols like MQTT and Ignition. Within weeks, their plant teams had:

One unified view of all production lines

Alarms and trends in real time

Seamless SCADA and MES interoperability

A roadmap to scale without rearchitecting systems

The result? 20% faster issue resolution, 40% reduction in reporting lag, and a team that finally felt empowered — not overwhelmed — by their tech stack.

Behind Every Architecture Is a Team That Listens

At INS3, we don’t believe in one-size-fits-all. We believe in partnerships. Our engineers walk your floors, ask the right questions, and design around your people, your priorities, your pace.

We bring 30+ years of industrial automation experience, but we lead with empathy — because technology should solve problems, not create more.

You won’t get buzzwords or cookie-cutter solutions. You’ll get resilient architectures, practical innovation, and a team that’s with you for the long haul.

Let’s Build the Backbone of Your Digital Future

Industry 4.0 isn’t about the next flashy tool. It’s about building a connected, future-ready foundation that empowers your team today — and tomorrow.

And that foundation starts with unified namespace architecture.

📞 Let’s talk. One conversation could unlock the clarity you’ve been chasing for years.

0 notes

Text

Ignition Scada

Company: Scan Infotech Private LimitedExperience: 1 to 4location: Mumbai CityRef: 29168231Summary: Working knowledge in ignition scada Apply for the job now! #Ignition #Scada

View On WordPress

0 notes

Photo

Supervisory control and data acquisition (SCADA) is a system of software and hardware elements that allows industrial organizations to: Directly interact with devices such as sensors, valves, pumps, motors, and more through human-machine interface (HMI) software. Record events into a log file.

The SCADA system utilizes a WAN and LAN networks, the WAN and LAN consist of internet protocols used for communication between the master station and devices. The physical equipment like sensors connected to the PLCs or RTUs. The RTUs convert the sensor signals to digital data and sends digital data to the master.

SCADA systems provide many advantages including increased reliability, reduced costs, improved worker safety, greater customer satisfaction and improved utilization. Their alarms and real-time views into operations can prevent small problems from becoming big ones, and can also speed restoration time.

Request a sample copy of report @ https://www.reportconsultant.com/request_sample.php?id=80997

Key players profiled in the report includes:

Litmus Edge

GENESIS64

Ignition SCADA

SIMATIC SCADA

Action NET

DAQFactory

EisBaer Scada

FactoryStudio

Foxboro IASCADA

IDOM

IntegraXor

Other Giants of the market: ANDRITZ AG, ABB Ltd, Fuji Electric Co., Ltd, General Electric, Hitachi, Ltd, Honeywell International Inc, Mitsubishi Electric Corporation, Siemens AG, Schneider Electric SE, Toshiba Infrastructure Systems and Solutions Corporation

The aim of the report is to equip relevant players in deciphering essential cues about the various real-time market based developments, also drawing significant references from historical data, to eventually present a highly effective market forecast and prediction, favoring sustainable stance and impeccable revenue flow despite challenges such as sudden pandemic, interrupted production and disrupted sales channel in the SCADA Software market.

This research report is an amalgamation of all relevant data pertaining to historic and current market specific information that systematically decide the future growth prospects of the SCADA Software market. This section of the report further aims to enlighten report readers about the decisive developments and catastrophic implications caused by an unprecedented incident such as the pandemic that has visibly rendered unparalleled implications across the market.

Get upto 40% Corporate Discount available on this Report @ https://www.reportconsultant.com/ask_for_discount.php?id=80997

SCADA Software Type

First Generation: Monolithic or Early SCADA systems

Second Generation: Distributed SCADA systems

Third Generation: Networked SCADA systems

Fourth Generation: Internet of things technology, SCADA systems

This report is well documented to present crucial analytical review affecting the SCADA Software market amidst COVID-19 outrage. The report is so designed to lend versatile understanding about various market influencers encompassing a thorough barrier analysis as well as an opportunity mapping that together decide the upcoming growth trajectory of the market. In the light of the lingering COVID-19 pandemic, this mindfully drafted research offering is in complete sync with the current ongoing market developments as well as challenges that together render tangible influence upon the holistic growth trajectory of the SCADA Software market.

Besides presenting a discerning overview of the historical and current market specific developments, inclined to aid a future-ready business decision, this well-compiled research report on the SCADA Software market also presents vital details on various industry best practices comprising SWOT and PESTEL analysis to adequately locate and maneuver profit scope. Therefore, to enable and influence a flawless market-specific business decision, aligning with the best industry practices, this specific research report on the market also lends a systematic rundown on vital growth triggering elements comprising market opportunities, persistent market obstacles and challenges, also featuring a comprehensive outlook of various drivers and threats that eventually influence the growth trajectory in the SCADA Software market.

SCADA Software Geographical Segmentation Includes:

– North America (U.S., Canada, Mexico)

– Europe (U.K., France, Germany, Spain, Italy, Central & Eastern Europe, CIS)

– Asia Pacific (China, Japan, South Korea, ASEAN, India, Rest of Asia Pacific)

– Latin America (Brazil, Rest of L.A.)

– Middle East and Africa (Turkey, GCC, Rest of Middle East)

Some Major TOC Points:

Chapter 1. Report Overview

Chapter 2. Growth Trends

Chapter 3. Market Share by Key Players

Chapter 4. Breakdown Data by Type and Application

Chapter 5. Market by End Users/Application

Chapter 6. COVID-19 Outbreak: SCADA Software Industry Impact

Chapter 7. Opportunity Analysis in Covid-19 Crisis

Chapter 9. Market Driving Force

And More…

In this latest research publication, a thorough overview of the current market scenario has been portrayed, in a bid to aid market participants, stakeholders, research analysts, industry veterans and the like to borrow insightful cues from this ready-to-use market research report, thus influencing a definitive business discretion. The report in its subsequent sections also portrays a detailed overview of competition spectrum, profiling leading players and their mindful business decisions, influencing growth in the SCADA Software market.

0 notes

Photo

***OPENING WITH COTRIX WORKS Pvt Ltd.**** Position- Project Enginèer Position- Permanent Salary - 20k to 30k + bonus+ Onsite Allowance Qualification B.E. / B. Tech (Electronics / Tele-communication, Instrumentation) Or Diploma with 5+ yrs exp Desired experience is 3-4 years Experience in engineering & commissioning of WinCC / RockWell / Wonderware / Ignition . Knowledge of software products & licensing of Scada Must have very Strong Knowledge on WinCC Server Client configuration, WinCC Web Client configuration. Experience in communication Protocols of Siemens,AB TCP/IP, OPC-DA/UA Knowledge of the programming languages (C, C++, VBA) Basic knowledge regarding Database Management eg MSSQL, MySQL, ORACLE Experience in Tag Management of Scada DBs Basic knowledge of Siemens PLC- s7300,400 & 1500, Allen Bradley, etc. Experience in server-client architecture of Scada Experience of unit testing of the SCADA Developing & maintaining tools and procedures for engineering & testing of SCADA Troubleshooting skills Must have Knowledge of working with Macros in MS Excel Ready to learn new technologies Flexible to work in any part of the SCADA development Good Communication Skills, able to work in a team, takes ownership Ready to travel internationally. Passport is must. (at Pravara Rural Engineering College) https://www.instagram.com/p/CKnuIO3MU2-/?igshid=snt0h5tc2cyq

0 notes