#DriveTrain Components

Explore tagged Tumblr posts

Text

📰 TAEVision Engineering 's Posts - Wed, Jul 12, 2023 TAEVision 3D Mechanical Design • Parts AutoParts Aftermarket Precision Universal Joint MOOG Automotive Chassis Steering Suspension • Automotive Machinery Agriculture MercedesBenz GClass IRON Project 01 / 06 • Automotive Fashion NY NYC MercedesBenz SLS AMG 1️⃣ Data 096 Parts AutoParts Aftermarket Precision Universal Joint PrecisionUniversalJoint DriveTrain Components - FederalMogul ▸ TAEVision Engineering's Post on Tumblr 2️⃣ Data 103 Parts AutoParts Aftermarket MOOG Automotive Chassis ChassisParts Steering and Suspension Parts MAKE IT EASY. MAKE IT MOOG. FederalMogul ▸ TAEVision Engineering's Post on Tumblr 3️⃣ Data 282 Automotive Machinery Agriculture Farm Farms Farming MercedesBenz GClass GWagon OffRoad IRON Project 01 Shöckl Suffolk County NY ▸ TAEVision Engineering's Post on Tumblr 4️⃣ Data 264 Automotive Machinery Agriculture Farm Farms Farming MercedesBenz GClass GWagon OffRoad IRON Project 06 Shöckl Suffolk County NY ▸ TAEVision Engineering's Post on Tumblr 5️⃣ Data 358 3D Design Applications Automotive Fashion NY NYC Dreams in Manhattan NY NYC 'where dreams are made' MercedesBenz SLS AMG ▸ TAEVision Engineering's Post on Tumblr

📰 I just updated my Pressfolio: TAEVision Mechanics's Online Portfolio - Global Data - Jul 12, 2023 ▸ TAEVision Mechanics's Online Portfolio (last update)

Global Data - Jul 12, 2023

#TAEVision#engineering#3d#mechanicaldesign#parts#autoparts#aftermarket#Precision Universal Joint#PrecisionUniversalJoint#DriveTrain Components#FederalMogul#MOOG Automotive#chassis#steering#suspension#automotive#machinery#agriculture#MercedesBenz#GClass#GWagon#IRONProject#Suffolk County NY#fashion#NY NYC#Dreams in Manhattan#Manhattan#AMG#SLS#SLS AMG

1 note

·

View note

Text

Strange Oval Yokes Built for Competitive Racing: Drive Like a Pro

Oval track racing is a great sport, but it is also very competitive. To stay ahead of your competition, the driver must use quality products that are built to deliver high-end performance when needed. Strange Oval has a legacy and years of excellence in delivering the best and innovative products for the racing motor vehicles to beat their competition and keep winning. When it comes to oval track racing, you must use Strange Oval Yokes, as they act as a critical connection point between the driveshaft, differential, and transmission, which ensures delivering maximum power transfer during high-speed and vigorous racing conditions.

Yokes for Ultimate Durability and Control

Strange Oval yokes are not just standard replacements—they are precision-engineered to meet the harsh demands of modern racing. Every product is built with the highest quality materials and machining standards to ensure long-lasting performance under pressure.

From front pinion yokes to transmission yokes, each component is crafted to maintain optimal balance, reduce vibration, and ensure maximum torque transfer. These aren't off-the-shelf parts; they are purpose-built for oval racing performance.

Front Pinion Yokes

The front pinion yokes offered by Strange Oval are built from high-grade materials and are designed to work seamlessly with most racing differentials. These yokes help ensure accurate driveshaft alignment, which is essential in preventing premature wear and mechanical failure.

Additionally, their design contributes to smoother power transmission, helping the drivetrain maintain peak efficiency throughout each lap. A Strange Oval yoke for racing guarantees the control and reliability that professional drivers demand.

Lightweight Rear End Yokes

For racing at high speed, racers always look for lightweight components for their vehicle as they provide maximum strength and speed for the track racing conditions. Lightweight rear-end yokes are a perfect match, as they are developed with weight-saving strategies that do not compromise power and structural integrity.

In a sport like motor racing, every millisecond matters a lot and can decide the winner. Therefore, racers should not compromise their small but necessary components that can make a difference. Strange Oval yokes minimize rotational torque and improve the vehicle’s ability to accelerate more quickly out of corners.

Transmission Yokes

Transmission yokes from Strange Oval are available in multiple spline options to suit a variety of driveline setups. These yokes are engineered to handle high loads while maintaining compatibility with commonly used transmission types in oval racing.

Precision fit and minimal backlash ensure that torque delivery remains consistent throughout the race, helping the car maintain better traction and power control.

Strange Billet Yokes: Engineered for Excellence

While all Strange Oval yokes deliver outstanding performance, the Strange Billet Yokes stand out for their exceptional strength and durability. These billet-machined components are created from solid blocks of high-grade steel or aluminum, offering superior resistance to flexing or cracking even in the most extreme conditions.

Engine builders and race teams trust Strange Billet Yokes for their proven reliability and their contribution to overall drivetrain integrity. The increased strength and reduced weight help balance the need for performance with longevity—an essential combination in competitive racing environments.

Why Choose Yokes from Strange Oval?

Strange Oval is an automotive company that builds the best racing components for the racers who want to stay ahead in their competitive sport. They prioritize the racing components that deliver power and are reliable at the rigorous racing tracks. Their yokes are well designed to keep them lightweight, and that meets the standards of racing sport.

Here are some compelling reasons to choose yokes from Strange Oval:

High-performance materials: Aluminum and steel alloys chosen for strength and weight savings

Precision engineering: CNC machining ensures perfect fit and performance consistency

Reduced vibration: Proper balance helps maintain smooth power delivery

Durability under load: Designed for high torque and aggressive racing conditions

Multiple fitment options: Compatibility with a wide range of transmissions and differentials

Final Thoughts

Yokes may not be the most glamorous parts of your build, but they’re vital to making sure your powertrain works as efficiently as possible. From front pinion to rear end to transmission yokes, Strange Oval has built a reputation for precision and quality that racers trust. With products like Strange Oval Billet Yokes, the brand continues to push the boundaries of what’s possible in oval track racing components.

Upgrade your drivetrain with confidence—explore the full range of yokes at Strange Oval and experience the difference that true engineering makes.

#Strange Oval yokes#racing yokes#billet yokes#Strange Billet Yokes#yoke for racing#racing drivetrain parts#aluminum yokes#performance yokes#driveshaft yokes#Strange Oval Racing Parts#lightweight yokes#oval track yokes#precision yokes#U-joint yokes#racing rear end yokes#high performance yokes#racing components#oval racing parts#drivetrain components#Strange Oval yoke for racing

1 note

·

View note

Text

Top 5 Automotive Companies and How Metalman Auto Ltd. Supports Them

The automotive industry is dominated by several key players that lead the market in terms of innovation, production, and market share. The top five automotive companies globally are typically considered to be Toyota, Volkswagen Group, Daimler AG (Mercedes-Benz), Ford Motor Company, and General Motors (GM).

How Metalman Auto Ltd. Supports These Automotive Giants

As a leading supplier of high-quality automotive components, Metalman Auto Ltd. is well-positioned to support these top automotive companies. Our expertise in metal fabrication and assembly allows us to provide critical components that meet the specific needs of these manufacturers.

Our Value Proposition:

High-Precision Components: We provide parts that are essential for the safety and performance of vehicles, adhering to the exact specifications required by these top manufacturers.

Collaborative Approach: We work closely with OEMs to understand their needs and provide innovative solutions that enhance vehicle performance and safety.

Sustainable Manufacturing: Our commitment to sustainable practices ensures we contribute positively to the automotive industry’s environmental goals.

By partnering with Metalman Auto, these top automotive companies can enhance their supply chain efficiency and maintain their competitive edge in the global market.

#EV components supplier#Electric car parts manufacturer#Battery components supplier for EVs#Electric vehicle drivetrain parts supplier#EV charging components manufacturer#Electric motor parts supplier#EV battery management system supplier#Electric scooter parts manufacturer#general motors#vintage automobiles#chevrolet#Volkswagen Group#automotive industry#automotive#automotive components#metal fabrication#oems#oemparts#oem manufacturing#oem#metal parts supplier#India automotive components manufacturer#Automobile parts production in India#OEM parts manufacturing in India#Indian automotive parts supplier#Vehicle parts manufacturing industry in India#Made in India automotive components#Indian car parts production#India-based automotive parts manufacturer"

2 notes

·

View notes

Text

Top Quality Driveline Components for Drag Racing | Strange Engineering

Explore race-proven driveline components built for strength, precision, and durability. From driveshafts to yokes, Strange Engineering delivers unmatched performance on the street or strip.

Our Key Driveline Components:

Chrome-Moly Driveshafts

Aluminum Driveshafts

Transmission Yokes

Rear End Yokes

Pinion Couplers

U-Joints

Contact Information:

For more details or to request a sample, visit Strange Engineering’s driveline components or contact Strange Engineering directly:

Phone: 800-646-6718

Visit: https://www.strangeengineering.net/

Address: 8300 N. Austin Ave, Morton Grove, IL

Stay in touch with the latest product developments and company news:

Facebook

Youtube

X

Instagram

#Driveline Components#Racing Driveline Parts#Drag Racing Driveline#Performance Driveshafts#U-Joints and Yokes#Strange Driveline#Drivetrain Parts#High-Performance Driveline#Street & Strip Driveline#Strange Engineering Driveline

1 note

·

View note

Text

1970 Dodge Challenger

This 1970 Dodge Challenger Has a Rare Feature You Probably Never Knew Existed

Introduced for the 1970 model year, the original Dodge Challenger was short-lived, being retired at the end of 1974. However, four years were enough for it to become an iconic nameplate. More than 50 years later and the first-generation Challenger is also a sought-after collectible.

With total production at almost 77,000 units, the 1970 Challenger is far from rare overall. Still, some versions are tricky to find nowadays. The HEMI variant is arguably the rarest at 356 examples made, including 60 cars fitted with the Special Edition package and only nine convertibles. The latter is rare in 440 and 440+6 guises, too, with only 163 and 99 units sold, respectively.

Conversely, the non-R/T cars are far more accessible, with about 56,000 units built. Interestingly enough, the base six-cylinder version is rarer at a little more than 10,000 examples. This leaves the non-R/T V8 cars as the most common, at 45,367 units. The list includes Challengers fitted with 318-, 340-, and two-barrel 383-cubic-inch (5.2, 5.6, 6.3-liter) mills.

Unfortunately, there's no production breakdown for each engine, so models fitted with them are usually considered mundane. But it's not always like that because some of these cars came with options that turned out to be rare. Like the Dark Burnt Orange example you see here, which carries the A66 340 Performance Package.

Available with the four-barrel version of the 340-cubic-inch V8 (less potent than the 3x2-barrel offered in the Challenger T/A), the bundle came with goodies such as Rallye wheels, heavy-duty brakes and suspension, wheel lip molding delete, and an R/T Performance hood. It's basically an R/T-like Challenger without a big-block engine.

So how rare are these A66-equipped Mopars? There are no specific figures to run by, but word has it only a few thousand units were ordered like this. But that's not the only thing that makes this Challenger rare. It's the fact that it's a very early A66 Performance Package model, a piece of info determined by the "340 four-barrel" decal on the hood.

You see, Dodge changed the decal to a metal badge after a few months, and the guy who restored this car claims it's a super-rare feature. Moreover, this Challenger was also fitted with a locking gas cap, yet another rare option from the 1970 model year. Too bad there are no records to determine how scarce this specific configuration is, but we're looking at fewer than ten units if we also include the color.

Rare features aside, this Challenger is also one of the very few classic muscle cars that have been in the same family since new. And as you might have already guessed, it got a rotisserie restoration a few years back. But it's still very original, down to numbers-matching body panels and drivetrain components. It's also proof that a Mopar doesn't necessarily need a 426 HEMI to stand out.

#dodge challenger#challenger#car#cars#muscle car#american muscle#mopar#moparperformance#moparworld#moparnation#dodge#plymouth

126 notes

·

View notes

Video

324 Morris Minor 4 door (Series V) (1968) TPG 156 F by Robert Knight Via Flickr: Morris Minor 1000 Series V (1962-72) Engine 1098cc S4 OHV Production 847,491 (Series III and Series V) Registration Number TPG 156 F (Surrey) MORRIS ALBUM www.flickr.com/photos/45676495@N05/sets/72157623690377489... Designed by Sir Alec Issigonis for William Morris's Nuffield Group the Morris Minor made its debut at the 1948 Earls Court Motorshow . The original Minor MM series was produced from 1948 until 1953, the range included a 2 door and 4 door four seater saloon, and a convertible An instant success and the baby car of its day, the new car featured rack and pinion steering, torsion bar independent front suspension and superb handling. Although the Minor was originally designed to accept a flat-4 engine, late in the development stage it was replaced by a 918 cc S4 side valve engine. The Series II was substantially re-engineered following the merger of the Nuffield Organisations merger with Austin (forming BMC), Cosmetically the car now had raised front lights in the wings, rather than at the sides of the grille. As part of a rationalisation programme to reduce the production of duplicate components for similar vehicles, the Minor drivetrain was completely replaced with an Austin-derived engine, gearbox, prop shaft, differential and axle casing. The more modern Austin-designed 803 cc (49.0 cu in) overhead valve A-series engine, designed for the Austin A30 which proved more lively than the 918cc SV it replaced. An estate version was introduced in 1952, known as the Traveller featuring an external structural ash (wood) frame for the rear bodywork, with two side-hinged rear doors. A horizontal slat grille was fitted from October 1954,[ as well as a new dashboard with a central speedometer 269,838 examples of the Series II had been built when production ended in 1956 In 1956, the Minor received a major programme of updates as the Series III Minor 1000. Now powered by a 948cc variant of the BMC A-Series engine, which increased fop speed from 63mph to 75mph. the engine was mated to a revised gearbox with longer ratios and a shorter gearchange. A series of changes to the body pressings allowed a wraparound rear windscreen and a curved front screen In 1961 the semaphore-style trafficators were replaced by flashing direction indicators In 1962 the final Series Minor 1000 (ADO 59) was launched the 'Series IV' designation having been assigned to the Morris Mini Minor. A new, larger 1098cc version of the BMC A Series engine with a Harry Weslake designed cylinder head Although fuel consumption suffered moderately at 38 mpg, the Minor's top speed increased to 77 mph and a significant increase in torque, this revised engine was mated to a new stronger gearbox and the size of the front drum brakes increased. The interior was refreshed, and revised again in 1964. Diolch am 92,828,339 o olygfeydd anhygoel, mae pob un yn cael ei werthfawrogi'n fawr. Thanks for 92,828,339 amazing views, every one is greatly appreciated. Shot 23.04.2022 at the Bicester Spring Scramble, Bicester, Oxfordshire 158-324

#Morris#British#1960s#1968#Morris.Minor#BMC#BMC.A.series#Sir.Alec.Issigonis#William.Morris#Swinging.Sixties#ADO58#Bicester.April.2022#TPG156F#Registered.in.Surrey#1945-70#Auto#Automobile#Car#cars#Classic#Motor#worldcars#flickr

21 notes

·

View notes

Text

1969 S14-Powered BMW 2002: currently on Craigslist. Here's a link.

"Offered for sale is this modified 1969 BMW 2002, a unique and well-executed build that combines vintage charm with modern performance enhancements. This example features a wide array of mechanical upgrades and cosmetic modifications designed to improve handling, driving dynamics, and style, while preserving the engaging driving experience BMW is known for.

Exterior & Body: The car is finished in Alpine white with a tasteful blue vinyl accent wrap, which can be removed if the new owner desires. The standout feature of this 2002 is its Alpina widebody kit, often referred to as "pig cheeks," which gives the car a muscular stance. It sits on 13-inch Minilite wheels wrapped in Toyo R888R tires that look to be nearly new, offering excellent grip for spirited driving. Other exterior modifications include a Koogle Works front lip, chrome molding delete, and a brand-new rear bumper. The bodywork shows some imperfections typical of a driver-focused car but remains in good overall condition.

Interior: The interior of this 2002 is equally well-appointed, featuring black vinyl seats with cloth inserts. The front seats are E21 Recaro buckets, while the rear seats have been upgraded to BMW E24 units, reupholstered in classic houndstooth fabric. The dashboard is in excellent condition, crack-free, and complemented by modern Alpina-style instrument cluster gauges for improved visibility and style. Additional updates include a suede Personal steering wheel, Alcantara headliner, and new carpeting and door panels.

Mechanical & Drivetrain: Under the hood, the car is powered by an S14 engine sourced from an E30 M3, with 105k miles on the donor motor. This engine provides significant performance improvements over the original powerplant, and is paired with a 5-speed manual transmission and a limited-slip differential (LSD) for improved handling and driving dynamics. The suspension has been upgraded with BC coilovers at the front and Bilstein shocks at the rear, providing an excellent balance of comfort and performance. Volvo front calipers help provide increased braking power, while the custom exhaust system adds a distinctive note to the driving experience. Other notable mechanical modifications include a relocated battery to the trunk, a strut brace, and an E21 radiator. The car also features a brand-new OEM clutch and fresh front and rear glass.

Electrical & Features: While most electrical components work as expected, the driver’s side blinker and the horn are currently non-operational. The car features a complete set of beautiful modern instruments and gauges, adding a sleek and functional touch to the cabin.

Condition: This 1969 BMW 2002 is in great running condition, with no rust present and a clear, clean title. While there are minor imperfections in the bodywork, it is far from a concours-level show car. Instead, this is a well-built, reliable example designed to be driven hard and enjoyed on the road. The car has never been involved in any accidents, and its modifications were made with performance in mind.

Included in the Sale: The sale includes no additional accessories, as the car is being offered as is. The new owner will enjoy a truly engaging driving experience, thanks to its upgraded suspension, potent engine, and timeless BMW styling.

Known Issues:

The driver’s side blinker and horn are currently not working.

Minor imperfections in the bodywork.

Will provide service history upon request.

This car is a fantastic example of a classic BMW that has been thoughtfully upgraded with performance-oriented parts while maintaining its iconic 2002 driving experience. With its combination of modern performance and vintage style, it is a true driver’s car that’s ready to be enjoyed."

7 notes

·

View notes

Video

youtube

Ford Mustang GTD 2025 - Full Tech Specs and Performance

The 2025 Ford Mustang GTD is a track-focused, street-legal performance vehicle engineered as a homologation-style special. Developed alongside the Mustang GT3 race car, the GTD integrates motorsport-derived technology into a road car format.

At the core is a supercharged 5.2-liter V8 engine, targeting over 800 horsepower. It utilizes a dry sump oiling system, enabling consistent lubrication during high-G cornering and reducing engine height for improved center of gravity. The redline exceeds 7,500 RPM. Power is sent to the rear wheels via an 8-speed rear-mounted dual-clutch transaxle, contributing to a near 50:50 front-to-rear weight distribution.

The Mustang GTD rides on a semi-active suspension with adaptive spool-valve dampers developed by Multimatic. The system features hydraulically adjustable ride height. In Track Mode, the car lowers by approximately 40 millimeters, enhancing aerodynamic efficiency and handling precision. The front suspension uses unequal-length control arms, while the rear features an integral link design, both tuned for high-performance cornering loads.

Aerodynamically, the car employs an active rear wing, integrated with a hydraulically controlled Drag Reduction System. Underbody components include a full carbon fiber belly pan with venturi tunnels to generate downforce. Optional aerodynamic enhancements include carbon fiber front splitters, dive planes, and rear diffusers. At speed, the car produces significant downforce, improving lateral grip and high-speed stability.

Braking is managed by carbon ceramic rotors—400 millimeters in front with six-piston Brembo calipers. The system is designed for repeated high-speed deceleration with minimal fade. The wheels are forged magnesium, available in 20-inch diameter, reducing unsprung mass and improving responsiveness. Tire specification includes Michelin Pilot Sport Cup 2 R, sized 325 in front and 345 in rear, mounted on 11.5 and 12.5 inch-wide wheels respectively.

The GTD also includes a titanium active-valve exhaust system, a front trunk due to the transaxle configuration, and extensive use of carbon fiber for the body panels, contributing to a targeted curb weight below 3,900 pounds.

Performance figures include a projected Nürburgring lap time under 7 minutes, and 0–60 mph acceleration estimated in the low 3-second range. Top speed is electronically limited but expected to exceed 190 mph.

Pricing starts at approximately $300,000 USD. Production will be limited, with availability beginning in late 2024. Given its motorsport pedigree, carbon composite materials, and performance engineering, the GTD positions itself as a high-value offering relative to exotic track-focused vehicles in the same price category.

2025 Ford Mustang GTD – Technical Specifications Powertrain Engine: 5.2-liter V8, supercharged

Horsepower: Targeting over 800 hp

Redline: over 7,500 RPM

Lubrication: Dry sump oil system

Exhaust: Titanium active-valve exhaust

Transmission Type: 8-speed dual-clutch transaxle (rear-mounted)

Drivetrain: Rear-wheel drive - RWD

Weight Distribution: Near 50:50

Chassis & Suspension Front Suspension: Unequal-length double wishbone

Rear Suspension: Integral link, independent

Damping: Multimatic adaptive spool-valve semi-active dampers

Ride Height Adjustment: Hydraulic, lowers ~40 mm in Track Mode

Brakes Front Brakes: Carbon-ceramic, ~400 mm rotors, 6-piston Brembo calipers

Rear Brakes: Carbon-ceramic, multi-piston calipers

Brake Cooling: Integrated ducts, track-optimized airflow

Wheels & Tires Wheels: 20-inch forged magnesium

Front Tires: 325 mm width – Michelin Pilot Sport Cup 2 R

Rear Tires: 345 mm width – Michelin Pilot Sport Cup 2 R

Wheel Widths: Front: 11.5 in | Rear: 12.5 in

Aerodynamics Rear Wing: Active, hydraulically adjustable

Drag Reduction System DRS: Integrated

Underbody: Carbon fiber venturi tunnels, full-length belly pan

Front Aero: Carbon splitter, dive planes optional

Rear Aero: Carbon fiber diffuser optional

Body & Dimensions Body Material: Carbon fiber hood, fenders, roof, rear cover, doors optional

Chassis: Based on Mustang GT3 architecture

Estimated Curb Weight: Under 3,900 lbs (targeted)

Performance 0–60 mph: Low 3-second range est.

Top Speed: over 190 mph electronically limited

Nürburgring Target Time: Sub-7 minutes

Interior & Features Seats: Track-oriented, Recaro-style racing seats

Storage: Front trunk (due to rear transaxle)

Infotainment & Tech: TBD – focused on performance, not luxury

Production & Pricing Production Start: Late 2024

Availability: Limited-run, application-based allocation

Base Price: around $300,000 USD (estimated)

6 notes

·

View notes

Text

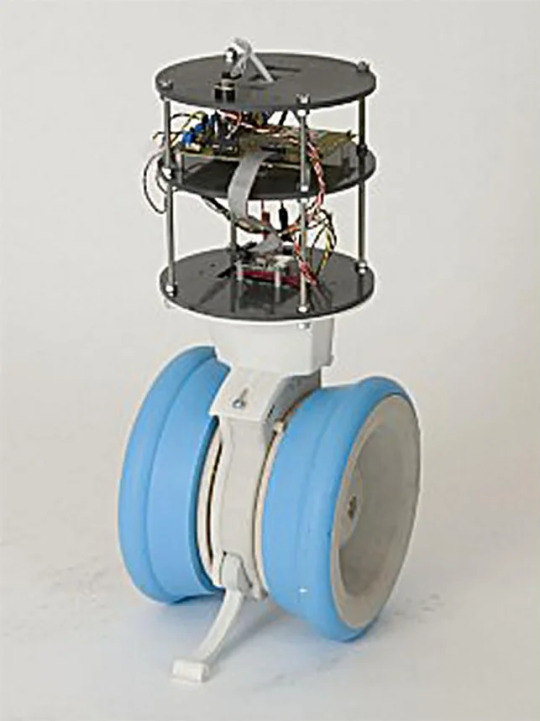

Glass Man (2006) by Ted Larson and Bob Allen, OLogic, CA, USA. Glass Man is the first real prototype of AMP, the "Automated Music Personality". The lower photo shows the prototype drivetrain for AMP, built at the same time.

"Hasbro thought that our balancing-robot idea could become a great consumer product, so they made the investment to start turning Flexo into something that could be sold as a toy. The first step was to get rid of the surplus parts and integrate consumer-grade components and motors. There were two robots made: One was a full 3D-printed prototype that was fragile as glass, and the other was just the drive system with our existing electronics mounted on it.

We broke both of these prototypes more times than I can remember. Every time it broke, I would call up Bob, and he would come over and we would figure out a clever way to glue it back together. After tons of trial and error we eventually had something that worked, and then it was time to make the real product. After a few trips to China and meeting some fantastic manufacturing experts, and a bunch more work on our part, we finally had the real product ready to go." – Ted Larson, From HomeBrew to Hasbro How two friends hacked a balancing robot and wrote a toy story of their own.

31 notes

·

View notes

Note

hi !!!! heard in the grapevine u do fs !!! whats ur position !!

hello!! glad to see another student saw team enjoyer on the interweb!!!! sorry i took so long to reply i had finals and then i moved out and started a new job etc etc

but first i do baja sae (not formula sae) which is a slightly different racing series. my uni doesn’t have fear (rip) but honestly as a meche i think baja is more interesting. its off road racing and the main event is a 4hr long wheel-to-wheel (there’s 100 different cars on track at once) endurance race and it’s very cool! just not fsae

with that said i work mostly on drivetrain parts :) design/analysis of drivetrain components, and then sometimes i’ll hop into the machine shop and churn something out

i also work on some logistical stuff like onboarding and cost events :P

4 notes

·

View notes

Text

TAEVision 3D Mechanical Design Parts AutoParts Aftermarket Precision Universal Joint PrecisionUniversalJoint DriveTrain Components - FederalMogul ▸ TAEVision Engineering on Pinterest ▸ TAEVision Engineering on Google Photos

Data 096 - Jul 12, 2023

#TAEVision#engineering#3d#mechanicaldesign#parts#autoparts#aftermarket#Precision Universal Joint#PrecisionUniversalJoint#DriveTrain Components#DriveTrainComponents#FederalMogul

1 note

·

View note

Text

Pinion Retainers for Unmatched Gear Stability | Strange Oval

Pinion Retainers from Strange Oval offer unmatched gear stability and strength for high-performance racing. Designed for durability, they keep your drivetrain aligned and reliable under the toughest track conditions.

Contact Information:

For more details or to request a sample, visit Pinion Retainers or contact Strange Oval directly:

Phone: 800-653-1099

Choose the Pinion Retainers for reliable and efficient performance.

Stay in touch with the latest product developments and company news:

Facebook

Youtube

X

#pinion retainers#Strange Pinion Retainers#racing pinion retainers#oval track pinion retainers#high performance pinion retainers#rear end components#drivetrain stability#race car pinion retainer#dirt track pinion retainer#asphalt racing pinion parts#Strange Oval pinion retainers#pinion support#rear end gear support#racing rear end parts#precision pinion retainers#durable pinion retainers#pinion gear stability#competitive racing components#Strange Oval racing parts#professional racing drivetrain

1 note

·

View note

Text

All Hard Parts for Motorcycle: Essential Upgrades for Performance and Safety

Motorcycles are more than just machines—they're expressions of freedom, power, and personal style. Whether you're a casual rider or a performance enthusiast, upgrading and maintaining your bike's hard parts is key to ensuring it runs smoothly, looks sharp, and remains safe on the road. These components form the mechanical backbone of your motorcycle, affecting everything from how it handles to how fast it goes.

What Are Motorcycle Hard Parts? Hard parts refer to the essential mechanical and structural components of a motorcycle. These are not cosmetic or soft accessories like seat covers or tank pads—they're the parts that keep the bike running and safe to ride. Common examples include engine parts, suspension systems, brakes, wheels, and frames. Unlike aesthetic upgrades, hard parts directly influence performance, safety, and durability.

Main Categories of Motorcycle Hard Parts Engine components include pistons, valves, camshafts, and crankshafts. Upgrading or replacing these can significantly improve your bike’s horsepower and responsiveness. Exhaust systems are another critical area, comprising headers, pipes, mufflers, and catalytic converters. A performance exhaust can reduce weight, increase power, and give your motorcycle a more aggressive sound. Suspension systems, such as forks, rear shocks, and swingarms, control how your bike handles and absorbs bumps. Quality suspension upgrades offer better control, smoother rides, and safer handling, especially at high speeds or rough terrain. Brake systems consist of rotors, calipers, pads, and master cylinders. These are essential for safety. Upgrading your braking system enhances stopping power and reduces brake fade during aggressive or prolonged riding. Transmission and drivetrain parts like clutches, chains, sprockets, and gearboxes dictate how power from the engine reaches the wheels. High-performance parts ensure smoother shifting, quicker acceleration, and better efficiency. Wheels and tires are foundational for traction, balance, and speed. Lighter wheels and high-performance tires can drastically change how your bike feels on the road or track. The frame and subframe are the bike’s skeleton, supporting every other part. Some riders choose lightweight frames for racing performance, while others upgrade for aesthetics or specific riding ergonomics. Controls and levers such as handlebars, footpegs, brake levers, and shifters are not just for comfort—they’re critical for proper bike control. Premium components offer better grip, adjustability, and feedback. Cooling systems like radiators, hoses, and fans are essential for high-performance engines to avoid overheating and maintain consistent power output. Fuel system parts, including tanks, pumps, injectors, and carburetors, affect how fuel is delivered and consumed. Efficient systems lead to better mileage and smoother throttle response.

Why Should You Upgrade Hard Parts? Upgrading hard parts enhances your motorcycle’s performance, making it faster, more responsive, and more reliable. It also adds to customization, allowing your bike to match your personal style or riding needs. High-quality hard parts offer better durability, meaning fewer breakdowns and lower maintenance in the long run. Most importantly, they improve safety—better brakes, suspension, and control systems make every ride more secure and predictable.

OEM vs. Aftermarket Hard Parts When upgrading your motorcycle, you'll face the choice between OEM (Original Equipment Manufacturer) and aftermarket hard parts. OEM parts are made by the bike's manufacturer and are guaranteed to fit and perform to factory standards. However, they tend to be more expensive and offer limited customization. On the other hand, aftermarket parts are made by third-party companies and come in a wide variety of designs and performance levels. They're often more affordable and customizable, but quality can vary. To ensure safety and reliability, it's crucial to choose well-reviewed brands and parts that are specifically designed to fit your motorcycle model.

Tips for Choosing the Right Hard Parts Before purchasing or installing hard parts, always check your motorcycle’s specifications. Knowing your bike’s make, model, and year helps ensure compatibility. Be clear about your goals—whether it’s increasing speed, improving ride comfort, enhancing safety, or achieving a specific look. Take time to research the best brands, read rider reviews, and if needed, consult with a mechanic for proper installation and advice.

Conclusion Investing in all hard parts for motorcycles is not just about upgrades—it's about transforming your machine into a safer, more efficient, and more personalized ride. From the engine to the brakes, each component plays a vital role in your motorcycle’s performance. Whether you’re tuning your bike for speed, comfort, or endurance, quality hard parts are essential. Choose wisely, maintain regularly, and enjoy the power and freedom your upgraded motorcycle can deliver.

#tail bags for motorcycles#tank bags#motorsport#motorcycle#hydration pack#motorcycle tail bags#motorcycle luggage#motorcycle accessories#motorbike#essential series

2 notes

·

View notes

Text

Race-Proven Driveline Components for Drag Racing by Strange Engineering

Strange Engineering delivers precision-engineered driveline components designed to handle the intense demands of drag racing and high-powered street applications. Whether it’s U-joints, transmission yokes, driveshafts, or pinion couplers, every part is built for unmatched strength, long-term durability, and proven track performance.

Our Key Driveline Components:

Chrome-Moly Driveshafts

Aluminum Driveshafts

Transmission Yokes

Rear End Yokes

Pinion Couplers

U-Joints

Contact Information:

For more details or to request a sample, visit Strange Engineering’s driveline components or contact Strange Engineering directly:

Phone: 800-646-6718

Visit: https://www.strangeengineering.net/

Address: 8300 N. Austin Ave, Morton Grove, IL

Stay in touch with the latest product developments and company news:

Facebook

Youtube

X

Instagram

#Driveline Components#Racing Driveline Parts#Drag Racing Driveline#Performance Driveshafts#U-Joints and Yokes#Strange Driveline#Drivetrain Parts#High-Performance Driveline#Street & Strip Driveline#Strange Engineering Driveline#Strange Engineering driveline components#high-performance racing driveline parts#custom driveshafts for drag racing#heavy-duty U-joints and yokes#performance drivetrain solutions#driveshaft yokes for race cars#complete drag racing driveline kits#street and strip driveline upgrades#performance rear driveline systems#Strange Engineering drivetrain products

1 note

·

View note

Text

1970 Dodge Challenger T/A

1970 Dodge Challenger T/A Sitting for 45 Years Is a Rare Barn Find in Sublime Green

Introduced in 1969 on the then-new E-body platform, the first-generation Dodge Challenger was a big hit, moving nearly 77,000 units in its first year on the market. And while it may seem rather common, the 1970 Challenger lineup included a few rare gems.

Nearly 73% of the cars were ordered in standard trim, leaving only 18,512 R/T models. Most of the latter left the assembly line with the 383-cubic-inch (6.3-liter) V8, and just 6,231 units were specified with the larger 440-cubic-inch (7.2-liter) RB and 426-cubic-inch (7.0-liter) HEMI mills.

The HEMI is arguably the rarest 1970 Challenger, with only 356 examples made. Just 60 were also ordered with the SE package, and only nine were convertibles. The 440 Six Pack version is also rare at 2,035 examples, while the regular four-barrel 440 found its way into 3,840 vehicles.

But Dodge also built a small-block gem that saw daylight in limited numbers. I'm talking about the Challenger T/A. Developed to homologate the Challenger for the SCCA Trans-Am series, the T/A was available for only a few months in 1970. And its short stint on the assembly line resulted in only 2,399 street-legal models being built and sold.

The T/A packs several unique features, including a low-restriction exhaust system with side-exiting pipes, a larger air scoop, a fiberglass hood, and a heavy-duty suspension. The stripe package is also unique to this car, as is the 340-cubic-inch (5.6-liter) V8 with a triple two-barrel carburetor setup.

An upgrade over the more common four-barrel 340, the Six Pack layout gave the T/A 290 horsepower to play with. And even though it's nowhere near as powerful as the big-block cars, the T/A has a solid advantage in terms of curb weight and handling.

Come 2023, the T/A is one of the most desirable versions of the 1970 Challenger. And while many cars are still around as restored gems, some are rotting away in junkyards and barns, often missing vital components. The Sublime green example you see here is one of them. But unlike other abandoned T/As, this survivor got a second chance at life, and it's roaming the streets again.

Documented by YouTube's "Auto Archaeology," this T/A spent most of its life off the road. According to our host, the Challenger was parked for unknown reasons sometime in 1977. So that's only seven years on the road and more than four decades in storage.

Parked with a four-barrel carburetor instead of the Six Pack setup, it remained in storage in Memphis and Arkansas until 2022. That's when the car was sold and dragged out of its barn. And surprisingly enough, the T/A emerged in surprisingly solid condition.

Sure, the Sublime paint has faded away, and the black vinyl top is long gone, but the body is straight and almost rust-free. There's some rust on the trunk floor, but it's an easy fix with a regular Challenger pan, which is relatively easy to find.

The engine bay was empty at the time of the rescue, but the car still had the original block. And even though the Six-Pack carb was gone, it came with a period correct unit. The driveshaft, air cleaner, automatic gearbox, and the original wheels (which are very rare) were still with the car.

Speaking of which, the automatic makes this T/A one of 1,410 vehicles built with this drivetrain combo. The vinyl top decreases that number even more. It's unclear if it came with a V1G gator grain top, but if it did, it's one of only 33 T/As built like this.

But the really good news about this Challenger is that it has since been revamped and put back on the road. It hasn't been restored just yet, but it's not a solid survivor that's no longer rotting away in a barn. And that's a win in my book.

#Dodge Challenger T/A#dodge challenger#dodge#challenger#T/A#car#cars#muscle car#american muscle#mopar#moparperformance#moparworld#moparnation#challengers

75 notes

·

View notes

Text

It's not particularly a historic site, or a monument, and none of the signs on the distant, roaring highways acknowledge it, a dilapidated metal shed off the side of a dusty backroad.

The roof is partially collapsed, wild grasses erupting through fissures in an ancient concrete floor, morning sunlight pouring across exposed trusses.

The charred, mangled wreck of a proud steel warrior sits still and silent, carapace bent outwards from the force of a long-forgotten explosion.

Faded, chipped red paint and hundreds of stickers are scorched nearly beyond recognition and rust creeps across scorched panels just as the vines climb her structures, brilliant spring flowers soaking in the sunlight along the steel hulk that used to be a body.

Nothing remains to function. Battery detonated, wiring and other important components melted, drivetrain annihilated in the blast.

The remnants of her processor, a cubic metal case, sit cold and dull, nestled in the deepest depths of the twisted steel statue.

Of course they couldn't save her when they'd found her in the rubble of the corpo skyscraper. There was nothing to repair, nothing even salvageable. But they wouldn't let those fuckers have her in death.

They smuggled the wreckage out under forged papers, used the last of her credits to have her sent home, sent here.

Some would consider it unfair that her death befit no monument, no great statue, no historical plaque.

But her actions live on. The records of a thousand robots working off debts, working under threat of repossession or reprogramming or worse-- destroyed.

She had accomplished what she had set out to do.

She had given her life meaning.

Self-determined.

Proved a machine was more than the will of its creators.

And that would be enough for her, if she were alive to see it.

Sleep well, o steel vagabond.

Lay down your cannons.

Your work is complete.

#transtanium fic#vera transtanium#doomed by the narrative#robots#sentient machine#knowing you're going to die from the start kind of begets a fucked up character

11 notes

·

View notes