#Dyeing Printing Auxiliaries Manufacturer

Text

What Are the New Inventions in the Textile Industry?

Innovation in the textile sector is surging thanks to developments in technology and the expanding need for sustainability.

These are a few of the most innovative new technologies that are revolutionizing the textile industry: Intelligent Textiles Electronic components are integrated into smart textiles, also known as e-textiles, to improve functionality.

Fit wear with integrated sensors to track vital signs and smart textiles that adjust color or temperature in reaction to environmental changes are examples of innovations.

Eco-Friendly and Sustainable Fabrics: Biodegradable and recycled materials are developed as a result of a strong emphasis on sustainability. Polyester that is bio-based and made from renewable resources like corn and sugarcane is durable while leaving less of an environmental impact.

Furthermore, by turning waste into new textiles, recycled fabrics—like those created from PET bottles or used clothing—support a circular economy.

Superior Textile Finishes: Durability and hygiene are being improved by new fabric treatments. Silver nanoparticle-treated antimicrobial textiles stop the growth of bacteria, and hydrophobic or photo catalytic coatings help self-cleaning textiles repel dirt and remove stains.

Weather-proof and UV-resistant materials shield outdoor textiles from the elements and UV rays, extending their lifespan.

Creative Methods of Production: Fabric creation is being revolutionized by advanced industrial techniques such as 3D knitting and printing. 3D knitting machines enable complicated designs and reduce waste by producing full clothes in one piece. Rapid prototyping and complex textile structures are made possible by 3D printing.

Without changing the feel of the fabric, nano textiles with nano coatings and nanofibers improve characteristics like strength, breathability, and stain resistance.

Textiles with Multiple Uses: Phase-change materials (PCMs), which control temperature by absorbing, storing, and releasing heat, are incorporated into new multipurpose textiles.

Thanks to the development of shape-memory alloys (SMAs), textiles may adapt to changes in shape and provide compression or fit depending on the wearer's actions and the surrounding environment.

Visit site

Contact

8866868394

Gmail

#textile dyes auxiliaries#textile finishing chemicals#textile finishing chemicals manufacturers#textile chemicals manufacturer#textile dyes manufacturers#textile auxiliaries#textile finishing chemicals suppliers#dyeing printing auxiliaries manufacturer#textile enzymes manufacturer

0 notes

Text

How Textile Chemical Dyes Impact the Environment?

In the vibrant world of fashion and textiles, colors play a pivotal role in capturing our imagination and defining our sense of style. The captivating hues of our garments owe their brilliance to a significant yet often overlooked aspect of the industry: chemical dyes.

These dyes have revolutionized the textile sector, making it possible to produce a wide array of colors and patterns that appeal to consumers' ever-changing tastes. However, amidst this rainbow of possibilities lies a dark truth - the environmental impact of textile chemical dyes.

In this blog, we delve into the consequences of using chemical dyes in textile production and explore sustainable alternatives that can help mitigate the ecological footprint of the fashion industry.

Water Pollution

One of the most significant environmental concerns associated with chemical reactive dyes in textiles is water pollution. Conventional dyeing processes often involve large amounts of water, which is used to rinse and treat fabrics. As a result, vast quantities of chemically-laden wastewater are discharged into rivers and water bodies, contaminating aquatic ecosystems. Many of these dyes are non-biodegradable and can persist in the environment for decades, disrupting the natural balance and threatening the health of aquatic organisms.

Energy Consumption

The process of digital textile sublimation inks requires substantial energy inputs, primarily during the dye application and fixation stages. Traditional dyeing methods may involve high-temperature dye baths and extended processing times, adding to the industry's carbon footprint. The energy-intensive nature of these processes contributes to greenhouse gas emissions, accelerating climate change and its devastating consequences.

Toxic Chemical Exposure

Chemical dyes used in textile auxiliaries manufacturers often contain hazardous substances such as heavy metals, formaldehyde, and volatile organic compounds (VOCs). Not only are these substances harmful to the environment, but they also pose significant health risks to the workers in the textile industry who are exposed to them daily. Moreover, consumers may experience allergic reactions and skin irritations when in contact with garments containing residual dye chemicals.

Biodiversity and Land Contamination

When dye wastewater finds its way into the soil, it can have severe consequences for terrestrial ecosystems. The toxic substances from the dyes can leach into the soil, affecting soil quality and disrupting the delicate balance of local flora and fauna. Moreover, the disposal of waste from dyeing processes can lead to the accumulation of harmful chemicals in landfills, further exacerbating the environmental impact.

Scarce Resource Consumption

Many chemical dyes rely on non-renewable resources for their production. For instance, some synthetic dyes use petroleum-based derivatives, placing additional strain on dwindling fossil fuel reserves. As these resources become scarcer, the textile industry must find more sustainable alternatives to safeguard the planet's future.

Embracing Sustainable Solutions

As we confront the ecological consequences of chemical dyes, the textile industry is gradually recognizing the urgent need for change. Embracing sustainable solutions can help mitigate the impact of dyes on the environment:

Natural Dyes: Traditional plant-based dyes, such as indigo, turmeric, and madder, offer a biodegradable and eco-friendly alternative. They can be sourced sustainably, reducing the strain on the environment.

Waterless Dyeing Technologies: Innovative technologies, like air dyeing and digital printing, minimize water usage and eliminate the discharge of wastewater, significantly reducing water pollution.

Biodegradable Dyes: Researchers are developing biodegradable dyes that break down naturally over time, circumventing the issue of persistent chemicals in the environment.

Eco-Friendly Dyeing Processes: Manufacturers can adopt low-impact dyeing techniques that consume less energy and minimize toxic chemical usage, ensuring a cleaner and safer environment for all.

The use of chemical dyes offers by textile printing ink exporter in the textile industry has undoubtedly made fashion more colourful and accessible. However, this innovation comes at a high cost to our environment. From water pollution to biodiversity loss, the impact of chemical dyes on the planet is far-reaching.

To ensure a sustainable future, it is imperative for the industry to embrace eco-friendly alternatives and implement responsible dyeing practices. By taking steps towards a more environmentally conscious approach, we can paint a brighter, greener canvas for the fashion world, where creativity and conscience coexist harmoniously.

#Textile Dyes Exporter#Textile Dyes Manufacturers#Textile Dyes Manufacturers in India#Digital Textile Reactive Inks#Digital Textile Printing Ink Manufacturer#Digital Textile Printing Ink Exporters#Textile Printing Ink Exporter#Digital Textile Sublimation Inks#Textile Auxiliaries Manufacturers#Textile Auxiliaries Exporter#Reactive Dyes Manufacturer#Reactive Dyes Exporter#Reactive Dyes Manufacturer in India#Textile Chemical Dyes

0 notes

Text

What Products can the Vacuum Homogeneous Emulsifier Produce?

The vacuum homogeneous emulsifier is a kind of cosmetic equipment, but due to the development of science, the production technology has been continuously innovated. The vacuum homogeneous emulsifier is not only used in the cosmetics industry, but also in many industrial production fields. Let’s follow the editor of YeKeey, a professional emulsifying machine manufacturer to see what products can be produced by the vacuum homogeneous emulsifier.

Vacuum Homogeneous Emulsifier Application

From the scope of application, the emulsifier can be used in a wide range of liquid products. For products with low viscosity, the emulsifier can handle them easily, and you don’t even need to turn on the homogenization function. You only need to mix, and even two-way mixing is sometimes a bit wasteful. To be precise, it is a bit overkill, and the price of the emulsifier is not cheap, and there is no need to use such a piece of good equipment. Ordinary stainless steel mixing tanks can be used for products such as lotion. But for products with a certain viscosity, it can only be produced by a vacuum homogeneous emulsifier.

The emulsifying machine

widely used in producing food sauces

Food sauces, such as salad dressing, mayonnaise, custard sauce, etc. The function of the emulsification tank of vacuum emulsification equipment is to dissolve one or more food materials in another liquid phase and make the combination into a relatively stable emulsion. Therefore, it is widely used in the emulsification and mixing of edible oils, powders, sugars, and other raw and auxiliary materials.

The emulsifier in the chemical industry

In the chemical industry, some ink coatings, paint emulsification, and dispersion also use vacuum emulsification tanks, especially suitable for mixing and emulsifying some insoluble colloidal additives CMC and other raw materials. The emulsifier is ideal for producing cosmetics, medicine, food, chemical dyeing, printing, ink, and other industrial products. It is more effective, especially for the emulsification of materials with high matrix viscosity and relatively high powder content.

High-shear vacuum homogenizing emulsifiers are widely used in the field of cosmetics

In the field of cosmetics, high-shear vacuum homogenizing emulsifiers are widely used in cosmetic creams, shampoos, shower gels, sunscreens, and other cream products. The emulsifier performs high-speed shearing, dispersion, and impact on the material through the high-speed rotation of the homogenizing head connected to the engine. In this way, the material will become more delicate and promote the fusion of oil and water. The material will be mixed with air during the production process, which will cause the product to become air-bubbled, bacterially polluted, easily oxidized and the appearance is not smooth. This situation will not occur when using a vacuum emulsifying machine.

It will disperse and emulsify evenly in a vacuum state, and air bubbles are no longer mixed in the process of production and mixing, so it can ensure the cream is delicate and stable.

Yekeey

YeKeey vacuum homogeneous emulsifier is easy to operate, has stable performance, good homogeneity, and high production efficiency. Moreover, this equipment also has the characteristics of convenient cleaning, reasonable structure, and a high degree of automation. YeKeey can also provide customers with the service of sending materials to the factory for test machines. If you have a demand for a vacuum homogeneous emulsifier, please consult YeKeey.

2 notes

·

View notes

Text

Global Top 7 Companies Accounted for 74% of total Card Personalization Equipment market (QYResearch, 2021)

A Card Personalization Equipment can produce a individually specific card instead of a generic card. During the personalization process, the plastic cards or smart cards are personalized according to the individual project or customer requirements. The personalization process includes different sub-systems and technologies such as laser engraving and high-end printing systems (thermal printing, dye-sublimation), lamination or embossing.

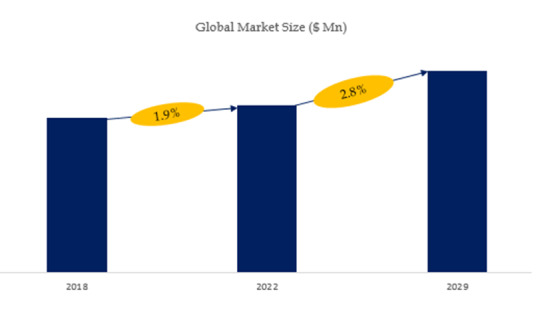

According to the new market research report “Global Card Personalization Equipment Market Report 2023-2029”, published by QYResearch, the global Card Personalization Equipment market size is projected to reach USD 0.57 billion by 2029, at a CAGR of 4.0% during the forecast period.

Figure. Global Card Personalization Equipment Market Size (US$ Million), 2018-2029

Figure. Global Card Personalization Equipment Top 7 Players Ranking and Market Share(Continually updated)

The global key manufacturers of Card Personalization Equipment include Entrust, Muehlbauer, etc. In 2021, the global top three players had a share approximately 64.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

How Textile Auxiliaries Manufacturers in India Are Shaping the Global Market

The textile industry is a cornerstone of the global economy, with India playing a pivotal role as one of the leading producers and exporters of textiles and garments. A crucial yet often overlooked component of this industry is the segment dedicated to textile auxiliaries. Textile auxiliaries are chemical substances used during various stages of textile processing, such as pre-treatment, dyeing, printing, and finishing. These auxiliaries enhance the quality, functionality, and aesthetic appeal of textiles. Textile auxiliaries manufacturers in India are making significant strides in this field, influencing the global market in numerous ways.

Innovation and Technology

Textile auxiliaries manufacturers in India are at the forefront of innovation and technological advancements. They invest heavily in research and development to create high-performance products that meet the evolving demands of the textile industry. Advanced technologies such as enzyme-based treatments, nano-coating, and eco-friendly chemical processes are being developed to improve the efficiency and sustainability of textile production. These innovations not only enhance the quality of the final product but also reduce environmental impact, making Indian manufacturers leaders in sustainable textile solutions.

Sustainable Practices

With increasing global awareness about environmental issues, there is a growing demand for sustainable and eco-friendly textile products. Indian manufacturers have responded to this demand by developing eco-friendly textile auxiliaries that minimize pollution and reduce the use of hazardous chemicals. For instance, biodegradable surfactants, low-impact dyes, and water-saving agents are some of the sustainable products being developed. These efforts align with global sustainability goals and position Indian manufacturers as responsible and forward-thinking leaders in the textile industry.

Competitive Pricing

One of the key advantages of textile auxiliaries manufacturers in India is their ability to offer high-quality products at competitive prices. The cost-effective production processes, coupled with the availability of skilled labor and raw materials, enable Indian manufacturers to provide value for money. This competitive pricing is a significant factor driving the global demand for Indian textile auxiliaries, making them attractive to textile producers worldwide who are looking to optimize their production costs without compromising on quality.

Customization and Versatility

Indian manufacturers are known for their ability to provide customized solutions tailored to the specific needs of their clients. Whether it is developing a unique dyeing auxiliary for a particular fabric or creating a finishing agent that imparts special properties to the textile, Indian companies excel in delivering versatile and customized products. This flexibility and responsiveness to customer needs enhance their reputation and reliability in the global market, attracting a diverse range of clients from various segments of the textile industry.

Strong Export Network

India’s strategic geographic location and well-established export network further bolster the position of its textile auxiliaries manufacturers in the global market. With efficient logistics and transportation systems, Indian companies can ensure timely delivery of their products to international markets. Additionally, trade agreements and favorable export policies facilitate smooth cross-border transactions, making it easier for Indian manufacturers to expand their reach and serve clients worldwide.

Quality Assurance

Maintaining high standards of quality is a priority for textile auxiliaries manufacturers in India. They adhere to stringent quality control measures and international standards to ensure that their products meet the highest levels of performance and safety. Certifications such as ISO, REACH, and OEKO-TEX are commonly obtained by Indian manufacturers, providing assurance to global clients about the quality and reliability of their products.

Collaboration and Partnerships

Indian textile auxiliaries manufacturers actively collaborate with global textile companies, research institutions, and industry associations to stay abreast of the latest trends and developments. These collaborations foster knowledge exchange, drive innovation, and open up new avenues for growth and expansion. By forming strategic partnerships, Indian manufacturers can leverage their expertise and resources to address global market challenges and opportunities effectively.

Conclusion

Textile auxiliaries manufacturers in India are playing a crucial role in shaping the global textile market. Through innovation, sustainable practices, competitive pricing, customization, and a strong export network, they are setting new benchmarks for quality and efficiency. Their commitment to excellence and adaptability to changing market demands position them as key players in the global textile industry. As the world continues to seek high-quality and sustainable textile solutions, the influence of Indian manufacturers is set to grow even further, solidifying their place as leaders in the global market.

0 notes

Text

The Role of Spectrophotometer in Color Management and Colorimetry

The spectrophotometer uses the grating spectrophotometer principle for color measurement. A grating is an optical element that is engraved with a set of parallel periodic lines or grooves (often inclined) on a plane.

When a beam of compound light is incident on the grating plane, its periodic structure will undergo diffraction, and the transmitted or reflected diffraction light will also interfere. The energy of the light will be redistributed, and different wavelengths of light will travel in different directions, forming a specific wavelength superposition extremum at a certain position, thereby achieving light splitting.

Spectroscopic colorimeters can produce spectral curves, which are equivalent to a color’s ID card and are unique. Therefore, the color data read by the spectrophotometer is absolutely accurate.

The role of spectrophotometer in colorimetry:

The chemical industries such as textiles, printing and dyeing, petroleum, and batteries often generate a lot of industrial wastewater during the production process. The national standards for detecting the chromaticity of wastewater mainly use platinum cobalt colorimetry and dilution multiple method.

The platinum cobalt chromaticity is expressed in Hazen units, with 1 milligram of platinum per liter of solution containing chloroplatinic acid and 2 milligrams of hexahydrate cobalt chloride solution having a platinum cobalt chromaticity of 1 unit. The general range of values is between 1 and 500. Suitable for measuring the color of liquid chemical products that are transparent or slightly close to the reference platinum cobalt color number, this color characteristic is usually brownish yellow.

Limitations of human eye colorimetry; The platinum cobalt colorimetric method is based on human eye judgment, and the color is influenced by environmental light sources, observation angles, and other factors. In actual visual colorimetry, there are certain differences.

Platinum cobalt chromaticity can not only be applied in water quality analysis, but also be used to measure the chromaticity of solutions of chemicals, petrochemical products, such as glycerol, solvents, plasticizers, carbon tetrachloride, petroleum alcohols, etc.

Given the shortcomings of the platinum cobalt colorimetric method in actual color comparison, a spectrophotometer can also be used to compare solution colors.

The use of a spectrophotometer for measurement has the following three major advantages:

1. There is no need to configure a solution and no need to consider material storage issues;

2. The instrument is easy to operate and can be directly measured;

3. Platinum cobalt data is clear at a glance.

The desktop spectrophotometer can measure the chromaticity indicators of platinum cobalt, Gardner, Saybolt, and ASTM.

The role of spectrophotometer in color management:

The spectrophotometer can display chromaticity information based on the internally set chromaticity space and calculation formula, and output it in digital form. In addition, spectrophotometer can also analyze potential spectral data information based on chromaticity data.

The spectrophotometer is designed for data comparison and simulation of visual chromaticity, and is also an important auxiliary tool for computer color matching, which can help major manufacturers complete the analysis, processing, and monitoring of spectral and chromaticity information perfectly.

In the use of spectrophotometer, a crucial data equation – the color tolerance equation – is involved. In fact, we usually refer to the tolerance range, and in industrial batch production, there are tolerances to control the product and qualification status, which is fast and reasonable.

The spectrophotometer wants to measure the color difference of the product and control it, which is the same as a regular color difference meter. Firstly, it needs to measure the information of the standard sample product, and then compare the color information of the measured sample to obtain color difference data.

Calculate whiteness. It can perform white measurement on the whitened sample according to relevant formulas, and then provide specific whiteness values to see if they can meet the standard requirements.

Calculate the strength of the dye. Different dye batches may result in dyeing differences. Therefore, a spectrophotometer can be used to read the relevant finished product samples, and then see the differences between the products produced by these two different batches of dyes. Then, the relevant differences can be filled in the correction coefficient, and the formula can be automatically adjusted to ensure consistent dyeing results.

Calculate the color depth. Because in the actual production process, there may be certain differences in color depth due to differences in formula or production process, and some of these differences cannot be judged by the naked eye. In this case, it is necessary to analyze them through professional equipment such as a spectrophotometer.

Application of spectrophotometer:

1. Food industry

The color of food has a significant impact on people’s appetite, so the food industry has very high requirements for color. The spectrophotometer can quickly measure the color of food to ensure good color and compliance with safety standards.

2. Cosmetics industry

The color of cosmetics is very important for consumers, and good colors can help consumers quickly distinguish different brands. A spectrophotometer can help cosmetic manufacturers ensure that their products have colors that match standard colors.

3. Textile industry

The color of textiles is also very important as it can affect consumers’ purchasing decisions. A spectrophotometer can help textile manufacturers ensure that their products have accurate color and chromaticity values.

4. Semiconductor industry

In the semiconductor manufacturing process, spectrophotometer can help detect the color of transistors, LEDs, and other electronic components. This is crucial for maintaining product consistency and quality.

Advantages of spectrophotometer:

1. High measurement accuracy

The spectrophotometer has high measurement accuracy and can achieve extremely high color accuracy. This is very important for applications that require high-precision color measurement, such as color identification, color matching, etc.

2. Overall measurement speed is fast

In traditional color measurement methods, multiple measurements are required to obtain high-precision results. The spectrophotometer can quickly complete the overall measurement, saving a lot of time.

3. With a recorder

The spectrophotometer has a recorder that can save measurement data during measurement. This is very convenient for later data analysis and comparison.

4. Easy to use

The spectrophotometer is convenient to use and easy to operate. There is no complex operation process, and color measurement can be completed in a few simple steps.

Benchtop Spectrophotometer (Transmittance) DSCD-910 is good performance and specially designed for testing the transparent material’s transmittance, absorbance, chromaticity value and other parameters.

DSCD-910_Benchtop Spectrophotometer (Transmittance)

Read the full article

0 notes

Text

Textile Auxiliaries Market to Reach US$ 11.7 Bn by 2031

The global textile auxiliaries market is poised for significant growth from 2023 to 2031, driven by the increasing demand for functional and sustainable textiles, technological advancements, and the expansion of the textile industry worldwide. Textile auxiliaries are specialty chemicals used in various stages of textile processing to enhance fabric properties, improve performance, and achieve desired finishing effects.

The wide range of use of textile auxiliaries chemicals in the processing of fabric underpins growth opportunities for firms in the textile auxiliaries market. Fabric producers are utilizing various textile auxiliaries to impart texture and colors to cater to the demands of the fashion and apparel industry. The value of the global textile auxiliaries market was pegged at US$ 8.0 Bn in 2021.

The textile auxiliaries market has been witnessing steady growth, propelled by the rising demand for innovative textile products with superior functional attributes. Textile auxiliaries play a crucial role in improving the quality, appearance, and performance of textiles, thereby catering to diverse consumer preferences and industry requirements.

Download Sample of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=22580

Market Segmentation:

The textile auxiliaries market can be segmented based on several factors including service type, sourcing type, application, industry vertical, and region. Understanding these segments allows for a detailed analysis of specific market trends and dynamics.

By Service Type: Pre-treatment, Dyeing & Printing, Finishing

By Sourcing Type: Synthetic, Natural

By Application: Apparel, Home Textiles, Technical Textiles, Others

By Industry Vertical: Textile Manufacturing, Fashion & Apparel, Home Furnishings, Others

By Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

Regional Analysis:

North America: Dominant market share attributed to technological advancements and the presence of key market players.

Europe: Significant growth potential driven by the increasing demand for sustainable textiles and stringent regulatory standards.

Asia-Pacific: Emerging market with rapid industrialization, growing textile manufacturing sector, and favorable government initiatives.

Latin America: Growing adoption of advanced textile processing technologies and increasing investments in the textile industry.

Middle East & Africa: Rising demand for high-quality textiles and expanding fashion and apparel industry driving market growth.

Market Drivers and Challenges:

Drivers:

Increasing consumer demand for functional and sustainable textiles.

Advancements in textile processing technologies.

Growth in the fashion and apparel industry.

Challenges:

Stringent environmental regulations pertaining to chemical usage in textile processing.

Volatility in raw material prices.

Intense competition from alternative materials and processes.

Market Trends:

Shift towards eco-friendly and biodegradable textile auxiliaries.

Adoption of digital printing technologies for textile decoration.

Growing focus on performance-enhancing auxiliaries for technical textiles.

Future Outlook:

The future outlook for the textile auxiliaries market appears promising, driven by increasing consumer awareness regarding sustainable and functional textiles, technological innovations, and the growing demand for high-quality textile products across various industry verticals. Market players are expected to capitalize on emerging opportunities by offering innovative solutions and addressing evolving consumer preferences.

Key Market Study Points:

Analysis of market dynamics including drivers, challenges, and opportunities.

Assessment of market segmentation and regional trends.

Evaluation of competitive landscape and key market players.

Examination of recent developments and emerging trends shaping the market.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=22580<ype=S

Competitive Landscape:

The textile auxiliaries market is characterized by intense competition among key players striving to enhance their market presence through product innovation, strategic partnerships, and expansion strategies. Major players in the market include:

Archroma

Huntsman Corporation

Dow Chemical Company

BASF SE

Evonik Industries AG

Recent Developments:

Launch of eco-friendly and sustainable textile auxiliaries.

Strategic collaborations with textile manufacturers and brands.

Investments in research and development to introduce advanced textile processing solutions.

About Transparency Market Research

Transparency Market Research, a global market research company registered in Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll-Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Auxiliaries for Textile Industry in Delhi | Textile Chemicals

Auxiliaries For Textile Industry In Delhi

Are you in search of high-quality auxiliaries for the textile industry? Look no further! Welcome to our premier service for textile auxiliaries in Delhi. The textile industry encompasses a wide array of materials, from yarns to various fabrics, fibers, and finished articles. Each requires specialized solutions for their chemical processing, and we are here to provide exactly that. Our range of products is diverse, catering to the unique needs of textile manufacturers. textile auxiliary producer Delhi

Why Choose Us?

As leading textile auxiliaries manufacturers in Delhi, we pride ourselves on several key points:

Diverse Product Range: We offer more than just a single product; our catalogue boasts a wide variety of auxiliaries for chemical processing.

Versatility: Our products cater to a range of fabrics and fibers, ensuring we are not limited to one specific type.

Quality: All our products are of exceptional quality, designed for optimal performance and excellent results.

Multi-Purpose: Whether it's dyeing, printing, or other fabric treatments, our auxiliaries are versatile and effective.

Comprehensive Solutions: Consider us your one-stop solution for all textile processing requirements.

These aspects set us apart as premier textile auxiliary producers.

Our Categories of Auxiliaries

Here's a glimpse into some of the textile industry auxiliaries we offer in Delhi:

Pretreatment Auxiliaries

Our pretreatment auxiliaries boast highly absorbent and low-foaming formulations, with impressive binding capabilities. They are eco-friendly, GOTS approved, and free of APEO/NPEO. Examples include Scowet TT Conc., Rikoclean – STR, and Trinitron. These auxiliaries include stain removers tailored for synthetic and natural fibers, such as Rikoclean – STR.

Dyeing Auxiliaries

Our dyeing auxiliaries feature excellent levelling properties, ensuring uniform distribution of dye. They offer high soaping and washing-off abilities, all while being GOTS approved. For instance, Milaniaks- R serves as a cationic retarder for controlled and uniform acrylic dyeing. Additionally, Trinitron – LTS is a low-temperature washing off agent suitable for various fibers, providing excellent soaping fastness and easy wash.

Finishing Agents

Our finishing agents consist of both silicone and non-silicone specialty softeners, crafted to meet the industry's specific needs. These auxiliaries are invaluable, offering versatile finishes tailored to the desired garment or fabric. From exhaustible to inexhaustible finishes, as well as hydrophobic and oleo phobic options, our range covers a spectrum of textile chemicals and auxiliaries in Delhi.

If you're in need of top-notch textile auxiliaries, don't hesitate to reach out to us today. We are your partners in achieving exceptional textile processing results.

#auxiliaries for textile industry in Delhi#textile auxiliaries manufacturers Delhi#textile auxiliary producer Delhi

0 notes

Text

Sustainability and Eco-friendly Solutions in the Asia Textile Chemicals Market

Definition: The Asia Textile Chemicals Market refers to the industry that produces and supplies various chemicals used in the textile manufacturing process. These chemicals play a crucial role in enhancing the quality, appearance, and performance of textiles, including fabrics, clothing, and other textile products.

Market Overview & Scope: The Asia Textile Chemicals Market encompasses a wide range of chemical products designed to improve different aspects of textiles. This includes dyeing and finishing chemicals, coating chemicals, and others used in the textile industry. The market caters to the needs of textile manufacturers across Asia, a region known for its significant contribution to the global textile industry. With a focus on improving textile properties such as color, durability, and texture, these chemicals are indispensable in the production of high-quality textiles.

Market Growth: The Asia Textile Chemicals Market has witnessed substantial growth in recent years, driven by the increasing demand for textiles in the region and the desire for better quality and performance. Factors such as population growth, rising disposable incomes, and changing fashion trends have contributed to the expansion of this market. Additionally, the adoption of sustainable and eco-friendly textile chemicals is gaining traction, aligning with the global emphasis on environmental sustainability.

Market Industry: The textile chemicals market industry in Asia is highly diverse, encompassing various subsectors. These include chemicals for dyeing and printing, finishing chemicals, colorants, and auxiliary chemicals used in processes like pretreatment, desizing, and scouring. Major players in the market include chemical manufacturers, textile mills, and garment producers, making it an integral part of the textile supply chain.

Trends: Several noteworthy trends are shaping the Asia Textile Chemicals Market. One prominent trend is the increased focus on eco-friendly and sustainable textile chemicals. Manufacturers are investing in research and development to create products that have minimal environmental impact. Furthermore, the digitalization of textile manufacturing processes, including the use of smart textiles and nanotechnology, is on the rise, transforming the industry and offering new opportunities for growth and innovation. As consumer awareness of sustainable and high-performance textiles continues to grow, the market is likely to see further advancements in these areas. Additionally, regulations and standards related to chemical usage in textiles are becoming more stringent, prompting the industry to adapt to evolving compliance requirements.

In conclusion, the Asia Textile Chemicals Market is a dynamic and evolving sector that plays a vital role in enhancing the quality and sustainability of textiles. With the region's continued growth in the textile industry and the adoption of innovative solutions, this market is poised for ongoing development and transformation.

#Asia Textile Chemicals Market#Asia Textile Chemicals Market Growth#Asia Textile Chemicals Market Trends

0 notes

Text

Textile Full Dyeing Process

The art of dyeing fabric involves imparting color onto textile materials, including yarn or finished fabric. This process dates back to at least 2600 BCE, with references found in historical texts. Initially, natural sources such as plants and animals were used to extract dyes and colors. However, from the mid-1800s, humans began developing synthetic dyes to expand the spectrum of available colors and increase the longevity of the dyeing process. There are a number of textile machinery manufacturers in India that offer best and efficient machineries to fulfil the textile manufacture needs and Weavetech is one amongst them. Weavetech is one of the best textile machinery manufacturers located in Gujarat which is a one stop solution for all your textile needs. With a quarter of a century of experience under its belt, Alidhra Weavetech is a prominent global entity that specializes in providing weaving and twisting machinery solutions. The organization has earned its reputation by offering innovative and locally developed designs that have been supplied to various parts of the world.

Textile Colorants

Dyes and pigments are colorants with distinct properties that greatly affect their application to textiles. Dyes are substances that color fabric and are typically used in a dissolved state, which then binds to the fabric. They are classified based on their chemical structure and usage, with each type of fibre requiring a specific dye. To ensure durability, dyes must possess the property of being "fast" or chemically stable, which means they should not wash away with soap and water or fade when exposed to sunlight. Dyes bind to fabrics through primary (ionic or covalent bonds) and secondary (hydrogen bonding) forces during the dyeing or printing process. Unlike dyes, pigments are insoluble and do not have an inherent attraction to textile fibres. If you are searching for textile machinery manufacturers in India, then you must get in touch with Weavetech as we have excellence and great expertise in this industry.

In the past, natural dyes sourced from various natural materials were the primary means of obtaining colors. However, with advancements in technology, synthetic dyes have gained more prominence due to their enhanced dependability, affordability, and ease of availability. Even so, certain natural dyes, including haematoxylin, carmine, and orcein, are still used today. Synthetic dyes, which are manufactured from either organic or inorganic substances, can be categorized into various types, including Direct, Acid, Basic, Reactive, Mordant, Metal complex, Vat, Sulfur, Disperse, or other types of dyes.

Dyeing Process

The techniques used for dyeing have remained relatively consistent over time and typically involve submerging textiles in a specialized solution containing dyes and other chemicals. Water is mainly used for cleaning, dyeing, applying auxiliary chemicals, and rinsing fabrics. The dyeing process comprises three primary stages, namely preparation, dyeing, and finishing, during which undesirable impurities are removed from the materials prior to the dyeing stage. To remove stains and natural color from fabrics, different cleaning methods can be employed such as using alkaline chemicals, detergents, or enzymes. Hydrogen peroxide or chlorine-based compounds are commonly used to bleach fabrics, especially when a white color is desired. Additionally, optical brightening agents may be added to enhance the whiteness of the textile before it is sold.

Textile dyeing is a process of coloring fabrics with water-based dyes, often performed under high temperatures and pressures. To ensure the dye evenly penetrates the fabric and resists fading, various chemical substances such as surfactants, acids, bases, electrolytes, carriers, leveling agents, chelating agents, emulsifying oils, and softening agents are added during the dyeing process. These chemical aids play a crucial role in achieving a uniform depth of color that is long-lasting and appropriate for the fabric's intended use.

Dyeing- The Imparting Colour

Dyeing is the art of imparting color to textiles, including fabrics, fibers, and yarns, and has been practiced by humans for millennia. Dyes are available in powder, paste, crystal, and liquid dispersion forms and dissolve readily in aqueous solutions. During dyeing, the textile material is immersed in the dye solution, and the dye molecules bond to the fibers through absorption and diffusion, which are influenced by temperature and other factors. Hand or machine dyeing can be used based on the fabric type, and it's crucial to select appropriate dyes for each fabric type. Weavetech is one of the best textile machinery manufacturers located in Gujarat and offering best quality of textile machineries.

Dyeing Methods

When it comes to dyeing textiles, the method used can either be batch or continuous. The optimal dyeing procedure depends on several factors such as the type of material being dyed (fiber, yarn, fabric, clothing), the type of fiber used, the desired quality of the dyed fabric, and the size of the dye batch. In batch dyeing, the textile material is loaded into a dyeing machine and allowed to reach equilibrium with the dye solution, whereby the dye molecules transfer from the solution into the fibers due to their affinity for the fibers. This process ensures that the textile is evenly and thoroughly dyed, resulting in high-quality dyed fabric.

If you are a textile manufacturer looking to improve the efficiency and productivity of your dyeing process, it's time to consider upgrading your dyeing machinery. Investing in Weavetech dyeing machines can significantly improve the quality of your dyed fabric, reduce dyeing time, minimize wastage, and increase your production output. Don't settle for outdated machinery that hinders your growth and profitability. Take action now and invest in advanced dyeing machinery to stay ahead of the competition and meet the ever-increasing demands of the textile industry.

This Blog Originally Posted:

https://www.weavetech.com/blog-detail/36/textile-full-dyeing-process/

0 notes

Text

Textile Chemicals Market Size, Share | Global Analysis, Growth & Forecast | ChemAnalyst

According to ChemAnalyst report, “Textile Chemicals Market Analysis: Plant Capacity, Production, Operating Efficiency, Demand & Supply, By Application, By Type, Distribution Channel, Regional Demand, 2015-2030", Textile Chemicals demand stood at 1.13 Million Tonnes in 2020 and is forecast to reach 1.90 Million Tonnes by 2030, growing at a healthy CAGR of 5.35% until 2030.

The textile chemicals market is witnessing significant growth and transformation as the textile industry adapts to changing consumer demands and sustainability requirements. Textile chemicals play a crucial role in various stages of textile production, including pre-treatment, dyeing, printing, and finishing. With the growing textile industry and increasing focus on quality, innovation, and sustainability, the global textile chemicals market is poised for substantial expansion.

One of the primary drivers of the textile chemicals market is the rising demand for high-quality and aesthetically appealing textiles. Textile chemicals are used to enhance the performance, durability, and appearance of fabrics. They help in achieving desired colors, prints, and finishes that meet consumer expectations. With evolving fashion trends, increasing disposable incomes, and a growing population, the demand for innovative and visually appealing textiles is on the rise, thereby driving the textile chemicals market.

Read Full Report Here: https://www.chemanalyst.com/industry-report/textile-chemicals-market-566

Furthermore, sustainability is a key factor shaping the textile chemicals market. The industry is increasingly focused on reducing its environmental impact and improving the sustainability of textile production. Textile chemicals manufacturers are investing in research and development to develop eco-friendly alternatives that minimize water and energy consumption, reduce waste generation, and lower emissions. Sustainable textile chemicals, including bio-based dyes and auxiliaries, are gaining prominence as they offer reduced environmental footprint without compromising performance.

Additionally, the growing adoption of digital printing technologies in the textile industry is fueling the demand for textile chemicals. Digital printing eliminates the need for traditional printing methods, such as screen printing, and offers advantages such as shorter lead times, customization options, and reduced water and chemical consumption. Textile chemicals specifically designed for digital printing, such as colorants and pretreatment agents, are in high demand, driving the growth of the market.

Moreover, stringent regulations regarding worker safety, environmental protection, and product quality are shaping the textile chemicals market. Manufacturers are required to comply with various regulations and standards to ensure the safe use of chemicals, minimize hazardous emissions, and meet quality standards. This has led to the development of safer and more sustainable textile chemicals that adhere to regulatory requirements.

Request sample Report: Textile Chemicals Market Research ReportMajor players for Textile Chemicals globally include Achitex Minerva S.p.A., Arkema Inc., Chemipol, Covestro AG, Dow, Formosa Organic Chemical Industry Co Ltd, Kemira, L. N. Chemical Industries, Nouryon, Sarex, Tanatex Chemicals B.V., The Lubrizol Corporation, Wacker Chemie AG.

Despite the positive growth prospects, the textile chemicals market faces challenges such as fluctuating raw material prices and the need for continuous innovation. Manufacturers are investing in research and development activities to develop advanced textile chemicals that offer improved performance, lower environmental impact, and cost-effectiveness.

In conclusion, the textile chemicals market is experiencing significant growth driven by the demand for high-quality textiles, sustainability concerns, and technological advancements. Innovation in textile chemicals, along with a focus on sustainability, is reshaping the industry. Manufacturers are striving to develop eco-friendly alternatives and comply with regulations to meet the evolving needs of the textile industry. With the increasing adoption of sustainable practices and the demand for innovative textiles, the textile chemicals market is set to expand further in the coming years.

About Us:

ChemAnalyst is a subsidiary of Techsci Research, which was established in 2008, and has been providing exceptional management consulting to its clients across the globe for over a decade now. For the past four years, ChemAnalyst has been a prominent provider of Chemical commodity prices in more than 15 countries. We are a team of more than 100 Chemical Analysts who are committed to provide in-depth market insights and real-time price movement for 300+ chemical and petrochemical products. ChemAnalyst has reverberated as a preferred pricing supplier among Procurement managers and Strategy professionals worldwide. On our platform, we provide an algorithm-based subscription where users can track and compare years of historical data and prices based on grades and incoterms (CIF, CFR, FOB, & EX-Works) in just one go.

The ChemAnalyst team also assists clients with Market Analysis for over 1200 chemicals including assessing demand & supply gaps, locating verified suppliers, choosing whether to trade or manufacture, developing Procurement Strategies, monitoring imports and exports of Chemicals, and much more. The users will not only be able to analyze historical data for past years but will also get to inspect detailed forecasts for the upcoming years. With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

ChemAnalyst is your one-stop solution for all data-related needs. We at ChemAnalyst are dedicated to accommodate all of our world-class clients with their data and insights needs via our comprehensive online platform.

Contact Us:

ChemAnalyst

B-44 Sector-57 Noida,

National Capital Region

Tel: 0120-4523990

Mob: +91-8882805349

Email: [email protected]

Website: https://www.chemanalyst.com/

0 notes

Text

The Significance of Dye Fixing Agents in Textile Industry

Enhanced Color Fastness: By chemically attaching colors to the fabric fibers, dye fixing agents increase the color fastness of textiles that have been dyed. This keeps the colors bright and true for the duration of the garment by stopping the dyes from leaking or fading when washed, rubbed, or exposed to light.

Long-lasting Color Retention: Dye fixing chemicals help textiles retain their original color intensity and brilliance even after repeated launderings or exposure to environmental variables by successfully fixing dyes onto fabric fibers. This guarantees that clothing will maintain its visual impact and aesthetic appeal over time.

Diminished Environmental Impact: By decreasing dye waste and run-off, dye fixing agents help to lessen the environmental impact of textile dyeing operations. Water and energy resources are conserved during the dyeing process when these chemicals improve the attachment of dyes onto fibers, hence reducing the need for unnecessary rinsing and washing.

Better Wash Fastness: Dye fixing chemicals help dyed textiles wash more quickly, keeping the colors vibrant and preventing them from smearing onto other fabrics. This keeps the appearance of the garment intact and stops color migration or staining—especially in textiles with several colors or prints.

Textiles treated with dye fixing agents: Have better stain resistance against typical things including food, drinks, and household chemicals. This increases the general durability and endurance of the fabric and makes clothing easier to clean and maintain, thereby decreasing the possibility of unattractive stains.

Compatibility with a Variety of Fibers: Cotton, wool, polyester, nylon, and other natural and synthetic fibers are among the many fabrics that dye fixing agents work well with. Due to its adaptability, textile producers are able to guarantee uniform coloration and performance by achieving consistent and dependable dye fixing outcomes on a variety of fabric types.

Regulatory Compliance: Dye fixing agents assist textile producers in adhering to strict safety regulations and standards pertaining to textile performance and color fastness. These agents help to produce high-quality and compliant textile goods by making sure dyed textiles meet industry standards for color fastness, durability, and consumer safety.

Consumer happiness: In the end, dye fixing agents are essential for raising consumer happiness since they guarantee that colored textiles keep their color vibrancy, look, and functionality throughout time. Clothes that hold their color and don't fade or bleed are more likely to live up to client expectations and provide long-term value.

Visit site

#Dyeing Printing Auxiliaries Manufacturer#Dyeing Printing Auxiliaries Manufacturer in India#Textile Finishing Chemicals Manufacturers#Textile Finishing Chemicals Manufacturers in India#Textile Finishing Chemicals Suppliers#Dyes Manufacturers#Textile Dyes Manufacturers#dyes manufacturers in india#textile finishing chemicals#textile dyes manufacturers#dyeing auxiliaries#Finishing Chemical Manufacturers#Printing Dyes Suppliers#Textile Auxiliaries#Textile Auxiliary Manufacturer#Pretreatment Textile Manufacturer#Textile Pretreatment Chemicals#Printing Dyes Manufacturers#Silicone softeners Manufacturer#Silicone softener for textiles#Desize Enzymes Manufacturer#Optical Brightener#Optical Brightener Manufacturer#Turkey red oil manufacturer#Printing Dyes#Printing Dyes Manufacturer#optical brightening agent in textile#textile auxiliaries manufacturers in india#dye manufacturers in india#dyeing and printing

0 notes

Text

#elpra21 #knitfabric #wovenfabric #denimfabric #apparels #garmentswashing #sourcing #textile #garments #manufacturer #supplier #exporter #textileindustry #

#tshirt #garmentmanufacturer #clothingmanufacturer #fiber #mansclothing #womensclothing #boysgirlsclothing #kidsclothing #summerwears #winterwears #sportswear #dyes #chemical #auxiliarries #digitalmarketing #SEO #SMM #remoteservice #graphicsdesign #tshirtdesign #civilengineering #buildingdesign #businessplan #businessdevelopment #brandpromotion #merchendising #marketing #technical #Research

We are Bangladeshi manufacturers GARMENTS PRODUCTS (Man's, WOMAN, BOYS, GIRLS, KIDS, summer wear, winter wears, sports wears

For more details, please check

www.elpra21.com

we are manufacturer of pineapple fiber.

We are supplier textile (denim, woven, knit, fabrics)as per our customers demand.

We are supplier textile (chemical, auxiliary, dyes) as per textile dyeing, washing, printing industry demand.

+8801620487648(WhatsApp)

cc

cc

merchandising@elpra21,com

Have a nice day.

Thanks

Md Eusuf Shanto

0 notes

Text

Garment Printing Ink Manufacturers in India

Want affordable and high-end textile printing solutions? Contact Chemical Brothers!

Textile printing is an intuitive process to add colors to the fabrics in specific patterns and designs. The proper process of textile printing required high-quality inks that resists the colors from washing and fading. Therefore, we at Chemical Brothers offering vast range of printing inks and pastes to textile manufacturers. We are becoming the premier suppliers of printing solutions for thriving garment printing industry in India. Thus, if you are associated with this sector and looking for the top-rated textile printing tools, just make a virtual tour to our website for viewing our printing product range.

Get superior ink quality

Textile industry in India is growing at rapid pace due to its versatile technology. But, in the massive growth of this industry, printing inks are playing pivotal role. We as the garment printing ink manufacturers in India offers superior inks which are used to add colors and designs to textile fabrics. We are the developers of low-cure silicone inks which are used for subtle, impressive, and quality textile printing. Our range of silicone inks is available in standardized colors. We can also provide these inks in unique colors to serve you with tailor-made textile printing solutions.

Get faster printing inks

In textile industry, printing process of fabrics takes place in bulk quantities. Therefore, this industry need inks which can speed-up the printing process. We have the pride to hold ranking among top 10 garment printing ink dealers in India. Our series of water-based printing inks is supporting the industry to swift the process of roll to roll yardage printing. Our water-based inks are capable to meet the requirements to work with advanced printing tools with faster drying capacity. Our water-based series of inks named as Nanowat and offers screen printing for t-shirts and largely for towels.

Best heat transfer ink printing

You can check for our advanced-tech range of heat transfer silicone inks for textile fabrics. These are the environment-friendly inks which comes with properties such as high temperature resistance, non-toxic and quality printing. You can use these inks to make easy printing of custom logos and design with thermal heating. The printing will be transferred from paper to your fabric using heat and pressure. These printing inks can make 3D printing a smoothing process for garment printing industry. You can get impressive printing effects for glossy and shiny fabrics.

Why choose us?

Chemical Brothers is the best textile printing auxiliaries manufacturer in India. We have vast range of auxiliaries to make the colors fast for garment printing. Look no further than the garment printing ink manufacturers in India if you want to looking for superior results. We not only have the best quality for garment printing inks, but can also provide you with extensive printing auxiliary collection. We ensure to deliver you with the right products that will make printing process smoother and quicker. You can explore our range of dyeing printing for your textile unit by visiting our official website..

Garment Printing Industry, Top 10 Garment Printing Ink Dealers in India, Garment Printing Ink Manufacturers in India

#Garment Printing Industry#Top 10 Garment Printing Ink Dealers in India#Garment Printing Ink Manufacturers in India

0 notes

Text

Global Top 5 Companies Accounted for 73% of total Retransfer ID Card Printers market (QYResearch, 2021)

A retransfer ID card printer that uses a two-step print process instead of a traditional dye-sub direct-to-card technology. The card design is first printed onto a durable overlay transfer film, which is then bonded onto the card’s surface using a combination of heat and pressure.

Using a retransfer printer will allow you to produce high-definition ID cards that are known as ‘over-the-edge ID cards. This means there is no white border left around the edge of the card; something that happens if you’re using a direct-to-card machine. You can watch more about the differences between direct-to-card and retransfer printers in the video below.

According to the new market research report “Global Retransfer ID Card Printers Market Report 2023-2029”, published by QYResearch, the global Retransfer ID Card Printers market size is projected to reach USD 0.22 billion by 2029, at a CAGR of 2.8% during the forecast period.

Figure. Global Retransfer ID Card Printers Market Size (US$ Million), 2018-2029

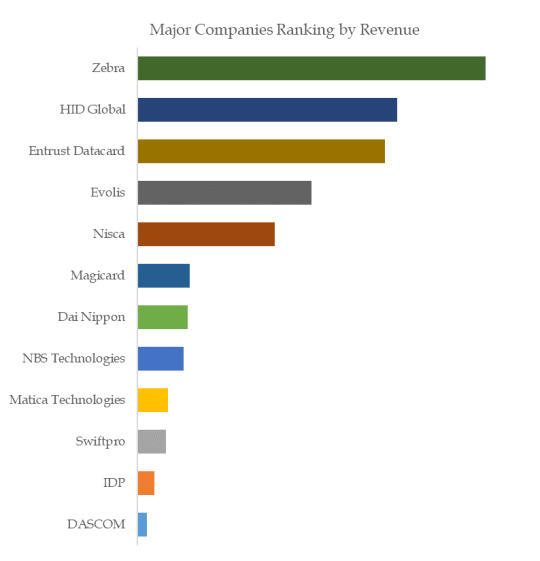

Figure. Global Retransfer ID Card Printers Top 12 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Retransfer ID Card Printers include Zebra, HID Global, Entrust Datacard, Evolis, Nisca, Magicard, Dai Nippon, NBS Technologies, Matica Technologies, Swiftpro, etc. In 2022, the global top five players had a share approximately 73.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Textile Auxiliaries Chemicals

The textile industry is a dynamic sector that constantly adapts to changing market demands and technological advancements. Within this industry, textile auxiliaries chemicals play a pivotal role in enhancing processes, improving product quality, and meeting customer expectations. However, like any other field, the world of textile auxiliaries chemicals faces its share of challenges while also embracing exciting trends. In this article, we will explore some of the prominent challenges and trends shaping this vital industry.

Challenges in Textile Auxiliaries Chemicals

Environmental Sustainability: One of the foremost challenges facing the textile auxiliaries chemicals sector is the need to address environmental concerns. The industry is under increasing pressure to reduce its carbon footprint, minimize water consumption, and limit the use of hazardous chemicals in textile processing. Regulatory bodies worldwide are enforcing stricter environmental standards, leading chemical manufacturers to develop eco-friendly alternatives.

Stringent Regulatory Compliance: Textile auxiliaries chemical manufacturers must navigate a complex landscape of regulations and standards. Compliance with local and international regulations, such as REACH in Europe, is essential. Meeting these stringent requirements while maintaining product quality and competitiveness can be challenging.

Customer Preferences and Sustainability: As consumers become more conscious of environmental and ethical concerns, they demand sustainable and socially responsible products. Textile auxiliaries chemicals must align with these preferences, leading to the development of eco-friendly and biodegradable solutions. Meeting these demands while remaining cost-effective poses a significant challenge.

Global Supply Chain Disruptions: The COVID-19 pandemic exposed vulnerabilities in global supply chains. The textile industry, including the production of textile auxiliaries chemicals, faced disruptions in the availability of raw materials and transportation. Ensuring a resilient supply chain and adaptability to unforeseen disruptions is crucial for the industry's stability.

Trends in Textile Auxiliaries Chemicals

Sustainable and Eco-Friendly Solutions: Sustainability is a dominant trend in textile auxiliaries chemicals. Manufacturers are investing in research and development to create products that minimize environmental impact. This includes the use of biodegradable chemicals, water-saving processes, and reducing energy consumption.

Smart Textiles: The integration of technology with textiles is gaining momentum. Smart textiles, which incorporate sensors, conductive materials, and electronic components, are becoming more prevalent. Textile auxiliaries chemicals play a role in making these materials functional and durable. Applications include sports apparel, healthcare garments, and even fashion.

Nanotechnology in Textile Auxiliaries: Nanotechnology has made its way into textile auxiliaries chemicals. Nanoparticles can enhance properties like stain resistance, UV protection, and anti-bacterial capabilities in textiles. These advanced chemical formulations are being used in sportswear, medical textiles, and military applications.

Digital Printing and Dyeing: Digital printing and dyeing techniques are gaining popularity due to their efficiency and reduced environmental impact compared to traditional methods. Textile auxiliaries chemicals are essential in optimizing these digital processes for precise coloration and printing results.

Customization and Personalization: Consumers increasingly seek unique and personalized textiles. Textile auxiliaries chemicals are used in processes like digital printing and dyeing to create customized designs on fabrics. This trend is especially prominent in the fashion and home textile sectors.

Automation and Industry 4.0: Automation and data-driven technologies are transforming the textile industry. Textile auxiliaries chemicals are being used in conjunction with automated processes to ensure quality control and consistency. Industry 4.0 practices are also being adopted for real-time monitoring and optimization.

Conclusion

The textile auxiliaries chemicals sector is in a state of transformation driven by environmental concerns, regulatory pressures, and technological advancements. While challenges related to sustainability, regulations, and supply chain disruptions persist, the industry is actively embracing trends that promise a more eco-friendly, efficient, and customer-centric future.

Manufacturers of textile auxiliaries chemicals are at the forefront of innovation, developing solutions that align with these trends while meeting the demands of a changing market. As consumer expectations continue to evolve and sustainability becomes a non-negotiable factor, the industry's ability to adapt will determine its long-term success and relevance in the global textile landscape.

0 notes