#Electronics System Design and Manufacturing (ESDM)

Explore tagged Tumblr posts

Text

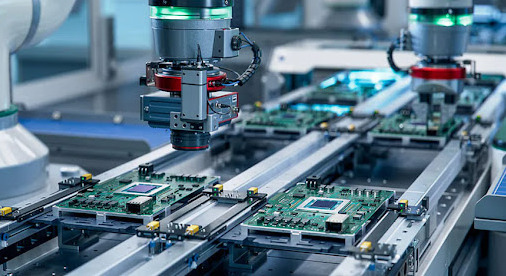

How to Overcome Common Challenges in PCB Assembly for ESDM Projects

In the dynamic world of Electronics System Design and Manufacturing (ESDM), success hinges not just on innovation, but also on precise execution—especially during PCB (Printed Circuit Board) assembly. As projects become more complex, so do the challenges faced during this critical phase. At Aimtron, we’ve seen firsthand how addressing these challenges early leads to smoother project flows, faster time-to-market, and higher quality products.

In this blog, we’ll dive into the most common PCB assembly challenges for ESDM projects and share proven strategies to overcome them.

1. Component Sourcing and Availability

The Challenge: Global supply chain disruptions, component shortages, and long lead times can delay PCB assembly, jeopardizing project timelines.

The Solution:

Early BOM Finalization: Lock your Bill of Materials (BOM) early and validate components for availability.

Multiple Sourcing Strategies: Partner with trusted suppliers and maintain alternate part options.

Inventory Management: Use just-in-time (JIT) inventory systems while keeping a buffer for critical components.

Leverage Aimtron’s Global Network: Our established supplier partnerships help mitigate shortages and ensure timely procurement.

2. Design for Manufacturability (DFM) Issues

The Challenge: PCBs designed without considering manufacturing capabilities often lead to rework, delays, and higher costs.

The Solution:

Early DFM Review: Engage manufacturing experts during the design phase for feedback on layout, spacing, and assembly feasibility.

Simulation and Validation: Use advanced tools to simulate manufacturing processes.

Collaboration with Aimtron's Engineering Team: Our design-for-assembly (DFA) and DFM services ensure your PCB designs are optimized for production from day one.

3. Soldering Defects

The Challenge: Soldering errors like cold joints, bridging, and voids can compromise the reliability of PCBs.

The Solution:

Precision Process Control: Strictly monitor solder paste application, reflow profiles, and hand-soldering techniques.

Quality Training: Continuous training of assembly staff in IPC standards.

Automated Optical Inspection (AOI): Aimtron uses AOI and X-ray inspection systems to detect and correct soldering issues in real-time.

4. Electrostatic Discharge (ESD) Damage

The Challenge: ESD can silently destroy sensitive electronic components during handling and assembly.

The Solution:

Strict ESD Protocols: Implement ESD-safe workstations, grounding systems, and employee training.

Continuous Monitoring: Use ESD monitoring devices to ensure protection throughout the facility.

Certified ESD-Safe Facilities: At Aimtron, our facilities meet global ESD standards to protect your PCBs during every step of assembly.

5. Maintaining Quality in High-Mix, Low-Volume Production

The Challenge: ESDM often requires the assembly of many different PCBs in small batches, making consistency a challenge.

The Solution:

Flexible Manufacturing Systems: Deploy agile production lines capable of quick changeovers.

Strong Documentation Practices: Use detailed work instructions and traceability systems.

Continuous Improvement Programs: Aimtron’s commitment to Kaizen ensures quality is never compromised, no matter the batch size.

6. Thermal Management During Assembly

The Challenge: Components that generate significant heat or require special handling (e.g., BGAs, high-power ICs) can complicate the assembly process.

The Solution:

Proper Heat Profiling: Develop accurate reflow oven profiles tailored to PCB thermal characteristics.

Use of Thermal Reliefs: Design PCBs with thermal relief pads to assist in proper soldering.

Thermal Simulation: At Aimtron, we utilize advanced modeling to predict and manage thermal challenges during assembly.

Conclusion

Navigating the complexities of PCB assembly in ESDM projects requires more than technical know-how—it demands a strategic, proactive approach. From sourcing components to ensuring ESD protection and optimizing for manufacturability, every step is critical.

At Aimtron, we don’t just assemble PCBs—we partner with you to engineer success at every stage of your ESDM journey. By combining cutting-edge technology, global resources, and a deep commitment to quality, we help you overcome challenges and deliver products that meet and exceed market expectations.

Need support for your next ESDM project? Contact Aimtron today and experience the difference that expertise makes.

#PCB Assembly#ESDM#Electronics System Design and Manufacturing#PCB Assembly Services#PCB Assembly Solutions#PCB Design

0 notes

Text

India’s Electronics Leap: How PLI Schemes and Infrastructure Are Redefining Manufacturing

India is fast-tracking its ambition to become a global electronics manufacturing powerhouse. With a mix of well-structured Production Linked Incentive (PLI) schemes and robust infrastructure development, the country is actively reducing its dependence on imports, boosting exports, creating jobs, and attracting international investments.

Building an Electronics Ecosystem: ECMS Initiative

Recognizing the need to strengthen the components ecosystem, the government introduced the Electronics Components Manufacturing Scheme (ECMS) with an outlay of ₹23,000 crore. This scheme aims to drive domestic production of passive electronic components, sub-assemblies, and capital equipment essential for electronic manufacturing.

Strategic Push Through PLI Schemes

The Indian government’s push for domestic electronics manufacturing revolves around targeted financial support for value chain expansion. The PLI initiatives reward companies for incremental manufacturing and sales in India.

1. PLI for Large-Scale Electronics Manufacturing

Introduced in April 2020, this scheme was designed to attract substantial investments in mobile and electronic components manufacturing. It provides 3% to 6% incentives on incremental sales over a five-year period.

Its success is evident—mobile phone production in India jumped from 5.8 crore units in 2014–15 to a massive 33 crore units in 2023–24, reducing import reliance and turning India into a net exporter of mobile phones.

2. PLI 2.0 for IT Hardware

This version extends support to the IT hardware segment—covering laptops, tablets, servers, and ultra-compact PCs. Companies receive about 5% incentive on incremental sales over six years.

The scheme emphasizes component localization, including semiconductor design and integrated circuit packaging, making India more self-reliant in high-tech electronics.

ECMS: Multi-Tiered Manufacturing Support

The ECMS offers flexible incentive models—turnover-linked, capital-expenditure linked, and hybrid. It targets key sectors such as telecom, power electronics, automobiles, and medical devices. With a projected ₹59,350 crore in investment and ₹4.56 lakh crore in production output, the scheme is expected to create over 91,000 direct jobs.

As of late 2024, PLI schemes across 14 sectors had brought in ₹1.61 lakh crore in investment, created over 11.5 lakh jobs, and generated about ₹14 lakh crore in production—transforming the manufacturing landscape.

Infrastructure as the Backbone

Beyond incentives, India is also investing heavily in industrial infrastructure to support electronics production.

Electronics Manufacturing Clusters (EMCs)

The EMC scheme supports the creation of state-of-the-art infrastructure for the Electronics System Design and Manufacturing (ESDM) ecosystem. Greenfield projects can receive up to 50% of project costs (up to ₹50 crore per 100 acres), while brownfield projects may receive 75% support.

So far, 19 greenfield EMCs and 3 Common Facility Centres (CFCs) have been approved, spanning 3,464 acres and backed by ₹1,470 crore in government grants. States such as Tamil Nadu, Uttar Pradesh, and Karnataka are rapidly emerging as new electronics hubs.

Improved Connectivity: Bharatmala, Sagarmala & PM Gati Shakti

Modern infrastructure is key to seamless manufacturing. Initiatives like Bharatmala and Sagarmala, along with the PM Gati Shakti National Master Plan, are transforming India’s logistics network. The development of dedicated freight corridors, automated cargo handling, and real-time tracking systems is helping cut costs and reduce transit delays.

Expected Impact: A New Era for Indian Electronics

Boosting Local Value Chains

By incentivizing domestic production of core components, these schemes reduce India's dependency on foreign imports—especially from China, Taiwan, and South Korea. Localization of even 50% of key components can lead to billions in foreign exchange savings.

Massive Employment Generation

With direct and indirect job creation at the core of every scheme, the electronics sector is expected to employ hundreds of thousands of skilled and semi-skilled workers across the country.

Rising Electronics Exports

India has set an ambitious goal of producing $300 billion worth of electronics by 2026, of which $120–140 billion is aimed at exports. The PLI schemes have already helped expand India's export base by attracting tech giants like Apple and Samsung to deepen their operations.

Innovation and Technological Capability

R&D and semiconductor design are integral to India’s future strategy. Initiatives like SPECS and the semiconductor-specific incentives under PLI aim to enhance indigenous design and manufacturing capabilities.

Road Ahead: Addressing Key Challenges

Despite rapid progress, certain challenges must be resolved:

Supply Chain Gaps: Continued import of certain high-tech components requires a stronger local supply network.

Infrastructure Bottlenecks: EMCs need consistent upgrades in power, water, and transport to match global standards.

Skilled Workforce Shortage: Scaling up training programs is essential to support high-volume manufacturing.

Ease of Doing Business: Simplifying regulations and approvals will accelerate investment flows and industrial growth.

Conclusion

India’s aggressive push through PLI schemes and infrastructure investment is redefining its electronics sector. From import substitution to export-led growth, the country is positioning itself as a global electronics manufacturing hub. With the right policy continuity, focus on skill development, and strategic global partnerships, India is well on its way to becoming a dominant player in the international electronics value chain.

Author Details: S. Ravi (Sethurathnam Ravi) Promoter and Managing Partner of Ravi Rajan & Co. LLP Former Chairman of the Bombay Stock Exchange

0 notes

Text

Haryana Government Committed to Promoting an Industry-Friendly Policy Ecosystem: Rao Narbir Singh

Chandigarh, May 17 – In a significant step towards enhancing direct engagement with the industrial sector and shaping policies that are more practical and impactful, the Haryana Government organized a stakeholder consultation meeting in Gurugram today for making Draft Haryana Electronic System Design & Manufacturing (ESDM) Policy 2025 and Draft Haryana AVGC-XR Policy 2025. The meeting was chaired…

0 notes

Text

ECSE: A Hybrid Pathway with Modern Relevance

If you're someone who enjoys both computing and electronics, ECSE might just be the right mix for you. It bridges the gap between electrical engineering and computer science, allowing you to build a strong foundation in circuit design, microprocessors, digital systems, and coding. In today’s world, where everything from smartphones to smart cities runs on interconnected systems, having skills in both domains is not just useful—it’s essential.

Institutes across India, including IITs and NITs, offer specialized ECSE programs. But not everyone gets into those top-tier institutes—and that’s absolutely okay. There are several respected private and state-level engineering colleges doing great work in this field.

In states like Odisha, for example, colleges like the NM Institute of Engineering and Technology (NMIET) in Bhubaneswar are gaining attention. Known for offering a broad set of engineering courses under Biju Patnaik University of Technology, NMIET also focuses on technical depth, hands-on labs, and placement support—important factors when you're entering a technical branch like ECSE.

Why Choose ECSE in 2025 and Beyond?

The industry is shifting toward automation, IoT, and smart devices. Whether it's your smartwatch or the sensor in a car, ECSE is at the core of such innovations. By choosing this branch, you are stepping into a world that’s constantly moving forward. Here’s what makes it worthwhile:

Multiple Career Options: From chip design and robotics to software development and cloud computing, ECSE offers a broad range of career choices.

Growing Industry Demand: According to India Brand Equity Foundation, the electronics system design and manufacturing (ESDM) sector in India is expected to grow at a CAGR of over 15% in the next five years.

Higher Studies and Research: ECSE graduates are well-prepared to pursue advanced studies in areas like VLSI design, embedded systems, or AI/ML.

Startup Potential: With coding and electronics knowledge combined, ECSE graduates are well-placed to launch tech startups—whether it's building IoT devices or app-based products.

What Should You Look for in an ECSE College?

When choosing a college for ECSE, don’t just go by the name. Focus on what the institute offers in terms of:

Curriculum: Is it updated with the latest in AI, IoT, and microelectronics?

Faculty: Do they have the industry or research background to support applied learning?

Labs and Infrastructure: Can you access modern tools like Raspberry Pi, microcontrollers, and simulation software?

Placement History: Are students getting placed in companies that align with your career goals?

Location Advantage: Colleges located in tech-friendly cities usually offer better internship and training opportunities.

If you look at the best engineering colleges in Orissa, many of them, especially in Bhubaneswar, are now integrating interdisciplinary training that suits modern industry requirements. NMIET, for example, maintains industry connections with companies like Cognizant, Capgemini, IBM, and BYJU’S—an important plus when you're preparing for your first job in tech.

Is ECSE Better than Other Branches?

That really depends on what you want. If you're passionate about both coding and electronic systems, ECSE offers the best of both worlds. It’s especially good for students who don’t want to limit themselves to just software or just hardware.

While traditional ECE or CSE branches are still popular, ECSE is becoming more relevant in today’s tech-driven world. As industries look for engineers who can think across disciplines, this hybrid branch helps you stand out.

Opportunities After Graduation

Some of the common job roles you can target with an ECSE degree include:

Embedded Systems Engineer

Software Developer

IoT Developer

Electronics Design Engineer

Systems Analyst

Data Scientist (with added skills)

You can also opt for government roles in DRDO, ISRO, and other public sector undertakings that require a blend of software and hardware understanding.

Final Thoughts

Electronics and Computer Science Engineering is not just a safe choice—it’s a smart one if you're aiming for versatility in your career. While IITs and NITs are well-known for this branch, many students today are getting solid education and industry exposure from best engineering colleges in Orissa, particularly from institutes that have stayed current with industry demands.

So if you’re looking to study in a place where you get both a strong academic foundation and industry-relevant training, do your homework. Check the college's labs, look at their placement links, and see what students are saying.

And if NMIET or a similar institute comes up in your research, take a closer look—it might offer exactly what you’re looking for.

#best colleges in bhubaneswar#college of engineering bhubaneswar#best engineering colleges in orissa#best engineering colleges in bhubaneswar#best private engineering colleges in odisha#best engineering colleges in odisha

0 notes

Text

Apollo Micro Systems Reports Strong Growth in Q3 & 9M FY25, Expanding its Footprint in Defense and Aerospace

Apollo Micro Systems Limited (AMSL), a Hyderabad-based leader in electronic, electromechanical, and engineering solutions, has reported a stellar financial performance for the third quarter (Q3) and nine months (9M) of the fiscal year 2025. The company, renowned for its expertise in designing and manufacturing advanced defense and aerospace technologies, has demonstrated remarkable growth, driven by a strong order pipeline and strategic initiatives.

Established in 1985, AMSL has positioned itself as a key player in the defense ecosystem, collaborating closely with the Defense Research and Development Organization (DRDO), Bharat Electronics Limited (BEL), and other prominent defense and aerospace institutions. With over 150 indigenous programs, 700 onboard technologies, and a dedicated R&D team of 165 experts, the company plays a crucial role in India's self-reliance mission for defense innovation.

The company operates across multiple domains, including missile systems, avionics, homeland security, satellite and space systems, and naval defense. By offering end-to-end Electronic System Design and Manufacturing (ESDM) services—from ideation and research to final production—AMSL has solidified its position as a critical link between system integrators and defense end-users.

Financially, AMSL has delivered an outstanding performance in Q3 FY25, with revenue from operations surging by 62.5% year-over-year (YoY) to ₹1,483.9 million, up from ₹913.4 million in Q3 FY24. The company’s EBITDA rose by 58.1% to ₹379.6 million, maintaining a robust margin of 25.6%. Net profit (PAT) saw an even more impressive increase of 83.1%, reaching ₹182.4 million, with a PAT margin of 12.3%.

For the nine-month period ending December 31, 2024, AMSL’s revenue from operations grew by an exceptional 69.5%, reaching ₹4,003.0 million. EBITDA for the period stood at ₹932.2 million, reflecting a 69.1% YoY increase, while PAT more than doubled to ₹424.0 million, marking a growth of 133.2%. These figures highlight AMSL’s consistent operational efficiency and ability to capitalize on the growing demand for indigenous defense solutions.

The company’s expanding order book further cements its strong market position. Recent contract wins include a ₹214.2 million order from Bharat Electronics Limited (BEL) and a private entity in December 2024, as well as a ₹73.7 million project from DRDO in January 2025. Additionally, AMSL has secured multiple contracts from the Indian Navy, Adani, and various public sector units, reinforcing its role in India’s defense modernization.

A significant milestone was achieved on January 29, 2025, when AMSL signed a five-year Memorandum of Understanding (MoU) with Garden Reach Shipbuilders & Engineers Limited (GRSE). This partnership aims to drive joint research and development, co-production, and export of advanced underwater weaponry, communication systems, and air defense technologies.

Looking ahead, AMSL is set to make a strong impact at Aero India 2025, scheduled from February 10 to 14 in Bangalore. As a premier event in the aerospace and defense sector, Aero India provides an ideal platform for AMSL to showcase its cutting-edge innovations and strengthen relationships with key stakeholders.

Further solidifying its financial position, AMSL has announced the issuance of equity shares and warrants on a preferential basis, aggregating up to ₹816 crores. The capital raised will support critical initiatives, including R&D investments, working capital requirements, and subsidiary expansion, ensuring continued innovation in defense technology.

The Indian defense sector is undergoing rapid transformation, fueled by government initiatives like Make in India and Atmanirbhar Bharat. These programs emphasize indigenous manufacturing and private-sector collaboration, creating substantial opportunities for companies like AMSL. With a strong foothold in advanced defense electronics, the company is well-positioned to drive innovation, contribute to national security, and expand its global footprint.

As AMSL continues its growth trajectory, backed by a robust order pipeline and strategic partnerships, it remains committed to delivering cutting-edge solutions and value to its stakeholders. The company’s unwavering focus on innovation and operational excellence ensures that it is poised for sustained success in the defense and aerospace industry.

0 notes

Text

0 notes

Text

Factors driving the growth of SMT PCB assembly in India

The electronics manufacturing industry of INDIA has shown a lot of growth in the recent years. India is soon coming up as electronics manufacturing destination with strong supply chain and skilled manpower acting as the catalysts. SMT PCB assembly is a standout technique that can exceptionally engage in electronics manufacturing, typically in Printed Circuit Board assembly.

SMT PCB Assembly is the process of placing electronic components onto the surface of the printed circuit board (fused with PCB). This new technology does away with the through-hole process where parts are inserted directly into drilled holes. SMT also enables the Manufacture of smaller and lightweight components which go well with the current small electronic gadgets that require improved performance.

Components

Surface Mount Devices (SMDs): These are the components that are screwed onto the circuit board surface such as resistors, capacitors, diodes, and integrated circuits.

Solder Paste: A combination of powder solder and a flux which is needed to hold the SMDs in position while in the PCB.

Pick-and-Place Machines: Special machines that are capable of correctly positioning SMDs on the PCB that has solder paste on it.

Reflow Oven: Used to heat the PCB and melt the solder paste to give strong connection between the SMDs and the PCB.

Factors

The electronics industry in India has also benefited from enormous economic growth over the last few decades. The drastic increase of SMT PCB assembly in India can be attributed to several factors in its economical aspect. Some of the most important factors include the development of sound government policies and incentives aimed at enhancing electronics manufacturing within the country. Rising internal consumption towards electronics and related products has played a key role in the growth of SMT PCB assembly in India.

The most important strength of the country is the demography factor which offers a large number of youths and qualified technical workforce. This skilled labor force is a valuable benefit because it contributes to the rate of increase and improved effectiveness of SMT PCB assembly in India.

To improve the skills of this competent workforce, various training schemes and interventions have been developed. Various government initiatives like the Skill India Mission and the Electronics System Design and Manufacturing (ESDM) program ensures that people are skilled in modern electronics manufacturing processes.

Several educational institutions prepare talent for SMT PCB assembly in India and these institutions are crucial to its growth. Smt Pcb Assembly has special modules included in the engineering colleges and technical institutes that focus on manufacturing electronics with electronics manufacturing courses.

Epsilon electronics emerges as the industry leader of SMT PCB Assembly in India that relies on the best technology and on the strict fulfillment of the highest quality standards. Epsilon Electronics offered efficient SMT PCB assembly solutions which improved the value of its communication devices. Epsilon Electronics has a big share in the SMT PCB Assembly in India along with many successful project work and good vision.

#SMT PCB Assembly in India#ems solution provides#pcb assembly service provider#pcb assembly service provider in gujarat#pcb assembly service provider in india#pcb design company in gujarat#circuit design company in india#ems solution provider#pcb design company in india#ems supplier in gujarat#ems supplier in india

0 notes

Text

Indian PCB Manufacturers Making Waves in Global Electronics Market

Thanks to aggressive policy measures taken by the Indian government, the electronics manufacturing sector in India has grown at an unparalleled rate during the last five years. It is anticipated that the "Make in India" flagship program and "Atmanirbhar Bharat" will quicken the pace even more.

To position India as a global hub for Electronics System Design and Manufacturing (ESDM), the National Policy on Electronics (NPE) 2019 will prioritize size and scale, export promotion, and enhancing domestic value addition by fostering an environment that will allow the industry to compete on a global scale. The goal established by the NPE 2019 is to produce 400 billion US dollars by 2025. It involves producing one billion mobile phones, valued at US$ 190 billion, with a US$ 110 billion export goal.

The Role PCBs Play in Electronics

Printed Circuit Boards, or PCBs, are the building blocks of contemporary electronics, serving as the backbone of the industry's rapid advancement. India has grown to be a significant force in the PCB manufacturing sector as technology advances. This article examines the function and expansion of PCB makers in India and highlights their contribution to the nation's technical advancement.

The complex, networked structures known as printed circuit boards are what give electronic components inside gadgets support and connectivity. Almost all electrical devices, including cell phones and medical equipment, depend on PCBs for proper operation. The need for more complicated, compact, and efficient PCBs is increasing as technology advances.

The PCB Manufacturing Industry in India

Significant progress and expansion have been made by India in the PCB manufacturing industry. As the electronics sector expands and the emphasis on "Made in India" grows, the nation's PCB producers can satisfy the needs of both local and global consumers.

Advantages of manufacturing PCB in India

India is an attractive hub for PCB manufacturing for the following reasons:

Skilled Manpower

India boasts of high-quality engineers, designers, and technicians who can design, assemble, and fabricate PCBs.

Cost Competitiveness

The country offers lower manufacturing costs compared to other regions, thus making it attractive for global electronics producers.

Highest Standards of Quality

The performance and dependability of the PCBs they make are guaranteed by the fact that many Indian PCB manufacturers follow global quality standards.

Personalization

Indian PCB makers can create customized products that satisfy the needs of different sectors.

Supporting the Advancement of Technology

The country's ambitions to become a technology-driven global leader are in line with the expansion of PCB makers in India. Indian manufacturers support innovations in several industries, such as healthcare, automotive, telecommunications, and more by providing high-quality printed circuit boards (PCBs) for various applications.

Influence and Global Reach

Indian manufacturers of printed circuit boards have expanded their global reach with the passage of time. Their products are used in devices and systems across the world, proving that India can supply solutions for different industries.

Indian Printed Circuit Board Market - An Overview

The Indian printed circuit board (PCB) industry has grown significantly in the last several years, and by 2023, it was worth USD 4.52 billion. The demand for electronic devices is growing across several industries, and this is driving significant growth in the Indian PCB market, which is expected to develop at a compound annual growth rate (CAGR) of 18.1% from 2024 to 2032. It is expected to be valued at USD 20.17 billion by 2032 according to the market research.

PCB board export shipments from India totalled to around 45.9K, according to Volza's data on Indian exports, and were sent by 1,830 Indian exporters to 4,622 buyers. The majority of India's PCB board exports go to China, Hungary, and the United States.

Conclusion

India is now a significant player globally for PCB manufacturing thanks to its thriving domestic infrastructure. With their competitive pricing, skilled workforce, and commitment to quality, PCB manufacturers and suppliers of PCB, such as Vishal International are leading the way for a more innovative and connected future.

0 notes

Text

"Discover the Futuristic Connection: Karnataka's Irresistible Allure for US Tech Giants in Groundbreaking Space Startups and ESDM Collaboration!"

A delegation from the Karnataka government, led by Industries Minister M.B. Patil, has embarked on a two-week trip to the United States of America to attract big investors to Karnataka. The delegation is particularly focused on the space technology and Electronic Systems Design and Manufacturing (ESDM) sectors, with an emphasis on attracting mobile phone manufacturers like Apple and aerospace…

View On WordPress

0 notes

Text

What Makes Aimtron Electronics a Leader in ESDM and PCB Assembly?

In today’s fast-paced world of electronics manufacturing, companies are constantly looking for ways to innovate, streamline operations, and improve the quality of their products. One company that stands out in this space is Aimtron Electronics, a leader in the field of Electronics System Design and Manufacturing (ESDM) and PCB (Printed Circuit Board) Assembly. But what sets AImtron apart from its competitors?

Let’s explore the key factors that have helped Aimtron Electronics become a trailblazer in the ESDM and PCB assembly industries.

1. Comprehensive End-to-End ESDM Solutions

Aimtron Electronics offers a complete range of services that span the entire product lifecycle, from initial concept to final delivery. This end-to-end capability allows the company to provide tailored solutions that meet the unique needs of its clients. Whether it's designing a custom PCB, developing complex electronics systems, or providing full-scale manufacturing, Aimtron integrates each step seamlessly, ensuring quality and efficiency throughout the process.

This ability to handle every phase of the development cycle means clients don't have to manage multiple vendors, which can lead to miscommunication, delays, and inconsistencies. Aimtron’s holistic approach not only simplifies the process but also accelerates time-to-market, which is crucial in today’s competitive electronics landscape.

2. Cutting-Edge PCB Assembly Technology

Aimtron Electronics has built a reputation for using the latest technology and techniques in PCB assembly. The company invests heavily in advanced manufacturing equipment, including pick-and-place machines, automated optical inspection (AOI) systems, and reflow soldering technology. These innovations ensure that each PCB assembly is completed with the highest level of precision and reliability.

Moreover, Aimtron’s facilities are designed to handle a wide range of PCB assembly types, including single-sided, double-sided, and multi-layer boards. This versatility means that the company can meet the needs of a variety of industries, from consumer electronics to automotive and industrial applications.

3. Uncompromising Quality Control Standards

One of the hallmarks of AImtron Electronics is its commitment to quality. The company adheres to strict industry standards, such as ISO 9001 and IPC-2221, ensuring that its products meet or exceed the highest benchmarks in the ESDM and PCB assembly industries. AImtron integrates quality control (QC) at every stage of the production process, from design to final assembly.

To further ensure the reliability of its products, AImtron employs automated testing systems, in-circuit testing (ICT), and functional testing to detect any potential defects early in the process. These rigorous quality control measures reduce the likelihood of failure and improve the overall performance of the final product.

4. Design Expertise and Innovation

At Aimtron, the design team is at the heart of everything. The company’s engineers are experts in Electronics System Design (ESD), with deep knowledge in a wide variety of industries and applications. AImtron’s design capabilities cover a broad spectrum, including analog circuits, digital circuits, RF (Radio Frequency) designs, and power electronics.

The team works closely with clients to understand their unique needs and provide innovative solutions that align with their business goals. This collaborative approach ensures that each design is optimized for performance, manufacturability, and cost-efficiency. Additionally, Aimtron’s design team uses state-of-the-art CAD (Computer-Aided Design) software to create accurate and detailed schematics, reducing the likelihood of errors and streamlining the design-to-manufacturing transition.

5. Scalability and Flexibility

Aimtron Electronics excels in delivering scalable solutions. Whether a customer needs a small batch run for prototyping or high-volume production for large-scale manufacturing, Aimtron has the capacity and flexibility to meet diverse demands. The company’s manufacturing facilities are designed for scalability, enabling it to accommodate both small and large orders with equal efficiency and quality.

This flexibility is particularly beneficial for clients in industries such as medical devices, telecommunications, automotive, and aerospace, where demands can fluctuate based on market conditions, regulations, and technological advancements.

6. Commitment to Sustainability

As industries increasingly focus on reducing their environmental footprint, Aimtron Electronics has taken significant steps to ensure that its operations are both efficient and eco-friendly. The company actively embraces green manufacturing practices, such as reducing waste, recycling materials, and utilizing energy-efficient technologies in its PCB assembly process.

Aimtron also works with clients to develop environmentally friendly products, ensuring that their designs are not only high-performing but also sustainable. This commitment to sustainability resonates with clients who are looking to reduce their carbon footprint and meet global environmental standards.

7. Customer-Centric Approach

Aimtron’s customer-centric approach is one of the key factors that sets it apart from other companies in the ESDM and PCB assembly space. From the initial consultation to after-sales support, Aimtron places a strong emphasis on building lasting relationships with its clients.

The company offers personalized service, ensuring that each customer’s unique needs are met with tailored solutions. Aimtron’s engineering team works hand-in-hand with clients to refine designs, troubleshoot issues, and optimize product performance. Additionally, the company’s customer service team is always available to provide ongoing support, from product updates to maintenance and repair services.

8. Global Reach with Local Expertise

While Aimtron Electronics operates on a global scale, it combines this reach with local expertise to serve a diverse client base across multiple industries. The company’s team understands the nuances of different markets, from regional regulations and certifications to cultural considerations in manufacturing.

Aimtron’s ability to navigate these complexities while delivering top-tier ESDM and PCB assembly services has earned the company a strong reputation as a trusted partner in the global electronics supply chain.

Conclusion

Aimtron Electronics stands out as a leader in Electronics System Design and Manufacturing (ESDM) and PCB Assembly due to its combination of cutting-edge technology, rigorous quality standards, innovative design expertise, and a customer-focused approach. The company’s commitment to excellence, scalability, and sustainability has positioned it as a trusted partner for companies across a variety of industries.

With a strong emphasis on precision, efficiency, and reliability, Aimtron Electronics continues to push the boundaries of what’s possible in electronics manufacturing, ensuring that its clients remain competitive in an ever-evolving market.

If you're looking for a partner who can handle all your ESDM and PCB assembly needs, Amitron Electronics offers the experience, technology, and customer care you need to succeed.

#Electronics System Design and Manufacturing (ESDM)#PCB Assembly#Electronics System Design#functional testing#automated optical inspection#reflow soldering#ESDM Solutions

0 notes

Text

Why Aimtron is a Trusted Name in ESDM Services

In the rapidly evolving electronics industry, Electronics System Design & Manufacturing (ESDM) plays a crucial role in bringing innovative solutions to life. Companies seeking reliability, expertise, and cutting-edge technology turn to Aimtron, a name synonymous with excellence in electronics manufacturing. But what makes Aimtron stand out as a trusted provider of ESDM solutions? Let’s explore the key factors behind its reputation.

Commitment to High-Quality Electronics Design

Aimtron’s journey in electronics design has been defined by precision engineering and innovation. From conceptualization to prototyping, the company ensures that each design meets industry standards and client-specific requirements. Its expertise in electronic circuits, embedded systems, and component selection has made it a go-to choice for businesses seeking robust, scalable solutions.

Excellence in PCB Assembly Services

One of Aimtron’s core strengths lies in PCB assembly services, where it delivers highly reliable and efficient printed circuit boards for various applications. Using advanced manufacturing techniques, stringent quality control measures, and state-of-the-art equipment, Aimtron provides cost-effective yet high-performance PCB solutions tailored to industry needs.

End-to-End ESDM Solutions

What sets Aimtron apart is its ability to offer comprehensive ESDM solutions—from design and prototyping to manufacturing and testing. Clients benefit from an integrated approach that streamlines production, reduces costs, and ensures seamless functionality. Whether it’s for consumer electronics, automotive systems, industrial machinery, or medical devices, Aimtron guarantees top-tier manufacturing expertise.

Trusted by Industries Worldwide

With years of experience in electronics manufacturing, Aimtron has built strong relationships with global clients across diverse industries. Its reputation is backed by consistent delivery, cutting-edge technology, and an unwavering commitment to quality. By prioritizing customer satisfaction and continual improvement, Aimtron remains a trusted name in ESDM services.

Conclusion

In the competitive world of electronics, reliability and expertise make all the difference. Aimtron’s dedication to electronics design, PCB assembly services, and ESDM solutions solidifies its standing as a trusted partner for businesses seeking world-class manufacturing. With a focus on quality, innovation, and customer success, Aimtron continues to lead the way in modern electronics development.

0 notes

Link

The Bangalore Chamber of Industry and Commerce (BCIC) has praised the major incentive announced by Karnataka Government for the Electronic System Design and Manufacturing Sector in Karnataka. The five-year plan, a great revoke to the ESDM sector was declared by Dr. Ashwathnarayan C. N. Deputy Chief Minister and Minister for IT & BT, Science & Technology; Skill Development, Entrepreneurship, and Livelihood, Karnakata, during the IESA Vision Summit – 2020.

1 note

·

View note

Text

Top 5 Amazing Facts About Apartments On Rent In Greater Noida

If you want to know about an apartment on rent in Greater Noida then this article will explain everything in detail. This article will also explain the top 5 amazing facts about apartments on rent in Greater Noida. As per the recent data there are over 2900 units for rent in Greater Noida.

There are several opportunities which are available once you rent an apartment in Greater Noida. Several amenities and facilities are available for the tenant community which will upgrade your lifestyle. For people who want to shift to better housing arrangements and lifestyle then apartments for rent in Greater Noida are worth considering.

Sector 1 and 3 in Greater Noida offers some of the best areas and housing facilities. The place offers one of the best residential housing in Greater Noida. The best apartments come in all ranges and varieties such as 1 BHK, 2 BHK, 3 BHK, 4 BHK apartments for rent in Greater Noida. This region has all the best quality living spaces which offers a great experience.

List of Top 5 Amazing Facts About Apartments On Rent In Greater Noida

Affordable rentals- the apartments in Greater Noida are available at affordable prices and various ranges. If you are looking for a 1 BHK unit then you will get the area of about 60 square meters which is priced in the approximate range of 5,800 rs to 6,500 rs monthly. All this is available in great facilities with well furnished apartments in Noida.

If you are looking for a 2 BHK unit then it can be easily available at a price of 7000 rs to 9000 rs per month. You can find the 3 bhk apartments also at a great pricing which can be easily available at a monthly rent of approximately 10000 rs to 15000 rs. If you look carefully and compare the prices of apartments from other areas then you’ll see that prices of apartments in Greater Noida are much affordable and are available at cheaper prices. 4 BHK apartments are also well furnished and are available at great prices.

Connectivity to the main places- the best part about renting a place in greater Noida is that it offers great connectivity to the main places of the city. You also enjoy the smooth connectivity to Noida from greater Noida with the connected Expressway Highway.

The highway is approximately 20 km in distance and one can easily cover the distance in about 30 to 40 minutes with minimal traffic. Greater Noida also offers great connectivity to Delhi for it One must have to take Delhi- Noida- Delhi flyway to escape the traffic which easily links the road.

Also the main feature is that the Aqua line of Noida Metro connects the place with Greater Noida and Delhi. The place is also well control to the main places such as hospitals, schools, parks, entertainment center, shopping malls, meteo stations and much more.

On the State Government’s Radar- state government is daily creating more job opportunities in Greater Noida for the economic development of the city. The state government has taken several steps to create a better business climate in the region. The city is one of the worldwide electronics manufacturing hubs in India. The Electronics System Design and Manufacturing (ESDM), is the fast track in Noida.

Greater Noida and Yamuna Expressway comes unders the manufacturing policy of 2017. There are almost three electronic manufacturing clusters which are earmarked at Yamuna Expressway and Greater Noida. The place has many national and international companies situated here.

Greater Noida is also the main sector for industrial manufacturing and development in Mumbai and Delhi which will increase the employment prospects and the property need and value in Greater Noida.

Amenities- the Noida Expressway is a favorable residential spot with high standards of education, health care centers. There are various international schools and hospitals available nearby such as Mayur school, Amity University, Amity, international school, Delhi, Public school, Jaypee Hospital, Max multi speciality Hospital, FelixHospital and other medical institutions.

Superb investment opportunity- the main pointer that makes a superb investment by purchasing the apartments. The real estate in India tends to rise and especially the value of apartments. So you are making a great investment plan by investing in the apartments of Greater Noida. Apartments in Greater Noida are a way to upgrade your lifestyle.

Original Source: https://noidarealty.weebly.com/blog/top-5-amazing-facts-about-apartments-on-rent-in-greater-noida

Before considering buying any apartment in Greater Noida you must check the society and should get the complete knowledge of the place through our site. Before confirming the apartments you must compare the facilities and rent with other available apartments on rent in Greater Noida. Must check all the amenities and facilities available which you are looking for in the resident. Make sure that the place is safe for you and your family to avoid any future trouble.

#apartments on rent in Greater Noida#Apartments in Greater Noida#4 BHK apartments for rent in Greater Noida

0 notes

Text

Dicing Tapes Market - Trends, Size, Share, Growth, Demand and Regional Outlook by 2026

Transparency Market Research offers key market acumens of global dicing tapes market in its newly published report, which includes global industry survey, share, growth, size, trends, along with forecast for 2022-2026. In terms of global revenue, the dicing tapes market is anticipated to register growth at 6.5% CAGR over the upcoming decade, of which TMR provides a detailed analysis of lucrative growth opportunities in the dicing tapes market report.

Dicing tapes are manufactured with a base polymer, oligomer, and a photo initiator, and are pressure-sensitive. These tapes can help to deal with harsh sunlight and other environmental variables. They create a strong adhesive bond to a variety of surfaces, making them an excellent alternative to duct tape. They are utilized to keep semiconductor wafers aligned with the ring frame during the dicing process and protect their surfaces during back grinding. They can be also on workpieces made of ceramics, glass, gemstones, and plastics that are exposed to UV light for long periods of time.

Get a Sample of This Report - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=46674

Growing Application in APAC Electronics Industry

The world’s fastest-growing industry, Electronics System Design and Manufacturing (ESDM) continues to transform lives, businesses, and economies across the globe. As per Invest India, a National Investment and Facilitation Agency, Indian electronics market was worth US$ 118 Bn in the year 2020 and the country is second largest mobile manufacturer in the world. Furthermore, it states that the Indian Electronics Manufacturing Service (EMS) Industry is expected to grow 6.5x its current market size by 2025. Furthermore, Electronic Goods Exports register a whopping growth of 49% in April-December 2021 by clocking US$ 11.0 Bn (Provisional) over US$ 7.4 Bn during same period in the year 2020. Moreover, availability of raw materials and advanced technology infrastructure are attracting global players to invest in emerging countries in APAC.

Dicing Tapes Market: Competition Landscape

Key market players in the dicing tapes market are focusing on strategic expansions and acquisitions to maintain their supremacy across the regions and eyeing lucrative growth offered by emerging markets:-

· In February 2019, the company acquired Acelity Inc. a manufacturer of medical products. This acquisition bolsters the Medical Solutions business and supports the growth strategy of the company. It also offers comprehensive advanced and surgical wound care solutions and improve outcomes and enhance experiences.

Make an Enquiry Before Buying - https://www.transparencymarketresearch.com/sample/sample.php?flag=EB&rep_id=46674

The tier structure is formed based on segmental revenues earned by the sales of sterile medical packaging by the company. According to the tier structure, 3M Company, Nitto Denko Corp, Mitsui Chemicals Inc., Furukawa Electric Co. Ltd., and Sumitomo Bakelite Co. Ltd. Have been considered Tier 1 players in the dicing tapes market. Tier 3 players are Lintec Corporation and Hitachi Chemical Company, Ltd. and other small-scale dicing tapes manufacturers.

More Trending Reports by Transparency Market Research –

Clamshell Blisters Market https://www.transparencymarketresearch.com/clamshell-blisters-market.html

Pharma Packaging Films Market https://www.transparencymarketresearch.com/pharma-packaging-films-market.html

ASEAN Flexible Packaging Market Survey on Emerging Opportunities

https://www.transparencymarketresearch.com/asean-flexible-packaging-market.html

Shuttle Blister packaging Systems Market

https://www.transparencymarketresearch.com/shuttle-blister-packaging-systems-market.html

Skin Care Packaging Market https://www.transparencymarketresearch.com/skin-care-packaging-market.html

Single-serve Water Packaging Market https://www.transparencymarketresearch.com/single-serve-water-packaging-market.html

Nail Care Packaging Market https://www.transparencymarketresearch.com/nail-care-packaging-market.html

Food Oil Packaging Market

https://www.transparencymarketresearch.com/food-oil-packaging-market.html

About Us

Transparency Market Research (TMR) is a global market intelligence company providing business information reports and services. The company’s exclusive blend of quantitative forecasting and trend analysis provides forward-looking insights to thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyse information.

TMR’s data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With extensive research and analysis capabilities, Transparency Market Research employs rigorous primary and secondary research techniques to develop distinctive data sets and research material for business reports.

Contact

Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

USA - Canada Toll Free: 866-552-3453

Email: [email protected]

Website: http://www.transparencymarketresearch.com

Follow Us: Twitter | LinkedIn

Original Source:

https://www.transparencymarketresearch.com/dicing-tapes-market.html

0 notes

Text

Kaynes Technology IPO

Kaynes Technology is a prominent integrated electronics manufacturing company with capabilities spanning the entire range of electronics system design and manufacturing (“ESDM”) services, as well as IoT solutions (Source: F&S Report). Kaynes Technology IPO will hit the stock market in September 2022. About Kaynes Technology Kaynes Technology India Limited have more than 3 decades of expertise…

View On WordPress

0 notes

Text

Foreign Investment in India- Some strong and Weak Points

Foreign company registration in India.

India has become a favorable destination for global investments in recent years. This has resulted in increase in Foreign company registration in India.

There has been an increase of 27% in foreign direct investment in the year 2020 as compared to year 2019. India’s ranking is 5th amongst the top 20 FDI host economies.

Some of the advantages and disadvantages of foreign direct investment (FDI) in India through foreign company registration are as under:

Strong points for FDI in India:

a) Effective and vibrant democratic set up which guarantees a peaceful and stable government which is idle for any sort of investments in India.

b) Independent judiciary and highly developed administrative set up

c) Availability of highly skillful, educated and hardworking work force both white collar and blue collared employees

d) Huge middle class consumer base with high purchasing power makes it world’s largest market base for goods and services.

e) Low development cost of the products as well as availability of cheap labor makes it quite an attractive destination for foreign companies who can export the goods and services to other emerging countries and markets.

f) Second largest English speaking youth makes it easier for multinationals for business set up in India.

Due to aforesaid factors, India has witnessed tremendous growth FDI through foreign company registration in India in the form of private limited company, public limited company, LLP and joint ventures.

Weak Points for FDI in India:

a) When it comes to infrastructure, India really lags behind from rest of the world which really slows down the entire pace of development.

b) Bureaucratic set up at federal level slows down the pace of approvals and it becomes difficult to start and manage business in India

c) Complex labor laws and regulations is another hindrance

d) High debt of the corporates and non-performing assets

All the aforesaid factors act as hindrance in the attracting FDI in India.

Government of India’s policy and incentives to encourage FDI in the country

Some of the measures taken by government to encourage FDI in India are as under:

a) Various tax incentives has been provided for making investments in specified sectors like electronics as well as for making investment in specific regions like North east region, Himachal Pradesh, Uttarakhand and Jammu and Kashmir.

b) Incentives have been provided to manufacturing companies for setting up plant in Special Economic Zones, National Investment and Manufacturing Zones, Export oriented units etc.

c) State governments have their own policy for providing investment incentives in the form of subsidized land price, low rate of interest on loans, reduced tariff on electric power supply and tax concessions.

d) Some government development banks and state industrial development banks provide offers for medium to long term loans for setting up new projects.

e) Recently, government has introduced one nation one tax in the form of Goods and Service Tax.

It has been introduced to make Indian economy competitive to global economies and to boost tax revenues. It is estimated that with the introduction of GST, Indian GDP will witness an overall growth of 1.5% to 2%

f) The government has removed the restriction and in most of the sectors, investment can be made under automatic route as against getting prior approval of Foreign investment Promotion Board (Government route)

g) The government has introduced 3 schemes in order to provide boost to electronic sector namely, the Production Linked Incentive Scheme (PLI), Scheme for Promotion of Manufacturing of Electronic Components and Semiconductors (SPECS) and Modified Electronics Manufacturing Clusters Scheme (EMC 2.0). Also, a national policy on Electronics(NPE) has been introduced in the year 2019 with a vision to make India a global hub for Electronics System Design and Manufacturing (ESDM)

From the foregoing, it may be inferred that India has become one of the most sought after destination for global investment. Further, various incentive schemes of the government also encourages global companies to make investment in India.

Therefore, India will continue to witness more and more foreign company registration in India in coming years provided it works in the areas of shortcomings mentioned above and really intent to become USD 5 Trillion economy in near future.

0 notes