#engineeringtips

Explore tagged Tumblr posts

Text

Types of Mandrel for Different Machining and Manufacturing: A Complete Guide

In the world of precision machining and manufacturing, mandrels play a silent but vital role. Whether you're working with metal, drilling operations, or even jewelry design, the mandrel is a go-to tool for holding, supporting, or shaping a workpiece during fabrication.

But what exactly is a mandrel, and why does it matter so much?

A mandrel, also referred to as an arbor, is a cylindrical or tapered rod used to secure workpieces or tooling components during machining. Instead of clamping directly to the machine’s chuck, the workpiece is mounted on the mandrel, which provides better balance, accuracy, and stability. This is especially crucial for items that are delicate or irregular in shape.

Why Use a Mandrel?

Mandrels allow for:

Improved workholding when a chuck or faceplate isn’t suitable

Higher precision in rotating the workpiece around its true center

Reduced deflection or misalignment during machining operations

Types of Mandrels You Should Know

There are many variations of mandrels, each designed for specific tasks:

1. Solid Mandrel: A plain, tapered cylindrical bar ideal for standard, symmetrical workpieces.

2. Step Mandrel: Features stepped diameters for holding parts with different hole sizes. Great for versatile operations.

3. Gang Mandrel: Used to hold multiple hollow workpieces at once—perfect for speeding up production.

4. Collar Mandrel: Has two fixed collars to grip large workpieces with diameters over 100 mm.

5. Screwed Mandrel: Includes a threaded end to securely hold parts with internal threads.

6. Cone Mandrel: Features a sliding cone to adjust for different workpiece diameters, useful for varying inner diameters.

7. Expanding Mandrel: Uses a tapered arbor and split bush design to expand and grip the inside of hollow parts tightly.

8. Ring Mandrel (Triblet): Popular in jewelry, this tapered tool is used to size, form, and shape rings accurately.

How Mandrels Improve Manufacturing

They help in forging and reshaping delicate pieces (especially in jewelry).

Ensure the workpiece rotates concentrically for precision.

Reduce errors and tool wear caused by unstable setups.

Support advanced operations like boring, grinding, or finishing.

From metal lathe operations to intricate ring making, mandrels are indispensable. Their role in securing workpieces and ensuring flawless rotation cannot be overstated. With so many types available, choosing the right mandrel for your application can significantly improve both quality and efficiency.

For a deep dive into specifications, design differences, and use cases, check out the full article here: Types of Mandrel for Machining and Manufacturing

#Mandrel#LatheTools#MachiningBasics#ManufacturingTech#PrecisionMachining#MachineShop#Metalworking#ToolTalk#CraftWithLathe#WorkshopGear#JewelryMaking#LatheMandrel#MachiningTools#SolidMandrel#EngineeringTips

0 notes

Text

Discover how to choose the perfect vibratory motor for your specific industry needs. This guide by JK Vibratory Motor covers essential factors like motor type, application, power, and mounting. Make informed decisions to boost efficiency and performance in your operations.

#VibratoryMotor#IndustrialMachinery#EngineeringSolutions#IndustrialEquipment#VibrationTechnology#MotorSelection#JKVibratoryMotor#MechanicalEngineering#ManufacturingIndustry#IndustrialAutomation#HeavyMachinery#VibrationMotor#EfficiencyMatters#SmartManufacturing#EngineeringTips

0 notes

Text

5 Common Machine Design Mistakes and How to Avoid Them

Even the smallest oversight in machine design can lead to major operational failures, increased downtime, and unnecessary expenses. This blog highlights the 5 most common machine design mistakes and how to avoid them ensuring your systems are efficient, reliable, and built for long term performance.

Understand the real-world consequences of poor mechanical design decisions

Learn how to optimize performance with proper component selection and layout

Avoid costly rework by identifying design flaws early in the process

Improve the reliability and durability of your machines

Ensure safety, compliance, and user efficiency through smarter custom machine design

Avoid setbacks and get your design right the first time. Discover the 5 mistakes you can’t afford to make in machine design:

👉 5 Common Machine Design Mistakes and How to Avoid Them

0 notes

Text

📏 Understanding Stainless Steel Pipe Thickness is crucial for choosing the right piping solution. Whether you're dealing with high-pressure systems or decorative uses, selecting the appropriate wall thickness affects performance, safety, and cost.

In this guide, you'll learn about:

Thickness classifications like Schedule 10, 40, and 80

Applications suited to different thicknesses

Tips for balancing durability and efficiency

🔍 Discover how to make the best choice for your project: 👉 https://vinssco.com/stainless-steel-pipe-thickness/

1 note

·

View note

Text

Top 3 VFD Maintenance Tips to Boost Motor Performance

Are you using Variable Frequency Drives (VFDs) in your facility? Don't let poor maintenance drain your energy or damage your motors.

Here are 3 expert tips to extend the life of your VFD and optimize performance:

Tip 1: Monitor the Temperature VFDs can overheat if not properly monitored.

➡️ Keep an eye on your VFD's temperature to prevent overheating, shutdowns, and expensive repairs. Tip: Use thermal sensors or smart alerts for early warnings.

Tip 2: Clean Fans & Filters Dust buildup is your worst enemy.

➡️ Clean your VFD’s fans and air filters regularly to maintain proper airflow and cooling efficiency. Clean equipment = stable performance.

Tip 3: Inspect Electrical Connections Loose or corroded wires can cause power loss or dangerous sparks.

➡️ Check all connections to ensure stability and prevent breakdowns. Never ignore signs of burnt smells or flickering indicators. Why VFD Maintenance Matters? - Boosts motor efficiency

Reduces downtime

Saves on energy costs

Prolongs the life of your equipment

Want to Know More? If you're dealing with VFD issues or just want to make sure you're on the right track, you can always reach out or explore helpful resources.

#VFD#MotorPerformance#ElectricalTips#FactoryMaintenance#IndustrialAutomation#PreventiveMaintenance#EnergyEfficiency#EngineeringTips

0 notes

Text

1 note

·

View note

Text

📏 How to decide which pressure angle to use for a gear system?

Guidelines to help you select the right gear angle for your project.

1 note

·

View note

Text

How to Choose the Right Cable Gland Size for Optimal Performance

Choosing the correct cable gland size prevents issues like inadequate sealing and electrical failures. Learn about different cable glands, key selection factors, and expert-recommended steps for a secure fit. Ensure safe and efficient electrical installations with the right gland size.

#CableGlands#ElectricalSafety#IndustrialSolutions#CableManagement#EngineeringTips#PowerDistribution#AtlasMetal

1 note

·

View note

Text

CNC Machining vs Metal Fabrication: Which Process Wins for Your Project?

⚙️ Struggling to choose between CNC machining and metal fabrication? Discover the pros, cons, and expert tips to pick the perfect manufacturing method for precision, speed, and cost-efficiency! 🔧 Dive into this ultimate comparison guide now:

1 note

·

View note

Text

Want to cut costs and stay ahead in the AEC industry? 🚀 Outsourcing is the answer! This video explains how it helps businesses save money, improve efficiency, and access top talent. Learn why outsourcing is a key strategy for 2025 and beyond.

🚀 Don’t Miss Out: https://www.youtube.com/shorts/oh2qfksEq1E

0 notes

Text

✨ Custom Polypropylene Plastic Machining: Challenges & Solutions for Engineers ✨

🔹 Struggling with polypropylene machining? Discover expert insights on overcoming challenges and ensuring precision & efficiency in your projects. ⚙️

🔹 Whether you need large-scale orders or OEM plastic products, this guide provides tailored solutions to streamline your production. 🏭💡

#PolypropyleneMachining#customplastics#OEMSolutions#EngineeringChallenges#PlasticManufacturing#IndustrialDesign#PrecisionEngineering#ManufacturingSolutions#EngineeringTips#materialscience

1 note

·

View note

Text

Different Types of Pipe Bends Explained | Uses & Applications

Pipe bends are essential in industrial piping systems, allowing directional changes while maintaining smooth fluid flow. Various types of pipe bends are used based on application, material, and bending angle. This guide explains different types of pipe bends, their applications, and key selection criteria.

Types of Pipe Bends

1. Short Radius (SR) Bend

Description: Compact bend with a radius equal to the pipe diameter.

Advantages: Saves space, used in tight piping layouts.

Applications: HVAC, plumbing, industrial piping.

2. Long Radius (LR) Bend

Description: Bend radius is 1.5 times the pipe diameter.

Advantages: Reduces pressure drop and turbulence.

Applications: Oil & gas pipelines, water distribution.

3. 3D Pipe Bend

Description: Radius is three times the pipe diameter.

Advantages: Ensures smooth flow with minimal resistance.

Applications: Petrochemical, marine, power plants.

4. 5D Pipe Bend

Description: Radius is five times the pipe diameter.

Advantages: Ideal for applications requiring gradual flow changes.

Applications: Refineries, chemical industries.

5. Miter Bend

Description: Made by cutting pipe segments and welding them at an angle.

Advantages: Cost-effective for large diameter pipes.

Applications: Industrial pipelines, water treatment plants.

6. J-Bend

Description: A 180-degree bend shaped like a 'J'.

Advantages: Used for drainage and condensate return.

Applications: HVAC, plumbing, condensers.

7. U-Bend

Description: A full 180-degree bend.

Advantages: Used in heat exchangers and condensers.

Applications: Power plants, industrial cooling systems.

8. Segmented Bend

Description: Created by welding multiple pipe segments.

Advantages: Customizable for large piping projects.

Applications: Large-scale industrial projects, HVAC.

9. Hot Induction Bend

Description: Made by heating and bending the pipe with induction coils.

Advantages: Precise bending with high strength.

Applications: Oil & gas, power plants.

10. Cold Bends

Description: Pipe bending done without heat.

Advantages: Retains material properties, used in small-diameter pipes.

Applications: HVAC, plumbing, automotive.

Comparison Table of Pipe Bends

Type of BendBend RadiusApplicationsShort Radius1DHVAC, plumbing, industrial pipingLong Radius1.5DOil & gas, water pipelines3D Bend3DPetrochemical, marine, power plants5D Bend5DRefineries, chemical industriesMiter BendCustomIndustrial pipelines, water treatmentJ-Bend180°HVAC, drainage systemsU-Bend180°Heat exchangers, cooling systemsSegmented BendCustomLarge-scale industrial applicationsHot Induction BendVariableOil & gas, power plantsCold BendVariablePlumbing, HVAC, automotive

FAQs

What is the difference between SR and LR bends?

Short radius (SR) bends have a compact design, ideal for tight spaces, while long radius (LR) bends ensure smoother fluid flow with minimal pressure loss.

Which pipe bend is best for oil and gas applications?

3D, 5D, and hot induction bends are commonly used in oil and gas pipelines for better fluid dynamics and durability.

How is a miter bend different from a standard bend?

A miter bend is made by welding multiple pipe segments, whereas standard bends are formed by heating or cold bending a single pipe.

Are U-bends and J-bends the same?

No, a U-bend is a full 180° bend used in heat exchangers, while a J-bend is a 180° bend but shaped like a 'J', commonly used in drainage systems.

#PipeBends#PipingSolutions#IndustrialPipes#PipelineEngineering#FluidFlow#OilAndGas#WaterPipelines#MechanicalEngineering#PipeFittings#Manufacturing#HVAC#SteelPipes#PlumbingSolutions#ProcessIndustry#EngineeringTips

1 note

·

View note

Text

The Ultimate Guide to Choosing the Right Shim for Your Industrial Applications

Shims play a vital role in ensuring precision in industrial machinery by aligning components and filling gaps. Selecting the right shim can be a challenge, but it’s essential for achieving the desired performance. In this guide, we’ll cover the key factors to consider when choosing shims, the available materials, and why working with trusted shim manufacturers in India is critical for high-quality products.

Types of Shims

There are various types of shims, each designed for specific applications. The most commonly used include:

Stainless Steel Shims: Ideal for heavy-duty applications, offering corrosion resistance and durability.

Brass Shim Sheets: Known for their flexibility and excellent conductivity, these are perfect for electrical applications.

Precut Shims: Ready-made shims that save time by offering precise and quick adjustments.

SS Shim Plates: Larger, stronger plates often used in industrial machinery for leveling and alignment.

Each type has its advantages, depending on your needs, whether it’s corrosion resistance, flexibility, or strength.

Material Selection

Choosing the right material for your shim is just as crucial as selecting the right type. Consider the following materials:

Stainless Steel: Best for rust-resistant, heavy-duty applications that require strength and longevity.

Brass: Offers excellent conductivity and flexibility, making it ideal for electrical or decorative uses.

Aluminum: Lightweight and corrosion-resistant, perfect for applications requiring less strength.

Your environment will largely dictate the material. For instance, if your shim will be exposed to high temperatures or moisture, stainless steel might be your best option.

How to Select the Right Shim

To ensure you choose the right shim, keep the following in mind:

Measure gaps accurately: Precision is key. You need to know the exact size of the gap or alignment issue.

Consider strength requirements: Choose a shim that can handle the load and conditions of your specific application.

Consult experts: For custom solutions, it’s wise to work with shim manufacturers in India, who can provide tailored options to suit your exact needs.

By carefully considering the type, material, and strength requirements, you can select the perfect shim for your industrial machinery. Working with trusted suppliers ensures you receive high-quality shim sheet metal, stainless steel shims, and brass shim sheets, whether you're opting for precut shims or SS shim plates.

#IndustrialSolutions#ShimSelection#EngineeringTips#IndustrialApplications#ManufacturingExcellence#PrecisionEngineering#IndustrialTools

0 notes

Text

Dive into the world of carbide rotary file grinding! 🌟 This video breaks down the essentials of using carbide files for effective decompression in your projects. From selecting the right file to practical grinding techniques, we've got you covered. Perfect for professionals and enthusiasts alike who are keen on precision and efficiency in their work. Don't miss out on these expert tips!

#CarbideGrinding#IndustrialTools#EngineeringTips#PrecisionMachining#ToolMastery#EfficiencyInAction#ProfessionalGrinding

0 notes

Text

Unlock the secrets to effortless disassembly! Discover how mastering screw puzzle matching leads to smooth dismantling.

1 note

·

View note

Text

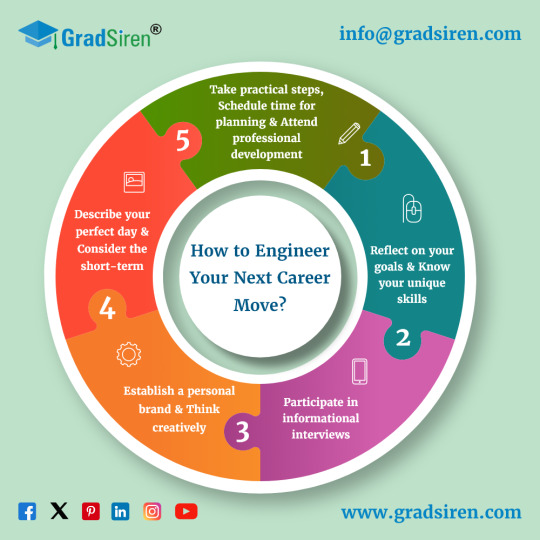

𝐍𝐚𝐯𝐢𝐠𝐚𝐭𝐞 𝐘𝐨𝐮𝐫 𝐂𝐚𝐫𝐞𝐞𝐫: 𝐄𝐧𝐠𝐢𝐧𝐞𝐞𝐫𝐢𝐧𝐠 𝐒𝐮𝐜𝐜𝐞𝐬𝐬 𝐎𝐧𝐞 𝐌𝐨𝐯𝐞 𝐚𝐭 𝐚 𝐓𝐢𝐦𝐞

#engineeringweek2024#engineeringlife#engineeringstudent#EngineeringExcellence#engineeringtech#engineeringtips#studentstips#careertips#engineeringchallenges#EngieeringCareer#StudentSuccess#studentslife#HappyEngineersDay#careerengineering#careerdevelopment#CareerGrowth

1 note

·

View note