#FBG sensors

Text

FiberStrike

The leader in FBG Sensors and Fiber Optic Sensors. The CEL Advanced Technologies Group pioneers the development of innovative Fiber Optic sensors and sensing systems for different applications. Our various fiber optic sensors, manhole switches, intrusion detection systems, and more offer unique solutions to monitoring challenges.

Address: 361 S. 52nd Street, Tempe, Arizona, 85281, United States

Phone : (480) 967-2501

Business Email : [email protected]

Website : https://fiberstrike.com/

youtube

#FBG interrogator#fiberoptic switch#fiber optic sensing#fiber optic security system#FBG sensors#Youtube

1 note

·

View note

Text

Fiber Bragg Grating (FBG) Sensors for Railways

Fiber optic solutions for monitoring systems in the railway industryFiber Bragg grating sensors characteristicsFiber Bragg grating sensors in field projects

Fiber Bragg grating (FBG) sensors have already been applied in various applications and still arouse great production interest. They are commonly used in structural health monitoring for aerospace, civil engineering, oil & gas, etc.

As for the railway industry, fiber optic technology has made a substantial contribution to its development. It is anticipated that within a few years the number of goods that will be transported by railways will be increased, as well as the number of passengers. This, in turn, will lead to the growth of the axle load and trains' faster speeds operating.

That's why there is a great need for a full understanding of the rails' structural and operating conditions as well as for providing safe and reliable operating conditions. So modern innovative technologies are required.

Fiber optic solutions for monitoring systems in the railway industry

In railways, common monitoring systems use strain gauge sensors. The sensors constantly measure resistance caused by the stress transmitted by the rail when the train runs through it. This fiber optic technology is already prominent due to its effectiveness. However, it still has several shortcomings. For example, it is expensive, huge and has difficulties in usage, in comparison with modern FBG sensors. Moreover, the most important disadvantage is that they can be affected by electromagnetic interference. FBG sensors are immune to the external interference such as electromagnetic interference, lightning and many other external disturbances.

Because of this, fiber Bragg grating sensors are getting more and more applications in high-speed railway networks. Applications are train weight estimation, measurement of train speed for real time, wheel imbalance detection, etc. It is clear from experiments that FBG sensors are more appropriate as railway monitoring systems compared to electrical ones.

Fiber Bragg grating sensors characteristics

FBG sensors provide many crucial features for unique operational conditions in railways. In comparison with usual electrical sensors, fiber Bragg grating sensors have EMI/RFI immunity, multiplexing capability and can offer interrogation for long distances. In FBGs the data is wavelength-encoded, which makes the signals less susceptible to intensity fluctuations. Moreover, the fiber optic cable can be interrogated from either end, offering redundancy to FBG sensing networks. Plus, FBGs have a self-calibration capability. The strain and temperature measured findings is an absolute parameter. So there is no dependency on the measurement value and losses between the interrogation unit and the FBGs. To fabricate FBG sensors, FBGs are packaged and transformed into different types of transducers. That makes it possible to install them on the rail track fasteners, clips, bogie, train body, chassis, and axle boxes of a train to provide ongoing inspection for health checking.

In addition to that, FBG sensors can be interrogated at very high-speeds.

Providing reliable operational conditions, fiber optic designs can measure a wide range of other parameters such as inclination and acceleration through the modulation of light in reaction to the environment. Therefore, one FBG interrogator can work with a lot of FBG sensors to measure many options at the same time at different locations over the vast territory. The sensing signals can be read at distances more than 100 km away.

These features are especially useful for the railway industry because they allow simplifying the installations a lot and reducing costs.

Fiber Bragg grating sensors in field projects

Over the past few years, specialists have safely held a number of field trial railway projects involving FBG sensors. For example, in 2007, about fifty FBG-based vibration sensors were installed along the East Rail Link that connects Hong Kong and Mainland China. Then fiber optic solutions were applied in metro lines of Hong Kong, part of the Beijing-Shanghai High-speed Rail Link, and in Delhi Airport Metro Express Line.

In Hong Kong this fiber optic technology was applied on a passenger rail system as a structural health monitoring system. The FBG sensors were attached to the bottom of the carriages. The goal was temperature and strain measurement. The fiber optic system supplied all the necessary data including rail tracks' and carriages' deformation. The acquired information helped to assess the rates of the corrosion and bearing wear.

According to the results, due to FBG sensors, costs of maintenance were greatly reduced. Moreover, it helped to avoid or prevent problems at early stages due to the early detection of excessive vibrations. All these works showed that FBG sensors are superior in comparison with conventional sensors in many essential aspects.

Nowadays, fiber optic solutions are regarded as one the most cost-effective technology that helps in monitoring the condition and structural health of the carriages, tracks, and under frame equipment in railway systems. There are still some parameters that need to be improved, like the lack of proprietary and custom specifications. However, in the future major railway operators can apply modern FBG sensors, gaining more field experience.

Optromix is a fast-growing vendor of fiber Bragg grating (FBG) product line such as fiber Bragg grating sensors, for example, fbg strain sensors, FBG interrogators and multiplexers, Distributed Acoustic Sensing (DAS) systems, Distributed Temperature Sensing (DTS) systems. The company creates and supplies a broad variety of fiber optic solutions for monitoring worldwide. If you are interested in structural health monitoring systems and want to learn more, please contact us at [email protected]

#fiber bragg grating sensors#structural health monitoring#fiber optic technology#fbg sensors#FBG interrogators#fiber optic solutions

0 notes

Text

Get Information About Optic Circulators

Fiber Circulator is used to minimize the dispersion of light within a fiber optic system. Fiber optic circulators, when used with a dispersion compensating module (DCM), may send light across the system while using half the fiber to produce the necessary compensatory effect.

Applications

Optical circulators enable bidirectional ports, allowing an optical signal to be transmitted and received using a single fiber. Fiber optic circulators are utilized in a variety of applications, including dense wavelength division multiplexing (DWDM) networks, polarization mode dispersion, chromatic dispersion correction, optical add-drop modules, optical amplifiers, and fiber optic sensors.

Division Multiplexing (DWDM) Networks

Fibre Circulators in DWDM networks provide 50 dB isolation between forward and backward propagating signals. Fiber optic circulators also have a cross-talk level of greater than 60 decibels.

Optical Add-drop Multiplexing (OADM)

Optical add-drop modules function as main filters. Optical couplers can produce this behavior by utilizing a Fiber Bragg Grating (FBG). The full bandwidth signal enters the coupler and is routed to the next port, where the FBG is inserted. The FBG reflects the required signal to the coupler, while the dropped channels depart via the port. PMD may be corrected using optical couplers, which rotate the optical signal's electric and magnetic fields.

Polarization mode dispersion (PMD)

Some fiber optic systems exhibit polarization mode dispersion (PMD), which is a natural feature of all optical media. PMD is created by a discrepancy in light propagation velocities between the transmission medium's orthogonal main polarization states. If the optical pulse contains both polarisation components, the individual polarisation components in fibre optic circulators will travel at different speeds and arrive at various times, causing the received optical signal to be distorted.

PMD may be corrected using optical couplers, which rotate the optical signal's electric and magnetic fields.

Chromatographic Dispersion Compensation

Optical Circulator uses a chipped Fiber Bragg Grating to adjust for chromatic dispersion. FBGs are wavelength-dependent reflectors. A portion of optical fiber is treated or doped with a substance that affects the fiber's refractive index, resulting in wavelength-dependent reflections. Chipped Fiber Bragg Gratings have numerous gratings displaced across fiber and can compensate for chromatic dispersion.

Follow our Facebook and Twitter for more information about our product.

2 notes

·

View notes

Text

Discussion of Fiber Bragg Grating Technology Applicability on Diagnostic Field Testing of Steel Girder Bridges

Abstract

The application of Fiber Bragg Grating (FBG) technology for purposes of diagnostic field testing on steel girder bridges is discussed in this paper based on the authors experience in field tests of highway bridges. The primary benefit of the FBG technology is the ability to have many sensors (strain gages) multiplexed in a single fiber optic line. In practice, the FBG system is problematic for field conditions of a typical highway bridge. In field tests, measured FBG data showed that the strain histories obtained for a load immediately above the girder of interest were accurate, but the accuracy of the strain histories decreases for adjacent girders as the transverse distance from the load increased. Moreover, protective measures are necessary for FBG systems to be utilized in highway bridge field testing.

Read More about this article: https://irispublishers.com/ctcse/fulltext/discussion-of-fiber-bragg-grating-technology-applicability-on-diagnostic-field-testing-of-steel-girder-bridges.ID.000681.php

Read More about Iris Publishers Google scholar Articles: https://scholar.google.com/citations?view_op=view_citation&hl=en&user=LoZ6uCQAAAAJ&cstart=20&pagesize=80&citation_for_view=LoZ6uCQAAAAJ:7T2F9Uy0os0C

2 notes

·

View notes

Text

Poste de travail laser pour réseaux de Bragg en fibre optique, Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 5 Premières Entreprises

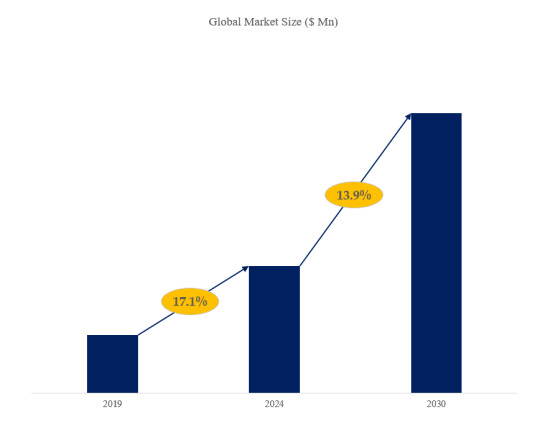

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de Poste de travail laser pour réseaux de Bragg en fibre optique 2024-2030”, publié par QYResearch, la taille du marché mondial de Poste de travail laser pour réseaux de Bragg en fibre optique devrait atteindre 1180 millions de dollars d'ici 2030, à un TCAC de 13.9% au cours de la période de prévision.

Figure 1. Taille du marché mondial de Poste de travail laser pour réseaux de Bragg en fibre optique (en millions de dollars américains), 2019-2030

Selon QYResearch, les principaux fabricants mondiaux de Poste de travail laser pour réseaux de Bragg en fibre optique comprennent WOP, Innofocus, etc. En 2023, les trois premiers acteurs mondiaux détenaient une part d'environ 82.0% en termes de chiffre d'affaires.

Figure 2. Classement et part de marché des 5 premiers acteurs mondiaux de Poste de travail laser pour réseaux de Bragg en fibre optique (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

The market for laser workstations used for the production and analysis of Fiber Bragg Gratings (FBGs) is influenced by several key drivers, which contribute to its growth and development. Here are some important market drivers:

1. Rising Demand for Fiber Bragg Gratings: FBGs are widely used in various applications, including telecommunications, structural health monitoring, temperature sensing, and pressure measurements. The increasing demand for these applications drives the need for advanced laser workstations capable of producing high-quality FBGs.

2. Advancements in Laser Technology: Continuous improvements in laser technologies, including sources that are more efficient, reliable, and capable of producing precise and high-resolution gratings, are driving the adoption of laser workstations. New types of lasers and improved fabrication techniques enhance the performance of FBGs.

3. Growth in Telecommunications Sector: The telecommunications industry is one of the largest consumers of Fiber Bragg Gratings, especially for applications in fiber-optic communications and signal processing. As demand for high-speed data transmission and 5G technology continues to grow, the need for FBGs and the corresponding laser workstations will increase.

4. Development of Smart Infrastructure: The expansion of smart building technologies and infrastructure monitoring systems that utilize FBG sensors for real-time condition monitoring and data collection is driving market growth. Laser workstations are essential for developing customized FBGs tailored to specific monitoring needs.

5. Innovations in Sensing Technologies: FBGs are increasingly being adopted in various sensing applications due to their advantages, such as high sensitivity and immunity to electromagnetic interference. The growth in industries such as aerospace, automotive, and energy sector—for structural and environmental monitoring—requires robust laser workstations for the production of specialized FBGs.

6. Focus on Research and Development: Research institutions and labs are actively engaged in developing new applications for FBGs, which drives the demand for laser workstations that can facilitate advanced experimental setups. This R&D focus contributes to the advancement of FBG-related technologies and products.

7. Miniaturization Trends: The growing trend toward miniaturization in various applications, especially in telecommunications and medical devices, requires precise and compact FBG solutions. Laser workstations equipped to produce smaller and more intricate FBGs are increasingly important.

8. Energy Efficiency and Cost Reduction: Advances in laser technology have enabled the development of more energy-efficient laser workstations, which can reduce operating costs. This is particularly attractive for businesses and research institutions looking to optimize their operations.

9. Customization and Flexibility: The ability to design and fabricate customized FBGs for specific applications is driving demand for adaptable laser workstations. Systems that allow for easy programming and adjustment for different grating patterns can enhance production efficiency and innovation.

10. Growing Adoption in Medical Applications: The healthcare sector is increasingly exploring the use of FBGs for applications such as biomedical sensing and imaging. As this trend grows, the need for specialized laser workstations for producing medical-grade FBGs will also increase.

11. Collaborative Industry Growth: Collaborations between universities, research institutions, and industries focused on fiber optics and sensor technologies promote innovation and lead to the development of new applications for FBGs. This collaborative growth stimulates demand for laser workstations.

In summary, the market for laser workstations for Fiber Bragg Gratings is driven by rising demand for FBGs in various sectors, advancements in laser technology, the growth of telecommunications and smart infrastructure applications, research initiatives, and the increasing adoption of FBGs in sensing and medical applications. These factors create a conducive environment for the expansion of this market.

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

#Poste de travail laser pour réseaux de Bragg en fibre optique#Laser Workstation for Fiber Bragg Gratings

0 notes

Text

Textile Technological Advances

Textile improvements have been achieved in a variety of disciplines. Synthetic fabrics, sensors and actuators, spinning jennies, digital printing, and changing the essence of clothes are among them.

Synthetic textiles are garments produced from synthetic fibers. They are utilized in a variety of applications, including clothes, footwear, home furnishings, and medical devices.

Synthetic textiles are a less expensive alternative to natural fibers. They also dry faster and are more resistant to perspiration. Furthermore, they are stain and wrinkle-resistant. They also retain their form better after repeated washing.

Chemical methods are used to create synthetic fibers. Their outstanding features are one of the primary reasons for their widespread usage in a variety of sectors. Polypropylene (PP), polyurethane, nylon, and polyamides are the most common synthetic fibers.

Because of its high thermal resistance and inexpensive cost, polypropylene is commonly employed in automotive applications. Polyester is yet another common synthetic material. It's found in carpets, upholstery textiles, and side panels.

James Hargreaves designed the spinning jenny machine in 1764. It was a precursor to the power loom. This device enabled the spinning of numerous threads at the same time, resulting in increased thread output and, consequently, textiles.

The spinning jenny was one of the most important inventions in the textile industry during the Industrial Revolution. It aided in increasing productivity in the textile industry, which aided in the sector's expansion.

The spinning jenny was a device invented in the 17th century for spinning numerous threads at the same time. However, James Hargreaves patented the apparatus in the mid-1760s.

Nonetheless, it was a significant advance over previous technologies and a giant stride forward in textile production. The jenny was a primary, low-cost, hand-operated device.

Textile digital printing innovations are reshaping the garment business. With a slew of new technologies on the horizon, the industry is expected to expand significantly in the following years.

In addition to lowering production costs and downtime, digital printing has various advantages over traditional methods. For example, technology is environmentally beneficial. It also provides color and design versatility.

Smaller fashion houses are also using technology to manufacture their own items. Some businesses have even created their own "micro-factories" to produce printed textiles. This allows them to provide on-demand clothing creation, decreasing the environmental effect of transportation.

Another benefit of the new technology is the ability to print on different textiles. Traditional techniques need unique inks and treatments for each cloth type.

Sensors and actuators of various sorts are increasingly being integrated into textiles. Physical and chemical inputs are collected and converted into electrical signals by these devices. Sensors can also be used to capture and monitor health information. Traditional textile production methods may be used to create electronic textiles. These technologies' benefits include lightweight, breathability, and washability.

Small photodetectors are used in optical textile sensors to monitor the amplitude of light. They can also sense changes in temperature. The diameters of small glass optical fibers are in the micron range. The first fiber Bragg grating (FBG) sensors were created in 1978.

Resistive pressure sensors, on the other hand, link electric resistance and pressure. Wires, flexible transistors, and metals are among the architectures accessible. Textile capacitors can be constructed from conductive plates separated by dielectrics. They can be made by sewing, weaving, or painting using conductive inks.

The fashion business has experienced tremendous growth in the number of clothes manufactured each year during the last 15 years. This clothing is becoming increasingly popular across the world.

Clothing is an essential component of our culture in both established and emerging nations. It is utilized to provide comfort and security, as well as to shape our identities. However, the sector faces substantial social and environmental issues and must adapt in order to reach its full potential.

The fashion business is dependent on nonrenewable resources such as petroleum-based polyester, cotton, and nylon. Using these materials can result in massive amounts of waste and greenhouse gas emissions. Furthermore, chemicals and dangerous substances are frequently used in the clothes manufacturing process.

The UNEP has published a roadmap for a more sustainable fashion industry. It addresses the need for a new textile economy based on circularity principles, as well as recommendations for decreasing consumer impacts and making the entire textile value chain more sustainable.

0 notes

Text

Binary editor innovate wideband

#BINARY EDITOR INNOVATE WIDEBAND FREE#

Many methods have been proposed to improve the coupling efficiency of the grating coupler, and blazed grating coupler is widely studied. In recent years, SOI fiber-to-chip grating couplers have been widely reported. The coupling efficiency of a conventional fiber-to-chip grating coupler, however, is at a maximum of 40% to 60% for a standard SOI with an incident angle of 0°.

#BINARY EDITOR INNOVATE WIDEBAND FREE#

Grating couplers are widely used to couple light between nanophotonic waveguides and free space optical components. The proposed AWG demodulation integration microsystem. In this work, the InP-based C-band LED and SOI waveguide are bonded by benzocyclobutene (BCB) using heterogeneous integration. Light source is very important for the integrated microsystem, and silicon-on-insulator- (SOI-) LEDs are difficult to achieve under the current process. The proposed AWG demodulation integrated microsystem is shown in Figure 1. The current work aims to study the integration of AWG demodulation system to achieve an AWG demodulation integrated microsystem. The fiber grating demodulation system based on arrayed waveguide grating (AWG) is a new potential method that can be used for fiber grating demodulation, which is smaller and cheaper than the conventional fiber grating demodulation system. These sensors are used to measure strain, temperature, pressure, and other physical quantities that can be converted into strain or temperature. Introductionįiber Bragg grating (FBG) sensors are widely known to have achieved great progress. When the incident angle of the light source is, the coupling efficiency of the binary blazed grating is 40.92%, and the 3 dB bandwidth is 72 nm at a wavelength of 1550 nm. The coupler was designed and optimized based on the finite difference time domain method. Both the length and width of the grating coupler are 360 μm, as large as the InP-based C-band LED light emitting area in the system. Through the coupler, light can be coupled into the SOI waveguide from the InP-based C-band LED for the AWG demodulation integrated microsystem to function. A large-area binary blazed grating coupler for the arrayed waveguide grating (AWG) demodulation integrated microsystem on silicon-on-insulator (SOI) was designed for the first time.

0 notes

Link

The Fiber Bragg Grating Market Growth impelled by use of fiber bragg grating in sensing applications and increasing adoption of fiber bragg grating due to their advantages.

0 notes

Link

0 notes

Text

India FBG Sensor Market

Market Reports on India Provides the Trending Market Research Report “FBG Sensor-India Market Status and Trend Report 2015-2026” under Electronics Category. The report offers a collection of superior market research, market analysis, competitive intelligence and Market reports.

FBG Sensor-India Market Status and Trend Report 2015-2026 offers a comprehensive analysis on FBG Sensor industry, standing on the readers’ perspective, delivering detailed market data and penetrating insights. No matter the client is industry insider, potential entrant or investor, the report will provides useful data and information.

Request a free sample copy of India FBG Sensor Market Report

http://www.marketreportsonindia.com/marketreports/sample/reports/2425561

Key questions answered by this report include:

-Whole India and Regional Market Size of FBG Sensor 2015-2019, and development forecast 2020-2026

-Main market players of FBG Sensor in India, with company and product introduction, position in the FBG Sensor market

-Market status and development trend of FBG Sensor by types and applications

-Cost and profit status of FBG Sensor, and marketing status

-Market growth drivers and challenges

Since the COVID-19 virus outbreak in December 2019, the disease has spread to almost 100 countries around the globe with the World Health Organization declaring it a public health emergency.The global impacts of the coronavirus disease 2019 (COVID-19) are already starting to be felt, and will significantly affect the Ammonium FBG Sensor market in 2020.COVID-19 can affect the global economy in three main ways: by directly affecting production and demand, by creating supply chain and market disruption, and by its financial impact on firms and financial markets.The outbreak of COVID-19 has brought effects on many aspects, like flight cancellations; travel bans and quarantines; restaurants closed; all indoor events restricted; over forty countries state of emergency declared; massive slowing of the supply chain; stock market volatility; falling business confidence, growing panic among the population, and uncertainty about future.This report also analyses the impact of Coronavirus COVID-19 on the FBG Sensor industry.

The report segments the India FBG Sensor market as:

India FBG Sensor Market: Regional Segment Analysis (Regional Consumption Volume, Consumption Volume, Revenue and Growth Rate 2015-2026):

North India

Northeast India

East India

South India

West India

India FBG Sensor Market: Product Type Segment Analysis (Consumption Volume, Average Price, Revenue, Market Share and Trend 2015-2026):

Point FPG

Distributed FPG

India FBG Sensor Market: Application Segment Analysis (Consumption Volume and Market Share 2015-2026; Downstream Customers and Market Analysis)

Civil Engineering

Transportation

Energy & Utility

Military

Others

India FBG Sensor Market: Players Segment Analysis (Company and Product introduction, FBG Sensor Sales Volume, Revenue, Price and Gross Margin):

Rockwell Automation

LUNA (Micron Optics)

Proximion AB

HBM FiberSensing

ITF Technologies Inc

NKT Photonics

FISO Technologies

Omron

FBGS Technologies

Keyence

Omnisens

WUTOS

Bandweaver

Smart Fibres Limited

Sensornet

In a word, the report provides detailed statistics and analysis on the state of the industry; and is a valuable source of guidance and direction for companies and individuals interested in the market.

Browse our full report with Table of Content :

http://www.marketreportsonindia.com/marketreports/fbg-sensor-india-market-status-and-trend-report-2015-2026/2425561

About Market Reports on India:

Market Reports on India is an excellent source to obtain top quality market research reports that helps you to understand the business in the Indian market. We cover various industries, identifying and understanding key macro and micro-economic trends, insights and futuristic growth opportunities. To help achieve all this and more, Market Reports on India is the answer to all your business needs.

Contact us at:

Market Reports on India

Tel: +91 22 27810772 / 27810773

Email: [email protected]

Website: www.marketreportsonindia.com

Follow us on: Twitter, Facebook, LinkedIn

0 notes

Text

Fiber Optic Sensing for the Steam Assisted Gravity Drainage

Fiber optic sensing technology has proved to be an effective method in well and reservoir management. Fiber optic sensors constantly track temperature changes along the wells at specified intervals and collect all the data.

This technique is also compliant with the other technologies such as Steam Assisted Gravity Drainage (SAGD).

What is Steam Assisted Gravity Drainage?

Steam Assisted Gravity Drainage (or SAGD) is an enhanced oil recovery drilling technique that helps in extracting heavy crude oil or bitumen from oil sands deposits. Mostly, the accustomed approaches in such cases are economically inefficient. Specialists may use it in particular cases when the production is difficult. With the help of the fiber optic technology this approach becomes more cost-effective.

How does Steam Assisted Gravity Drainage work?

In short, the SAGD system's principle is heating the heavy oil or bitumen by the steam for further extraction. For that two horizontal wells are drilled at an angle of 90 degrees to a vertical bore well. In the wells, there are two pipes, one above the other for around 4-5 meters.

At the very beginning, the cold heavy oil is essentially immobile because of the high viscosity, and it needs to be warmed up to extract it. To do so, the steam is applied. It travels through the upper well into the reservoir and expends the heat in all directions of the formation, making a steam chamber. The heat warms the bitumen and reduces its viscosity. Then the bitumen flows downward into the production well and is pumped to the surface. Both processes are going at the same time.

Current Applications of the Steam Assisted Gravity Drainage

Due to the growing level of oil consumption, the level of its development needs to be increased. Not the last role is played by the SAGD and fiber optic systems such as fiber optic sensors and fiber Bragg gratings.

Like any exploration, heavy oil production needs accurate analysis and planning, especially if there are other factors that make the production difficult. Such aspects as great depth, high temperature conditions, etc. are essential. All of these issues need to be considered. The low mobility and high viscosity make the oil producing complicated and lead to low recovery indexes. However, due to the SAGD and fiber optic technology, there is an opportunity to maximize the recovery indexes.

For SAGD technology, FBG sensors are usually applied in wells to track the steam as it moves along the wellbore. Due to the fiber optic sensors, there is an opportunity to see the data in real time. According to the achieved data, the velocity of the steam can be identified. Besides, temperature sensors can also define the speed of the heating. The accurate settings of the temperature, pressure and steam-injection rates can lead to the operational savings. All the information can be used to plan the further work of the production operations.

Fiber Optic Sensors in Downhole Monitoring

Fiber optic sensors have proved to be effective for various parameters' monitoring in downhole applications. Most of all, distributed temperature sensing (DTS) is applied for these purposes. Distributed sensing has demonstrated good results. It has high recommendations in the oil industry. DTS can monitor well temperature all over the fiber optic cable.

Due to the modernly developed fiber optic designs and improvement of fiber optic sensing technology, a range of issues related to downhole production have been solved. However, the harsh environmental conditions in the downhole can still bring some problems to the fiber optic sensors.

The sensors still need to cope with hydrogen in the severe environmental conditions. It has a great impact on the optical fibers. Firstly, it can cause pressure and temperature errors. The appearing errors are connected to the hydrogen diffusion into the microstructure and to the changes of the refractive index when hydrogen penetrates into micro holes and fiberglass. So the hydrogen leads to the additional Bragg wavelength shift.

With this in mind, specialists are constantly developing fiber optic monitoring systems based on fiber Bragg grating technology.

Advantages and disadvantages of the SAGD

SAGD has played a crucial role in the rapid development of the oil resources. However, as everything, this method has some pros and cons that should be taken into account.

Most Common Disadvantages for SAGD technology

Firstly, as any other technology, SAGD has its restrictions. It is not well-suited for every production area with heavy oil. It has several aspects to be fulfilled, like homogeneous and relatively thick reservoirs.

Secondly, high water and fuel consumption. To work effectively, SAGD needs a large amount of water and natural gas. Both of them are used in the process of steam production. That's why the energy consumption is high but worth it. When all these conditions are satisfied, SAGD technology can be used. Moreover, the specialists advise using deep water sources that are not appropriate for consumption or agricultural uses. In fact, the majority of deployments’ developers follow this recommendation for environmental protection.

Thirdly, some think that SAGD technology is an expensive tool for oil production. However, specialists consider this technology as a superior alternative to reduce the high expenses and at the same time increase productivity. The reason for the cost reduction is that less horizontal wells are required to be drilled.

Fourthly, concerns about an environmental effect of the steam assisted gravity drainage (SAGD) are still a topic of discussion. However, according to the statistics, over the last 20 years the environmental analysis is getting better. It is obvious that the production of the crude bitumen and oil cause environmental consequences, but due to the development of modern cleaner extraction technologies, the situation is improving.

The Main Advantages of the SAGD technology

The main benefit of the whole SAGD technology is the improved steam-oil ratio and high ultimate recovery. Besides, the DTS systems help in optimization of the oil and bitumen production.

The other SAGD advantage is the constant evolution. Every next project makes a great contribution and brings new ideas and experiences. Meanwhile, the diversity of newly developed methods leads to new approaches to different types of oil fields.

So there are other modified types of SAGD technique:

Shaft and Tunnel Access (SATAC);

Single Well SAGD (SW-SAGD);

Multi-drain SAGD;

Fast-SAGD;

Enhanced Steam Assisted Gravity Drainage (ESAGD).

The SAGD was firstly implemented in Canada, where there are the largest reservoirs of crude bitumen. This allowed to advance the recovery factors in excess of 50%.

SAGD (steam assisted gravity drainage) well temperature monitoring provide:

Temperature profile control of injection and production wells;

Determination of inflow (injection) intervals of the fluid;

Determination of the fluid level in the well and perforation intervals;

Identification of issues in the well.

Plus, as any fiber optic technology, distributed temperature sensing for SAGD offers:

Maximum protection of the cable against chemical and physical effects;

Longer service life;

Convenience and speed of the installation;

Operations in the well without the extraction of the cable sensor.

The SAGD wells have implemented all the advantages of fiber optic sensing. FBG sensors offer real-time, precise temperature measurements along the fiber optic cable in the wellbore. Fiber optic solutions allowed us to monitor the objects that were unapproachable before. For example, fiber optic sensors with extended temperature range were applied in the oil wells for temperature control during oil production using SAGD technology.Steam assisted gravity drainage is commonly believed to be applied for complex deployments. It aims to make the process simpler. And the fiber optic technology is good at helping it. However, the specialists should discuss and decide how fiber optic technology can fit into the development at the planning stage. Fiber optic solutions may simplify the production process.

Optromix is a fast-growing vendor of fiber Bragg grating (FBG) product line such as fiber Bragg grating sensors, for example, fbg strain sensors, FBG interrogators and multiplexers, Distributed Acoustic Sensing (DAS) systems, Distributed Temperature Sensing (DTS) systems. The company creates and supplies a broad variety of fiber optic solutions for monitoring worldwide. If you are interested in structural health monitoring systems and want to learn more, please contact us at [email protected]

#Fiber Optic Sensing#Fiber Optic Sensors#fiber optic technology#fiber bragg gratings#FBG sensors#temperature sensors#distributed temperature sensing#fiber optic solutions

0 notes

Text

Global and French Fiber Optics Sensors Market Research Report in 2020 -, Micron Optics, Honeywell, FISO Technologies, Omron, Fbgs Technologies GmbH and Others

Global and French Fiber Optics Sensors Market Research Report in 2020 -, Micron Optics, Honeywell, FISO Technologies, Omron, Fbgs Technologies GmbH and Others

[ad_1]

This report provides a strategic analysis of the Sensor Optical Fibers market and growth forecasts for the period 2020 to 2027. The duration of the report covers the competitive analysis of various market segments according to types and the analysis of applications of the Sensor Optical Fibers market in different geographic segments. To support strategic decision-making, the report also…

View On WordPress

#Fbgs#fiber#FISO#French#Global#GmbH#Honeywell#market#Micron#Omron#Optics#REPORT#research#sensors#Technologies

0 notes

Text

FBG Strain Sensors Market Size and Growth Factors Research and Projection to 2024

FBG Strain Sensors Market 2019

FBG Strain Sensors Market Insights 2019, Global and Chinese Scenario is a professional and in-depth study on the current state of the global FBG Strain Sensors industry with a focus on the Chinese market. The report provides key statistics on the market status of the FBG Strain Sensors manufacturers and is a valuable source of guidance and direction for companies and individuals interested in the industry.Overall, the report provides an in-depth insight of 2014-2024 global and Chinese FBG Strain Sensors market covering all important parameters. The FBG Strain Sensors market research report is a professional and in-depth study on the current state of the global FBG Strain Sensors Industry with a focus on the regional market. The report provides key statistics on the market status of the FBG Strain Sensors players and is a valuable source of guidance and direction for companies and individuals interested in the industry.

You Can Request a Sample Version of Report before Buying (Just use the corporate email address to Get Higher Priority): @https://www.acquiremarketresearch.com/sample-request/188999/

The report provides a basic overview of the industry including its definition, applications, and classifications. Then, the report explores the international and regional major industry players in detail. In this part, the report presents the company profile, product specifications, capacity, production value, and market shares for each company.

For competitor segment, the report includes At least 4 companies are included: * HBM * National Instruments * Proximion * AtGrating The information for each competitor includes: * Company Profile * Main Business Information * SWOT Analysis * Sales, Revenue, Price and Gross Margin * Market Share For product type segment * Product Type I * Product Type II * Product Type III For end use/application segment, this report focuses on the status and outlook for key applications. End users sre also listed. * Application I * Application II * Application III

FBG Strain Sensors Market

Go For special offer price @https://www.acquiremarketresearch.com/discount-request/188999/

Key Highlights from FBG Strain Sensors Market Study:-

Production Analysis – Production of the FBG Strain Sensors market is analyzed with respect to different regions, types, and applications. Here, price analysis of various FBG Strain Sensors Market key companies is also covered.

Competitors – In this section, various FBG Strain Sensors industry-leading players are studied with respect to their company profile, product portfolio, capacity, price, cost, and revenue.

Sales and Revenue Analysis – Both, sales and revenue are studied for the different regions of the FBG Strain Sensors Market. Another major aspect, price, which plays an important part in the revenue generation, is also measured in this section for the numerous regions.

Supply and Consumption – In continuation with sales, this section studies supply and consumption for the FBG Strain Sensors Market. This part also shelters light on the gap between supply and consumption. Import and export statistics are also given in this part.

Other analyses– Apart from the above-mentioned information, trade and distribution analysis for the FBG Strain Sensors Market, the contact information of major manufacturers, suppliers and key consumers are also given. In addition, SWOT analysis for new projects and viability analysis for new investment are included.

Research objectives:

1) To study and analyze the FBG Strain Sensors consumption (value & volume) by key regions/countries, product type and application, history data from 2014 to 2019.

2) To understand the structure of FBG Strain Sensors market by identifying its various sub-segments.

3) Focuses on the key global FBG Strain Sensors manufacturers, to define, describe and analyze the sales volume, value, market share, market competition landscape, SWOT analysis, and development plans in the next few years.

4) To analyze the FBG Strain Sensors with respect to individual growth trends, future prospects, and their contribution to the total market.

5) To share detailed information about the key factors influencing the growth of the market (growth potential, opportunities, drivers, industry-specific challenges and risks).

The Report Highlights :

SWOT Analysis Import/Export Strategies

Policy & Regulation.

Distribution Channel Analysis

Diabetic Retinopathy Market Dynamics (Market Trends, Key Drivers, Restraints)

Product Benchmarking and Pricing Analysis of Key Industry Players

Last, It offers in-depth information obtained through extensive primary and secondary research methods. The information has been further assessed using various effective analytical tools. Therefore, the report provides a 360-degree view of the FBG Strain Sensors market.

For More Details @https://www.acquiremarketresearch.com/industry-reports/fbg-strain-sensors-market/188999/

Request a customized copy of FBG Strain Sensors report

We are grateful to you for reading our report. If you wish to find more details of the report or want customization, contact us. You can get a detailed of the entire research here. If you have any special requirements, please let us know and we will offer you the report as you want.

0 notes

Text

Analysis of FBG Sensor Market in Global Industry: Demand, Growth Factors, Supply, Latest Rising Trend & Forecast to 2018

Excell Reports announces the addition of new study based research report on FBG Sensor Market to their suite of offerings. The report provides key statistics on the market status of the FBG Sensor manufacturers and is a valuable source of guidance and direction for companies and individuals interested in the industry. Firstly, the report provides a basic overview of the industry including its definition, applications and manufacturing technology. Then, the report explores the international major industry players in detail. In this part, the report presents the company profile, product specifications, capacity, production value, and 2013-2018 market shares for each company. Through the statistical analysis, the report depicts the global total market of FBG Sensor industry including capacity, production, production value, cost/profit, supply/demand and Chinese import/export.

The total market is further divided by company, by country, and by application/type for the competitive landscape analysis. The report then estimates 2018-2023 market development trends of FBG Sensor industry. Analysis of upstream raw materials, downstream demand, and current market dynamics is also carried out. In the end, the report makes some important proposals for a new project of FBG Sensor Industry before evaluating its feasibility. Overall, the report provides an in-depth insight of 2013-2023 global FBG Sensor industry covering all important parameters.

For Free Sample Copy, click here: https://www.excellreports.com/request-for-sample/?id=151632

The report features in-depth analysis of the global market with a focus on factors that influence the market, such as drivers, restraints, and key trends. The report will let you discover the future market prospects along with the most lucrative areas in the industry. This research based study lets you assess forecasted sales at overall world market and regional level with the interviews, financial results, and revenue predictions. It also analyses the import and export and draws a market comparison focused upon the Development Trend.

The report features:

Overview of the industry, including definitions, classification and segmentation on the basis of application, product, geography and competitive market share

All-inclusive assessment of the market

Industry validated and statistically-supported market data

Facts and statistics

Business outlook and developments

Market forecasts for the projected time frame

Qualitative analyses (including SWOT analysis), product profiles and commercial developments.

Key participants, company profiles, market trends, and business strategies

To view the table of contents and know more details please visit: https://www.excellreports.com/product/technology-media-telecommunications/semiconductor-electronics/global-fbg-sensor-market-report-2019-history-present-and-future/

Competitive Landscape:

The FBG Sensor market is characterized by the presence of a significant number of market participants. The research report lets you identify key organizations holding the greatest potential. Is also helps you stay ahead by figuring out capabilities, commercial prospects and progress of the key players. It also analyzes latest advancements in technology along with major industry participants profiled in the report. A review of macro and micro factors vital for the present market participants and new companies lets you evaluate competitive dynamics. The commercial analysis and insights of FBG Sensor market will let you stay well-versed with valuable business intellect on FBG Sensor market.

Ask for Discount @ https://www.excellreports.com/inquire-for-discount/?id=151632

About Us:

Excell reports is one of the leading distributors of Market research reports produced by premium publishers. Being a one stop solution for research requirements, our Market research reports help our clients to keep abreast of thousands of industries all-round the globe. A better understanding of the predicted market conditions, a clear picture of supply and source industries allows our clients to closely monitor competitor activities. Our large database of more than 50,000 quality driven reports from over 40+ leading publisher ensures that your market research requirements are sufficed

Contact Us:

Mr. Abhishek Shinde

Excell Reports

9701 Wilshire Boulevard 10th Floor

Beverly Hills,

California 90212

Tel - +18448939235

Email : [email protected]

WebSite : www.excellreports.com

0 notes

Text

FBG Temperature Sensor

The sensitivity of the FBG temperature sensor is sometimes referred to as the resolution or temperature sensitivity of the sensor, that is, the minimum temperature change that the sensor can measure.

To be precise, the sensitivity of each FBG temperature sensor is different, mainly determined by the reflection wavelength of the FBG and the natural characteristics of the glass filament used in the fiber, and sometimes it is also related to the sensor packaging method. The method can sensitize or desensitize the FBG.

Types of FBG Temperature Sensor

FBG Temperature Sensor CT-01

Ceramic housed temperature sensor CT-01, high temperature and electric power resistance, makes it perfectly suitable for the temperature sensing in power station, oil & gas industries.

FBG Temperature Sensor ST-01

Stainless Steel tube housed temperature sensor ST-01, waterproof, commonly used in long-time harsh environmental temperature sensing in railway, bridge, dam, tunnel, etc.

What Is Fbg Temperature Sensor's Sensitivity?

The FBG temperature sensor from AtGrating, in the vicinity of our common 1550nm C-band, the sensitivity (resolution) of the FBG temperature sensor is about 11pm/℃, which means that the measured object or the measured environment is for every 0.1℃ change in temperature, the reflected wavelength of the fiber grating temperature sensor changes by 1pm. At this point we can say that the sensitivity (resolution) of the fiber grating temperature sensor is 0.1℃.

It should be further pointed out that the sensitivity or resolution of the FBG temperature sensor we are talking about is 0.1℃. This statement is more from or limited by the fiber grating interrogator (not limited by the sensor itself), if a interrogator with higher resolution is used, so that it can detect wavelength changes below picometers, the sensitivity or resolution of the fiber grating temperature sensor we define here will also be correspondingly improved.

1 note

·

View note

Text

Fiber Optic Sensors Market Size, Share, By Type, Application, Top Key Players - Global Opportunity Analysis and Industry Forecast 2022-2030

Global “Fiber Optic Sensors Market” 2022 Reports give a Key study on the industry status of the Fiber Optic Sensors Manufacturer with the specific statistics, meaning, definition, SWOT Analysis, expert opinion, and recent development across the globe. The research report also covers the Market Size, Price, Sales, Revenue, Market share, Gross Margin, growth rate, and cost structure. The report aims to give an additional sample of the latest scenario, economic slowdown, and Covid-19 impact on overall Industry.

The Fiber Optic Sensors research report will also study market share for major stakeholders in their global capacity as transformers of the global scale. This qualitative and quantitative analysis will include key product offerings, key differentiators, revenue share, market size, market status, and strategies. The report will also cover key agreements, collaborations, and global partnership soon to change dynamics of the market on a global scale.

Click the link to get a free Sample Copy of the Report @ https://crediblemarkets.com/sample-request/fiber-optic-sensors-market-452805?utm_source=Kaustubh&utm_medium=Free

By Market Verdors:

Micron Optics

Honeywell

FISO Technologies

Omron

FBGS TECHNOLOGIES GMBH

Proximion

Smart Fibres Limited

Sensornet

ITF Labs / 3SPGroup

Keyence

IFOS

NORTHROP GRUMMAN

O/E LAND, Inc

KVH

Photonics Laboratories

Chiral Photonics

FBG TECH

OPTOcon GmbH

Redondo Optics

Broptics

Wutos

Pegasus (Qingdao) Optoelectronics

BEIYANG

Bandweaver

DSC

By Types:

Intensity Modulated Fiber Optic Sensors

Phase Modulated Fiber Optic Sensors

Wavelength Modulated Fiber Optic Sensors

Polarization Modulated Fiber Optic Sensors

By Applications:

Oil & Gas

Buildings and Bridges

Tunnels

Dams

Heritage Structures

Power Grid

Aerospace Applications

Some Point from Table of Content:

Global Fiber Optic Sensors Market Analysis, Key Company Profiles, Types, Applications and Forecast to 2030

1 Fiber Optic Sensors Market Definition and Overview

2 Research Method and Logic

3 Market Competition Analysis

4 Market Segment by Type, Historical Data and Market Forecasts

5 Market Segment by Application, Historical Data and Market Forecasts

6 Global Fiber Optic Sensors by Region, Historical Data and Market Forecasts

7 United State Market Size Analysis 2018-2030

8 Canada Market Size Analysis 2018-2030

9 Germany Market Size Analysis 2018-2030

10 UK Market Size Analysis 2018-2030

11 France Market Size Analysis 2018-2030

12 Italy Market Size Analysis 2018-2030

13 Spain Market Size Analysis 2018-2030

14 Russia Market Size Analysis 2018-2030

15 China Market Size Analysis 2018-2030

Direct Purchase this Market Research Report Now @ https://crediblemarkets.com/reports/purchase/fiber-optic-sensors-market-452805?license_type=single_user;utm_source=Kaustubh&utm_medium=Free

16 Japan Market Size Analysis 2018-2030

17 South Korea Market Size Analysis 2018-2030

18 Australia Market Size Analysis 2018-2030

19 Thailand Market Size Analysis 2018-2030

20 Brazil Market Size Analysis 2018-2030

21 Argentina Market Size Analysis 2018-2030

22 Chile Market Size Analysis 2018-2030

23 South Africa Market Size Analysis 2018-2030

24 Egypt Market Size Analysis 2018-2030

25 UAE Market Size Analysis 2018-2030

26 Saudi Arabia Market Size Analysis 2018-2030

27 Market Dynamic Analysis and Development Suggestions

Report includes Competitor's Landscape:

➊ Major trends and growth projections by region and country

➋ Key winning strategies followed by the competitors

➌ Who are the key competitors in this industry?

➍ What shall be the potential of this industry over the forecast tenure?

➎ What are the factors propelling the demand for the Fiber Optic Sensors?

➏ What are the opportunities that shall aid in significant proliferation of the market growth?

➐ What are the regional and country wise regulations that shall either hamper or boost the demand for Fiber Optic Sensors?

➑ How has the covid-19 impacted the growth of the market?

➒ Has the supply chain disruption caused changes in the entire value chain?

Contact Us

Credible Markets

99 Wall Street 2124 New York, NY 10005

Email: [email protected]

0 notes