#fiber bragg grating sensors

Text

Fiber Bragg Grating (FBG) Sensors for Railways

Fiber optic solutions for monitoring systems in the railway industryFiber Bragg grating sensors characteristicsFiber Bragg grating sensors in field projects

Fiber Bragg grating (FBG) sensors have already been applied in various applications and still arouse great production interest. They are commonly used in structural health monitoring for aerospace, civil engineering, oil & gas, etc.

As for the railway industry, fiber optic technology has made a substantial contribution to its development. It is anticipated that within a few years the number of goods that will be transported by railways will be increased, as well as the number of passengers. This, in turn, will lead to the growth of the axle load and trains' faster speeds operating.

That's why there is a great need for a full understanding of the rails' structural and operating conditions as well as for providing safe and reliable operating conditions. So modern innovative technologies are required.

Fiber optic solutions for monitoring systems in the railway industry

In railways, common monitoring systems use strain gauge sensors. The sensors constantly measure resistance caused by the stress transmitted by the rail when the train runs through it. This fiber optic technology is already prominent due to its effectiveness. However, it still has several shortcomings. For example, it is expensive, huge and has difficulties in usage, in comparison with modern FBG sensors. Moreover, the most important disadvantage is that they can be affected by electromagnetic interference. FBG sensors are immune to the external interference such as electromagnetic interference, lightning and many other external disturbances.

Because of this, fiber Bragg grating sensors are getting more and more applications in high-speed railway networks. Applications are train weight estimation, measurement of train speed for real time, wheel imbalance detection, etc. It is clear from experiments that FBG sensors are more appropriate as railway monitoring systems compared to electrical ones.

Fiber Bragg grating sensors characteristics

FBG sensors provide many crucial features for unique operational conditions in railways. In comparison with usual electrical sensors, fiber Bragg grating sensors have EMI/RFI immunity, multiplexing capability and can offer interrogation for long distances. In FBGs the data is wavelength-encoded, which makes the signals less susceptible to intensity fluctuations. Moreover, the fiber optic cable can be interrogated from either end, offering redundancy to FBG sensing networks. Plus, FBGs have a self-calibration capability. The strain and temperature measured findings is an absolute parameter. So there is no dependency on the measurement value and losses between the interrogation unit and the FBGs. To fabricate FBG sensors, FBGs are packaged and transformed into different types of transducers. That makes it possible to install them on the rail track fasteners, clips, bogie, train body, chassis, and axle boxes of a train to provide ongoing inspection for health checking.

In addition to that, FBG sensors can be interrogated at very high-speeds.

Providing reliable operational conditions, fiber optic designs can measure a wide range of other parameters such as inclination and acceleration through the modulation of light in reaction to the environment. Therefore, one FBG interrogator can work with a lot of FBG sensors to measure many options at the same time at different locations over the vast territory. The sensing signals can be read at distances more than 100 km away.

These features are especially useful for the railway industry because they allow simplifying the installations a lot and reducing costs.

Fiber Bragg grating sensors in field projects

Over the past few years, specialists have safely held a number of field trial railway projects involving FBG sensors. For example, in 2007, about fifty FBG-based vibration sensors were installed along the East Rail Link that connects Hong Kong and Mainland China. Then fiber optic solutions were applied in metro lines of Hong Kong, part of the Beijing-Shanghai High-speed Rail Link, and in Delhi Airport Metro Express Line.

In Hong Kong this fiber optic technology was applied on a passenger rail system as a structural health monitoring system. The FBG sensors were attached to the bottom of the carriages. The goal was temperature and strain measurement. The fiber optic system supplied all the necessary data including rail tracks' and carriages' deformation. The acquired information helped to assess the rates of the corrosion and bearing wear.

According to the results, due to FBG sensors, costs of maintenance were greatly reduced. Moreover, it helped to avoid or prevent problems at early stages due to the early detection of excessive vibrations. All these works showed that FBG sensors are superior in comparison with conventional sensors in many essential aspects.

Nowadays, fiber optic solutions are regarded as one the most cost-effective technology that helps in monitoring the condition and structural health of the carriages, tracks, and under frame equipment in railway systems. There are still some parameters that need to be improved, like the lack of proprietary and custom specifications. However, in the future major railway operators can apply modern FBG sensors, gaining more field experience.

Optromix is a fast-growing vendor of fiber Bragg grating (FBG) product line such as fiber Bragg grating sensors, for example, fbg strain sensors, FBG interrogators and multiplexers, Distributed Acoustic Sensing (DAS) systems, Distributed Temperature Sensing (DTS) systems. The company creates and supplies a broad variety of fiber optic solutions for monitoring worldwide. If you are interested in structural health monitoring systems and want to learn more, please contact us at [email protected]

#fiber bragg grating sensors#structural health monitoring#fiber optic technology#fbg sensors#FBG interrogators#fiber optic solutions

0 notes

Text

Get Information About Optic Circulators

Fiber Circulator is used to minimize the dispersion of light within a fiber optic system. Fiber optic circulators, when used with a dispersion compensating module (DCM), may send light across the system while using half the fiber to produce the necessary compensatory effect.

Applications

Optical circulators enable bidirectional ports, allowing an optical signal to be transmitted and received using a single fiber. Fiber optic circulators are utilized in a variety of applications, including dense wavelength division multiplexing (DWDM) networks, polarization mode dispersion, chromatic dispersion correction, optical add-drop modules, optical amplifiers, and fiber optic sensors.

Division Multiplexing (DWDM) Networks

Fibre Circulators in DWDM networks provide 50 dB isolation between forward and backward propagating signals. Fiber optic circulators also have a cross-talk level of greater than 60 decibels.

Optical Add-drop Multiplexing (OADM)

Optical add-drop modules function as main filters. Optical couplers can produce this behavior by utilizing a Fiber Bragg Grating (FBG). The full bandwidth signal enters the coupler and is routed to the next port, where the FBG is inserted. The FBG reflects the required signal to the coupler, while the dropped channels depart via the port. PMD may be corrected using optical couplers, which rotate the optical signal's electric and magnetic fields.

Polarization mode dispersion (PMD)

Some fiber optic systems exhibit polarization mode dispersion (PMD), which is a natural feature of all optical media. PMD is created by a discrepancy in light propagation velocities between the transmission medium's orthogonal main polarization states. If the optical pulse contains both polarisation components, the individual polarisation components in fibre optic circulators will travel at different speeds and arrive at various times, causing the received optical signal to be distorted.

PMD may be corrected using optical couplers, which rotate the optical signal's electric and magnetic fields.

Chromatographic Dispersion Compensation

Optical Circulator uses a chipped Fiber Bragg Grating to adjust for chromatic dispersion. FBGs are wavelength-dependent reflectors. A portion of optical fiber is treated or doped with a substance that affects the fiber's refractive index, resulting in wavelength-dependent reflections. Chipped Fiber Bragg Gratings have numerous gratings displaced across fiber and can compensate for chromatic dispersion.

Follow our Facebook and Twitter for more information about our product.

2 notes

·

View notes

Text

Discussion of Fiber Bragg Grating Technology Applicability on Diagnostic Field Testing of Steel Girder Bridges

Abstract

The application of Fiber Bragg Grating (FBG) technology for purposes of diagnostic field testing on steel girder bridges is discussed in this paper based on the authors experience in field tests of highway bridges. The primary benefit of the FBG technology is the ability to have many sensors (strain gages) multiplexed in a single fiber optic line. In practice, the FBG system is problematic for field conditions of a typical highway bridge. In field tests, measured FBG data showed that the strain histories obtained for a load immediately above the girder of interest were accurate, but the accuracy of the strain histories decreases for adjacent girders as the transverse distance from the load increased. Moreover, protective measures are necessary for FBG systems to be utilized in highway bridge field testing.

Read More about this article: https://irispublishers.com/ctcse/fulltext/discussion-of-fiber-bragg-grating-technology-applicability-on-diagnostic-field-testing-of-steel-girder-bridges.ID.000681.php

Read More about Iris Publishers Google scholar Articles: https://scholar.google.com/citations?view_op=view_citation&hl=en&user=LoZ6uCQAAAAJ&cstart=20&pagesize=80&citation_for_view=LoZ6uCQAAAAJ:7T2F9Uy0os0C

2 notes

·

View notes

Text

Poste de travail laser pour réseaux de Bragg en fibre optique, Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 5 Premières Entreprises

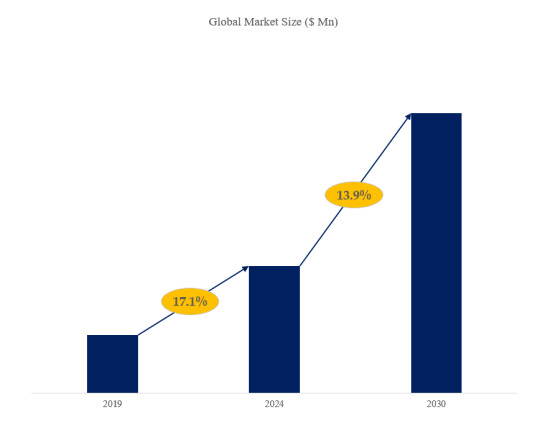

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de Poste de travail laser pour réseaux de Bragg en fibre optique 2024-2030”, publié par QYResearch, la taille du marché mondial de Poste de travail laser pour réseaux de Bragg en fibre optique devrait atteindre 1180 millions de dollars d'ici 2030, à un TCAC de 13.9% au cours de la période de prévision.

Figure 1. Taille du marché mondial de Poste de travail laser pour réseaux de Bragg en fibre optique (en millions de dollars américains), 2019-2030

Selon QYResearch, les principaux fabricants mondiaux de Poste de travail laser pour réseaux de Bragg en fibre optique comprennent WOP, Innofocus, etc. En 2023, les trois premiers acteurs mondiaux détenaient une part d'environ 82.0% en termes de chiffre d'affaires.

Figure 2. Classement et part de marché des 5 premiers acteurs mondiaux de Poste de travail laser pour réseaux de Bragg en fibre optique (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

The market for laser workstations used for the production and analysis of Fiber Bragg Gratings (FBGs) is influenced by several key drivers, which contribute to its growth and development. Here are some important market drivers:

1. Rising Demand for Fiber Bragg Gratings: FBGs are widely used in various applications, including telecommunications, structural health monitoring, temperature sensing, and pressure measurements. The increasing demand for these applications drives the need for advanced laser workstations capable of producing high-quality FBGs.

2. Advancements in Laser Technology: Continuous improvements in laser technologies, including sources that are more efficient, reliable, and capable of producing precise and high-resolution gratings, are driving the adoption of laser workstations. New types of lasers and improved fabrication techniques enhance the performance of FBGs.

3. Growth in Telecommunications Sector: The telecommunications industry is one of the largest consumers of Fiber Bragg Gratings, especially for applications in fiber-optic communications and signal processing. As demand for high-speed data transmission and 5G technology continues to grow, the need for FBGs and the corresponding laser workstations will increase.

4. Development of Smart Infrastructure: The expansion of smart building technologies and infrastructure monitoring systems that utilize FBG sensors for real-time condition monitoring and data collection is driving market growth. Laser workstations are essential for developing customized FBGs tailored to specific monitoring needs.

5. Innovations in Sensing Technologies: FBGs are increasingly being adopted in various sensing applications due to their advantages, such as high sensitivity and immunity to electromagnetic interference. The growth in industries such as aerospace, automotive, and energy sector—for structural and environmental monitoring—requires robust laser workstations for the production of specialized FBGs.

6. Focus on Research and Development: Research institutions and labs are actively engaged in developing new applications for FBGs, which drives the demand for laser workstations that can facilitate advanced experimental setups. This R&D focus contributes to the advancement of FBG-related technologies and products.

7. Miniaturization Trends: The growing trend toward miniaturization in various applications, especially in telecommunications and medical devices, requires precise and compact FBG solutions. Laser workstations equipped to produce smaller and more intricate FBGs are increasingly important.

8. Energy Efficiency and Cost Reduction: Advances in laser technology have enabled the development of more energy-efficient laser workstations, which can reduce operating costs. This is particularly attractive for businesses and research institutions looking to optimize their operations.

9. Customization and Flexibility: The ability to design and fabricate customized FBGs for specific applications is driving demand for adaptable laser workstations. Systems that allow for easy programming and adjustment for different grating patterns can enhance production efficiency and innovation.

10. Growing Adoption in Medical Applications: The healthcare sector is increasingly exploring the use of FBGs for applications such as biomedical sensing and imaging. As this trend grows, the need for specialized laser workstations for producing medical-grade FBGs will also increase.

11. Collaborative Industry Growth: Collaborations between universities, research institutions, and industries focused on fiber optics and sensor technologies promote innovation and lead to the development of new applications for FBGs. This collaborative growth stimulates demand for laser workstations.

In summary, the market for laser workstations for Fiber Bragg Gratings is driven by rising demand for FBGs in various sectors, advancements in laser technology, the growth of telecommunications and smart infrastructure applications, research initiatives, and the increasing adoption of FBGs in sensing and medical applications. These factors create a conducive environment for the expansion of this market.

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

#Poste de travail laser pour réseaux de Bragg en fibre optique#Laser Workstation for Fiber Bragg Gratings

0 notes

Text

diode laser module

Diode laser module are versatile components used in a variety of applications, such as semiconductor wafer defect detection, hair removal, and plastics welding. They offer high power and homogeneity with a range of wavelengths from 808 nm to 1550 nm and can achieve up to 95% beam homogeneity with the help of specialized optics .

These modules can be configured with single emitters for high power applications, like MOPA (Master Oscillator Power Amplifier) systems, or as single bars for direct diode applications with wavelengths extending from 640 nm to 2.1 µm and continuous wave (CW) powers up to 80 W . They also come with options for locking and narrow linewidth using Volume Bragg Gratings (VBG) to improve spectral performance .

Diode laser module typically include not only the diode itself but also optics, cooling devices, and electrical elements. They facilitate ease of use by shaping the output beam, often into a collimated beam for efficient transmission and coupling with optical fibers . Fiber-coupled modules, also known as "pig-tailed" laser diodes, can launch light directly into an optical fiber, with options for single-mode or multimode fibers depending on the power level .

Diode laser module also feature power and wavelength stabilization to ensure consistent performance. This can be achieved through internal feedback loops with monitor photodiodes, and some modules are designed for very careful stabilization to minimize relative intensity noise . Furthermore, they can support power modulation and pulse generation, with some modules capable of producing nanosecond or picosecond light pulses .

For applications requiring specific beam shapes, such as lines, crosses, or squares, laser diode modules can be equipped with the necessary optics to achieve the desired output . Additionally, some modules include internal frequency doublers for wavelength conversion, such as creating green light from a laser diode emitting at a different wavelength .

Cooling and temperature stabilization are crucial for maintaining the performance of high-power laser diode modules. Modules may include metallic surfaces for easy mounting on coolers or thermoelectric coolers with feedback systems to stabilize the diode temperature, leading to a more stable output wavelength and power .

Diode laser module find use in a wide range of applications including optical alignment, printing, imaging, displays, bar code scanning, data storage, sensors, solid-state laser pumping, free-space optical communications, and medical applications like photodynamic therapy and ophthalmology . They are also commonly used as OEM components in larger devices .

Newport offers CW laser diode modules with various wavelengths from UV to 1550 nm, featuring high optical power levels and models with ultrafine PID temperature control . Diode laser module are designed for easy mounting and are available in different series to cater to various budget and performance requirements, although they are not CE marked .

0 notes

Text

Know About The Fiber Cable Cutting and FBT Fiber Taper Machine

The foundation of connectivity in the quickly developing field of telecommunications, where dependability is crucial and data transmission speeds are constantly rising, is found in the complex field of fiber optics. The intricately designed FBT Fiber Taper Machine and Fiber Cable Cutting Machine are essential tools for molding and optimizing fiber optic cable performance.

The Fiber Optics Revolution

Fiber optics has completely changed communication networks all over the world by enabling data to be sent over great distances at the speed of light. The optical fibers, which are pliable, thin strands of plastic or glass that transmit data as light pulses, are the central component of this technology. The need for dependable and effective fiber optic components is growing as demands for higher internet speeds, high-definition video streaming, and strong communication networks rise.

Accurate Engineering Precision: The Machine for FBT Fiber Taping

The FBT Fiber Taper Machine, a high-precision tool that can tape optical fibers with unmatched accuracy, is the center of fiber optic production. For optimum performance, fiber Bragg gratings, couplers, and other crucial parts need to be precisely tapered. This is accomplished by the FBT Fiber Taper Machine by precisely regulating the fiber's stretching and heating, which results in consistent taper profiles and little insertion loss.

The adaptability of the FBT Fiber Taper Machine is one of its key features. It is essential for many different applications since it can handle several types of fibers, such as polarization-maintaining, multimode, and single-mode fibers. The FBT Fiber Taper Machine meets the industry's strict requirements by producing consistent and dependable results for laser, sensor, and telecommunications applications.

Increasing Productivity: The Fiber Cable Cutting Device

To manufacture high-quality components, fiber optic cables must be precisely cut in addition to being tapered. The Fiber Cable Cutting Machine is useful in this situation. These machines minimize fiber end-face imperfections and reduce signal attenuation by ensuring clean and accurate cuts through the use of modern cutting mechanisms like laser or diamond blades.

The Fiber Cable Cutting Machine is incredibly efficient and can handle many fibers at once with a high throughput. These devices cut ribbon cables and individual fibers with remarkable speed and accuracy, producing reliable results every time.

1 note

·

View note

Text

Market Expansion: Predictions for the Structural Health Monitoring Sector

The global structural health monitoring market is poised for significant growth, with revenues expected to reach a staggering US$13,155.4 million by the year 2032, according to recent market analysis. This surge is driven by the escalating demand for evaluating and monitoring the structural health of critical assets such as bridges, dams, buildings, wind turbines, and machinery.

In 2022, the market for structural health monitoring recorded revenues of US$3,409.4 million, marking a substantial milestone in the sector’s growth trajectory. The market is projected to expand at an impressive Compound Annual Growth Rate (CAGR) of 14.5% from 2022 to 2032, underscoring the increasing emphasis on ensuring the safety and durability of infrastructural elements.

Request a Sample of this Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-1167

Key Takeaways: Structural Health Monitoring Market

By component, the software segment is anticipated to account for the leading share of around 40% in 2022 while the hardware segment is estimated to grow at the highest CAGR of 17.6% through 2032.

By type, the wireless SHM system segment is expected to grow at a highest CAGR of 14.8% between 2022 & 2032

By application, the vessels and platforms segment is anticipated to grow at a CAGR of 19.0% during the forecast period.

South Asia and Pacific structural health monitoring market is expected to progress at the highest CAGR of around 17.8% through 2032.

The structural health monitoring market in Japan is expected to grow at a CAGR of around 18.6% through 2032.

In India, sales of structural health monitoring systems are expected to grow at a CAGR of close to 19.9% over the next ten years.

“Demand for structural health monitoring is increasing in monitoring of bridges and dams because dam monitoring instrumentation plays an important role in security monitoring for people and dams, offering important details on the performance of the dam and detecting issues at an early and preventable step. says FMI analyst.

Competition Analysis and Regional Trends

The competition in the structural health monitoring market is intensifying, with various players vying to offer innovative solutions and advanced technologies. As demands for precision, reliability, and real-time data analysis continue to rise, market participants are focusing on delivering cutting-edge solutions to gain a competitive edge.

Additionally, regional trends indicate a significant market traction in various parts of the world. As infrastructure projects gain momentum across different regions, the need for efficient structural health monitoring solutions is becoming increasingly evident, driving market growth on a global scale.

Data-Driven Advantage: Obtain Your Custom Report Unifying Regional Insights and Competitor Analysis :

https://www.futuremarketinsights.com/customization-available/rep-gb-1167

Key Components and Sensors

The realm of structural health monitoring encompasses a range of components such as data acquisition systems, data diagnostics, and digital processing. Diverse sensors are instrumental in this domain, including microwave sensors, imaging ultrasonic sensors, smart sensors or sensor coatings, acoustic emission sensors, inclinometers slope indicators, and fiber Bragg diffraction grating sensors. These technologies collectively contribute to ensuring the integrity and safety of structures.

With the global structural health monitoring market poised for exponential growth, it is evident that the sector is evolving to meet the demands of an expanding infrastructure landscape. As the world’s critical assets undergo increasing scrutiny, the market is set to play a pivotal role in enhancing the longevity and reliability of vital structures.

Key Segments Profiled in the Global Structural Health Monitoring Market

Structural Health Monitoring Market by Component:

Structural Health Monitoring in Hardware

Structural Health Monitoring in Sensors

Structural Health Monitoring in Data Acquisition Systems

Structural Health Monitoring in Others

Structural Health Monitoring in Software

Structural Health Monitoring in Design and Analysis

Structural Health Monitoring in Parameter Identification and Tracking

Structural Health Monitoring in Others

Structural Health Monitoring in Service

Structural Health Monitoring in Installation Service

Structural Health Monitoring in Design and Consulting Service

Structural Health Monitoring in Operation and Maintenance Service

Structural Health Monitoring Market by Type:

Wired Structural Health Monitoring Systems

Wireless Structural Health Monitoring Systems

Structural Health Monitoring Market by Application:

Structural Health Monitoring for Bridges and Dams

Structural Health Monitoring for Building and Stadiums

Structural Health Monitoring for Vessels and Platforms

Structural Health Monitoring for Airframes and Wind Turbines

Structural Health Monitoring for Large Machines and Equipment

Structural Health Monitoring Market by Region:

North America Structural Health Monitoring Market

Latin America Structural Health Monitoring Market

Europe Structural Health Monitoring Market

East Asia Structural Health Monitoring Market

South Asia & Pacific Structural Health Monitoring Market

Middle East and Africa (MEA) Structural Health Monitoring Market

0 notes

Text

Sysargus excels in Data Acquisition Systems (DAS), providing state-of-the-art solutions for efficient data collection and analysis. Leveraging cutting-edge technology, Sysargus designs and implements robust DAS tailored to diverse industry needs. Their systems ensure accurate real-time data capture from various sensors and sources, fostering informed decision-making. With a focus on reliability and scalability, Sysargus empowers businesses with seamless integration of data acquisition into their operations. Whether in industrial automation, research, or monitoring applications, Sysargus' expertise in Data Acquisition Systems enhances productivity and facilitates a deeper understanding of processes, contributing to overall efficiency and competitiveness for their clients.

0 notes

Text

"Innovations in Optical Connectivity: The Role of Fiber Optic Circulators in Next-Generation Networks"

Fiber optic circulators are essential components in optical communication systems that enable the routing and control of light signals. They are based on the principle of non-reciprocity, meaning that the light propagation is directional and can flow in one direction while being blocked or attenuated in the opposite direction. Fiber optic circulators are commonly used in various applications, including telecommunications, fiber optic sensing, and optical testing.

The key features and functions of fiber optic circulators include:

Light Routing: Fiber optic circulators allow the routing of light signals from one optical fiber to another in a specific direction. They typically have three or more ports that facilitate the bidirectional transmission of light. The circulator can route light from port 1 to port 2 while blocking or minimizing the signal loss in the reverse direction.

Signal Isolation: Fiber optic circulators provide high isolation between ports, ensuring that light signals transmitted in one direction do not interfere with or affect signals traveling in the opposite direction. This isolation property is crucial in preventing signal degradation and maintaining the integrity of optical communication systems.

Wavelength Division Multiplexing (WDM): Fiber optic circulators can be designed to operate at specific wavelengths, enabling the implementation of wavelength division multiplexing techniques. In WDM systems, multiple wavelengths of light are simultaneously transmitted through a single optical fiber, effectively increasing the data transmission capacity. Fiber optic circulators play a key role in directing the different wavelengths to their respective destinations.

Optical Signal Processing: Fiber optic circulators can be integrated into optical signal processing systems to perform various functions such as signal amplification, filtering, and dispersion compensation. By combining fiber optic circulators with other optical components, complex optical signal processing tasks can be achieved, enhancing the performance and efficiency of optical communication systems.

Fiber Optic Sensing: Fiber optic circulators are also used in fiber optic sensing applications where the detection of changes in light signals is critical. By directing light signals through different sensing elements, such as fiber Bragg gratings or interferometric sensors, fiber optic circulators enable precise and accurate measurement of physical parameters like strain, temperature, pressure, and vibration.

In summary, fiber optic circulators play a vital role in controlling and directing light signals in optical communication systems. They enable the efficient routing of light, provide isolation between different ports, support wavelength division multiplexing, and can be integrated into optical signal processing and sensing applications. With their unique non-reciprocal properties, fiber optic circulators contribute to the advancement of high-speed telecommunications, fiber optic sensing technology, and various other optical applications.

Read more @ https://techinforite.blogspot.com/2023/05/shedding-light-on-fiber-optic.html

0 notes

Text

Textile Technological Advances

Textile improvements have been achieved in a variety of disciplines. Synthetic fabrics, sensors and actuators, spinning jennies, digital printing, and changing the essence of clothes are among them.

Synthetic textiles are garments produced from synthetic fibers. They are utilized in a variety of applications, including clothes, footwear, home furnishings, and medical devices.

Synthetic textiles are a less expensive alternative to natural fibers. They also dry faster and are more resistant to perspiration. Furthermore, they are stain and wrinkle-resistant. They also retain their form better after repeated washing.

Chemical methods are used to create synthetic fibers. Their outstanding features are one of the primary reasons for their widespread usage in a variety of sectors. Polypropylene (PP), polyurethane, nylon, and polyamides are the most common synthetic fibers.

Because of its high thermal resistance and inexpensive cost, polypropylene is commonly employed in automotive applications. Polyester is yet another common synthetic material. It's found in carpets, upholstery textiles, and side panels.

James Hargreaves designed the spinning jenny machine in 1764. It was a precursor to the power loom. This device enabled the spinning of numerous threads at the same time, resulting in increased thread output and, consequently, textiles.

The spinning jenny was one of the most important inventions in the textile industry during the Industrial Revolution. It aided in increasing productivity in the textile industry, which aided in the sector's expansion.

The spinning jenny was a device invented in the 17th century for spinning numerous threads at the same time. However, James Hargreaves patented the apparatus in the mid-1760s.

Nonetheless, it was a significant advance over previous technologies and a giant stride forward in textile production. The jenny was a primary, low-cost, hand-operated device.

Textile digital printing innovations are reshaping the garment business. With a slew of new technologies on the horizon, the industry is expected to expand significantly in the following years.

In addition to lowering production costs and downtime, digital printing has various advantages over traditional methods. For example, technology is environmentally beneficial. It also provides color and design versatility.

Smaller fashion houses are also using technology to manufacture their own items. Some businesses have even created their own "micro-factories" to produce printed textiles. This allows them to provide on-demand clothing creation, decreasing the environmental effect of transportation.

Another benefit of the new technology is the ability to print on different textiles. Traditional techniques need unique inks and treatments for each cloth type.

Sensors and actuators of various sorts are increasingly being integrated into textiles. Physical and chemical inputs are collected and converted into electrical signals by these devices. Sensors can also be used to capture and monitor health information. Traditional textile production methods may be used to create electronic textiles. These technologies' benefits include lightweight, breathability, and washability.

Small photodetectors are used in optical textile sensors to monitor the amplitude of light. They can also sense changes in temperature. The diameters of small glass optical fibers are in the micron range. The first fiber Bragg grating (FBG) sensors were created in 1978.

Resistive pressure sensors, on the other hand, link electric resistance and pressure. Wires, flexible transistors, and metals are among the architectures accessible. Textile capacitors can be constructed from conductive plates separated by dielectrics. They can be made by sewing, weaving, or painting using conductive inks.

The fashion business has experienced tremendous growth in the number of clothes manufactured each year during the last 15 years. This clothing is becoming increasingly popular across the world.

Clothing is an essential component of our culture in both established and emerging nations. It is utilized to provide comfort and security, as well as to shape our identities. However, the sector faces substantial social and environmental issues and must adapt in order to reach its full potential.

The fashion business is dependent on nonrenewable resources such as petroleum-based polyester, cotton, and nylon. Using these materials can result in massive amounts of waste and greenhouse gas emissions. Furthermore, chemicals and dangerous substances are frequently used in the clothes manufacturing process.

The UNEP has published a roadmap for a more sustainable fashion industry. It addresses the need for a new textile economy based on circularity principles, as well as recommendations for decreasing consumer impacts and making the entire textile value chain more sustainable.

0 notes

Link

The Fiber Bragg Grating Sensor Market is segmented by Type (Temperature Sensor, Strain Sensor, Pressure Sensor), End-user Industry (Telecommunication, Aerospace, Construction & Infrastructure), and Geography.

#fiberbragggratingsensormarket#fiberbragggratingsensormarketoverview#fiberbragggratingsensormarketsize#marketresearchreports#researchreports

0 notes

Text

Optical Sensor Market - Forecast 2022-2027

Optical Sensor Market Overview

The Optical Sensor Market forecast to reach $4.5 billion by 2027, growing at a CAGR of 9.1% from 2022 to 2027. The Optical Sensor Market is estimated to witness a sustainable growth over the forecast period majorly because of the increasing priorities on building automation. Along with this rising demand from the automotive, industrial, consumer electronics and defense sector, the government regulations on safety measures have also been increasing in recent years. These factors are expected to enhance the market growth of Optical Sensor in forecast period, particularly Metal Oxide Semiconductor and Photoelectric sensor technologies. An optical sensor converts light rays into an electronic signal. The purpose of an optical sensor is to measure a physical quantity of light and, depending on the type of sensor, then translates it into a form that is readable by an integrated measuring device. The rising adoption of technological innovations such as nanoparticles, optical fibers, photonic devices, biosensors, fabry perot interferometers based optical sensors have driven the applications in optical sensor market.

Request Sample

Report Coverage

The report: “Optical Sensor Market– Forecast (2022-2027)”, by IndustryARC covers an in-depth analysis of the following segments of the Optical Sensor Market Report.

By Type – Extrinsic and Intrinsic.

By Measurands – Temperature, Pressure, Flow, Liquid level, Position, Rotation, Displacement, Humidity, Strain, Velocity, Electric fields and Others.

By End-Use Industry – Automotive, Aerospace and Defense, Chemical, Logistics, Manufacturing, Healthcare, Food & Beverage and Others.

By Geography - North America (U.S, Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Netherlands and Others), APAC(China, Japan India, SK, Australia, Indonesia and Others), South America(Brazil, Argentina, Chile, Colombia and others), and RoW (Middle East and Africa)

Key Takeaways

The Optical Sensor Market is estimated to witness sustainable growth over the forecast period as these sensors offer several features such as high accuracy, compact size, electromagnetic radiation free and offer operation at difficult sites which are not accessible to humans. These features at various industries uplift its market growth.

With the growing demand of safety and adoption of high-grade wearable devices for the operators at majority of industrial sites has also enhanced the Optical Sensor Market growth.

Optical Sensors are resistant to electromagnetic interference due to which they are suitable to implement in high frequency microwave applications.

Optical sensors are capable of working in a dynamic wavelength range and are resistant to high temperatures and chemically reactive environments. They are highly sensitive and posses a high optical resolution. These features propel their applications in various industries, thus enhancing its market growth.

Inquiry Before Buying

Optical Sensor Market Segment Analysis - By Type

Extrinsic Sensors have dominated the Optical Sensor Market as compared to the Intrinsic sensors with a share of 69.0% in 2021. When light beam leaves the fibre cable and the path gets changed due to object before it reaches to the optical detector end, then it is known as extrinsic optical sensor. Extrinsic sensors are adopted widely in various end-use industries as compared to Intrinsic sensors because they are easy to multiplex, less expensive and are easier to use in various applications such as temperature, pressure, liquid level, flow and other measurements. The implementation of new technologies such as fiber braggs grating, fabry perot interferometers will also drive the market growth. These advantages uplift the market growth of Extrinsic Optical Sensors globally. On the other hand, Extrinsic sensors are less sensitive and are more prone to connection problems at entering and exit points which tend to hinder its market growth.

Optical Sensor Market Segment Analysis - By End Use Industry

Optical Sensors are widely used in Automotive industry and the sector is growing at 11.8% CAGR through 2027. One of the major reasons for boost in market of Optical sensors in Automotive industry is because the optical sensors are used in several camera-enabled systems such as autonomous driving, advanced safety systems, and in-vehicle infotainment (IVI) systems and others. These sensors offer various in-built features such as 3D gesture recognition, vehicle-to-everything (V2X) communications, and interior lightening control applications and many others. These wide applications of Optical sensors in Automotive industry propel its market growth globally. Optical sensors are also used in Defense sector. Various temperature sensors, Electric field sensors, Motion sensors are used by Defense sector in different operations. Optical sensors are also used in Material Handling Industry, where the warehouse management system is of large scale, and optical sensors play a very important role in monitoring and controlling logistic processes. This wide range of applications across various different industries enhance its growth in global market.

Schedule a Call

Optical Sensor Market Segment Analysis - By Geography

North America accounts for being the highest market with a share of 32.9% in 2021. The market growth in this region is predominantly rising due to leading economies such as United States, Canada and Mexico. Due to the growing demand for automation across various industries and rising adoption of Optical sensors in different industrial sector has brought a major pace in the Optical Sensor Market growth. With the increasing industrialization in Automotive sector in North America, the demand for Artificial Intelligent automobiles has increased rapidly which has further uplifted the adoption of optical sensors in automobiles. This has brought a significant pace in uplifting adoption of Optical Sensor, especially those based on fiber braggs grating, fabry perot interferometer technology. During the Covid-19 pandemic, North America remained at the top in balancing its economic status in global market. North America is closely followed by Asia-Pacific and Europe in the Optical Sensor Market.

Optical Sensor Market Drivers

Rise in Technology Advancement drives market growth

With the increasing demand for automation across various industries, there has been a rapid adoption of Optical Sensors of different measurands such as Temperature sensors of wide range of temperatures and different environments, Motion sensors with latest technology of human detectors, wide range of Pressure sensors and Electric field sensors of different electric fields. Amkor, the world leader in optical sensor packaging technology and the largest OSAT for sensor packages aims to increasingly rely on developments in optical sensors to enhance reliable and fast sensing applications for the future. The rising adoption of technological innovations such as fiber braggs grating, fabry perot interferometers based optical sensors have driven the applications in spectroscopy market. Optical sensors convert various wavelengths into electrical signals for enhanced sensing applications. Ambient, infrared (IR) and ultraviolet (UV) light are some wave types that optical sensors measure to create applications for autonomous cars, in-display fingerprint scanners, secure facial recognition, and many others.

Buy Now

Increasing adoption of Genetic encoded Optical Sensors in Healthcare

Optical sensors are powerful tools for live cell research as they permit to follow the location, concentration changes or activities of key cellular players such as lipids, ions and enzymes. Most of the current optical sensors probes are based on fluorescence which provides great spatial and temporal precision. This high-end microscopy is used and that the timescale of the event of interest fits the response time of the sensor. These developments in Healthcare sector enhance the growth of Optical Sensors in global market. Genetically encoded sensors began to emerge after the discovery of fluorescent proteins, This brought a major development in improving the optical properties and the study of their structure through application of circular permutation. Genetically encoded biosensors, including those for intensiometric and ratiometric sensors are based on single fluorescent proteins. UK silicon photonics startup Rockley Photonics has raised $50m, bringing the total investment to over $225m. The Oxford-based developer of optical sensing chips is also targeting healthcare sensing with the appointment of a chief commercial officer with 25 years of experience in the medical device industry. These rising adoptions and rising investments Optical sensors tend to drive the market growth of Optical Sensor Market globally.

Optical Sensor Market Challenges

Rising Substitutes of Optical Sensors

One of the major challenges faced by Optical Sensor Market globally is the rising substitutes of Optical Sensors. Many applications of Optical sensors, primarily for those in the Healthcare and Manufacturing industries of semiconductors cannot be solved with optical sensors or miniature photoelectric sensors because they are physically too large to fit in the instruments. Additionally, these sensors are typically not flexible enough to be routed through these instruments. Nowadays, highly flexible and miniature sensors are being incorporated in other industries due to recent demands of smaller machines and tools. These rising demands and manufacturing of miniature sensors tends to hinder Optical Sensor Market growth in forecast period. Recently launched, MICROmote sensors are miniaturized photoelectric sensors with separate amplifiers that are also available with a variety of functionalities. It is highly flexible, electric sensor cables which makes them a genuine technical alternative to conventional optical sensors.

Optical Sensor Market Landscape

Product launches, acquisitions, and R&D activities are key strategies adopted by players in the Optical Sensor Market. The Optical Sensor Market is dominated by major companies such as

Hamamatsu Photonics K.K

Sofradir Ec Inc.

Carlo Gavazzi Automation Spa

Teledyne Dalsa

Aptina Imaging

ROHM Company Ltd

Oxsensis Ltd

Sony Corporation

Infineon Technologies AG

TE Connectivity Ltd.

Recent Developments

In June 2019 Hamamatsu Photonics launched InGaAs, an area image sensor for hyperspectral cameras which are capable of detecting short-wavelength-infrared light up to 2.55 m. It is the world’s longest wavelength detectable by this type of area image sensor.

In July 2020, Microsoft filed patent for ‘multidimesional ‘optical heart rate sensor that could strengthen accuracy. The heart rate sensor is being called multidimensional because it could theoretically detect heart rate, pulse wave velocity, blood and tissue oxygenation and more, including metrics that can proxy for blood pressures.

In April 2019, Osram Opto Semiconductors announced that it is part of a new project through 2021, which is exploring the principles of high-resolution visualization solutions using µLEDs (micro LEDs) and optical sensors. The project, which began in November 2018, is funded by the Bavarian State Ministry for Economic Affairs, Regional Development, and Energy. The project is expected to be completed in October 2021, with an initial demonstrator.

#Optical Sensor Market#Optical Sensor Market size#Optical Sensor Market share#Optical Sensor Market trends

0 notes

Text

Binary editor innovate wideband

#BINARY EDITOR INNOVATE WIDEBAND FREE#

Many methods have been proposed to improve the coupling efficiency of the grating coupler, and blazed grating coupler is widely studied. In recent years, SOI fiber-to-chip grating couplers have been widely reported. The coupling efficiency of a conventional fiber-to-chip grating coupler, however, is at a maximum of 40% to 60% for a standard SOI with an incident angle of 0°.

#BINARY EDITOR INNOVATE WIDEBAND FREE#

Grating couplers are widely used to couple light between nanophotonic waveguides and free space optical components. The proposed AWG demodulation integration microsystem. In this work, the InP-based C-band LED and SOI waveguide are bonded by benzocyclobutene (BCB) using heterogeneous integration. Light source is very important for the integrated microsystem, and silicon-on-insulator- (SOI-) LEDs are difficult to achieve under the current process. The proposed AWG demodulation integrated microsystem is shown in Figure 1. The current work aims to study the integration of AWG demodulation system to achieve an AWG demodulation integrated microsystem. The fiber grating demodulation system based on arrayed waveguide grating (AWG) is a new potential method that can be used for fiber grating demodulation, which is smaller and cheaper than the conventional fiber grating demodulation system. These sensors are used to measure strain, temperature, pressure, and other physical quantities that can be converted into strain or temperature. Introductionįiber Bragg grating (FBG) sensors are widely known to have achieved great progress. When the incident angle of the light source is, the coupling efficiency of the binary blazed grating is 40.92%, and the 3 dB bandwidth is 72 nm at a wavelength of 1550 nm. The coupler was designed and optimized based on the finite difference time domain method. Both the length and width of the grating coupler are 360 μm, as large as the InP-based C-band LED light emitting area in the system. Through the coupler, light can be coupled into the SOI waveguide from the InP-based C-band LED for the AWG demodulation integrated microsystem to function. A large-area binary blazed grating coupler for the arrayed waveguide grating (AWG) demodulation integrated microsystem on silicon-on-insulator (SOI) was designed for the first time.

0 notes

Text

Fiber Optic Sensing for the Steam Assisted Gravity Drainage

Fiber optic sensing technology has proved to be an effective method in well and reservoir management. Fiber optic sensors constantly track temperature changes along the wells at specified intervals and collect all the data.

This technique is also compliant with the other technologies such as Steam Assisted Gravity Drainage (SAGD).

What is Steam Assisted Gravity Drainage?

Steam Assisted Gravity Drainage (or SAGD) is an enhanced oil recovery drilling technique that helps in extracting heavy crude oil or bitumen from oil sands deposits. Mostly, the accustomed approaches in such cases are economically inefficient. Specialists may use it in particular cases when the production is difficult. With the help of the fiber optic technology this approach becomes more cost-effective.

How does Steam Assisted Gravity Drainage work?

In short, the SAGD system's principle is heating the heavy oil or bitumen by the steam for further extraction. For that two horizontal wells are drilled at an angle of 90 degrees to a vertical bore well. In the wells, there are two pipes, one above the other for around 4-5 meters.

At the very beginning, the cold heavy oil is essentially immobile because of the high viscosity, and it needs to be warmed up to extract it. To do so, the steam is applied. It travels through the upper well into the reservoir and expends the heat in all directions of the formation, making a steam chamber. The heat warms the bitumen and reduces its viscosity. Then the bitumen flows downward into the production well and is pumped to the surface. Both processes are going at the same time.

Current Applications of the Steam Assisted Gravity Drainage

Due to the growing level of oil consumption, the level of its development needs to be increased. Not the last role is played by the SAGD and fiber optic systems such as fiber optic sensors and fiber Bragg gratings.

Like any exploration, heavy oil production needs accurate analysis and planning, especially if there are other factors that make the production difficult. Such aspects as great depth, high temperature conditions, etc. are essential. All of these issues need to be considered. The low mobility and high viscosity make the oil producing complicated and lead to low recovery indexes. However, due to the SAGD and fiber optic technology, there is an opportunity to maximize the recovery indexes.

For SAGD technology, FBG sensors are usually applied in wells to track the steam as it moves along the wellbore. Due to the fiber optic sensors, there is an opportunity to see the data in real time. According to the achieved data, the velocity of the steam can be identified. Besides, temperature sensors can also define the speed of the heating. The accurate settings of the temperature, pressure and steam-injection rates can lead to the operational savings. All the information can be used to plan the further work of the production operations.

Fiber Optic Sensors in Downhole Monitoring

Fiber optic sensors have proved to be effective for various parameters' monitoring in downhole applications. Most of all, distributed temperature sensing (DTS) is applied for these purposes. Distributed sensing has demonstrated good results. It has high recommendations in the oil industry. DTS can monitor well temperature all over the fiber optic cable.

Due to the modernly developed fiber optic designs and improvement of fiber optic sensing technology, a range of issues related to downhole production have been solved. However, the harsh environmental conditions in the downhole can still bring some problems to the fiber optic sensors.

The sensors still need to cope with hydrogen in the severe environmental conditions. It has a great impact on the optical fibers. Firstly, it can cause pressure and temperature errors. The appearing errors are connected to the hydrogen diffusion into the microstructure and to the changes of the refractive index when hydrogen penetrates into micro holes and fiberglass. So the hydrogen leads to the additional Bragg wavelength shift.

With this in mind, specialists are constantly developing fiber optic monitoring systems based on fiber Bragg grating technology.

Advantages and disadvantages of the SAGD

SAGD has played a crucial role in the rapid development of the oil resources. However, as everything, this method has some pros and cons that should be taken into account.

Most Common Disadvantages for SAGD technology

Firstly, as any other technology, SAGD has its restrictions. It is not well-suited for every production area with heavy oil. It has several aspects to be fulfilled, like homogeneous and relatively thick reservoirs.

Secondly, high water and fuel consumption. To work effectively, SAGD needs a large amount of water and natural gas. Both of them are used in the process of steam production. That's why the energy consumption is high but worth it. When all these conditions are satisfied, SAGD technology can be used. Moreover, the specialists advise using deep water sources that are not appropriate for consumption or agricultural uses. In fact, the majority of deployments’ developers follow this recommendation for environmental protection.

Thirdly, some think that SAGD technology is an expensive tool for oil production. However, specialists consider this technology as a superior alternative to reduce the high expenses and at the same time increase productivity. The reason for the cost reduction is that less horizontal wells are required to be drilled.

Fourthly, concerns about an environmental effect of the steam assisted gravity drainage (SAGD) are still a topic of discussion. However, according to the statistics, over the last 20 years the environmental analysis is getting better. It is obvious that the production of the crude bitumen and oil cause environmental consequences, but due to the development of modern cleaner extraction technologies, the situation is improving.

The Main Advantages of the SAGD technology

The main benefit of the whole SAGD technology is the improved steam-oil ratio and high ultimate recovery. Besides, the DTS systems help in optimization of the oil and bitumen production.

The other SAGD advantage is the constant evolution. Every next project makes a great contribution and brings new ideas and experiences. Meanwhile, the diversity of newly developed methods leads to new approaches to different types of oil fields.

So there are other modified types of SAGD technique:

Shaft and Tunnel Access (SATAC);

Single Well SAGD (SW-SAGD);

Multi-drain SAGD;

Fast-SAGD;

Enhanced Steam Assisted Gravity Drainage (ESAGD).

The SAGD was firstly implemented in Canada, where there are the largest reservoirs of crude bitumen. This allowed to advance the recovery factors in excess of 50%.

SAGD (steam assisted gravity drainage) well temperature monitoring provide:

Temperature profile control of injection and production wells;

Determination of inflow (injection) intervals of the fluid;

Determination of the fluid level in the well and perforation intervals;

Identification of issues in the well.

Plus, as any fiber optic technology, distributed temperature sensing for SAGD offers:

Maximum protection of the cable against chemical and physical effects;

Longer service life;

Convenience and speed of the installation;

Operations in the well without the extraction of the cable sensor.

The SAGD wells have implemented all the advantages of fiber optic sensing. FBG sensors offer real-time, precise temperature measurements along the fiber optic cable in the wellbore. Fiber optic solutions allowed us to monitor the objects that were unapproachable before. For example, fiber optic sensors with extended temperature range were applied in the oil wells for temperature control during oil production using SAGD technology.Steam assisted gravity drainage is commonly believed to be applied for complex deployments. It aims to make the process simpler. And the fiber optic technology is good at helping it. However, the specialists should discuss and decide how fiber optic technology can fit into the development at the planning stage. Fiber optic solutions may simplify the production process.

Optromix is a fast-growing vendor of fiber Bragg grating (FBG) product line such as fiber Bragg grating sensors, for example, fbg strain sensors, FBG interrogators and multiplexers, Distributed Acoustic Sensing (DAS) systems, Distributed Temperature Sensing (DTS) systems. The company creates and supplies a broad variety of fiber optic solutions for monitoring worldwide. If you are interested in structural health monitoring systems and want to learn more, please contact us at [email protected]

#Fiber Optic Sensing#Fiber Optic Sensors#fiber optic technology#fiber bragg gratings#FBG sensors#temperature sensors#distributed temperature sensing#fiber optic solutions

0 notes

Link

The Fiber Bragg Grating Market Growth impelled by use of fiber bragg grating in sensing applications and increasing adoption of fiber bragg grating due to their advantages.

0 notes