#Fiber Laser Machine

Explore tagged Tumblr posts

Text

Why Fiber Laser Machines Are Revolutionizing Precision Manufacturing

In today’s competitive manufacturing landscape, Fiber Laser Machines have emerged as the gold standard for high-precision cutting, engraving, and marking. Whether you're in metal fabrication, jewelry production, or industrial component design, investing in a fiber laser machine can significantly improve your productivity, accuracy, and profit margins.

At IEHK.com, we offer cutting-edge Fiber Laser Machines that combine advanced technology, industry-grade durability, and unbeatable value—making them the go-to choice for businesses across the globe.

What Makes Fiber Laser Machines Superior?

Unlike traditional CO2 or plasma cutters, fiber laser machines use a solid-state laser source to generate a highly concentrated beam of light. This results in exceptional precision, cleaner edges, and faster cutting speeds—especially when working with metals such as stainless steel, aluminum, brass, and copper.

These machines are known for:

Minimal maintenance and long service life

Lower operating costs due to high electrical efficiency

Ability to cut reflective materials without damaging the lens

Compact, user-friendly designs for easy integration into any workspace

IEHK’s line of fiber laser machines also features intuitive software, customizable power levels (ranging from 20W to 2000W), and support for complex design formats—empowering you to take on a wide range of applications with confidence.

Unlock Productivity and Profits

Time is money. And with a fiber laser machine from IEHK, you're looking at faster turnaround times and significantly reduced post-processing work. Whether you're engraving serial numbers on tools, creating custom jewelry, or cutting industrial parts, fiber laser technology offers unmatched speed and consistency.

This isn’t just a tool—it’s an investment in productivity and business growth. Our clients report ROI in as little as 6 months thanks to the machine’s high output, low maintenance, and minimal material waste.

Why Choose IEHK?

IEHK is a trusted global supplier of Fiber Laser Machines, delivering industry-leading equipment at factory-direct pricing. When you buy from us, you’re not only getting high-quality hardware—you’re getting:

Expert technical support

Comprehensive warranties

User-friendly training resources

Worldwide shipping and customer service you can count on

We stand behind every machine we sell. Our goal is simple: to help you succeed through precision engineering and reliable performance.

Ready to Transform Your Workshop?

Whether you're a small business looking to expand into new services or a manufacturer aiming to improve efficiency, IEHK’s Fiber Laser Machines are the smart choice. Experience superior performance, flexibility, and savings in one powerful package.

Explore our full range of Fiber Laser Machines now and request a quote today.

Make the leap into precision laser technology—your future in high-performance cutting starts here.

0 notes

Text

Divine Laser Technologies, Ahmedabad - Manufacturer & Supplier for Laser Marking Machines and Fiber Laser Marking Machine

Industrial manufacturing, precision, speed, and reliability have become non-negotiable. From the automotive industry to electronics, aerospace to medical equipment—laser marking technology has revolutionized how manufacturers mark, engrave, and identify their products. One name that stands out in this competitive space is Divine Laser Technologies, a leading Fiber Laser Marking Machine Manufacturer in Ahmedabad.

Based in Gujarat’s industrial hub, Divine Laser Technologies has carved a niche as a trusted Laser Marking Machines manufacturer and supplier, offering cutting-edge solutions for a wide range of materials including metals, plastics, ceramics, and more. With a focus on quality, performance, and affordability, the company is helping Indian and international manufacturers enhance productivity and brand identity through world-class marking systems.

What is a Fiber Laser Marking Machine?

A Fiber Laser Marking Machine is a type of laser engraver that uses a fiber laser beam to make permanent marks on surfaces. It’s known for its high precision, fast speed, low maintenance, and long lifespan. The fiber laser operates with a high-frequency beam that interacts with the material's surface, resulting in permanent markings without physical contact or significant material removal.

Common applications of Fiber Laser Machines include:

Barcodes and serial numbers

Logos and QR codes

Electrical component markings

Jewelry and metal engraving

Medical device identification

Automotive parts labeling

This versatility makes fiber lasers essential across various sectors where traceability, compliance, and aesthetics matter.

Why Choose Divine Laser Technologies?

As a Fiber Laser Marking Machine Supplier and Manufacturer in Ahmedabad, Divine Laser Technologies brings more than just hardware. Here’s what makes the company stand out:

State-of-the-Art Manufacturing Facility: Divine Laser Technologies operates from a fully equipped, modern production unit in Ahmedabad. The facility includes advanced CNC machining, R&D labs, and testing centers, enabling end-to-end quality control.

Extensive Product Range

The company offers a comprehensive selection of Laser Marking Machines, including:

Metal Laser Marking Machine

Portable Fiber Laser Marking Machine

Desktop Laser Marking System

High-Speed Galvo Laser Machines

Custom solutions for specific industrial needs

Whether you're a small manufacturer or a large-scale enterprise, Divine Laser Technologies has the right marking solution.

Affordable and Reliable Solutions: Affordability is key, especially for SMEs and startups. Divine Laser Technologies is committed to delivering Affordable Fiber Laser Machines without compromising on durability or performance. Their machines are designed to offer high return on investment with minimal downtime.

Customization and Flexibility: Each industry has unique marking requirements. That’s why Divine Laser offers customization options including wattage variations (20W, 30W, 50W, etc.), software integration, automation compatibility, and compact designs. Their solutions are designed to integrate easily into existing production lines.

Strong After-Sales Support: As a responsible Fiber Laser Marking Machine Supplier, the company offers excellent after-sales services, including installation, training, remote diagnostics, and prompt maintenance. Their dedicated support team ensures your operations stay seamless.

Applications of Fiber Laser Marking Machines

Automotive Industry: Fiber lasers are used for marking engine parts, VIN numbers, gearboxes, and other high-value components that require permanent traceability.

Electronics and Electrical: Printed circuit boards (PCBs), electronic components, cables, and switches are precisely marked using high-speed fiber laser engravers.

Medical and Surgical Instruments: Markings on surgical tools must be sterile, corrosion-resistant, and highly legible. Fiber lasers deliver superior results with minimal thermal impact.

Jewelry and Luxury Items: Fine engraving on gold, silver, and platinum is made possible with fiber lasers, ensuring aesthetic excellence with precision.

Industrial Tools and Machinery: Industrial tools such as drills, bearings, and machine parts benefit from fiber laser marking, offering durability and clarity.

Benefits of Choosing Fiber Laser Machines from Divine Laser Technologies

If you're on the lookout for a reliable Fiber Laser Manufacturer in Ahmedabad, Divine Laser Technologies offers benefits that go beyond machinery:

High-Speed Marking

With scanning speeds up to 7000 mm/s, their machines significantly cut down production times.

High Precision

Accuracy levels up to 0.01mm ensure perfect detail, even on small parts or intricate logos.

Long Life and Low Maintenance

The fiber laser source comes with a lifespan of 100,000 hours, translating to years of uninterrupted performance.

Eco-Friendly Operation

No consumables, minimal power consumption, and no waste—fiber lasers are sustainable and cost-effective.

User-Friendly Software

Integrated with advanced marking software that supports a variety of file formats (DXF, PLT, BMP, etc.) and allows for variable data marking (date, time, serial numbers, etc.).

Serving Ahmedabad and Beyond

Ahmedabad has emerged as a significant industrial cluster in India, and Divine Laser Technologies is proud to be a leader in this space. As a Fiber Laser Marking Machine Manufacturer in Ahmedabad, they serve clients not only across Gujarat but pan-India and export to international markets. Their commitment to innovation, affordability, and service excellence is trusted by hundreds of businesses across various sectors.

What Sets Divine Lasers Apart from Other Fiber Laser Suppliers?

🔹 Local Manufacturing, Global Standards

Their machines are made in India with components that meet global standards—ensuring top quality at competitive prices.

🔹 Quick Delivery and Spare Parts

Being based in Ahmedabad allows them to offer fast deliveries and ready availability of spare parts across the region.

🔹 Trusted by Industry Leaders

From small workshops to large-scale factories, clients rely on Divine Laser Technologies for consistent quality and long-term support.

Whether you're looking to enhance traceability, boost productivity, or improve product aesthetics, investing in a Fiber Laser Marking Machine is a game-changer. And when it comes to finding the right partner, Divine Laser Technologies stands tall as a reputed Fiber Laser Marking Machine Manufacturer in Ahmedabad.

With affordable prices, robust engineering, and unmatched support, Divine Laser Technologies is your one-stop solution for all types of Laser Marking Machines. Their machines are built to last and designed to perform under the toughest industrial environments.

Ready to transform your production with high-speed, precision marking solutions?

Connect with Divine Laser Technologies today—your trusted Fiber Laser Marking Machine Supplier in Ahmedabad.

✅ Affordable | Durable | Customizable | Made in India For more information: https://www.lasermarkingmachine.info/Call us:8069220249E-mail ID:[email protected]: 10 Grand Vishala Odhav Ring Road Ahmedabad, Gujarat, (India)

#Fiber Laser Marking Machine Manufacturer in Ahmedabad#Laser Marking Machines#Fiber Laser Marking Machine in Ahmedabad#Fiber Laser Machine#Metal Laser Marking Machine#Affordable Fiber Laser Machine#Fiber Laser Manufacturer in Ahmedabad#Fiber Laser Marking Machine Supplier

0 notes

Text

JPT M8 100w Fiber Laser Marking Machines Suppliers

Hl-yeah provides JPT M8 100w Fiber Laser Marking Machine at reasonable prices worldwide. It is used for quick and permanent marks or etching on firearms, tools, metal parts, jewelry, barcodes, serial numbers, nameplates, and many more. It is a compact, portable, and easy-to-use machine. For more details call us at 86-18025348056.

0 notes

Text

Laser marking machine can help you customize your own keychain #lasermarking #Customizable

3 notes

·

View notes

Text

Fiber Laser Marking Machine Manufacturer in ahmedabad | Divine Laser Technologies

Divine Laser Technologies stands as a leading Fiber Laser Marking Machine Manufacturer in Ahmedabad, committed to delivering precision marking solutions tailored to meet the evolving needs of modern industries. With cutting-edge technology and robust engineering, our fiber laser marking machines are designed for high-speed, high-accuracy engraving on a variety of materials including metals, plastics, ceramics, and more. Whether you need permanent barcodes, serial numbers, QR codes, or intricate logos, our machines ensure clear, consistent, and durable markings with minimal maintenance. As a trusted manufacturer in Ahmedabad, we emphasize quality, customization, and customer satisfaction in every product we deliver. Buy Fiber Laser Marking Machine at Best Price. For More Details Contact Us!

Visit: https://www.lasermarkingmachine.info/ahmedabad/fiber-laser-marking%C2%A0machine/ITB-8644020A

Call Now: 8069220249

Location: 10 Grand Vishala Odhav Ring Road Ahmedabad, Gujarat, (India) 382415

#Fiber Laser Marking Machine Manufacturer in Ahmedabad#Laser Marking Machines#Fiber Laser Marking Machine in Ahmedabad#Fiber Laser Machine#Metal Laser Marking Machine#Affordable Fiber Laser Machine#Fiber Laser Manufacturer in Ahmedabad#Fiber Laser Marking Machine Supplier

0 notes

Text

Empowering Smart Manufacturing: The Rise of Fiber Laser Marking Machines

As industries rapidly shift toward customization, miniaturization, and automation, the demand for high-precision marking and engraving technologies is more critical than ever. Fiber laser marking machines have emerged as a game-changing solution, delivering unmatched speed, accuracy, and long-term durability.

These systems are engineered for permanent marking of metals and select non-metals, making them indispensable in the electronics, automotive, medical device, and industrial manufacturing sectors.

What Is a Fiber Laser Marking Machine?

A fiber laser marking machine is an advanced, third-generation system that utilizes a fiber laser source and high-speed galvanometric scanners to mark, engrave, or etch surfaces with extreme precision. Operating at a wavelength of 1064 nm, these machines are ideal for marking stainless steel, aluminium, brass, and certain industrial plastics, ensuring clear, permanent identification marks.

Key Applications in Lithium-ion Battery Manufacturing

In the world of lithium-ion battery manufacturing, where precision, cleanliness, and traceability are paramount, fiber laser machines meet and exceed industry requirements:

Laser Cleaning of Cell Tabs and Terminals Removes oxides and contaminants from battery tabs, busbars, and cell terminals without damaging the surface, ensuring optimal electrical contact and weld integrity.

Traceability Marking on Cell Casings and Modules Permanently engraves QR codes, barcodes, and serial numbers on battery cells, modules, and pack casings for complete lifecycle traceability.

Marking Insulation Layers and Protective Films Enables non-invasive marking on insulation films and separators, aiding component identification during automated assembly processes.

Core Benefits of Fiber Laser Marking Machines

Ultra-Fine Marking Precision – Ideal for detailed micro-text, data matrix codes, and alphanumeric identifiers.

Fast, Continuous Operation – Speeds up production lines by minimizing cycle time.

No Consumables – A cost-effective, eco-friendly solution suited for cleanroom environments.

Maintenance-Free Design – Delivers up to 100,000 hours of reliable operation.

Air Cooling System – Simplifies system integration and reduces operational complexity.

Broader Industrial Applications

Electronics Industry – Circuit boards, microchips, mobile phone casings

Automotive Sector – Gears, engine components, VIN plates

Medical Field – Surgical tools, implants, product IDs

Consumer Goods – Watches, designer accessories

Tool Manufacturing – Precision tools, calibration equipment

Conclusion

Fiber laser marking machines are revolutionizing the landscape of smart manufacturing by delivering the precision, efficiency, and traceability that modern industries demand. Their critical role in lithium-ion battery production—from laser cleaning to traceability marking—ensures safer, smarter, and more streamlined production lines.

Whether you're handling microscopic components or large-scale battery packs, fiber laser technology empowers your operations with consistent marking and cleaning processes essential for high-volume, high-precision manufacturing.

#fiber laser marking machines#smart manufacturing#laser cleaning#traceability in battery production#laser engraving technology#high-precision marking#battery manufacturing equipment#non-contact marking systems

0 notes

Text

https://www.imrmarketreports.com/reports/ultra-precision-fiber-laser-cutting-machine-market

0 notes

Text

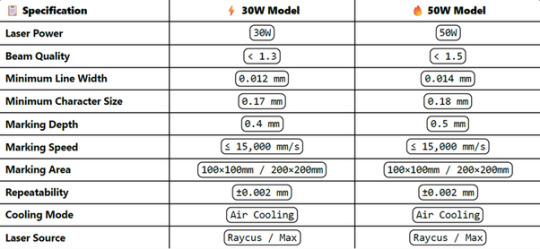

In this episode, we explore the Semco Fiber Laser Marking Machine, its cutting-edge speed, accuracy, and applications across materials. Learn how this 30W/50W system transforms your marking efficiency while saving cost and time.

Listen now to hear why manufacturers are upgrading to Semco’s third-generation fiber laser solution.

#fiber laser machine benefits#industrial laser podcast#laser marking for manufacturing#fiber laser engraving explained#cost-effective laser solutions#laser machine audio introduction#smart marking technology

0 notes

Text

Unleash Creativity and Precision with XT LASER's Compact Wonders! 🌟

Hey there, creative minds and industry enthusiasts! XT LASER brings you an amazing lineup of compact yet powerful machines. Our mini laser marking machine is a dream for adding personalized, permanent marks on all sorts of items, from trendy jewelry to unique DIY crafts. The handheld laser welding machine? They're perfect for those delicate joins, whether you're into small - scale metalwork or electronics tinkering. And don't forget our laser cleaning machine, which can easily remove dirt and rust from precious antiques or small - sized industrial parts. These little powerhouses pack a punch. Discover more about XT LASER's innovative products at https://xtfiberlaser.com/. Let's get creative together! 💥

1 note

·

View note

Text

Why Fiber Laser Machines Are Revolutionizing Precision Cutting

In the world of manufacturing, precision and efficiency are paramount. Businesses looking for the best cutting-edge technology are increasingly turning to fiber laser machines for their superior performance and cost-effectiveness. Whether in metal fabrication, automotive, or electronics, fiber laser technology is setting new industry standards.

What Are Fiber Laser Machines?

Fiber laser machines utilize high-powered laser beams transmitted through fiber optic cables to cut, engrave, or mark various materials with extreme accuracy. Unlike traditional CO2 lasers, fiber laser machines offer enhanced energy efficiency, lower maintenance costs, and greater precision. They are particularly well-suited for cutting metals like stainless steel, aluminum, brass, and copper.

Key Benefits of Fiber Laser Machines

1. Unmatched Precision and Speed

One of the standout advantages of fiber laser machines is their ability to achieve incredibly fine details at rapid speeds. Their high-intensity laser beams enable clean cuts with minimal heat distortion, reducing the need for secondary processing.

2. Cost-Effective and Low Maintenance

Unlike CO2 lasers, fiber laser machines have fewer moving parts and require significantly less maintenance. This translates into lower operational costs and a higher return on investment for businesses looking to scale their production.

3. Versatility Across Industries

From intricate jewelry engraving to heavy-duty metal fabrication, fiber laser machines serve a wide range of applications. Their ability to process reflective metals without compromising on quality makes them a preferred choice in industries like aerospace, medical device manufacturing, and signage production.

4. Energy Efficiency and Eco-Friendliness

Energy consumption is a growing concern for businesses striving for sustainability. Fiber laser machines consume significantly less power compared to traditional laser systems, reducing both energy costs and carbon footprints.

Why Choose a Fiber Laser Machine from IEHK?

If you’re looking for top-quality fiber laser machines, IEHK offers a range of reliable and high-performance models to meet diverse industrial needs. At IEHK, you’ll find machines built with cutting-edge technology, ensuring precision, speed, and durability.

Competitive Pricing

IEHK provides cost-effective solutions without compromising on quality, making advanced fiber laser technology accessible to businesses of all sizes.

Exceptional Customer Support

Purchasing a fiber laser machine is a significant investment, and IEHK ensures seamless customer support, from installation to troubleshooting.

High-Quality Performance

With robust design and advanced software integration, IEHK’s fiber laser machines guarantee optimal performance for a variety of cutting and engraving applications.

Final Thoughts

Investing in fiber laser machines is a game-changer for businesses looking to enhance precision, efficiency, and profitability. Whether you’re in metal fabrication, automotive manufacturing, or industrial engraving, a high-quality fiber laser machine from IEHK can elevate your production capabilities. Explore the latest models today and stay ahead in the competitive world of manufacturing!

0 notes

Text

youtube

Discover how Semco’s SI-N FLCMT 30W/50W Fiber Laser Marking Machine delivers super-fast, ultra-precise results on metal and plastic surfaces. With high-speed scanning and a compact build, it's perfect for industries demanding quality and durability.

🔧 Ideal for: stainless steel, plastics, ICs & more 💡 Benefits: 3-12x faster, 100,000 hrs life, low maintenance

📞 Call: +91-8920681227 | 🌐 semcoinfratech.com

#fiber laser marking machine demo#high-speed laser engraving#laser marking machine video#industrial laser marker#30w vs 50w laser comparison#fiber laser for stainless steel#portable fiber laser engraver#Youtube

0 notes

Text

This 30W fiber laser engraver is powerful, easy to use, and works on metals, some plastics, and varying thicknesses. Available for sale, it includes adjustable power, a 2-year warranty, and lifetime support.

0 notes