#FingerParallelGripper

Explore tagged Tumblr posts

Text

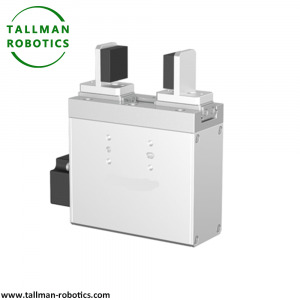

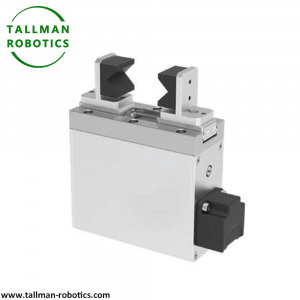

Dust Proof Electric Grippers Will Be Transported to America

Dust Proof Electric Grippers from Tallman Robotics Limited are ready for delivery to USA.

Dust Proof Electric Grippers are designed to be able to securely hold objects while also protecting them from dust or other particles in the surrounding environment. These grippers typically employ special sealing mechanisms or coatings to prevent any dust ingress into the internal components. When choosing dust proof electric grippers, here are a few factors to consider: 1. Sealing: Look for grippers that have effective sealing mechanisms, such as gaskets or O-rings, to provide a reliable barrier against dust particles. 2. IP Rating: Check the Ingress Protection (IP) rating of the gripper. A higher IP rating indicates a greater degree of protection against dust. Look for a rating of at least IP65 or higher for effective dust-proof capabilities. 3. Construction: Consider the materials used in the gripper's construction. High-quality materials that are resistant to dust accumulation, such as stainless steel or dust-repellent coatings, can help maintain the gripper's performance over time. 4. Cleaning and Maintenance: Determine how easy it is to clean and maintain Dust Proof Electric Grippers. Grippers with smooth surfaces and minimal crevices are typically easier to clean, ensuring optimal performance during operation. 5. Gripping Force and Size: Assess the gripping force and size range of the gripper to ensure it is suitable for the objects you will be handling. Different grippers may have varying capabilities depending on the application. Remember to consult the manufacturer's specifications and documentation for each specific gripper model you are considering. This will provide detailed information about its dust proof capabilities, operating parameters, and any additional features that may be relevant to your application. Dust proof electric grippers typically use various sealing mechanisms to prevent the ingress of dust particles into their internal components. Here are a few commonly used sealing mechanisms: 1. Gaskets: Grippers may incorporate gaskets made of rubber or similar materials. These gaskets create a tight seal between the different parts of the gripper, preventing dust from entering. 2. O-Rings: O-rings are mechanical seals typically made of rubber or elastomer materials. These rings are placed in grooves or channels within the gripper to create a tight seal. O-rings are effective at preventing dust penetration. 3. Lip Seals: Also known as oil seals or rotary shaft seals, lip seals are used to prevent the entry of contaminants, including dust, along a rotating shaft. These seals have a flexible lip that comes into contact with the shaft, creating a barrier against dust particles. 4. Diaphragm Seals: Diaphragm seals are flexible membranes made of materials such as rubber or elastomers. They are often used in grippers to provide a barrier against dust and other particles. Diaphragm seals can be designed to compress and seal tightly when the gripper is in use. 5. Dust-Repellent Coatings: Some grippers may use specialized coatings that are designed to repel dust. These coatings create a smooth surface that makes it difficult for dust particles to adhere to the gripper, thereby reducing the risk of contamination. It's important to note that the specific sealing mechanisms used in dust proof electric grippers may vary depending on the manufacturer and the model of the gripper. Therefore, it's recommended to refer to the manufacturer's documentation or reach out to them directly for detailed information on the sealing mechanisms used in a particular gripper model. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#2-fingerparallelgripper#ALeadingGlobalManufacturerofElectricGripper#DustproofElectricGrippers#highlydurableelectricgrippersthatarewaterproofanddustproof#IP67WaterproofElectricGrippers#SplashproofElectricGrippers#WaterProofRobotArmGripper

0 notes

Text

Servo Electric Grippers

Servo Electric Grippers: Designed for gripping hard, soft, shaped and fragile objects. You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects.

Technical Parameters about Tallman Robotics Servo Electric Grippers Model No. TM-GB-11-20-1.6 TM-GB-11-40-1.6 TM-GB-17-60-2 Applicable Controller TM-C TM-C TM-C Max Clamping Force (N) 65 110 250 Max clamping speed(mm/s) 100 100 100 Lead (mm) 1.6 1.6 2 Stroke (mm) 20 40 60 Repeatability (mm) ±0.05 ±0.05 ±0.05 Backlash (mm) Less than 0.1 on one side Less than 0.1 on one side Less than 0.1 on one side Allowable Load Torque (N.m) MR:9.0、MP:6.5、MY6.5 MR:9.0、MP:6.5、MY6.5 MR:58.5、MP:25.0、MY25.5 Mass (kg) 0.8 1.1 2.1 Recommended Use Environment (temperature and humidity) 0~40℃, below 85%RH (without condensation) 0~40℃, below 85%RH (without condensation) 0~40℃, below 85%RH (without condensation) https://youtu.be/vmLYDdPPiQc Electric gripper (also called "servo gripper") is an intelligent electric cylinder that is composed of non-standard structural parts, transmission parts, servo motor, PLC control system and control program. Its speed, stroke and clamping force can be separately Independent control. Compared with pneumatic grippers, it has more powerful functions and a wider range of applications. Commonly used in food, medical, laboratory and other precision gas-free environment. Tallman Robotics has developed Servo Electric Grippers, servo pushers, servo slides, servo rotary cylinders and integrated drive and control controllers, and offers servo electric cylinders. Driven by the motor to realize the tightening and releasing of the claw fingers, the positioning point can be controlled, and the clamping force can be controlled; controlled by the host computer such as PLC, industrial PC, single chip computer and motion controller to realize the grasping and positioning of objects And other functions are the flexible execution terminals of the device. Widely used in industrial automation industry: a. Mobile phone, TV, home appliance and other electronic manufacturing enterprises b. Automobile/auto parts manufacturers c. Medical equipment manufacturing enterprises d. Factory automation, complete equipment supplier f. Non-standard automation equipment in various industries g. Industrial robot integration Suitable for the clamping of easily deformed and fragile work pieces in industrial automation; Speed, position, clamping force and other parameters can be controlled; Work piece transfer discharge; Picking and placing materials in narrow spaces; Laboratory, medical and other places where there is no compressed air source and other places where pneumatic grippers are not suitable; To achieve high-speed opening and closing and high clamping force; Available in parallel opening and closing type and lever type; Multi-point positioning and clamping force adjustment are possible; Built-in clamping confirmation and dimensional measurement functions Common robots often have errors such as not being able to get the clips, dropping them up, or damaging the work pieces during the clamping operation in running water. In order to reduce errors, companies will install various sensors on the gripper, which makes the robot huge and bulky. Robust Motion Limited has a "clamp confirmation" function built into the servo gripper, which enables the "automatic identification of the clamping state" without the need for external sensors. In addition, it also has a built-in "clamp measurement" function, which can judge the size of the work piece through tolerance identification. Powerful adaptive gripping function In the face of clamping objects of various shapes, soft and hard, and different sizes, the problems of slow gripping, difficult debugging, and low work efficiency of the traditional air gripper are obvious. If the air gripper is to be held flexibly, the engineer must reduce the air pressure or the gripping speed, so that the gripping time is too long, and the gripped items are easy to fall. SGA-RM servo gripper, while not changing the gripping speed, adds an "adaptive gripping" function, which automatically grips objects of various shapes using an adaptive force. Even when fragile eggs, egg rolls, glass bottles or small heat sinks are gripped, they are as natural as human hands. No drop after power off TM servo gripper also has an intelligent protection mechanism. During the gripping process, the work piece is not dropped due to power failure, which maximizes the protection of the company's production interests. This is something that traditional cylinders cannot do. Read the full article

#All-in-oneServoGrippers#CollaborativeRobotGrippers#ElectricGrippersforIndustrialAutomation#ElectricSmallComponents#FingerParallelGripper#FreelyProgrammableElectricGrippers#IndustrialRobotsElectricGrippers#IntelligentRobotGrippers#ServoElectricGrippers#ServoMotorElectricGripper#SmallPartsGripper#SmartAngularGripper#SmartCompliantRoboticGripper#SmartIndustrialRoboticClaw#Three-fingerElectricGrippers#Three-jawElectricGrippers

0 notes

Text

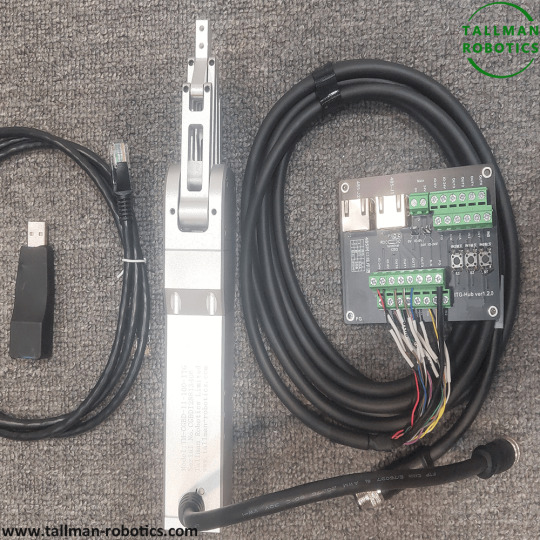

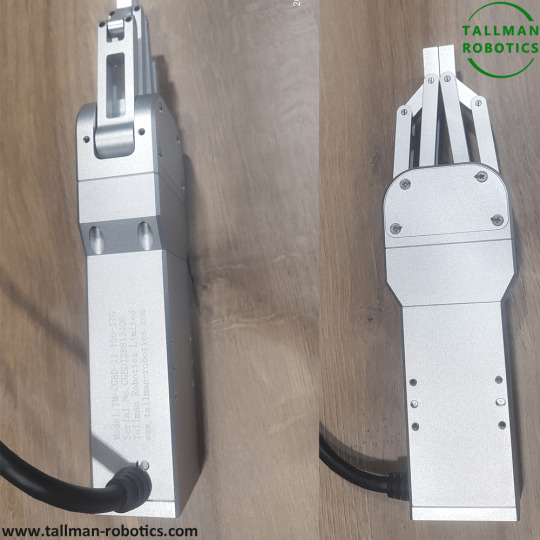

Long-Stroke Servo-Electric Grippers are ready for Delivery to Clients

Long-Stroke Electric Grippers from Tallman Robotics Limited are packed well for delivery to customer. Length of Long-Stroke Electric Grippers suitable for clamping large workpieces. Long stroke and high rigidity. High clamping force can be adjusted according to the workpiece demand. Standard built-in or external drive controller Long stroke gripper is a special kind of gripper, and its arm is also relatively long, which can grasp objects. When the robot works at a fixed point, Long Stroke Electric Grippers can effectively extend the working range with its long arm.

Detailed parameters: Description item TM-CGBD-ITG- series Technical Parameters Size number 11 17 Specifications 100 100 Stroke (mm) 90 90 Maximum clamping force (n) 40 70 Force repeatability ±10% Repeatability (mm) ±0.05 control mode Bus Modbus RTU/CANopen Interface IO control PID interface Input 2 points (NPN), output 3 points (NPN, load 3.5ma) Rated voltage (V) DC24±10% Rated current (a) 2 4 Mass (kg) 0.7 1.6 Recommended environment 0 ~ 40 ℃, below 85% RH (without condensation) Degree of protection IP40 You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects. Read the full article

#2FingerElectricGripper#2-fingerAdaptiveElectricRobotGripper#2-jawparallelself-centeringelectricgripper#Doublefingerclawelectricclampingclaw#Electricactuator2-fingerGripperMotorizedGrippers#ParallelRobotGripper#Twofingeradaptivegripper#Two-FingerGripper#Two-FingerParallelGripper#two-fingerservogripper

0 notes