#Fitness Equipment Assembly Services

Text

#Handyman Services in Pittsburgh#Fitness Equipment Assembly Services#Furniture Assembly Services#Airbnb Cleaning Services#Home Staging Pittsburgh Pa#Cleaning Services Pittsburgh Pa#TV Mounting Service#Interior Decorator Pittsburgh

1 note

·

View note

Text

"Unité d’Habitation / La Cité Radieuse", 280 Boulevard Michelet, 13008, Marseille, France [1947-52] _ Architect: Le Corbusier _ Photos by: Spyros Kaprinis [25.05.2024].

"The building takes the form of a housing bar 135 metres long, 24 metres wide, 56 metres high and mounted on stilts. Three hundred and thirty apartments, divided into twenty-three different types, can accommodate a population of between 1,500 and 1,700 occupants having at their disposal on the seventh and eighth floors a shopping street and a hotel-restaurant, together with a kindergarten and sports facilities on the roof terrace. The constructive principle adopted, the so-called “bottle rack”, consists in building apartments inside an independent frame of posts and reinforced concrete beams. The apartments are made up of standard elements assembled on the site. All the apartments are dual-aspect, except those on the south side. A sun-break loggia provides an open-air facility at the same time as limiting exposure to sunlight. Protected by double glazing, the apartment interiors are subject to the two basic rules of naval and monastic architecture: rationalism and simplicity. The living room, open on two levels, is the nucleus of the family “home”; upstairs the parents’ room occupies the mezzanine. The kitchen is equipped like a laboratory: electric cooker, refrigerator, rubbish chute and storage racks. The entire apartment is fitted with racks replacing traditional storage. The ventilation of the kitchen, bathroom and toilets is mechanically operated, while the entire apartment is supplied with clean air by an air conditioning system. These facilities were not found in the low-cost collective housing units of the time, and the standard surface areas of the Unité d’Habitation are greater than these by between 40% and 50%. The seventeen-storeys below the terrace are connected by eight interior streets which, given the overlap of the two-storey apartments, each serve three floors. Each street is accessed by a battery of four elevators complemented by a service elevator and three emergency staircases. The entire building and its equipment are designed in terms of the Modulor, the universal measuring unit conceived by Le Corbusier."

#Unité d’Habitation#La Cité Radieuse#Marseille#France#Le Corbusier#1947#1952#Spyros Kaprinis#2024#Concrete#Brutalism#Housing#Architecture

217 notes

·

View notes

Text

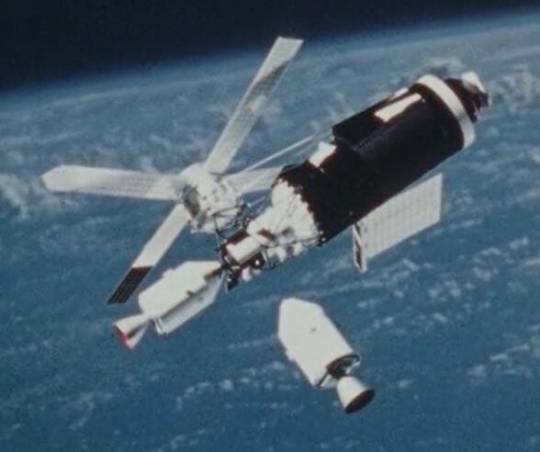

Cancelled Missions: Skylab Rescue Mission (SL-R)

Mission patch for rescue mission for SL-3

Spacecraft: CSM-119

Launch Vehicle: Saturn IB AS-208, later AS-209

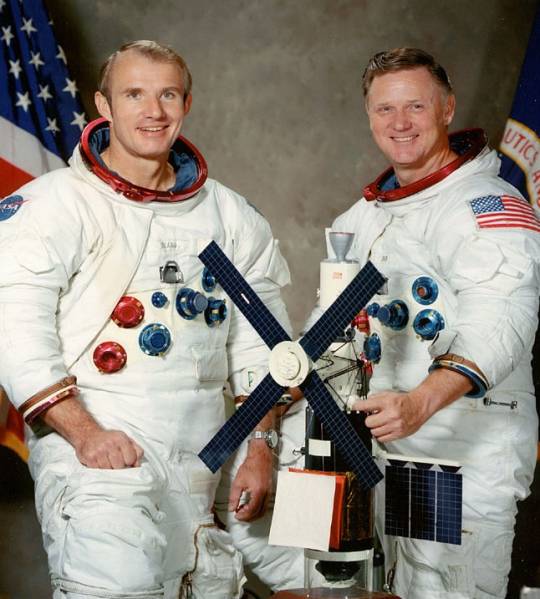

Commander: Vance D. Brand

Command Module Pilot: Don L. Lind

Intended launch date: September 1973, (on standby from August 1973 - February 1974)

Skylab rescue mission crewmen Vance Brand (left) and Don Lind.

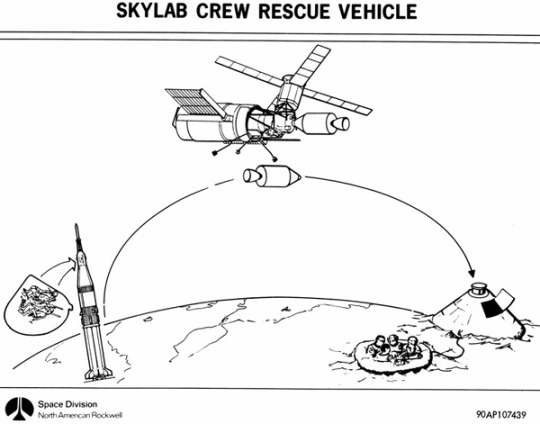

"Influenced by the stranded Skylab crew portrayed in the book and movie 'Marooned', NASA provided a crew rescue capability for the only time in its history." Prepared for launch during Skylab 3."

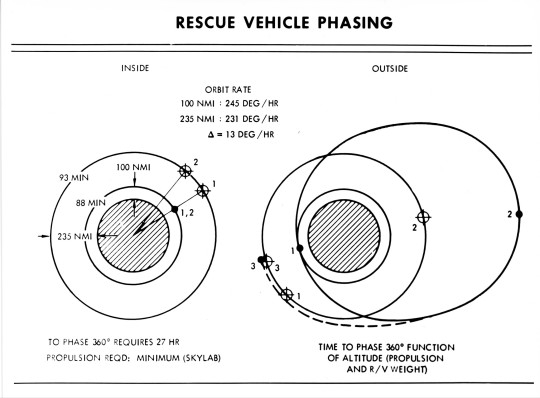

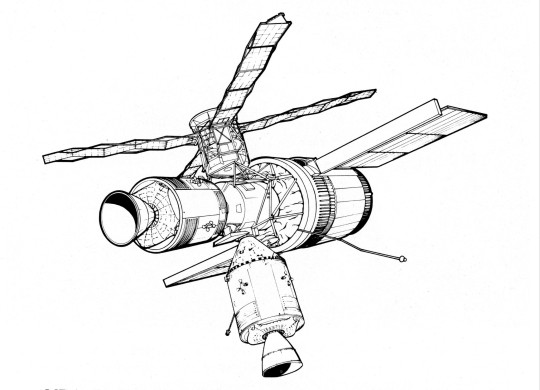

"Skylab rescue vehicle phasing - NAR Space Division drawing illustrates phasing of 5-seater Skylab rescue vehicle for a Skylab mission."

Date: April 5, 1971

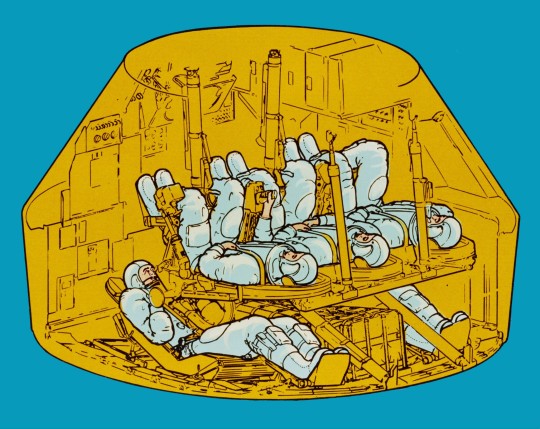

"A kit was developed to fit out an Apollo command module with a total of five crew couches. In the event a Skylab crew developed trouble with its Apollo CSM return craft, a rescue CSM would be prepared and launched to rendezvous with the station. It would dock with the spare second side docking port of the Skylab docking module."

- information from Astronautix.com: link

"The Apollo Command Module as modified to rescue stranded crews for the Skylab program. Two crew + three rescuees packed like sardines...."

"Skylab 3 astronauts Alan Bean and Jack Lousma helped design the "field modification kit" to use a standard CSM for rescue, and would have flown the CSM for their mission to rescue Skylab 2 if necessary. The standard Skylab Command Module accommodated a crew of three with storage lockers on the aft bulkhead for resupply of experiment film and other equipment, as well as the return of exposed film, data tapes and experiment samples. To convert the standard CSM to a rescue vehicle, the storage lockers were removed and replaced with two crew couches to seat a total of five crewmen."

Posted on Flickr by Mike Acs. NASA ID: 108-KSC-70P-69

"Soon after Skylab 3's launch the crew's CSM developed a problem with Quad B, one of its four reaction control system thrusters. On August 2, 1973, six days later, a snowstorm-like effect outside the station startled the crew during breakfast. What appeared to be 'a real blizzard' was fuel leaking from Quad D, opposite from Quad B. The malfunctions left two available quads, and while the spacecraft could operate with just one, the leaks posed a possible risk to other systems. The fuel for all quads and the main service propulsion system (SPS) engine were from the same batch; if the SPS fuel was contaminated, the CSM might not be able to deorbit.

source

NASA considered bringing the crew home immediately, but because the astronauts were safe on the station with ample supplies and because plans for a rescue flight existed, the mission continued while the Saturn IB rocket AS-208 with CSM-119 was assembled in the Vehicle Assembly Building at Launch Complex 39 for possible use. It was at one point rolled out to LC-39B.

Illustration of the rescue Apollo spacecraft preparing to dock at Skylab’s lateral port. source

NASA announced on August 4 that Skylab 3 and Skylab 4 backup crewmen Vance Brand and Don Lind would fly any rescue mission; they had immediately begun training for the flight once the second quad had failed on August 2. After engineers found that the leaks would not disable the spacecraft, the two men used simulators to test reentry using two quads. If ground personnel worked 24 hours a day and skipped some tests, the mission could launch on September 10, and would last no more than five days. The astronauts would attempt to prepare Skylab for further use but returning experimental data and diagnosing the cause of the problem were more important, with Lind choosing what would be brought back. Human urine and feces samples and Apollo Telescope Mount and other film were the priorities. Although Skylab had two docking ports the primary one would be used if possible, jettisoning the Skylab crew's CSM if necessary.

Posted on Flickr by Drew Granston: link

While many within NASA believed that the rescue mission would occur, within hours of the failure of the second quad the agency canceled the rescue mission. Beyond NASA's conclusion that the failed quads would not disable the Skylab 3 CSM and the SPS fuel was uncontaminated, Brand and Lind had already shown during their training as backup Skylab crewmen that a reentry with failed quads was safe. They also devised a method to deorbit with the command module's attitude control system. Later joking that they were 'very efficient but perfectly stupid, because we have literally worked ourselves out of the mission', Brand and Lind continued to train for a rescue mission, as well as for their backup roles, but the Skylab 3 crew was able to complete its full 59-day mission on the station and safely return to Earth using the two functional RCS thruster quads, using the SPS engine once instead of twice as precaution."

- Information from Wikipedia: link

Posted on Flickr by Ed Dempsey: link

Saturn IB SA-208 was used for Skylab 4 and SA-209 was assigned to the standby rescue mission. At one point, CSM-119/SA-209 was slated for the Skylab 5 mission but it was cancelled when SL-4 was extended and completed all of it objectives.

Mission patch for rescue mission for SL-4

Later, CSM-119/SA-209 was the backup launch vehicle for Apollo-Soyuz Test Project mission and standby rescue vehicle. After the Apollo program ended, the surplus rocket and spacecraft were displayed at the Kennedy Space Center, Florida.

NASA ID: 71-H-662, S73-31922

source, source

#Skylab Rescue#SL-R#Apollo CSM Block II#CSM-119#Saturn IB#SA-208#SA-209#Rocket#NASA#Apollo Program#Apollo Applications Program#Cancelled#Cancelled Mission#September#1973#my post

90 notes

·

View notes

Text

25 Avro Lancaster Facts | Classic Warbirds

Roy Chadwick was born on the 30th April 1893 in Farnworth, Lancashire and joined Avro in September 1911 as a draughtsman at the age of 18. He would become the company's chief designer seven years later in 1918. A number of aircraft designed by Roy Chadwick would be used during the Second World War, such as the Avro Anson, but it is the Avro Lancaster which is perhaps the most well known. At the age of 54 Roy Chadwick died when the Avro Tudor prototype he was on crashed on take-off on the 23rd August 1947.

Derived from the Avro Manchester

The twin-engined Avro Manchester suffered mainly due to its Rolls-Royce Vulture engines, which were unreliable and unable to reach their optimal performance. So before the aircraft had performed its first operational sortie, the 4th November 1940 saw Avro given the green light to work on what was known as the Manchester Mk III by the Air Ministry. This would have a wingspan 10 ft 2 in longer than the Manchester and was powered by four Rolls-Royce Merlins. It was this aircraft that would be developed into the Lancaster.

10,500 Individual Drawings

During the production of the Lancaster around 10,500 individual drawings were needed and each aircraft required approximately 10 tonnes of light aluminium alloy.

Cost of a Lancaster

On average a Lancaster, minus its armament, bomb sight, radio and radar equipment, cost, at the time, £59,000, which included its four engines.

Crew of Seven

The Lancaster typically had a crew of seven, made up of pilot, bomb-aimer, flight engineer, navigator, wireless operator, mid gunner and rear gunner.

Lancaster fuselage assembly at Castle Bromwich | Photo by Birmingham Museums Trust, licensed under CC0

First Flight

The first Lancaster prototype (BT308) flew on the 9th January 1941 from Ringway Airport. Captain Harry Brown and Sydney Thorn were at the controls. This featured an increased wingspan over the Manchester and a central fin on the tail, which was removed on the second prototype.

Entry into Service

It would be with No. 44 Squadron, based at RAF Waddington that the Lancaster would first enter Royal Air Force service, when they took delivery of their first three aircraft on the 24th December 1941. These would replace their twin-engined Handley Page Hampdens.

First Operational Sortie

No. 44 Squadron would perform the Lancaster's first operational sortie, which took place on the 3rd March 1942. This saw four aircraft lay mines in the Heligoland Bight.

Bristol Hercules Powered Lancaster B.II

Of the Lancaster variants produced all would be powered by either Rolls-Royce or Packard Merlins, the exception was the Lancaster B.II, which was powered by the 1,735-hp Bristol Hercules XVI engine. It was 10 mph slower than the Merlin powered Lancasters, with a top speed of 205 mph, its service ceiling was 18,500 ft, which was 6,000 ft lower. Only 301 Lancaster B.IIs were built.

Basis for the Avro York

Another Roy Chadwick design, the Avro York was a transport aircraft that featured the wings, tail and landing gear of the Lancaster, fitted to a new fuselage. The aircraft would be used by Transport Command and the British Overseas Airways Corporation.

Lancaster B.I (HK535) | Photo by Birmingham Museums Trust, licensed under CC0

Flew Under Sydney Harbour Bridge

During 1943 Lancaster B.III (ED930) Q for Queenie embarked on a promotional tour of Australia to sell war savings bonds. With Flight Lieutenant Peter Isaacson at the controls, the 22nd October 1943 saw hm fly the aircraft under Sydney Harbour Bridge.

'Clapper Kites'

Some Lancaster B.Is would have their front and mid-upper turrets removed and some interior items removed. Powered by Rolls-Royce Merlin 24 engines, they were renamed to Lancaster B.I (Special). Due to their high speed without a bomb load they were nicknamed 'Clapper Kites'.

Lancaster Test Beds

A number of Lancasters would be used as test beds or for research, this included Lancaster B.II (LL735) which was used to test the Metropolitan-Vickers F2 turbojet. Fitted towards the rear of the fuselage, with the exhaust where the rear turret would've been.

Very Long Range Lancaster

To increase the range of the aircraft, for potential operations in the Pacific, a pair of Lancaster B.Is (HK541) and (SW244) would have a 'saddle tank' installed. This was fitted behind the cockpit and extended down past the wings, increasing fuel capacity by 50%.

Operation Exodus

Beginning on the 3rd April 1945 until the 31st May 1945, Operation Exodus saw many prisoners of war flown home by a number of aircraft, including the Lancaster, which with modifications could transport 20 to 24 people.

Lancaster B.I of the Royal Air Force Battle of Britain Memorial Flight

Equipped at least 59 Squadrons

During its service in the Second World War the Lancaster would equip at least 59 frontline Bomber Command squadrons.

Lancaster Users

As well as the Royal Air Force a number of other countries used the Lancaster, including the Royal Australian Air Force, Royal Canadian Air Force and Royal New Zealand Air Force.

Ten Victoria Cross Winners

Ten Lancaster aircrew would be awarded the Victoria Cross during the Second World War. The first was awarded to Squadron Leader John Nettleton as a result of his actions with No. 44 Squadron flying Lancaster B.I (R5508) during a daylight attack on Augsburg, Germany on the 17th April 1942 (read the citation). With Captain Edwin Swales DFC of No. 582 Squadron the last, after being posthumously awarded the Victoria Cross for his actions flying Lancaster B.III (PB538) when acting as a Master Bomber when Pforzheim, Germany was raided on the 23rd February 1945 (read the citation).

Total Built

In total 7,377 Lancasters were built during its production run between 1941 and 1946. The last example, a Lancaster B.I, was built on the 2nd February 1946. A number of companies apart from Avro were also involved in the production of the aircraft, including Austin Motors Limited and Victory Aircraft Limited based in Canada.

Ton Up Lancs

On average the number of operational sorties flown by a Lancaster was 21. However, 35 aircraft would take part in 100 sorties or more during the Second World War. One of these was Lancaster B.I (R5868) S for Sugar which completed 137 sorties whilst with No. 83 Squadron and No. 467 Squadron, Royal Australian Air Force. May 1944 saw it reach the 100 sortie milestone, with a raid on Flensburg Harbour, Germany on the 23rd April 1945 seeing the aircraft performing its last operational sortie. This aircraft is on display at the Royal Air Force Museum, London.

Lancaster B.I (R5868) S for Sugar at the Royal Air Force Museum, London

'Tiger Force'

After the war in Europe ended on the 8th May 1945, it was intended to send a number of Lancaster squadrons to the Pacific. This would be known as the 'Tiger Force' and was to attack targets in Japan in the lead up to invasion, known as Operation Downfall. However, Japan surrendered before the force could be fully established.

Goodwill Tour

No. 35 Squadron were chosen to undertake a five week goodwill tour of the United States during July and August 1946. They would visit a number of airfields in the country.

Developed into the Avro Lincoln

As development of the Lancaster continued, a high altitude version featuring an increased wingspan and fuselage was produced, known as the Lancaster B.IV. However, with so many changes it was renamed the Avro Lincoln I, with the Lancaster B.V known as the Lincoln II.

Avro Lancastrian

The Lancastrian was a civil version of the Lancaster able to carry a small number of passengers and mail. Early Lancastrians were converted Lancasters with later aircraft built as Lancastrians from the start. Changes to the aircraft included the removal of its armament and armour. It would be used by a number of airlines, including British Overseas Airways Corporation.

15 Years Service with the Royal Air Force

The Lancaster's time with the Royal Air Force came to an end on the 15th October 1956 when the School of Maritime Reconnaissance retired their Lancaster MR 3, ending 15 years service with the RAF.

Avro Lancaster in the white and black camouflage scheme of the 'Tiger Force' © ww2images.com

@classicwarbirds via X

8 notes

·

View notes

Text

The Heart of Boiler Systems: Exploring the Role of IBR Fitting and Flanges

Boiler systems serve as the backbone of numerous industrial processes, powering everything from heating and hot water supply to steam generation in various manufacturing operations. Within these systems, ensuring safety, efficiency, and reliability is paramount, and this is where IBR (Indian Boiler Regulations) fitting and flanges play a pivotal role. As a trusted distributor in Vadodara and a leading dealer in Gujarat, Tubetrading is dedicated to providing top-quality IBR fitting and flanges to industries across the region. In this blog post, we'll delve into the significance of IBR fitting and flanges in boiler systems, explore their crucial functions, and highlight the expertise of Tubetrading in supplying these essential components.

Understanding IBR Fitting and Flanges

IBR fitting and flanges are integral components of boiler systems that ensure seamless operation and compliance with safety standards mandated by the Indian Boiler Regulations. These regulations are designed to safeguard the integrity of boiler components, prevent accidents, and promote efficient energy utilization. IBR fitting and flanges are manufactured according to stringent specifications outlined by the IBR to guarantee durability, reliability, and performance in demanding industrial environments.

The Role of IBR Fitting and Flanges in Boiler Systems

1. Pressure Regulation: IBR fitting and flanges are designed to withstand high-pressure environments commonly found in boiler systems. They play a crucial role in regulating and controlling the flow of fluids, gases, and steam within the system, ensuring optimal pressure levels for efficient operation.

2. Sealing and Joint Integrity: Proper sealing and joint integrity are essential to prevent leaks and maintain the integrity of boiler systems. IBR fitting and flanges are equipped with robust sealing mechanisms, such as gaskets and O-rings, to create a tight seal between interconnected components, minimizing the risk of leaks and ensuring system integrity.

3. Connection and Interoperability: IBR fitting and flanges serve as connection points between various components of boiler systems, including pipes, valves, and vessels. Their standardized dimensions and configurations enable seamless interoperability, facilitating efficient assembly, maintenance, and repair of boiler systems.

4. Compliance and Certification: Compliance with IBR regulations is mandatory for all boiler components used in India. IBR fitting and flanges undergo rigorous testing and certification processes to ensure compliance with safety standards and regulatory requirements, providing peace of mind to industries reliant on boiler systems.

Tubetrading: Your Trusted Supplier of IBR Fitting and Flanges in Gujarat

As a reputable distributor and dealer of IBR fitting and flanges in Vadodara and Gujarat, Tubetrading prides itself on delivering superior-quality products and exceptional service to its customers. Here's why industries trust Tubetrading for their IBR fitting and flanges needs:

1. Extensive Product Range: Tubetrading offers an extensive range of IBR fitting and flanges, including elbows, tees, reducers, bends, and flanges in various sizes, materials, and specifications. Whether you need standard or customized components, we have the expertise and resources to meet your requirements.

2. Quality Assurance: At Tubetrading, quality is our top priority. We partner with reputable manufacturers who adhere to strict quality control measures and comply with IBR regulations. Our products undergo thorough inspection and testing to ensure they meet the highest standards of performance, reliability, and safety.

3. Expert Guidance: With years of experience in the industry, the team at Tubetrading possesses in-depth knowledge of IBR fitting and flanges and their applications in boiler systems. We provide expert guidance and technical support to help our customers select the right components for their specific needs, ensuring optimal performance and efficiency.

4. Timely Delivery: We understand the importance of timely delivery to our customers' operations. With our efficient logistics network and inventory management systems, we strive to fulfill orders promptly and ensure on-time delivery of IBR fitting and flanges to our customers across Gujarat.

Conclusion

In conclusion, IBR fitting and flanges are the heart of boiler systems, playing a critical role in ensuring safety, efficiency, and compliance with regulatory standards. As a trusted distributor and dealer in Vadodara and Gujarat, Tubetrading is committed to supplying top-quality IBR fitting and flanges to industries across the region. With our extensive product range, quality assurance, expert guidance, and timely delivery, we are your reliable partner for all your IBR fitting and flanges needs. Contact Tubetrading today to learn more about our products and services and discover how we can support your boiler system requirements.

#IBR Fitting and Flanges distributor in Gujarat#IBR fitting and flanges distributor in Vadodara#IBR fitting and flanges dealer in Gujarat#IBR fitting and flanges#Gujarat#Maharashtra#Rajasthan#Madhya Pradesh#Daman#Uttar Pradesh

7 notes

·

View notes

Video

youtube

🚛 #ButlerUmzügeGmbH #Removalservice our service offers affordable & prof...

Moving Made Easy with Butler Umzüge!https://www.Butler-Umzuege.de/en So, you're getting ready to pack up and move to a new place. The thought of moving can be daunting - the packing, the lifting, the organizing, it all adds up to a lot of stress. But fear not, because Butler Umzüge is here to help make your move as smooth and stress-free as possible.Business Relocationhttps://www.butler-umzuege.de/en/business-move-berlin/Moving your business to a new location can be a complicated process. There are so many things to consider, from packing up office supplies to coordinating with vendors and clients. With Butler Umzüge, you can trust that your business relocation will be handled with care and efficiency. Our experienced team will take care of everything from dismantling and assembling furniture to safely transporting your equipment to your new location.Office Movehttps://www.butler-umzuege.de/en/office-moving/An office move can disrupt the flow of your business operations if not handled properly. At Butler Umzüge, we understand the importance of minimizing downtime during an office move. Our team will work closely with you to create a customized moving plan that fits your needs and schedule. We offer a full range of services, including dismantling and assembling office furniture, packing and unpacking, and safely transporting sensitive equipment. With Butler Umzüge, you can trust that your office move will be smooth and efficient, so you can get back to business as soon as possible.Why Choose Butler Umzüge?https://www.butler-umzuege.de/en/express-moving/We support you in moving safely and inexpensively with our assembly and moving services. Our team of experienced professionals is equipped to handle all your moving needs, from dismantling and assembling cupboards, dressers, display cabinets, beds, and kitchen furniture. We take the stress out of moving so you can focus on more important things like your work, hobbies, or organizing your move.With our comprehensive moving services, you can count on us to make your move smooth and efficient. Whether you're moving your business or office, Butler Umzüge is here to support you every step of the way. Don't let the thought of moving overwhelm you - let us take care of the heavy lifting so you can relax and enjoy the journey to your new place.Ready for a stress-free move? Book our services now at Butler Umzüge and discover how easy moving can be with the help of our experienced team. Make your move with Butler Umzüge and see why we're the go-to choice for all your moving needs in Berlin and the surrounding area.ConclusionMoving doesn't have to be a stressful experience. With Butler Umzüge, you can trust that your move will be handled with care and efficiency. We offer a wide range of services, from dismantling and assembling furniture to safely transporting your belongings. Let us take the stress out of moving so you can focus on what's important. Book our services now and experience the difference that Butler Umzüge can make in your next move.Discover our moving service in Berlin! #UmzugsserviceBerlin #UmzugBerlin #BerlinUmziehen #Umzugsfirma #ButlerUmzügeGmbH#Professionalmovers#Smoothmove#Movingsoon#Umzugshelfer#Movingstress#MovingEurope#Umzugsmaterialyoutube.com #ButlerUmzügeGmbH #Removalservice our service offers affordable & professional services in BerlinMoving Made Easy with Butler Umzüge!https://www.Butler-Umzuege.de/en So, you're getting ready to pack up and move to a new place. The thought of moving ca...

#youtube#Umzugsunternehmen#Umzugsfirma#Umzüge#UmzugsService#Umzugshilfen#Umzugshelfer#UmzugsService Berlin#Umzugsunternehmen Berlin#Umzugsfirma Berlin#Umzüge Berlin#Umzugshilfen Berlin#Umzugshelfer Berlin#Umzug Berlin#Berliner Umzugsfirma#Berliner Umzugsunternehmen#Umzugshelfer in Berlin#Umzugsservice in Berlin#Umzugsservice aus Berlin#Umzugsunternehmen aus Berlin#Umzugsunternehmen in Berlin#umziehen in Berlin#Umzug in Berlin#Moving services in Berlin#umziehen nach Berlin#umziehen von Berlin

2 notes

·

View notes

Text

What are the Uses of Custom Plastic Manufacturing ?

In this day and age, custom plastic manufacturing has turned into a foundation of current industry, giving custom-made solutions across a wide cluster of areas. From medical services to auto, the versatility of plastics and the accuracy of custom manufacturing methods have made it conceivable to address explicit issues with unmatched productivity. We should probably dig into the main purposes of custom plastic manufacturing and grasp its effect on different businesses.

1. Medical and Healthcare Applications

Custom plastic manufacturing is reforming the medical services industry. Medical gadgets, prosthetics, and parts of symptomatic machines are progressively being produced using custom-planned plastics. A plastic manufacturing company offers a few benefits, including solidness, lightweight properties, and the capacity to be cleaned. Custom plastic parts are utilized in creating needles, IV cylinders, catheters, and, surprisingly, perplexing parts of medical imaging machines. The accuracy presented by custom manufacturing guarantees that these parts fulfill severe medical guidelines, adding to better understanding consideration and results.

2. Automotive Industry

In the automotive sector, custom plastic parts are fundamental for both execution and style. From dashboard parts to many-sided motor parts, custom plastics give arrangements that assist with lessening the general load of vehicles, further developing fuel efficiency. They also offer resistance to corrosion and wear, enhancing the longevity of parts. Custom plastics are used in manufacturing bumpers, interior trims, and even under-the-hood components. Their versatility, akin to the innovations seen with plastic bottle manufacturers, allows for innovative designs and improved safety features, making modern vehicles more reliable and efficient.

3. Consumer Electronics

The consumer electronics industry depends intensely on custom plastic assembling for making solid and smooth items. Cell phones, workstations, and domestic devices frequently consolidate custom plastic parts that are intended to fit definitively and capability perfectly. These parts need to withstand day to day wear and tear while keeping an engaging look. Custom plastics are utilized in housings, buttons, connectors, and different inward parts, offering both underlying respectability and plan adaptability.

4. Packaging Solutions

Custom plastic manufacturing assumes an urgent part in the packaging business. It empowers the formation of packaging arrangements that are custom fitted to secure and protect items during transportation and capacity. Custom plastic packaging can be intended to meet explicit necessities, for example, being lightweight, strong, and impervious to dampness and synthetics. This is especially significant in the food and refreshment industry, where keeping up with the newness and security of items is principal. Custom packaging likewise takes into consideration creative shapes and plans that upgrade brand character and purchaser advance.

5. Industrial and Mechanical Parts

Businesses that require hearty and high-performance components frequently go to custom plastic manufacturing. Plastics can be designed to display properties like high rigidity, protection from outrageous temperatures, and compound strength. This makes them ideal for making parts utilized in apparatus, gear, and different modern applications. Custom plastic pinion wheels, orientation, seals, and lodgings are normally utilized in manufacturing settings, adding to the productivity and dependability of modern tasks.

6. Aerospace and Defense

In aerospace and defense, the demand for lightweight yet solid materials is basic. Custom plastic manufacturing meets this need by providing components that can withstand harsh environments while reducing the overall weight of aircraft and defense equipment. From interior cabin parts to specialized components in satellites and military gear, custom plastics offer the necessary performance characteristics and design flexibility required in these high-stakes applications.

Ely Global Pte. Ltd - Leaders in Custom Plastic Manufacturing

Ely Global Pte. Ltd spends significant time in custom plastic manufacturing, giving fitted solutions to different businesses. With state of the art innovation and a pledge to quality, they convey accurately designed plastic parts that meet explicit client needs, upgrading item execution and productivity across multiple sectors.

#plastic manufacturing company#wholesale plastic bottle suppliers#plastic water bottle caps recyclable

2 notes

·

View notes

Text

It's been a long while since I yap about Links Assemble, so I'm gonna ramble about it now. Nothing here is guaranteed to make it into LA canon, they're just random thoughts I had.

1) Karusa the bluepee, which is Wild's pet. Because comic Bucky has Alpine the spoiled white cat and movie Bucky falls off the train somewhere in the Alpine mountains and Karusa valley is the entrance to the Yiga hideout in botw and I want to make that place where LA Wild 'died', so. I just think it's really funny, you know.

2) Sun named her loftwing Hylia, because of reasons she can't even remember. Which becomes slightly awkward and extremely hilarious when she awakened as, you know, The Goddess Hylia Herself. Also Sky's loftwing is named Redwing, of course. Still debating if I should let him talk to birds like comic Sam, but regardless he can definitely talk to Redwing.

3) Instead of the Hulk we have a gigantic Twili Wolf. That both is and isn't Twilight, like Banner and the Hulk. First because of the transformation thing, and how Twilight was chased out of Ordon by Rusl, which might replace Harem and general Ross, now that I think about it. But besides that it's also fitting because the Hulk is really good with animals in the comics and Wolf Link can literally talk to animals.

4) Yuga Ravio Hilda, Obadiah Tony Pepper, do you see my vision? Although rather than personally becoming Ironman, Ravio hired a body guard to do it for him, like Tony's cover story in the comics except they're actually two separate people here. And rather than Ironman Legend's skill set is more like Steven Strange. Even the weird name checks out. Ravio provided Legend with any and all gear he requested, all with a price, of course. In exchange he pays Legend for his 'bodyguard services', and somehow the fees for the equipments always cancels out the pay.

5) Peter Parker Hyrule. Not the spider bite part but the vibe. Idk I just think he really suits the whole 'highschooler superhero that has homework to deal with after patrol' thing. And he gets to apprentice under Legend, which would be neat.

6) If Ravio is Tony Stark then Sheerow would definitely be Jarvis. God damn I love Jarvis so much.

7) Wait if Twilight is Hulk and Ghirahim is Loki... Yeah Twi can definitely punt Ghirahim into the ground it's literally perfect.

2 notes

·

View notes

Text

Circuit Board, PCB assembly & electronics manufacturing service provider from China (hitechcircuits.com)

What is a prototype PCB assembly?

PCB prototyping is the experimentation pilot stage of the product which is to be mass produced at a later stage. This is more of an experiment which is done after the initial discussions and the design. This offers a pre-production analysis of the boards that are to be manufactured, reducing the possible number of errors in the PCB design. PCB prototypes help the manufacturer analyze the strengths as well as weak areas of their proposed circuit boards. Prototypes also serve as a reference point for future versions of the same product. At Hitechpcba, we handle PCB prototype assembly in quantities from one to hundred printed circuit boards.

We have acquired capabilities that enable us to serve our clients better. All these years, we have worked on many complex prototype PCB assembly projects, and we believe the following capabilities have helped us serve our clients better.

Prototype PCB Assembly Services: We specialize in the following prototype printed circuit board assembly services.

SMT: We can provide single-sided and double-sided surface mount PCB assemblies in different specifications.

Plated Through Hole: We offer plated through hole assembly with selective soldering.

Mixed Assemblies: We often work on projects involving mixed assemblies – through-hole and SMT and electromechanical assemblies.

PCBA Testing: All the PCBA functional testing is performed in-house. Over the years, we have invested in various test fixtures and equipment, which helps us ensure the quality of PCBA. Currently, we provide the following types of PCBA testing services:

Flying probe testing for PCB

Functional testing including system and board-level testing

General PCB Assembly Capabilities: Our general PCB assembly capabilities are not limited to these:

RoHS, leaded or lead free, clean and no chemistries

PCB components including various types of QFNs, BGAs, 0105, 0201, 0804, and press fit components in small quantities.

What are the benefits of a prototype PCB assembly?

Prototype PCB assembly comes with several advantages. These benefits play a major role in the facilitation of your PCB manufacturing. Some of these benefits include:

Detection of Flaws Early

With prototype PCB, you will easily detect whatever flaws are present during the product’s development stages. This will allow you to solve the issues thereby saving you some money if you had gone ahead to make the production having the flaws in them.

If you go ahead to make changes during the production, there may be a need for more technicalities, and this may be expensive.

Testing of Each Component

With a prototype, you will be able to test all your system’s elements individually before you go ahead to set it up. You should do this because it is important especially for very complex projects composed of several parts that are PCB based.

When you validate each of these components, you will be able to identify those areas having issues that you should look into. This is the only way the project can function the right way.

Reduction in Total Costs

Utilizing the prototype bare PCB for any of your projects could go a long way in reducing what you’ll have spent in total for the project. With prototyping, you will be able to notice those errors in your project and then make corrections before you start the real production.

As soon as these flaws have been checked and rectified, then you may continue with the manufacturing of your Printed circuit boards in large quantities, thereby saving you unnecessary costs.

High-Quality PCBs

Why prototyping your PCB is important is to help you test if your project will function effectively. When we talk of testing, it involves the identification of errors present and then rectifying and making corrections to them.

Therefore, the eventual PCB after the prototyping will be of high quality that surely meets standards set internationally.

Less Turnaround Time

With prototype PCB assembly, you will be able to reduce the total time used in producing your printed circuit board. While making use of prototype printed circuit boards, you’ll be able to see the errors and then make corrections before you start the actual production.

Therefore, the eventual prototype will be free of defects. This implies that your PCBs will be produced quickly by your manufacturer.

What are the different types of prototype PCB assembly services you offer?

With years of market presence and experience, we specializes in the following prototype PCB assembly services.

Plated through-hole (PTH): We can provide the through-hole assembly with selective soldering.

Surface mount technology (SMT): We offer single-sided as well as double-sided SMT board assemblies in varied specifications.

Mixed Assemblies: Our experts often work on projects involving both PTH and SMT assemblies.

What are the types of testing Hitechpcba use for prototype PCB assembly?

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

These techniques help us ensure the reliability and accuracy of the circuit boards. In addition to this, it ensures a long operational life of equipment, minimal production losses, streamlined processes, and much more.

What are the capabilities Hitechpcba offer for prototype PCB assemblies?

We specialize in offering IPC compliant, and quick turn PCB assemblies. We are very particular about our scheduled deliveries and timelines, and we deliver without compromising the quality. Our PCBA capabilities are not limited to these. Here are some capabilities we offer through prototype PCB assemblies.

RoHS compliance

Stringent testing procedures

Device encapsulation

Full turnkey, partial turnkey, and kitted/consigned services

Assemblies using Surface Mount (SMT), Thru-hole, Mixed Technology (SMT/Thru-hole), Single and double-sided SMT/PTH, Large parts on both sides, BGA on both sides.

Do you perform a component analysis for prototype PCB assemblies?

Yes, we check the quality and performance of components before mounting them on the circuit boards. This is because a malfunctioning component can affect the performance of the entire circuit board assembly and also pose risks.

What is your standard turnaround time for a prototype PCB assembly?

Our turnaround time for standard applications is two weeks. This timeframe varies depending on the complexity of the applications. However, we are committed to offering quick turnaround times without compromising on quality, functionality, and accuracy, which offers our client a competitive advantage and reduced time to market. You can also request any emergency assistance or queries related to any type of PCB assembly. Our experts will assist you in all possible ways.

How is the cost of prototype PCB assembly estimated?

PCBA costing varies based on the different factors, such as PCBA parts, type of materials to be used, order quantity, and much more. We can also offer quotes and customization options once you share the detailed requirement with us.

We focus on quality and customer satisfaction over anything else. This has helped us build a long list of happy and satisfied customers. So, if you wish to partner with a manufacturer of prototype PCB assembly in China, then don’t hesitate to reach us. Our experts will assist you through all the phases of the prototype PCB assembly process. We look forward to making your experience with us better and memorable.

How to choose prototype pcb assembly manufacturer?

Our pcb prototype assembly service includes the sourcing of components. This allows you to concentrate on what you do best: layout design. We have a dedicated sourcing staff that coordinates with multiple suppliers and distributors to purchase electronic parts as per client requirements, and our staff completes these purchasing particulars in a most efficient manner. We have advanced processes for optimal selection of packaging (cut tape, tube, bulk, etc.) to reduce the total cost. Furthermore, we are capable of cross-referencing parts and even locating hard-to-find and obsolete parts. Customers can be rest assured that when Hitech Circuits substitutes components that they are high quality: we only use the electronic component numbers and manufacturers specified in the BOM. We will not modify your original layout design. Part substitutions take place only with your permission.

The final pcb prototype assembly service cost includes assembly labor charges, bare circuit board rates, and part costs. We understand the importance of prompt delivery. The sooner the components are sourced, the sooner we can begin circuit board fabrication. We thoroughly evaluate engineering inquiries and concerns related to the related parts with our clients before commencing circuit board assembly. The average time taken for pcb manufacturing assembly is about two weeks, which can be further reduced if there are no hard-to-locate components or documentation mistakes.

We have specialized experts to deliver fast turnarounds for prototype circuit board assembly with surface-mount (SMT), through-hole (THT) and mixed-technology components.

Anyone interested in electronics and electronic circuit boards needs to understand the various stages of developing and producing a printed circuit board. It can come in handy when you are seeking a top prototype smt assembly provider. The various production stages of printed circuit boards entail design, prototyping (prototype PCB development and rapid prototyping pcb assembly), and PCB high volume production. Different entities will always seek part of the whole production process depending on their electronic circuit board needs.

However, this article seeks to help you understand everything about prototype PCB assembly, a fundamental aspect of the PCB production process.

Rapid prototyping pcb assembly represents a fundamental phase of the printed circuit production process. It is also inferred as PCBA prototype assembly, SMT or surface-mount technology PCB prototype, PCB sample assembly, etc. From these alternative names, the meaning of prototype assembly regarding printed circuit boards becomes apparent. So what is assembly prototype?

PCB prototype assembly service is a fast prototype printed circuit board assembly primarily used to test fresh or new electronic designs. Consequently, it assists with checking and ensuring quality assurance of the PCB. For instance, it verifies that no bug exists in the test PCB, updates the design, and finds bugs. In most instances, prototype assembly of an electronic project will require two or three iterations to ensure everything is perfect.

Why Choose Hitech Circuits PCB Assembly for Your Prototype PCB Assembly Projects?

There are several PCB manufacturers specializing in prototype PCB assembly services. However, Hitech Circuits stands out owing to the following:

1.Strong Supply Chain: Over the years, we have built strong supply chain relationships in the industry, which helps us fulfill the requirements of turnkey prototype assembly services easily.

2.Fastest Turnaround Times: Our engineering expertise coupled with our understanding of industry requirements and a well-equipped facility enables us to assure the fastest turnaround times of 24-48 hours.

3.Reliability: All the printed circuit boards that we produce are IPC compliant, which helps us assure reliability.

4.Competitive Pricing and Quick Quote: Our supply chain relationships enable us to assure competitive prices. The cost of the PCB prototype assembly will be made available within 24-48 hours.

2 notes

·

View notes

Text

Transform Your Home with Professional Housekeeping Cleaning Services from Shinymaids

Introduction:

Maintaining a clean and organized home is essential for our overall well-being and peace of mind. However, the demands of modern life often leave us with little time or energy to dedicate to thorough Professional Home Cleaning Service, Sidewalks Cleaning, Patios Cleaning, Deck Cleaning, Roof Cleaning, Driveway Cleaning. This is where Shinymaids comes to the rescue! As a leading provider of professional Commercial Cleaning Services and Residential Cleaning Services in Washington, DC. Shinymaids is committed to delivering exceptional results, giving you a spotless and inviting living environment.

Benefits Of Hiring Shiny Maid Cleaning Services for Your Home Cleaning Needs.

A Team of Trained Professionals:

At Shinymaids, we understand that your home is your sanctuary. That's why we have assembled a team of highly skilled and trained cleaning professionals who take pride in their work. Our maids are experienced in using the most effective cleaning techniques and eco-friendly products to ensure a thorough and safe cleaning process. They pay attention to detail and go the extra mile to make your home shine.

Customized Cleaning Plans:

Every home is unique, and so are its cleaning needs. Shinymaids offers customizable cleaning plans tailored to suit your specific requirements. Whether you need a one-time deep cleaning or regular maintenance cleanings, we've got you covered. Our team will work with you to create a cleaning schedule that fits your lifestyle and preferences. We can clean your entire home or focus on specific areas, such as bathrooms, kitchens, or bedrooms. With Shinymaids, you can enjoy a clean home without the stress and hassle.

Time and Energy Savings:

Cleaning can be a time-consuming and physically demanding task, especially if you have a busy schedule or a large household. By entrusting your cleaning needs to Shinymaids, you free up valuable time and conserve your energy for the things that matter most to you. Whether it's spending quality time with your family, pursuing hobbies, or simply relaxing, our professional cleaners will take care of the cleaning chores, allowing you to enjoy a well-deserved break.

Healthier Living Environment:

Maintaining a clean and sanitary home is crucial for a healthy living environment. Dust, allergens, and bacteria can accumulate over time, leading to respiratory issues, allergies, and other health problems. Shinymaids utilizes advanced cleaning techniques and equipment to eliminate dirt, dust, and allergens from your home, promoting a healthier indoor environment. We use eco-friendly and non-toxic cleaning products that are safe for you, your family, and your pets.

Convenience and Flexibility:

Shinymaids strives to make the cleaning process as convenient and hassle-free as possible. Our online booking system allows you to schedule your cleaning service with just a few clicks. We offer flexible appointment times to accommodate your busy schedule, including evenings and weekends. Our reliable team will arrive promptly at the scheduled time, fully equipped with everything they need to deliver exceptional cleaning results.

Satisfaction Guarantee:

Customer satisfaction is our top priority at Shinymaids. We take pride in our work and stand behind the quality of our cleaning services. If you're not fully satisfied with any aspect of our Professional Roof Cleaning Services or Sidewalks Cleaning Services, simply let us know, and we'll make it right. Your feedback is valuable to us, and we are committed to continuously improving our services to exceed your expectations. Shinymaids offers customizable cleaning plans to suit your needs. Experience the convenience, quality, and satisfaction of professional home cleaning services. Visit https://www.shinymaids.com/

Source: https://shinymaids.blogspot.com/2023/05/Transform-Your-Home-with-Professional-Housekeeping-Cleaning-Services-from-Shinymaids.html

#ShinyMaidCleaningServices#ProfessionalHomeCleaningService#RoofCleaningService#ProfessionalHousekeepingCleaningServices#HousekeepingCleaningServices#ResidentialCleaningServices#CommercialCleaningServices#ProfessionalHomeCleaningServices#SidewalksCleaningService#PatiosCleaningService#DeckCleaningService

2 notes

·

View notes

Text

Organize Your Space with Heavy Duty Shelving in UAE

If you're tired of cluttered spaces and struggling to find storage solutions for heavy items, then heavy-duty shelving is the perfect solution for you. Heavy duty shelving is designed to withstand weight, making it ideal for storing bulky items such as tools, equipment, and boxes. In the UAE, there are many options for heavy-duty shelving, making it easy to find the perfect fit for your needs.

Materials:

When it comes to heavy-duty shelving, steel is the most popular material due to its durability and strength. However, there are also other materials available such as aluminum and plastic, which can be a more affordable option. The material you choose depends on your budget and the weight of the items you plan to store.

Designs:

There are several designs of heavy-duty shelving available in the UAE, including boltless shelving, pallet racks, and wire shelving. Boltless shelving is easy to assemble and disassemble, making it ideal for those who frequently move their storage around. Pallet racks are perfect for storing large, bulky items, while wire shelving is great for ventilation and storing items such as food products.

Load Capacity:

Load capacity is an essential factor to consider when choosing heavy-duty shelving. Make sure to select a shelving unit that can handle the weight of the items you plan to store. Most heavy-duty shelving units in the UAE have a load capacity ranging from 500kg to 2000kg, depending on the design and material.

Cost:

The cost of heavy-duty shelving varies depending on the materials, design, and load capacity. Steel shelving is generally more expensive, while plastic and aluminum shelving are more affordable.

Installation:

Most heavy-duty shelving units in the UAE are easy to install, with minimal tools required. However, some manufacturers offer installation services for an additional fee.

4 notes

·

View notes

Text

"Unité d’Habitation / La Cité Radieuse", 280 Boulevard Michelet, 13008, Marseille, France [1947-52] _ Architect: Le Corbusier _ Photos by: Spyros Kaprinis [25.05.2024].

"The building takes the form of a housing bar 135 metres long, 24 metres wide, 56 metres high and mounted on stilts. Three hundred and thirty apartments, divided into twenty-three different types, can accommodate a population of between 1,500 and 1,700 occupants having at their disposal on the seventh and eighth floors a shopping street and a hotel-restaurant, together with a kindergarten and sports facilities on the roof terrace. The constructive principle adopted, the so-called “bottle rack”, consists in building apartments inside an independent frame of posts and reinforced concrete beams. The apartments are made up of standard elements assembled on the site. All the apartments are dual-aspect, except those on the south side. A sun-break loggia provides an open-air facility at the same time as limiting exposure to sunlight. Protected by double glazing, the apartment interiors are subject to the two basic rules of naval and monastic architecture: rationalism and simplicity. The living room, open on two levels, is the nucleus of the family “home”; upstairs the parents’ room occupies the mezzanine. The kitchen is equipped like a laboratory: electric cooker, refrigerator, rubbish chute and storage racks. The entire apartment is fitted with racks replacing traditional storage. The ventilation of the kitchen, bathroom and toilets is mechanically operated, while the entire apartment is supplied with clean air by an air conditioning system. These facilities were not found in the low-cost collective housing units of the time, and the standard surface areas of the Unité d’Habitation are greater than these by between 40% and 50%. The seventeen-storeys below the terrace are connected by eight interior streets which, given the overlap of the two-storey apartments, each serve three floors. Each street is accessed by a battery of four elevators complemented by a service elevator and three emergency staircases. The entire building and its equipment are designed in terms of the Modulor, the universal measuring unit conceived by Le Corbusier."

#Unité d’Habitation#La Cité Radieuse#Marseille#France#1947#1952#Le Corbusier#2024#Spyros Kaprinis#Concrete#Brutalism#Housing#Architecture

142 notes

·

View notes

Text

DESTINY OC LORE: Adri-8

I tried doing this earlier and this website decided to delete my post mid-way through. So here we GO AGAIN.

NOTE: This is my personal head-canon. Timelines are funky, especially in active-service games like Destiny. I make sweeping decisions about dates and events that DEFINITELY don't fit with the recognized official canon. I don't care; this is my headcanon. Be advised; My Name Is Byf has no power here. lol

CONTENT WARNINGS

spoilers | mental illness | death | identity crises | self-harm

STATS

NAME: Adri-8

AGE: 216 - (Just before The Great Disaster)

GENDER: Female

CLASS: Warlock

SPEC: Dawnblade

GHOST: Nix

LOADOUT

KINETIC: Lumina - Catalyzed

ENERGY: Judgement of Kelgorath - New Age Black Armory

POWER: Hezen Vengeance - New Age Black Armory

HELMET: Prodigal Hood - Rustberry

GLOVES: Starfarer's Gloves - Whispered Sheen

ROBES: High-Minded Complex - Monochromatic

BOOTS: Boots of the Assembler - Whispered Sheen

BOND: Streetscholar Bond - Golden Trace

EQUIPMENT

SHELL: No Love Lost - Amethyst Veil - Stasis Projection

SPARROW: Archangel's Refit - Default Shader

SHIP: Spirit of the Warmind - Default Shader - Stasis Transmat FX

FINISHER: Security Breach

EMOTE: Tripwire Dodge

EMBLEM: Eclipsed Sunset - Crucible K/D Tracker

BACKGROUND

BIRTH --------

Adrian Perry was born to two Braytech researchers living in Eventide on Europa. He was schooled from a very early age in the same fields that his parents worked. However, as he neared puberty, it became increasingly obvious that he did not mesh well with his inborn body. Being of a very protected and secluded upbringing, it wasn't until he was in his mid-30s that he discovered that he was transgender. He researched the topic thoroughly in his free time, eventually approaching his parents about the subject. Due to the rampant mental health issues that he suffered throughout his childhood and early adulthood, his parents were eager to finally find some route to a solution for Adrian's condition; naming the problem was a large step forward for him. And so, he began identifying as female and changed her name to Adriana with support from her parents.

Despite the shift in her identity and her expression as who she felt she truly was, Adriana still suffered greatly with self-image issues. She reported feeling itchy in her own skin, and had a great aversion to mirrors, saying that they would never truly reflect her true self. She had many psychotic episodes, injuring herself on multiple occasions. Her parents were avoidant of returning to civilization for their daughter's treatment and instead began medicating her, taking away her independence in their fear. Eventually, Adriana escaped and stumbled out of Eventide into the cold wastes.

DEATH --------

Adriana was recovered by a scouting team on their way back to Braytech Exoscience. She was nearly dead, only her most basic biological functions still operable. She was convalesced under the watchful eye of Nero Nix, a scientist working on the Exomind project under Clovis Bray I.

When she awoke, Adriana was noncommunicative, either unwilling or unable to speak. Her body was severely damaged by exposure and most of her arms and legs had been amputated. She was fitted with Exo prosthetics. However, she kept injuring herself with them, seemingly at random. It was quickly discerned that she was knowingly self-harming, clearly angry at her own malformed body. She was put forward as a candidate for the Exomind project without delay.

Due to Adriana's lack of communication, as well as her lack of any identification on her person when she was found, her preferences were not taken into account when she was eventually transferred to an Exo body. She was referred to as male, and given the name Nix, after her caretaker. However, the wiping of her memory seemed to have suppressed her self-harmful behavior.

Adriana ceased to exist as Nix settled into his new body.

A wild success for the Exomind project, Nix-1 was immediately trained as a Seraph operative and deployed on hundreds of missions before the Collapse came.

As the system fell to chaos around him, Nix worked with other operatives to protect and evacuate Eventide's population. During this mission, he encountered his parents. A spark of recognition sounded deep within him, causing a fatal moment of hesitation... A dark beast claimed him, granting the others around him a moment to escape.

As darkness fell around him and his Exo eyes grew dark, he heard the faintest whisper of a name, and knew that he was remembering a girl, trapped in the wrong body, treated the wrong way, screaming to be let out...

Adri--

REBIRTH --------

The Exo woman awoke to the chittering and whirring of a Ghost. When it spoke, it reminded her of an Exo... But she couldn't place why she thought that or what an Exo actually was. The Ghost urged her to find shelter, to find a ship, to go to The Last City... But she had an itch at the back of her mind. Something she was forgetting... All of it? The Ghost told her that this was normal. That she'd get over it.

All she remembered were those four letters: A-D-R-I.

Her... Name? Must've been the last thing she thought before she died.

She... Did die, right?

Adri spent a long time wandering Eventide's ruins, getting occasional pangs of recognition, investigating, finding nothing... Until one day, an idle security system came alive and scanned her. It welcomed her: "Operative Nix". Her Ghost was excited: the systems knew her! Maybe they could find a ship now!

Adri explored the derelict labs that opened up before her. It was so scary to her: clearly there had been a massacre here, but there were no corpses, not even skeletons... So much time had passed that nothing remained but the blasted out shell of a building.

After days of searching, trying to find any other systems that were still online, Adri found a personal terminal in one of the quarters. She was able to log in with her biometrics and accessed personnel logs. She searched for "Nix" and found her own file. But it was off on many details she herself knew to be true: it was marked male, named Nix, and marked currently active... She'd died, hadn't she? And... Male? That seemed wrong somehow. But then she realized that she had a male Exo body. Strange, but this whole situation was strange.

Adri pushed through the notes and logs of various missions, her Ghost chiding her, telling her it wasn't okay, that she shouldn't look for her old self... But then she saw a note: "lost woman from Eventide; maybe Nix?" She found details about a missing person: Adriana Perry. She knew it was her old self. She had found enough to calm the itch.

Using the data she'd found in her file, she decided on a new name for herself: Adri-8. As Nix, she'd been rebooted seven times, and she counted her resurrection in the Light as the eighth. She named her Ghost Nix, so as to never forget her past. (Her Ghost wasn't too thrilled, but went along with it because he didn't actually care that much.) With her security clearance, she accessed the hangars, found her old Warmind-styled ship and sparrow, and left for the Last Safe City.

RISE --------

It was a hot, still day up on the Tower. Adri and Nix sat in the Courtyard, waiting. TWO new Guardians were arriving! The Twin Ghosts, Apollo and Artemis, had finally finished their centuries-long mission: to raise a pair of twins for themselves. It was a momentous day for the Twins, to finally find their other halves.

What was also a big deal was that these new Guardians, fresh out of the grave, had beaten an Archon Priest on their own. With scavenged weapons and their blazing Light. Then, as if that wasn't enough, they activated the old Skywatch array, reconnecting the City's networks to old Golden Age outposts on Venus, Mars, and even the Moon... Nobody had been to the Moon since The Great Disaster some 100 years back, so it was a major event to finally have eyes up there again.

Adri was incredibly excited to meet these New Lights; they seemed like they were very strong and could finally be her ticket back out into the field. Guardians weren't allowed to just fly off into the system unaccompanied except on very rare occasions, so she'd been urged by Ikora to find a fireteam. Nobody seemed willing or able to go exploring with her, so she'd been stuck on guard duty for over 50 years since Twilight Gap. She wanted action, adventure, and most importantly... Loot! She could learn so much about Golden Age humanity from the strange knick-knacks found throughout the system. And the number one best things were OBVIOUSLY the crazy weapons!

As the Arcadia-class jumpship maneuvered toward the Tower's landing area, Adri's mechanical heart galloped under her chestplate. What would they look like? Would they be in scraps like she'd been? Would they still be in the armor that'd failed them as warriors in their past lives?

Two bursts of transmat energy and there they stood: twin Awoken, a man and a woman, blazing red hair, pale skin glinting in the late-summer sun, radiant red eyes shining even in the daylight as they took in their surroundings. Across their bodies they bore the violet armor of Awoken Pathfinders, muddy and battlescarred.

Adri jumped up, startling Nix; it was uncommon for her to show this much energy. She waved enthusiastically and approached the two Awoken, their Ghosts bobbing excitedly in greeting.

"Eyes up, Guardians! Welcome to the Tower!" Adri held her arms wide, almost as if to hug the two newcomers. "I know you've been through a lot and you prolly just wanna put your feet up for a bit, but I just KNOW the honchos downstairs wanna meet you!" She turned on her heel, her Ghost whipping out of the way as she almost knocked him out of the air. "I'll take you to them! Then I'll take you to the best ramen shop in the City!"

The two scarlet-haired Awoken mutely followed Adri across the Courtyard and down the stairs into the Vanguard Headquarters. There, the man met with Cayde-6 and the woman with Zavala; a Hunter and a Titan! Perfect for filling out Adri's dream fireteam! The pair were given their first tasks as new Guardians: learn their abilities, grow stronger in the Light.

Ikora smiled as Adri bounced on her heels in the background.

"I'm sure Adri would love to assist you." Ikora murmured softly. Adri's eyes literally lit up with joy. "She is one of our brightest, and I've never seen her this excited..." Ikora smiled wider, glancing sideways at her protégé. "...you must have truly made an impression on her with your exploits."

Cayde grunted a chuckle. "Never seen a Warlock so antsy for fieldwork. You sure she's not one o' mine, Ikora?"

"She may have wanderlust, but her discipline is unmatched... Especially not by any of your ruffians, Cayde."

"Ooh! Ach! You wound me, Spymaster! Say, we should have another round of cross-training in the Crucible. I'm still stinging a bit from that loss and think your order could REALLY use a humbling..."

Adri pulled up beside the new Hunter and Titan. "We should leave them to it. The last time they got heated like this, it ended with Cayde's Ghost on standby..."

With a nod of her head, Adri led her new friends back out to the Courtyard. They followed silently until they could no longer hear the squabbling Vanguard leaders behind them. It was the female twin that broke the silence.

"I don't like that robot guy."

Adri's gaze snapped to her for a moment, then she burst out laughing. The Hunter laughed too. When he spoke, it was with a voice that made Adri double-take; for an Awoken, he was very laid back.

"He DOES seem like an acquired taste! I'm sure I'll get along with him fine... YOU--" He shouldered the Titan, who grunted and took a half-hearted swing at him. "--can have glum and serious Awoken man all to yourself."

The Titan grumbled something that sounded like "not into dudes" before clearing her throat and looking up to meet Adri's gaze. The Titan's eyes were somehow much more striking than her brother's, like she was seeing more than just the physical...

Adri recovered quickly. "Well, I'm sure you heard, but my name's Adri. I'm happy to be your guide. And if we hit it off well enough, we can form a proper fireteam and go exploring! I hear you guys opened up some avenues for new horizons for us..." She gasped suddenly. "I'm sorry! I didn't even think... What are your guys' names? Did you pick new ones, or...?"

The Hunter chuckled. "We had dogtags... Kinda? Little coins on the inside of our armor. Mine said 'Claros Vita'. So I guess that's my name?"

The Titan shrugged. "Clara."

Adri clapped her hands. "Alright! Clara, Claros. Let me show you to the Speaker's chamber, then we'll get you off those tired feet and fill you up with some of the most primo ramen you'll ever have..."

--------

From that day on, the three were inseparable. They traveled to the Moon, Venus, and Mars. They treated with the Queen of the Awoken. They cracked open a Vex Gate Lord. They silenced the Black Garden's Heart... Their first adventure solidified their Legend. They would go on to make their own fates in the Vault of Glass, defeat the Kell of Kells, become Crota's End, bring about the Kingsfall, become Young Wolves, and destroy the Archon Prime... Their Legend grew with every triumph.

Even when the Tower fell, the Traveler was caged, and the City was lost, they stuck together. Clara reclaimed her Light. She led the charge to retake the City, to destroy Ghaul and the Red Legion. They reclaimed their Light, and a new age began. They rescued the future and the past from Panoptes. They helped secure the Warmind and destroyed Xol...

And when the unthinkable happened... When the Hunter Vanguard was slain... The fireteam stood together. They sieged the Tangled Shore, hunted the Scorn Barons, and together with Petra Venj... Killed Uldren Sov...

But nothing lasts forever.

When Adri delves into the Scarlet Keep alone, without her fireteam, and discovers the Pyramid Ship deep within...

The Darkness reaches out to Adri and touches something in her very soul.

Adri's curiosity is piqued, and Nix is all for another excursion.

Claros and Clara try to reach out to Adri, but she does not respond.

Adri eventually communes with the Pyramid... and is forever changed.

Adri reforges Dredgen Yor's Thorn. She wields it with pride, despite the taboo it invites. Clara and Claros are outraged, appalled... Hurt. Such a weapon belongs in a pit, somewhere dark and forgotten. Not in the hands of a Guardian. Adri doubles down: the Light is not all there is; there is something deeper, and just as powerful.

Adri's fireteam appeal to Ikora, warn her that the brightest Light is turning to Darkness... But Ikora trusts in Adri, believes that she won't fall.

Claros and Clara leave the City, abandon their fireteam. Adri doesn't know where they went, but she doesn't care: she must learn more about the Darkness. And if her fireteam would stand against her, then it's best that they not be there at all.

Adri learns more about the Darkness. Communes with it multiple times with help from Eris Morn. And when the Traveler heals itself and the Black Fleet arrives, Adri is not in the Tower.

Adri heads for Europa.

Adri heads for home.

DRIFT --------

Adri sits crosslegged on the ice by Elizabeth Bray's campfire on Europa. Her Thorn rests before her, but her hands are busy with the fine parts she holds up to the fire's light. Elsie stands nearby, pondering the Pyramid in the distance. Drifter and Eris Morn lounge a bit away in silence.

After an extended period, Drifter stands straight and cracks his back loudly. One could almost hear it echo off the icy cliffs around them.

"Is somethin gon happen, or can I just bail?" His voice drips with sarcasm.

"Your presence is never required, Rat." Eris doesn't move even an inch when she speaks, making her voice seem colder than the ice around them. "You are free to do as you wish."

"Tch." Drifter clicks his tongue, but doesn't retort; he's learned that the Hive-touched Hunter is impossible to argue with. Instead, he casually saunters over to Adri and squats next to her, observing her work. "Whatcha workin on there, Stardust?"

Adri doesn't speak. Instead, she rolls the object into the palm of her hand, calling Nix to realspace. She holds the device up to him. He considers it for a moment, then his shell flashes away. He slips into the shell in Adri's hand, rolling the separate parts around to see how they feel. A mechanical whirring sounds off before he shunts it back into her hand and reforms his original shell.

"Still too rigid. Everything else is monumentally better."

Adri smirks, then goes back to tinkering with the vacant shell. Drifter whistles through his teeth.

"Makin a shell yer Ghost'll like can't be easy. I think we stopped carin what we wore a loooong time ago..." He grins suddenly. "Not like anyone's gonna be actually SEEIN my Ghost. I don't make it a habit o gettin shot!"

Adri shakes her head, but doesn't respond. Drifter stays squatting next to her for a long minute before grunting and standing up.

"Ain't none of ye got more interestin things to talk about than yer crafts and tellin me to shut the hell up?" He sends a steely glare at Eris, who returns it unblinking. Elsie sighs, clearly annoyed.

"Have you forgotten? We're waiting for the energy to line up. So Adri can focus her next shard." Elsie doesn't turn from the Pyramid on the horizon, but her target is clear. "Squawking away while I'm trying to focus isn't helping."

"Well EXCUUUUUUSE ME, princess!" Drifter puts his hands up in false surrender before dropping them dramatically to his sides. "Just tryin to lighten th mood, is all. Y'all are so serious all the damn time... I thought ye'd be a bit more swashbucklin, bein the rebellious Darkness tamers y'are!" He kicks his boots, feigning dejectedness. He stops suddenly and points at Elsie. "An I don't squawk. My voice is the purr of a newborn kitt--"

A pulse of energy rolls across the icy plain. Elsie nods, clearly having expected it. "Time to train, Addie."

Adri shoves the shell into her robes and picks up Thorn. She looks at the gun for a long moment, thoughts racing through her simulated synapses. Else clears her throat. No time to complain. There's power to be seized.

Adri summons her sparrow and races off toward the Ziggurat, ready to dive deeper into the Darkness.

--------

Adri spent most of her time after defeating Eramis training. She heard of her old fireteam defeating other enemies of humanity, encountering Uldren Sov as a Risen, making pacts with the Cabal... But Adri had to focus. She did a lot of introspective meditation and came to realize that she could NOT succeed against the forces of Darkness alone. She might be able to wield Stasis, and had tamed a Weapon of Sorrow, but it meant nothing if their missions as sources of power didn't change.

She had turned Stasis into a weapon of good. It came from her enemy, but she had turned it against them.

Now...

...Thorn.

A weapon made to sunder the Light from those who bore it.

Thorn had no place in a future of good. So Adri set about cleansing it. Restoring it and turning its power to the Light.

Lumina was born.

A weapon made to bolster the Light in those who bore it.

With her new weapon in-hand, she returned to the City. She discovered that her fireteam had joined with Mara Sov and was working to collect the lost Techeuns from the Ascendant Plane. They planned on enacting a ritual to cleanse Savathun of her worm familiar.

Adri offered Lumina to Claros and Clara as a gift of good faith. That she would fight for them and with them, until all days were gone. Having seen the duality of the universe, having been taught the unbias of paracausal forces, the twins accepted.

Fireteam Vitalia thus reunited, they saved Osiris, cleansed Savathun of her worm, raided the Throne World and uncovered the truths that even the Witch Queen herself didn't know...

But after the climb, there comes the...

FALL --------

Adri looked up from her ramen as Ikora wisped through the Bazaar. Her face was a mask of worry and determination. Not far behind her strode a white-robed human female, carrying a wrapped bundle that was longer than she herself was tall. Adri and the package bearer locked eyes for a moment and Adri saw her counterpart hesitate for a moment before jogging around the corner to catch up with Ikora.

Slightly perturbed by the visitor's obvious recognition of her, Adri returned to her ramen. Most likely one of Ikora's agents. She thought to herself. Who knows what kinds of freaks the Hidden could be...

But as she turned her chopsticks through the noodles before her, an itch began at the back of Adri's mind. She looked up slightly, out across the Bazaar. There was a slight shimmer in the air where the robed woman had walked... Pyramid resonance? As soon as she recognized it for what it was, her Deepsight triggered. She saw a ghostly visage of the robed woman walking the same path she just had... Except the package she bore was starkly different.

Unlike the wispy visual echoes that Deepsight usually revealed, the huge single-edged blade that rested within the specter of the package was completely solid. Adri could see the Pyramid alloy, etched with runes of various types; some Hive runes, some Pyramid symbols, and even some old Earth characters that had once been used by...

The Order.

Adri leapt to her feet, heart racing, teeth chattering suddenly in excitement. An Order artifact! Here! In the Tower! And the white robes with gold trim... Was that woman a member of the long-dead Order of Orbis Vitae?!

The Warlock stumbled toward Ikora's office, her Ghost pinging the leader of Fireteam Lucid to join her as soon as possible.

----

Anna Vita and Ikora Rey pondered the readings from the Tower's systems in silence. Using advanced scanners and a hefty amount of shielding, Ikora had been able to get a look through the sheath that Destin Tsurugi had said must never come off. The Sol Blade lay bare in digital form before them as a hologram, the physical object laying on the table beneath.

The body of the blade was very obviously forged from Pyramid alloys. It reeked of dark resonance, warping the space around it with its psychic energy. However, the edge of the blade seemed to be a sharpened piece of the Traveler, its Light shining visibly in the office's gloom. The Hive, Pyramid, and Human runes etched into the blade pulsed with green, orange, and blue light, seeming to flow from one to the next in a cycle. The hilt was wrapped with fine thread, tied into complex knots that would never come undone; a familiar design from ancient Japan, used by nearly all the City's manufactured swords. The Sol Blade was a thing of great beauty... And incredible power, barely contained within its sheath.

"Destin was right about one thing for sure." Ikora broke the silence with a pensive murmur. "Unsheathing this blade would have catastrophic effects."

Anna looked sideways at the Warlock Vanguard. "But... Not system-destroying effects, right?"

Ikora was silent for a very long time. The ticking of an antique clock in the corner seemed to slow to a near standstill as Anna waited her answer.