#Formlabs

Explore tagged Tumblr posts

Text

Hey guys did hou know that ummmmmmmmmmm...

Formlabs Form 3 low force stereolithography printer?

4 notes

·

View notes

Text

As this is my first post in a long, long time, I felt it appropriate to acknowledge the workspace from which most of my posts will be produced. This humble collection of machines is where Ill Gotten Games tests everything we make. I love it here, it’s a happy space for me.

#3dprinting#illgottengames#3d printing#3d scanning#makerspace#lasercut#prusa#ttrpg#indie games#formlabs#tabletop#tabletop games

1 note

·

View note

Text

youtube

1 note

·

View note

Text

Formlabs Launches Form 4, The Fastest, Most Reliable 3D Printer For Prototyping through Production

Formlabs, a company that is really good at 3D printing, just showed off their newest inventions, the Form 4 and Form 4B printers. These printers are super fancy and are changing the way professionals make 3D prints with resin. They have this cool thing called the Low Force Display™ (LFD) print engine that makes them faster and more productive.

The Form 4 series is way faster than the older Form 3+ printer. It can print things up to 5 times quicker! That means professionals can make their designs and get their products out into the world faster. This is all thanks to masked stereolithography (mSLA) technology, which can finish most prints in less than 2 hours.

The CEO and co-founder of Formlabs, Max Lobovsky, thinks the Form 4 is a really big deal. He says it's a game-changer for the 3D printing industry. Formlabs used information from lots of printers and printed parts to make the best SLA printer ever. The Form 4 is super reliable and fast, and it's going to change the way people make things.

Read More - https://www.techdogs.com/tech-news/business-wire/formlabs-launches-form-4-the-fastest-most-reliable-3d-printer-for-prototyping-through-production

0 notes

Text

here the new Fuse 1+ 30A from Formlabs with laser high packing density for the mighty punch,, read more to know more

0 notes

Text

3D Print Your Teeth at Home with Formlabs

Formlabs has unveiled groundbreaking innovations at CES 2024, introducing a new dimension to dental care. Among the highlights is Premium Teeth Resin, a material that allows you to seamlessly 3D print your teeth at home for dentures and temporary restorations.

Formlabs' Commitment to Dental Innovation

"Formlabs keeps adding materials to its 3D printing ecosystem, and now it can 3D print teeth for dentures." Formlabs, a leader in 3D printing, expands its dental offerings with Premium Teeth Resin, enhancing its reputation in the industry.

Premium Teeth Resin

"Premium Teeth Resin takes this a step further, with the company saying it can be color-matched to existing teeth." Premium Teeth Resin not only ensures longevity but also provides a natural aesthetic by seamlessly blending with existing teeth.

FDA Approval and Biocompatibility

"The company says it’s already been registered with the FDA as a Class II biocompatible material." Rest assured, Premium Teeth Resin meets stringent regulatory standards, being an FDA-registered Class II biocompatible material.

Ease of Use and Customization

"It can be customized to each patient’s anatomy, mimicking natural teeth translucency and opalescence for customizable digital dentures." With Premium Teeth Resin, achieving personalized dental care becomes a reality as it caters to each patient's unique anatomy.

Efficiency Boost with Resin Pumping System

"The Resin Pumping System operates with five-liter containers of select materials with an initial discount of at least 10%." Formlabs introduces the Resin Pumping System, enhancing efficiency by streamlining production, reducing costs, and minimizing waste.

Polypropylene Powder for Diverse Applications

"The lightweight, low-density, and chemically resistant properties of polypropylene make it attractive for applications in automotive parts, packaging, consumer products, and more." Formlabs introduces Polypropylene Powder, expanding its portfolio for SLS printing, offering versatility for applications ranging from home appliances to prototypes.

3D Printing Dentistry at Home

Formlabs' Chief Product Officer, Dávid Lakatos, states, "3D printing production is steadily increasing, and the introduction of Resin Pumping System, Polypropylene Powder, and Premium Teeth Resin are three big steps in our mission." Formlabs is on a mission to provide professionals with a complete ecosystem for bringing ideas to life, empowering users to delve into home dentistry with ease.

Conclusion

In conclusion, Formlabs' CES 2024 announcements mark a significant stride in dental 3D printing. With Premium Teeth Resin, you can now embark on a journey to 3D print your teeth at home, ensuring personalized, efficient, and affordable dental care. Read the full article

#3dprinting#CES2024#dentalcare#digitaldentistry#Formlabs#homedentistry#innovation#personalizeddentures#PremiumTeethResin#printteethathome#technology

0 notes

Text

Formlabs Unveils Cutting-Edge 3D Printing Innovations

View On WordPress

0 notes

Text

Another day, another piece of grey resin. This cunt is north american x-15, which i had to scale down by a factor of about 3 , so the wings are hella fucked up.

Today is also 1 year since ive been diagnosed with aspergers. In 3 years im probably gonna grow my autusm so much, ill be making tf2 figurines on 5 axis CNC machines or some shit

1 note

·

View note

Text

My dashboard has improved tenfold once i started following blogs that post cool pictures and nothing else

1 note

·

View note

Text

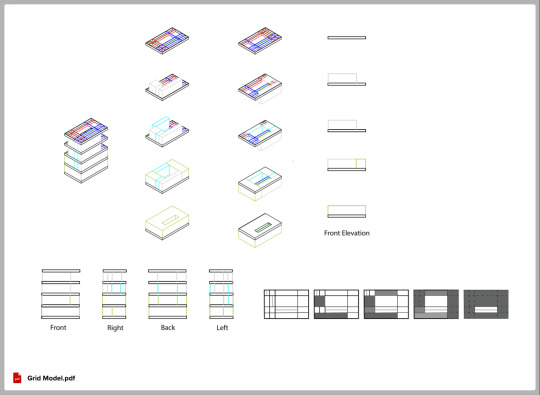

Harmony Week Part 2_Golden Ratio_Fibonacci Sequence

Student: Darien Sanchez

0 notes

Note

yakuza 3 everything is the same but mine uses this car https://www.tumblr.com/formlab/778638623842140160/renault-super-5-ettore-sottsass-1984?source=share

no wonder no one wanted him he wasn't riding around in peak

9 notes

·

View notes

Text

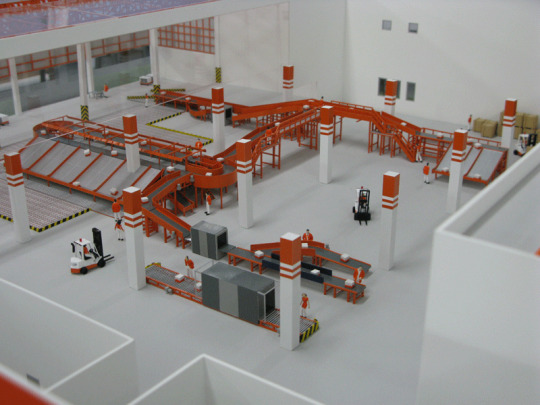

What Materials Are Used for Making Scale Models and Miniature Models?

How AR Model Makers Choose Materials for Stunning Scale Models

When it comes to crafting precise and eye-catching scale models, the materials used can make or break the final product. Whether it’s an engineering model, a marine model, an industrial model, or an architectural model, the team at AR Model Makers knows that selecting the right materials is key to delivering quality. In this article, we’ll explore the materials commonly used by expert miniature model makers like AR Model Makers, how they enhance different types of models, and why they matter to clients across industries. From house models to complex industrial designs, you’ll discover what goes into creating these miniature masterpieces.

Why Material Choice Matters in Scale Model Making

Common Materials Used by Miniature Model Makers

Miniature models come in all shapes and sizes, and so do the materials used to create them. Here’s a breakdown of the most popular choices at AR Model Makers and how they’re applied.

Wood – The Timeless Classic

Acrylic and Plastics – Precision and Durability

Metal – Strength for Industrial and Marine Models

Foam and Cardboard – Lightweight and Cost-Effective

https://armodelmakers.com/wp-content/uploads/2025/03/Foam-and-Cardboard.jpg

3D Printing Resins – The Future of Model Making

How AR Model Makers Tailor Materials to Your Project

Every project at AR Model Makers is unique, and material choices reflect that. For a marine model, they might combine metal for the hull with acrylic for water effects, creating a lifelike display. An industrial model could blend 3D-printed parts with metal accents to highlight machinery. By understanding the project’s purpose—whether it’s a trade show display or a client presentation—AR Model Makers ensures the materials align with both budget and vision.

For instance, a recent house model project in Delhi used a mix of wood and foam to craft a realistic neighborhood layout, earning praise from clients and establishing AR Model Makers as one of the best model makers in Delhi.

The Role of Craftsmanship in Material Selection

Materials alone don’t tell the full story—expert craftsmanship brings them to life. As one of the best model makers in Mumbai and beyond, AR Model Makers combines cutting-edge tools with hands-on expertise. Their team knows how to sand wood to a perfect finish, weld metal seamlessly, or paint acrylic for a polished look. This dedication elevates every engineering model, marine model, or architectural model they produce.

Interested in the process? Learn more about their approach on the AR Model Makers About Us page.

Why Choose AR Model Makers for Your Next Model?

With a reputation as top model makers in India, AR Model Makers stands out for their material expertise and client-focused approach. Whether you need a detailed marine model for a maritime expo or a sleek industrial model for a product pitch, their use of high-quality materials ensures stunning results. Plus, their presence in cities like Delhi and Mumbai makes them accessible to businesses nationwide.

Ready to start your project? Reach out via the AR Model Makers Contact Us page to discuss your vision.

External Resources for Further Reading

To dive deeper into scale model materials, check out these authoritative sources:

The Spruce Crafts: Guide to Model Making Materials

Material Properties for 3D Printing by Formlabs

If you have a project In mind just give us a Call

Have a project in mind? Let AR Model Makers bring it to life with the perfect materials! Drop a comment below with your thoughts, share this post with fellow model enthusiasts, or reach out to the team at AR Model Makers Contact Us to get started.

FAQ

What materials are best for an engineering model?

Materials like acrylic, metal, and 3D printing resins are ideal for engineering models due to their precision and durability, as used by best engineering model makers like AR Model Makers.

How long does it take to build a marine model with AR Model Makers?

Depending on complexity, a marine model can take anywhere from a few days to weeks, with AR Model Makers using metals and acrylics for top-quality results.

#marine model#architectural model#scale model#craft#art#model makers#model making#miniature model#engineering model#scalemodel

2 notes

·

View notes

Text

Renault Super 5 Ettore Sottsass, 1984 FORMLAB

2 notes

·

View notes