#Gas Flow Meter Types

Explore tagged Tumblr posts

Text

Industry Standard: Gas Flow Meter Manufacturer

Set the industry standard with the Gas Flow Meter Manufacturer. Discover how our meters redefine precision and reliability in gas flow measurement.

#Gas Flow Meter Types#Gas Flow Meter Manufacturers in Maharashtra#Gas Flow Meter Suppliers#Gas Flow Meter Suppliers in Mumbai#Natural Gas flow Meter#Natural Gas Flow Meter Types

0 notes

Text

Imagine... you're pulling up to the gas station/petrol station. You (somehow) convince them that it's okay for you to pump your own gas/petrol. You get out, you pay at the pump, get the nozzle in the hole, and now you gotta wait... but you're bored and you've noticed that your windshield looks a little dirty, so you pick up the windshield cleaner and start cleaning all your windows because the pollen this year has been terrible. As you are cleaning your back windshield, a car passes by and you get catcalled... here's how I think the 141 boys would react:

Simon hears this and smirks a little. He knows he got a baddie. He knows you are hot as shit. But you are also his. And only his.

So he puts on a mask. Not a surgical mask like he usually wears, not just the balaclava... the mask. The one he doesn't like wearing when he's at home. He doesn't wanna scare his bird. But he puts it on and gets out before you can stop him.

Some "Simon, darling, this is really not necessary-" "Luv, stop." type ahh shit. This hulking monster in a hot ass outfit that looks vaguely military-esque but not his fatigues and lacking the usual gear, but just as initimidating, gets out and stares at the boys in the car as they slowly pass, as if them driving slower will somehow keep them from Simon's hard stare. The same stare that sends his enemies running for the hills… if they aren’t dead yet.

This man is using your car as an arm rest, leaning forward. You know when your mom/dad/parent or whoever get's really mad and puts there hands together and lean forward like 'Now listen here, Jimothy-'. Same vibe. SAME. VIBE. I AM NOT STUTTERING.

And he just stares at them as they pass before hurriedly (definitely speeding) away.

"Simon, darling, you didn't have to do that." You wrap your arms around his waist and hug him from the side.

"I gotta make sure everyone knows your mine. Everyone, pretty bird." And he smacks your ass lightly as a pat for you to get back in the car, passenger seat, where you belong.

(a.k.a. Simon didn't like it and now you never pump your own gas again.)

Johnny has the same reaction as Simon. Initially, at least. He knows you’re a hottie and he’s happy that other people know it too.

Johnny does realize something though… You are pumping gas… by yourself. While he stays in the ca- Yeah, that won’t do, not even a little bit.

So he gets out of the vehicle in his tight jeans that accentuate his thighs and wonderful ass, and a too-tight t-shirt that strains against his pecs and is tight around the arms, and he immediately takes the pump from you. Gently! He doesn’t want to waste petrol… He sets it locked so it continues to pump until the meter notices and automatically stops the flow.

Then… he spins you around, pressing you against the car and kisses you. Not gently, like a Nicholas Sparks movie. More like he’s trying to eat your face off. One of his hands is caressing the back of your head to make sure it doesn’t hit on the car while the other holds you by the back of the neck, keeping you close.

When you part, he is the first to speak, “I would say I’m sorry, bonnie, but I think we both know that’d be a lie.”

You don’t even catch the tail end of the boys’ car. But Soap does. And while at home, he may be ‘Johnny’, to protect his girl, he’ll be Soap too. And Soap remembers their license plate, and make and model of said car.

“Now get in there, where you belong, lass.” Johnny directs you to the passenger seat he was occupying, a hand in your back pocket. Don’t worry… you get an ass-pat too.

Kyle is immediately worried. He is upset for your sake, but he understands that his anger may not be what you need right now. So he gets out and wordlessly takes the pump from you, gently.

“How about I finish pumping the petrol, love?” His request was more rhetorical than his captain giving him an order posed like a question. He locks the petrol pump in place before gently guiding you to the passenger seat of the car, where you don’t have to worry about paying for your own petrol, pumping it, or any more filthy boys.

His ideal is coming to life: a woman that is protected and loved thoroughly by him.

He does promise a private show when you get home, a shirtless Kyle cleaning the car (ohshitimdrooling-)

That doesn't mean he hasn't already texted his captain about some 'plans' for the night... he might need help if it's more than one boy.

Now... John... I have no idea how you managed to convince him to let you pump the petrol. But you do. Somehow. Maybe it was the puppy eyes, maybe it was the pouty lip, maybe it was the promise of giving him head when you get home. The world may never know.

But you can bet your ass that as soon as he hears that first note, he gets out, slamming the car door shut, and takes the cleaning stick away from you.

"Love, I just remembered that you pumped the petrol last time." Lie. "How about I do it?" He gently guides you back to the passenger seat, and opens the door for you, letting you slide in, and closing the door behind you (maybe a bit more forcefully than he has to). He walks to the dip station and puts the cleaning stick in the solution, catching the plate number of the car.

Cause no one treats his pretty baby like that and gets away with it.

"Simon. You busy tonight?"

Hey guys! I'm sorry Kyle's is so short. I just felt like his would be so straightforward and dealt with, you'd barely recognize that he did anything at all. Anywho- GAZ LOVE! PEW

#caffies#x reader#writing#simon riley x reader#cod#ghost x reader#simon riley x you#johnny mactavish x reader#soap x reader#captain price x reader#john price x reader#gaz x reader#kyle garrick x reader#drabbles are my favorite#plz excuse my shitty writing

254 notes

·

View notes

Text

Moonscapes of Idaho

In summer 1969, four astronauts from NASA’s Apollo program visited Craters of the Moon National Monument and Preserve in southern Idaho. Trained as pilots, not geologists, the astronauts were there to study the volcanic landscape—similar to what they might encounter on the Moon—and learn field geology techniques in preparation for their investigation and sampling of the lunar surface.

Like the surface of the Moon, the national monument in Idaho is covered in fields of lava. While most of the Moon’s volcanism occurred more than 1 billion years ago, the lava flows in Craters of the Moon are quite young: between 15,000 and 2,100 years old. They erupted from a series of fissures over 50 miles (80 kilometers) long known as the Great Rift to create an expanse of dark basaltic rock.

The lava fields of Craters of the Moon are shown in the images above in summer (top) and winter (lower). They were acquired with the OLI (Operational Land Imager) on Landsat 8 in July 2024 and the OLI-2 on Landsat 9 in January 2025, respectively. The photos below show this moonscape from the ground in 2024 and in 1969 (bottom of the page), when astronauts Eugene Cernan and Joe Engle were working with NASA geologist Ted Foss.

The assemblage of lava flows in the area contains nearly every type of volcanic feature associated with basaltic eruptions. Many, including lava tubes and three distinct types of ropy pahoehoe lava, are too small to be visible at the scale of these images. A number of cinder cones—conical hills formed when gas-filled magma erupted in fiery fountains—stand out in the snowy winter scene above. These features are usually topped by a prominent crater. (Note that the craters of Craters of the Moon are volcanic in origin, whereas the round depressions on Earth’s Moon formed when meteoroids, asteroids, and comets struck its surface.)

The area’s ecology is closely connected to the volcanic landscape. Lichens are some of the first organisms to colonize new lava flows, and plants gradually find places to grow in the cracks in the lava. Sagebrush is common in the park, especially where rocks are older and soil is more developed.

Islands of lusher plant life called kipukas are scattered throughout the region, becoming isolated when lava flowed around elevated patches of land. Hundreds exist in the park, ranging in size from less than one acre to tens of thousands of acres. Larger kipukas may be crisscrossed by roads and altered by other human activity, while smaller ones are relatively undisturbed. These ecological havens contain some of the oldest juniper trees in Idaho and are valuable for long-term scientific study.

The plant and animal life here, in addition to coexisting with lava rock, must also endure long winters. At approximately 6,000 feet (1,800 meters) in elevation, the area can experience cold, snowy conditions from November through March.

In the decades since the Apollo program, Craters of the Moon has continued to garner interest from scientists for its commonalities not only with the Moon but also with Mars. Subsequent research programs have used the lava landscape to test instrumentation and advance our planetary exploration capabilities. In one recent study, researchers pointed out that Craters of the Moon lava tubes support diverse microbial communities and have some structural similarities to lava tubes on Mars. These Martian features, shielded from less hospitable surface environments, are of particular interest to scientists because of their potential to harbor biological communities.

NASA Earth Observatory images by Michala Garrison, using Landsat data from the U.S. Geological Survey. Photo of NASA geologist Ted Foss and astronauts Eugene Cernan and Joe Engle by NASA. Story and 2024 photo of Craters of the Moon lava and cinder cone by Lindsey Doermann.

4 notes

·

View notes

Text

The Role of Conical Strainers in Protecting Pumps and Valves

Protecting pumps and valves from debris during system startup ensures reliable operation and avoids costly downtime. New or modified pipelines often carry leftover construction materials—like rust, welding slag, and scale—that can seriously damage sensitive components. This is where conical strainers play a critical role.

What Are Conical Strainers and Why Are They Important?

Conical strainers (temporary cone strainers )are cone-shaped mesh or perforated metal filters placed between pipe flanges. They're designed for short-term use during pipeline systems' commissioning or startup phase.

When fluid flows through a newly installed system, it can carry construction debris that may damage pumps, control valves, and meters. Conical strainers capture this debris early on, offering essential protection when the system is most vulnerable.

Why Startup Debris Is Dangerous

New pipeline systems often contain:

Welding slag

Rust particles

Pipe scale

Jointing compound

These materials can lead to:

Abrasion and erosion of the pump and valve components

Clogging of narrow passages and filter elements

Seizing of moving parts due to large debris

Reduced performance and internal leakage

How Conical Strainers Work

The effectiveness of conical strainers lies in their design. Inserted between two pipe flanges, their cone shape offers a large surface area for filtering. As the fluid passes through, solid contaminants get trapped inside or outside the cone—depending on the orientation.

This setup ensures:

High filtration efficiency

Low pressure drop

Easy debris collection and removal

Benefits of Using Conical Strainers

Using a conical strainer during startup provides several advantages:

Protects expensive components from early failure

Extends equipment lifespan by preventing wear

Reduces maintenance costs and emergency interventions

Prevents unplanned downtime

Improves overall system reliability

Material Options:

Stainless Steel 304 / 316 (corrosion resistance)

Carbon Steel

Monel and other specialty alloys

Key Specs to Consider:

Mesh/perforation size (determines what particles are captured)

Open area ratio (impacts flow capacity)

Installation Best Practices

To maximize performance:

Orientation: Install the cone upstream or downstream based on system needs.

Sizing: Match pipe diameter, flange rating, and bolt circle.

Sealing: Use appropriate gaskets to ensure leak-free operation.

Temporary Use and Maintenance

Most conical strainers are designed for short-term use. Once the system has been flushed and debris removed, the strainer should be taken out to prevent pressure drop and clogging.

To remove:

Isolate the section

Depressurise the line

Unbolt the flanges

Remove the strainer carefully.

Conical vs. Permanent Strainers

Use Conical Strainers for temporary protection during startup.

Use Permanent Strainers (like basket or Y-type strainers) for ongoing filtration needs.

Industries That Use Conical Strainers

Conical strainers are widely used in industries where clean fluid flow is essential from the start:

Oil & Gas

Chemical Processing

Power Generation

Marine

Water Treatment

Food & Beverage / Pharmaceutical

Pulp & Paper

Final Thoughts: Start Clean, Stay Efficient

A smooth startup sets the foundation for reliable operations. Conical strainers are a cost-effective, temporary filtration solution that protects your pumps, valves, and instrumentation from damaging debris. They help avoid unexpected downtime and reduce long-term maintenance costs.

If you're commissioning a new system, don’t overlook this small but powerful piece of equipment. It’s been the smart way to protect your bigger investments from day one.

For more information, please visit.

#conical suppliers#conical strainers suppliers#conical strainers manufacturers#duplex strainers manufacturers

0 notes

Text

Biogas Plant: A Sustainable Energy Solution for the Future

Introduction to Biogas Plants

A biogas plant is an eco-friendly facility that produces renewable energy by processing organic waste materials such as agricultural residues, animal manure, food waste, and sewage sludge. Through anaerobic digestion, these materials are broken down by microorganisms to produce biogas—a mixture primarily composed of methane (CH₄) and carbon dioxide (CO₂).

As the world shifts toward clean energy alternatives, biogas plants play a crucial role in waste management, energy generation, and reducing greenhouse gas emissions.

How a Biogas Plant Works

The core process of a biogas plant involves the following stages:

Feedstock Collection – Organic waste such as crop leftovers, food scraps, and animal waste are gathered.

Anaerobic Digestion – The waste is placed in a sealed digester, where bacteria break it down in an oxygen-free environment.

Biogas Generation – Methane-rich gas is produced and collected for use as fuel.

Digestate Separation – The remaining material, known as digestate, is separated and used as a nutrient-rich organic fertilizer.

Types of Biogas Plants

There are different types of biogas plants, each designed to meet specific needs:

Fixed Dome Biogas Plant – Cost-effective and durable, commonly used in rural areas.

Floating Drum Biogas Plant – Provides easy gas measurement and storage.

Plug Flow Digester – Suitable for high-solids waste like cow dung or crop waste.

Industrial Biogas Plant – Large-scale facilities designed for cities, factories, or agricultural cooperatives.

Benefits of Biogas Plants

1. Renewable Energy Production

Biogas is a clean, renewable fuel that can replace fossil fuels for electricity generation, heating, and even vehicle fuel when upgraded to biomethane.

2. Waste Reduction

Biogas plants convert waste into energy, significantly reducing landfill usage and mitigating methane emissions.

3. Climate Change Mitigation

By capturing methane—a potent greenhouse gas—biogas plants help reduce global warming and promote carbon neutrality.

4. Soil Enrichment

The by-product, digestate, serves as an excellent organic fertilizer, enhancing soil fertility and crop yields.

5. Energy Independence

Communities and industries using biogas can reduce reliance on imported fossil fuels, promoting energy security.

Applications of Biogas

Electricity and Heat Generation via Combined Heat and Power (CHP) units

Cooking Fuel in households and commercial kitchens

Vehicle Fuel (Biomethane for CNG engines)

Industrial Energy for processing plants and greenhouses

Challenges and Solutions

While biogas plant installation can be capital-intensive and technically demanding, the long-term benefits outweigh the initial costs. Government incentives, carbon credits, and technological advancements have made biogas more accessible and cost-effective.

Common challenges:

High upfront costs

Technical expertise for operation

Seasonal variation in feedstock

Solutions:

Government subsidies and feed-in tariffs

Training programs for operators

Diversified feedstock sourcing

Biogas Plants and Sustainability Goals

Biogas technology aligns with several UN Sustainable Development Goals (SDGs), including:

Affordable and Clean Energy (SDG 7)

Climate Action (SDG 13)

Sustainable Cities and Communities (SDG 11)

Responsible Consumption and Production (SDG 12)

Conclusion

Investing in a biogas plant is a smart step toward a cleaner, greener future. Whether for individual farms, businesses, or municipalities, biogas offers a powerful combination of sustainable energy, waste management, and climate action. As demand for renewable energy grows, biogas plants are poised to become a key player in the global energy transition.

Frequently Asked Questions (FAQs)

What is the main purpose of a biogas plant?

To convert organic waste into renewable energy (biogas) and organic fertilizer.

How much biogas can be produced from 1 ton of food waste?

Approximately 100–200 cubic meters, depending on the composition and digestion conditions.

Is biogas plant installation expensive?

Initial setup costs can be high, but government incentives and energy savings offer strong long-term returns.

Can biogas be used for cooking?

Yes, biogas is an excellent fuel for household and commercial cooking applications.

0 notes

Text

Gas Meters Unveiled: The Unsung Hero of Energy Management

Often overlooked, sitting quietly outside homes and inside utility rooms, the gas meter plays a critical role in our everyday lives. It’s not just a mechanical or digital box that counts numbers—it’s the guardian of energy accountability, the bridge between resource consumption and intelligent usage. In a world where energy conservation, efficiency, and smart living are the goals, understanding the gas meter is more essential than ever.

The story of the gas meter is one of evolution, precision, and purpose. As natural gas continues to power industries, warm homes, and run appliances, the gas meter ensures we measure, manage, and respect this powerful energy source.

Expert Market Research Insight: A Silent Revolution in Measurement

According to Expert Market Research, the role of gas meters has expanded rapidly due to the rising demand for smart and efficient energy systems. The research indicates that households and industries are increasingly adopting advanced metering infrastructure (AMI) not just for consumption tracking, but to meet sustainability goals, enhance energy conservation, and respond faster to safety risks.

Expert Market Research further notes that regions investing in smart infrastructure are seeing direct benefits in operational efficiency, customer satisfaction, and regulatory compliance. The integration of IoT and AI in gas metering is helping create a more transparent, data-rich, and resilient energy grid.

What Exactly is a Gas Meter?

At its core, a gas meter is a device that measures the volume of gas flowing through a pipe. It doesn’t care what appliance you’re using or what time of day it is—it simply records how much gas passes through it. But that simple function supports a huge structure of energy billing, leak detection, and efficiency analysis.

There are different types of gas meters, ranging from traditional diaphragm meters to advanced ultrasonic and turbine meters. Residential areas often use diaphragm meters for their accuracy at low flow rates, while commercial or industrial setups might lean towards rotary or turbine meters due to higher consumption demands.

Modern smart gas meters go beyond measurement. They provide real-time data, send alerts during abnormal consumption, and enable utilities to read usage remotely. This shift from analog to smart metering reflects a larger move toward data-driven energy ecosystems.

The Heartbeat of Energy Accountability

Gas meters aren’t just technical components—they’re instruments of trust. They ensure that the energy used is fairly charged, that no excess gas is leaking undetected, and that households and industries alike can budget with confidence.

They also support governments and utility providers in identifying consumption patterns and implementing better energy policies. With advanced meters in place, it’s easier to manage load during peak hours, detect theft, and even integrate renewable gas sources more seamlessly into the grid.

Why Modern Homes and Smart Cities Need Smart Gas Meters

We live in a time of “smart” everything—phones, homes, cars, thermostats. Gas meters are joining this revolution. Smart meters are internet-connected devices that allow homeowners and utilities to monitor usage in real-time, detect leaks before they become disasters, and receive automatic updates without the need for manual readings.

Smart gas meters bring the advantage of awareness. Consumers can see how much gas they use daily, weekly, or monthly, and make changes in behavior based on actual data. For smart cities, this is invaluable—it enables predictive analysis, efficient distribution, and fast emergency response.

Also, the ability to remotely disconnect gas supply in case of emergency adds an important layer of safety, especially in regions prone to earthquakes or industrial incidents.

The Unseen Safety Shield

Beyond convenience and billing, gas meters play a major role in safety. A malfunctioning or poorly calibrated meter could result in overflows, leaks, or unbilled usage—all of which pose financial and health risks. That’s why calibration and regular inspection are mandatory, especially in industrial settings where even a minor miscalculation can lead to serious outcomes.

Today’s advanced meters come equipped with built-in alarms and pressure regulators. They don’t just measure gas—they help control it. By maintaining proper flow and pressure, they prevent accidents that could otherwise go unnoticed until it’s too late.

Installation, Maintenance, and Everyday Impact

Installing a gas meter may seem like a straightforward task, but it involves technical know-how. It needs to be positioned correctly to ensure accurate readings, avoid external damage, and comply with legal standards. Once installed, meters require routine maintenance and periodic upgrades to maintain efficiency.

From a consumer’s perspective, learning to read the meter and understand usage patterns can help save energy and reduce bills. With smart meters, this becomes even easier—data can be accessed via apps, email updates, or in-home displays.

Whether you're boiling water for tea or running industrial furnaces, the gas meter quietly calculates every cubic foot used. This silent, constant calculation gives meaning to our energy usage and empowers us to make smarter choices.

0 notes

Text

Air Compressor Tank You Should Know

The air compressor air tank or receiver is an important part of the compressed air system. It is mainly used to store compressed air for use during peak demand periods.

Working principle of air compressor tank The air tank stores compressed air to balance the contradiction between the continuous exhaust of the air compressor and the intermittent demand of the gas-using equipment, eliminating air pressure pulsation. When the gas consumption increases, the gas in the tank can be replenished instantly; when the gas consumption decreases, the excess gas is stored in the tank to avoid frequent start and stop of the air compressor, resulting in waste of resources.

Understanding of compressor air tank parameters 1. Pressure level Working pressure ≥ maximum exhaust pressure of the air compressor, working pressure > 10Bar belongs to high pressure type, working pressure < 8bar belongs to low pressure type, and 8bar~10bar belongs to medium pressure type.

2. Material 1. Carbon steel: economical and durable, suitable for general industry 2. Low alloy steel: high strength and pressure resistance, used in special working conditions

The role of air compressor tank 1. Provide a constant pressure compressed air flow. Uniform airflow makes pneumatic tools easier to use and reduces the pressure on the compressor.

2. Temporary storage of compressed air. Storing compressed air allows the system to evenly distribute the peak of compressed air demand within a shift.

Notes on air compressor installation 1. It needs to be installed vertically and the foundation load-bearing capacity is ≥1.5 times the weight of the tank 2. Keep 3-5 meters from the air compressor, and a check valve needs to be installed in the middle 3. The inlet and outlet adopt a "low in and high out" layout to enhance water removal

#air compressor tank#air compressor storage tank#air tank for compressor#1000L air tank#100L air tank#5000L air receiver tank#Airfler air compressor parts supply

0 notes

Text

All SS Pipe Sizes in One Chart – Seamless & ERW | Udhhyog India

When working with stainless steel (SS) pipes, selecting the right size is crucial for system compatibility, flow requirements, and installation accuracy. Whether you're in fabrication, plumbing, infrastructure, or industrial projects, having access to a complete SS pipe size chart for seamless and ERW pipes simplifies the process.

At Udhhyog India, we supply SS seamless and ERW pipes in all standard sizes, thicknesses, and finishes. This comprehensive guide includes our verified size chart, applicable standards (IS/ASTM), and downloadable reference tables for engineers, buyers, and contractors.

🔍 What Are Seamless and ERW Stainless Steel Pipes?

🔧 SS Seamless Pipe:

Manufactured without welding, seamless pipes offer uniform strength and pressure handling. Made by extrusion or hot rolling, they are ideal for:

High-pressure fluid systems

Oil & gas pipelines

Boiler and heat exchanger tubes

Pharma and sanitary pipelines

🔩 SS ERW Pipe:

ERW (Electric Resistance Welded) pipes are formed by rolling SS coils and welding the seam. ERW pipes are widely used due to cost efficiency, availability in large diameters, and smooth internal finish.

📌 Udhhyog supplies both types across all major grades: SS 304, 316, and 202.

📏 All SS Pipe Sizes in One Chart – Nominal Bore, OD, Thickness

Here is a consolidated chart of commonly used SS pipe sizes, suitable for IS, ASTM (ASME B36.19M), and DIN-based systems.

✅ Seamless & ERW Pipe Size Chart (Inches + mm):

NB Size (Inch)OD (mm)Wall Thickness (mm)SCH 10SSCH 40SSCH 80S½”21.31.65 – 3.73✓✓✓¾”26.91.65 – 3.91✓✓✓1”33.42.0 – 4.55✓✓✓1½”48.32.0 – 5.08✓✓✓2”60.32.0 – 5.54✓✓✓3”88.92.11 – 7.62✓✓✓4”114.32.11 – 8.56✓✓✓6”168.32.77 – 10.97✓✓✓8”219.13.18 – 12.70✓✓✓10”273.03.4 – 15.09✓✓✓12”323.83.96 – 17.48✓✓✓

🧾 Full PDF chart available from Udhhyog for sizes up to 24” and all thickness schedules.

🧰 Grades Supplied by Udhhyog

GradeApplicationsSS 202Economy-grade furniture, railings, light-duty useSS 304Plumbing, food processing, general structural useSS 316Chemical, coastal, pharma, and marine applications

All Udhhyog pipes are compliant with:

ASTM A312 / A554

IS 1239 / IS 3589

DIN 11850 / EN 10217-7

📦 Available Finishes

Mill Finish

Brush Finish (Matt)

Mirror Polish

2B or BA finish (for decorative & sanitary use)

💰 Pricing Guide (Indicative – June 2025)

SizeGradeTypePrice/Kg (₹)Price/Meter (₹)1”SS 304ERW₹270 – ₹285₹380 – ₹4202”SS 316Seamless₹360 – ₹375₹630 – ₹6903”SS 304ERW₹265 – ₹275₹740 – ₹7804”SS 304Seamless₹280 – ₹290₹1,050 – ₹1,150

📞 Get official quotation and updated bulk rate from Udhhyog sales team.

🏭 Industries We Serve

Udhhyog supplies SS pipes to a wide range of sectors:

✅ Real Estate & Infrastructure

✅ Food & Beverage

✅ Chemical & Petrochemical

✅ Water Treatment & RO Systems

✅ Fire Protection (Sprinkler Pipes)

✅ OEM Fabricators & EPC Projects

📘 Request Your Free Pipe Size Chart PDF from Udhhyog

The downloadable chart includes:

✅ Sizes from ½” to 24”

✅ OD, ID, and wall thickness

✅ Schedule 5S to 160

✅ Seamless and ERW data

✅ Weight per meter details

📎 [Click here to request Udhhyog’s 2025 SS Pipe Size Chart PDF]

🙋 Frequently Asked Questions (FAQ)

❓1. What is the difference between seamless and ERW SS pipe?

Answer: Seamless pipes have no weld seam and are ideal for high-pressure applications. ERW pipes have a welded seam and are more cost-effective for general usage.

❓2. What sizes are available in seamless vs ERW?

Answer: Seamless pipes are typically available from ½” to 12”, while ERW pipes are offered from ½” up to 24”. Udhhyog supplies both types with full MTC certification.

❓3. How do I select the correct thickness or schedule?

Answer: It depends on pressure, flow, and application. Udhhyog’s technical team helps clients choose the right SCH (Schedule 10, 40, 80, etc.) based on your requirements.

❓4. Are Udhhyog pipes ISI marked?

Answer: Yes. All ERW and seamless pipes conform to ISI, ASTM, or DIN standards, with ISI stamping available for government and civil tenders.

❓5. Can I buy custom-length pipes?

Answer: Absolutely. We offer cut-to-length, threading, and polish finishing for all pipe sizes. Minimum order quantity may apply for customized processing.

0 notes

Text

What Is the Difference Between On-Grid, Off-Grid, and Hybrid Solar Systems?

Currently, the majority of homeowners are installing grid-tied solar systems that interact with their utility. However, there are other types of solar PV plus battery systems, like Off-Grid, and Hybrid solar systems. These alternatives help reduce carbon emissions, lower electricity costs, and enhance energy security.

While finding the best solar system for your home, the choice between these three installation categories may depend on your location, budget, and overall energy goals. Each type suits different needs and scenarios, making it essential to understand their features before investing in a solar power system.

Let’s break down the core differences in a way that’s easy to understand.

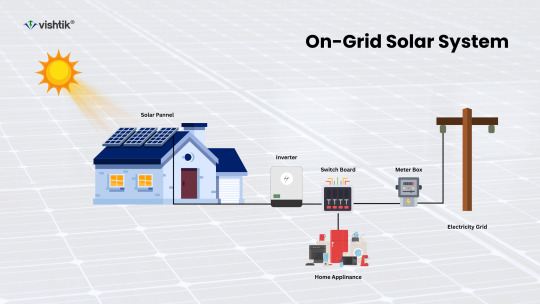

On-Grid Solar Systems (Grid-Tied)

An on-grid solar system, also known as a grid-tied system, operates like a silent partner with your local utility company like PG&E in California or Con Edison in New York. In this setup, your solar panels generate electricity, which an inverter converts into usable AC power, first meeting your home’s immediate energy needs. Any excess electricity your panels produce is then automatically fed back into the main electricity grid; under Net Metering policies—which are available in many states though constantly evolving—you receive credit for this power, effectively lowering your overall utility bill and making it a primary reason homeowners choose solar. However, your home remains grid-dependent, meaning that when your solar panels aren’t producing enough power, like at night or on cloudy days, your home seamlessly draws electricity from the grid, and typically, these systems do not include battery storage. This is a primary driver for homeowners to go solar, with the average cost of an 11 kW residential solar system in the U.S. being about $29,360 before federal tax credits in 2025, dropping to around $20,552 after the 30% federal tax credit.

Pros:

Cost-Effective: Generally the most affordable solar option as there are no expensive batteries to buy or maintain.

Maximum Savings: Leverages net metering to reduce or even eliminate your electricity bill by selling excess power back to the grid.

Simple Maintenance: Fewer components mean less to maintain.

Cons:

No Power During Outages: If the main grid goes down due to storms, accidents, or scheduled maintenance, your solar system will also shut down for safety reasons. This is known as “anti-islanding.”

Grid Reliance: You are still dependent on the utility grid.

Best For: Homes and businesses with reliable grid connections who want to maximize electricity bill savings and don’t require backup power during outages.

https://vishtik.com/wp-content/uploads/2025/06/Off-Grid-Solar-System-2.png

Off-Grid Solar Systems (Stand-Alone)

An off-grid solar system functions as your own independent power island, operating completely disconnected from the main electricity grid. With this setup, all the electricity consumed by your home must come directly from your solar panels or from batteries that have been charged by your panels, making battery storage essential for storing excess solar energy for use at night or during cloudy periods. A dedicated charge controller is crucial for regulating the power flow to these batteries, safeguarding them from overcharging or deep discharging, and many off-grid systems also include an optional but recommended backup generator (running on gas, propane, or even diesel) to supplement power during extended periods of low sunlight or exceptionally high energy demand. While highly appealing for complete energy independence, especially where extending power lines can cost anywhere from $5 to $25 per linear foot or $2,500 to $12,500 for the first few hundred feet, off-grid systems require careful sizing to ensure sufficient power storage.

Pros:

Total Energy Independence: Freedom from utility bills and grid outages.

Ideal for Remote Locations: Perfect for properties far from the main grid where extending power lines would be prohibitively expensive.

Cons:

Higher Upfront Cost: Batteries significantly increase the initial investment.

Battery Maintenance & Replacement: Batteries have a limited lifespan and require maintenance or eventual replacement, adding to long-term costs.

System Sizing Complexity: Requires accurate sizing to ensure sufficient power storage for all demands, even during extended cloudy periods.

Limited Power: You can only use as much power as your system can generate and store.

Best For: Remote homes, cabins, RVs, or businesses where grid connection is unavailable, unreliable, or too expensive to establish.

https://vishtik.com/wp-content/uploads/2025/06/Hybrid-Solar-System1.png

Hybrid Solar Systems

A hybrid solar system offers the best of both worlds, effectively acting as an on-grid system with an intelligent backup by combining the benefits of grid-tied solar with the crucial security of battery storage. Like on-grid setups, hybrid systems maintain a connection to the main electricity grid but crucially incorporate a battery bank and a specialized hybrid inverter, which is capable of smart energy management: it first directs solar power to supply your home, then channels any excess to charge the batteries, and once the batteries are full, any remaining surplus power can be exported to the grid via net metering. Furthermore, during grid outages, the system automatically switches to battery power, providing seamless backup, and when solar production is low, your home can draw power from either the batteries or the grid, depending on your system’s settings and current battery charge level.

Pros:

Power During Outages: Provides essential backup power during grid failures, offering peace of mind.

Optimized Self-Consumption: Reduces reliance on the grid by using stored solar energy at night.

Potential for Peak Shaving: Can be programmed to use battery power during expensive “peak” or “time-of-use” (TOU) tariff hours to reduce costs.

Cons:

Higher Cost than On-Grid: The addition of batteries and a hybrid inverter increases the initial investment.

Battery Lifespan & Maintenance: Similar to off-grid systems, batteries require eventual replacement.

Best For: Homeowners and businesses who want to maximize savings through net metering and have reliable backup power during grid outages – a highly attractive option, especially in areas prone to severe weather or with evolving utility rate structures.

Conclusion

The choice depends on your priorities, location, and budget:

If your primary goal is to reduce your electricity bill and you have a reliable grid connection: On-Grid is likely your best bet.

If you live in a remote area without a grid connection or desire complete energy independence: Off-Grid is the way to go.

If you want the benefits of bill reduction PLUS the security of backup power during outages: A Hybrid system offers the ideal balance.

Why Choose Vishtik as Your Solar Engineering Partner?

Navigating the complexities of solar system design and obtaining rapid approvals can be challenging for solar installers and homeowners across the USA. This is where a reliable solar engineering partner like Vishtik comes in. For solar installers and EPC firms looking for top-tier design and engineering services, Vishtik stands out by consistently delivering on three crucial aspects:

Read More: https://vishtik.com/what-is-the-difference-between-on-grid-off-grid-and-hybrid-solar-systems/

0 notes

Text

Massive stellar feedback influences star formation, finds study of W4 super-large HII region

A new study has unveiled new insights into the effects of massive stars on nearby molecular gas and star formation in the W4 super-large HII region.

The study, published in Astronomy & Astrophysics, was conducted by Shen Hailiang, a Ph.D. student from the Xinjiang Astronomical Observatory of the Chinese Academy of Sciences (CAS) and his collaborators.

Massive stars, through their powerful stellar winds and radiation, play a critical role in shaping the structure and evolution of surrounding molecular clouds. In particular, their feedback can either initiate or inhibit further star formation in the vicinity, particularly within rare, super-large HII regions.

One such region, W4, is a well-known cavity structure filled with ionized material and a chimney that carries hot material to the galactic disk.

In this study, Shen and his team conducted a large-scale CO (1–0) observation of the W4 super-large HII region and the neighboring W3 giant molecular cloud. Using 12CO/13CO/C18O data collected from the 13.7-meter millimeter-wave telescope at the Purple Mountain Observatory of CAS, they analyzed the distribution of molecular gas surrounding the W4 super-large HII region.

Their findings offer valuable insights into how feedback from massive stars influences the evolution of molecular gas and clumps in the area.

According to the researchers, the W3/4 molecular cloud is divided into three distinct regions based on its gas distribution: the high-density layer (HDL region), shaped by feedback and containing dense gas; the diffuse "bubble region," influenced by feedback but with low-density gas; and the "spontaneous star formation region," located far from the feedback area.

This unique structure allowed the researchers to examine how stellar feedback can both trigger and suppress star formation.

The results revealed that the CO gas at the boundary of the W4 HII region exhibits strong radiation, with intensity sharply increasing before gradually decreasing in the direction away from the HII region. The temperature of the gas at the boundary also shows a strong correlation with the 8μm radiation, both exhibiting higher values.

These observations provide clear evidence for the expansion sweeping and radiation heating at the boundary of the HII region, as well as ionized flow erosion.

In addition, the researchers identified 288 clump structures within the region, classifying them into three categories based on their distribution: HDL, bubble, and quiescent clumps. The analysis showed that HDL clumps tend to have higher excitation temperatures, lower virial parameters, higher thermal velocity dispersions, and lower L/M ratios when compared to clumps in the quiescent regions.

On the other hand, bubble clumps showed the opposite trends. The mass-radius relationship and mass cumulative distribution function also clearly distinguish the three types of clumps, confirming that feedback from the W4 HII region triggers star formation activity in the W3 HDL layer while suppressing it in the bubble boundary shell.

IMAGE: Optical Digitized Sky Survey (DSS) red–green–blue (RGB) image (Red: DSS2 Red (F+R); Blue: DSS2 Blue (XJ+S); Green: DSS2 NIR (XI+IS).) of the W3/4 region. Credit: Astronomy & Astrophysics (2024). DOI: 10.1051/0004-6361/202450914

2 notes

·

View notes

Text

Air Velocity Calibration | Gas Flow Meter, Wind Sensor Dubai, UAE

Middle East Calibration Lab L.L.C. is a UAE-based ISO/IEC 17025:2017 accredited calibration laboratory recognized by the Emirates National Accreditation System (ENAS). MIDDLE EAST CALIBRATION LAB L.L.C is one of the leading organizations in the field of calibration and repair of measuring instruments, testing equipment and weighing systems.

Expert Air Velocity, Wind Sensor, and Gas Flow Meter Calibration Services in the Middle East

Middle East Calibration Services (MECL) is a trusted name in the field of precise and professional calibration solutions across the UAE and the wider Middle East. With a commitment to accuracy, reliability, and compliance, we offer specialized services including Air Velocity Calibration, Wind Sensor Calibration, and Gas Flow Meter Calibration for a wide range of industrial applications.

Air Velocity Calibration You Can Trust

Air Velocity Calibration is essential for maintaining the accuracy of airflow measurement devices used in HVAC systems, cleanrooms, laboratories, and industrial ventilation setups. At MECL, we use state-of-the-art wind tunnels and certified reference instruments to calibrate anemometers, vane-type sensors, hot-wire probes, and other airflow measuring devices.

Regular air velocity calibration ensures your equipment delivers consistent and accurate readings, helping you maintain safety, energy efficiency, and regulatory compliance.

Accurate Wind Sensor Calibration

Whether used in meteorological applications, wind turbines, or environmental monitoring systems, Wind Sensor Calibration is critical to ensure real-time wind speed and direction data remains reliable. MECL calibrates cup anemometers, ultrasonic sensors, and vane sensors with precision, following international calibration standards.

Our experienced technicians conduct wind sensor calibration in controlled conditions, offering high accuracy and full traceability. We help you maintain data integrity, whether you're monitoring weather, controlling emissions, or optimizing wind energy systems.

Professional Gas Flow Meter Calibration

Gas flow measurement is vital in industries such as oil and gas, pharmaceuticals, chemical processing, and environmental monitoring. MECL’s Gas Flow Meter Calibration service ensures your mass flow controllers, thermal flow meters, and volumetric flow meters are operating within specified limits.

We calibrate using high-precision flow standards under controlled conditions, providing certificates that meet ISO and industry-specific requirements. With MECL, you can minimize process variability, ensure regulatory compliance, and improve process efficiency through accurate gas flow measurement.

Why Choose Middle East Calibration Services?

ISO-compliant calibration procedures

Fully traceable results with detailed certification

On-site and laboratory-based services available

Skilled technicians with extensive industry experience

Fast turnaround times with minimum disruption

We understand that accurate measurements are crucial for your business operations, quality control, and safety standards. That’s why we invest in advanced equipment, continuous training, and strict quality assurance procedures to deliver best-in-class calibration services.

Whether you're calibrating instruments for airflow, wind monitoring, or gas flow control, MECL provides the expertise and reliability you can count on.

For more details, call us at +971 6 524 1472 or get in touch via email at [email protected]. Our team is ready to provide tailored calibration solutions to meet your industry-specific needs.

0 notes

Text

Top Water Meter Supplier: What to Look for Before You Buy

In effective water consumption management, selecting the perfect provider of the highest quality water meter is no different from picking the equipment. A good water meter, for your residential complex, business property, or manufacturing facility, ensures correct measurement, affordability, and longevity. However, not all providers are of equal quality, assistance, and product variety. If you require the best water meter supplier, there are certain criteria to focus on prior to making a decision.

1. Products and Availability

A good supplier must possess a variety of water meters for various requirements. These can include:

Mechanical water meters

Ultrasonic or digital smart water meters

Residential and commercial types

Volumetric and velocity-type meters

For instance, Ali Yaqoob Trading Co. LLC provides a wide range of flow measurement and pump solutions, which are specially designed for various industries and applications.

2. Product Quality and Compliance

Ensure that the supplier provides water meters of international quality standards like ISO, OIML, or MID certifications. Quality water meters should offer long life, wear-and-tear resistance, and reliability in tough conditions.

Inquire about whether the water meters are corrosion-proof material, particularly if they are to be used in harsh weather or water conditions areas.

3. Technical Support and After-Sales Service

High-quality technical support is a significant consideration in selecting a water meter supplier. Select a supplier that provides:

On-site consultation

Installation guidance

Calibration service

Maintenance and troubleshooting assistance

A seller that stands behind its merchandise with guarantees and rapid-response customer support is reassuring and of enduring value.

4. Industry Expertise and Reputation

Identify a supplier with decades of experience in your sector and a stellar customer base. Suppliers such as Ali Yaqoob Trading have established themselves as leaders in the UAE when it comes to delivering high-performing water systems and fixtures. A seasoned supplier comprehends the unique requirements of your sector—utilities, construction, agriculture, or oil & gas.

5. Options for Customization and Integration

Certain projects demand something beyond an off-the-shelf meter. A high-quality supplier must offer:

Custom configurations

Remote monitoring ability

Smart integration with building management systems (BMS)

This is particularly applicable in the case of bigger commercial or industrial buildings that are looking to implement smart infrastructure and IoT-based solutions.

6. Delivery Time and Stock Availability

Lead time could be the breaking or making point for your schedule on time-critical projects. Select a supplier that has inventory in stock or has fast shipping options within your region. If your company operates from the UAE or GCC countries, selecting a regional water meter supplier does away with shipping charges and time.

7. Competitive Pricing and Value

Although it might be attractive to buy the lowest price, always balance price and value. A cheaper meter might turn out expensive in the long term if it is of poor quality and will not last for a long time, or does not accurately read. Ask for the total quote that encompasses installation, warranty conditions, and post-sales service.

Conclusion

Finding a good water meter supplier is all about getting a balance between product quality, technical expertise, and long-term support. Don't look for a vendor—look for a trusted business partner who understands your requirements and will provide sound advice for years to come. Vendors like Ali Yaqoob Trading Co. LLC demonstrate what to look for in a quality supplier: extensive product range, local footprint, technical knowledge, and exemplary customer support.

If you compare, research, and ask the right questions before you purchase, it is no longer about the meter—now it is about performance, accuracy, and peace of mind.

0 notes

Text

Reliable Metering Pumps Manufacturer in India | Unique Dosing

Discover high-performance Metering Pumps from Unique Dosing System – India’s trusted manufacturer of precision Metering Pump solutions for industrial dosing and fluid control.

Unlock Precision Dosing with High- etPerformance Mering Pumps by Unique Dosing System

In modern industrial processes, precision and control are paramount—especially when dealing with critical chemical dosing or fluid transfer applications. Whether it's in water treatment, food and beverage, pharmaceuticals, or oil and gas industries, a Metering Pump plays a vital role in ensuring the exact amount of fluid is delivered consistently and reliably.

What is a Metering Pump?

A Pump, also known as a dosing pump, is a positive displacement pump used to inject a precise volume of liquid into a process stream. These pumps are designed to move fluids at accurate flow rates over specific time intervals.

Metering Pumps are widely used in industries such as:

Water and wastewater treatment

Food and beverage manufacturing

Pharmaceuticals and chemical processing

Agriculture and irrigation systems

Petrochemical and refinery plants

Key Features of Unique Dosing System’s Metering Pumps

Unique Dosing System’s Metering Pumps are built to deliver unmatched precision, longevity, and operational efficiency. Here are some of the features that set them apart:

High Accuracy Dosing – Ensure accurate and repeatable flow rates. Corrosion-Resistant Construction – Built with durable materials such as stainless steel, PVDF, and PTFE. Flexible Flow Capacity – Ranges from small to large volume dosing applications. Energy-Efficient Operation – Designed to reduce operational cost without compromising performance. Low Maintenance Design – Engineered for easy servicing and extended operational life. Custom Configurations Available – Tailored to meet unique application requirements.

Types of Metering Pumps Available

At Unique Dosing System, you can find a range of Metering Pump to suit various industrial operations, including:

Plunger Type Ideal for high-pressure applications where rigid and pulsating fluid dosing is needed.

Diaphragm Type Perfect for chemically aggressive or hazardous liquids, with a leak-proof and low-maintenance design.

Electromagnetic Best suited for low-pressure and accurate flow applications. Compact, reliable, and easy to install.

Motor-Driven Designed for large-scale operations that require adjustable stroke and flow control for demanding applications.

Applications of Metering Pumps

essential wherever accurate and consistent dosing is critical. Some of the key applications include:

🔹 Water Treatment – Chlorine dosing, pH correction, and coagulant addition. 🔹 Chemical Industry – Controlled chemical injection in reactors and pipelines. 🔹 Pharmaceuticals – Accurate dosing of liquid medicine or ingredients. 🔹 Food & Beverage – Flavoring, coloring, and additive control. 🔹 Agriculture – Fertilizer and pesticide injection in irrigation systems.

Why Choose Unique Dosing System for Metering Pumps?

Trusted Manufacturer: Backed by years of experience and an excellent market reputation.

Made in India: Proudly designed and manufactured to global standards.

Technical Support: Dedicated team to provide pre-sales consultation and after-sales service.

Customization: Pumps designed to match the precise flow rate, pressure, and chemical compatibility requirements.

Cost-Effective Solutions: Competitive pricing without compromising on quality or performance.

With clients across sectors and regions, Unique Dosing System is committed to innovation, reliability, and customer satisfaction.

Tips for Selecting the Right Metering Pump

When choosing a Metering Pump, it is crucial to consider the following:

Flow Rate Requirement – Determine the volume of liquid to be transferred.

Type of Liquid – Understand the viscosity, temperature, and chemical nature of the fluid.

System Pressure – Match the pump with the system’s working pressure.

Control Type – Choose between manual or automated flow control systems.

Maintenance Needs – Opt for pumps that offer easy access and low maintenance components.

Visit: https://www.uniquedosingsystem.com/metering-pumps-manufacturers.php

Contact: +91 9822420535

0 notes

Text

What is a Duplex Strainer? How It Ensures Continuous Filtration

What is a Duplex Strainer?

A duplex strainer, also known as a twin basket strainer, is a type of industrial filter that removes solid particles and debris from liquids or gases. It protects pipelines, pumps, and sensitive equipment from clogging and wear.

Its twin-chamber design ensures continuous filtration, while one basket is in use, the other can be cleaned without shutting down the system. This makes it perfect for industries that demand zero downtime.

How Does a Duplex Strainer Work?

The working mechanism of a duplex strainer is simple yet smart:

Fluid enters the active chamber, where it passes through a filter basket that captures contaminants.

Clean fluid exits, continuing through the system.

When the first basket is full, a changeover valve redirects the flow to the second chamber.

The clogged basket can then be cleaned or replaced, without interrupting operations.

This seamless switch makes duplex strainers ideal for continuous, around-the-clock operations.

Key Components of a Duplex Strainer

Strainer Chambers – Hold filter baskets to catch dirt and particles.

Changeover Valve – Allows switching between baskets without stopping the flow.

Filter Baskets – Capture contaminants based on the selected mesh size.

Outer Casing – A durable shell that protects internal components.

Pressure Gauges – Indicate clogging by showing pressure changes.

Drain & Vent Ports – Make cleaning and maintenance quick and easy.

Why Duplex Strainers Are Better Than Traditional Filters

Uninterrupted Filtration – No downtime, even during maintenance.

Easy to Clean – Simple basket removal and cleaning without halting operations.

Lower Maintenance Costs – Less wear and tear on equipment.

Long-Term Savings – Prevents breakdowns and extends equipment life.

Space-Efficient Design – Compact units fit into tight spaces.

Strong & Durable – Built for high-pressure, high-temperature environments.

Where Are Duplex Strainers Used?

Duplex strainers are used in a wide range of industries:

Water Treatment Plants – Remove sand, silt, and algae before purification.

Oil & Gas Industry – Filter out debris that can damage pumps and meters.

Food & Beverage – Maintain hygiene by filtering out solids from liquids.

Power Generation – Protect turbines and heat exchangers from contaminants.

Pulp & Paper – Remove fibres and bark to ensure smoother processing.

How to Choose the Right Duplex Strainer

Here are five key factors to consider:

Flow Capacity – Match the strainer to your system’s flow rate.

Mesh Size – Choose based on the particle size you want to remove.

Material Compatibility – Make sure it's suitable for your fluid or chemical.

Operating Pressure & Temperature – Check if it can withstand your system’s conditions.

Ease of Maintenance – Go for user-friendly designs with easy access for cleaning.

Conclusion

A duplex strainer ensures your industrial system runs efficiently by removing harmful particles without halting operations. It's a smart investment that reduces downtime, saves money, and protects critical equipment.

For more information, please visit

0 notes

Text

GI Round vs Square Pipes – Price & Use Case Breakdown (Udhhyog 2025 Guide)

When it comes to choosing between GI round pipes and GI square pipes, understanding the price difference, application suitability, and strength characteristics is essential for making the right decision. Whether you’re working on plumbing, fabrication, fencing, or structural works, both types offer distinct benefits.

In this 2025 breakdown from Udhhyog, we compare:

Differences in structure and design

Price comparison (per meter & per kg)

Best applications for each

Stock and size range

FAQs on GI pipe selection

🔍 What Are GI Round and Square Pipes?

✅ GI Round Pipe

Circular cross-section

Used for plumbing, scaffolding, water lines

Easier to bend, thread, and flow liquids

✅ GI Square Pipe

Square hollow section (SHS)

Used for fabrication, railings, and structural frameworks

Provides even load distribution in box designs

Both pipe types are made from mild steel (MS) and undergo hot-dip galvanization, forming a zinc-coated outer layer that protects against rust and corrosion.

🧾 GI Round vs Square Pipe – Price Comparison (2025)

Prices depend on size, wall thickness, and coating weight (GSM). Below is a general rate overview:

🔹 GI Round Pipe Price (B-Class, Per Meter)

Size (NB)OD (mm)Price/ Meter (₹)Price/ Kg (₹)½ inch21.3 mm₹100 – ₹115₹74 – ₹761 inch33.7 mm₹140 – ₹160₹72 – ₹752 inch60.3 mm₹170 – ₹190₹68 – ₹72

🔹 GI Square Pipe Price (Approximate)

Size (mm)Thickness (mm)Price/ Meter (₹)Price/ Kg (₹)25 x 251.5 – 2.0₹95 – ₹110₹72 – ₹7540 x 402.0 – 2.5₹135 – ₹155₹70 – ₹7450 x 502.5 – 3.0₹175 – ₹195₹70 – ₹75

📌 Actual price may vary by brand (Tata, Jindal, Zenith), stockyard, and volume. Contact Udhhyog for accurate quotes.

🏗️ Use Case Breakdown – Where Each Pipe Is Best

ApplicationGI Round PipeGI Square PipePlumbing (residential, rural)✅ Highly suitable❌ Not recommendedFabrication (gates, grills)⚠️ Possible but less efficient✅ Ideal – clean edges and aestheticsFencing & railing✅ Commonly used✅ Better for modern designsWater & gas piping✅ Standard choice❌ Not suitable for fluid flowStructural support⚠️ Used with bracing✅ Stronger for frames and loadsSolar & rooftop structures⚠️ Round used occasionally✅ Preferred due to flat surface & weldability

📐 Sizes Available at Udhhyog

Round GI Pipes:

Sizes from ½” to 6” NB

IS 1239 (A/B/C Class) & IS 3589 (heavier wall)

Square GI Pipes:

Sizes from 20x20 mm to 100x100 mm

Thickness from 1.2 mm to 5.0 mm

✅ Why Choose Udhhyog?

Udhhyog is a trusted supplier of both GI round and square pipes across India, offering:

ISI-certified stock

Competitive per meter or per kg pricing

Custom cut lengths and galvanized finishes

Tata, Jindal, and cost-effective brands

Fast delivery to cities, towns, and rural sites

🚚 Delivery & Billing Info

Length: 6-meter standard

Packaging: Bundle with strapping + labeling

Dispatch: 1–3 working days

Invoice: GST + test certificates on request

❓ Frequently Asked Questions (FAQs)

Q1. Which pipe is better for water supply – round or square? A: Round GI pipes are the industry standard for water lines due to better pressure handling and fluid dynamics.

Q2. Can I weld both types of GI pipes? A: Yes, but square pipes offer easier flat-surface welding, while round pipes need saddle joints.

Q3. Which is more economical – round or square GI pipe? A: Round GI pipes are slightly cheaper per meter, but square pipes offer better value in fabrication applications.

Q4. Can I mix both types in a project? A: Yes, especially in hybrid structures like solar panel supports or fencing, where frames may be square and braces round.

Q5. Do both types come in ISI-marked options? A: Yes, Udhhyog supplies ISI-marked GI pipes in both round and square sections.

📞 Contact Udhhyog for Best Price & Supply

Need help choosing the right pipe for your project?

👉 Call or WhatsApp Udhhyog today for:

Price comparison

Stock availability

Brand options (Tata, Jindal, etc.)

Bulk and retail order support

0 notes

Text

Why Industrial Strainers Are Critical for Pipeline Efficiency

In the world of industrial processing and fluid transport, pipeline efficiency isn’t just a matter of performance — it’s about safety, cost-effectiveness, and long-term reliability. One of the unsung heroes that play a vital role in maintaining smooth operations is the industrial strainer.

Whether in oil and gas, chemical manufacturing, or water treatment, industrial strainers help protect equipment, maintain product integrity, and reduce downtime. Let’s explore why these components are essential and how the right strainer manufacturers in the USA are helping industries achieve operational excellence.

What Are Industrial Strainers?

An industrial strainer is a device used to filter out solid particles and debris from liquids or gases flowing through a pipeline. They act as the first line of defense, preventing contaminants from damaging critical components like pumps, valves, heat exchangers, and meters.

Strainers are typically installed at the intake side of the equipment to ensure that only clean fluid enters the system. From simple basket strainers to more complex duplex and Y-type designs, the choice of strainer depends on the application and flow requirements.

Why Pipeline Strainers Matter

When pipelines carry fluids under high pressure or over long distances, even minor contamination can lead to blockages, corrosion, or mechanical failure. This is where pipeline strainers come into play.

Key benefits include:

Equipment Protection: Strainers keep internal systems safe from wear caused by particulate matter.

Improved Efficiency: Clean flow means less friction, more consistent output, and better energy efficiency.

Reduced Maintenance Costs: By trapping debris early, strainers reduce the frequency and severity of equipment failures.

Product Quality: Contaminant-free fluids result in higher product quality in industries like food processing or pharmaceuticals.

Without proper strainers, pipelines are vulnerable to gradual degradation and costly shutdowns.

Why Working with the Right Strainer Manufacturer Matters

Choosing the right strainer manufacturer is as critical as the component itself. Not all strainers are built to withstand the unique pressures and conditions of industrial systems. When performance, safety, and durability are non-negotiable, it’s crucial to work with experienced strainer manufacturers in the USA who understand the industry’s needs.

Manufacturers like SG Industries provide customized solutions designed to fit specific flow rates, pressure levels, and media types. With a focus on quality materials and precise engineering, they help companies reduce risks and improve system reliability.

SG Industries — Delivering Industrial Strainers That Perform

At SG Industries, we design and manufacture robust industrial strainers tailored for various industrial applications. From high-pressure oil pipelines to chemical plants and utility systems, our strainers are engineered to meet global standards while ensuring seamless performance.

What sets us apart is our attention to detail, customer-first approach, and ability to deliver customized pipeline strainer solutions that work reliably under real-world conditions.

Final Thoughts

In high-stakes industrial environments, the smallest components often make the biggest difference. Industrial strainers are one such example — critical to pipeline performance, equipment protection, and long-term operational success.

If you’re looking for reliable pipeline strainers or trusted strainer manufacturers in the USA, SG Industries is ready to support your infrastructure with precision and reliability.

Interested in learning more? Visit SG Industries for a full range of industrial straining solutions or contact our team for tailored recommendations.

0 notes