#Gear Pump

Text

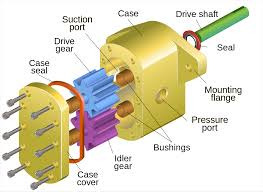

External Gear Pump — Internal gear pump Manufacturer & Supplier | Rotarygearpumpsindia

Being External Gear Pump , Internal gear Pump and Rotary lobe pump manufacturer , supplier we provide excellent quality range. Our Rotary Gear Pump are manufactured using a premium quality material for accurate and speedy functioning.

A Internal gear Pump is a type of positive displacement (PD) pump. Gear pumps use the actions of rotating cogs or gears to transfer fluids. The rotating gears develop a liquid seal with the pump casing and create suction at the pump inlet.

An internal gear can also be called a ring gear. Internal gears are used in planetary gear box applications, but can also be applied in other situations. Advantages of the use of a planetary gear train are low vibration, high speed reduction ratio, and the low cost for the entire train layout.

An External Gear Pump moves fluid by trapping it between the teeth of two gears that mesh together inside a housing

Our Products

Rotary Gear Pumps

External Gear Pumps

Internal Gear Pumps

Rotary Lobe Pumps

Rotary Shuttle Block Pumps

Rotary Screw Pumps

Twin Screw Pumps

Triple Screw Pumps

For more Details

Click here : https://www.rotarygearpumpsindia.com/

0 notes

Text

6 Tips for Choosing the Right Viking Pumps

In the world of industrial usage, ensuring smooth and dependable fluid transfer is crucial. This is where Viking Pumps shine, known for their dependable construction and outstanding performance. However, with a wide range of pump options to choose from, picking the Viking pump for your requirements can seem like navigating through challenging terrain. This article provides you with the insights needed to meet your industrial flow needs.

#Gear Pump#Internal gear pump#Stainless Steel gear pump#Viking Pumps#Viking Spares#pump and valves#Idex India

0 notes

Text

What is a Gear Pump?

A gear pump is a type of positive displacement pump featuring two interlocking gears to move fluids efficiently. Used in industries like chemical, petrochemical, oil, and gas, it is known for its durability and ability to handle high-pressure liquids. Gear pumps maintain consistent flow rates and are highly efficient. For high-quality hydraulic gear pumps, visit Hydraulic.net or call (630) 543-7630.

Visit Here:

0 notes

Text

What is Gear Pump and it's Uses?

There are various types of pumps available in the market. Basically, they are categorised into two main groups.

(i) Centrifugal Pumps

(ii) Positive Displacement Pumps. Internal gear pump is a type of PDP (Positive Displacement Pump).

Knowing the uses of Gear Pumps:

The basic functionality of a gear pump is to use the meshing of gears to pump fluid by displacement. A gear pump is the most common type of pump which is used for hydraulic fluid power applications. It is also used widely in chemical installations to pump high viscosity fluids (which is the main functionality of a PDP).

Gear pumps are further categorised into two main variations:

• External gear pump — which use two external spur gears

• Internal gear pumps — which use an external and an internal spur gears

Gear pumps are able to pump a constant amount of fluid in each revolution. Some are even designed to function as either a motor or a basic pump.

A short brief on internal Gear Pump

Internal gear pump is exceptionally versatile. This kind of pump is often used on thin liquids like solvents and fuel oil, however it is also good for thick liquids such as asphalt, chocolate, and adhesives. In addition to its wide viscosity range, the pump has a wide temperature handling capability. This is possible due to the single point of end clearance (the distance between the ends of the rotor gear teeth and the head of the pump). The clearance can be adjusted to accommodate high temperature and maximise efficiency for handling high viscosity liquids.

The internal gear pump is self-priming, non-pulsing and can even run dry for short periods. They are also bi-rotational, which means that the same pump can be used for both loading and unloading vessels. Because internal gear pumps have only two moving parts, they are reliable, simple to operate, and easy to maintain.

How they work?

• Liquid enters through the suction port between the rotor (large exterior gear) and idler (small interior gear) teeth.

• The crescent shape divides the liquid and acts as a seal between the suction and discharge ports.

• Intermeshing gears of the idler and rotor form locked pockets that assure volume control.

• Rotor and idler teeth mesh completely to form a seal equidistant from the discharge and suction ports.

If your business is based on terminal unloading, marine, chemical, petrochemical, food and general industries you can surely choose gear pumps as they work the best in these fields. Contact Us today.

#hydraulic hoses#hydraulic pump#hydraulic cylinder#hydraulic gear pump#gear pump#gear pump manufacturer

0 notes

Text

Building Trust Through Quality: Ensuring Reliability in Hydraulic Gear Pump Manufacturing

In the realm of hydraulic gear pump manufacturing, where precision and performance are paramount, quality control stands as the cornerstone of reliability. At Suryansh, we recognize the pivotal role that stringent quality control measures play in delivering pumps that exceed expectations. Let's explore why quality control is of utmost importance in ensuring the reliability of hydraulic gear pump manufacturing.

Consistency in Performance: Quality control processes ensure that each hydraulic gear pump manufactured adheres to strict performance standards. By meticulously monitoring every stage of production, from raw material inspection to final assembly, we guarantee consistency in performance across all our products. This consistency instills confidence in our clients, knowing that each pump they receive will deliver the expected level of performance.

Mitigating Defects and Failures: Through comprehensive quality control protocols, we identify and rectify potential defects or weaknesses in the manufacturing process. By implementing rigorous testing procedures and quality checkpoints, we minimize the risk of defects or failures in our hydraulic gear pumps. This proactive approach not only enhances product reliability but also safeguards our clients against costly downtime and repairs.

Customer Satisfaction: Quality control is not just about meeting industry standards; it's about exceeding customer expectations. By prioritizing quality at every stage of manufacturing, we ensure that our clients receive hydraulic gear pumps that meet their stringent requirements for reliability and durability. This commitment to quality translates into heightened customer satisfaction and long-term partnerships built on trust and reliability.

Compliance with Regulations: In the highly regulated landscape of manufacturing, adherence to quality control standards is non-negotiable. Our quality control processes are designed to comply with industry regulations and certifications, ensuring that our hydraulic gear pumps meet the highest quality and safety standards. By maintaining compliance, we provide our clients with peace of mind, knowing that they are investing in products that meet or exceed regulatory requirements.

Continuous Improvement: Quality control is not a one-time endeavor but an ongoing commitment to excellence. At Suryansh, we continually evaluate and refine our quality control processes to incorporate the latest advancements and best practices. By embracing a culture of continuous improvement, we strive to raise the bar for quality in hydraulic gear pump manufacturing, driving innovation and excellence in our industry.

In conclusion, quality control plays a pivotal role in ensuring the reliability of hydraulic gear pump manufacturing. From maintaining consistency in performance to mitigating defects, enhancing customer satisfaction, ensuring regulatory compliance, and fostering a culture of continuous improvement, quality control is the bedrock upon which our reputation for reliability is built. Choose Suryansh for hydraulic gear pumps that embody the highest standards of quality and reliability.

0 notes

Text

Quality Industrial Pump And Gear Pump Manufacturer in India

As a result, there are many Industrial gear pump manufacturers in India, but not all of them meet the high standards demanded by industrial applications. Soltech Pumps & Equipment Pvt. Ltd. is the leading Gear Pump Manufacturers in India that has earned an envious reputation for providing high-quality gear pumps well-suited to your diverse industrial demand within budget.

Visit Us:-

#Gear Pump Manufacturers#Gear Pump Manufacturers In India#Gear Pump#Gear Pump Manufacturers In Delhi

0 notes

Text

MS Radix Impex Solutions Supplier and Exporter Of Rotary Gear Pump, Centrifugal Pump, Band Saw Machine in India.

1 note

·

View note

Photo

Gear pumps are made by many different companies, and we promise to fix any type of equipment or pump from any manufacturer. Gear pumps work well with oils and other fluids with high viscosities. ServiceEp provides the best repair and maintenance services all over India.

#Gear Pump#Best Repair and Maintenance Services#pump#pumpsrepaireandmaintenance#centrifugal pumps reapair service in pune

0 notes

Text

Gear Pumps — Gear Pump Manufacturer, Supplier And Exporter In India

We have the best deals for Gear Pumps at Indian Trade Bird. We are leading manufacturer, supplier and exporter of Gear Pumps like gear oil pump, Voith Gear Pump, Series Gear Pumps and many more.

Gear Pumps are a type of positive displacement pump widely used in various industries for pumping fluids. Gear pumps are reliable and efficient solutions for transferring a wide range of fluids in various industrial applications. Gear pumps are reliable and efficient solutions for transferring a wide range of fluids in various industrial applications.

Buy Gear Pumps in Ahmedabad, Belgaum, Chennai, Delhi, Ghaziabad, Jaipur, Mumbai, Pune, Rajkot, Vapi.

For more Dettails

Click here : https://www.indiantradebird.com/product/gear-pumps

0 notes

Text

Understanding the Mechanics: How Viking’s Internal Gear Pump Works

Viking pumps are well known for their performance and effectiveness, especially due to their internal gear pump design. This article delves into the workings of Viking’s gear pump, shedding light on how it operates through positive displacement. Additionally, we will discuss the materials utilised in Viking gear pumps, such as cast iron and stainless steel tailored for usage scenarios.

0 notes

Text

+62 878-8811-1796 Distributor Pompa Industri Pompa Ebara 150X100 FSKA Malang

Distributor Pompa Industri Pompa Ebara 150X100 FSKA Malang, Distributor Pompa Industri Pompa Ebara 150X100 FSNA Malang, Distributor Pompa Industri Pompa Ebara 150X125 FSHA Malang, Distributor Pompa Industri Pompa Ebara 150X125 FSJA Malang, Distributor Pompa Industri Pompa Ebara 100X80 FSJA Malang, Distributor Pompa Industri Pompa Ebara 100X80 FSGCA Malang, Distributor Pompa Industri Pompa Ebara 100X80 FSHCA Malang, Distributor Pompa Industri Pompa Ebara 125X100 FSJCA Malang, Distributor Pompa Industri Pompa Ebara 125X100 FSKA Malang, Distributor Pompa Industri Pompa Ebara 125X100 FSLA Malang

#Web : http://dalla-teknik.com/#Dalla Tehnik (General Supplier-Mechanical-Electrical)#Komplek Arcadia Blok H3#No 5#Daan Mogot-Tangerang#15122#.#Model : Booster Pump#Close Couple Staimless Stell#"Wa : +62 878-8811-1796#Centrifugal And Suction Pump#Coupling#Diaphragm Pump#Gear Box#Gear Pump#Gear Motor#Induction Motor#In Line Pump#Industion Motor Explosion Proof#Inverter#Hydrant#Magnetic Pump#Material Pump#Mixed Flow Pump#Ring Blow#Horizontal Multistage#Root Blower#Self Priming Pump#Splite Case. Vertical Multistage#Submersible Pump

0 notes

Text

WHICH IS WHAT !! WHAT IS WHICH ?? OKAY OKAY

#I was doodling then decided to clean this one up#simplify them to hell RAAAHAHHHGGG#the reason why was bc I was listen to I LIKE TO PUMP IT by prodkaz#this is a reference to popn’ music I’m thinking about getting it for the original hardware#I WILL GO BACK TO DRAWING KEY OKAY SOON ITS JUST THAT IDK IDK!!!#fanart#a.b.a#guilty gear strive#aba guilty gear#guilty gear a.b.a#guilty gear aba#human paracelsus#paracelsus guilty gear#abacelsus

375 notes

·

View notes

Text

@heckitall HECKY I DID YOUR DTYIS!!! :DDD IM YOUR CO DIRECTOR FOR THIS COMIC HOW COULD I NOT DRAW OUR BOYS AT SOME POINT :D

Also people should go read Heck's comic Same as it Never Will Be, it is amazing and Heck is a really great story teller and artist :3 <3

#2003 tmnt my beloved#rottmnt#crossover#almost2ksainwbdtyis#sainwb#same as it never will be#my art#i went back to check on the deadline for this and saw it was literally 2-3 days away so i really pumped out the gears to get this done xD#again i dont really care about winning i just wanted an excuse to draw the lads#has also never drawn the 03 turts prior to this except for baby don#so i really like how this came out :D#and maybe im overthinking this part but i gotta know Heck if the thumbtacks and photos are a reference to Rise!Don's conspiracy theory boar#since he had photos of the other turtle iterations on it :V

789 notes

·

View notes

Text

How Our Innovative Hydraulic Gear Pump Design Maximizes Efficiency and Performance?

In today's industrial landscape, where efficiency and performance are paramount, choosing the right hydraulic gear pump can make all the difference. At Suryansh, we pride ourselves on our innovative design that not only meets but exceeds the expectations of our clients. Let's delve into how our cutting-edge hydraulic gear pump design maximizes efficiency and performance in various applications.

Precision Engineering: Our hydraulic gear pumps are meticulously engineered to deliver optimal performance. We employ state-of-the-art design techniques and utilize high-quality materials to ensure durability and reliability. Every component is crafted with precision to minimize internal leakage and friction, resulting in smoother operation and enhanced efficiency.

Advanced Hydraulic Technology: Our pumps incorporate advanced hydraulic technology that enhances efficiency while maintaining high performance levels. By optimizing flow paths and minimizing pressure drops, we maximize the utilization of hydraulic energy, leading to improved overall efficiency. Additionally, our designs are tailored to specific application requirements, ensuring optimal performance in diverse operating conditions.

Compact and Lightweight Design: Our hydraulic gear pumps feature a compact and lightweight design without compromising on performance. This design optimization not only reduces space requirements but also minimizes energy consumption, making our pumps ideal for applications where space and energy efficiency are critical.

Enhanced Durability and Longevity: Our innovative design focuses on durability and longevity, ensuring reliable performance over the pump's lifespan. We incorporate robust materials and employ advanced manufacturing techniques to withstand harsh operating environments and prolonged use. This results in reduced downtime and maintenance costs, ultimately maximizing the pump's efficiency and performance.

Customization Options: We understand that every application is unique, which is why we offer customization options to meet specific requirements. Whether it's adjusting flow rates, pressure ratings, or mounting configurations, our design flexibility allows us to tailor our hydraulic gear pumps to suit the exact needs of our clients, further enhancing efficiency and performance.

Continuous Improvement: At Suryansh Earth Movers, innovation is a continuous process. We invest in research and development to stay at the forefront of hydraulic technology and continually improve our pump designs. By incorporating feedback from our clients and leveraging the latest advancements, we ensure that our hydraulic gear pumps consistently deliver unmatched efficiency and performance.

In conclusion, our innovative hydraulic gear pump design is engineered to maximize efficiency and performance across various applications. With precision engineering, advanced technology, compact design, durability, customization options, and a commitment to continuous improvement, our pumps set the standard for excellence in the industry. Choose Suryansh, JBS industries for hydraulic gear pumps that not only meet but exceed your expectations.

0 notes