#Diaphragm Pump

Text

The Advantages of Sandpipers: A Comprehensive Guide

In the world of industrial and environmental uses, ensuring the effective transfer of fluids is crucial. Sandpipers, a type of pneumatic air pump known for their adaptability and reliable performance, play a role in achieving this goal. This detailed guide explores the advantages offered by Sandpiper portable pumps, shedding light on their characteristics and how they contribute to different industries & sectors.

#air operated double diaphragm pump#AODD Pump#diaphragm pump#Pneumatic Air Pump#Portable Pump#Sandpiper Diaphragm#IDEX India

0 notes

Text

Effective Methods to Reduce the Noise of Miniature Diaphragm Pumps

Miniature diaphragm pump is widely used in various fields such as chemical processing, medical devices, food processing, environmental monitoring and ect.. However, as we all know, the noise generated miniature diaphragm pumps during operation has a negative impact on the working environment and the health of operators.

For example, in the medical industry, micro diaphragm pumps are used to transport medicines, liquid medicines, biological products, etc. Its precise delivery ability and protection of liquids make it an important part of medical equipment. However, the hospital environment usually requires quietness, and the noise generated by micro diaphragm pump may interfere with the work efficiency of medical staff and even affect the rest and treatment of patients. So in this article, we will discuss the source of noise and how to take effective measures to reduce the noise level of diaphragm pumps, thus ensuring production efficiency and the safety and comfort of the working environment.

Like most machinery, micro diaphragm pumps inevitably generate operational noise during operation. Usually, it is crucial to distinguish between actual loudness in decibels and perceived loudness, which depends on the sound characteristics of each component when it is working, such as sharp sound (harsh and unpleasant), noisy sound (multiple mixtures), vibrating sound, etc.

Miniature diaphragm pumps are usually composed of pump heads, diaphragms, valve plates, motors, bearings and other components. Any component may produce a certain amount of noise during operation.

For example, when the motor is running at high speed or under heavy load, the motor will generate running noise and mechanical noise caused by friction with bearings and other components. The opening and closing of the valve under high-frequency operation will also generate vibration and noise. We will discuss feasible measures to reduce noise based on the structure of the pump:

1. Optimize the design structure

The design structure of mini diaphragm pump directly affects its noise level. By optimizing the design, the noise generation can be reduced.

1) Reducing the bearing gap

In miniature diaphragm pumps, the bearing gap in the motor and compressor housing is often the main source of noise. Bearing gap refers to the spacing between the inner and outer rings of the bearing. When the bearing gap is too large, it will cause unstable vibration and friction of the bearing during operation, thereby generating noise. Using higher quality bearings with tighter tolerances can help reduce the noise of the pump.

2) Choosing the right diaphragm material

The elasticity and softness of the diaphragm are crucial to the stable operation of the pump. If the diaphragm is too stiff or not elastic enough, it may cause unstable operation of the pump, increase vibration and noise.

The diaphragm needs to maintain good sealing performance during operation to prevent fluid leakage and pressure loss. If the sealing performance is poor, it may cause the pump to generate additional noise during operation.

Therefore, choosing the right diaphragm material and thickness can minimize vibration transmission and thus reduce noise.

3) Customizing valve material

The valve controls the flow direction and flow rate of the fluid in the diaphragm pump. Its design and working principle directly affect the performance and noise level of the pump. The faster the pump runs, the higher the frequency of the valve hitting the valve seat.

TOPSFLO is committed to optimizing the diaphragm structure, valve plates with excellent sealing performance, and precise bearing structures. TOPSFLO carefully select a series of high-performance materials, such as PP, PPS, PTFE, FKM, FFKM and EPDM. For customizing the core components of the pump, such as diaphragms, valve plates and pump heads. Which ensures that the installation and operation of each item meet the design requirements, which can effectively reduce the contribution of the internal structure to the noise.

2. Adjust working parameters

Adjusting the working parameters of miniature diaphragm pump can effectively reduce noise. For example, reducing the working pressure and flow rate can reduce the vibration and injection sound of the liquid; adjusting the working speed so that it works within the appropriate speed range can also reduce the noise.

3. Use low-noise materials

The housing and pipes of mini diaphragm pump are also one of the sources of noise. Therefore, it is very important to choose low-noise materials to make these parts. Common low-noise materials include rubber, silicone, polyethylene, etc. In addition, sound-absorbing materials such as foam and plastics can be added to the inside of the diaphragm pump housing to further reduce the spread of noise.

4. Reasonable installation

Reasonable installation of miniature diaphragm pumps is also an important measure to reduce noise. When installing the pump, choose a suitable location, away from work areas and crowded places. Take effective sound insulation measures, such as setting up soundproof covers and sound-absorbing walls, to prevent the spread of noise. Ensure that the foundation and supporting structure of the motor are stable and reliable, and reasonably install shock-absorbing devices to reduce the vibration and noise of the diaphragm pump. By adding a silencer at the inlet or outlet of the pump, the sound will be suppressed when passing through the porous material layer, thereby reducing noise and slightly reducing the pump flow.

In summary, the noise generated by diaphragm pumps can be effectively reduced through optimizing the design structure, adjusting the working parameters, using low-noise materials and reasonable installation. With the advancement of science and engineering technology, it is anticipated that the noise issues associated with diaphragm pumps will be further mitigated, leading to an improved working environment and better protection for employee health.

Wanna to get custom pump service? Feel free to contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Mini daiprahgm liquid pumps: https://www.topsflo.com/mini-diaphragm-pump/

Mini daiprahgm gas pumps: https://www.topsflo.com/mini-diaphragm-pump/

youtube

youtube

youtube

#diaphragmliquidpump#diaphragmairpump#diaphragm pump#miniature diaphragm pump#diaphragm air pump#mini vacuum pump#liquid pump#gas pump#dc air pump#mini air pump#micro air pump#12v air pump#airpumps#Youtube

0 notes

Text

EODD Pump: Understanding Its Mechanism

An EODD pump, or Electrically Operated Double Diaphragm pump, combines the reliable mechanics of a double diaphragm pump with the efficiency of electric operation. Unlike traditional diaphragm pumps, electric driven diaphragm pumps offer enhanced precision and energy savings. These electric operated diaphragm pumps are ideal for various industries due to their durability and low maintenance. The electric double diaphragm pump variant further optimizes performance, providing consistent flow rates and reducing pulsation. Understanding the mechanism of electric operated double diaphragm pumps is crucial for selecting the right equipment for your needs, ensuring efficient and reliable fluid handling.

VISIT: https://www.idexcognito.com/cognito

0 notes

Text

Diaphragm Pump is a fluid transfer device that uses compressed air or gas to move liquids. Ceracin offers a versatile solution for fluid-handling tasks across various pharmaceutical and chemical industries. In fluid handling applications, Diaphragm Pump stands out as a reliable workhorse, capable of efficiently moving various liquids delivering performance and value like no other. For more information, visit here:

0 notes

Text

Are you interested in learning about Diaphragm Pumps and their features? Nirmala Pump has released a new video providing a brief overview. Watch this video to learn more about this pump!

0 notes

Text

What Are Double Diaphragm Pumps Used For?

The Iwaki Air is a brand of Air-Operated Double Diaphragm (AODD) pumps, which are manufactured under stringent ISO 9001 Ver. 2008 standards. Iwaki Air AODD pumps are engineered for maximum utility. They are portable and easy to install, operate, and maintain.

1 note

·

View note

Text

Supply 6V, 12V, 24V miniature water pump DC water pump ink pump diaphragm pump small water pump

Features:

Strong performance

Noise floor

sustainable operation

Operating noise is not greater than 65dB

Corrosion resistance, long service life

Suitable for clear water, weak acid, weak base, weak salt and other liquids

Wide range of applications:

household appliances

medical instruments

soap dispenser

Disinfection equipment

printing ink

Available from stock, please contact:

WhatsApp:+8613735842547

Email: [email protected]

0 notes

Text

Jual Alat Lab Pompa Diafragma Murah

Jual Alat Lab Pompa Diafragma Murah

Kami perusahaan penyedia alat-alat laboratorium dan disini kami akan menawarkan kepada anda sebuah alat lab yang bernama Diaphragm Pump atau biasa disebut Pompa Diafragma, disini alat yang kami tawarkan terdiri dari dua jenis tipe alat untuk tipe VP410 Chemistry-Design Diaphragm Pump dan VP1C Chemistry-Design Diaphragm Pump untuk info lebih jelas mengenai alatnya silahkan lihat penjelasan…

View On WordPress

0 notes

Link

The diaphragm pump's operation may be impacted by the chemical's corrosiveness. Your DIAPHRAGM PUMPS may experience a variety of problems, some of which may prevent the pumps from operating effectively. We have answers to all of your difficulties, so you don't need to worry about anything.

0 notes

Text

What is negative suction in a pump?

Negative suction in a pump refers to the scenario where the pump is drawing liquid up from below its centerline. We measure the space between the pump's centre and the liquid's surface in "head feet." It can be a negative value (below the pump) or a positive value (above the pump).

Visit: https://idexindia.blogspot.com/2023/11/what-is-negative-suction-in-pump.html

0 notes

Text

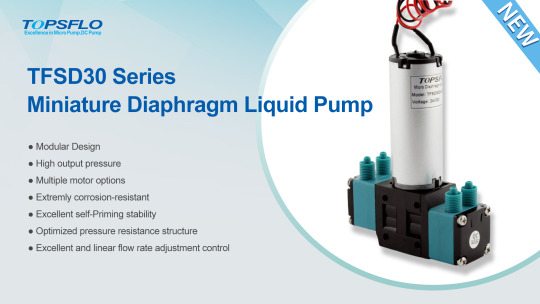

【New Product】| TFSD30 Series New-Generation High Performance Diaphragm Liquid Pump

Currently, in the fields of IVD and analytical instruments, high performance liquid pumps have long relied on imports. After the occurrence of global trade disputes and the COVID-19, issues such as the price and supply cycle of high-performance liquid pumps have significantly impacted the production of high-end medical and analytical instruments in China.

TOPSFLO has been deeply involved in the field of micro diaphragm pumps for more than ten years. In response to the above problems, the R&D center established a special project in 2020. After countless improvements and upgrades, it will finally launch a high-performance diaphragm liquid pump suitable for a variety of medical scenarios in the second half of 2022—TFSD30 Series. The launch of TFSD30 Series marks that domestically independently developed diaphragm liquid pumps have fully reached and surpassed German and Japanese products in performance, reliability and other fields.

High-performance diaphragm pumps face multiple challenges during operation, such as lifespan and reliability under high working pressure, tolerance to various corrosive chemical media, sealing performance under high pressure, the impact of noise and vibration on instruments, and issues related to valve plate adhesion and suction reliability when extracting viscous liquids.

To meet a wide range of customer needs and application scenarios, TOPSFLO focused on independent research and innovation in the development of TFSD30 Series pump. In the early stages of technical development, new technologies, structures, materials, and processes were employed. Multiple high-precision devices accumulated test data, and with collaboration from various sources, TFSD30 Series achieved another leap in product quality and performance.

1. Modular Design: TOPSFLO diaphragm pumps is designed with modularity, allowing flexible combinations of core components, materials, and processes. This enables rapid customization and production delivery with the shortest development cycle and minimal cost:

Miniature diaphragm pumps need to be integrated into fluid systems in various industries. Customers' working points, conditions, media, pipe types, power supply, and control systems vary significantly across different application industries. Even the same customer will have different requirements for fluid properties in different projects and systems. Our rapid customized services based on customer needs have always been well received and recognized by customers.

From the inception of the TFSD30 Series, TOPSFLO adopted a product mindset based on modular design, planning and designing the components, materials, and structure of the product. This approach allows us to provide customers with various high-quality and rapid customization services at the minimum cost. Customers can choose different pump heads, connectors, materials, and motors as needed, obtaining customized models with corrosion resistance, pressure, and flow characteristics. TOPSFLO sample line immediately customizes production based on customer choices, ensuring that customized products have fast delivery times and cost advantages comparable to standard products.

2. High output pressure for continuous operation in high-pressure conditions, providing a continuous power source for inkjet and cleaning applications:

TFSD30 Series is a liquid pump with a wide range of operating pressures. It can operate under -35kPa negative pressure, drawing liquid from a negative pressure container or from a location below the pump body installation position of 3.5m. It can also output liquid under +600kPa positive pressure, achieving a liquid lift of over 60 meters. Specially designed and pressure-resistant diaphragms and pump bodies, with optimized processes, not only enable the output of high-pressure liquid but also ensure continuous operational lifespan under rated high output pressure. When TFSD30 Series is connected to a micro atomizing nozzle, sufficient working pressure can produce ideal micro-sized mist droplets. When connected to a needle nozzle, it can output a strong high-pressure water column.

3. Adopt high-end corrosion-resistant materials to meet chemical compatibility requirements for various corrosive media applications:

Facing various corrosive media, TOPSFLO, in the selection of rubber and sealing materials, introduced not only conventional EPDM rubber but also fluororubber. Collaborating with leading suppliers of special rubber materials, TOPSFLO developed perfluoroether rubber (FFKM) valve plates and sealing systems with excellent corrosion resistance. Additionally, corrosion-resistant materials widely praised in the industry, such as polytetrafluoroethylene (PTFE), were also applied. The variety of corrosion-resistant material choices allows TFSD30 Series to be compatible with strong oxidizing agents, strong acids, strong bases, and organic solvents. It can be widely used in the transfer, washing, disinfection, cleaning, and inkjet applications involving highly corrosive liquids.

4. Optimized pressure resistance structure, elevating the pressure resistance capability of the micro diaphragm pump from 500kPa to 800kPa:

To meet the sealing and pressure resistance requirements for high-pressure applications, TOPSFLO R&D team comprehensively referred to the design features of various domestic and foreign high-pressure liquid pumps in the structural design, and made multiple improvements. Such as using glass fiber-reinforced polyphenylene sulfide (PPS) engineering plastic as the pressure-resistant pump body. This not only optimized the part structure but also reduced points of seal failure. The pressure-resistant pump body components' sealing and fastening pressure were optimized and strengthened, achieving a comprehensive pressure resistance performance of TFSD30 Series surpassing similar products at the 800kPa (0.8mPa) level. In addition to enhancing the pump body's pressure resistance, TFSD30 Series has undergone specific optimizations for pipe connection reliability and prevention of pipe detachment under high pressure. When used in high-pressure conditions, it can be equipped with a sleeve-type pipe sealing joint to enhance pipe pressure connection reliability.

5. Non-adhesive one-way valve structure for excellent self-Priming stability:

In order to minimize the industry-wide issue of self-priming failure caused by one-way valve adhesion when extracting viscous liquids, TOPSFLO significantly enhanced and improved the product structure during the development of TFSD30 Series. For example, the surface-sealing structure of the one-way valve plate was changed to a line-sealing structure to reduce medium retention and adhesive surface area. Fluid structure calculation simulations and 3D printing technology were introduced to minimize the working dead zone of the volumetric pump. This achieved higher suction negative pressure than similar imported foreign products, resulting in more stable and reliable self-priming performance.

6. Multiple motor options covering a wide range of lifespan and price ranges:

TFSD30 Series offers various motor options, including DC brushed motors, conventional brushless motors, and enhanced bearing custom brushless motors. These options cater to intermittent users, customers working under long-term continuous low loads, and those operating under long-term high-pressure and high-load conditions. This provides the most suitable configuration options, meeting the high reliability demands of challenging conditions and the cost-effective options for applications prioritizing cost. The diverse motor options also give users a broader range of choices in terms of power supply voltage, speed control mode, electromagnetic compatibility, and more.

7. Excellent and linear flow rate adjustment control characteristics:

To achieve stable liquid output flow rate control, TFSD30 Series can control motor speed through PWM signals. Optimizations were made for speed-flow characteristics. With the combined effect of the motor controller control program and optimized internal structure, the speed control curve of TFSD30 Series exhibits superior linearity compared to conventional diaphragm pumps. This enables customers to easily adjust and control the pump's output flow rate through programming and control signals in various applications.

The new generation high performance diaphragm pump TFSD30 Series has started prototype testing for initial users and will continue to iterate and improve based on customer feedback. TOPSFLO adheres to the core value of "creating value for customers" and is willing to work together with all customers to advance the continuous improvement of diaphragm pump technology and product quality. If you would like further information on TFSD30 Series high-performance diaphragm pump or apply for prototype testing, please contact our pre-sales engineers.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

0 notes

Text

Exploring the Latest Technological Advancements in Electrically Operated Double Diaphragm Pumps

The fluid handling industry is undergoing a transformation with the emergence of Electrically Operated Double Diaphragm pumps. These cutting-edge pumps provide a versatile and reliable solution, presenting an alternative to traditional pneumatic diaphragm pumps.

#pump and valves#eodd pumps#idexcognito#cognitotm eodd#diaphragm pump#eodd pump#diaphragm pump electric driven#double diaphragm pump#Electrically Operated Double Diaphragm pumps

0 notes

Text

+62 878-8811-1796 Distributor Pompa Industri Pompa Ebara 150X100 FSKA Malang

Distributor Pompa Industri Pompa Ebara 150X100 FSKA Malang, Distributor Pompa Industri Pompa Ebara 150X100 FSNA Malang, Distributor Pompa Industri Pompa Ebara 150X125 FSHA Malang, Distributor Pompa Industri Pompa Ebara 150X125 FSJA Malang, Distributor Pompa Industri Pompa Ebara 100X80 FSJA Malang, Distributor Pompa Industri Pompa Ebara 100X80 FSGCA Malang, Distributor Pompa Industri Pompa Ebara 100X80 FSHCA Malang, Distributor Pompa Industri Pompa Ebara 125X100 FSJCA Malang, Distributor Pompa Industri Pompa Ebara 125X100 FSKA Malang, Distributor Pompa Industri Pompa Ebara 125X100 FSLA Malang

#Web : http://dalla-teknik.com/#Dalla Tehnik (General Supplier-Mechanical-Electrical)#Komplek Arcadia Blok H3#No 5#Daan Mogot-Tangerang#15122#.#Model : Booster Pump#Close Couple Staimless Stell#"Wa : +62 878-8811-1796#Centrifugal And Suction Pump#Coupling#Diaphragm Pump#Gear Box#Gear Pump#Gear Motor#Induction Motor#In Line Pump#Industion Motor Explosion Proof#Inverter#Hydrant#Magnetic Pump#Material Pump#Mixed Flow Pump#Ring Blow#Horizontal Multistage#Root Blower#Self Priming Pump#Splite Case. Vertical Multistage#Submersible Pump

0 notes

Text

Diaphragm Pumps - Latest Facts About These Industrial Products

Diaphragm Pumps – Latest Facts About These Industrial Products

Pumps have been used for a long time now, and they existed from 2000 before Christ and were initially used to fetch water. Even if it does not function in the best possible mechanical wave, it was accepted widely and served best for pumping activities. In the 21st century, the diaphragm pump is widely used and implemented in different pumping activities.

Basics about the diaphragm…

View On WordPress

#best diaphragm pump exporters#best diaphragm pump exporters in India#diaphragm pump#Diaphragm pump manufacturers in India

0 notes

Text

High Pressure Powerful Pump Multi-Drain Plunger Bathroom Kitchen Toilet Shower Sinks (Black)

High Pressure Powerful Pump Multi-Drain Plunger Bathroom Kitchen Toilet Shower Sinks (Black)

Price: [price_with_discount](as of [price_update_date] – Details)

[ad_1]

Powerful Multi Drain Plunger – Stronger then ordinary plungers Powerful Pump Multi-Drain Plunger. Will work on toilets, bath tubs, sinks and showers 2 Interchangeable Rubber Plunger Heads included for dual purposes and sized drains. Easy to clean easy to store PlasticPowerful Multi Drain Plunger – Stronger then ordinary…

View On WordPress

#centrifugal pump#chemical pump#deep well pump#diaphragm pump#dosing pump#double acting pump#high volume discharge#jet pump#metering pump#multistage centrifugal pump#multistage pump#plunger pump#Positive Displacement Pump#pump seals#reciprocating piston pump#Reciprocating Pump#sewage treatment pump#Single Acting Reciprocating Pump#volumetric pump#wastewater treatment pumps#water jet cutting pumps

0 notes