#Graphite Crucible

Explore tagged Tumblr posts

Text

Graphite Crucible Providers & Manufacturers

Features:

We provide graphite crucibles for a variety of applications.

In vacuum / high-density graphite crucibles are used

Furnaces with an inert atmosphere

The best crucibles for quality melting

Applications for Graphite Crucibles:

Graphite crucibles are excellent for use during the casting process because they are non-reactive.

Their superior heat performance speeds up metal melting, allowing for shorter production cycles.

The resistance of graphite crucibles to chemicals, corrosion, and the workshop environment is attributed to their durability and longevity.

There are two types of graphite:

natural and artificial. The differences in manufacturing methods can be attributed to the distinctive characteristics of each material. In order to leverage the refractory qualities of silica and carbon fibers to conduct heat while preserving structural strength, natural graphite crucibles are composed of clay graphite ceramics that have been fused or bonded with silica carbon bound graphite. To create synthetic graphite, carbon black, pitch, and petroleum must be treated. Pitch impregnation or densification, baking, shaping, graphitization, and powder preparation are some of the processes.

0 notes

Text

Mastering the Art of Graphite Crucibles: Unveiling Unrivaled Quality

Introduction

In metallurgy and material sciences, the graphite crucible is an indispensable tool, acting as the silent hero behind the scenes in various industrial processes. At Ants Lab, we are dedicated to unraveling the secrets of the graphite crucible, showcasing its unmatched capabilities and superior quality that set it apart from the rest.

Understanding the Essence of Graphite Crucibles

The Core Composition

Graphite crucibles are crafted from a unique combination of high-purity graphite, making them resistant to extreme temperatures and chemical reactions. This composition ensures durability and longevity, making them ideal for applications in metallurgical processes, foundries, and laboratories.

Unparalleled Thermal Stability

One of the distinguishing features of graphite crucibles is their exceptional thermal stability. These crucibles can withstand extreme temperatures without compromising their structural integrity. This quality is crucial for metal melting, casting, and alloy production industries.

Applications in Metallurgical Processes

Melting and Casting Metals

Graphite crucibles play a pivotal role in the melting and casting metals, providing a reliable and stable environment for these processes. Industries ranging from jewelry crafting to large-scale foundries benefit from graphite crucibles' consistent and controlled conditions.

Alloy Production

In the realm of alloy production, precision and consistency are paramount. Graphite crucibles ensure a homogeneous blend of metals, creating high-quality alloys with desirable properties. This makes them an indispensable tool for manufacturers aiming for excellence in their final products.

Advantages Over Traditional Crucibles

Longer Lifespan

Compared to traditional crucibles, graphite crucibles boast a significantly longer lifespan. Their ability to resist wear and tear, even under extreme conditions, translates to cost savings for industries, reducing the frequency of replacements and downtime.

Chemical Inertness

The chemical inertness of graphite crucibles prevents unwanted reactions with molten metals, preserving the purity of the processed materials. This is crucial for applications where the integrity of the final product is of utmost importance.

Choosing the Right Graphite Crucible

Size and Capacity Considerations

Selecting a graphite crucible's appropriate size and capacity is vital for efficient operations. Our experts at Ants Lab guide you through the process, ensuring you choose a crucible that aligns perfectly with your requirements.

Customization Options

To cater to the diverse needs of different industries, we offer customization options for graphite crucibles. Our team can tailor the crucible to your specifications, whether it's a specific shape, size, or special coating.

Maintenance and Care Tips

Cleaning Procedures

Maintaining the cleanliness of your graphite crucible is crucial for optimal performance. Regular cleaning, using recommended procedures, prevents the buildup of impurities and extends the crucible's lifespan.

Proper Storage Practices

Storing graphite crucibles in a controlled environment, away from extreme temperatures and corrosive substances, ensures their longevity. Our guidelines provide insights into best practices for storing these valuable tools.

Conclusion

In conclusion, graphite crucibles stand as an epitome of reliability and precision in metallurgical processes. Their unique composition, thermal stability, and numerous advantages over traditional crucibles make them an essential tool for industries aiming for excellence in their operations.

0 notes

Text

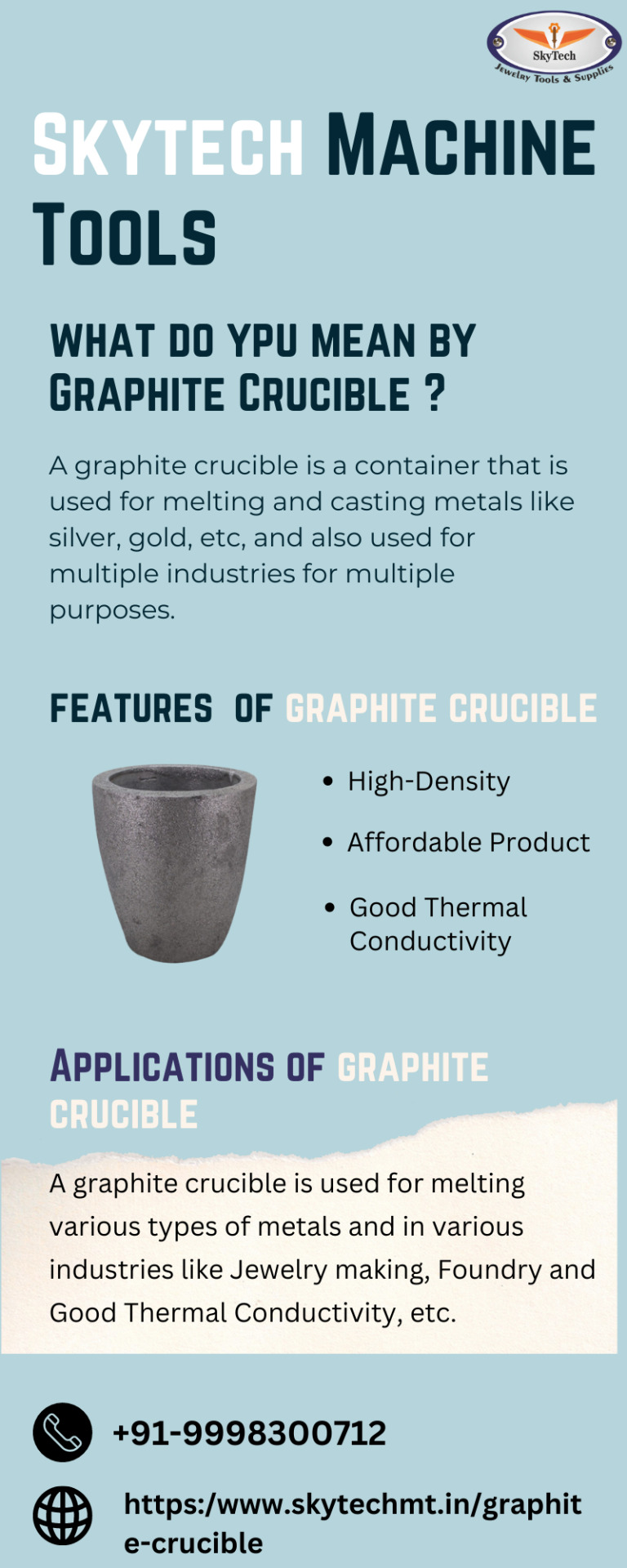

Latest document on Graphite Crucible!

Skytech Machine Tools provides an informative document on Graphite Crucible that describes a technical specification and various benefits about it. For more information, contact us!

#Graphite Crucible#Graphite Crucible manufacturer#Graphite Crucible supplier#Graphite Crucible exporter

0 notes

Text

Premium Graphite Crucibles for Faridabad's Industrial Applications:

Ensure efficient and precise melting processes with our premium graphite crucibles in Faridabad. We specialize in manufacturing high-quality crucibles that deliver outstanding performance, exceptional heat resistance, and excellent thermal conductivity. Our crucibles are designed to withstand extreme temperatures and provide optimal conditions for your melting applications. Reach out to us today to explore our range of graphite crucibles and elevate your industrial processes.

Contact Details:

Phone: +919958837764

E-mail: [email protected]

Website: https://www.faridabadgraphiteindia.com/

0 notes

Text

Hankay Hydraulics: Excellence in Hydraulic Press & Power Packs

In the dynamic world of industrial machinery, Hankay Hydraulics Private Limited stands as a beacon of innovation and excellence. Specializing in the manufacturing of high-quality hydraulic equipment, the company has carved a niche for itself, particularly in the domains of Clay Graphite Crucible Forming Machines, SMC Moulding Presses, Rubber Moulding Presses, Hydraulic Presses, and Hydraulic Power Packs.

Unparalleled Expertise in Clay Graphite Crucible Forming Machines

At Hankay Hydraulics, the design and production of Clay Graphite Crucible Forming Machines are approached with meticulous attention to detail. These machines are engineered to deliver precision and consistency, ensuring that each crucible meets the stringent quality standards required in various industrial applications. By integrating advanced technology and robust construction, the company ensures durability and optimal performance, making them a preferred choice for industries reliant on high-quality crucibles.

SMC Moulding Presses: Precision and Efficiency Combined

As leading SMC Moulding Press, Hankay Hydraulics offers state-of-the-art presses designed for Sheet Moulding Compound (SMC) applications. These presses ensure uniform pressure distribution, energy efficiency, and enhanced durability, making them ideal for composite molding industries.

Rubber Moulding Presses: Meeting Diverse Industrial Needs

The company's Rubber Moulding Presses Manufacturers are designed to cater to a wide array of industrial requirements. These presses are integral in creating various rubber products, from automotive components to industrial seals. By utilizing heat and pressure to shape rubber into durable, high-performance items, Hankay Hydraulics ensures that their presses can handle various rubber compounds and product specifications, operating efficiently under challenging conditions.

Hydraulic Presses: Engineering Excellence

As a prominent Hydraulic Press Manufacture, Hankay Hydraulics delivers presses that are vital in various industries, from automotive to metalworking. Their hydraulic presses are engineered to handle substantial loads and provide precise control, ensuring optimal results in operations. Whether a standard model or a custom solution is required, their presses are designed to meet specific needs, enhancing productivity and efficiency.

Hydraulic Power Packs: Powering Industrial Operations

The Hydraulic Power Packs offered by Hankay Hydraulics are robust and energy-efficient systems that power various hydraulic machinery. As superior Hydraulic Power Pack Manufacturers, the company ensures that their power packs are designed for reliability and performance, supporting the seamless operation of hydraulic systems across industries.

Commitment to Quality and Innovation

Established in 2018, Hankay Hydraulics Private Limited has rapidly gained a reputation for quality and innovation. Their ethical business policies and customer-centric approach have guided them in ensuring total customer satisfaction. By setting well-drafted marketing policies, they have connected with a large number of clients, raising awareness of their brand and expanding their reach.

Looking forward, Hankay Hydraulics aims to expand further and cater to the requirements of global clients. Their goal is to support industrial growth with innovative solutions that meet the unique demands of clients across various sectors, solidifying their position as a trusted leader in hydraulic solutions.

In conclusion, Hankay Hydraulics Private Limited exemplifies excellence in the manufacturing of hydraulic machinery. Their dedication to quality, precision, and customer satisfaction positions them as a preferred partner for industries seeking reliable and efficient hydraulic solutions.

#Clay Graphite Crucible Forming Machine#SMC Moulding Press#Rubber Moulding Press Manufacturers#Hydraulic Press Manufacturers#Hydraulic Power Pack Manufacturers

1 note

·

View note

Text

Pyrolytic Graphite Coated PBN Crucible for Electron Beam Evaporation

Pyrolytic graphite coated PBN (pyrolytic boron nitride) crucible refers to a crucible made of PBN material with a coating of pyrolytic graphite on its surface. The purity of Pyrolytic Graphite Coated Crucible is over 99.99% and the air tightness is good, which has high-temperature resistance, chemical stability, good thermal shock resistance, good thermal conductivity, low coefficient of thermal expansion, resistance to acid, alkali, salt, and organic reagent corrosion. In addition, it has a long service life.

By coating a PBN crucible with a layer of pyrolytic graphite, several advantages can be achieved: 1.Enhanced thermal conductivity: The pyrolytic graphite coating improves the thermal conductivity of the PBN crucible, allowing for efficient heat transfer during high-temperature processes. 2.Chemical resistance: The PBN material already exhibits exceptional chemical inertness, and the additional pyrolytic graphite coating further enhances its resistance to corrosive substances, ensuring greater durability and lifespan of the crucible. 3.Non-wetting properties: Pyrolytic graphite has a non-wetting surface, meaning it repels and does not absorb liquids. This property prevents molten materials from sticking to the crucible, facilitating easy removal and preventing contamination. 4.Electrically insulating: PBN itself is an excellent electrical insulator, and the pyrolytic graphite coating maintains the insulating properties of the crucible. This trait is valuable in electrical and electronic applications, where electrical isolation is necessary. 5.Reduced thermal stress: The combination of PBN and pyrolytic graphite helps reduce thermal stress caused by temperature variations, extending the crucible's lifespan. Pyrolytic graphite coated PBN crucibles are commonly used in high-temperature applications, such as semiconductor manufacturing, crystal growth, metallurgical processes, and materials research, where both high thermal stability and chemical resistance are critical. Read the full article

#PBNCrucible#PBNCrucibles#PyrolyticBoronNitrideCrucible#PyrolyticBoronNitrideCrucibles#Pyrolytic Graphite Coated Crucible

0 notes

Note

so sorry to pepper you with questions rapidly, but I do have one more. Regarding your (somewhat joking I think) post about Iterator cans not being made of metal, I propose that they might be made of a stronger than normal graphite-based compound.

My shop got a graphite casting crucible today and I was struck by how metallic and strong it was. Because it’s still graphite the thing was obviously not super strong, but still enough so that I think a modified compound could be load bearing. It would also explain the color of the cans (if they aren’t metal) as graphite and its compounds are all a dark, metallic gray.

Idk, kind of a random thought but I wondered what you’d think of it.

also I think that graphite might be a superconductor under some circumstances? (Too lazy to double check) so that would help solve the signal delays between parts of the structure as well as supply the vast amounts of wiring needed.

Graphite might be used in some parts, yeah. But that post was ENTIRELY serious. I was not joking about that, I believe their exterior is made up of stone, carbonate, and calcium

And maybe it does include the outer parts of the can. But it'd probably be some form of organically grown graphite, rather than anything dug up from the ground and then used for the cans.

11 notes

·

View notes

Text

its been a while since i write abt terrafirmacraft... well its because i've been busy rebuilding the house. its a two story house with a wing dedicated for cooking and forging. the roof was burnt down twice until i replaced it with mudbricks instead of wood blocks. it also has a basement where i kept barrels of limewater, tallows, and preserved foods. limewater is useful for a lot of things, but right now im using it just for leather. tallows are candles. turns out whale hunting is a lot easier than i think. i crossed the ocean many times during my move, and some of them lingers and follow you on boat. candles are better light source than torches. you cant exactly hang it off the walls or ceiling, but it lasts longer. i'll be using candles until i finally get materials to make lamp glass.

as i get settled, i started farming. plants grow better here, and i can forage things from the forest, but they overheat fast so i need to provide crops with lots of fertilizers. i planted tomatoes, but i forgot they need a stick to prop them up. and then i find some animals, a cow, horse, and a llama i think? idk. i also got some chicken but it dies lol.

the cow was probably the worst animal i had to drag back. theyre so stupid! i brought three, but only one survives because one of them escaped the leash and ran off while the other fell in a hole and gets bit to death by crocodiles. i hate crocodiles so much, theyre demons that trap you in swamps.

winter came, and i started preparing for a trek to find graphite. i found a bunch of coppers, cooked, don my leather armor, i vaguely remember that there was an exposed bit of rock that might contain graphite in one of the lakes near my super super first base. i spent at least one and a half prospective pick just to get graphite. its tedious, long, and arduous. i think it took me two weeks to get it. i play the game in 2 hour duration twice a week so yea im a casual. its super satisfying to hit a super large stack though and coming home with a bonus of pyrite and beets. also now i know how to mine deep underwater <3

my plan here is to make glass for lamps and jars. to do that i need tools like paddle, jacks, blowpipe, and gem saw. i need brass to make jacks. and for gem saw i would need gems like pyrite and brass rod. to make brass you need a tin and copper and a way to process said tin and copper to be brass. by that i mean i need a crucible. its made out of fire clay. fire clay is made out of kaolinite clay and graphite. i just need One Thing.

but of course finding kaolinite isnt as easy as it sounds. it took me a week before i start using cheats. i already live SOMEHWERE where kao is supposed to spawn. but all i see is sylvite and saltpeters. its drudget i use locate biome to see other places like highlands and old mountains that might give me what i need, but so far i found zero. im starting to think my world just doesnt have kao. so i just give up and type give tfc:kaolin_clay.

i gave myself just enough to make a crucible. i made my brass rods and once i got it, i have to weld and work said rods on the anvil to make my blowpipe.

i blew all my coal and brass ingots to zero results. i just suck, suck so bad at working the anvil. so i took a long break. i didnt touch tfc for quite a while. i focused on making gifsets and such. but i get bored with only dabbling with photoshop so i look up tips on anvil working on tfc. there's no way around it. the mod is meant to slow you down and make you learn and explore. some suggested i practiced working on an anvil using copper. some suggested i work on other shit before coming back to the anvil.

so, i went back, and realized how much i neglected my house. my animals still doesnt have a barn. i havent fixed the burned kitchen roof. my bookshelves are empty. my leather armor have been worn down to a nub. my inventory shelves are a mess. i havent restored the decorations that got burned down on the third (or was it fourth?) house fire. i went to work slowly fixing those things. i made copper armor again, a helmet and boots. to tell you the truth, i think i did metalworking better when im just going by vibes instead of overthinking the maths.

im gonna complete the armor i wear, but for now i think i want to make a proper barn first and a warehouse. as i was working, the chest near the forge caught fire. i realized then the space im working in is too small. i need to make a storage space and a building dedicating for forging.

7 notes

·

View notes

Text

If we suddenly found a giant boulder of pure iridium somewhere I feel like we probably still wouldn't end up using it for things like that because of what a royal pain it is to work, since iridium doesn't corrode and its melting point is higher than basically everything so you have to use graphite crucibles

nuclear power is impressive until you get up to why. "we use the most precisely engineered machinery ever created to split atoms to release energy" oh yeah how come? "boil water to turn a fan" get the fuck out

73K notes

·

View notes

Text

Application of Boron Nitride Ceramics in Crucible Field

Boron nitride crystals belong to the hexagonal system, and their structure is similar to that of graphite; and their performance also has many similarities, so they are also called "white graphite". It has good heat resistance, thermal stability, thermal conductivity, and high-temperature dielectric strength, and is an ideal heat dissipation material and high-temperature insulation material. Boron nitride has good chemical stability and can resist the erosion of most molten metals. It also has good self-lubrication. Boron nitride products have low hardness and can be machined.

Boron nitride can be used to manufacture crucibles for melting semiconductors and high-temperature containers for metallurgy, semiconductor heat dissipation insulation parts, high-temperature bearings, thermocouple sleeves, and glass forming molds.

Performance characteristics

1. Purity>99%, no adhesion to products, no pollution to products, and long service life.

2. The maximum operating temperature is 2100 degrees, resistant to repeated impact of high and low temperatures, and resistant to carbon corrosion.

3. It can be used for sintering and melting alloys, ceramics, rare earths, and other materials. It is also used for electron beam evaporation coating, etc.

Boron nitride crucible can be used for sintering and melting metal materials, rare earth, ceramics, and other materials. It is resistant to thermal shock and corrosion and does not react or bond with metal and ceramic materials. It can replace graphite and alumina crucibles by using a temperature of 1500 degrees for 10 minutes and cooling rapidly to room temperature and repeatedly at 900 degrees.

Precautions for use

1. Boron nitride is easy to absorb moisture, and the crucible cannot be stored in a humid area or washed with water. It can be directly wiped with sandpaper or wiped with alcohol.

2. The temperature in the air cannot exceed 1000 degrees. The surface of boron nitride will oxidize and peel off when it comes into contact with oxygen.

0 notes

Text

0 notes

Text

Graphite Crucible Manufactures in Surat

What is a Graphite Crucible?

A graphite crucible is a container used for melting and holding metal or glass at high temperatures. Made primarily from graphite and clay, these crucibles can withstand extremely high heat without deforming or contaminating the material being processed. Their non-reactive nature makes them ideal for working with precious metals like gold, silver, and aluminum.

Applications of Graphite Crucibles

Graphite crucibles are widely used in:

Metal casting and melting operations

Jewelry manufacturing and refining

Laboratory testing and research

Glass production

Alloy and non-ferrous metal processing

Their excellent heat retention and resistance to chemical attacks make them a preferred choice across industries that require high-temperature operations.

Why Choose Okosu Ceratech?

Okosu Ceratech combines modern technology with deep industry experience to manufacture graphite crucibles that meet the strictest quality standards. Here’s what sets us apart:

Use of high-purity graphite for enhanced durability

Wide range of sizes and shapes to suit different industrial needs

Resistance to thermal shock and chemical erosion

Competitive pricing and prompt delivery

Each crucible undergoes rigorous testing to ensure reliability and long service life, even under the most demanding conditions.

Based in Surat, Serving All of India

Located in Surat, Gujarat—a growing hub for industrial manufacturing—we are well-positioned to serve clients across India and beyond. Whether you need bulk orders or customized crucible designs, Okosu Ceratech is your trusted partner.

Contact Us Today

Looking for dependable graphite crucible suppliers and manufacturers in Surat? Get in touch with Okosu Ceratech for premium products that meet your specific melting and casting requirements with precision and performance.

0 notes

Text

Graphite Crucible

Introducing the Conical Graphite Crucible by AntsLab – a pinnacle of craftsmanship for your melting needs. Engineered with precision and designed for durability, this crucible sets the standard for excellence in metallurgy. Upgrade your melting game with the Conical Graphite Crucible from AntsLab. Elevate your craftsmanship, achieve precise results, and enjoy the durability that only top-notch materials can provide. Order now and witness the transformation of your melting endeavors with this exceptional graphite crucible. Your next masterpiece awaits – seize the opportunity today!

0 notes

Text

Check the new infographics on graphite crucible

Skytech machine tools upload the latest infographics in the top high-quality graphite crucible that is a container used for various industries. For more information contact us.

0 notes

Text

8 Uses of Quartz Crucible

Quartz crucibles are bowl-shaped containers made of high-purity quartz glass. They can withstand high temperatures and are chemically stable. Many fields extensively use them.

1. In the chemical industry, quartz crucibles are often used in experiments. This includes high-temperature reactions and substance analyses.

2. In the metallurgical industry, quartz crucibles play a key role. Researchers use them in metal smelting, ore smelting, and combustion experiments. Their ability to withstand high temperatures makes them essential for these processes.

3. In materials science, quartz crucibles are vital for high-temperature tests. These include powder metallurgy and material crystal growth.

4. In environmental monitoring, researchers use quartz crucibles for sample analysis.

5. In drug manufacturing, the pharmaceutical industry uses quartz crucibles. Researchers use them in equipment and experiments. They can withstand high-temperature sterilization, ensuring the sterility of the drugs.

6. In mineral analysis, researchers can use quartz crucibles to dissolve samples with iron and sulfur. This provides more accurate results in mineral composition analysis.

7. In powder sintering, quartz crucibles are key for sintering graphite and metal materials. They can handle powder materials at high temperatures. quartz crucibles won’t damage the processed materials. They can also heat samples to higher temperatures, ensuring complete sintering.

8. In the manufacturing of biochemical products, manufacturers extensively use quartz crucibles. They are high-quality and stable. They keep biological samples safe at high temperatures.

0 notes

Text

0 notes