#Hastelloy C276: Chemical Composition

Text

Hastelloy C276: Chemical Composition, Mechanical Properties

Introduction:

Hastelloy C276, known by its UNS N10276 designation, is a versatile and highly sought-after nickel-molybdenum-chromium alloy. In this comprehensive guide, we will delve into its chemical composition, explore its remarkable properties, and shed light on its wide range of applications across various industries. Additionally, we will discuss its exceptional resistance to corrosion, and the essential aspects of fabrication and heat treatment.

Hastelloy C276 Chemical Composition:

ElementContent (%)Nickel, Ni57Molybdenum, Mo15-17Chromium, Cr14.5-16.5Iron, Fe4-7Tungsten, W3-4.50Cobalt, Co2.50Manganese, Mn1Vanadium, V0.35Silicon, Si0.080Phosphorous, P0.025Carbon, C0.010Sulfur, S0.010

Hastelloy C276 Physical Properties:

PropertiesMetricImperialDensity8.89 g/cm³0.321 lb/in³Melting point1371°C2500°F

Hastelloy C276 Mechanical Properties:

PropertiesMetricImperialTensile strength (@thickness 4.80-25.4 mm, 538°C/@thickness 0.189-1.00 in, 1000°F)601.2 MPa87200 psiYield strength (0.2% offset, @thickness 2.40 mm, 427°C/@thickness 0.0945 in, 801°F)204.8 MPa29700 psiElastic modulus (RT)205 GPa29700 ksiElongation at break (in 50.8 mm, @thickness 1.60-4.70 mm, 204°C/@thickness 0.0630-0.185 in, 399°F)56%56%Hardness, Rockwell B (plate)8787

Hastelloy C276 Thermal Properties:

PropertiesMetricImperialThermal expansion co-efficient (@24-93°C/75.2-199°F)11.2 µm/m°C6.22 µin/in°FThermal conductivity (-168 °C)7.20 W/mK50.0 BTU in/hr.ft².°F

Equivalent materials to Hastelloy C276:

ASTM B366ASTM B574ASTM B622ASTM F467DIN 2.4819ASTM B575ASTM B626ASTM B619ASTM F468

Chemical Composition:

Hastelloy C276 primarily consists of the following key elements:

Nickel (Ni): The primary component, providing a strong base for the alloy’s exceptional performance.

Molybdenum (Mo): Enhances corrosion resistance, particularly in reducing environments.

Chromium (Cr): Contributes to the alloy’s resistance to oxidizing agents like chlorides and oxidizing acids.

Iron (Fe): An essential element, which when present in controlled amounts, maintains the required mechanical properties.

Tungsten (W) and Cobalt (Co): Elements that further strengthen the alloy and provide stability against crevice corrosion.

Properties:

Hastelloy C276 boasts several remarkable properties that make it an ideal choice for challenging environments:

Corrosion Resistance: Its outstanding resistance to a wide range of aggressive media, including strong acids, chlorides, and seawater, sets it apart from conventional alloys.

High Temperature Resistance: The alloy retains its mechanical strength and integrity even at elevated temperatures, making it suitable for high-temperature applications.

Excellent Fabricability: Hastelloy C276 can be easily formed, welded, and machined, providing flexibility during fabrication processes.

Good Mechanical Properties: The alloy exhibits excellent tensile and impact strength, further enhancing its suitability for various industrial applications.

Applications:

Due to its exceptional properties, Hastelloy C276 finds applications in diverse industries, including:

Chemical Processing: It is extensively used in handling corrosive chemicals and acidic solutions.

Petrochemical Industry: The alloy is employed in reactor vessels, heat exchangers, and other equipment exposed to aggressive media.

Oil and Gas: In offshore drilling environments and sour gas wells, Hastelloy C276 ensures reliable performance.

Pollution Control: It plays a vital role in the construction of flue gas desulfurization systems and other pollution control equipment.

Pharmaceutical and Pulp & Paper: Its corrosion resistance makes it valuable in pharmaceutical production and pulp and paper processing.

Resistance to Corrosion:

Hastelloy C276 stands out for its exceptional resistance to both uniform and localized corrosion. It maintains its integrity in aggressive environments, where other materials might fail. The alloy’s resistance to pitting, crevice corrosion, and stress corrosion cracking makes it highly reliable, especially in chloride-rich conditions.

Fabrication and Heat Treatment:

Hastelloy C276 offers ease of fabrication, allowing it to be formed into various shapes using standard techniques. Weldability is excellent, and the alloy can be joined using common welding processes like TIG and MIG welding. To achieve the desired properties, post-weld heat treatment is recommended.

Conclusion:

Hastelloy C276 is a remarkable nickel-based alloy that excels in demanding environments, thanks to its exceptional properties and resistance to corrosion. Its wide range of applications across industries underscores its versatility and reliability. Whether in chemical processing, petrochemicals, or other challenging settings, Hastelloy C276 Pipe continues to prove its worth, ensuring the integrity and longevity of critical equipment. Contact Now for more information

Learn More: Erw vs Spiral Pipe : Difference

0 notes

Text

Hastelloy C276 is a remarkable alloy with a pivotal role in the pharmaceutical and food processing industries. At MV Super Alloy, we take immense pride in our position as India’s leading Hastelloy C276 stockist, serving as suppliers, traders, importers, dealers, and exporters.

0 notes

Text

#hastelloy c-276 composition#hastelloy c 276 composition#hastelloy c276 suppliers#c276 composition#hastelloy c276 chemical composition#hastelloy c276 composition

0 notes

Photo

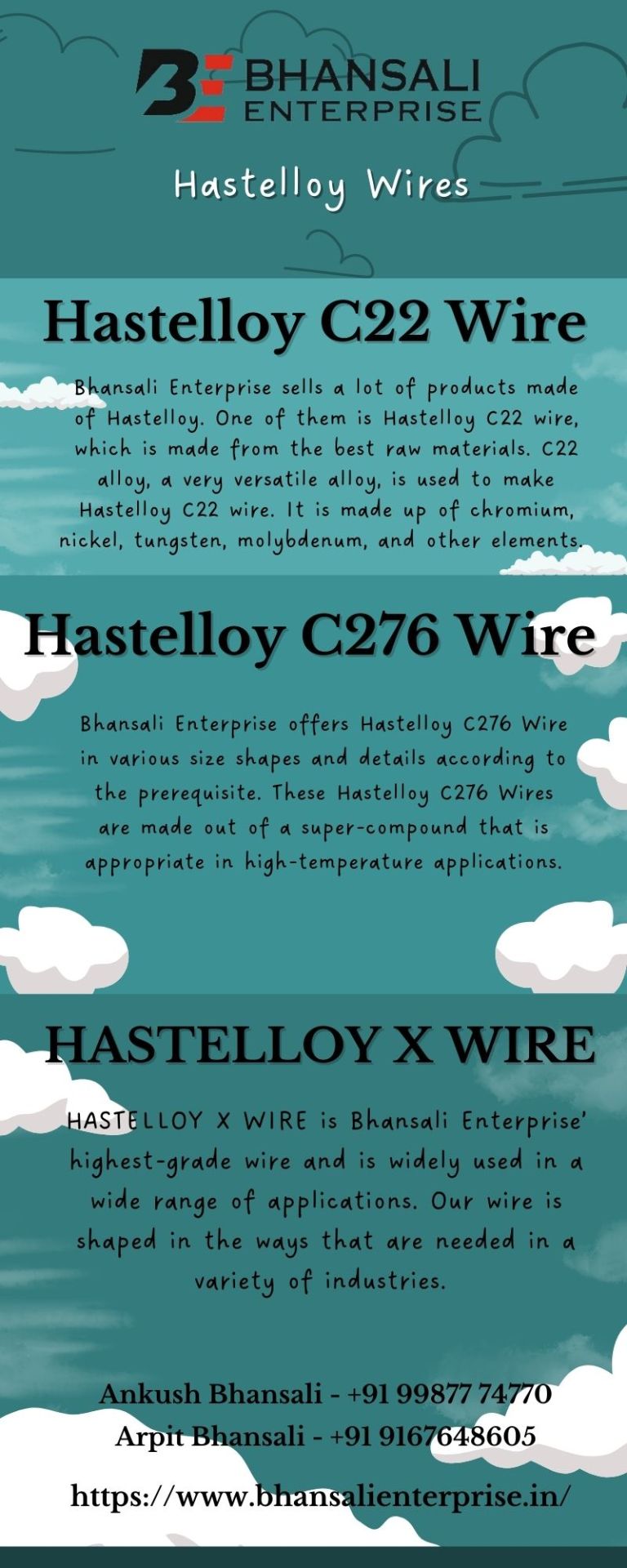

"Hatelloy Wires Manufacturer & Exporter."

Bhansali Enterprise sells a lot of products made of Hastelloy. One of them is Hastelloy C22 wire, which is made from the best raw materials. C22 alloy, a very versatile alloy, is used to make Hastelloy C22 wire. It is made up of chromium, nickel, tungsten, molybdenum, and other elements. Components made of material grade C22 have increased resistance to corrosion and a variety of industrial chemicals as a result of these elements. Bhansali Enterprise offers Hastelloy C276 Wire in various size shapes and details according to the prerequisite. These Hastelloy C276 Wires are made out of a super-compound that is appropriate in high-temperature applications. It is made up of chromium, nickel, and molybdenum alloy, which has excellent resistance to corrosion in an oxidizing environment. It is a corrosion-resistant alloy made of nickel, chromium, and molybdenum. Stress corrosion cracking, crevice corrosion, and pitting are all prevented by this alloy. These Hastelloy C276 Wires shows the capacity to limit the carbide precipitation while welding. Additionally, it exhibits excellent resistance to minimizing or preventing grain boundary precipitates during welding. HASTELLOY X WIRE is Bhansali Enterprise’ highest-grade wire and is widely used in a wide range of applications. Our wire is shaped in the ways that are needed in a variety of industries. These wires are held to specified standards, and dimensional changes define various specifications. With a higher Hastelloy grade, these wires are easier to form and more ductile. It has a higher tensile strength and is made specifically for use in applications at higher temperatures. HASTELLOY X, also known as a superalloy, is a high-performance alloy that keeps features like super strength, resistance to creep and cracking, and sustainability under high temperatures and corrosion.

#stainless steel wire#wire manufacturers#stainless steel wire manufacturers in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#hastelloy composition#hastelloy c276 chemical composition#polished stainless steel#stainless steel manufacturers in india

0 notes

Text

Humming a tune, walking into the empty Stark Laboratory, whistling a tune as I settle down...

'J.A.R.V.I.S, come in, it's playtime...'

Monitor system buzzing, activating processing units...

Evening Ma'am. Feeling Creative, I see. How would you like your ambience, Miss Grace?

'What can I say, J, I'm in the mood for work tonight, Aren't you too? Smiles...Just play whatever Mister Stark has on his playlist...'

Noted. Now Playing- Paint it Black by The Rolling Stones

Going into Creative, Miss Grace...

'Restore all of the last few browsings and display into list, please.'

LAST BROWSINGS:

What are the fundamental principles for designing high-entropy alloys with superior strength, ductility, and corrosion resistance for specific applications?

How can we optimize the microstructure of metallic materials to achieve a balance between strength, toughness, and fatigue resistance for specific applications, such as aerospace and automotive?

How can we ensure the long-term durability and safety of nuclear power plant components, considering the harsh radiation and temperature environments?

What are the environmental impacts of metal extraction, processing, and recycling, and how can we develop sustainable strategies to minimize these impacts?

How can we effectively integrate advanced characterization techniques to understand the degradation mechanisms of metallic components in service, and use this knowledge to improve component life and reliability?

Smiles...

'Thank you, I'll be needing that next...Now give me....sustainable microfibre alloy proportions...'

Very Well. You will now need narrowing down from your records.

Iron-based alloys: Often used in machinery due to abundance and cost-effectiveness.

Nickel-based alloys: Known for high-temperature strength and corrosion resistance, suitable for nuclear components.

Titanium alloys: Lightweight and corrosion-resistant, but expensive. High-entropy alloys: Emerging class of alloys with potential for unique properties.

'Now give the proportions we've considered the last time we looked into our simulators, Only for....the Nickel Based Alloys, make a list...'

Looks over thoughtfully as the list is being formulated...scrolls down the list, switching screens on the holograms...

Monel: A nickel-copper alloy known for corrosion resistance. 63% nickel, between 29% and 34% copper, between 2% and 2.5% iron, and between 1.5% and 2% manganese.

Inconel: A family of nickel-chromium-based alloys, often used in high-temperature applications. 61% nickel, 22% chromium, and 9% molybdenum

Hastelloy: A group of nickel-based alloys with exceptional corrosion resistance in various media. Hastelloy C276, also known as UNS N10276, has the following chemical composition: Nickel (Ni): 57%, Molybdenum (Mo): 15–17%, Chromium (Cr): 14.5–16.5%, Iron (Fe): 4–7%, Tungsten (W): 3–4.5%, Manganese (Mn): 1% maximum, Cobalt (Co): 2.5% maximum, Vanadium (V): 0.35% maximum and Silicon (Si): 0.08 maximum

Incoloy: Nickel-iron-chromium alloys designed for high-temperature applications and resistance to oxidation. Nickel: 38–46%, Chromium: 18–22%, Iron: Balance, Aluminum: 0.3–0.7%, Titanium: 0.15–0.6%, Manganese: 1.5% max, Silicon: 1% max, Carbon: 0.05% max, Sulfur: 0.015% max and Phosphorus: 0.02% max

Smirks, clapping my hands twice, the data reducing to 17 little fragments of hologram, flicking away the unnecessary bits that remain of the non highlighted data...

Data Compiled, Miss.

'Yeah, good... you've been writting down what I've been saying while I was in the simulation unit the other day and today, haven't you...?'

Yes Ma'am.

'Turn all of that, into that research booklet we were asked for, so we can give him what....roughly, an estimated idea of the whole entire suit, merits and demerits, budgeting and assemblance...give him the blueprints too, at the end of it...I have a feeling this one will not... disappoint...'

Working on it, Ma'am.

Runs hands on my face tiredly, waiting for it to compile, drumming fingers onto the table, cracks neck, shifts head...

Report Compiled, Ma'am.

'Good boy, J. You've been a darling, tonight, great help, I can never thank you enough... sometime when you're human, or if...Imma owe you big time.'

No worries, Ma'am. You've been quite amazing to work with as well.

Smiles...

'Let's call it a night, J.A.R.V.I.S...Thank you...Good Night...'

Hologram goes off...

Goodnight Ma'am.

______________________________________

( @tony-starkinator @the-loss-of-my-life )

2 notes

·

View notes

Text

Hastelloy C276 Round Bars Manufacturer in India | Reliable Overseas

The Need for High-quality Corrosion-Resistant Materials in Critical Industries

In industries like chemical processing, oil and gas, marine, and power generation, equipment is constantly exposed to harsh environments that can cause rapid corrosion, oxidation, and wear. These challenges can lead to costly downtime, increased maintenance, and even failure of critical components. In such demanding environments, the need for durable and corrosion-resistant materials becomes crucial for the safety, efficiency, and longevity of industrial processes.

When it comes to high-performance materials, Hastelloy C276 is a top choice. This nickel-molybdenum-chromium alloy, known for its exceptional corrosion resistance, is widely used in industries that operate under extreme conditions. However, finding a reliable manufacturer of Hastelloy C276 round bars in India can be challenging, as not all suppliers meet the strict quality standards required for these critical applications.

The Consequences of Choosing the Wrong Manufacturer

Choosing the wrong manufacturer for Hastelloy C276 round bars can have severe consequences. Substandard materials can lead to premature failure of components, resulting in unexpected downtime, expensive repairs, and potential safety hazards. Additionally, poor-quality materials may not meet industry specifications, leading to project delays, compliance issues, and reputational damage for businesses.

Imagine a scenario where a chemical processing plant relies on low-quality Hastelloy round bars for its equipment. Over time, these bars corrode and weaken, leading to a breakdown in the system. The plant faces significant downtime, production losses, and safety risks. The cost of replacing the faulty components and the resulting impact on operations could have been avoided by choosing a reliable manufacturer from the start.

In a competitive market, where every decision counts, businesses cannot afford to take risks with inferior materials. This is where Reliable Overseas steps in, offering top-quality Hastelloy round bars that meet the highest industry standards and ensure long-lasting performance.

Reliable Overseas – Your Trusted Partner for Hastelloy C276 Round Bars in India

Reliable Overseas stands out as a top manufacturer and supplier of Hastelloy round bars in India. With years of industry experience, they have established a solid reputation for providing high-quality products that satisfy the stringent demands of critical sectors. Here's why Reliable Overseas is the go-to choice for Hastelloy C276 round bars:

1. Superior Material Quality

Reliable Overseas understands the importance of material quality in industries where failure is not an option. Their Hastelloy round bars are manufactured using premium-grade raw materials sourced from trusted suppliers. The company follows stringent quality control processes to ensure that every batch of round bars meets the highest standards of strength, durability, and corrosion resistance.

Hastelloy C276 is known for its ability to withstand a wide range of corrosive environments, including those containing sulfuric acid, hydrochloric acid, chlorine, and more. Reliable Overseas ensures that their round bars retain these properties by maintaining precise chemical compositions and manufacturing processes. This ensures that their products can perform reliably in even the most challenging environments.

2. Compliance with International Standards

One of the critical factors that set Reliable Overseas apart from other manufacturers is their commitment to meeting international standards. Their Hastelloy C276 round bars comply with industry specifications such as ASTM B574, ASME SB574, and UNS N10276. This compliance guarantees that the round bars are suitable for use in industries that demand high-performance materials, such as chemical processing, pharmaceuticals, power generation, and more.

By adhering to these standards, Reliable Overseas ensures that their customers receive round bars that meet the exact requirements of their applications. This not only provides peace of mind but also reduces the risk of compliance issues during inspections and audits.

3. State-of-the-Art Manufacturing Facility

Reliable Overseas operates a state-of-the-art manufacturing facility equipped with modern machinery and technology. Their production process is designed to optimize efficiency, precision, and quality. Every stage of the manufacturing process, from selecting raw materials to the final inspection, is closely supervised to guarantee precision and consistency.

The company's advanced machinery allows it to produce Hastelloy round bars in a variety of sizes and dimensions, catering to the specific needs of its customers. Whether you require standard sizes or custom dimensions, Reliable Overseas can deliver products that meet your exact specifications.

4. Rigorous Testing and Inspection

To ensure that their Hastelloy C276 round bars meet the highest quality standards, Reliable Overseas conducts rigorous testing and inspection at every stage of production. This involves mechanical testing, chemical analysis, dimensional inspections, and non-destructive testing (NDT). The company employs a team of experienced engineers and quality control professionals who oversee the testing process and ensure that all products meet the required specifications.

Reliable Overseas also provides material test certificates (MTC) and third-party inspection reports upon request. This transparency allows customers to verify the quality and performance of the round bars, giving them confidence in their choice of manufacturer.

5. Timely Delivery and Customer Support

In industries where downtime can result in significant losses, timely delivery of materials is crucial. Reliable Overseas understands this and is committed to delivering their Hastelloy C276 round bars on time, every time. Their efficient supply chain management and well-established logistics network enable them to meet tight deadlines and ensure that their customers receive their products when they need them.

In addition to timely delivery, Reliable Overseas offers excellent customer support. Their team is always available to assist with product inquiries, technical specifications, and order tracking. Whether you need assistance with selecting the right round bars for your application or require post-purchase support, Reliable Overseas is dedicated to providing exceptional service to their customers.

Applications of Hastelloy C276 Round Bars

Hastelloy round bars are widely used in industries that require materials with excellent corrosion resistance and high strength. These round bars are frequently used in essential applications such as:

Chemical Processing: Hastelloy C276 round bars are commonly used in equipment such as reactors, heat exchangers, and piping systems in chemical plants. Their resistance to a wide range of corrosive chemicals makes them ideal for use in harsh environments.

Oil and Gas: In the oil and gas industry, Hastelloy round bars are used in components that are exposed to corrosive media, such as offshore drilling equipment, pipelines, and valves. Their ability to withstand high temperatures and corrosive environments ensures the reliability of critical equipment.

Marine Industry: Marine environments are highly corrosive due to the presence of saltwater and other harsh elements. Hastelloy C276 round bars are used in shipbuilding, offshore platforms, and other marine applications where corrosion resistance is essential.

Power Generation: In power plants, especially those that use fossil fuels or nuclear energy, Hastelloy round bars are used in components that are exposed to high temperatures and corrosive gases. Their durability and resistance to oxidation make them suitable for use in turbines, boilers, and exhaust systems.

Pharmaceuticals: The pharmaceutical industry requires materials that can withstand exposure to chemicals and high-purity environments. Hastelloy round bars are used in the manufacturing of pharmaceutical equipment, such as mixers, reactors, and storage tanks.

Conclusion:

When it comes to choosing a manufacturer for Hastelloy C276 round bars, reliability, quality, and performance are paramount. Reliable Overseas stands out as a trusted manufacturer in India, delivering high-quality products that meet the stringent requirements of critical industries. With their commitment to superior material quality, compliance with international standards, state-of-the-art manufacturing facility, rigorous testing and inspection, and timely delivery, Reliable Overseas is the ideal partner for businesses seeking durable and corrosion-resistant materials.

#Hastelloy C276 Round Bars#Hastelloy C276 Round Bars Supplier#Hastelloy C276 Round Bars Exporter#Inconel 600 Round Bars#Inconel 600 Round Bars Supplier#Inconel 600 Round Bars Exporter#Stainless Steel 446 Tubes#Stainless Steel 446 Tubes Manufacturers#Stainless Steel 446 Tubes Suppliers#Stainless Steel 446 Sheets and Plates#Stainless Steel 446 Sheets and Plates Suppliers#Stainless Steel 446 Sheets and Plates Exporters

0 notes

Text

Ultimate hints for excessive-performance composites

If you're looking for top-notch alloy products, Siddhagiri Metals and Tubes has been given you protection. With such a lot of products to be had, in addition to SS 304 tube fittings, Inconel 625 round bars, hastelloy c276 plate, and more, this newsletter may be your go-to useful resource for finding statistics and choosing a product that works nicely approximately. It's a totally effective combination of substances to fit your needs.

Inconel 625 flanges are designed to provide a watertight and durable connection underneath hot temperature rise and corrosive situations. Siddhagiri Metals and Tube gives a choice of Inconel 625 flanges designed to fulfil enterprise needs and specifications.

Hastelloy C276 tube fittings from Siddhagiri Metals and Tubes provide super resistance to pitting, crevice corrosion, and strain corrosion cracking, making them best for important packages in medicine, sewage remedy, and different fields.

Duplex 2205 is a low-rate, bendy duplex stainless steel that is evidence of corrosion in hundreds of conditions.Siddhagiri Metals and Tubes offers a complete line of Duplex 2205 Tube Fittings designed for excessive overall performance and long-term reliability.

Super Duplex 2507 tube fittings are recognized for their robust tensile energy and advanced corrosion resistance below excessive situations. Siddhagiri Metals and Tubes offers a huge variety of Super Duplex 2507 Tube Fittings for bundle necessities in oil and gas, chemical production, and plenty of other industries. Copper-nickel filters are acknowledged for their excessive resistance to saltwater corrosion and fouling, making them an excessive first-class desire for marine and offshore applications. Siddhagiri Metals and Tubes gives fantastic copper-nickel tube fittings which can withstand harsh marine situations.

Selecting the Right High-Performance Alloy Products Selecting precise, high-standard performance alloy products is critical to the success and persistence of your packages.When combining materials such as titanium grade 2 round bar, Monel 400 plate, and chrome steel 304 pipe, the following factors must be kept in mind: Corrosion Resistance All of the above high-performance alloys boast extremely high corrosion resistance properties. do, ensuring overall reliable performance. bad environment Whether you need Inconel 625 Round Bar or Hastelloy C276 flanges, you should not forget that Siddhagiri alloys and tubes offer the trade-off with advanced corrosion resistance.

Mechanical Strength From Monel four hundred spherical bars to Duplex 2205 tube fittings, the mechanical strength of high-normal overall performance alloy merchandise is a key consideration. Siddhagiri Metals and Tubes ensures that all products meet stringent mechanical strength requirements, presenting the sturdiness and reliability wanted for numerous business programmes.

High-performance alloys are engineered to go through excessive temperatures and demanding thermal situations. When deciding on items that include Inconel 625 tube fittings or Super Duplex 2507 tube fittings, it's crucial to test their temperature resistance tendencies to assure maximum typical overall performance in high-temperature applications.

Each excessive-standard overall performance alloy product is designed to fulfil precise commercial enterprise requirements and necessities. Whether you want Hastelloy C276 tube fittings or Titanium Grade 2 plate, Siddhagiri Metals and Tubes assures that each product meets relevant industry necessities, ensuring compatibility and conformity with requirements.

Siddhagiri Metals and Tubes is a reliable and appeared company of high-ordinary overall performance alloy items at the side of Inconel 625 plate, Stainless Steel 304 spherical bar, Hastelloy C276 plate, and masses more. Siddhagiri Metals and Tubes is your one-prevent save for immoderate-performance alloy solutions, emphasising fantastic, dependability, and adherence to business enterprise standards. Siddhagiri Metals and Tubes no longer gives anything short of excellence in excessive-overall performance alloy products.

0 notes

Text

Why Choose Hastelloy Flanges for Corrosive Environments?

The unresolved confrontation of hastelloy flanges to a diversity of corrosive chemicals, acids, and gases, such as sulfuric acid, hydrochloric acid, and chlorine dioxide, sorts them the material of high quality for corrosive settings. The alloy has unresolved resistance to both oxidizing and reducing circumstances because to its composition, which is often a mixture of nickel, chromium, molybdenum, and tungsten. For subdivisions like chemical processing, petrochemicals, and pollution control where exposure to abrasive media is common, this makes Hastelloy flanges faultless. Since they consistently uphold structural integrity and resist leaks in severe environments, they are an economical option for demanding applications needing strong corrosion resistance. This guarantees operational safety and endurance.

A Complete Guide to Flanges and Fittings for Specialty Plumbing

Inconel flanges and Hastelloy C276 pipe fittings are energetic parts for any industry demanding robust solutions against corrosion and high temperatures. These alloys find wide application in demanding situations due to their excellent mechanical makings and resistance to corrosion.

How to Decide Amongst Inconel and Hastelloy Flanges

Since of their separate alloy compositions, Inconel and Hastelloy flanges help separate purposes. Hastelloy alloys, such as C276; have unresolved resistance to a broad diversity of corrosive substances, which makes them faultless for use in pollution control and chemical treating. On the other hand, Inconel alloys—which are well known for their corrosion resistance and great temperature power—are used in gas turbine, airplane, and marine requests where high temperatures and mechanical stress are mutual.

Pricing visions for 304 and 316 stainless steel pipe fittings and flanges

Budgeting and purchasing selections require a thorough understanding of the Stainless steel 304 flange Price list and Stainless steel 316 flange Price list, as well as the price lists for matching pipe fittings. Stainless steel 304 is well known for existence approximately resistant to corrosion and being simple to fabricate, which makes it suitable for a range of industrial uses. Stainless steel 316, on the other hand, is recommended for marine and coastal applications since to its enhanced corrosion resistance, particularly in chloride situations.

Stainless Steel Price-Relating Factors

Prices of raw materials, industrial difficulty, and consumer demand are some of the basics that affect the Stainless steel 304 pipe fittings Price list and Stainless steel 316 pipe fittings Price list. Indian producers have the skill to provide customers through affordable solutions without forgoing functionality or longevity by striking a balance among competitive pricing and quality.

It's vital to take certain application necessities like corrosion resistance, temperature tolerance, and mechanical power into account when selecting Inconel flanges, Hastelloy flanges, or stainless steel pipe fittings and flanges. Through their knowledge in alloy selection, precision in production, and devotion to international standards, Indian vendors offer a wide choice of items that are specifically intended to satisfy these wants. This guarantees that, even in the most demanding circumstances, businesses across the globe can depend on these components for dependable performance.

0 notes

Text

The Versatility of Hastelloy C276 Pipe: From Chemical Processing to Aerospace

Hastelloy C276, a high-performance superalloy that's taking industries by storm! From chemical processing to aerospace applications, this versatile material is a game-changer in terms of durability and reliability. Let's dive into the fascinating world of Hastelloy C276 pipe and discover why it's the go-to choice for demanding environments.

Alloy C-276 Pipe Processing Services

When it comes to Alloy C-276 pipe processing services, precision is key. Manufacturers offer cutting-edge solutions to customize pipes according to specific requirements, ensuring a perfect fit for every project. From seamless welding to intricate bending techniques, these services guarantee top-notch quality and performance.

Advanced machining technologies are employed to shape Hastelloy C276 pipes with utmost accuracy and efficiency. Whether it's drilling, threading, or shaping complex designs, these services cater to a wide range of industrial needs. With strict adherence to industry standards, Alloy C-276 pipe processing ensures optimal functionality in challenging environments.

Alloy C-276 Pipe Chemical Composition

Alloy C-276 pipe is renowned for its exceptional chemical composition. This high-performance nickel-molybdenum-chromium alloy contains significant amounts of nickel, ensuring superior corrosion resistance in various environments. Molybdenum and chromium add to its overall strength and durability, making it a top choice for demanding applications.

Additionally, the presence of tungsten enhances the alloy's resistance to pitting and crevice corrosion. The low carbon content minimizes carbide precipitation during welding, maintaining the material's corrosion-resistant properties. With precise control over elements like iron and cobalt, Alloy C-276 pipe offers unmatched reliability in challenging industrial settings.

Characteristics of C-276 Nickel Pipe

Hastelloy C276 nickel pipe is renowned for its exceptional corrosion resistance in a variety of harsh environments. This high-performance alloy can withstand corrosive substances like sulfuric acid, hydrochloric acid, and chlorine without succumbing to degradation. Its versatility extends to both acidic and non-acidic conditions, making it a top choice for industries where corrosion is a concern.

Additionally, the C276 nickel pipe boasts impressive mechanical properties that contribute to its durability and longevity. With high tensile strength and excellent fabricability, this alloy can be easily formed into various shapes and sizes for different applications. Its ability to maintain structural integrity under extreme temperatures further enhances its reliability in demanding settings.

Furthermore, Hastelloy C276 exhibits superior resistance to stress-corrosion cracking and pitting, ensuring prolonged service life even in challenging operating environments. This makes it an ideal choice for critical applications where performance under pressure is crucial. The combination of these characteristics solidifies Hastelloy C276 as a go-to material for industries requiring dependable corrosion resistance and mechanical strength.

Applications of C-276 Nickel Pipe

Hastelloy C276 pipe is a versatile material widely used in various industries due to its exceptional corrosion resistance and durability. In the chemical processing industry, C-276 nickel pipe is utilized for handling corrosive chemicals such as sulfuric acid, acetic acid, and chlorine gas without degradation or leakage.

Moreover, in the aerospace sector, Hastelloy C276 pipe plays a crucial role in aircraft components where high-strength materials are required to withstand extreme conditions. Its ability to resist pitting, crevice corrosion, and stress corrosion cracking makes it an ideal choice for critical applications in aerospace engineering.

Additionally, the pharmaceutical and oil & gas industries rely on C-276 nickel pipe for its reliability in conveying aggressive fluids while maintaining product purity. From reactors to heat exchangers, this alloy offers unparalleled performance across a wide range of demanding environments.

Alloy C276 Tubing Product Specifications

When it comes to Hastelloy C276 tubing, the product specifications are crucial. This alloy is known for its exceptional resistance to a wide range of corrosive environments, making it ideal for various applications. The tubing typically comes in different sizes and thicknesses to meet specific project requirements.

Hastelloy C276 tubing is available in seamless and welded forms, providing flexibility in design and installation. The material composition ensures high strength and durability while maintaining excellent corrosion resistance properties. These tubes can withstand extreme temperatures and pressures, making them suitable for demanding industrial settings.

Whether used in chemical processing plants or aerospace engineering projects, Alloy C276 tubing offers reliability and performance that meets stringent industry standards. Its versatility extends to diverse applications where superior corrosion resistance and mechanical strength are essential for long-term operational success.

Corrosion Resistance and Mechanical Properties of Hastelloy C276

Hastelloy C276 is renowned for its exceptional corrosion resistance in a wide range of aggressive environments. Whether facing acidic solutions, seawater, or high-temperature gases, this alloy stands strong. The ability to resist pitting and crevice corrosion makes it a top choice for industries where reliability is paramount.

Moreover, the mechanical properties of Hastelloy C276 pipe are equally impressive. With high tensile strength and excellent fabricability, this alloy can withstand extreme conditions without compromising on performance. Its superior ductility allows for easy forming and shaping to meet specific project requirements.

In essence, the combination of outstanding corrosion resistance and robust mechanical properties makes Hastelloy C276 a versatile solution for various industrial applications where durability and longevity are essential factors to consider.

Fabrication and Welding with Hastelloy C-276

Hastelloy C-276 pipe and tubing offer exceptional versatility across various industries, from chemical processing to aerospace. With its superior corrosion resistance, mechanical properties, and ease of fabrication and welding, it has become a go-to choice for demanding applications where reliability is paramount. Whether you need a reliable material for handling aggressive chemicals or requiring high-temperature strength in extreme environments, Hastelloy C-276 stands out as a top performer. Consider this alloy for your next project where performance and durability are non-negotiable factors.

0 notes

Text

Hastelloy X Round Bars Manufacturers in India

Omkar Metal Corporation distinguishes itself as a reputable provider and distributor of Hastelloy X round bars within the metallurgical sector. Our steadfast dedication is evident in our extensive array of sizes and configurations, spanning from minuscule 0.5mm diameters to substantial 500mm variants, boasting lengths of up to 6 meters. As your dependable outlet for alloy X rods, we take pride in furnishing top-tier round bar products at competitive prices.

As an ISO-certified entity, our manufacturing processes prioritize precision, harnessing cutting-edge technology to fabricate Hastelloy UNS N06002 bars with unparalleled accuracy. The widespread acclaim garnered by our Hastelloy X bars can be attributed to their exceptional corrosion resistance, mechanical robustness, weldability, cost-effectiveness, and outstanding physical attributes. Additionally, explore our repertoire of offerings, including Hastelloy C276 round bars.

ASTM B572 Alloy X Bars find extensive utilization across a myriad of global sectors, ranging from petrochemical facilities to nuclear power installations. Its adaptability in high-temperature settings, such as aerospace components and pharmaceutical applications, underscores its broad-spectrum utility. Our inventory encompasses Hastelloy X rods across round, square, and hexagonal configurations.

At Omkar Metal Corporation, our primary focus revolves around delivering premium-grade rods with tailored customization options. Should you require personalized AMS 5754 round bars, our seasoned professionals stand ready to offer expert guidance tailored to your specific requisites.

As a reputable hastelloy round bar supplier based in India, entrust Omkar Metal Corporation with all your round bar needs. Engage with us by clicking here or directly reach out via email at [email protected].

UNS N06002 round bars are meticulously crafted through the amalgamation of various metals, including nickel, chromium, molybdenum, tungsten, and iron. This distinctive chemical composition imparts exceptional resilience in harsh environments, affording formidable corrosion resistance against acids, chlorine, and oxidizing agents.

0 notes

Text

HASTELLOY C276 PLATES PROPERTIES, CHARACTERISTICS, AND APPLICATIONS

Hastelloy C276 Plates is a high-performance, nickel-based alloy widely used in various industries due to its excellent properties and characteristics. It is known for its superior corrosion resistance, especially in highly corrosive environments. In this blog post, we will explore the properties, different characteristics, and applications of Hastelloy C276 Plates in detail.

WHAT ARE HASTELLOY C276 PLATES?

Hastelloy C276 Plates are an alloy commonly used in the chemical industry and engineering applications due to their high resistance to both corrosion and oxidation. The composition of this alloy includes nickel, molybdenum, chromium, tungsten, manganese, iron and cobalt. This combination gives it excellent resistance to various corrosive materials, even under extreme temperatures. It has outstanding formability, weldability, and machinability, making it a popular choice for many components, from pipelines to tanks.

PROPERTIES OF HASTELLOY C276 PLATES

Hastelloy C276 Plates comprise a combination of nickel, molybdenum, and chromium, lends them unique physical properties. It has fantastic corrosion resistance in oxidizing and reducing environments, making it an excellent choice for chemical and petrochemical industries. It also exhibits exceptional heat resistance and maintains its strength up to temperatures of 1900°F. The overall combination of these properties makes Hastelloy C276 Plates an excellent choice for high-stress environments and use in fabrication.

CHARACTERISTICS OF HASTELLOY C276 PLATES

Hastelloy C276 Plates offer outstanding characteristics, making it the go-to choice for most industrial applications. It is highly resistant to corrosion cracking, pitting, and crevice corrosion, ensuring an extended lifespan. It is also cold-formable and weldable. Hastelloy C276 Plates are immune to chloride-induced stress corrosion cracking, making them the ideal choice for use in marine environments. In addition, it is an excellent choice for gaseous environments due to its resistance to hydrogen chloride and chlorine dioxide gas.

APPLICATIONS OF HASTELLOY C276 PLATES

Hastelloy C276 Plates are widely used across various industries due to their excellent corrosion resistance. Some common applications include chemical processing, oil and gas production, marine environments, pollution control, and pulp and paper production. Due to its exceptional resistance to corrosive environments, it is also used in manufacturing reactors, heat exchangers, and pipes for chemical and petrochemical industries.

ADVANTAGES OF USING HASTELLOY C276 PLATES

The various advantages of using Hastelloy C276 Plates are as follows:

• It has excellent resistance to corrosion in both oxidizing and reducing environments.

• It offers superior strength to higher temperatures, making it a reliable choice in high-stress environments.

• It can be cold-formed, rolled, and welded while retaining strength and quality.

• It is immune to stress corrosion cracking in marine environments.

CONCLUSION

Hastelloy C276 Plates are the most reliable nickel-based alloy in the market, widely used in various industries due to their superior properties and characteristics. Its excellent corrosion-resistant properties, strength, and heat resistance make it a top choice for use in various industrial applications. So, if you are looking for an alloy that can withstand highly corrosive environments, Hastelloy C276 Plates should be your first choice.

To Know More: https://www.smmindustriesllp.com/hastelloy-c276-plates-properties-characteristics-applications/

0 notes

Text

Dependable performance in challenging conditions with the help of Inconel 625 fasteners

Hot forged fasteners manufacturer in India to satisfy various industrial requirements. To create high-quality fasteners, these producers use cutting-edge forging techniques and rigorous adherence to quality standards.

For large or customised requirements, purchasing your preferred Inconel 625 fasteners straight from the manufacturer is a good option. Not every manufacturer, meanwhile, is able to provide medium-volume customised fasteners. For instance, Werkstoff 2.4856 flat washers typically have a two-week lead time. It may take 15 to 20 days for delivery. These bolts' and the 625 Inconel dowel pins' temperature tolerance are advantageous for engineering applications as well. Their resistivity and fabricability accommodate a range of requirements.

For all of our components, we use precise dimensional tolerance and premium production techniques. The Mill Test Certificates (MTCs) for Hastelloy C276 fastener bolts display the quality profile, which includes the chemical composition, mechanical attributes, and tests carried out. Additionally, it lists the product's standards—in this example, an ASTM F468 UNS N10276 threaded rod. A radiography report and a raw materials certificate are examples of additional paperwork. Buyers have the option to commission a third-party inspection or request certain tests.For all of our components, we use precise dimensional tolerance and premium production techniques. The Mill Test Certificates (MTCs) for Hastelloy C276 fastener bolts display the quality profile, which includes the chemical composition, mechanical attributes, and tests carried out.

Titanium fasteners manufacturer in India Extreme temperatures are no match for this material's solid reputation of withstanding embrittlement. Industrial customers can select the screw, bolt, rod, stud, and other design that best fits their requirements. Ti alloy washers are also used in oil refineries, chemical processing, defence, and related fields. They are extremely important for dental equipment and tooth implants due to their inherent biocompatibility.Extreme temperatures are no match for this material's solid reputation of withstanding embrittlement.

A popular and adaptable grade of stainless steel pipe, stainless steel 304 pipe is For pipe fittings, producers usually select one of the following production processes: The process of forging involves heating, forming, and machining the raw material into the necessary forms and sizes. Larger fittings are better suited for open-die forging, whereas intricate components are better suited for closed-die forging.

Hastelloy C276 flanges have many benefits that make them necessary. Good resistance to corrosion (pitting, intergranular corrosion, stress-induced cracking, and crevice corrosion) Because of the low carbon content, it is easily machined. Cutting is simple and doesn't generate excessive heat. heightened power Good formability and ductility oxidation-resistant up to 1250°C.

These nickel-copper flanges are strong, resistant to corrosion, and suitable for a range of temperatures. Monel 400 flanges are utilised in the presence of corrosive media and exhibit exceptional strength. One of the main goals is to withstand saltwater (which moves quickly) and hydrofluoric acid, an abrasive substance that can be difficult to control. Typically, these flanges are utilised in maritime applications and petroleum processing.

0 notes

Text

How to select the Right ASTM B574 C276 Hastelloy Wire?

In the realm of commercial engineering, precision is paramount. From critical packages in aerospace to demanding strategies in chemical manufacturing, the choice of the proper substances can make all the distinction. Hastelloy c276 filler wire suppliers, renowned for its extraordinary corrosion resistance and mechanical energy, stands as a pinnacle cloth in various industries. When it comes to selecting the correct ASTM B574 C276 Hastelloy cord, meticulous consideration is fundamental. Let's delve into the important thing elements to guide you on this crucial decision-making procedure.

Understanding ASTM B574 C276 Hastelloy Wire

Astm b574 c276 hastelloy wire units the usual for nickel-molybdenum-chromium alloy wires, including Hastelloy C276. This specification guarantees that the cord meets stringent requirements for chemical composition, mechanical residences, and dimensional tolerances, making sure premier performance in diverse applications.

Factors to Consider When Selecting Hastelloy C276 Wire

1. Application Requirements

Corrosive Environment: Assess the specific corrosive dealers and conditions the cord will encounter, making sure compatibility with the supposed surroundings.

Temperature Range:Consider the working temperature variety to ensure the twine keeps its mechanical houses under thermal pressure.

Mechanical Strength: Evaluate the mechanical load and stress necessities to pick a wire with the right tensile electricity and ductility.

2. Quality and Compliance

ASTM B574 Compliance: Verify that the Hastelloy wire meets the specs mentioned in ASTM B574, ensuring adherence to industry standards and rules.

Certifications: Look for certifications and fine assurance measures from legit providers, providing warranty of product exceptional and compliance.

3. Supplier Reliability

Reputation: Choose a supplier regarded for reliability and best, making sure constant performance of the wire.

Stock Availability: Ensure the dealer maintains good enough stock stages to fulfill your on the spot and future requirements, minimizing lead instances and downtime.

Elevate Your Operations

Selecting the right ASTM B574 C276 nickel alloy c276 filler wires is pivotal for accomplishing excellence and reliability in your operations. With meticulous attention to detail and attention to key factors, you could make certain the success of your initiatives and programs. Remember, precision isn't always only a requirement but a dedication to excellence.

Partnering for Excellence

In the journey closer to excellence, collaboration is fundamental. At MV Super Alloys, we view our customers as companions, running hand in hand to attain mutual achievement. We consider building long-lasting relationships primarily based on agreement, integrity, and a shared dedication to quality. When you select MV Super Alloys as your associate, you benefit more than only a supplier – you benefit a group devoted to your fulfillment. Together, let's increase your operations to new heights of precision, reliability, and excellence.

Conclusion

In the search for perfection, each decision matters. Trust within the understanding of your supplier and the pleasantness of the materials they provide. With the right ASTM B574 C276 hastelloy c276 filler wire stockist, sourced from a dependable dealer, you can embark on your projects with confidence, knowing which you have the assist and basis for fulfillment.

#astm b574 c276 hastelloy wire#hastelloy c276 filler wire suppliers#hastelloy c276 filler wire stockist#nickel alloy c276 filler wires

0 notes

Text

Fabricate with Confidence: High-Performance Hastelloy C276 Round Bars

Hastelloy C276 round bars are well-known for their outstanding performance in challenging conditions. Whether in corrosive chemical settings or high-temperature applications, these alloys stand out for their reliability and durability.

Introduction to Hastelloy C276 Round Bars

Hastelloy C276 round bar belongs to a family of nickel-molybdenum-chromium superalloys known for their versatility in harsh conditions. Engineered to withstand extreme temperatures and resist corrosion, these bars are vital components in various industrial sectors.

Properties of Hastelloy C276 Alloy

Corrosion Resistance

Hastelloy C276 shows exceptional resistance against various corrosive substances, including both oxidizing and reducing environments. This property makes it ideal for applications where exposure to acids, salts, and solvents is common.

High-Temperature Performance

Hastelloy C276 retains its mechanical strength even at high temperatures, with a melting point surpassing 1300°C. This attribute ensures stability and reliability in environments where heat endurance is crucial.

Mechanical Strength

The alloy's high mechanical strength enables it to withstand intense pressures and stresses without compromising structural integrity. This makes the Hastelloy C276 round bar suitable for critical load-bearing applications.

Applications of Hastelloy C276 Round Bars

Aerospace Industry

In aerospace engineering, Hastelloy round bars are utilized in structural components and engine parts due to their lightweight nature and superior corrosion resistance.

Chemical Processing

Chemical plants rely on Hastelloy C276 round bar for equipment exposed to corrosive chemicals, ensuring longevity and safety in operations.

Oil and Gas Sector

In the oil and gas industry, where harsh drilling conditions prevail, these round bars are used in downhole tools and pipelines, offering protection against corrosive fluids and gases.

Manufacturing Processes of Hastelloy C276 Round Bars

Alloy Composition

Hastelloy C276 round bar are composed of nickel, molybdenum, and chromium, combined in precise proportions to achieve optimal performance characteristics.

Melting and Casting

The alloy is melted in a controlled environment and cast into billets or ingots, which are subsequently hot worked into round bars of varying diameters.

Hot and Cold Working

Hastelloy C276 round bars undergo hot forging and cold drawing processes to refine their structure and enhance mechanical properties, ensuring uniformity and durability.

Comparison with Other Alloys

Hastelloy C276 vs. Inconel Alloys

Unlike Inconel alloys, Hastelloy C276 offers superior resistance to a broader range of corrosive chemicals, making it preferred in aggressive industrial environments.

Hastelloy C276 vs. Stainless Steel

Compared to stainless steel, Hastelloy C276 provides better performance in highly corrosive conditions and at elevated temperatures, making it a cost-effective choice for critical applications.

Quality Standards and Certifications

ASTM Specifications

Hastelloy C276 round bars adhere to ASTM B574/B575 standards, ensuring consistent quality and performance in various applications.

ISO Certifications

Manufacturers of Hastelloy round bars comply with ISO 9001 standards, demonstrating their commitment to quality management and customer satisfaction.

Factors to Consider When Choosing Hastelloy C276 Round Bars

Environmental Factors

Evaluate the operating environment's temperature, pressure, and chemical exposure to determine if Hastelloy round bars are suitable for the application.

Cost Considerations

While initially more expensive than some alternatives, the Hastelloy C276 round bar offers long-term cost savings due to its durability and minimal maintenance requirements.

Maintenance and Care Tips

Cleaning Procedures

Clean Hastelloy C276 round bar regularly using mild soaps and non-abrasive materials to preserve their corrosion-resistant properties and aesthetic appeal.

Storage Recommendations

Store Hastelloy round bars in a dry, ventilated area away from corrosive substances to prevent surface damage and maintain their integrity over time.

Future Trends in Hastelloy C276 Round Bar

Research and Development

Ongoing research aims to enhance Hastelloy C276's properties further, potentially expanding its applications in emerging industries and challenging environments.

Innovations in Alloy Design

Advancements in alloy design may lead to new formulations of Hastelloy round bars with enhanced mechanical strength and improved resistance to specific chemicals.

Conclusion

In conclusion, Hastelloy C276 round bars are indispensable in industries requiring robust, corrosion-resistant materials capable of withstanding extreme conditions. Their superior performance, coupled with ongoing advancements in alloy technology, ensures they remain at the forefront of engineering solutions.

#Hastelloy C276 Round Bars#Hastelloy C276 Round Bars Supplier#Hastelloy C276 Round Bars Exporter#Hastelloy C276 Round Bars Manufacturer in India#Stainless Steel 422 Bright Bars#Stainless Steel 316L Round Bars#Stainless Steel 304 Round Bars#Stainless Steel 446 Round Bars#Super Duplex Steel UNS S32760 Round Bars#Monel 400 Round Bars#Inconel 600 Round Bars#Stainless Steel 446 Tubes#Stainless Steel 446 Sheets and Plates

0 notes

Photo

"Hastelloy C-276 Round Bar."

Alloy C276 welding products are used as matching composition filler material for welding C276 alloy wrought and cast products, for dissimilar welding applications including other nickel-chromium-molybdenum alloys and stainless steels, and for weld overlay or cladding of steels. Alloy C-276 (UNS N10276) is an austenitic nickel-molybdenum- chromium alloy with a small addition of tungsten. It is one of the premier corrosion resistant materials available for process industries. Alloy C-276 has excellent corrosion resistance in both oxidizing and reducing environments and Bhansali Enterprise is one of the leading manufacturers and distributors of Hastelloy alloys and other steel products that offers you with the widest range and finest quality products at the most competitive pricing.

#hastelloy composition#hastelloy c276 chemical composition#steel companies of india#steel industries in india#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#hastelloy c276#manufacturer of stainless steel in india

0 notes

Text

Hastelloy C-276

Hastelloy C-276

C276 alloys are widely used in chemical and petrochemical fields, such as in components and catalytic systems that are exposed to chlorinated organics. This material is especially suitable for use in high temperature, inorganic and organic acids (such as formic acid and acetic acid) mixed with impurities, and seawater corrosion environment.

Chemical composition

Alloy % Nickel chromium molybdenum iron tungsten cobalt carbon manganese silicon vanadium phosphorus sulfur

Ha C Minimum allowance 14.5 15 4 3

Max 16.5 17 7 4.5 2.5 0.08 1 1 0.35 0.04 0.03

C276 Minimum Margin 14.5 15 4 3

Max 16.5 17 7 4.5 2.5 0.01 1 0.08 0.35 0.04 0.03

peculiarity

1. In oxidation and reduction state, it has excellent corrosion resistance to most corrosive media.

2. Excellent resistance to spot corrosion, crevice corrosion and stress corrosion cracking.

Metallographic structure of HastelloyC-276

C276 has a face-centered cubic lattice structure.

Corrosion resistance of HastelloyC-276

C276 alloys are suitable for a variety of chemical process industries containing oxidizing and reducing media. The high content of molybdenum and chromium make the alloy resistant to chloride ions, and the tungsten element further improves its corrosion resistance. C276 is one of the only materials that can resist the corrosion of humid chlorine, hypochlorite and chlorine dioxide solutions, and the alloy has significant corrosion resistance to high concentrations of salt chloride solutions (such as ferric chloride and copper chloride).

HastelloyC-276 Application range Application areas are:

C276 alloys are widely used in chemical and petrochemical fields, such as in components and catalytic systems that are exposed to chlorinated organics. This material is especially suitable for use in high temperature, inorganic and organic acids (such as formic acid and acetic acid) mixed with impurities, and seawater corrosion environment.

Other application areas

1. Pulp and paper industry, such as boiling and bleaching containers

2. Scrubber, reheater, wet steam fan in FGD system

3. Equipment and components operating in acidic gas environments

4. Reactor for acetic acid and acidic products

5. Sulfuric acid condenser

6. Methylene diphenyl isocyanate (MDI)

7. Production and processing of impure phosphoric acid

0 notes