#Heating Polyester Yarn

Explore tagged Tumblr posts

Text

Heating Polyester Yarn

Heating Polyester Yarn Specification

30-500D/36-576F

Test standard: GB/30127-2013 Test index: Far infrared emissivity ≥ 0.88 Far infrared radiation temperature rise ≥ 1.7 ° C

Measured value: far infrared emissivity is 0.92/far infrared radiation temperature rise 2.6 ° C

Application fields:bed sheets,underwear,down jacket,socks

Contact us Email: [email protected] Tel: 86-57585510907

0 notes

Text

That is the very high-end, luxury cotton

Sea Island Yarn

Sea Island Yarn is usually a high-end, luxury yarn manufactured from the extra-long staple fibers belonging to the Gossypium barbadense cotton plant that is grown exclusively for the West Indies islands. The long, silky fibers on this special cotton are prized therefore to their strength, luster, along with softness. They are sometimes blended with other fibers for instance silk or cashmere to generate even more high quality textiles.

In the hands of any skilled spinner, that silky fiber can easily yield exquisitely good, cool-to-the-touch fabrics along with yarns. Fine lawns as well as handkerchief cottons are among the most used and recognizable products of the special variety with cotton. 36-576F Heating Polyester Yarn Manufacturers This type of cotton is used to make heirloom quality cargo area linens and clothing along with other fine fabric goods for instance handbags and gloves.

The heirloom quality of this sort of cotton is on account of several factors, most of all the exceptionally much time staple lengths belonging to the plant. The regular staple length connected with Sea Island cotton is 4. 26 inches, which is over twice providing the average staple time-span of other commercial cotton varieties. The particular longer fibers generate the cotton a lot easier to spin, plus the resulting yarn will be smoother and stronger than some others of cotton.

Longer staple plans also reduce how much twist in that resulting yarn, and also this produces a smoother plus much more silky finish. Which allows the yarn to be easily dyed in addition to gives it a nice sheen that some others of cotton are not able to match.

Sea Island cotton is a very rare commodity, which is only available in small quantities by several growers around the globe. The quality on this specialty cotton is so outstanding that it is a sought after diet material for high-end manner and apparel brands, manufacturers of high class linens, and other producers of extravagance textiles.

In truth, this type regarding cotton is coveted a whole lot that it is actually protected under this trademark laws connected with some countries. Additionally it is highly regulated to ensure the proper raising practices are adopted, and that only the best possible examples of this special different cotton are used in the production of Sea Island Yarn.

That is the very high-end, luxury cotton that is certainly often sold throughout blends with other fibers to form higher-end products, and it really is quite expensive. But to the dedicated knitter who will be willing to spend the amount of money on this pretty special and rare kind of cotton, it is often worth the expense.

If you choose to try this exquisite yarn by yourself, we are pleased to make available it at Inventive Ewe. Enter the value VeryPink at checkout to be handed a 25% discount on your own order of just about any of our Sea Island yarns in the end of February.

0 notes

Text

HEY guess what you can do with wool? That's right!

DYE IT

With food coloring and kool-aid!! And also acid dyes, which are designed for this, but acid dyes can't be used with cookware you put food in, and Kool-Aid packets are 50 cents.

.. did they go up in price? Didn't they used to be 20 cents? Anyway

Tbh a big part of the allure of spinning my own yarn is dying either the fibers or the final product. I just like the sense of independence that comes from going "ah, I need a color, and I have a lot of white and a handful of dyes!". I did this a lot with my posable critters too, though acrylic and polyester are a lot more strict about what dyes will actually work.

(Though tbh? Soaking acrylic faux fur in watered down acrylic paint, waiting for it to dry, and then taking a slicker brush and brushing out the clumps will get you pretty far!)

The evidence of crimes past with that paint permanently on there. I think this fucker is almost old enough to make its own Tumblr account (but not in Australia 8()

I digress! Because I haven't been dyeing acrylic, but KERATIN!

I did actually try dyeing a chunk with the same semi-permanant magenta dye I use on my own hair, cos like. Hair is also keratin.

Actually, it was supposed to be a bisexual gradient from pink to blue, but when it came time to heat set the color, the manic panic blue just fucking vanished.

Lesson learned: Ion Color Brilliance is a good brand, Manic Panic is not.

My bestie has inquired about me spinning the yarn and knitting them a scarf, so I wanted to make what was basically a mockup of the different ways you can spin the fibers to get different colors effects. And also I got Kool-Aid this past grocery visit and have been chomping at the bit to use it.

@sivilityy enables me <3

BEHOLD, MY CHILDREN!

Dyeing wool with kool-aid or food coloring is very easy!

Step 1: Soak wool in warm to hot water with about a 1/3rd of a cup of white vinegar for 15 to 45min. The vinegar is a mordant, something that helps the fibers take up the dye.

Step 2: Mix your dye of choice into a pot of warm to hot water, close in temperature to the soaking bath. The more kool-aid or food coloring, the stronger the color. I was going for pastels, so I used half a pack for the blue and pink, and a single drop of yellow food coloring for the yellow. The purple... 8') We won't talk about the purple.

Step 3: Fish your wool out of its soak, give it a gentle squeeze, then plop it into the pot. I like to scoop out some of the vinegar water and pour it into the pot as well. For insurance!

Step 4: Heat your pot to just below boiling. You want steam, but little to no bubbles. Agitation + heat or sudden temperature changes = felt. You can't spin felt. If you want to to make felt, though, now you know.

Step 5: leave your wool at simmering for around 30 min. How do you know when its done?

it fucking sucks all the color out of the water. How sick is that?! In the few batches I've done, I haven't always gotten it to be clear like that but don't stress it. About 30 min seems to be good even if there's still some color in the water.

Turn off the burner and let your creations cool down in their soup. Or, if you're impatient like me, run your hottest tap water into a different pot, then pour your wool into the slightly cooler but still hot water, so it doesn't get a HUGE temperature shock. Don't use cold water, or you're gonna get felt! Give em a rinse in the hot water to get any extra color out.

Let 'em hang and dry, and you're done!

So far all of mine have felted a little bit? Which hasn't been so bad, I've just needed to fluff them up a little once they're dry. I want to try indirect heat with a steamer basket and see if that helps, but I only got the one basket and 4 colors this time, so I used the pots.

SCIENCE

#Technically art#Hey butters how is chapter 19 coming along#*flips water pitcher* YARN#If you want to try this yourself please look up a tutorial that wasn't written on a phone on Tumblr#I haven't skipped any steps but I didn't elaborate as much as I could have#Tbh I just wanted to show off how the color got complete sucked out of the water#But then my Adderall kicked in

17 notes

·

View notes

Text

SO! You might be wondering what I've been doing while I was on hiatus! Outside of working, of course. That one is a given.

Well, I haven't really been writing, unfortunately. I have, of course, been continuing to post Stolen Child. Decided I'm going to do a double update on the 8th to celebrate getting older.

Mainly thought?

I have been going absolutely crazy dyeing yarn!

I've been shifting back into a natural dye phase, as I do from time to time, and was bemoaning the fact I don't really use wool yarn much (wool moths? In my house? ...just a couple...) and that most of the knitting Mum and I do these days is for a charity that doesn't insists on using synthetic yarns anyway because they need something warm - which cotton, silk, and such aren't - and will not give the poor kids with wool allergies a massive rash when suddenly it hit me!

I have a cupboard full of RitDyemore that I got for dyeing dolls, synthetic wigs, etc!

I CAN DYE SYNTHETIC YARN!

Along with allowing me to make colours that just aren't popular in stores at the moment (I guess green is out?), I can dye various types of yarn colours that they normally just...aren't! Ombré metallics! Jewel toned baby yarn! TIE DYE!

Needless to say I was very shortly at JoAnn selecting things to play with. I went with Big Twist, because Mum is going to be the one working with this, and she likes that brand. Then I added Big Twist Metallic, because I like shiny things, Bernat Pipsqueak, because I like soft things, and Caron Simply Soft, because really nice finish! I wanted to try Lionbrand Re-Spun, but they didn't have any in parchment, which is the closest they get to white. Bummer. Have to try that later.

Some of my more interesting findings are as follows:

They all took the dye nicely, but varied in which colours they absorbed from the bath!

The Pipsqueak tended to dye duller colours than the others, although they could still be nice and strong.

While the Pipsqueak (100% Polyester) retained it's super soft, fluffy texture when dyed, the acrylic yarns would up feeling like cotton? Not a bad thing, but kind of interesting. It's obviously something to do with the heat required for using Dyemore.

Getting a super even dye job is near impossible. There are too many factors that result in light patches. The good news is that the variation makes the yarn more interesting!

I have found multiple ways to make ombré and other variegated yarn. They are all fun. I think my favorite is to ball the yarn and then dye it.

Tie dyeing yarn does not work like you'd think it would! Basically the places where the yarn is tied are white, but they don't scrunch the surrounding strands together enough to cause fading or spidering or anything like that...which is ironic since not getting dye between the strands is one of the things that causes uneven dyeing and light spots? The end result is yarn with random white speckles through it, which is still super cool! (See the dark blue-green hank of Pipsqueak)

And that's what I've got for now! Most of these have been exhaust dyed (I've dyed multiple batches in the same dye bath, so they get progressively lighter), with the occasional variation. I'm planning on getting another skein of the Big Twist Metallic and just exhaust dyeing the entire thing with the same formula to see how consistent I can get. And, of course, hoping for some parchment Re-Spun. It'll be very interesting to see what the texture does on that one, given that is also 100% Polyester, but not fluffy and recycled. Does it make a difference?

...and definitely more variegated yarns in the future! Hands down my favorite!

And I have some wool, so I can play with natural dyes!

#diy#yarn#yarn dyeing#big twist yarn#pipsqueak yarn#simply soft yarn#rit dye#rit dyemore#hand dyed yarn

4 notes

·

View notes

Text

Exploring the Cost Dynamics: Non-Woven Fabric vs. Traditional Woven Fabric

Non-woven fabric has emerged as a popular choice in various industries due to its versatility, durability, and cost-effectiveness. As a leading provider of fabric solutions, Mavazi Fabrics understands the importance of cost considerations for our clients. In this article, we'll explore how the cost of non woven fabric manufacturer

compares to traditional woven fabric and the factors that influence this comparison.

1. Production Process

One of the primary factors influencing the cost of non woven fabric manufactureris the production process. Non-woven fabrics are manufactured using a process that does not involve weaving or knitting yarns together. Instead, fibers are bonded together mechanically, chemically, or thermally. This results in a simpler and more streamlined manufacturing process compared to traditional woven fabric, which requires yarn spinning, weaving, and finishing. The reduced complexity of the production process often translates to lower production costs for non woven fabric manufacturer.

2. Raw Material Costs

The cost of raw materials also plays a significant role in determining the overall cost of non-woven fabric. Non-woven fabrics can be made from a variety of materials, including natural fibers such as cotton and wool, synthetic fibers such as polyester and polypropylene, and recycled materials. The availability and cost of these raw materials can vary depending on factors such as market demand, production capacity, and geographical location. In general, non woven fabric manufacturer made from synthetic fibers tend to be more cost-effective compared to those made from natural fibers.

3. Labor Costs

Labor costs are another important consideration when comparing the cost of non woven fabric manufacturer to traditional woven fabric. Non-woven fabric manufacturing typically requires less labor compared to weaving or knitting processes. This is because non-woven fabrics can be produced using automated machinery and require fewer manual interventions. As a result, labor costs associated with non woven fabric manufacturer production are often lower, contributing to overall cost savings.

4. Energy Consumption

Energy consumption during the manufacturing process is another factor that influences the cost of non-woven fabric. Non-woven fabric production generally requires less energy compared to traditional weaving or knitting processes. This is because non-woven fabric manufacturing involves fewer mechanical motions and heating processes. As a result, non woven fabric manufacturer production can be more energy-efficient, leading to lower operating costs and reduced environmental impact.

5. Customization and Versatility

Non-woven fabrics offer greater customization and versatility compared to traditional woven fabrics. They can be engineered to meet specific performance requirements, such as strength, absorbency, and filtration efficiency. This customization capability allows non-woven fabric manufacturers to tailor their products to the unique needs of their clients, potentially adding value and justifying higher costs compared to traditional woven fabrics.

In conclusion, the cost of non woven fabric manufacturer compared to traditional woven fabric depends on various factors, including the production process, raw material costs, labor costs, energy consumption, and customization capabilities. While non-woven fabrics often offer cost advantages due to their simpler production process and lower labor and energy costs, the final cost comparison may vary depending on specific requirements and market conditions. As a trusted provider of fabric solutions, Mavazi Fabrics offers a wide range of non-woven fabrics tailored to meet the diverse needs of our clients while ensuring cost-effectiveness and quality.

#nonwovenfabric#manufacturer#fabricengineer#innovativematerials#textileindustry#sustainableproducts#technicaltextiles#manufacturingexcellence#madeinUSA#materialsourcing#productionprocesses#ecofriendlytechnology#qualityassurance#industrialmaterials#textiledesigns#nonwovenmaterials#advancedmanufacturing#productionefficiency#environmentallyfriendlyinfos .

2 notes

·

View notes

Text

Joe Burrow Shirt, Vintage Joe Burrow T-Shirt, Joe Burrow Football Shirt

Important Notes: 1/ Please note that the mockup images and product titles displayed are for illustrative purposes only. We offer a diverse range of custom products, and it is crucial for customers to select the appropriate shirt style based on their specific requirements. 2/ If you want to wear oversized, please up to 1-2 sizes. 3/ We have many other colors. Please contact us directly for advice. We also have Gildan, Bella Canvas and Comfort Colors fabric. * Color of Comfort Colors Fabric: Army, Azalea, Banana, Bay, Berry, Blue Jean, Carolia Blue, Chalky Mint, Charcoal, Forest, Granite, Grape, Graphite, Gray, Heliconia, Hemp, Hot Pink, Ice Blue, Ivory, Kelly, Lavender, Light Green, Lime, Maroon, Moss, Natural, Peachy, Pepper, Royal Caribe, Sandstone, Sapphire, Texas Orange, Turquoise, Violet, Washed Denim, Water Melon **Color of Bella Canvas fabric: Heather Red, Lilac, Heather, Orange, Berry, Heather Maroon, Cherry Red, Cardinal, Olive, Natural, Chestnut, Pink,Storm, Silver, Mauve, Aqua, Army, Asphalt, Atlantic, Autumn, Baby Blue, Brown, Burnt Orange, Canvas Red, Charity Pink, Citron, Clay, Columbia Blue, Cool Blue, Coral, Dark Lavender, Dark Olive, Deep Teal, Dust, Dusty Blue, Electric Blue, Evergreen, Fuchsia, Kelly, Lavender Blue, Lavender Dust. MATERIALS: *Gildan Unisex Shirt GL5000: – 99% cotton (fiber content may vary for different colors) – Medium fabric (5.3 oz/yd² (180 g/m²)) – Classic fit – Tear-away label – Runs true to size *Gildan Sweatshirt GL 18000: – 50% Cotton 50% Polyester Runs true to size – 50% cotton: Made with special yarn spun into a very durable and smooth fabric, perfect for printing – 50% Polyester: Extremely strong polyester yarn, resistant to most chemicals, stretching and shrinking. Viscose added Pleated and soft great for shirts *Gildan Unisex Hoodie GL 18500: – 50% cotton, 50% polyester – Medium-heavy fabric (8.0 oz/yd² (271 g/m²)) – Classic fit – Tear-away label – Runs true to size Tank Top Unisex: – 99% Airlume combed and ring-spun cotton (fiber content may vary for different colors) – Extra Light fabric (3.8 oz/yd² (110 g/m²)) – Retail fit – Sewn in label – Runs true to size Youth T-Shirt: - 5.3 oz./yd² (US) 8.8 oz./L yd (CA), 100% cotton, 20 singles - Ash Grey is 99/1 cotton/polyester - Sport Grey is 90/10 cotton/polyester - Dark Heather, Graphite Heather, Heather, Neon & Safety Colors are 50/50 cotton/polyester - Safety Green is compliant with ANSI / ISEA 107 high-visibility standards - Classic fit - Classic width, rib collar - Taped neck and shoulders for comfort and durability - Tear away label - CPSIA Tracking Label Compliant - Proud member of the U.S. Cotton Trust Protocol - Made with OEKO-TEX certified low-impact dyes Youth Sweatshirt: - 8 oz./yd² (US) 13.3 oz./L yd (CA), 50/50 cotton/polyester, 20 singles - Classic fit - 1x1 rib with spandex for enhanced stretch and recovery - Tear away label - CPSIA Tracking Label Compliant - Proud member of the U.S. Cotton Trust Protocol - Made with OEKO-TEX certified low-impact dyes. Youth Hoodie: - 8 oz./yd² (US) 13.5 oz./L yd (CA), 50/50 cotton/polyester, 20 singles - Heather colors are 60/40 polyester/cotton - Classic fit - Double-lined hood - 1 x 1 rib with spandex for enhanced stretch and recovery - Pouch pocket - Tear away label - CPSIA Tracking Label Compliant - Proud member of the U.S. Cotton Trust Protocol - Made with OEKO-TEX certified low-impact dyes CARE INSTRUCTIONS: – Machine wash in cold water – Do not use bleach – Tumble dry low – Iron on low heat with shirt inside-out – Never iron directly over design EXCHANGE POLICY : Due to the custom nature of our products, unless the item arrives damaged or defective due to printing errors. We do not accept returns or exchanges that: – Customers do not clearly mention the customization requirements. – Customers set wrong sizes and styles (Every item is custom printed on demand as you order them. Please be sure to check size charts and measurements for the best fit. ) Should you need assistance please contact us prior to purchasing so that we can help you achieve that perfect fit. We are always happy (and quick!) to help answer any sizing and fit questions you may have CARE INSTRUCTIONS: – Machine wash in cold water – Do not use bleach – Tumble dry low – Iron on low heat with shirt inside-out – Never iron directly over design EXCHANGE POLICY ( please read carefully!) Due to the custom nature of our products, unless the item arrives damaged or defective due to printing errors. We do not accept returns or exchanges that: – Customers do not clearly mention the customization requirements. – Customers set wrong sizes and styles (Every item is custom printed on demand as you order them. Please be sure to check size charts and measurements for the best fit. ) Should you need assistance please contact us prior to purchasing so that we can help you achieve that perfect fit. We are always happy (and quick!) to help answer any sizing and fit questions you may have Read the full article

4 notes

·

View notes

Text

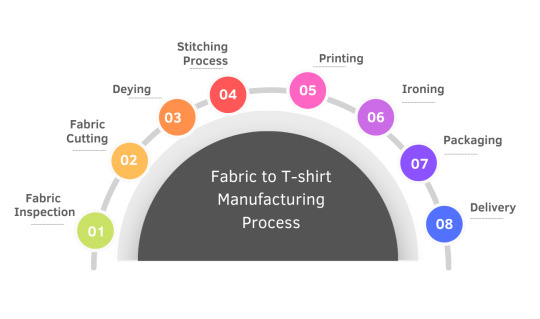

Have you wonder how a t-shirt is manufactured? Learn about t-shirt manufacturing process

The first t-shirt was manufactured in 1920. There are a huge variety of t-shirts manufactured all around the world starting with different types of neckband such as crew neck, V-neck, scoop neck and tank top. There are variations in sleeves such as full sleeves, half sleeves, capped, raglan and yoked. Raw materials used in the t-shirt manufacturing process are cotton and polyester. The neckband is made with a fabric named twill. A particular thread is used for stitching and sewing.

T-shirt Manufacturing Process

Cotton Farming: T-shirt manufacturing process starts from procuring cottons from farmers. Cottons are then converted into bales and transported to Ginning mills.

Ginning Mill: This is the place where cotton fiber and cotton seeds are separated. The cotton fiber is then used in manufacturing garments and cotton seeds are used in manufacturing vegetable oil.

Spinning : The cotton fibers are now separated and in this unit they are cleaned and cotton yarns are made out of it. Spinning unit involves many steps starting with Blow room → Combing → Carding → Drawing → Roving → Spinning.

Dyeing: The yarn is dyed using three dyeing processes: package dyeing, hank dyeing and warp dyeing. Package dyeing is the most popular dyeing process where yarn rolls are heated together with dye inorder to dye the yarn.

Knitting: Yarn enters the knitting machine as a raw material. There are various yarn inserted into the circular knitting machine, various yarn are intertwined together to make a sheet of fabric.

Inspection: Once the fabric is purchased by a garment manufacturer it is inspected by them in order to check any defectiveness or to check any shade variation. If the shade variation is found the cutting process is done accordingly.

Cutting: Many layers of the fabric are stacked together in this process and then using a bend knife cutting machine they are cut into different dimensions like front, back, sleeves, neckband and pocket if any.

Stitching: Different dimensions of fabric are stitched in this step using 2 methods of stitching overlock and superimposed. First front and back part are stitched then sleeves then neckband and at last the hem of the t-shirt.

Printing: Printing is done to the t-shirt to make it stylish. There are several types of printing. Screen-printing, digital printing, heat embossing and spray printing. Then these bulk printed t-shirts are transferred to the stitching department.

Finishing: This process is divided into 2 parts. Firstly, t-shirts are ironed in order to give it a finishing and appealing look and secondly, the tagging and packaging takes place. Then wholesalers and retailers offered to buy t-shirts in bulk.

#textile#textiles#dyeing#pattern#fiber art#fiber#fabric#knitting#sewing#patterns#business#clothing#manufacturing

2 notes

·

View notes

Text

Women's 4" Endurance Pro Running Shorts: The Ultimate Fusion of Performance, Comfort & Style

Discover the Women's 4" Endurance Pro Running Shorts: featuring breathable, moisture-wicking fabric, built-in boy shorts, reflective design, and ample pockets. Ideal for runners seeking unmatched comfort and performance.

Introduction: Why the Right Running Shorts Matter

For serious runners and everyday joggers alike, the gear you wear can significantly influence your comfort, confidence, and performance. That's why choosing the right running shorts isn't just a matter of style—it's about functionality, fit, and innovation. The Women's 4" Endurance Pro Running Shorts stand out as a premium choice, carefully crafted for athletes who expect more from their apparel. These shorts combine cutting-edge fabric technology, ergonomic design, and thoughtful features that elevate your running experience.

Whether you're training for your next race, enjoying a morning jog, or heading into a high-intensity workout, these shorts offer the breathability, support, and versatility you need. Let’s dive into why they are a must-have in your activewear collection.

Section 1: Design & Fabric Breakdown

The Women's 4" Endurance Pro Running Shorts are made from 100% high-performance polyester, renowned for its lightweight feel and durability. The fabric has been carefully selected to offer:

Moisture-wicking capabilities to keep you dry during long runs.

Anti-static properties to reduce cling and enhance comfort.

Ultra-light feel that doesn’t weigh you down, even in humid weather.

In addition to the outer shell, the shorts include a mesh inner lining that enhances airflow while preventing chafing. The built-in boy shorts layer adds an extra level of support and modesty, giving you the freedom to move without distractions.

The 4-inch inseam provides the perfect balance of coverage and mobility, ideal for runners who prefer moderate-length shorts that don’t interfere with stride length or leg movement.

Section 2: Moisture-Wicking & Breathability Technology

One of the key features of these shorts is the integration of advanced moisture-wicking technology. Sweat is a natural part of every workout, but staying drenched is neither comfortable nor hygienic. That’s why these shorts use a hydrophobic polyester yarn that draws moisture away from your skin and releases it through the fabric’s outer surface.

Coupled with the mesh crotch panel, this fabric enhances breathability in critical sweat zones. As a result, airflow is maximized, temperature is regulated, and your skin remains dry even during intense exercise sessions.

Additionally, these features make the shorts suitable not just for running, but also for cycling, HIIT, and gym workouts—any activity where heat and sweat buildup can affect performance.

Section 3: Built-In Boy Shorts Advantage

Built-in boy shorts offer more than just modesty—they provide critical anti-chafing protection and enhanced muscle support. Unlike generic liner shorts, the boy shorts in the Endurance Pro are:

Made from breathable, stretchable fabric that moves with your body.

Designed to reduce skin-on-skin friction.

Cut for anatomical fit, reducing bunching or rolling.

The result is a smooth, secure feel that empowers you to move without adjustments. Whether you're doing sprints, running trails, or stretching post-run, the inner shorts offer consistent comfort and protection.

Section 4: Pocket Power: Storage for Runners

Storage is one of the most requested features by women runners, and the Endurance Pro delivers with 5 built-in pockets:

Three power mesh waistband pockets — perfect for gels, keys, or cards.

Two hidden inner lining pockets — secure enough to hold your phone or earbuds.

These storage options allow you to head out without a running belt or backpack. The pockets are thoughtfully placed to prevent bounce and eliminate the need for extra gear, giving you a streamlined silhouette and a distraction-free run.

Section 5: Reflective Design for Night & Low-Light Safety

Running doesn’t always happen in broad daylight. That’s why the reflective accents on the Endurance Pro shorts enhance visibility during low-light conditions. Strategically placed, these reflective elements catch headlights and street lamps, increasing your safety without sacrificing aesthetics.

For runners who train before dawn or after dusk, this feature could be a game-changer, offering peace of mind and an extra layer of protection.

Section 6: Fit, Waistband & Elastic Design

A secure yet flexible waistband is key to uninterrupted performance. The elasticated waistband on these shorts provides a snug fit without digging into your skin. It’s soft, supportive, and maintains shape even after multiple washes.

Combined with the lightweight construction and ergonomic stitching, the fit accommodates different body shapes and running styles. There’s no riding up, slipping down, or awkward adjustments needed.

Section 7: Perfect for All Types of Runners

Whether you’re a beginner logging your first 5K or a seasoned marathoner, the Endurance Pro shorts adapt to your performance needs. Their versatility makes them suitable for:

Road running

Trail running

Treadmill workouts

Cross-training and yoga

Their practical design also makes them an excellent travel companion—comfortable enough to wear for airport travel, hikes, or casual athleisure styling.

Section 8: Styling, Color Options & Versatility

With a range of vibrant and neutral colors, these shorts pair effortlessly with tanks, sports bras, or oversized tees. Whether you’re going for a minimalist look or a bold style statement, there’s a shade that matches your vibe.

Their clean silhouette also makes them a favorite for casual wear—just add sneakers and a hoodie for a post-run coffee or errand run.

Section 9: Customer Testimonials & Use Cases

Customers consistently praise the Endurance Pro shorts for their:

Flattering fit

Breathable design

Game-changing pocket setup

Stylish yet functional look

Use cases range from early morning runners to college athletes, busy moms fitting in a quick jog, or weekend warriors hitting the trail.

Section 10: Why It Outperforms Other Brands

While many running shorts offer either performance or comfort, the Endurance Pro delivers both. Compared to brands like Nike, Adidas, or local generic options, these shorts stand out for their:

Double-layer design

Functional pocket placement

Reflective safety features

Premium-quality polyester

All this comes at a competitive price point, with no compromise on quality.

Section 11: Care Instructions, Fabric Longevity & Sustainability

Caring for your shorts is easy:

Machine wash cold

Do not bleach

Line dry

Avoid fabric softeners

The durable construction ensures the shorts maintain their form and function even after repeated washes. Made with sustainable practices, the production process minimizes water waste and energy consumption, aligning with eco-conscious values.

Section 12: Call-to-Action + FAQ

Ready to elevate your run?

Shop the Women’s 4" Endurance Pro Running Shorts today and feel the difference in every stride. Whether you're pushing your pace or enjoying a recovery jog, these shorts move with you.

FAQs:

Are the boy shorts detachable? No, they are built-in for enhanced support.

Can I use them for gym workouts? Absolutely. They're perfect for various workouts.

Do they stretch over time? The waistband retains elasticity even with frequent use.

Conclusion

In the world of women’s running gear, the Endurance Pro 4" Shorts set a new standard. Built for breathability, designed for real runners, and tailored for versatility—this is your next running essential.

SHOP HERE!

#running gear#running apparel#workout outfit#gym outfit#activewear#running#marathon runner#fitness#gym#running clothing

0 notes

Text

Dreamy Handwoven Fringe Throw

Construction Handwoven of 95% acrylic and 5% polyester. Yarn-dyed fiber has incredibly rich color that holds its vibrancy over time. OEKO-TEX® STANDARD 100: tested for 1000+ harmful substances to keep you and your family safe. 14.HUS.42449 HOHENSTEIN HTTI. Imported. Care Machine wash in cold water, gentle cycle. Use only non-chlorine bleach, as needed. Tumble dry, low heat; remove promptly. Do…

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] SOBBY microfiber car cleaning cloth designed with AA-Grade Microfiber Yarn (The Best Available) , which are super softer and ultra-absorbent than other towels. The soft microfiber used in this cloth is super absorbent and made to trap dirt, grime, and other particles. Absorbs water more & faster and dries faster than cotton, Safe for all hard surfaces. This microfiber cleaning cloth is safe for all finishes and surfaces! Cleans fine automobile finishes, glass, stone, television & other delicate surfaces without worrying or leaving messy streaks behind. The offered micro fibre clothes for car cleaning holds up to 8 times their weight in water, making it great for wet washing with or without cleaning products. Use then dry to dust, polish, or buff as per the specific application needs. It Removes Dust And Dirt Like Magnet Without Chemical. So It Is Best Recommended For Wet and Dry Washing . Material : Microfibre cloth are made from 80% Polyester and 20% Polyamide Which makes it highly absorbent and perfect material for cleaning. Usage : Floor Cleaning, Home cleaning, Dusting , wiping dishes, Cleaning Slab, counter, Car cleaning, detailing & polishing, Bathroom cleaning, window, clean electronics gadgets like laptop, led tv screen, mobile phone, camera lens etc. Size : 40 cm x 60 cm (16 In x 24 In) Approx, Colour : Assorted Colours, Thickness : 350 GSM Approx (each cloth weigh 85 Grams Approx) Features : 1. Strong water absorption 2. Durable and lint-free 3. Easy washing and quick-dry 4. No bad smell 5. Soft and breathable Care instructions : 1. Wash it before initial use is highly recommended for best result 2. Use separate cloth for wet and dry wash. 3. Dry with normal heat. 4. Store cloth in a dust free area. 5. Do not iron. 6. Don't use any fabric softener when washing. Hand-wash and machine-wash both are ok. [ad_2]

0 notes

Text

This balaclava may make you forget what you look like This men's thermal ski hat combines innovative thermochromic yarn technology, which can gradually change from a calm and low-key dark color to a warm and vibrant bright color in the cold wind, adding a dynamic aesthetic to winter sports. The integrated hooded design with a detachable mask can fully fit the head, neck and face, effectively resist the wind and cold, and the ventilation system can be quickly opened according to needs. The hat body is made of polyester and spandex blended knitted fabric, with excellent four-way elasticity, and can easily fit a variety of head shapes. Multifunctional wearing method: It can be flexibly switched as a neck cover, mask or integrated hood, suitable for skiing, cycling, mountaineering and urban outdoor scenes, combining functionality and fashion.

https://www.alibaba.com/product-detail/Top-Hot-Fashion-Heat-Reactive-Style_1601403968097.html?spm=a2747.product_manager.0.0.179471d2PPjYpm

1 note

·

View note

Text

Borana Weaves IPO: Price band set at ₹205–216 per share; check issue details, key dates, more

Borana Weaves IPO: Borana Weaves IPO will open for subscription on May 20 at a price band of ₹205 to ₹216 per share. The company plans to use IPO proceeds for a new manufacturing facility and working capital, with listing expected on May 27.

Borana Weaves IPO: Borana Weaves IPO price band has been fixed in the range of ₹205 to ₹216 per equity share of the face value of ₹10 for its upcoming public issue. Borana Weaves IPO date of subscription is from Tuesday, May 20 to Thursday, May 22. The allocation to anchor investors for Borana Weaves IPO is scheduled to take place on Monday, May 19.

The IPO floor price is 20.5 times the face value of the equity shares, and the cap price is 21.6 times the face value of the equity shares. The price-to-earnings ratio based on diluted EPS for fiscal 2024 at the lower end of the price band is 17.33 times, and at the upper end of the price band is 18.26 times.

Investors can apply for Borana Weaves IPO in a lot size of 69 equity shares, and in multiples thereafter.

Borana Weaves IPO has reserved not less than 75% of the shares in the public issue for qualified institutional buyers (QIB), not more than 15% for non-institutional investors (NII), and not more than 10% of the offer is reserved for retail investors.

Tentatively, Borana Weaves IPO basis of allotment of shares will be finalised on Friday, May 23, and the company will initiate refunds on Monday, May 26, while the shares will be credited to the demat account of allottees on the same day following the refund. Borana Weaves share price is likely to list on BSE and NSE on Tuesday, May 27.

About Borana Weaves

Borana Weaves Limited is a producer of unbleached synthetic grey fabric located in Surat, Gujarat. The company’s unbleached synthetic grey fabric is commonly utilised as a foundation for additional processing (including dyeing and printing) in sectors such as fashion, traditional textiles, technical textiles, home decor, and interior design.

Additionally, the firm produces polyester textured yarn (PTY Yarn), which is made by heating polyester oriented yarn (POY Yarn), the raw material used in creating grey fabric.

Borana Weaves Limited operates three manufacturing facilities in Surat, Gujarat, that are equipped with textile manufacturing technologies for various processes, including texturising, warping, operating water jet looms, and folding textiles.

As of September 30, 2024, the company had 15 operational texturising machines, 6 warping machines, 700 water jet looms, and 10 folding machines in its three facilities.

According to the red herring prospectus (RHP), there are no listed industry competitors in India or overseas, which could pose challenges in comparing and assessing their financial performance against other firms within the same sector.

Borana Weaves has shown impressive growth over the last three fiscal years. In FY 2024, the company disclosed revenue of ₹199.10 crore, representing a significant rise from ₹135.40 crore in FY 2023 and ₹42.30 crore in FY 2022.

Borana Weaves IPO details

Borana Weaves IPO, which is worth ₹144.89 crore, comprises of fresh issue of 67,08,000 equity shares. There’s no offer-for-sale (OFS) component.

Borana Weaves IPO objective is to use the net proceeds from the offering for several purposes, including financing the establishment of a new manufacturing facility to enhance its production capacity for grey fabric in Surat, Gujarat, India; providing additional working capital; and covering general corporate needs.

Beeline Capital Advisors Pvt Ltd serves as the book-running lead manager for Borana Weaves IPO, and Kfin Technologies Limited acts as the registrar for this offering.

“Investments in the securities market are subject to market risks.”

Intensify Research services is a SEBI registered Research analyst Indore committed to empowering investors with the most reliable stock market insights. Our team of expert analysts uses advanced tools and strategies to provide that enhance your chances of success. To visit- Intensifyresearch.com »

1 note

·

View note

Text

Understanding Textured Yarn and BCF Yarns in Simple Words

When you hear the term Textured Yarn, you might think of softness, stretch, or comfort. And if you're into carpets or upholstery, you’ve likely come across BCF Yarns too. So what exactly are they, and why are they important?

Let’s break it down.

What is Textured Yarn?

Textured Yarn is a type of yarn that’s been processed to create a specific texture—usually to make it bulkier, stretchier, or softer. These yarns are mostly made from synthetic fibers like polyester, nylon, or polypropylene.

Through processes like crimping, twisting, and heat-setting, the smooth synthetic filaments are turned into more natural-looking, stretchable yarns. This makes textured yarn perfect for clothing, sportswear, and home furnishings.

Some benefits of textured yarn:

Increased softness and comfort

Better elasticity

Improved moisture-wicking

Enhanced insulation properties

What are BCF Yarns?

BCF Yarns, or Bulk Continuous Filament yarns, are long continuous filaments that are bulked using heat or air to add volume. These yarns are ideal for heavy-duty applications, especially in carpets and rugs.

Unlike staple fibers (short lengths), BCF yarns are continuous, meaning they don’t shed or fuzz easily. That makes them highly durable and low-maintenance—perfect for commercial and residential carpeting.

Common uses of BCF yarns:

Wall-to-wall carpets

Carpet tiles

Automotive carpets

Rugs and mats

Textured Yarn vs. BCF Yarns: What’s the Difference?

While both involve bulked or processed synthetic fibers, textured yarns are typically used in apparel and soft furnishings, focusing on comfort and flexibility. On the other hand, BCF yarns are engineered for performance, especially in flooring, thanks to their strength and continuous structure.

Why Do These Yarns Matter?

From sportswear to carpets, both textured yarn and BCF yarns play a major role in how we live and feel. The texture, durability, and function of a product often come down to the type of yarn used.

0 notes

Text

How Geo Bag Manufacturers Ensure Quality and Strength Standards

In civil engineering, environmental protection, and infrastructure development, geo bags play a critical role in preventing soil erosion, reinforcing riverbanks, and protecting coastal areas. These durable, high-performance bags are often used in highly sensitive and high-risk projects where failure is not an option. As a result, maintaining the highest standards of quality and strength is a top priority for every reputable Geo Bag Manufacturer.

In this article, we explore how geo bag manufacturers ensure that their products meet rigorous industry standards, perform in challenging environments, and deliver long-term results.

Understanding the Role of Geo Bags

Before diving into the quality aspect, it’s important to understand what geo bags are. These are specially engineered textile bags, typically made from woven or non-woven synthetic fabrics like polypropylene or polyester. Geo bags are filled with sand or other materials and used in erosion control, flood protection, land reclamation, and slope stabilization.

Given the environmental conditions they are exposed to—such as heavy rainfall, strong currents, UV radiation, and physical stress—it is crucial that every Geo Bag Manufacturer focuses on durability, strength, and reliability.

1. Material Selection and Sourcing

High-quality geo bags begin with high-quality raw materials. Manufacturers typically use UV-stabilized, high-tenacity synthetic fibers like polypropylene (PP) or polyester (PET). These materials are known for their resistance to chemicals, abrasion, and UV degradation.

A trustworthy Geo Bag Manufacturer will always source certified raw materials from reputable suppliers. The chosen material should have a high tensile strength, elongation capacity, and puncture resistance—qualities essential for field performance.

2. Precision in Weaving and Fabrication

The manufacturing process itself greatly affects the performance of geo bags. For woven geo bags, the weaving density and yarn quality are critical factors. For non-woven bags, the bonding process and fabric uniformity are essential.

Advanced manufacturing facilities use automated looms, heat cutters, and precision stitching machines to ensure consistent quality. Stitching techniques, such as double-lock or chain stitches, are employed to prevent seam failures under pressure. This level of precision ensures that every bag produced by the Geo Bag Manufacturer meets the required dimensional and mechanical standards.

3. In-House Testing and Quality Control

A top-tier Geo Bag Manufacturer will always have an in-house laboratory or tie-ups with accredited testing agencies to conduct rigorous quality checks. These tests include:

Tensile Strength Test: To assess the fabric’s ability to withstand pulling forces.

Puncture Resistance Test: To ensure the fabric resists sharp objects and tearing.

UV Resistance Test: To verify the fabric’s ability to withstand prolonged sun exposure without degradation.

Burst Strength Test: To evaluate the seam strength and bag integrity under pressure.

Water Permeability Test: Especially for applications where controlled drainage is required.

All results are benchmarked against global standards such as ASTM, ISO, or BIS, ensuring reliability and compliance.

4. Customization for Project-Specific Needs

Every project is unique, and so are its demands. Reputable geo bag manufacturers work closely with engineers, project managers, and procurement teams to understand load conditions, environmental factors, and application goals. Based on this input, manufacturers provide customized solutions in terms of size, weight capacity, coating, and seam design.

This tailored approach not only enhances performance but also ensures long-term durability in harsh field conditions.

5. Certifications and Compliance

Another key quality indicator is the set of certifications a Geo Bag Manufacturer holds. Compliance with ISO 9001 for quality management, ISO 14001 for environmental management, and industry-specific standards helps establish credibility. Many public and private sector projects also mandate third-party testing and documentation, further ensuring that the products meet international benchmarks.

Final Thoughts

In projects where the stakes are high—whether it’s preventing a landslide or protecting a coastline—there is no room for compromise. A reliable Geo Bag Manufacturer understands this and integrates quality at every stage, from material selection to final testing. By choosing a manufacturer committed to high standards, you ensure that your infrastructure or environmental project has the robust foundation it needs to withstand nature’s challenges and deliver long-term performance.

0 notes

Text

Joe Burrow tshirt, Joe Burrow Comfort Colors T-Shirt

Important Notes: 1/ Please note that the mockup images and product titles displayed are for illustrative purposes only. We offer a diverse range of custom products, and it is crucial for customers to select the appropriate shirt style based on their specific requirements. 2/ If you want to wear oversized, please up to 1-2 sizes. 3/ We have many other colors. Please contact us directly for advice. We also have Gildan, Bella Canvas and Comfort Colors fabric. * Color of Comfort Colors Fabric: Army, Azalea, Banana, Bay, Berry, Blue Jean, Carolia Blue, Chalky Mint, Charcoal, Forest, Granite, Grape, Graphite, Gray, Heliconia, Hemp, Hot Pink, Ice Blue, Ivory, Kelly, Lavender, Light Green, Lime, Maroon, Moss, Natural, Peachy, Pepper, Royal Caribe, Sandstone, Sapphire, Texas Orange, Turquoise, Violet, Washed Denim, Water Melon **Color of Bella Canvas fabric: Heather Red, Lilac, Heather, Orange, Berry, Heather Maroon, Cherry Red, Cardinal, Olive, Natural, Chestnut, Pink,Storm, Silver, Mauve, Aqua, Army, Asphalt, Atlantic, Autumn, Baby Blue, Brown, Burnt Orange, Canvas Red, Charity Pink, Citron, Clay, Columbia Blue, Cool Blue, Coral, Dark Lavender, Dark Olive, Deep Teal, Dust, Dusty Blue, Electric Blue, Evergreen, Fuchsia, Kelly, Lavender Blue, Lavender Dust. MATERIALS: *Gildan Unisex Shirt GL5000: – 99% cotton (fiber content may vary for different colors) – Medium fabric (5.3 oz/yd² (180 g/m²)) – Classic fit – Tear-away label – Runs true to size *Gildan Sweatshirt GL 18000: – 50% Cotton 50% Polyester Runs true to size – 50% cotton: Made with special yarn spun into a very durable and smooth fabric, perfect for printing – 50% Polyester: Extremely strong polyester yarn, resistant to most chemicals, stretching and shrinking. Viscose added Pleated and soft great for shirts *Gildan Unisex Hoodie GL 18500: – 50% cotton, 50% polyester – Medium-heavy fabric (8.0 oz/yd² (271 g/m²)) – Classic fit – Tear-away label – Runs true to size Tank Top Unisex: – 99% Airlume combed and ring-spun cotton (fiber content may vary for different colors) – Extra Light fabric (3.8 oz/yd² (110 g/m²)) – Retail fit – Sewn in label – Runs true to size Youth T-Shirt: - 5.3 oz./yd² (US) 8.8 oz./L yd (CA), 100% cotton, 20 singles - Ash Grey is 99/1 cotton/polyester - Sport Grey is 90/10 cotton/polyester - Dark Heather, Graphite Heather, Heather, Neon & Safety Colors are 50/50 cotton/polyester - Safety Green is compliant with ANSI / ISEA 107 high-visibility standards - Classic fit - Classic width, rib collar - Taped neck and shoulders for comfort and durability - Tear away label - CPSIA Tracking Label Compliant - Proud member of the U.S. Cotton Trust Protocol - Made with OEKO-TEX certified low-impact dyes Youth Sweatshirt: - 8 oz./yd² (US) 13.3 oz./L yd (CA), 50/50 cotton/polyester, 20 singles - Classic fit - 1x1 rib with spandex for enhanced stretch and recovery - Tear away label - CPSIA Tracking Label Compliant - Proud member of the U.S. Cotton Trust Protocol - Made with OEKO-TEX certified low-impact dyes. Youth Hoodie: - 8 oz./yd² (US) 13.5 oz./L yd (CA), 50/50 cotton/polyester, 20 singles - Heather colors are 60/40 polyester/cotton - Classic fit - Double-lined hood - 1 x 1 rib with spandex for enhanced stretch and recovery - Pouch pocket - Tear away label - CPSIA Tracking Label Compliant - Proud member of the U.S. Cotton Trust Protocol - Made with OEKO-TEX certified low-impact dyes CARE INSTRUCTIONS: – Machine wash in cold water – Do not use bleach – Tumble dry low – Iron on low heat with shirt inside-out – Never iron directly over design EXCHANGE POLICY : Due to the custom nature of our products, unless the item arrives damaged or defective due to printing errors. We do not accept returns or exchanges that: – Customers do not clearly mention the customization requirements. – Customers set wrong sizes and styles (Every item is custom printed on demand as you order them. Please be sure to check size charts and measurements for the best fit. ) Should you need assistance please contact us prior to purchasing so that we can help you achieve that perfect fit. We are always happy (and quick!) to help answer any sizing and fit questions you may have CARE INSTRUCTIONS: – Machine wash in cold water – Do not use bleach – Tumble dry low – Iron on low heat with shirt inside-out – Never iron directly over design EXCHANGE POLICY ( please read carefully!) Due to the custom nature of our products, unless the item arrives damaged or defective due to printing errors. We do not accept returns or exchanges that: – Customers do not clearly mention the customization requirements. – Customers set wrong sizes and styles (Every item is custom printed on demand as you order them. Please be sure to check size charts and measurements for the best fit. ) Should you need assistance please contact us prior to purchasing so that we can help you achieve that perfect fit. We are always happy (and quick!) to help answer any sizing and fit questions you may have Read the full article

2 notes

·

View notes

Text

The Science Behind Nonwoven Textiles: How Innovation Shapes the Industry

Nonwoven textiles might not grab headlines, but they’re central to how modern infrastructure quietly operates. These materials skip the loom altogether—no weaving, no knitting—just fibers aligned, bonded, and pressed into forms that serve everything from hospital masks to highway underlayers. This post outlines the technical and industrial dynamics at play in nonwoven textiles, their historical backdrop, and where the science is heading next.

Understanding Nonwoven Textiles

Think of nonwoven textiles as engineered mats. Instead of looping yarns over and under, these fabrics come from fibers—synthetic or natural—that are bonded together through mechanical force, thermal processing, or chemical bonding. It’s an industrial shortcut that’s anything but crude. These fabrics are engineered for performance: filtration efficiency, moisture control, tensile strength, and more.

Common fibers include polypropylene, polyester, and biopolymers, each selected depending on what the final product needs to achieve. The alignment of fibers—randomized for softness or directional for strength—also affects the final structure. Bonding completes the process. Whether via heat, resin, or physical entanglement, this stage locks the web into a usable material.

Historical Context and Evolution

The commercial rise of nonwoven textiles kicked off in the mid-20th century, largely tied to wartime material innovation and the postwar consumer boom. With synthetic polymers like nylon and polyester becoming more accessible, industries started looking beyond weaving for high-volume, disposable materials.

Technologies like meltblown and spunbond enabled finer control of fiber size and layering. This meant products like surgical masks or geotextiles became not just feasible but reliable. Nonwoven products evolved from being disposable conveniences to industrial components with specialized functionality.

Fiber Selection and Material Science

Everything in nonwoven performance begins at the fiber level. Polypropylene is cheap and hydrophobic, ideal for hygiene applications. Polyester brings strength and thermal resistance. Cellulose-derived fibers like viscose add absorbency and are compostable under specific conditions.

Recent advances include fibers with intricate cross-sections, smaller diameters for higher surface area, or dual-polymer structures that respond to stimuli like heat or moisture. With sustainability under the microscope, materials like PLA (derived from corn) and lyocell are emerging in the mix. But these come with trade-offs in cost, strength, and compatibility with existing manufacturing lines.

Fabrication Techniques and Technologies

Dry-laid methods rely on mechanically aligning and layering fibers, which are then bonded. Wet-laid systems suspend fibers in water before draining and drying them into sheets. Spunbond and meltblown involve polymer extrusion, with fibers laid down directly from molten streams—ideal for fast, scalable production.

Needle punching uses barbed needles to physically tangle the fibers into a cohesive sheet. While it’s not as fast as spunbonding, it’s great for thicker, more durable products like automotive insulation or protective underlays. Composite methods like SMS (spunbond-meltblown-spunbond) combine strengths of each system.

Functional Enhancements and Applications

Most nonwovens get post-treatment. Want it waterproof? Hydrophobic coating. Need antimicrobial properties? Add a silver-based finish. Specific use cases drive these decisions. A crop cover needs UV resistance; a face mask needs breathability and filtration.

Applications span sectors. Hospitals use them for gowns and drapes. Construction integrates them into roofs and drainage systems. In agriculture, they’re laid across soil for weed suppression and microclimate control. They even show up in fashion—think disposable shoes or eco-tote alternatives. What unifies all of this is engineered performance, not aesthetics.

Environmental Considerations and Sustainability

Environmental critique of nonwovens tends to focus on their disposability. Most are petroleum-based and not easily recyclable. But change is underway. Biopolymers like PLA are entering the space, especially where composting infrastructure exists.

Recycling is tricky but not impossible. Post-industrial waste is already being reintegrated into production. For consumer waste, solutions are still in early stages. Energy and water usage are also areas of concern, particularly in thermal bonding and water-intensive wet-laid methods. Life Cycle Assessments are increasingly used to guide better material and process choices.

Market Dynamics and Industry Structure

The industry is global and segmented. Some companies handle everything from polymer sourcing to finished rolls. Others specialize in one part—say, filtration media or medical-grade fabrics. North America, Europe, and Asia-Pacific dominate production, but demand is rising in Latin America and Africa.

COVID-19 temporarily reoriented global capacity toward PPE. Post-pandemic, demand is shifting back toward hygiene, filtration, and construction, with a sharper eye on quality and environmental impact. Intellectual property—especially around fiber structure and machinery—is a differentiator. Compliance standards like ISO and ASTM govern product acceptability in regulated markets.

Innovation in Needle Punch Technology

Needle punching hasn’t stood still. Modern systems allow precise control over needle depth, density, and web layering. This enables products with varying textures and performance zones—one layer might resist compression, another might insulate.

Recycled content is increasingly incorporated without compromising quality, thanks to improved fiber handling and web formation controls. While not suited for lightweight applications, needle-punched products remain vital where structure and reuse matter more than breathability or thinness.

The Role of Advanced Manufacturing

Digitization is now integral. Automated systems monitor temperature, humidity, line speed, and bond strength in real-time. Predictive maintenance tools flag wear before breakdowns. Digital twins—virtual replicas of manufacturing systems—enable scenario testing without disrupting output.

Traceability platforms help companies meet regulatory standards and reassure clients. They also support small-batch customization, which is becoming more viable as brands seek specialized materials. The non woven textile manufacturers leading this charge are setting a new bar for process sophistication.

Emerging Frontiers in Material Development

Material innovation is heading toward multifunctionality. Smart textiles embed sensors or conductive threads into nonwovens for health tracking or temperature response. Nanofibers allow new levels of breathability and filtration. Hybridization—mixing synthetic and biodegradable fibers—is also gaining ground.

Sustainability is not just a moral stance but a product spec. That’s reshaping the manufacturing of non woven fabric. Cross-functional R&D teams are working on everything from enzyme-degradable polymers to solvent-free bonding techniques.

Final Notes

Nonwovens are neither glamorous nor new. But their quiet adaptability and scientific depth make them one of the most relevant industrial materials of our time. If the future of materials is smart, responsive, and sustainable, nonwovens are already halfway there.

0 notes