#High Speed Mixer Machine

Explore tagged Tumblr posts

Text

High Speed Mixer Machine Manufacturer

High Speed Mixer Machine https://www.invoitplast.com/granules-mixer-machine/plastic/high-speed-mixer-machine/ Application Of High Speed Mixer Machine: To manufacture any Plastic components or product it is must require that plastic raw material will be moisture free to eliminate the defects like black dots, pins, holes etc in final component or product. So to eliminate this problems we’ve designed the best solution for that which is High Speed Mixer machine.

It is also used to preheat the raw material like LD , PVC, EWA, HDPE etc before inserting into Extrusion process. Industries Cattered : Blown film plant, Lamination Plant, Packaging Industries, PVC pipe Plant, HDPE pipe Plant etc.

5 notes

·

View notes

Text

Vertical Glue Mixer: Efficient and Uniform Adhesive Mixing for Plywood Manufacturing

In plywood production, efficiency and precision are the most important factors in ensuring high-quality board production. One of the most crucial elements in this production is the Vertical Glue Mixer—a revolution in uniform adhesive mixing for better plywood bonding. If what you're searching for is an advanced glue mixing technology that maximizes productivity and reduces waste, this futuristic machine is a production-line essential.

Why a Vertical Glue Mixer?

A Vertical Glue Mixer is specifically designed to provide homogeneous adhesive mixing for plywood, ensuring a consistent glue spread on veneers. Unlike conventional mixers, a vertical mixer offers better blending, reduced glue wastage, and improved bonding strength, making it a preferred choice for modern plywood factories.

Key Benefits of a Vertical Glue Mixer

1. Superior Mixing Efficiency

Vertical design allows for complete and even blending of adhesives, which creates even viscosity and consistency across the batch. This produces improved plywood adhesion, minimizing defects in the finished product.

2. Economical Glue Use

Effective adhesive dispensing implies that manufacturers can lower the use of glue without affecting the quality, resulting in extensive cost benefits in the long run.

3. Reduced Production Cycle Times

Using a high-speed mixing device, a vertical glue mixer reduces preparation time, enabling production cycles to be completed quickly and output to be maximized.

4. Minimal Maintenance & Longevity

Designed with robust parts and sophisticated automation, these mixers have negligible maintenance needs, making them a sound long-term investment for plywood production.

5. Eco-Friendly Operations

By minimizing glue waste and maximizing adhesive blending efficiency, a Vertical Glue Mixer supports an environmentally friendlier plywood production process with decreased ecological footprint.

Selecting the Most Suitable Vertical Glue Mixer for Your Plywood Operation

In selecting a Vertical Glue Mixer, there are important considerations to make:

✔️ Mixing Capacity – Select a machine in conformity with your volume of production.

✔️ Automation Features – Choose a model with easy-to-use controls for convenient operation.

✔️ Material Compatibility – Use one that can handle different adhesive types for general applications.

✔️ Manufacturer Reputation – Buy equipment from a reputable plywood machinery manufacturer for guaranteed quality.

A Vertical Glue Mixer is an important investment for plywood plant owners who want to improve efficiency, quality, and cost savings. By adopting this performance-intensive adhesive mixing system into your production process, you can achieve smooth operations, better plywood bonding, and increased profitability.

Want to find the ideal Vertical Glue Mixer for your plywood factory? Contact DNH Engineers a renowned manufacturer of plywood machinery and give your production a boost! Visit www.dnhengineers.com for more details.

#In plywood production#efficiency and precision are the most important factors in ensuring high-quality board production. One of the most crucial elements in this#this futuristic machine is a production-line essential.#Why a Vertical Glue Mixer?#A Vertical Glue Mixer is specifically designed to provide homogeneous adhesive mixing for plywood#ensuring a consistent glue spread on veneers. Unlike conventional mixers#a vertical mixer offers better blending#reduced glue wastage#and improved bonding strength#making it a preferred choice for modern plywood factories.#Key Benefits of a Vertical Glue Mixer#1. Superior Mixing Efficiency#Vertical design allows for complete and even blending of adhesives#which creates even viscosity and consistency across the batch. This produces improved plywood adhesion#minimizing defects in the finished product.#2. Economical Glue Use#Effective adhesive dispensing implies that manufacturers can lower the use of glue without affecting the quality#resulting in extensive cost benefits in the long run.#3. Reduced Production Cycle Times#Using a high-speed mixing device#a vertical glue mixer reduces preparation time#enabling production cycles to be completed quickly and output to be maximized.#4. Minimal Maintenance & Longevity#Designed with robust parts and sophisticated automation#these mixers have negligible maintenance needs#making them a sound long-term investment for plywood production.#5. Eco-Friendly Operations#By minimizing glue waste and maximizing adhesive blending efficiency#a Vertical Glue Mixer supports an environmentally friendlier plywood production process with decreased ecological footprint.#Selecting the Most Suitable Vertical Glue Mixer for Your Plywood Operation

0 notes

Text

Laboratory machines play a pivotal role in research, product development, and quality testing across industries. These machines are designed for precision, efficiency, and versatility to meet the unique demands of modern laboratories.

#laboratory machines#types of laboratory machines#laboratory machines benefits#lab attritor mill#lab basket mill#lab ribbon blender#lab high-speed disperser#lab sigma mixer machine#lab mixer

0 notes

Text

JCT Machinery is professional in making high speed disperser, double planetary mixer and triple shaft mixer.

These three high speed dispersion machines can be used in different materials. If you are confused what equipment you need, feel free to contact us, we are pleased to give you advice.

#equipment#machine#industrial#mixer#machinery#chemical#high speed dispersing machine#high speed disperser#double shaft mixer#double planetary mixer#planetary mixer#triple shaft mixer#multifunctional dispersing power mixer#multi shaft mixer#twisted blade mixer

0 notes

Text

Top bread making machine manufacturer & Suppliers | iframachine

IFRA Machine Technology is the go-to choice for businesses looking to enhance their bread production capabilities. bread making machine manufacturers in india, bread making machine manufacturers, bread making machine manufacturers in delhi, bread making machine manufacturer in Haryana,

#bread making machine manufacturers in india#bread making machine manufacturers#bread making machine manufacturers in delhi#bread making machine manufacturer in Haryana#bread machine manufacturer in Haryana#bakery machine manufacturers in india#bakery machine manufacturers in Sonepat#top manufacturers bakery machine in delhi#Automatic Bakery Machine Manufacturers In haryana#commercial bread making machine in delhi#bakery machine manufacturers in delhi#bread loaf run belt conveyor#Top bakery Equipment Suppliers in india#rusk toast making machine#depanner rusk manufacturer in delhi#Tunnel Oven Manufacturers & Suppliers in India#swing baking oven manufacturers in delhi#Stacker Conveyor Manufacturers & Suppliers#rusk feeding conveyor india#Cooling Tunnel Supplier and Exporter#Tray Type Bread Cooling Tunnel Manufacturer#high speed mixer supplier in delhi#high speed slicer machine#dough divider machine manufacturers in delhi#roto rack oven manufacturers in india#bread ms trolley manufacturers in delhi#stainless steel bakery trolley manufacturers in delhi#dough proofing chamber manufacturer & supplier#dough tunnel proving chamber manufacturer in delhi#bakery machines and bakery equipments manufacturers

1 note

·

View note

Text

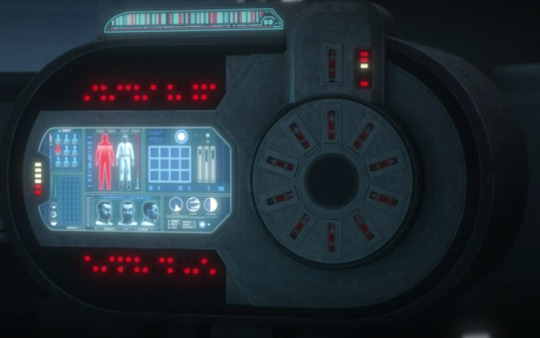

The former bench scientist in me can hold back no longer.

This is not a centrifuge.

A centrifuge spins at an absurdly high rate of speed to separate out samples into fractions. We're talking thousands of RPMs, up to 150k for the ones doing superfine separation. (They also don't, that I've ever encountered or know of, rotate in a vertical plane either, for practical reasons more than anything else, but practicality isn't important in Star Wars so we'll set that aside.)

This is a centrifuge.

What the thing from ep 3 is, is a VERY COOL LOOKING automated mixer and testing platform not unlike our modern day liquid handlers or sequencing machines. Mixers often do come in a clock-style, vertical orientation, especially for small sample tubes, and combining that with a testing platform would make sense in a scifi setting.

No I'm not posting this to correct anyone in particular. I've called it a centrifuge myself because that's what everyone seems to think it is and that's easier to communicate than 'I have used many centrifuges in my day and that's not what this is'. Also because the former allows for a conversation but the later would be a dick thing to whip out when you're trying to vibe with fans about your shared blorbos.

So here is an FYI post instead! It's not a centrifuge. It's a mixer/liquid handler/testing automation machine. I fully acknowledge centrifuge is far easier to say and a word many more people will know. Also that my life experience in this area is a little broad and weirdly applicable to scifi.

80 notes

·

View notes

Text

okay okay yes chef sanji is wonderful but baker sanji. confectioner sanji. think about it.

sanji kneading dough on a saturday morning with his shirtsleeves rolled up to the elbow. he has flour on his cheeks and one of those cute canvas aprons the colour of a brown paper bag with a million pockets and he keeps getting pissed off because strands of his bangs are constantly falling into his face. he makes sourdough and cheesecake and strawberry pavlova and tangerine tarts and dried mango nougat and carrot cupcakes that everybody eyed suspiciously before they actually tried them and now they're a friend group favourite.

he makes monthly batches of those agar-agar edible crystals for vivi's entire family and ships them by the crate to alabasta. he bakes robin and franky's blue raspberry black forest wedding cake. all of the straw hats have multiple packets of his dark chocolate dried fruit and nut and oat yoghurt brittle in their bags at any one time because they're the perfect snack and they're delicious. he makes red bean matcha mochi for zoro because the mosshead can't tolerate anything too sweet.

he has jar upon jar of aromatic infusions on the shelf: vanilla, black pepper, florals, all steeped in liquor to make high-quality extracts that he has gotten MULTIPLE offers to start a business out of, but he always declines because hello. he's busy cooking for straw hats and co.. luffy and fam. he has no time he is a busy busy man and would you look at that chopper's upside-down apple crumble is ready.

usopp makes him all sorts of contraptions, a high-speed blender, a state-of-the-art stand mixer, an ice-cream machine; sometimes if he's feeling lazy he'll go equipment shopping with sanji and just modify whatever they buy. sanji has a toffee hook on the wall of the galley and a very formidable collection of cookie cutters and piping tips. he's managed to make fondant that doesn't taste like utter trash and it's legendary. his salted caramel cashew macadamia popcorn has and will continue to make grown men cry.

but sometimes, he just chucks some charcoal in a pot and plops it in the middle of the dining table with a bowl of chocolate on top and brings out the fruit skewers, or the marshmallows and graham crackers. sometimes they eat rice krispy treats out of the packaging as they huddle together on the lawn and stargaze just because they can. sometimes the almond and dried cranberry combo just can't be beat and sometimes plain toast with butter makes you see god. but you'd best believe the next day he's up and at it again; his sourdough starter's looking more and more like a sentient life form by the hour and he has seven different things going on at once with two more bowls cooling off in the fridge and the oven preheating. i love baker confectioner sanji.

#black leg sanji#sanji#one piece sanji#one piece#strawhat pirates#straw hat pirates#straw hat crew#mugiwara pirates#op sanji#look he's just a silly little candy man okay#he's sweet let him make sweet things#ino writes#more of a braindump than anything else but i love sanji and i want to squish him into a waffle maker.

115 notes

·

View notes

Text

7 Insider Secrets: How Are Cement Bricks & Blocks Manufactured for Superior Construction?

How are cement bricks and blocks manufactured?

Cement bricks and blocks form the backbone of modern construction, and understanding their manufacturing process can provide invaluable insights for contractors, engineers, and investors alike. In today��s competitive market, knowing what goes behind creating these essential building components not only improves decision-making but also instills confidence in the durability and quality of construction materials. In this article, we uncover the secrets behind the manufacturing process, address frequently asked questions, and highlight key statistics that underline the importance of precision in production.

Introduction

The construction industry relies heavily on the consistent quality of building materials. Cement bricks and blocks, known for their strength and longevity, are manufactured through a systematic, multi-step process that transforms raw materials into essential components for modern infrastructure. This blog post will walk you through the manufacturing process, answer common queries, and reveal industry insights that every professional and enthusiast should know. Whether you’re a seasoned builder or new to the industry, these insider secrets will elevate your understanding and guide your next project.

The Manufacturing Process Uncovered

1. Raw Materials: The Foundation of Quality

The journey begins with sourcing high-quality raw materials. The primary ingredients include cement, aggregates (like sand and gravel), water, and sometimes additives to enhance performance. Each component plays a crucial role:

Cement: Provides binding strength.

Aggregates: Offer structural stability.

Water: Initiates the hydration process.

Additives: Enhance durability and workability.

Ensuring the correct proportions is essential. For example, maintaining a water-to-cement ratio between 0.4 and 0.6 is critical for achieving optimal strength and durability. Industry statistics indicate that up to 80% of the final product’s quality is determined during this initial stage.

2. Mixing: Precision in Every Batch

Once raw materials are selected, the next step is mixing. Modern facilities employ high-speed mixers that blend the materials to a uniform consistency. This stage is crucial because even a minor imbalance in the mix can result in compromised strength or an inconsistent texture.

Mixing involves:

Batching: Precise measurement of each component.

Blending: Combining materials uniformly to ensure consistent distribution.

Monitoring: Continuous quality checks to ensure the mix adheres to industry standards.

Transitioning to the next phase, advanced monitoring systems now utilize sensors and automation to fine-tune the process, reducing human error and enhancing quality control.

3. Molding and Shaping: Crafting the Perfect Form

After mixing, the homogeneous material is transferred to molds to create bricks or blocks. The manufacturing process here can vary:

Cement Bricks: Typically, the mixture is compressed in a mold using a hydraulic press. The pressure applied can reach up to 10,000 psi, ensuring that the bricks are dense and robust.

Cement Blocks: Larger in size, these blocks are often cast using automated machines. The molds are designed to produce uniform shapes, which is critical for ensuring ease of installation and structural consistency.

Storytelling element: Imagine the precision of an orchestra playing in perfect harmony; every press and cast is a note contributing to the grand symphony of construction excellence.

4. Curing: Transforming Fresh Casts into Durable Structures

Curing is perhaps the most critical phase in the manufacturing process. Once molded, the bricks or blocks must cure—essentially, they undergo a controlled hardening process. This is achieved through:

Moisture Retention: Maintaining adequate moisture levels to allow the chemical reactions in cement to complete.

Temperature Control: Ensuring that environmental conditions support optimal hydration.

Time: Curing can take anywhere from 7 to 28 days depending on the product specifications and environmental conditions.

Statistics show that proper curing can improve the strength of cement bricks and blocks by up to 50% compared to those that are not cured under controlled conditions.

5. Quality Assurance: The Final Seal of Approval

Before cement bricks and blocks reach the market, they undergo rigorous quality assurance tests. These tests include:

Compression Strength Tests: Verifying that each unit can withstand heavy loads.

Dimensional Checks: Ensuring uniformity in size and shape.

Surface Inspections: Checking for any defects that could impact the performance or aesthetics of the final product.

Quality assurance protocols are not just about meeting regulatory standards—they provide peace of mind to builders and investors, ensuring that every brick or block contributes to a safe and sustainable construction.

Frequently Asked Questions

How are cement bricks different from cement blocks?

Cement bricks are usually smaller and are often used for walls and smaller constructions, whereas cement blocks are larger, offering enhanced structural stability for load-bearing walls. Their manufacturing process is similar, but the molding and curing processes may differ slightly to accommodate size differences.

What are the key factors that affect the quality of cement bricks and blocks?

The quality of these products largely depends on the quality of raw materials, the precision of the mixing process, the effectiveness of the molding and pressing systems, and the rigor of the curing and quality assurance processes. Maintaining the optimal water-to-cement ratio and ensuring a controlled curing environment are paramount.

How long does it take to manufacture cement bricks and blocks?

The manufacturing process itself is relatively quick, with mixing and molding taking just a few hours. However, the curing phase can take anywhere from 7 to 28 days, which is essential to achieve the desired strength and durability.

Can the manufacturing process be automated?

Yes, automation plays a significant role in modern production facilities. Automated mixers, robotic molding systems, and digital monitoring for curing are now common, increasing both efficiency and product consistency.

What are the environmental impacts of manufacturing cement bricks and blocks?

While the production process does involve energy consumption and carbon emissions, many manufacturers are adopting eco-friendly practices. Innovations like using recycled materials, optimizing energy usage, and exploring alternative fuels are gradually reducing the environmental footprint.

#BrickAndBlockManufacturers#InterlockingBlockMakingMachine#AutomaticInterlockingBlockMakingMachine#ManualFlyAshBrickMakingMachine#AutomaticFlyAshBrickMakingMachine#FullyAutomaticFlyAshBrickMakingMachine#AutomaticSolidBlockMakingMachine#AutomaticPaverBlockMakingMachine#PanMixerMachine#ConcretePanMixerMachine#RollerPanMixerMachine#PipeBendingMachineManufacturers#HydraulicShearingMachineManufacturers#ArecaLeafPlatesMakingMachine

2 notes

·

View notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description India's Finest Mixer-grinder Nutri-blend is India’s best-selling mixer-grinder-blender thanks to its powerful motor, beautiful looks, unbreakable transparent jars and awesome performance. Nutri-blend is a complete system – you can begin with the 3 jars and keep adding the chopper, juicer & food processor attachments separately as your needs evolve. It also comes with two useful lids for storing and sprin- kling purposes. Get ready to make luscious smoothies, finely ground masalas, tangy chutneys, chopped veggies and so much more in a jiffy. 100% Full Copper Motor The compact yet powerful machine grinds the toughest of chutneys and masalas thanks to its incredibly high speed of 22,000RPM, which is almost twice that of normal mixer-grinders. Transparent & Unbreakable Jars Unbreakable Polycarbonate jars enable you to see inside, so you don’t need to keep opening the lids to check the results. Simple operation - no buttons – simply Place, Twist and Play to make all kinds of chutneys, shakes, smoothies, and masalas! Super Sharp Blades Surgical grade steel blades grind the hardest of ingredients and still stay sharp. They extract every drop of immunity enhancing anti-oxidants, pain-relieving Omega 3 acids, proteins, vitamins & minerals from your foods. Dips Be it a house party or a family get-together, nothing works better than delicious dips! Prepare the most rich and creamy dips for vegetables, chips, pita breads, or even for salad toppings. Smoothies Give yourself a boost of antioxi- dants and make your meals even yummier by preparing healthy smoothies in Nutri-blend. Dry Masalas With the super sharp blades and powerful motor, you can make finely ground masalas in a jiffy! Stylish Looks Choose your favorite colour from these bold colours and up the style quotient of your kitchen! Reliable Wonderchef Service We are confident of our quality. In case of any manufacturing defect found within the service period, we shall get it resolved immediately.

Recipe Book by Chef Sanjeev Kapoor Each box includes a special treat: a printed recipe book by renowned Chef Sanjeev Kapoor, filled with over 100 healthy & unique recipes. Comes with 3 interchangeable jars Steady and safe to use with non-skid rubber. Power: 400 watts , 50 Hz Includes: Mixer grinder, Mixer Jar (750ml), Tall Jar (500ml) with Blending Blade, Short Jar (300ml) with Grinding Blade and Seasoning Cap [ad_2]

2 notes

·

View notes

Text

Denver Restaurant Equipment

Denver Restaurant Equipment: The Essential Guide for Aspiring Restaurateurs

Introduction

Denver, Colorado, known for its vibrant culture, scenic beauty, and booming culinary scene, is an ideal city for aspiring restaurateurs. However, the journey from dream to reality involves many intricate details, one of the most crucial being the acquisition of the right restaurant equipment. Whether you're opening a cozy café, a bustling bistro, or a high-end dining establishment, understanding the landscape of Denver restaurant equipment is vital. This guide delves into the nuances of choosing, purchasing, and maintaining restaurant equipment in Denver, offering insights and tips to help you navigate this essential aspect of your culinary venture.

Understanding the Importance of Quality Restaurant Equipment

Before diving into the specifics, it's important to comprehend why quality equipment is fundamental to any restaurant's success. High-quality restaurant equipment ensures efficiency, consistency, and safety in your kitchen operations. It can significantly affect the speed of service, the quality of food, and overall customer satisfaction. Investing in reliable equipment minimizes downtime due to breakdowns and reduces long-term maintenance costs. Moreover, it adheres to health and safety regulations, which is crucial for maintaining a reputable business.

Types of Essential Restaurant Equipment

Cooking Equipment

Ovens and Ranges: The backbone of any kitchen, ovens and ranges come in various types, including convection ovens, deck ovens, and combi ovens. Each type serves different cooking needs, from baking and roasting to steaming and grilling.

Grills and Griddles: Ideal for preparing a variety of dishes, from steaks to pancakes, grills and griddles are essential for any kitchen aiming to offer a diverse menu.

Fryers: Essential for any establishment that serves fried foods, fryers come in countertop and floor models, with options for gas or electric power.

Refrigeration Equipment

Walk-in Coolers and Freezers: These provide ample storage for perishable items, ensuring they remain fresh and safe to use.

Reach-in Refrigerators and Freezers: Convenient for quick access to frequently used ingredients, these units come in various sizes and configurations.

Undercounter Refrigeration: Perfect for smaller kitchens or specific stations, undercounter units save space and provide efficient cooling right where it's needed.

Food Preparation Equipment

Mixers and Blenders: From dough mixers to high-speed blenders, these tools are vital for preparing a wide range of dishes and beverages.

Food Processors: These versatile machines can chop, slice, and puree ingredients, speeding up prep work and ensuring consistency.

Slicers: Essential for delis and sandwich shops, slicers provide uniform cuts for meats, cheeses, and vegetables.

Storage and Shelving

Dry Storage Shelving: Proper shelving is crucial for keeping dry goods organized and accessible. Stainless steel shelves are durable and easy to clean.

Pantries and Cabinets: Secure storage for utensils, cookware, and ingredients helps maintain an efficient and clutter-free kitchen.

Cleaning and Sanitation

Dishwashers: From undercounter models to large conveyor dishwashers, these machines ensure your dishes, glasses, and utensils are clean and sanitized.

Sinks and Faucets: Multiple compartment sinks and pre-rinse faucets are essential for washing produce, pots, pans, and other kitchen tools.

Sanitizing Stations: Essential for maintaining health standards, these stations include handwashing sinks and sanitizer dispensers.

Smallwares and Utensils

Pots and Pans: A variety of sizes and types, including non-stick, stainless steel, and cast iron, are necessary for different cooking methods.

Cutlery: Quality knives and cutting tools are essential for efficient and safe food preparation.

Utensils and Gadgets: From spatulas and ladles to thermometers and measuring cups, having the right tools can make a significant difference in kitchen operations.

Choosing the Right Equipment Supplier in Denver

Selecting a reliable equipment supplier is crucial for getting quality products and excellent customer service. Here are some factors to consider when choosing a supplier in Denver:

Reputation and Reviews: Look for suppliers with positive reviews and a good reputation in the industry. Word-of-mouth recommendations from fellow restaurateurs can also be valuable.

Product Range: Ensure the supplier offers a wide range of equipment from reputable brands. This variety allows you to compare and choose the best options for your needs.

Service and Support: A good supplier should provide comprehensive support, including delivery, installation, and maintenance services. Check if they offer warranties and after-sales support.

Price and Financing Options: Compare prices from different suppliers to get the best deals. Additionally, inquire about financing options if you need to manage your budget more effectively.

Local Expertise: Suppliers with local knowledge can offer insights into Denver's market trends and regulations, helping you make informed decisions.

Navigating Health and Safety Regulations

Compliance with health and safety regulations is non-negotiable in the restaurant industry. In Denver, the Department of Public Health and Environment oversees these regulations. Key areas to focus on include:

Food Handling and Storage: Ensure your equipment supports proper food handling and storage practices to prevent contamination and spoilage.

Sanitation Standards: Equip your kitchen with the necessary tools for maintaining hygiene, such as commercial dishwashers, handwashing stations, and sanitizers.

Fire Safety: Install fire suppression systems, smoke detectors, and fire extinguishers as required by local regulations. Regular maintenance of cooking equipment can also prevent fire hazards.

Ventilation and Air Quality: Proper ventilation systems are essential for maintaining air quality and preventing the buildup of smoke and grease.

Accessibility: Ensure your establishment complies with the Americans with Disabilities Act (ADA) by providing accessible facilities and equipment.

Sustainable and Energy-Efficient Equipment

With increasing awareness of environmental issues, many restaurateurs are opting for sustainable and energy-efficient equipment. Benefits include reduced utility bills, a smaller carbon footprint, and positive customer perception. Here are some tips for choosing eco-friendly equipment:

Energy Star Ratings: Look for equipment with Energy Star certification, which indicates high energy efficiency.

Eco-Friendly Materials: Choose equipment made from sustainable materials, such as stainless steel, which is durable and recyclable.

Water Efficiency: Opt for water-efficient dishwashers and faucets to reduce water consumption and waste.

Waste Management: Implement waste management practices, such as composting and recycling, and choose equipment that supports these efforts.

Local Sourcing: Whenever possible, source equipment and ingredients locally to reduce transportation emissions and support the local economy.

Financing Your Restaurant Equipment

Purchasing restaurant equipment can be a significant investment. Fortunately, several financing options are available to help manage costs:

Leasing: Leasing equipment allows you to conserve capital and upgrade to newer models as needed. It also includes maintenance and repair services.

Loans and Credit Lines: Business loans and lines of credit from banks or other financial institutions can provide the necessary funds for purchasing equipment.

Vendor Financing: Some suppliers offer financing options directly, which can be convenient and tailored to your purchase.

Government Grants and Programs: Explore local and federal programs that offer grants or low-interest loans for small businesses, particularly those promoting sustainability.

Maintaining and Repairing Your Equipment

Proper maintenance is key to extending the lifespan of your equipment and ensuring it operates efficiently. Here are some maintenance tips:

Regular Cleaning: Follow manufacturer guidelines for cleaning and sanitizing equipment. Regular cleaning prevents buildup and reduces wear and tear.

Scheduled Inspections: Conduct routine inspections to identify potential issues before they become major problems. This includes checking for leaks, unusual noises, and performance issues.

Professional Servicing: Hire professional technicians for regular servicing and repairs. They have the expertise to handle complex equipment and ensure it operates safely and efficiently.

Employee Training: Train your staff on the proper use and care of equipment. Misuse can lead to damage and increased maintenance costs.

Record Keeping: Maintain detailed records of maintenance and repairs. This helps track the history of each piece of equipment and plan for future replacements or upgrades.

Conclusion

Starting a restaurant in Denver is an exciting venture, filled with potential for creativity and success. However, the foundation of any successful restaurant lies in its equipment. From selecting the right ovens and refrigerators to navigating health regulations and financing options, every decision plays a critical role in your establishment's operational efficiency and customer satisfaction. By investing in quality equipment, choosing reliable suppliers, and committing to proper maintenance, you can build a robust kitchen that supports your culinary vision and stands the test of time. Denver's dynamic culinary scene offers endless opportunities, and with the right tools and knowledge, you can carve out your own niche in this vibrant market. Remember, the journey of a thousand dishes begins with a single piece of equipment. Choose wisely, maintain diligently, and watch your culinary dreams come to life in the Mile-High City.

2 notes

·

View notes

Text

Trini Christmas Deserts

METHOD

Cream butter and sugar using a whisk or paddle in your mixer and start at slow speed. You can manually batter with a spoon, but it is a longer process. For the mixer, gradually increase to a fast speed. Cream until light and fluffy.

In a blender add eggs, essence, bitters, zest and blend on medium speed until fluffy.

Pour into butter and sugar mixture and beat until light and fluffy.

Mix all the dry ingredients like flour, cinnamon and baking powder together in a separate bowl.

Remove the mixture bowl from the stand and add the dry ingredients a little at a time folding the batter with carnation milk using a spatula. Combine all ingredients, do not over mix.

METHOD

In a deep bottle add in the prunes, cherries, raisins/currants, mixed peel and pour in the dark rum and cherry brandy. Mix well and allow fruit to soak in alcohol for a minimum of three days straight up to many months. (If soaking for numerous months, be sure to top up with more alcohol as fruits will absorb it as time goes by). Cover bottle and place to soak for your selected period of time.

Place 2-3 cups of soaked fruits and its liquor into a food processor and process until semi coarse in texture, somewhat similar to a liquid paste consistency or leave whole. Set aside.

Place either the beater or paddle attachment onto your stand mixer and in the mixing bowl; add in the softened butter, and sugar. On high speed, cream ingredients until light, fluffy and batter has increased in volume. (About five minutes)

On medium speed, add in the eggs one at a time just until they are all incorporated evenly into batter.

Switch the machine off and using a rubber spatula, clean the sides of the bowl to allow all ingredients to thoroughly combine.

Into a separate bowl, sift the dry ingredients such as the flour, baking powder, cinnamon and nutmeg. Set aside.

Add in orange zest, 2 dash of angostura bitters, almond and vanilla essences as well as the addition of the sifted flour in two or three portions simultaneously as you fold in the batter until completely combined

Add in the processed fruits and combine well before adding the browning last to desired color little at a time. Mix well, ensuring to scrape down the sides of the bowl. Do not mix the batter too much, just until the fruits are evenly combined with the browning.

Preheat the oven to 280 degrees Fahrenheit.

Prepare a 9-inch pan by greasing it with some softened butter, cut a circular piece of grease proof paper that fits the circumference of the pan's base and carefully lay inside. Pour fruit cake batter into the pan, then tap gently against the counter to settle the batter evenly.

Place the cake pan into the heated oven on the middle rack and bake for about 1 hour and 10 minutes or until a toothpick or skewer, inserted in the cake, comes out clean. If still gooey, return cake back into the oven for an additional 10 to 15 minutes and monitor so it doesn’t burn.

When the cake is done as soon as it comes out of the oven, pour the alcohol all over the cake to allow the alcohol to soak in.

Let sit for 10 minutes to cool. Allow the cake to rest until completely cool, then slice and enjoy.

. You can also continue to soak the cake a few more times over the course of the next few days to allow it to absorb more alcohol and truly become stronger in flavor before slicing. This I recommend fully. Be sure to keep the cake tightly covered in the pan to prevent it from drying up.

3 notes

·

View notes

Text

Enhance Soldering Quality with a Reliable Solder Paste Mixer in India – Available at Ascomp Inc

In the high-precision world of PCB manufacturing and SMT assembly, the quality of solder paste directly influences the reliability of solder joints. Uneven consistency, trapped air bubbles, or separated flux can cause significant defects during reflow. That’s why using a professional-grade solder paste mixer in India is critical to ensuring consistent, high-quality soldering results. At Ascomp Inc, we supply advanced solder paste mixers designed to meet the needs of Indian electronics manufacturers, labs, and assembly lines.

What is a Solder Paste Mixer?

A solder paste mixer is a machine that evenly blends solder paste before it’s used in the stencil printing or dispensing process. Solder paste contains a mixture of tiny solder particles and flux. Over time, this mixture can separate or settle due to storage or temperature variations. Manual stirring often introduces air bubbles or inconsistencies.

A solder paste mixer in India from Ascomp Inc ensures:

Uniform texture and viscosity

Proper redistribution of flux and metal particles

No air entrapment

Reduced paste waste

Reliable printing and soldering outcomes

Key Features of Ascomp Inc’s Solder Paste Mixers

✅ Centrifugal mixing technology for even blending

✅ Dual-can rotation system for balanced and efficient mixing

✅ Timer and speed control for precise mixing profiles

✅ Vacuum mixing options to prevent air bubbles

✅ No blade contact – prevents contamination

✅ Compatible with standard solder paste jars (500g/1kg)

These features help maintain solder paste performance from the first print to the last, avoiding costly defects or rework.

Applications of Solder Paste Mixers

SMT stencil printing

Manual or automated paste dispensing

R&D labs and QA testing

LED and sensor manufacturing

Repair and reballing stations

Defense, aerospace, and telecom equipment production

Whether you’re running a high-speed production line or a prototyping facility, consistent solder paste quality is essential—and our mixers deliver just that.

Why Solder Paste Mixing Matters

Without proper mixing, solder paste can:

Create printing inconsistencies

Cause bridging, tombstoning, or cold joints

Increase reflow defects

Compromise joint strength and conductivity

Shorten stencil life due to clogging or paste slumping

Using a solder paste mixer in India is not just about convenience—it’s about ensuring reliability in every PCB you produce.

Why Choose Ascomp Inc?

🔧 Industry-proven machines used in top EMS facilities

📦 PAN-India shipping and fast delivery

🛠️ After-sales support and spare part availability

💼 Pre-sales consultation for compatibility and setup

🧪 Training and process optimization for SMT teams

🔍 Custom models for specific paste or container types

With years of experience in electronics manufacturing tools, Ascomp Inc is your trusted partner for quality, precision, and process control.

#SolderPasteMixerIndia#AscompInc#SMTToolsIndia#ElectronicsManufacturingIndia#PCBAssemblyEquipment#SolderingSolutionsIndia#ESDCompliantTools#SolderPasteHandling#ReflowSolderingIndia#QualityControlSMT

0 notes

Text

Twin Shaft Mixers stand out as versatile and efficient solutions for achieving homogeneous mixtures of various materials. Whether in the production of concrete, asphalt, or specialty chemicals, maximizing the Impact of A Twin Shaft Mixer requires a combination of proper operation, maintenance, and understanding of its capabilities.

#Twin Shaft Mixer#Twin Shaft Mixer in India#High Speed Twin Shaft Mixer#Disperser Machines#Twin Shaft Disperser#Twin Shaft Disperser Machine

0 notes

Text

Rapid Mixer Granulator

Rapid Mixer Granulator designed for mixing powder components and forming granules out of them. RMG Machine equipped with two different type of blenders called Impeller and Chopper. Impeller is bigger size blender perform slow speed mixing whereas Chopper is smaller blade perform fast speed mixing. Chopper uses for blending and granules preparation process. Rapid Mixer Granulator designed to provide superior mixing and reliable granules at reduced production costs with increased output. Improved mixing and closed granule size control resulting higher tableting speeds, better quality and fewer rejections.

RMG Machine form granules by tumbling and whirling motion of particulate. High speed rotation of chopper provide edge while adding mixing ingredients. Machine granulate powder by applying shearing force hence it is also called as high shear mixer. Adinath International is one of the leading rapid mixer granulator manufacturers produce laboratory rapid mixer granulator 5 liters to production scale rapid mixer granulator 400 liters.

Rapid Mixer Granulator also known as RMG Machine, High Shear Mixer Granulator, Rapid Mixer Granulator Machine, High Shear Mixer Granulators, Dry Powder mixer granulator, Wet Granulator, Pharma Saizoner, High Shear Granulator, High shear granulation machine, Granulator, Wet Mixing, Granulation Machine.

#RMG Machine#High Shear Mixer Granulator#Rapid Mixer Granulator Machine#Dry Powder mixer granulator#Wet Granulator

2 notes

·

View notes

Text

JCT Machinery on sale chemical mixing equipments

#machine#equipment#machinery#reactor#chemical reactor#sigma mixer#double arm mixer#z blade mixer#horizontal kneader#planetary mixer#high speed disperser#dual shaft mixer#multifunctional mixer

0 notes

Text

Grind Like a Pro with Butterfly Bhima 1000W 4 jar Mixer Grinder!

When it comes to effortless cooking and seamless kitchen performance, a reliable mixer grinder is your best companion. Say hello to the Butterfly Bhima 1000W Mixer Grinder (4 Jars, Green) – a powerful and vibrant kitchen essential designed to elevate your cooking experience. With its strong motor, stylish green finish, and multiple jars to suit every need, the Butterfly Bhima is truly a multitasking champion that adds beauty and utility to any Indian kitchen.

Overview: Meet the Mighty Bhima

Inspired by the strength and endurance of its mythological namesake, Butterfly Bhima 1000W Mixer Grinder delivers unmatched performance for tough grinding, blending, and mixing. Whether you’re making idli batter, spicy chutneys, or fresh fruit smoothies, this appliance handles it all with ease.

With 4 thoughtfully designed jars, a powerful 1000W motor, and ergonomic design, this mixer grinder is built for performance, durability, and convenience. And let’s not forget the gorgeous green finish that brings a refreshing pop of color to your countertop!

Key Features of Butterfly Bhima 1000W Mixer Grinder

High-Power 1000W Motor

At the heart of this machine lies a 1000-watt motor, built to crush, grind, and pulverize with ease. From whole spices to coarse dals, you get consistent results without overheating or lag.

4 Versatile Stainless Steel Jars

The mixer grinder comes with:

1.5L Liquidizing Jar – Ideal for juices, shakes, and smoothies.

1L Dry Grinding Jar – Perfect for grinding masalas, pulses, and coffee beans.

0.5L Chutney Jar – Specially designed for small portions of chutney, ginger-garlic paste, and more.

1.5L Juicer Jar with Extractor – Enjoy fresh juices with an in-built strainer for pulpy fruits.

Each jar is made of rust-proof stainless steel, ensuring durability and hygiene.

Sharp Razor-Tech Blades

The multi-purpose stainless steel blades are engineered for precision grinding and smooth blending. Whether you're making coarse powders or creamy purees, the results are consistent.

3-Speed Control Knob with Whip

The user-friendly 3-speed rotary knob gives you control over the texture and thickness. The whip function offers a burst of power for quick mixing and aeration.

Safety Lock & Overload Protection

The Butterfly Bhima includes auto cut-off protection to prevent motor damage during overload. The safety lock mechanism ensures the jars are securely placed before operation, offering peace of mind.

Easy to Clean Design

The mixer’s smooth, shockproof ABS body is not only attractive but easy to wipe clean. The jars and blades are detachable and dishwasher-safe, saving your time and effort.

Design & Aesthetics: A Fresh Splash of Green

While most mixer grinders stick to traditional blacks and whites, the Butterfly Bhima breaks the monotony with its vibrant green body. The color is not only unique but adds a touch of cheer to your kitchen decor. The combination of modern design and ergonomic structure makes it a true showstopper.

Why Choose Butterfly Bhima?

✅ Perfect for Indian Kitchens

From grinding dry spices to preparing wet masalas, Indian cooking demands versatile appliances. Butterfly Bhima is designed to tackle the complexities of Indian cuisine with minimal effort.

✅ Built to Last

The sturdy motor, high-quality jars, and robust ABS body make this mixer grinder a long-term investment for your kitchen.

✅ Time-Saving Efficiency

Cook more in less time! With 4 jars ready for different tasks, you no longer have to rinse and reuse. Save time on prep and spend more time enjoying meals.

✅ Reliable Brand

Butterfly has been a trusted name in Indian households for decades. Known for innovative kitchen appliances, the brand ensures quality, durability, and great customer support.

What’s in the Box?

Butterfly Bhima 1000W Mixer Grinder (Green)

4 Jars with Lids

Multi-purpose Blade Attachments

User Manual

Perfect For:

Homemakers looking for a durable daily-use mixer

Students or working professionals needing quick blending options

Small to medium families for everyday cooking needs

Health-conscious users who make smoothies, juices, and nut pastes

Where to Buy?

The Butterfly Bhima 1000W Mixer Grinder (4 Jars, Green) is available at leading retailers like Poorvika, where you can enjoy:

✅ Competitive pricing

✅ Genuine product guarantee

✅ Easy EMI options

✅ In-store pickup or fast delivery

Visit your nearest Poorvika store or shop online at https://www.poorvika.com/ to bring home this powerful performer today!

Final Thoughts

If you're on the hunt for a high-performance mixer grinder that’s powerful, stylish, and built to last, the Butterfly Bhima 1000W Mixer Grinder (4 Jars, Green) ticks all the right boxes. It’s not just another appliance—it’s a dependable kitchen partner that helps you cook smarter, faster, and better.

Click here: https://www.poorvika.com/butterfly-bhima-1000w-mixer-grinder-4-jars-green/p

#kitchenware#mixer grinder#butterfly mixer grinder#butterfly bhima mixer grinder#4 jar butterfly mixer grinder#butterfly mixer grinder price

0 notes