#Twin Shaft Disperser Machine

Explore tagged Tumblr posts

Text

A Twin Shaft Disperser is a versatile and essential piece of equipment for industries involved in mixing, dispersing, and emulsifying products. At Tipco Engineering, we provide high-quality Twin Shaft Dispersers designed to enhance your production processes.

#Twin Shaft Disperser#Twin Shaft Disperser Machine#Twin Shaft Disperser Price#Twin Shaft Disperser Manufacturer#Twin Shaft Disperser in India#High Speed Twin Shaft Disperser

1 note

·

View note

Note

sunlight shafts stream through the apartment - decorating the walls in dappled rays of red and orange and yellow. each fragment illuminates some strange aspect of their lives - the all might memorabilia lining the walls, trinkets from their classmates, bits and baubles from the midoriya and bakugo families respectively. their bedroom is even worse, an explosion of their shared interests and eclectic tastes punctuated by the rumpled navy sheets, sleep mussed with 18 pillows (at izuku's behest) scattered throughout. you could easily tell which side of the bed was his - no doubt due to the extra pile of 5 blankets and the singular sheet occupying katsuki's.

both bed dwellers have left, instead loitering in the kitchen around the gently whirring coffee machine. where izuku would normally have already left and been on campus grounds to teach his class by now - summer break affords him the occasional day off, and instead he loiters at katsuki's back, cheek pressed to his shoulder, and strong arms looped about his waist. a scarred left hand flattens upon his bare abdomen, cold wedding band trailing ice in his wake.

"what is on the schedule for today, kacchan?" comes his words, watching as the liquid energy is divvied up between the two matching all might mugs. "or should i say... great explosion murder god dynamight?" each word punctuated with a kiss to the elder's nape, nails tickling down a bare side - reveling, just for now, in the warmth of the bubble they'd worked so hard to earn.

contentment as recompense for the perpetual conflict waged between heroes and villains, at the time they had been young, vehemently chasing dreams that felt almost within their grasp. Now, as one might cast a meandering gaze across the eclectic and meticulously arranged memorabilia it felt like a reprieve even if their days were still filled with their individual pursuits. Bakugo remembers rather clearly that for every all-might statue and each ornamental addition from their classmates, Izuku had sedulously dedicated himself arranging their display. Once, he would have made a disparaging comment about it, loud and commanding, then, his fervent gaze had remained affixed to those scarred hands as they diligently sorted offering an off-handed remark here and there, a: you really think that looks good ? are you sure your eyes aren’t going to shit ? and then he’d taken over, marshalling Izuku’s hands as they finalized their set-up. For all the abrasions they had, their personalities a collision of shuddering sparks and wreathing, lucent power, did their lives not intertwine effortlessly now. In that quiet way he often did, where the tumult of him was subdued into a soft, intermittent hum, he appreciated the places Izuku touched his life. It was most prevalent around his finger where the cool, gold of their twin bands pressed flush to his skin. They’ve forsaken their bed as the first shafts of gilded dawn play across crumpled sheets, Izuku’s precariously stacked pillows dispersed between similarly amassed blankets and his, solitary in comparison, haphazardly shoved to the bottom of their bed and hanging half on half off of it. Coffee summoned him from the somnolent stupor of a long night ending curled around Izuku, an arm strewn carelessly over his waist, his chin resting indolently on his shoulder. No matter how calamitous his days were when it came to returning to his home, to izuku, he could always find respite, as if that fond smile and the crinkles around the corners of his eyes were a salve. He pours coffee into Izuku’s mug first, lurid and yellow with all-might’s silhouette painted amidst a spattering of sharp, stylistic lines and stars and then his, a black one with his catch phrase accentuated with a stark, intensely coloured outline. The coffee, much like him, huffs a breath of billowing steam amongst the crisp morning. He doesn’t recoil from the affection, in fact, the relaxed nature of his posture invites it, as if he were leaning into it and wordlessly demanding more. ❝ damn it. ❞ he scoffs, nudging the handle of the mug against his fingers as if commanding him to take his share. ❝ you’re never gonna let that die, are you ? ❞ but for all the whetted edges of his cadence was there not the implication of amusement wreathed between, his gaze cast to where those fingers idled against his stomach and the aureate glint of his band as the first - rays of dawn cavorted across the corrugating skin decorating his prominent knuckles.

❝ not all of us got the day off today, sensei. ❞ brandishing his title as a riposte, proffering the mug to him before claiming his own and relishing both the emanating heat and the promise of caffeine flooding his veins and coaxing his sluggish brain into full throttle. Just another of the Izuku shaped side effects in his life, as calm as he was, did it not also take longer to be fully prepared to pry himself from his grasp, to breach the threshold into the new-dawn and greet another day of heroism. ❝ kick some villain ass, maintain the peace, somethin’ like that.❞ and a slight grin tugs at the corners of his mouth as he takes the first of many less then tentative sips.

1 note

·

View note

Link

Twin shaft disperser machine has optimized design, wherein assembling of mixing tools help in generating a perfectly homogeneous mixture. You can rest assured about the quality of mixing as the materials are processed and dispersed in batches quickly in a Twin Shaft Disperser. Utilizing less power and hence saving electricity, it offers an intense mixing of materials.

Pick from pieces of equipment from veracious Twin shaft disperser manufacturers and thus get to install an efficient driving system in your industry. Also, this equipment renders larger capacity to dissolve the prodigious amount of substances with high pressure consuming less power.

#Twin Shaft Mixer#Twin shaft Dissolver#Twin shaft disperser machine#Twin shaft disperser manufacturer#Twin Shaft Disperser

0 notes

Text

Liquid mixer agitator

A mixer is a machine in which a shaft with blades rotates in a cylinder or a tank to stir and mix a variety of raw materials to form a mixture or a suitable consistency.

There are many kinds of mixers, such as forced mixers, single-shaft mixers, twin-shaft mixers, etc. Note: The mixer and automatic feeder must be cleaned inside, especially in winter, which can prolong the life. A mixer is a mixer, because the usual function of a mixer is to mix and mix various dry powder mortars, so it is commonly called a mixer.

Filtrate tank stirring device is a commonly used chemical equipment, mainly used for filtering, separating and stirring liquid. The following introduces the characteristics and principle of the filtrate tank stirring device.

1. Features:

1. High efficiency: During the stirring process, the stirring device of the filtrate tank can promote the precipitation of particulate matter in the solution, and filter through the filter screen, so as to realize high-efficiency filtration and separation.

2. Stability: The stirring device of the filtrate tank adopts advanced control technology, which can ensure the stable operation of the equipment and is not prone to failure.

3. Multifunctional: The stirring device of the filtrate tank can perform a variety of different filtration and separation operations, and is suitable for different chemical production processes.

4. Easy maintenance: The structure of the filtrate tank stirring device is simple, easy to maintain and clean, reducing the difficulty and workload of maintenance and cleaning.

5. Energy saving and environmental protection: The filtrate tank stirring device uses advanced filtration technology, which can achieve high-efficiency filtration and separation, reduce waste of energy and resources, and achieve the purpose of energy saving and environmental protection.

2. Principle:

The principle of the filtrate tank stirring device is to settle the particulate matter in the liquid to the bottom of the tank through the action of the stirrer, and then filter and separate through the filter screen.Liquid mixer agitatormain principles are as follows:

1. Sedimentation: Under the action of the agitator, the particulate matter will be dispersed into the solution, and then settle to the bottom of the tank under the action of centrifugal force.

2. Filtration function: the particulate matter that settles to the bottom of the tank is filtered and separated through the filter screen, and the impurities and particulate matter in the liquid are filtered out.

3. Recycling function: The filtered liquid flows back to the filtrate tank and is stirred again to clean the impurities on the filter net and make the filtering effect more perfect.

To sum up, the filtrate tank stirring device is an efficient, stable, multi-functional, easy-to-maintain, energy-saving and environmentally-friendly chemical equipment. Its principle is to achieve liquid filtration and separation through stirring, sedimentation and filtration.

0 notes

Text

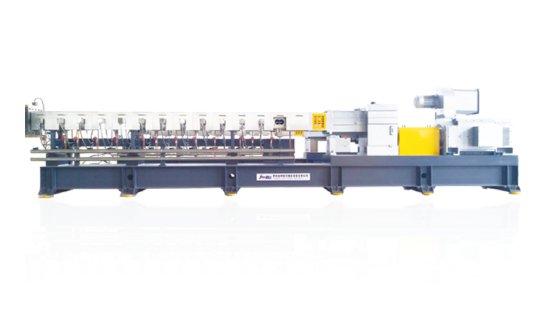

Plastic Compounding Machine

https://www.jwellextrusions.com/products/plastic-compounding-machine/

The twin-screw extruder is composed of a transmission device, a feeding device, a barrel, and a screw, and the functions of each component are similar to single-screw extruder. The difference from the single-screw extruder is that there are two parallel screws in the twin-screw extruder.

The complex flow pattern of the material in the twin screw compounding machine macroscopically shows the advantages that the single-screw extruder cannot match, for example, sufficient mixing, good heat transfer, large melting ability, strong exhaust ability and good temperature control of the material, etc.

Description About Plastic Compounding Machine

Item

Description

Place of origin

China

Brand name

JWELL

Model number

CJWH-85

Capacity

300-500kg/hr

Typical application

TPU

Packaging details

Wooden pallet packing

Delivery time

90days

Payment terms

TT. LC

Specifications of Plastic Compounding Machine

Model

Diameter

L/D

Screw speed

Motor Power

Torque per shaft

Specific torque

Capacity Range

mm

rpm/min

KW

N.m

T/A3

kg/hr

CJWH35

35.6

24~68

600

30

235

8.7

75~150

1000

45

8.7

110~220

CJWH40

41.1

24~68

600

45

357

8.7

110~220

1000

75

8.7

190~380

CJWH52

51.4

24~68

600

90

692

8.7

220~440

900

132

8.7

330~660

CJWH65

62.4

24~68

600

160

1224

8.7

400~800

900

220

8.7

550~1100

CJWH75

71

24~68

600

220

1880

8.7

550~1100

800

315

8.7

800~1600

CJWH85

81

24~68

600

315

2713

8.7

800~1600

800

450

8.7

1100~2200

CJWH95

93

24~68

600

500

4131

8.7

1250~2500

700

600

8.7

1500~3000

CJWH110

108

24~68

500

630

6346

8.7

1500~3000

600

800

8.7

2000~4000

CJWH120

120

24~68

500

900

8705

8.7

2250~4500

600

1000

8.7

2500~5000

CJWH135

132

24~68

400

900

11586

8.7

2250~4500

500

1000

8.7

3000~6000

Plastic Compounding Machine Application

Plastic Compounding Machine Application

Petrochemical Powder Pelletizing and Powder Compouding:

Petrochemical powder pelletization and powder modification are one of the most important applications for twin screw extrusion machine. Through continuous efforts, optimization, and improvement, the integration of industry resources has been widely recognized by the market.

Bio-degradable Plastic Compouding and Pelletizing Series:

Typical application as plastic alloy, starch filled compound, bio-mass filled compound or mineral power filled compound for bio degradable plastics as PLA, PBAT, PBS, PPC, PCL, TPS, and PHA, etc.

Plastic Compounding Machine Performance and Advantages

The screw and barrel adopt the "building block" structure, which has good interchangeability, and can be used in any combination according to the different material processing technology;

The cylinder body is made of nitrided steel and bimetal materials, which are wear-resistant and corrosion-resistant, and extend the service life; the threaded elements are made of nitrided steel and high-speed steel. Normal tooth surface clearance, and good self-cleaning;

The specially designed connection method and transmission device enhance the strength of the threaded element and the mandrel. The above measures achieve the purpose of uniform material dispersion, good mixing and plasticizing effect, short material retention time, and high conveying efficiency.

0 notes

Text

Wahal Engineersscope of rapid dispersers/dissolvers are generally utilized in different ventures in assembling of colors, paints, inks, glue, synthetic concoctions and numerous different items. High Speed Disperser >Twin/Dual Shaft Dispersers >Triple/Multi Shaft Dispersers Wahal Engineers United Arab Emirates manufacturer of Paint Mixing machine which define paint grinding machine. We are largest Paint making machine for the worldwide.

1 note

·

View note

Text

Development of key technology of coaxial twin screw extruder

1. Spiral groove depth

The depth of screw groove is an important parameter of the twin - screw extruder. Usually it is expressed indirectly by the ratio of screw diameter and screw root diameter. The value is an important parameter to indicate the technical level of the twin screw extruder. At present, the ratio of the external diameter of the screw to the root diameter of the screw in the latest generation (sixth generation) coaxial twin-screw extruder represented by WP of Germany is D/Di = 1.55.There are many factors limiting D/Di, in addition to the center distance of the gearbox output shaft of the driving screw, the screw itself also has a greater impact on D/Di: such as the shear resistance of the screw mandle-shaft, the torque transfer mode between the screw element and the mandle-shaft, the structure of the screw element itself, etc.

(1) The breakthrough in material selection, processing technology and heat treatment performance of mandrel makes the torque capacity of mandrel bearing greatly improved, and the length-diameter ratio of screw increases from the initial 36 to 50, or even higher.

(2) The technological breakthrough of the special gear drive system of the co-directional twin-screw extruder provides the power transmission guarantee for the torque input required by the deep groove screw under the condition of the constant center distance, making the screw D/Di goes to 1.55.

(3) The torque transfer mode between screw and mandrel is the key to realize the deep screw groove. The torque transfer between the screw element and the mandrel was initially connected by flat keys, which not only limited the deepening of the screw groove and increased the free volume of the screw, but also the strength of the flat keys could not meet the requirements of some production operations. Using multi - key torque transmission in the form of involute can greatly improve the depth of the screw groove under the same outer diameter of the screw. In recent years, while learning from foreign advanced technologies, China has made great breakthroughs in processing and manufacturing. At present, it has been able to manufacture involute spline structure with the same connection form with foreign screw, thus making great breakthroughs in the depth of screw groove.

(4) The breakthrough of element structure. The structure of the kneading block solves the key technology of manufacturing, its structure changes from the original single piece type, the assembling type to the present integral type, thus guarantees the deepening of the screw groove from the strength of the element, also makes the adjustment of the screw combination and the assembly of the screw more reliable and convenient.

To sum up, breakthroughs in the aspects of gear transmission system, shear strength of mandrel, torque transmission form of screw element and mandrel, and design and manufacture of screw element ensure the successful development of a new generation of high-speed and deep screw slot extruder.

2. New screw element

Synthetic twin screw extruder is the core part of the screw, after the advent of synthetic double screw extruder, and development of screw and screw element has always been a developer research and the main direction, screw structure from the integral development early to "building block", three thread from single head to head, later when the double structure, type of screw elements, structure and function differences. Develop self-cleaning type mixer type screw element, edge type mixer type screw element, toothed screw element, pressure regulating screw element, etc., of the twin screw extruder screw element made greater innovation, supplement and perfect, strengthen and improve the direction of the twin screw extruder mixing and plasticizing effect, dispersion, shear, pressure, and adjustable.

3. Gear box torque rating parameters

The torque grade parameter M/A3 of the gear box is an important performance indicator parameter of the coaxial twin-screw extruder. Its value represents the technical level of the coaxial twin-screw extruder and represents the torque output capacity of the gear box under a certain screw center distance. Due to the particularity of the transmission form of the coaxial twin-screw extruder, the torque of the gear is input into the gear box by a high-speed shaft. Through deceleration and torque distribution, the torque is transmitted to the twin-screw by two output shafts with limited center distance under the condition of great axial force. Therefore, the ratio parameter M/A3 between the center distance of the output shaft and the output torque has become an important symbol to measure its technical level. So the design of gear box of twin screw extruder is very difficult compared with the design and development of general gear transmission system. At present, China has made great breakthroughs in gear transmission mode, torque uniform distribution and axial force solution. The torque grade parameters of the experimental extruder have been changed from 4.Seven goes up to eight.8. It lays a good foundation for the development of high speed and high torque gear box of production extruder.

In terms of the service life of the gear box, by improving and driven by new type of multi-channel way, not only greatly improve the transmission capacity, and through the reasonable arrangement of the axis, solved the gear and thrust bearing load distribution, greatly reduced the gear drive and work process of the additional force, making long-term restricting the service life of the gear box of the anti-fatigue performance of the gear, thrust bearing system performance are greatly improved, after adopts multiplex drive, output the stress of the bearing diameter of axle direction decrease greatly, therefore, in many ways to improve the gear, the thrust bearing system, the torque distribution part of the bearing service life, Designed life up to 10 a.

4. Screw speed

Screw speed is another important parameter to measure the performance grade of the extruder with the same direction and it is an important way to improve the performance index of the extruder. It directly affects the torque grade parameters and production capacity of the equipment. The screw rotation speed increase mainly depends on the innovation and development of gear transmission system drive, the ability of the screw torque under and anti-fatigue performance, by developing a new type transmission way and optimize the innovation design, selection of key parts imported bearing, means, the strict screening of screw spindle materials and the improvement of heat treatment process, and the screw element and spindle, involute spline breakthrough made in the form of uniform stress distribution, making it possible to screw rotation speed increase, has been in a small high-speed experimental synthetic twin-screw extruder machine through industrial test.

5. Production capacity

The technical level and performance of the equipment are aimed at improving production capacity, reducing energy consumption and improving reliability. Production capacity is the main factor to evaluate the performance of a unit:

(1) improve the screw speed, the same type of production can be doubled;

(2) the use of deep screw groove screw, increase the screw free volume, improve the unit speed and unit time transport capacity;

(3) the use of twin screw and gear pump combined technical route, improve the reliability of the transmission box, reduce the axial force borne by the gear, eliminate the limit of the axial force to reduce the output of the factor, improve the output of the extruder.

0 notes

Text

Thickeners — Types, Working Principle & Applications

What is a Thickener?

In very simple words, a thickener is a machine that separates liquid from solids. It is defined as a method of continuous dewatering of a dilute pulp, wherein a regular discharge of a thick pulp takes place which is of uniform density, concurrently with an overflow of clarified solution. The solids particle size range in thickeners is generally from 0.5 mm to a few microns. Thickeners are often rated on lbs. of solids per square foot of surface area.

Briefly, its functioning can be explained with Scraper blades or “rakes” that are used in a thickener, which rotate slowly over the bottom of the tank, and slope down towards the centre and move the material settled on the bottom to a central opening or discharge. Thickeners are generally used in metallurgical field with the purpose of thickening prior to agitation, filtration, in the countercurrent washing of cyanide slime, and more thickening ahead of floatation, for dewatering tailing to recover the water for reuse in the mill and for thickening concentrates.

Fundamentally, thickeners and clarifiers (which look visually like thickeners) are both used to settle solids which results in the separation of liquids and solids. The difference however is that thickeners are used to concentrate solids, while clarifiers are used to purify liquids.

Historically, thickeners were introduced to the mining industry in 1905. They are widely used in various industries including mining, coal, chemical, industrial, environmental (wastewater management), municipal and paper industry.

Working of a Thickener

Let us understand in detail about how thickeners work. To start with, it works on the principle of Gravity sedimentation and the most common construction of a thickener would be of iron or steel.

The continuous thickener consists of a cylindrical tank. Pulp is fed into the centre of the tank via a feed-well placed up to 1 m below the surface of the suspension. The clarified liquid overflows a trough, while the solids which settle at the bottom of the tank are withdrawn as a thickened pulp from an outlet at the centre. One or more rotating radial arms are there within the tank, from each of which are suspended a series of blades, shaped so as to rake the settled solids towards the central outlet.

With modern thickeners, there is a functionality of these arms rising automatically if the torque exceeds a certain value, thus preventing any damage which can result due to overloading. The blades also help in concentration of the settled particles by simple setting which enable a thicker underflow. In this way, solids move downwards, and then inwards towards the thickened underflow outlet and the liquid moves upwards and radially outwards.

Types of thickeners

The thickeners can be classified into two types depending on location of rake driving mechanism. They are known as either Centrally driven or Peripherally driven.

Further, under centrally driven type there are two types depending on method of supporting the drive mechanism and the raking arms.

a) Column type: A kind of thickener where a central steel or concrete column takes vertically the reaction to the weight of the mechanism and horizontally the torque load.

b) Bridge type: Here, a structure spans across the tank and is subjected vertically to the weight of the mechanism plus any solids that accumulate within the arms truss and horizontally to the twin forces imposed by the density of the raked underflow.

Generally, and for larger diameters the former type is used and for tanks up to 25–30 meter diameter the later type is preferred.

What are high-capacity thickeners and how they work?

In the 1980’s, machines known as “high capacity” or “high rate” thickeners were introduced by various manufacturers. These machines are characterized by a reduction in unit area requirement for conventional installations.

Here, the feed enters through a hollow drive shaft where flocculent (used to help thickening) is added and is rapidly dispersed by staged mechanical mixing. Further, this staged mixing action helps to improve and enhance thickening. This feed is then added into a blanket of slurry where the feed solids are further flocculated by contacting previously flocculated material. Since there is a direct contact between rising fluid and settling solids, which is common to most thickeners, it is averted with slurry blanket injection. There are radially mounted inclined plates which are partially submerged in the slurry blanket; the settling solids in the slurry blanket slide downwards along the inclined plates, producing faster and more effective thickening than vertical descent. Level sensor are used to automate the height of the slurry blanket.

Factors determining efficiency of Thickener

Several types of thickeners have been developed and classified according to the arrangement of feed and discharge in the various compartments.

For effective thickener control, key considerations are bed mass inventory, underflow density and flow, bed level, overflow clarity and flocculent dosing. All these parameters and measurements of these are not easy and one must factor in accuracy and reliability to select and install the proper equipment. Some of thickening equipment from well-known and respected brand names such as Eimco, FLSmidth, Dorr-Oliver, Phoenix, Lamella and Westech are popularly used.

Choosing a right thickener for your process and industry shall determine efficiency in its output and we strive to help you find one here!

0 notes

Text

Why is the twin shaft concrete mixer so good?

Concrete mixer has many kinds, but the machine commonly used as a host is JS concrete mixer, which is related to JS concrete mixer good mixing effect, so why double shaft concrete mixer mixing effect so good?

Twin shaft paddle mixer mixing device consists of two horizontal axis and installed on the shaft of the stirring arm and blade, blade directions on the two axis are different also, so that it can guarantee the mixture in the cylinder inner loop movement.

When twin shaft mixer in operation, in theory, the end of blade cuts the concrete from the top to the tank, the other end with a blade grabbed from the concrete, in the process of two groups of blade alternates work, discharge blade mixes up under the side at the bottom to form no or less material space, at the same time cutting blade to mix from one end to the other side of the axial and circumferential displacement of the composite, and the other shaft on the blade mix the concrete in the opposite direction, which makes concrete circular movement within the cylinder.

Also piqued concrete is at the back of the blade, which produces the continuous friction between the mix. Due to the different linear velocities at the cutting end of the blade, the mixing materials have a large relative displacement when they are compressed, so the larger cement aggregates will be dispersed and refined.

0 notes

Text

How do I select a concrete batching plant?

As we all know, almost all the construction project need concrete as construction material, so concrete batching plant for producing concrete is need everywhere. Due to the difference project, there are many types of concrete batching plant to be chosen. Therefore, how to select the right concrete batching plant becomes a technical task for the project managers. For choosing concrete batching plant, there are some principle for pay attention to.

1, The performance label of construction concrete, so as to choose what kind of mixer host. Such as water conservancy project must chose twin shaft forced type concrete mixer. In addition, the concrete batching machine and cement silo should be selected according to the types of concrete materials. 2, The construction tasks and duration period, use of these two parameters to choose the size of the concrete batching plant. The transportation of finished concrete should also be considered in the selection. For example: direct pumping or vehicle delivery. The volume of the transport vehicle is also an important basis for deciding the type of mixing plant. 3, The construction quantity and construction period, when the site required one-time pouring concrete in large quantities, high quality requirements, and no concrete batching plant nearby, the best choice is two sets small batching plant, or choose a pair of double principal preparation. 4, When the site traffic is inconvenience, the maintenance staff need to spend a lot of time on entering and leaving site, the best choice is two smaller size of concrete plant, or to prepare enough spare parts, so as to ensure the smooth progress of construction. 5, The transport distance, when the construction site is dispersed, but the distance between the site is not too far, concrete mixer truck transport radius is not more than 30 minutes, dump truck delivery is not more than 10 minutes. It is better to adopt multiple concentration agitation to improve the utilization ratio of the mixing plant and the economic benefit of the construction.

0 notes

Text

Twin Shaft Mixers stand out as versatile and efficient solutions for achieving homogeneous mixtures of various materials. Whether in the production of concrete, asphalt, or specialty chemicals, maximizing the Impact of A Twin Shaft Mixer requires a combination of proper operation, maintenance, and understanding of its capabilities.

#Twin Shaft Mixer#Twin Shaft Mixer in India#High Speed Twin Shaft Mixer#Disperser Machines#Twin Shaft Disperser#Twin Shaft Disperser Machine

0 notes

Text

New Post has been published on Top Auto Blog

New Post has been published on http://topauto.site/japanese-hypercar-aspar/

Japanese hypercar Aspark Owl promises a record-breaking momentum

Rear-wheel drive hypercar Koenigsegg Regera accelerates to 100 km/h in 2.8 seconds, a top twin-engined Tesla Model S P100D — for 2.7 seconds and all-wheel drive Porsche 918 Spyder and the Bugatti Chiron do it for 2.6 and 2.5 seconds, respectively. Fantastically fast! But for the President of the Japanese company Aspark am masamichi Yoshida’s, it was not enough, and he initiated the creation of one of the most dynamic road car in the world under the name of Owl, which translated to English means “owl”. Himself Yoshida-San and introduced Owl in Frankfurt.

Work on the Owl started in 2014 by just three engineers. Curiously, before this firm Aspark, founded in 2005, has generally not been associated with cars. Its core business is the outsourcing and recruitment experts in the field of electrical engineering, electronics, medicine, chemical industry, advertising and IT. So looking for Owl people was not difficult.

Wedge-shaped nose, the delicate wheel arches, the pronounced hood salon, gills on the side and a huge rear wing — I think that Owl has combined all the solution from hypercars of the past and present. Internal combustion engine no, Aspark Owl is a four-wheel drive electric vehicle with an unusual layout.

Two electric motors located transversely to the axes as, for example, Tesla, and longitudinally in the base, a little on the sides of the longitudinal axis of symmetry of the machine. In the center is the propeller shaft, which gives this pair of motors. One end of the “universal joint” comes on the front main gear, the other on the rear, the center differential with this arrangement no. Agree, to put it mildly, not the most effective scheme both from the point of view of weight savings and handling.

As energy storage supercapacitors are used, which produce a large amount of energy per unit time and quickly charged. Unfortunately, the detailed specifications of the Owls has yet to be announced: presumably, the return of electric motors greater than 1,000 HP

According to the creators, the body is entirely made of CFRP, making the mass of the compartment will be modest 850 kg. Height is 990 mm, and therefore, Owl is also one of the lowest cars in the world. However, while under the outer shell of the concept lies not the usual giperkara modern monocoque made of composite, while the conventional spatial frame. This can be seen in the report from the test drive that the company spent in the beginning of the year. The purpose of the test, but like all ambitious project — dispersal to “hundred” for two seconds or even faster. And to achieve this goal, the company is prepared to sacrifice other consumer qualities of the car.

By the way, the absolute record of speed up to normal, not saturated with adhesive asphalt belongs to the Swiss students and their electroblade class Formula student. On credit-in a tiny machine weighing 168 pounds with four motor-wheels total impact of 200 HP and 1700 Nm catapulted to “hundreds” for 1,513 seconds. However, the student’s car is not designed for public roads, and Owl the creators want to sell — of course, not cheap. Yet on tests the Owl managed two seconds to score only around 90 km/h and, therefore, there is still a lot of work. Market entry is planned in 2019.

0 notes

Link

Nowadays, machines have made great importance in the world around us. Hence, there have been introduced various kinds of latest and unique machines for numerous different purpose. Because of the rapid development that can be witnessed effortlessly, there is a need for improving the quality of activities. This is one reason that Twin Shaft Mixer has been quite in demand by many of us who belong to the industrial sector. Being a very practical device, a Twin Shaft disperser machine is a great boon in all those areas where materials shaping and moulding is a customary activity. It smoothly gives out the desired mixture by consuming a very short mixing time with high pressure.

#Twin shaft Dissolver#Twin Shaft Disperser#Twin shaft disperser manufacturer#Twin shaft disperser machine

0 notes

Text

Exploring the Versatility of Twin Shaft Disperser Machines

In the realm of industrial mixing and dispersion, the Twin Shaft Disperser machine stands out as a powerhouse, offering efficient and reliable performance across diverse applications. From paints and coatings to adhesives and chemicals, the Twin Shaft Disperser mixer plays a pivotal role in ensuring thorough blending and dispersion of materials. Let's delve deeper into the features and advantages of this essential piece of equipment, as well as the importance of choosing the right Twin Shaft Disperser Supplier and Manufacturer.

Understanding the Twin Shaft Disperser Machine:

The Twin Shaft Disperser Machine is a specialized mixing and dispersion equipment designed to handle a wide range of materials. It consists of two shafts equipped with high-speed dispersion blades, rotating in opposite directions to create intense shear forces. This unique design allows for efficient breaking down of agglomerates and thorough mixing of ingredients, resulting in uniform dispersion and homogeneity.

Benefits of Twin Shaft Disperser Mixer:

Thorough Mixing and Dispersion: The Twin Shaft Disperser mixer ensures thorough mixing and dispersion of materials, resulting in consistent product quality and performance.

High-Speed Operation: With high-speed dispersion blades, the Twin Shaft Disperser mixer accelerates the mixing process, reducing production time and increasing efficiency.

Versatility: Twin Shaft Disperser mixers are versatile and can be used in various industries, including paints, coatings, adhesives, chemicals, and pharmaceuticals.

Customization Options: Leading Twin Shaft Disperser Manufacturers offer customization options to meet specific application requirements, ensuring optimal performance and compatibility.

Choosing the Right Twin Shaft Disperser Supplier and Manufacturer:

Selecting the right Twin Shaft Disperser Supplier and Manufacturer is crucial for ensuring the quality and reliability of the equipment. Look for suppliers with a proven track record of delivering high-quality dispersers and excellent customer service. Consider factors such as experience, reputation, product range, and after-sales support when making your decision.

Why Choose Us as Your Twin Shaft Disperser Supplier:

At our company, we take pride in being a leading Twin Shaft Disperser Manufacturer and Supplier. We offer a comprehensive range of dispersers designed to meet the diverse needs of our customers. Our dispersers are crafted with precision engineering and superior craftsmanship, ensuring durability, efficiency, and performance. With our commitment to quality and customer satisfaction, we strive to be your trusted partner in industrial mixing and dispersion solutions.

In conclusion, the Twin Shaft Disperser machine plays a vital role in modern industrial processes, offering efficient mixing and dispersion capabilities across various industries. By choosing the right Twin Shaft Disperser Supplier and Manufacturer, businesses can ensure reliable performance and optimal results in their production processes. Trust us for your Twin Shaft Disperser needs, and experience the difference in quality and performance.

#Twin Shaft Disperser.#Twin Shaft Disperser Supplier#Twin Shaft Disperser Manufacturer#Twin Shaft Disperser Machine

0 notes

Text

In the realm of mixing and dispersing applications, the (TSD) Twin Shaft Disperser Machine stands out as a powerhouse, offering efficient and reliable performance.

#Twin Shaft Disperser Machine#Twin Shaft Disperser Supplier#Twin Shaft Disperser in India#Twin Shaft Disperser Manufacturer

0 notes

Text

A Twin Shaft Mixer is a powerful piece of equipment essential for producing high-quality mixtures in various industries. From construction to food processing, this machine ensures consistent and efficient mixing. At Tipco Engineering, we specialize in providing top-notch Twin Shaft Mixers that meet diverse industrial needs.

#Twin Shaft Mixers#Twin Shaft Mixers Price#Twin Shaft Disperser#Twin Shaft Mixer Supplier#Disperser Machine

0 notes