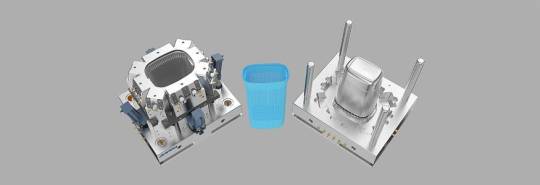

#Houseware Blow Mould

Text

How to Choose a Reliable Houseware Mould Manufacturer?

Experience and Expertise:

One of the first factors to consider is the manufacturer’s experience and expertise in the industry. Look for a company with a solid track record and a long history of manufacturing houseware mould. An experienced manufacturer will have a deep understanding of mould design, materials, and manufacturing processes, ensuring the production of high-quality mould.

R. D. Mould & Industries boasts a rich history spanning several years, demonstrating their deep understanding of mould design, materials, and manufacturing processes.

Customization Capabilities:

Every houseware product is unique, and a reliable mould manufacturer should be able to accommodate customization. R. D. Mould & Industries understands the importance of tailored solutions and offers customization options to meet diverse client requirements. Their team of skilled professionals works closely with clients to ensure that the mould are designed and manufactured to precise specifications.

Materials and Durability:

R D Mould & Industries involves considering the materials used by the manufacturer to make the mould. Material selection can significantly affect mould durability and lifespan. Trusted household mould manufacturers will have knowledge of different materials and recommend the most suitable options for your specific houseware mould products.

Product Range and Specialization:

Consider the product range and specialization of the manufacturer. R. D. Mould & Industries offers a diverse range of houseware mould, catering to various product categories such as kitchenware, storage containers, and more. Their specialization in houseware mould manufacturing ensures that they understand the specific requirements and challenges of this industry.

Conclusion:

Choosing a reliable houseware mould manufacturer is crucial for the success of your product manufacturing. R. D. Mould & Industries stands out as a trusted and reputable choice in the industry. With their extensive experience, specialization, customization capabilities, and commitment to quality, they are well-equipped to meet your houseware mould requirements. By partnering with R. D. Mould & Industries, you can have confidence in the reliability, precision, and timely delivery of your houseware mould.

#Houseware Mould#Plastic Houseware Mould#Houseware Mould Manufacturer#Houseware Mould Exporters#Plastic Food Container Mould Manufacturer#Houseware Injection Mould#Houseware Blow Mould

0 notes

Text

5 Common Plastic Resins Used in Injection Molding

ABS With outstanding impact and mechanical strength, ABS (Acrylonitrile Butadiene Styrene) is used in a wide range of industries and applications, from automotive to piping. Metal coatings can easily adhere to this material, making it well suited for products such as desktop phones, shower heads, and handles. ABS does not have good chemical resistance, however, and should not be used in applications requiring electrical insulation or UV resistance.

Apart from Plastic Toy Mould Exporters We're also dealing in Plastic Toy Injection Mould And Plastic Toy Blow Mould & Etc.

Celcon (Acetal)

Celcon, a common brand name for Acetal, offers excellent surface lubricity, creep resistance (memory), and chemical solvent resistance. Ideal for food and beverage, mechanical, automotive, and household applications, this is our resin of choice for manufacturing K’NEX toy parts, as well as gears and bearings. It’s also often used in automotive applications and household appliances. It should not be used for applications in high heat environments.

Polypropylene

Polypropylene (PP) is known for its flexibility in packaging, fluid management and processing, and household goods, as well as some automotive applications. While polypropylene is flammable and vulnerable to UV radiation, it still offers good resistance to chemical solvents and electricity. Most grades of Polypropylene are flammable and degraded by UV radiation.

We R D Mould & Industries are a renowned Plastic Toy mould manufacturer in Ahmedabad,Gujarat, India, provide various types of Plastic Toy Mould Including Plastic Toy Injection Mould, Plastic Toy Blow Mould & Etc.

HIPS

High Impact Polystyrene (HIPS) provides tough, low-cost performance and highly customizable surfaces: It can be printed, glued, bonded, and decorated easily. This material is especially popular in merchandising applications and displays, printed graphics and prototypes. Although flammable, flame-retardant varieties are available.

LPDE

The most flexible version of polyethylene, LPDE, or Low-Density Polyethylene, offers moisture resistance and high impact strength. LPDE can be found in many consumer goods and housewares, as well as medical products and electronic wiring. It is difficult to bond, however, and should not be used in harsh weather or high-temperature applications.

0 notes

Text

Ultimate Guide for Selecting the Right Injection Mould

Introduction:

Factors: Five Key Items to Consider Before Selecting a Mould

Speed:

Efficient production is essential for meeting market demands and maximizing profitability. When selecting an injection mold, consider the speed at which it can produce houseware products. Look for molds that offer fast cycle times, as this will help increase productivity and reduce manufacturing costs. R.D. Mould & Industry understands the importance of speed and provides molds designed for optimal production efficiency.

Costs:

Cost-effectiveness is a significant aspect of any manufacturing process. Evaluate the costs associated with the injection mold, including its initial purchase, maintenance, and long-term performance.

Stage:

The complexity of your houseware products and the stage of production should align with the capabilities of the injection mold. Consider whether you require a single-cavity mold or a multi-cavity mold to meet your production goals.

Geometry:

Houseware items come in various shapes and sizes, requiring molds that can accommodate diverse geometric designs. It is essential to select a mould that can accurately reproduce the intricate details of your houseware products

Quantity:

The anticipated production volume of your houseware items is a crucial factor in mold selection. Determine whether you require low-volume production or high-volume production molds. R.D. Mould & Industry understands the importance of quantity and offers molds designed for both small-scale and large-scale houseware exporter. They can cater to your specific production requirements.

Your Mold Selection Process:

Identify your houseware product requirements, including size, shape, and material.

Research reputable injection mould manufacturers like R.D. Mould & Industry, who specialize in houseware molds.

Evaluate the speed, costs, stage compatibility, geometry capabilities, and quantity options provided by the mold manufacturer.

Request quotes and compare the features and pricing of different molds.

Consider the manufacturer’s experience, reputation, and customer reviews.

Consult with the mold manufacturer to ensure they can meet your specific houseware production needs.

Make an informed decision based on the above factors and choose the mold that best fits your requirements.

Conclusion:

Selecting the right injection mold is a critical step in the houseware manufacturing process. By considering factors such as speed, costs, stage compatibility, geometry capabilities, and quantity options, you can ensure efficient and cost-effective production. R.D. Mould & Industry, a trusted company specializing in houseware molds, offers a wide range of options to meet your specific requirements. With their expertise and commitment to quality, they can help you achieve exceptional results in plastic houseware production We also manufacture different types of Houseware Blow Mould like,Plastic Round Food Container Mould,Plastic Square Food Container Mould,Multipurpose Plastic Storage Container Mould,Plastic Sweet Box Mould,Plastic Ice Cream Box & Cup Mould,Plastic Khajoor Box Mould, etc.

0 notes

Text

Houseware Mould | Plastic Round Food Container Mould and Plastic Square Food Container Mould

Established in the year 2002, we R D Mould & Industries is a leading houseware mould manufacturer, supplier and exporter of a wide range of toy moulds. We have a wide range of household moulds as per market requirements. Our company can design and supply all kinds of molds to customers. We have enough exposure in the houseware mould industry so if we talk about the range of houseware moulds, it includes plastic round food container mould, plastic square food container mould, plastic sweet box mould and plastic ice cream box and cup mould. The organization is established to analyze the various needs and specifications of our customers and accordingly offers Houseware Moulds and Toy Moulds. To ensure our moulds are safe, strong and long lasting, we use only the best quality materials. R D Mould & Industries offers a wide range of houseware blow molds including plastic dry fruit box moulds, lead type multipurpose plastic storage container mould, plastic fruit and vegetables basket moulds and other popular plastic lunch box moulds.

1 note

·

View note