#Plastic Food Container Mould Manufacturer

Text

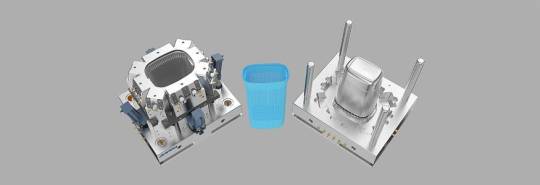

How to Choose a Reliable Houseware Mould Manufacturer?

Experience and Expertise:

One of the first factors to consider is the manufacturer’s experience and expertise in the industry. Look for a company with a solid track record and a long history of manufacturing houseware mould. An experienced manufacturer will have a deep understanding of mould design, materials, and manufacturing processes, ensuring the production of high-quality mould.

R. D. Mould & Industries boasts a rich history spanning several years, demonstrating their deep understanding of mould design, materials, and manufacturing processes.

Customization Capabilities:

Every houseware product is unique, and a reliable mould manufacturer should be able to accommodate customization. R. D. Mould & Industries understands the importance of tailored solutions and offers customization options to meet diverse client requirements. Their team of skilled professionals works closely with clients to ensure that the mould are designed and manufactured to precise specifications.

Materials and Durability:

R D Mould & Industries involves considering the materials used by the manufacturer to make the mould. Material selection can significantly affect mould durability and lifespan. Trusted household mould manufacturers will have knowledge of different materials and recommend the most suitable options for your specific houseware mould products.

Product Range and Specialization:

Consider the product range and specialization of the manufacturer. R. D. Mould & Industries offers a diverse range of houseware mould, catering to various product categories such as kitchenware, storage containers, and more. Their specialization in houseware mould manufacturing ensures that they understand the specific requirements and challenges of this industry.

Conclusion:

Choosing a reliable houseware mould manufacturer is crucial for the success of your product manufacturing. R. D. Mould & Industries stands out as a trusted and reputable choice in the industry. With their extensive experience, specialization, customization capabilities, and commitment to quality, they are well-equipped to meet your houseware mould requirements. By partnering with R. D. Mould & Industries, you can have confidence in the reliability, precision, and timely delivery of your houseware mould.

#Houseware Mould#Plastic Houseware Mould#Houseware Mould Manufacturer#Houseware Mould Exporters#Plastic Food Container Mould Manufacturer#Houseware Injection Mould#Houseware Blow Mould

0 notes

Text

The truth about recycling is even worse than most think, some have a conservative estimate that only 5% of plastics are recycled. In reality the number is probably around 2-3% on a global scale. Recyclable plastics can’t just be shredded(let’s call it regenerate) and then moulded again into whatever it was again the material has already undergone a change in structure that is somewhat permanent, making something out of 100% polypropylene regenerate will make it brittle so you use up to 40% of regenerate, 15% on average. A lot of things that aren’t everyday use items usually are either fibre reinforced or in the case of containers for foods and drinks only fresh plastic can be used due to sanitary concerns(most of the plastics for this usually have a melting point of 60°C). And non recyclable plastics like car parts, toilet seats, faux leather have to be dumped in a landfill. And not to mention most people see the plastics being sold not the amounts of manufacturing defects and waste.

15 notes

·

View notes

Text

A Guide to Sourcing Pet Bottles in Delhi

If you're looking to source (Polyethylene Terephthalate) pet bottles in Delhi, here’s a guide that can help you find the right suppliers and navigate the market efficiently:

1. Analyzing the Market for PET Bottles

PET bottles in Delhi applied for beverage, Cosmetic, medicine and many other products. Delhi being the largest market for PET bottles the buyers & sellers, that operates within varies sectors are many.

2. Identify Your Specific Needs

Before reaching out to suppliers, determine:

Size and Volume: Either in terms of volume that you need the bottles to hold, or the type of bottles, what do you require? PET bottles vary in size, from small volumes where 1 PET bottle can hold, for instance, 100 ml of the consumable to huge receptacles or containers holding 5 liters or more of the consumable.

Shape and Design: Determine if your production requires just typical forms and templates or if more elaborate ones are necessary. Non standard moulds are more expensive but can be branded.

Quantity: Through quantity purchase, or purchase through purchase orders or tenders, one will be able to access lower prices. Think about how many bottles you require by the month or the year.

Food Grade or Non-Food Grade: When in the food and beverage industry, make sure that the PET bottles, which may likely come into contact with the food items, complies with the laid down food standards.

3. Major centers of sale and production.

There are several industrial hubs and markets in and around Delhi known for packaging materials, including PET bottles:

Bawana Industrial Area: Well known for manufacturing units in connection to plastic used in packaging.

Narela Industrial Area: It is one of the origin of raw materials as well as final products such as PET bottles.

Kirti Nagar: Manufacturers and distributors of packaging materials for various uses and trades are based in this region.

Sadar Bazaar & Chandni Chowk: Virtually all can be used those which are originally wholesale markets of various products may also have packaging supplies.

Get in touch with pet bottles manufacturers and distributors. Here are a few common approaches:

Direct Manufacturers: Like all other products, manufacturers have the most attractive prices particularly to the large scale buyers. Most of the PET bottle makers have their base in Delhi NCR.

Wholesale Distributors: For smaller quantities or more flavours, one can procure from distributors. They may even provide even better minimum order quantities than those of the manufacturers above.

Online Platforms: Local vendors can be some of the best sources and contacts can be made from sites such as IndiaMart, TradeIndia, Alibaba.

Notable Pet Bottles Suppliers in Delhi

Some PET bottle manufacturers and suppliers in Delhi you can look up include:

Teknobyte India Pvt Ltd : Concentrates on packaging products for for baverages, cosmetics, personal care, and medications. A company which has several pet preform and bottles manufacturing centres in India including some in the Delhi area.

Bansal Poly Plast Pvt. Ltd. : Provides a wide range of PET bottles for both, the beverage companies and the pharmaceutical industries.

Pearl Polymers Ltd. : More popularly recognized for its custom design services as well as for its ability to manufacture product in large quantities.

Quality and Compliance

It is a must that PET bottles should conform to certain quality assurance measures. Check for:

ISO Certification: This helps the manufacturer to meet the international quality standards hence produce high quality products.

BIS Certification: The regulation of quality PET bottles relating to foods and beverages and for other uses is done by the Bureau of Indian Standards (BIS).

FDA Compliance: When using the PET bottles in the food and beverage industry, the bottles should be FDA approved for use with food.

Negotiate and Build Relationships

Pricing: Book in large quantities in order to get lower prices and lock-in the prices in the future.

Samples: In large orders always ask for samples first in order to check the quality of the items.

Logistics and Delivery: Any contract with the supplier should have a strong logistics channel that will support the supply of the product. Add the cost of transpiration and delivery time if you are not situated in Delhi NCR.

Sustainability and Recycling

With increasing focus on sustainability, inquire about:With increasing focus on sustainability, inquire about:

Recycled PET (rPET): If sustainability is a concern in your beverages brand, one needs to consider supplier who sells Recycled PET bottles.

Post-Consumer Waste: Certain suppliers make an effort to incorporate post-consumer waste to bottles and as an outcome, minimize environmental effects.

Regulatory and Legal Considerations

For those whose businesses deal with packaged food or beverages, you should educate yourself with some rules regarding the PET bottles in India. Sign a legal agreement with your suppliers so that they meet today’s legal requirements of packaging.

To buy PET bottles in Delhi, India the following strategies are recommended; Local markets, industrial areas and online platforms. Stability in supply chain will also be achieved by ensuring that the company develops close associations with the suppliers.

#teknobyteindia#petbottles#petbottlesmanufacturer#petbottlesindelhi#petbottlessupplier#petbottlesexporter#petbottlesmanufacturerinindia

1 note

·

View note

Text

Injection Blow Moulding Machine Manufacturers: Who’s leading the Market?

Injection blow moulding (IBM) machines play a crucial role in the manufacturing of hollow plastic products, such as bottles, jars, and containers. This process combines injection moulding and blow moulding to produce high-quality, uniform products in large quantities. As the demand for plastic products continues to grow across industries, the market for injection blow moulding machine manufacturers has seen significant advancements, with several manufacturers emerging as leaders in the field. This blog explores the key players driving innovation and excellence in the injection blow moulding machine market.

1. Technological Innovation

In the competitive landscape of injection blow moulding machine manufacturing, technological innovation is a key differentiator. Leading manufacturers are investing heavily in research and development to introduce advanced technologies that improve efficiency, precision, and sustainability. These innovations include multi-layer moulding capabilities, which allow for the production of containers with enhanced barrier properties, and servo-driven systems that offer greater energy efficiency and precision control.

Moreover, some manufacturers are integrating Industry 4.0 principles into their machines, enabling real-time monitoring, predictive maintenance, and seamless integration with other production systems. The companies that are at the forefront of these technological advancements are setting new benchmarks in the industry.

2. Customization and Flexibility

In today’s dynamic market, the ability to offer customized solutions is a significant advantage. Top manufacturers of injection blow moulding machines are focusing on providing flexible machines that can be tailored to meet the specific needs of different industries, whether it’s pharmaceuticals, food and beverage, cosmetics, or household products. These manufacturers understand that one size does not fit all, and they offer a range of machine sizes, configurations, and capabilities to cater to diverse production requirements.

Leading companies often work closely with their clients to ensure that their machines are optimized for specific applications, providing a competitive edge in the market. By offering tailored solutions, these manufacturers build strong, long-term relationships with their customers.

3. Global Reach and Market Presence

The injection blow moulding machine market is global, with leading manufacturers operating across multiple continents. Companies with a strong global presence are better positioned to serve the needs of multinational corporations and respond to market trends in different regions. These manufacturers often have extensive networks of sales and service centers, ensuring that they can provide timely support and spare parts to their clients worldwide.

Global reach also enables these manufacturers to tap into emerging markets where the demand for plastic products is rapidly increasing. By establishing a presence in these markets, leading companies can expand their customer base and stay ahead of the competition. Additionally, a global presence often means that these manufacturers can source high-quality materials and components from around the world, further enhancing the reliability and performance of their machines.

4. Sustainability and Eco-Friendly Solutions

As environmental concerns grow, the demand for sustainable manufacturing practices has become more pressing. Leading injection blow moulding machine manufacturers are responding to this trend by developing machines that reduce energy consumption, minimize waste, and support the use of recycled materials. Some manufacturers are also exploring the use of bio plastics, which are derived from renewable resources and have a lower environmental impact compared to traditional plastics.

These eco-friendly machines are not only better for the environment but also offer cost savings for manufacturers by reducing material and energy costs. Companies that prioritize sustainability are increasingly being recognized as industry leaders, as they align with the growing demand for environmentally responsible manufacturing solutions.

5. Strong Customer Support and Service

In an industry where downtime can lead to significant financial losses, having reliable customer support is crucial. The top manufacturers of injection blow moulding machines distinguish themselves by offering comprehensive after-sales services, including regular maintenance, troubleshooting, and technical support. These companies often provide training programs to ensure that their clients’ operators are well-versed in the use and maintenance of the machines.

In addition to reactive support, proactive services such as predictive maintenance, remote diagnostics, and software updates are becoming standard offerings from leading manufacturers. By ensuring that their machines operate at peak performance, these companies help their customers maintain high productivity levels and reduce the total cost of ownership.

Conclusion

The market for injection blow moulding machine manufacturers is highly competitive, with several manufacturers leading the way through technological innovation, customization, global reach, sustainability, and strong customer support. These companies are setting new standards in the industry, offering advanced machines that meet the evolving needs of manufacturers across the globe. As the demand for high-quality plastic products continues to grow, the manufacturers that prioritize innovation, efficiency, and customer satisfaction will continue to lead the market.

0 notes

Text

Crafting Quality: Awanti Polymoulds’ Precision moulds for PET

Plastic bottles and containers serve a diverse range of purposes across industries such as beverages, food processing, pharmaceuticals, liquor, and home care products. They are utilized for packaging water, soda, juice, oil, jams, medicines, liquor, as well as personal and home care items, with sizes varying from small volumes to several litres.

At Awanti, we specialize in manufacturing blow moulds for PET bottles, employing advanced designing, high precision manufacturing and accelerated testing. Established in 1990, Awanti Polymoulds has been at the forefront of designing, manufacturing, and testing PET blow moulds to meet international standards. Precision and accuracy are paramount in our manufacturing process to ensure consistent, high-quality bottles that meet our customers’ expectations.

Our commitment to customer satisfaction extends both domestically and internationally, driving our continuous efforts to excel. Our moulds are engineered for durability, precision, and longevity. Properly matched with moulding machines, they have the capacity to endure for years and produce millions of bottles. We prioritize precision, customization, and attention to detail throughout the bottle designing, mould manufacturing, and testing phases.

With a longstanding presence in the beverage industry and tooling industry, Awanti Polymoulds has been a trusted supplier of blow moulds for brands like Coca-Cola, Unilever, Parle Agro, Bisleri, Pepsi, AJE and many more. Whether it’s fruit juices, carbonated beverages, natural mineral water, packaged drinking water, personal care products, or edible oils, Awanti has consistently delivered, always aiming for customer satisfaction.

0 notes

Text

Stainless Steel Lunch Boxes and Food Safety: Preventing Bacterial Growth

Pack Your Peace of Mind: Stainless Steel Lunch Boxes and Food Safety

Packing lunch is a fantastic way to save money and control what you eat throughout the day. But with packed lunches comes the responsibility of keeping food safe to avoid unpleasant surprises. This is where your choice of lunch box becomes crucial. While there are many lunch box options available, opting for a stainless steel lunch box can significantly enhance food safety and provide peace of mind.

Why Stainless Steel?

Unlike plastic lunch boxes that can harbour bacteria and potentially leach chemicals into your food, stainless steel offers a superior and safer alternative. Here's why:

Non-porous Surface: Stainless steel has a naturally non-porous surface, which means bacteria and mould have a hard time clinging to it. This reduces the risk of food spoilage and contamination compared to plastic lunch boxes with crevices where bacteria can lurk.

Easy Cleaning: The smooth, non-porous surface of stainless steel also makes it incredibly easy to clean. You can simply wash it with warm soapy water or toss it in the dishwasher (be sure to check the manufacturer's instructions for specific dishwasher compatibility). This ease of cleaning helps ensure proper hygiene and prevents the build-up of bacteria over time.

Leak-proof Potential: Many stainless steel lunch boxes come with leak-proof lids and compartments, which is a major plus! This not only prevents messy spills in your bag but also helps prevent cross-contamination between different food items in your lunch.

Maximizing Food Safety with Your Stainless Steel Lunch Box

While a stainless steel lunch box provides a significant advantage in terms of food safety, there are still some additional steps you can take to ensure your lunch stays fresh and delicious:

Pack Cold Foods Cold: Use insulated lunch bags or ice packs to keep your food cold, especially if it contains perishable items like meat, poultry, or dairy products.

Pre-chill Your Lunch Box: Pre-chilling your empty lunch box before packing can help maintain a cooler temperature for a longer period.

Portion Control: Packing the right amount of food helps avoid leftovers that may spoil if not consumed within a reasonable timeframe.

Clean Up Promptly: Don't let dirty lunch boxes become breeding grounds for bacteria! Wash your stainless steel lunch box thoroughly after each use and allow it to dry completely before storing.

MyneeMoe: Your Partner in Safe and Stylish Lunch Packing

At MyneeMoe, we understand the importance of packing healthy and safe lunches. That's why we offer a variety of high-quality stainless steel lunch boxes perfect for kids and adults alike. Our lunch boxes come in various sizes, styles, and designs to suit your needs and preferences.

Lunch boxes for kids: We have fun and colorful options that will make lunchtime exciting for little ones. The easy-to-clean stainless steel makes them a breeze to maintain, giving parents peace of mind.

Office lunch box: Our sleek and stylish stainless steel lunch boxes are perfect for busy professionals. They'll keep your food fresh and delicious all day long, ensuring you stay fueled and focused throughout your workday.

Packing a healthy and safe lunch doesn't have to be complicated. By choosing a stainless steel lunch box and following some simple food safety practices, you can ensure your meals stay fresh and delicious, wherever you may be. So ditch the plastic and embrace the safety and convenience of a MyneeMoe stainless steel lunch box! For more tips on making your lunchtimes fun and nutritious, check out our blog on Bento Box Hacks: Creative Ways to Make Lunchtime Fun and Nutritious. With these creative ideas, you can add variety to your meals and make healthy eating an enjoyable experience.

Ready to pack lunches with confidence? Explore our collection of stainless steel lunch boxes at https://www.youtube.com/watch?v=PchSYAbm3sg and find the perfect one for you!

0 notes

Text

What Commonly Used Injection Molding Materials Have: An Insight into Their Properties and Applications.

Injection molding is a widely utilized manufacturing process that involves injecting molten material into a mold to create a wide array of products. The choice of material is crucial as it influences the properties, cost, and applications of the final product.

Here, we delve into some of the most used injection molding materials, exploring their characteristics and common applications.

1. Polypropylene (PP)

Characteristics:

Polypropylene is a type of plastic that is very versatile. It is lightweight, resists chemicals well, and can handle repeated stress without breaking. This makes it perfect for uses that need to be durable.

Applications:

PP is often used in packaging, car parts, everyday products, and medical devices. Repeated bending makes it great for items like living hinges that need to bend a lot.

2.Acrylonitrile Butadiene Styrene (ABS)

Characteristics:

ABS is a type of plastic made by mixing styrene and acrylonitrile with polybutadiene. This makes it very strong, tough, and keeps its shape well.

Applications:

ABS is commonly used in car parts, electronic cases, everyday items, and toys. Its strength and easy shaping also make it popular for 3D printing.

3. Polyethylene (PE)

Characteristics:

Polyethylene comes in different types like HDPE and LDPE. It resists chemicals, insulates electricity, and is flexible. HDPE is harder and more rigid, while LDPE is softer, more flexible, and melts at a lower temperature.

Applications:

PE is used for many items like containers, bottles, plastic bags, and toys. It is also great for medical and food packaging because it is safe and non-reactive.

4. Polycarbonate (PC)

Characteristics:

Polycarbonate is a strong type of plastic known for being tough and clear. It can be shaped easily and is used in many ways.

Applications:

Polycarbonate is often used in eyeglass lenses, medical tools, car parts, and electronics. Its clearness and strength make it perfect for things that need to be strong and easy to see through.

5. Polystyrene (PS)

Characteristics:

Polystyrene is a type of man-made plastic that comes in two types: solid and foam. It is light, stiff, and cheap to make.

Applications:

PS is used in things like disposable utensils, plastic models, CD cases, and foam packaging. The foam kind, called expanded polystyrene (EPS), is common in insulation and packing materials.

6. Nylon (Polyamide - PA)

Characteristics:

Nylon is a man-made material that is strong and flexible. It can handle being pulled hard, resist wear and tear, and is good with heat and chemicals.

Applications:

Nylon is used in cars, machines, everyday items, and clothes. It is tough and strong, perfect for parts that get a lot of use and pressure.

7.Polyethylene Terephthalate (PET)

Characteristics:

PET is a thermoplastic polymer resin of the polyester family. It is known for its strength, thermostability, and resistance to moisture.

Applications:

PET is widely used in beverage bottles, food packaging, and synthetic fibers. Its recyclability makes it a popular choice for environmentally conscious manufacturers.

Different materials used in injection molding have special qualities that suit various needs. For example, polypropylene is versatile and tough, while polycarbonate is strong and clear. Knowing these traits helps manufacturers pick the best material for their specific use, ensuring good performance, cost-efficiency, and eco-friendliness. As technology and materials improve, more options for injection molding become available, opening new possibilities for innovation in manufacturing.

There are 7 Most Common Injection Moulding Gate Types - Choosing a Gate for Your Project

An injection molding gate is a specially designed opening that controls how molten plastic flows into the mold. Its main job is to manage the amount and direction of the plastic as it fills the mold. There are different kinds of gates, such as edge gates, sub gates, and direct sprue gates, each with its own unique features and uses. We will look at these types more closely below.

Most common types of injection moulding gate:

Edge Gates

Tunnel / Submarine (Sub) Gates

Cashew Gates

Sprue or Direct Gates

Fan Gates

Diaphragm Gates

Pin Gates

Inject moulding is a prototyping tool made by HLH Rapid. Before beginning production, our engineers choose the ideal gate for your design and build bespoke moulds and parts based on your CAD drawings. Simply use our site contact form to send us your CAD designs and project specifics, including quantity, material, and any surface finishing. In a span of 24 to 48 hours, our staff will furnish an estimate.

Do you want to learn about Injection Molding or need a Free Quote? Submit your CAD drawings and project details, including quantity, material, and surface finish, through our site contact form. Our team will send you a quote within 24-48 hours.

0 notes

Text

The Role Of Plastic Moulds

Plastic moulds have become an integral part of our daily lives, playing a significant role in the production of various household items. From storage containers to kitchen utensils, the versatility and affordability of plastic moulds have made them a popular choice for manufacturers and consumers alike.

Applications of Plastic Moulds in Household Items:

1. Kitchenware: Plastic moulds are extensively used in the production of kitchenware such as plates, bowls, cups, and cutlery. They are lightweight, durable, and easy to clean, making them a practical choice for everyday use.

2. Storage Solutions: Plastic moulds are used to create a wide range of storage containers, from small food containers to large storage boxes. These moulds allow for the creation of containers with various shapes, sizes, and compartments to suit different storage needs.

3. Bathroom Accessories: Toothbrush holders, soap dishes, and shower caddies are examples of bathroom accessories that can be made using plastic moulds. These items are typically designed to be water-resistant and easy to clean.

4. Furniture Components: Plastic moulds are also used in the production of certain furniture components, such as chair legs, table edges, and decorative trims. They offer a cost-effective alternative to traditional materials like wood or metal.

5. Toys and Games: Many toys and games are made using plastic moulds, including building blocks, puzzles, and board games. The use of plastic moulds allows for intricate designs and bright colours, making these products appealing to children.

0 notes

Text

Breaking Down Sustainability: Cardboard Egg Cartons and Sustainable Poultry Packaging

In today's world of environmental awareness, sustainable packaging is a must. Businesses and consumers are more concerned than ever with reducing waste and cutting carbon footprints. The cardboard egg carton is one such solution that has stood the test of time.

Environmental Advantages of Cardboard Egg Cartons

Cardboard egg cartons have been used in homes for many years now. They are made from recycled paper pulp which makes them renewable and biodegradable unlike plastics. Through the use of recycled materials, they help to reduce virgin paper demand thus saving natural resources as well as lowering energy consumption.

Environmental Advantages

Cutting Waste: Cardboard egg cartons can be recycled or composted when they are no longer needed, unlike plastic packaging. Doing this avoids dumping rubbish into the ground, which is still a major environmental concern mainly because of plastics.

Bio-degradability: Over time, cardboard egg containers rot naturally without causing much harm to the environment around them. Therefore, these types of packages are preferred by many environmentally friendly buyers who want to reduce their carbon footprint as much as possible.

Saving Resources: Trees and water are among the vital natural assets that can be preserved with paper pulp from recycled materials used in making cardboard egg cases. Besides this, producing such cartons requires less energy compared to plastics hence lowering their ecological impact even further.

Sustainability in Poultry Packaging

Apart from cardboard egg cartons, sustainable poultry packaging is also being revolutionised by other creative ideas. Their purpose is to heighten security, reduce wastage and foster ecological responsibility across the supply chain.

Moulded Pulp Packaging: For poultry products such as eggs, some manufacturers are resorting to moulded pulp packaging. This kind of wrapping is made from recycled paper pulp which cushions fragile items well like eggs. Moreover, it can degrade and thus compost after use too making it more eco-friendly still.

Biodegradable Films: Another new development involves using biodegradable films derived from plants when packing poultry goods. Such wrappings provide a green substitute for conventional plastic packages which can be composted or recycled later on.

Conclusion

To sum up, sustainable poultry packaging solutions and cardboard egg cartons are much better for the environment than their plastic equivalents. Companies and customers can reduce rubbish, save the earth’s raw materials and offset food package production ecological consequences by choosing green packaging.

With more demand placed on sustainable packaging every day businesses need to start investing in environmentally friendly options as well as finding creative ways to promote sustainability throughout their supply chains. Let us work hand in glove towards a sustainable future for our children.

0 notes

Text

Exploring Emerging Applications: Thermoformed Plastics Market Dynamics

Thermoformed Plastics: An Essential Part of Modern Packaging

Introduction to Thermoforming

Thermoforming is a plastic forming process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. The key advantages of thermoforming are its ability to produce complex, high-volume shapes in a single continuous process. Some common thermoformed products include food and medical packaging, containers, automotive interior parts, signs and displays.

Sheet Forming Process

In the thermoforming process, plastic sheet material such as PVC, polystyrene, polyethylene, polypropylene, or acrylic is used. The sheet is first heated to high temperature using infrared heaters until it softens and sag. It is then placed over a matched mold cavity and a vacuum is applied from below, forcing the softened sheet tightly against the mold surface. The sheet cools and hardens to the exact shape of the mold profile before being trimmed and ejected. This allows consistent high-volume production of parts with complex 3D shapes.

Applications in Food Packaging

Thermoformed plastics play a crucial role in food packaging where packaging needs to be inexpensive yet functional. Common examples include:

- Meat and produce trays - Polystyrene and polypropylene trays of varying sizes are used in supermarkets for packaging sliced meats, cheeses, fruits and vegetables.

- Cereal liner bags - PET and polypropylene sheets are thermoformed into shape-retaining liner bags that fit inside cereal boxes for moisture and freshness protection.

- Egg cartons - Recyclable polystyrene cartons thermoformed into compartments provide protection for transporting eggs.

- Takeout containers - Disposable clamshell containers made from polystyrene or polypropylene are used ubiquitously for serving and carrying out foods from restaurants and fast food outlets.

- Yogurt and snack cups - PET, polypropylene or polylactic acid (PLA) cups are thermoformed for packaging single-serve yogurt, pudding, juice boxes and snack products.

Sustainability Considerations

As concerns grow around plastic waste and sustainability, thermoformers are increasingly focusing on use of recycled resins and design of packaging for recyclability. Some key trends include:

- Incorporation of post-consumer recycled (PCR) content in packaging to promote circular economy.

- Mono-material thermoformed containers made of PET, PP or PE for improved sorting and recycling.

- Reduced plastic thickness and shaping features to minimize material usage.

- Compostable thermoformed products made from PLA or paper for composting or recycling streams.

The future of thermoformed plastic packaging lies in sustainable design, efficient processes, and alternative biodegradable resins to balance performance, cost and environmental impact. Continued innovation is ensuring this technology remains relevant in a changing regulatory

landscape.

In Summary, thermoformed plastics have become integral components of modern packaging solutions, offering versatility, durability, and cost-effectiveness. This manufacturing process involves heating plastic sheets and molding them into various shapes to create packaging for a wide range of products. From food and beverages to consumer goods and medical supplies, blow moulding plastics provide lightweight and customizable packaging options that protect products during storage and transportation. Their ability to conform to specific shapes and sizes, along with their transparency and barrier properties, make them ideal for showcasing and preserving goods while reducing packaging waste. As a vital element in modern packaging, blow moulding plastics continue to play a crucial role in meeting the evolving needs of industries worldwide.

0 notes

Text

Pet Bottle Blowing Machine- Seppasolutions.com

The pet blowing machine is a revolutionary packaging technology that molds and shapes PET plastic material into various shapes and sizes, making it ideal for packaging a wide range of products, including beverages, food items, cosmetics, and pharmaceuticals. Its primary application is in bottle manufacturing, where PET bottles are produced in large quantities with consistent quality. PET containers also provide excellent protection against moisture, oxygen, and other external factors, ensuring the stability and safety of pharmaceutical formulations.

#pet blowing machine#pet bottle blowing machine#bottle blowing machine#automatic pet bottle blowing machine#pet making machine#pet bottle making machine#pet blowing machine manufacturer in india

0 notes

Text

The Advantages Of Plastic Packaging Pallets

Packaging Pallets plays a crucial role in today’s modern logistics. It pays to think long-term about what kind of pallet is ideal for all facets of your organization, as they are an essential component of any supply chain. Various materials, mainly wood and plastic, are used to make pallets, and almost every item you see in a store is transported on a pallet. Pallets come in a wide variety of materials, with wood and plastic being the most popular. Plastic pallets are made via plastic injection moulding, allowing durability and space-saving design.

You can carry everything from furniture to clothes using plastic pallets, whether relocating or intending to operate a business.

Choosing plastic pallets from printing and packaging plastic pallets manufacturers offers several benefits:-

Pallets made of plastic are simpler to move.

Plastic is more resilient than wood and is less prone to malfunction after several flights. Plastic pallets are also excellent for moving objects with a forklift in a warehouse and hauling extensive material during shipment. In addition, plastic pallets are better equipped to tolerate more extreme weather conditions while in transportation compared to wood pallets.

Plastic pallets are reasonably priced.

Whether you’re shipping products by land, sea, or air, freight costs are often less expensive when using plastic pallets than wooden ones. Plastic pallets frequently cost more upfront, but because of their longevity, the cost of each trip is frequently much lower. Recent technological advancements have reduced the price of plastic pallets.

Hygienic pallets made of plastic

Common problems with wood pallets, such as decay, infestation, fumigation, and smell absorption, are no longer a concern since plastic pallets do not absorb moisture. Because of this, cleaning plastic pallets’ flat surfaces after each usage is straightforward and comprehensive. Plastic pallets are ideal for businesses with strict regulations and cleanliness standards, such as the pharmaceutical and food and beverage sectors. Termites are drawn to wood, which is never good for a business that is shipping a lot of goods. Additionally, you don’t want germs or fungus to get onto your merchandise. On the other side, cleaning plastic pallets is a breeze. A quick water hose spray will do wonders for cleaning a plastic pallet. A wood pallet is more challenging to clean since termites and fungi grow on damp wood.

Plastic packaging pallets make everyone safer.

In contrast to wood pallets, plastic pallets don’t have weak points at specific locations. This results from how plastic pallets are made as single pieces. As a result, the likelihood of units collapsing under an oversized load is reduced. Nails, splinters, and broken boards are all avoided using plastic pallets rather than wooden ones. This denotes that your priceless items are less likely to be harmed, and the workplace is safer for your employees.

Plastic packaging pallets takes up less room.

The ability to nest plastic pallets gives them a significant advantage over wooden pallets. A nine-leg bottom is a common characteristic of nestable pallets, which may save valuable warehouse space by nesting into other pallets. Many businesses attempting to go green have made it one of their goals to produce less garbage. Plastic can be recycled entirely; plastic is reusable and can be recycled if something happens. Damaged wooden pallets are typically either dumped at a landfill or burnt.

More adaptable and versatile than wooden pallets

Plastic pallets come in various styles and can be utilized for multiple settings and objectives. They are more pliable and durable, may be created to meet the individual requirements of various industries, regardless of whether the majority of your operations occur in the warehouse or during export. Plastic pallets don’t contain splinters, as was already explained. Additionally, they lack sharp edges and nails. When goods are transported on wooden pallets, there is a greater danger of damage. Plastic pallets will efficiently and securely meet your transportation demands. Plastic pallets are more cost-effective since they are more space-efficient and more adaptable.

Wooden pallets survive less time than plastic ones.

When deciding between plastic and wood pallets, it’s a good idea to think about how you’ll use them. Purchasing pallets made for lifespan makes sense if you often ship goods or use them in a warehouse. Plastic pallets may be used repeatedly without suffering significant damage. By doing your part to remove garbage from the ecosystem rather than adding to it, you can fight the throwaway culture that fuels climate change and position your company on the right side of history.

Flexibility

Plastic is not only strong, but it is also flexible. It has the benefit of allowing various sizes and types of items to fit on a single pallet. Only one kind of item can be packed on a wooden pallet. Most plastic pallets come with dividers of different widths, making loading a wide range of things simple. Our plastic pallets and boxes are molded under intense pressure in highly polished molds for consistency, dimensional precision, and loading capabilities. When compared to wood, a plastic pallet has unmatched strength and durability. Heavy strength plastic pallets and boxes can resist demanding, closed-loop settings with high repetition.

Conclusion

Plastic pallets are known to survive almost ten times longer than wood as a company asset. Using a specific plastic pool pallet, an owned pallet pool may be built that can even produce its income, providing a significant return on investment. Because plastic packaging pallets are exempt from International Standards for Phytosanitary Measures No. 15 (ISPM15), which eliminates the requirement to heat treat and certify them for usage, they are cost-effective for export.

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#hdpepallets#plasticproducts#hdpeplastic#swifttechnoplastprivatelimited#printing pallet#packaging pallet

0 notes

Text

Exploring The Dominance Of Gallons Package Bucket Moulds In The Industry

In recent years, the demand for highly durable and reliable packaging solutions has witnessed a significant surge across industries. One such unique product that has gained immense popularity is the Gallons Package Bucket Mould. This innovative packaging option offers numerous benefits, including enhanced durability, versatility, and ease of use. We will delve into the world of Gallons Package Bucket Moulds and shed light on the leading manufacturers in the industry.

Gallons Package Bucket Mould: A Game-Changer in the Packaging Industry

Gallons Package Bucket Moulds have revolutionized the packaging industry with their exceptional features and versatile uses. These moulds are specifically designed to cater to the diverse needs of various industries, ranging from chemicals and paint to food and beverage. The sturdy construction of these moulds ensures that they can withstand the hard environmental conditions, making them an ideal choice for storing and transporting hazardous materials.

Good Durability and Versatility

The Gallons Package Bucket Moulds are made from high-quality materials, ensuring durability and longevity. The moulds can withstand heavy loads and resist breakage, providing a reliable packaging solution. Additionally, these moulds are available in different shapes and sizes, offering versatility to suit the specific requirements of different products and industries.

Manufacturers in the Industry

When it comes to Gallons Package Bucket Moulds, several manufacturers have established their reputation for delivering top-notch quality and innovative designs. One such prominent player in the industry is the Oil Bucket Moulds Manufacturers. Their commitment to quality and continuous investment has made them a leading name in the competitive market. With their advanced manufacturing facilities and skilled workforce, Oil Bucket Moulds Manufacturers have successfully carved a niche for themselves in the packaging industry.

Quality Assurance and Customization Options

Oil Bucket Moulds Manufacturers prioritize quality and ensure that their products adhere to stringent international standards. They use advanced technology and techniques to manufacture Gallons Package Bucket Moulds that meet the highest quality benchmarks. Moreover, these manufacturers offer customization options, allowing businesses to tailor the moulds according to their specific requirements, branding, and labeling.

Meeting Sustainability Goals

As the world gravitates towards sustainable solutions, Gallons Package Bucket Moulds have emerged as an eco-friendly alternative to plastic containers. The manufacturers, including Oil Bucket Moulds Manufacturers, have embraced sustainable practices by utilizing recyclable materials and incorporating eco-friendly designs. This shift towards sustainable packaging solutions not only reduces environmental impact but also helps businesses align with their sustainability goals.

The Gallons Package Bucket Moulds have undoubtedly brought about a paradigm shift in the packaging industry. Their goodl durability, versatility, and eco-friendly attributes make them an ideal choice for diverse sectors. With leading manufacturers like Oil Bucket Moulds Manufacturers constantly pushing the boundaries of innovation and quality, these moulds are set to dominate the packaging industry. As businesses strive for efficient and sustainable packaging solutions, Gallons Package Bucket Moulds are poised to play a crucial role in shaping the future of the industry.

0 notes

Text

Guide to Understanding Different Types of Plastic Processing Machines

Plastics are everywhere. We use them daily in our consumer goods, kitchen, and drive cars made of plastic materials. But have you ever realised how the everyday plastic product is built before it reaches the retail market?

Different plastic processing machinery that streamline the plastic-making process are available in the manufacturing unit. That said, each machine is integrated with other functions to give the final shape to a plastic.

Understanding plastic processing machines involves knowledge about the various types of devices, their components, processes, and applications. In this blog, we will discuss the kinds of plastic processing machines, their method of making plastic products, and their applications in various industries.

Types of Plastic Processing Machines

Let’s discover the four main types of plastic processing machines and understand each machine’s functions and applications. Here are the most common types of plastic processing machines that you should know if you are a manufacturer of plastic materials.

1. Injection Moulding Machines

Injection moulding is one of the most useful plastic processing machinery for making large volumes of single plastic products. Smaller, low-density and recycled plastic granules are heated and shaped to make one plastic product in the injection moulding process.

● Process of Injection Moulding Machines

In the injection moulding process, the three main units i.e. injection unit, mould, and clamping unit, work together to make a plastic product. Inside the injection unit, plastic granules are put down in a hopper. Further, the hopper feeds the barrel unit, where the barrel screw warms up the plastic. Gradually, the screw in the barrel pushes the plastic into the mould cavity until it is completely molten. Lastly, the plastic firms itself during the process and gets completely cool.

As the process begins, the clamping unit closes the mould cavity securely during the injection and moulding process. And as soon as the plastic takes shape, the clamp pushes out the final product.

● Application of Injection Moulding Machines

Injection moulding machines are highly in demand in various industries.

Packaging industry: Plastic containers, Plastic bottles, Bottle caps

Automobile Industry: Car interiors, mechanical parts

Electrical components, electrical switches, electric connectors

Medical devices and Lego toys

Furniture industry: Chairs, tables, seat covers or cushions

2. Blow Moulding Machines

Blow moulding machines are a simpler process that involves making hollow plastic products. Interestingly, you can rely on blow moulding machines to make hollow-shaped bottles, containers, and other hollow parts due to the very nature of hollow moulds used in them.

● Process of Blow Moulding Machines

The process of blow moulding, as the name suggests, is to blow the melted plastic into the hollow shape of the mould. It starts when the molten plastic is squeezed into a hollow form. Then, the clamping unit securely holds and closes the mould to prevent plastic leaks in the next steps. A tube-like structure allows air to inflate the plastic and form its desired shape during the process.

● Applications of Blow Moulding:

Blow moulding is a plastic processing machinery that can create plastic objects for the following industries.

Plastic packaging industry: jars, drums and jugs.

Food packaging industry: Beverage bottles

Household use: Personal care items

Industrial tanks, water storage tanks, and cosmetic plastic bottles

Automobile industry: Fuel tanks, air ducts, interior and exterior vehicle parts

3. Plastic Granulator Machines

Plastic granulator machines are the most commonly used systems to recycle waste plastic and industrial scraps. These machines have in-built rotor blades that crush the polymers into small particles. The smaller granules are then processed in the plastic manufacturing industries to make the final product.

● Applications of Plastic Granulator Machines

Similar to other plastics processing machinery, granulated plastic is useful for various purposes:

Construction materials, including pipes and profiles.

Automobile parts

Plastic toys

Medical Packaging

4. Inspection Machines

Inspection machines are designed with a high-state technology to detect the capabilities of the final product. Once the final product passes through the last stage, detection systems provide more accurate information about the durability of the plastic or glass products.

Many businesses use leak detection, drum tester and spark testing machines to check the following attributes:

Plastic leaks to prevent the product from melting in high temperatures

Sparks to avoid extremely hot plastic from running into fire hazards

Sizes of bottlenecks

Takeaway

Each machine plays a distinctive role in plastic processing, transforming raw materials into a myriad of everyday wonders. Injection moulding efficiently presents large volumes of consistent plastic products, while blow moulding breathes life into bottles. Plastic recycling granulator champions sustainability and inspection systems and highly regards precision quality control.

Together, any plastics processing machinery focuses on innovation, shaping our world from intricate components to versatile packaging. In plastic processing, even inspection machines are critical—a testament to the resilience and adaptability of this ever-evolving industry.

If you liked this blog, please share and pass on the knowledge to fellow readers.

Follow Mitchell Industries for all your Plastic Manufacturing Processes

We are highly committed to keeping the plastic production process easy. Mitchell Industries is an exporter, importer and manufacturer of plastic processing machinery in Australia. We have highly trained engineers, designers and workers who can provide valuable guidance in installing and maintaining our high-end machines.

The best thing about our service is that we sell small plastic recycling machines like granulators to intricate injection moulding machines at a fair price. Further, our devices have advanced software to help you achieve a faster production rate. We don’t settle for less – call us today for further enquiries.

0 notes

Text

Premier Injection Blow Moulding Machine Manufacturers in India

Injection blow moulding is a pivotal process in the manufacturing of plastic products, combining the precision of injection moulding with the flexibility of blow moulding. This process is essential for producing high-quality, consistent, and durable plastic containers, bottles, and other hollow products. In India, several manufacturers have established themselves as leaders in producing state-of-the-art injection blow moulding machines. This blog explores the premier injection blow moulding machine manufacturers in India, highlighting their innovations, technological advancements, and contributions to the industry.

Understanding Injection Blow Moulding

Before delving into the manufacturers, it’s essential to understand the injection blow moulding process. This method involves three main stages: injection, blowing, and ejection. Initially, plastic is injected into a perform mold to create a perform. Finally, the product is ejected from the mold. This process is highly efficient, allowing for the production of complex shapes with excellent surface finish and structural integrity.

Technological Excellence in Manufacturing

India's premier injection blow moulding machine manufacturers have leveraged advanced technology to enhance the efficiency, precision, and versatility of their machines. These manufacturers utilize cutting-edge CNC (Computer Numerical Control) machinery, automation, and robotics to ensure that their machines meet the highest standards of performance and reliability. The integration of Iota (Internet of Things) and Industry 4.0 principles further enables real-time monitoring and control, optimizing the production process and minimizing downtime.

Customization and Versatility

One of the hallmarks of leading manufacturers in India is their ability to offer customized solutions tailored to the specific needs of their clients. Whether it’s designing machines for producing small pharmaceutical bottles or large industrial containers, these manufacturers provide versatile options that cater to various industries, including pharmaceuticals, food and beverage, cosmetics, and automotive. Their machines are designed to handle different types of plastics, such as PET, PP, HDPE, and LDPE, ensuring broad applicability.

Innovation and Research

Innovation is at the core of the top injection blow moulding machine manufacturers in India. By continuously exploring new materials, process improvements, and design innovations, they are able to introduce machines that offer superior efficiency, reduced energy consumption, and enhanced product quality. Collaboration with academic institutions and global industry leaders also plays a crucial role in driving innovation.

Quality Assurance and Certification

Quality is paramount in the production of injection blow moulding machines, and India’s leading manufacturers adhere to stringent quality assurance protocols. These companies are often ISO certified and comply with international standards, ensuring that their machines deliver consistent performance and longevity. Rigorous testing and inspection at various stages of manufacturing guarantee that each machine meets the specified quality criteria before it reaches the customer.

After-Sales Support and Training

a significant advantage of working with premier injection blow moulding machine manufacturers in India is the comprehensive after-sales support they provide. These manufacturers offer installation assistance, maintenance services, and prompt troubleshooting to ensure smooth operation of the machines. Additionally, they provide training programs for the clients’ technical staff, equipping them with the necessary skills to operate and maintain the machines effectively.

Sustainable Manufacturing Practices

In response to the growing emphasis on sustainability, leading manufacturers in India are adopting eco-friendly practices in their production processes. They are focusing on energy-efficient machines that reduce carbon footprint, utilize recyclable materials, and minimize waste. These efforts align with global sustainability goals and help clients achieve their own environmental objectives.

Conclusion

India is home to some of the premier injection blow moulding machine manufacturers in india that have made significant strides in technology, innovation, and quality. Their commitment to excellence, customization, and sustainable practices makes them reliable partners for businesses across various industries. By choosing to work with these manufacturers, companies can ensure that they have access to advanced, efficient, and versatile injection blow moulding solutions that meet their specific production needs and contribute to their overall success.

#injection blow moulding machine manufacturers in india#injection blow moulding machine manufacturers#injection blow moulding machine

0 notes

Text

Crafting Quality: Awanti Polymoulds’ Precision moulds for PET

Plastic bottles and containers serve a diverse range of purposes across industries such as beverages, food processing, pharmaceuticals, liquor, and home care products. They are utilized for packaging water, soda, juice, oil, jams, medicines, liquor, as well as personal and home care items, with sizes varying from small volumes to several litres.

At Awanti, we specialize in manufacturing blow moulds for PET bottles, employing advanced designing, high precision manufacturing and accelerated testing. Established in 1990, Awanti Polymoulds has been at the forefront of designing, manufacturing, and testing PET blow moulds to meet international standards. Precision and accuracy are paramount in our manufacturing process to ensure consistent, high-quality bottles that meet our customers’ expectations.

Our commitment to customer satisfaction extends both domestically and internationally, driving our continuous efforts to excel. Our moulds are engineered for durability, precision, and longevity. Properly matched with moulding machines, they have the capacity to endure for years and produce millions of bottles. We prioritize precision, customization, and attention to detail throughout the bottle designing, mould manufacturing, and testing phases.

With a longstanding presence in the beverage industry and tooling industry, Awanti Polymoulds has been a trusted supplier of blow moulds for brands like Coca-Cola, Unilever, Parle Agro, Bisleri, Pepsi, AJE and many more. Whether it’s fruit juices, carbonated beverages, natural mineral water, packaged drinking water, personal care products, or edible oils, Awanti has consistently delivered, always aiming for customer satisfaction.

1 note

·

View note