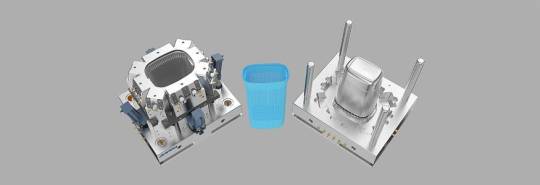

#Houseware Mould Exporters

Text

How to Choose a Reliable Houseware Mould Manufacturer?

Experience and Expertise:

One of the first factors to consider is the manufacturer’s experience and expertise in the industry. Look for a company with a solid track record and a long history of manufacturing houseware mould. An experienced manufacturer will have a deep understanding of mould design, materials, and manufacturing processes, ensuring the production of high-quality mould.

R. D. Mould & Industries boasts a rich history spanning several years, demonstrating their deep understanding of mould design, materials, and manufacturing processes.

Customization Capabilities:

Every houseware product is unique, and a reliable mould manufacturer should be able to accommodate customization. R. D. Mould & Industries understands the importance of tailored solutions and offers customization options to meet diverse client requirements. Their team of skilled professionals works closely with clients to ensure that the mould are designed and manufactured to precise specifications.

Materials and Durability:

R D Mould & Industries involves considering the materials used by the manufacturer to make the mould. Material selection can significantly affect mould durability and lifespan. Trusted household mould manufacturers will have knowledge of different materials and recommend the most suitable options for your specific houseware mould products.

Product Range and Specialization:

Consider the product range and specialization of the manufacturer. R. D. Mould & Industries offers a diverse range of houseware mould, catering to various product categories such as kitchenware, storage containers, and more. Their specialization in houseware mould manufacturing ensures that they understand the specific requirements and challenges of this industry.

Conclusion:

Choosing a reliable houseware mould manufacturer is crucial for the success of your product manufacturing. R. D. Mould & Industries stands out as a trusted and reputable choice in the industry. With their extensive experience, specialization, customization capabilities, and commitment to quality, they are well-equipped to meet your houseware mould requirements. By partnering with R. D. Mould & Industries, you can have confidence in the reliability, precision, and timely delivery of your houseware mould.

#Houseware Mould#Plastic Houseware Mould#Houseware Mould Manufacturer#Houseware Mould Exporters#Plastic Food Container Mould Manufacturer#Houseware Injection Mould#Houseware Blow Mould

0 notes

Text

5 Common Plastic Resins Used in Injection Molding

ABS With outstanding impact and mechanical strength, ABS (Acrylonitrile Butadiene Styrene) is used in a wide range of industries and applications, from automotive to piping. Metal coatings can easily adhere to this material, making it well suited for products such as desktop phones, shower heads, and handles. ABS does not have good chemical resistance, however, and should not be used in applications requiring electrical insulation or UV resistance.

Apart from Plastic Toy Mould Exporters We're also dealing in Plastic Toy Injection Mould And Plastic Toy Blow Mould & Etc.

Celcon (Acetal)

Celcon, a common brand name for Acetal, offers excellent surface lubricity, creep resistance (memory), and chemical solvent resistance. Ideal for food and beverage, mechanical, automotive, and household applications, this is our resin of choice for manufacturing K’NEX toy parts, as well as gears and bearings. It’s also often used in automotive applications and household appliances. It should not be used for applications in high heat environments.

Polypropylene

Polypropylene (PP) is known for its flexibility in packaging, fluid management and processing, and household goods, as well as some automotive applications. While polypropylene is flammable and vulnerable to UV radiation, it still offers good resistance to chemical solvents and electricity. Most grades of Polypropylene are flammable and degraded by UV radiation.

We R D Mould & Industries are a renowned Plastic Toy mould manufacturer in Ahmedabad,Gujarat, India, provide various types of Plastic Toy Mould Including Plastic Toy Injection Mould, Plastic Toy Blow Mould & Etc.

HIPS

High Impact Polystyrene (HIPS) provides tough, low-cost performance and highly customizable surfaces: It can be printed, glued, bonded, and decorated easily. This material is especially popular in merchandising applications and displays, printed graphics and prototypes. Although flammable, flame-retardant varieties are available.

LPDE

The most flexible version of polyethylene, LPDE, or Low-Density Polyethylene, offers moisture resistance and high impact strength. LPDE can be found in many consumer goods and housewares, as well as medical products and electronic wiring. It is difficult to bond, however, and should not be used in harsh weather or high-temperature applications.

0 notes

Photo

Welcome to Nagual Houseware Limited.

Nagual Housware was founded in 2007, and its business continues to grow and develop.Now it has become a large-scale manufacturing company with integrated design, research and development, OEM, and ODM. The business involved includes: Best custom cutlery manufacturer,Kitchen knife tools,Stainless steel tableware ,Stainless steel cookware ,Stainless steel kettle ,Stainless steel houseware , stainless steel flatware,Plastic handle flatware,Silicone kitchen tools and grill tools。

Passed BSCI commercial society standard certification and SMETA Sedex member moral trade audit。

Company research and development of many years of production experience, with Europe and the United States synchronized advanced mould processing center and a large number of high-quality industry elite, and continuously produce products designed to satisfy the masses of customers friend. Our products are all made of imported superior stainless steel, with excellent quality, beautiful shape, reasonable price and perfect and thoughtful after-sales service to win the market. For many years to improve the quality of products, product quality, process achieves the domestic advanced level, best-selling domestic major cities, are exported to Europe, America, Middle East, southeast Asia and other countries and regions, favored by domestic and overseas customers trust and praise. Our company always adhere to "quality survival, reputation and promote development" as the enterprise objective, continuous reform and innovation. Welcome new and old customers at home and abroad, for processing manufacturing, negotiate business cooperation!

It is believed that innovative ideas and attentive service are far more important than price. Therefore, we pay close attention to our clients' demands and do our utmost to offer them our best service. Our distinguished customers can get the most competitive quotation with their brand-new designs since we have our own factory, so originality and OEM are highly welcome. Furthermore, the fresh designs, at your request, will be completed within 5 business days.

Please tell us your brilliant ideas and wait for us to turn them into the hot-selling goods on your shelves.

2 notes

·

View notes

Text

Different Types of Dip Moulding Products

Shraddha Dip Moulding are engaged in manufacturing, supplying, and exporting a wide range of dip moulded products and a versatile technique for the production of flexible and semi-rigid PVC components. Here are a few products which lead the show and make Shraddha Dip Moulding products a leader in the development of the process and applications.

Dip Moulded PVC Coating

The dip moulded products are available in various lengths, colours, textures, and chemical formulations. A few ideal features of dip moulded PVC products are high-temperature resistance, anti-stat, copper staining, and flame resistance. Some of the types are Dip moulded Vinyl Caps, PVC angle caps, PVC Rectangular Caps, and PVC Grab Tab Caps. They are used in innumerable industries like medical, industrial equipment, military, security, and protection. To dip mould an object the mould is first heated and then submerged into the PVC material. Next, the mould is removed, drained, and left to dry.

Dip Moulded Vinyl

The Dip moulded Vinyl products form the basics for candle manufacturing. It is made by heating a mould at the required temperature and dipping it in a tank of liquid plastisol. Once the heat from the metal mould attracts the liquid plastisol, a part is formulated. Then the parts are cured, post which the parts are cooled and set apart from the metal moulds. The category includes Hex Vinyl End caps, the loop-type vinyl end caps, the vinyl grip end caps, and the vinyl pull tab caps. The vinyl special materials ensure more vibrant colours to be achieved and come in innovative textures. Moreover, multi-dipping capabilities help in low tooling costs and provide customer-friendly exteriors.

Dip Moulded PVC Grip

The dip moulded PVC grips include an array of custom-designed components like the protection caps, long gaps, square caps, E-Z tab caps, square end caps, and much more. They provide ultimate grip technology and provide economical as well as volume production of flexible and semi-rigid PVC components. The dip moulding handles to grip, custom dip moulding and the dip moulded grips with long caps are used across various industries like security, packaging, machine tools, and housewares. They are extremely precise, simple, and inexpensive.

Dip moulded PVC caps

The dip moulded PVC caps are found in a multitude of options with various diameters, finishing, colors, and formulations. They are useful in ensuring customized requirements with the added advantage of being temperature resistant, non-staining in copper, and flame resistant. The types come in plastic moulded, Dip moulded PVC caps multicolor, dip moulded PVC battery terminal caps, and silicone and PVC dip moulding. There are ones with PVC banjo cap as well as the black PVC pipe end cap. The reputed Dip Moulded PVC cap manufacturers suit the client's exact requirement in a pocket-friendly manner.

Dip Moulded PVC prototypes

The Dip moulded PVC prototypes benefit in such a manner that they are a low-priced alternative that provides a significant reduction in air clearances and are soft and flexible. The PVC moulded Bellows Manufacturer ensures innovation and creativity with solutions and all the processes are carried out stringently promising the best of quality.

Dip Moulded PVC Bellows

The dip moulded PVC bellows are most commonly used in industries to protect the machinery against dirt and grime. What makes them distinct is their ability to be highly resistant to UV rays and ozone. They also find its use in gear rods of automobile industries and electrical insulations. The added advantage is that they provide resistance against corrosion. Black PVC Dip Moulded Flexible Bellows, Dip-Moulding Process Moulded Bellows, and the star electrical components are a few that serve the requirement of the client based on specifications. Shraddha Dip moulding products have years of experience in the design of moulded and sealing bellows with proven application experience with end-users.

Dip Moulded PVC Plastisol

The Dip moulded PVC Plastisol is specially formulated for coating electroplating jigs, hand tools, and other metal coating applications. The high-grade PVC Plastisols can be pumped, sprayed, and compounded in any hardness or clarity. They can be elongated and are resistant to any weather. The plastisol can go from shiny to matte to foam. The PVC Plastisol Coatings and Plastisol inks come in varied colours including fluorescent ones. The Dip moulded PVC Plastisol is the best alternative to enhance the product's appearance, design, and performance.

#PlasticMoulded#PVCSleeves#PlastisolInks#SealingBellows#AutomobileAncillary#CableendCap#PVCShroud#PVCPlastisol#VinylCaps#VinylCap#PVCDipMoulding#PVCHandleGrip#DipMouldingProducts#PVCDipCoating#PVCplasticcaps#CustomDipMoulding

0 notes

Link

Shenzhen Caratte Technology Co., Ltd.

86-186-65119954 86-18665119954

No. 3, Yuanxia Road, Xiabian Village, Dongguan, Guangdong, China

Shenzhen Caratte Technology Co., Ltd, established in 2010,is a professional enterprise engaged in R&D, production and sales of all kinds of silicone rubber products and pet supplies. The main products are various of silicone gifts, silicone food kitchen utensils, silicone housewares, silicone beauty products, silicone sex toys and a variety of pet products etc.We own a professional R&D team (6 engineers) and sales&service team (12 people), as well as having more than 80 skilled production workers with 3,000 square meters production base. Our factory has it’s own mold workshop which equipped with imported CNC, sparks machines and other professional mold production equipments, with 10 sets moulding machine, automatic printing equipments, spray cabinets and infrared industrial ovens etc, to provide one-stop service for our customers.Our company has been pursuing “Customer first, Quality is our culture” and “High cost performance” principle, since its establishment, we have won all of our customer’s supports and trust through our excellent quality and sincere services, our products have been widely exported to more than 50 countries and regions in Europe, the United States and Asia etc! Sincerely look forward to working together with all of you to create a brilliant future.

0 notes

Video

youtube

Best custom cutlery manufacturer processing

Welcome to Nagual Houseware Limited.

Nagual Housware was founded in 2007, and its business continues to grow and develop.Now it has become a large-scale manufacturing company with integrated design, research and development, OEM, and ODM. The business involved includes: Best custom cutlery manufacturer,Kitchen knife tools,Stainless steel tableware ,Stainless steel cookware ,Stainless steel kettle ,Stainless steel houseware , stainless steel flatware,Plastic handle flatware,Silicone kitchen tools and grill tools。

Passed BSCI commercial society standard certification and SMETA Sedex member moral trade audit。

Company research and development of many years of production experience, with Europe and the United States synchronized advanced mould processing center and a large number of high-quality industry elite, and continuously produce products designed to satisfy the masses of customers friend. Our products are all made of imported superior stainless steel, with excellent quality, beautiful shape, reasonable price and perfect and thoughtful after-sales service to win the market. For many years to improve the quality of products, product quality, process achieves the domestic advanced level, best-selling domestic major cities, are exported to Europe, America, Middle East, southeast Asia and other countries and regions, favored by domestic and overseas customers trust and praise. Our company always adhere to "quality survival, reputation and promote development" as the enterprise objective, continuous reform and innovation. Welcome new and old customers at home and abroad, for processing manufacturing, negotiate business cooperation!

It is believed that innovative ideas and attentive service are far more important than price. Therefore, we pay close attention to our clients' demands and do our utmost to offer them our best service. Our distinguished customers can get the most competitive quotation with their brand-new designs since we have our own factory, so originality and OEM are highly welcome. Furthermore, the fresh designs, at your request, will be completed within 5 business days.

Please tell us your brilliant ideas and wait for us to turn them into the hot-selling goods on your shelves.

www.nagualware.com

0 notes

Link

Logam Jawa is part of Maspion Group. The largest manufacturer of cookwares, kitchen utensils and household appliances in Indonesia.

0 notes

Text

Indian manufacturers of housewares

The Advantages of Using Ceramic in Kitchen and Hotelware Accessories Availability of online data is making individuals aware of health-related problems. In this scenario, the hoteliers and restaurateurs need to be selective about kitchen and hotelware accessories. You need to choose the cooking and serving items discreetly to offer healthful service to your customers. The earthenware is ideal for serving purposes. It is not a feasible solution for regular cooking in restaurants or hotels. The chefs need to prepare larger amount of foods in comparison to the homeowners. They also need to prepare these foods quickly. The clay vessels may rupture due to extreme heat or due to excessive use. The ceramic utensils are thus ideal options for use in the kitchen. The Indian handicrafts exporters choose Delhi Fair India 2017 to bring a variety of ceramic items to thousands of buyers.

Non-Toxic Cooking

The chefs use high-temperature to quickly prepare foods at hotels or restaurants. The non-sticky cooking vessels contain a coating of Teflon. The Teflon coating starts to break down at high temperature. The breakdown of Teflon coating releases toxic PFOA and PFC gases. These toxic elements leach into the food particles and become the source of many physical ailments. The PFOAs/PFCs are known to cause thyroid problems, organ damage, birth defects, reproductive problems and cancer. The use of ceramic utensils releases no toxic elements into the food.The ceramic is a non-metallic and inorganic material. The Indian craftsmen use earthen elements, water and powder to create the mould. They shape the mould and create a variety of cooking vessels/utensils. They use natural gas to burn the vessels at kilns. The use of natural gas eliminates the insertion of any toxic element. The method of burning increases the durability of ceramic items in comparison to the earthenware. You can also use the bespoke handcrafted ceramic utensils to serve food or to create unique interior décor.Non-Metallic StructureThe ceramic’s non-metallic constitution makes the ceramic vessels ideal for any type of cooking. It is better than the aluminium or stainless-steel cooking utensils. The stainless steel is an alloyed metal. It may contain chromium, nickel, carbon, molybdenum and a variety of metals. These metals may release into the food after a few months of use due to steel’s degeneration. On the other hand, the aluminium instantly reacts to the salty or acidic food particles. Hence, aluminium vessels are unsuitable for any type of cooking or baking.The absence of any metallic element turns ceramic utensils into the world’s healthiest cookware. The ceramic vessels release no toxic metal or chemical even at 2500-degree Fahrenheit temperature. You can use the cookware during baking or cooking without any worries.

Elegance with Durability

The handcrafted ceramic utensils not only allow you to serve the healthiest foods to your customers. They allow you to present these foods with a touch of elegance. The graceful designs of handcrafted ceramic pots, plates, cups and other serving utensils enhance the appearance of served items.The ceramic utensils offer all benefits of earthenware with added advantage. The kilned items do not chip easily. It is possible for you to use these utensils for extended periods. The absence of frequent damage saves you from purchasing new utensils at frequent intervals. Hence, the ceramic utensils decrease your expenses with its unique utilitarian features. The ceramic utensils are ideal choice for kitchen and hotelware accessoriesdue to these features.

#India Autumn Fair 2017 , #HomeTextiles, #HandicraftExports, #GiftsShow

#Natural fragrances#Home Linen#handicrafts accessories#indian jewelry show#Garden Accessories#Soft Furnishing#Wall Décor#Handicraft fair#Autumn Fair India#Fair Trade#houseware fair#asia's largest fair#indian trade fair#indian furnishings#home textiles#jewellery fair in india

0 notes

Text

Ultimate Guide for Selecting the Right Injection Mould

Introduction:

Factors: Five Key Items to Consider Before Selecting a Mould

Speed:

Efficient production is essential for meeting market demands and maximizing profitability. When selecting an injection mold, consider the speed at which it can produce houseware products. Look for molds that offer fast cycle times, as this will help increase productivity and reduce manufacturing costs. R.D. Mould & Industry understands the importance of speed and provides molds designed for optimal production efficiency.

Costs:

Cost-effectiveness is a significant aspect of any manufacturing process. Evaluate the costs associated with the injection mold, including its initial purchase, maintenance, and long-term performance.

Stage:

The complexity of your houseware products and the stage of production should align with the capabilities of the injection mold. Consider whether you require a single-cavity mold or a multi-cavity mold to meet your production goals.

Geometry:

Houseware items come in various shapes and sizes, requiring molds that can accommodate diverse geometric designs. It is essential to select a mould that can accurately reproduce the intricate details of your houseware products

Quantity:

The anticipated production volume of your houseware items is a crucial factor in mold selection. Determine whether you require low-volume production or high-volume production molds. R.D. Mould & Industry understands the importance of quantity and offers molds designed for both small-scale and large-scale houseware exporter. They can cater to your specific production requirements.

Your Mold Selection Process:

Identify your houseware product requirements, including size, shape, and material.

Research reputable injection mould manufacturers like R.D. Mould & Industry, who specialize in houseware molds.

Evaluate the speed, costs, stage compatibility, geometry capabilities, and quantity options provided by the mold manufacturer.

Request quotes and compare the features and pricing of different molds.

Consider the manufacturer’s experience, reputation, and customer reviews.

Consult with the mold manufacturer to ensure they can meet your specific houseware production needs.

Make an informed decision based on the above factors and choose the mold that best fits your requirements.

Conclusion:

Selecting the right injection mold is a critical step in the houseware manufacturing process. By considering factors such as speed, costs, stage compatibility, geometry capabilities, and quantity options, you can ensure efficient and cost-effective production. R.D. Mould & Industry, a trusted company specializing in houseware molds, offers a wide range of options to meet your specific requirements. With their expertise and commitment to quality, they can help you achieve exceptional results in plastic houseware production We also manufacture different types of Houseware Blow Mould like,Plastic Round Food Container Mould,Plastic Square Food Container Mould,Multipurpose Plastic Storage Container Mould,Plastic Sweet Box Mould,Plastic Ice Cream Box & Cup Mould,Plastic Khajoor Box Mould, etc.

0 notes

Text

How to Design plastic houseware mould.? What Are the Steps?

Introduction:

Plastic houseware items have become an integral part of our daily lives, offering convenience and functionality. Behind the production of these items lies the intricate process of mould design. One company that excels in this field is R D Mould & Industries. In this blog post, we will delve into the steps involved in designing a plastic houseware mould, offering insights into the process and highlighting the expertise of R D Mould & Industries.

Step 1: Conceptualization and Design Brief:

The first step in designing a plastic houseware mould is to clearly define the design requirements. This involves understanding the purpose of the houseware item, its size, shape, functionality, and any specific features or details. R D Mould & Industries works closely with clients to gather all the necessary information and create a comprehensive design brief.

Step 2: Mold Flow Analysis:

Before proceeding with the actual Houseware Mould Manufacturer, it is crucial to analyze the flow of molten plastic during the injection molding process. Mold flow analysis helps identify potential issues such as air traps, sink marks, or flow imbalances. R D Mould & Industries employs sophisticated simulation software to simulate the injection molding process, optimizing the design and ensuring efficient production.

Step 3: Prototype and Testing:

Once the mould design is complete, a prototype of the houseware item is manufactured using the newly designed mould. This step allows for testing the functionality, fit, and finish of the product. R D Mould & Industries has a well-equipped facility for prototype production and testing, ensuring that the final houseware mould design meets all the required specifications.

Step 4: Manufacturing and Production:

After the prototype has been approved, the final houseware mould design is used for mass production. R D Mould & Industries employs state-of-the-art manufacturing techniques and machinery to fabricate high-quality mould that are durable and long-lasting. The company adheres to strict quality control measures throughout the manufacturing process to ensure the production of flawless plastic houseware mould items.

Conclusion:Designing a plastic houseware mould requires a systematic approach, technical expertise, and attention to detail. R D Mould & Industries, with its extensive experience and commitment to excellence, excels in this field. By following the steps outlined above, R D Mould & Industries consistently delivers top-notch mould designs that meet the requirements of the houseware mould exporters. If you're looking for reliable and innovative mould design solutions, R D Mould & Industries is a company worth considering.

0 notes

Text

Houseware Mould | Plastic Round Food Container Mould and Plastic Square Food Container Mould

Established in the year 2002, we R D Mould & Industries is a leading houseware mould manufacturer, supplier and exporter of a wide range of toy moulds. We have a wide range of household moulds as per market requirements. Our company can design and supply all kinds of molds to customers. We have enough exposure in the houseware mould industry so if we talk about the range of houseware moulds, it includes plastic round food container mould, plastic square food container mould, plastic sweet box mould and plastic ice cream box and cup mould. The organization is established to analyze the various needs and specifications of our customers and accordingly offers Houseware Moulds and Toy Moulds. To ensure our moulds are safe, strong and long lasting, we use only the best quality materials. R D Mould & Industries offers a wide range of houseware blow molds including plastic dry fruit box moulds, lead type multipurpose plastic storage container mould, plastic fruit and vegetables basket moulds and other popular plastic lunch box moulds.

1 note

·

View note

Link

Taizhou City Huangyan Huaguang Hengjiu Platic Co., Ltd.

0086-0576-84188811 0086-17858527752

Shilipu Village, Nancheng Street, Taizhou, Zhejiang, China

Huaguang Nancheng Huaguang Plastic Factory was established in 1997. Located in Huangyan of Zhejiang Province, the transportation is very convenient. It is 15 kilometers apart from Huangyan airport, and it only takes 1.5 hours to drive from Ningbo seaport, and only 45 minutes to Ningbo by train.Huaguang Plastic Factory is specialized in producing and exporting “as seen on TV” products. The main products are kitchenware and some other houseware. We have our own workshop, production line and all series of moulds. Also we have exquisite mould factory and blade factory to develop new moulds and provide many kinds of blades to fit all series of choppers and dicers. We can design products according to your requirement. We also can develop new moulds according to your 3D artwork. Our products are selling well in many countries and set up a good image in international market.Huaguang Plastic Factory takes “customer first” as our service tenet, keeps the spirit of “perfecting myself, improving myself” to attend the market competition positively. We welcome friends from all over the world, both old customers and new customers, to patronage and create more wonderful future together with us.We are looking forward to building long-term and mutual-beneficial business relationships with new and old clients around the world in the near future. Please feel free to contact us for further information.

0 notes

Text

Quality Silicone Kitchen Utensils & Silicone Kitchen Accessories Manufacturer

Nagual Houseware is best , Silicone Kitchen Accessories and Silicone Chopping Board supplier, we has good quality products & service from China.

Alisa Zhou's insight:

Nagual Housware was founded in 2007, and its business continues to grow and develop.Now it has become a large-scale manufacturing company with integrated design, research and development, OEM, and ODM. The business involved includes: Best custom cutlery manufacturer,Kitchen knife tools,Stainless steel tableware ,Stainless steel cookware ,Stainless steel kettle ,Stainless steel houseware , stainless steel flatware,Plastic handle flatware,silicone kitchen tools,stainless steel straw and grill tools 。

Passed BSCI commercial society standard certification and SMETA Sedex member moral trade audit。

Company research and development of many years of production experience, with Europe and the United States synchronized advanced mould processing center and a large number of high-quality industry elite, and continuously produce products designed to satisfy the masses of customers friend. Our products are all made of imported superior stainless steel, with excellent quality, beautiful shape, reasonable price and perfect and thoughtful after-sales service to win the market. For many years to improve the quality of products, product quality, process achieves the domestic advanced level, best-selling domestic major cities, are exported to Europe, America, Middle East, southeast Asia and other countries and regions, favored by domestic and overseas customers trust and praise. Our company always adhere to "quality survival, reputation and promote development" as the enterprise objective, continuous reform and innovation. Welcome new and old customers at home and abroad, for processing manufacturing, negotiate business cooperation!

www.nagualware.com

0 notes

Text

Quality Silicone Kitchen Utensils & Silicone Kitchen Accessories Manufacturer

Nagual Houseware is best , Silicone Kitchen Accessories and Silicone Chopping Board supplier, we has good quality products & service from China.

Alisa Zhou's insight:

Nagual Housware was founded in 2007, and its business continues to grow and develop.Now it has become a large-scale manufacturing company with integrated design, research and development, OEM, and ODM. The business involved includes: Best custom cutlery manufacturer,Kitchen knife tools,Stainless steel tableware ,Stainless steel cookware ,Stainless steel kettle ,Stainless steel houseware , stainless steel flatware,Plastic handle flatware,silicone kitchen tools,stainless steel straw and grill tools 。

Passed BSCI commercial society standard certification and SMETA Sedex member moral trade audit。

Company research and development of many years of production experience, with Europe and the United States synchronized advanced mould processing center and a large number of high-quality industry elite, and continuously produce products designed to satisfy the masses of customers friend. Our products are all made of imported superior stainless steel, with excellent quality, beautiful shape, reasonable price and perfect and thoughtful after-sales service to win the market. For many years to improve the quality of products, product quality, process achieves the domestic advanced level, best-selling domestic major cities, are exported to Europe, America, Middle East, southeast Asia and other countries and regions, favored by domestic and overseas customers trust and praise. Our company always adhere to "quality survival, reputation and promote development" as the enterprise objective, continuous reform and innovation. Welcome new and old customers at home and abroad, for processing manufacturing, negotiate business cooperation!

www.nagualware.com

0 notes

Text

Quality Silicone Kitchen Utensils & Silicone Kitchen Accessories Manufacturer

Nagual Houseware is best , Silicone Kitchen Accessories and Silicone Chopping Board supplier, we has good quality products & service from China.

Alisa Zhou's insight:

Nagual Housware was founded in 2007, and its business continues to grow and develop.Now it has become a large-scale manufacturing company with integrated design, research and development, OEM, and ODM. The business involved includes: Best custom cutlery manufacturer,Kitchen knife tools,Stainless steel tableware ,Stainless steel cookware ,Stainless steel kettle ,Stainless steel houseware , stainless steel flatware,Plastic handle flatware,silicone kitchen tools,stainless steel straw and grill tools 。

Passed BSCI commercial society standard certification and SMETA Sedex member moral trade audit。

Company research and development of many years of production experience, with Europe and the United States synchronized advanced mould processing center and a large number of high-quality industry elite, and continuously produce products designed to satisfy the masses of customers friend. Our products are all made of imported superior stainless steel, with excellent quality, beautiful shape, reasonable price and perfect and thoughtful after-sales service to win the market. For many years to improve the quality of products, product quality, process achieves the domestic advanced level, best-selling domestic major cities, are exported to Europe, America, Middle East, southeast Asia and other countries and regions, favored by domestic and overseas customers trust and praise. Our company always adhere to "quality survival, reputation and promote development" as the enterprise objective, continuous reform and innovation. Welcome new and old customers at home and abroad, for processing manufacturing, negotiate business cooperation!

www.nagualware.com

0 notes

Text

Quality Silicone Kitchen Utensils & Silicone Kitchen Accessories Manufacturer

Nagual Houseware is best , Silicone Kitchen Accessories and Silicone Chopping Board supplier, we has good quality products & service from China.

Alisa Zhou's insight:

Nagual Housware was founded in 2007, and its business continues to grow and develop.Now it has become a large-scale manufacturing company with integrated design, research and development, OEM, and ODM. The business involved includes: Best custom cutlery manufacturer,Kitchen knife tools,Stainless steel tableware ,Stainless steel cookware ,Stainless steel kettle ,Stainless steel houseware , stainless steel flatware,Plastic handle flatware,silicone kitchen tools,stainless steel straw and grill tools 。

Passed BSCI commercial society standard certification and SMETA Sedex member moral trade audit。

Company research and development of many years of production experience, with Europe and the United States synchronized advanced mould processing center and a large number of high-quality industry elite, and continuously produce products designed to satisfy the masses of customers friend. Our products are all made of imported superior stainless steel, with excellent quality, beautiful shape, reasonable price and perfect and thoughtful after-sales service to win the market. For many years to improve the quality of products, product quality, process achieves the domestic advanced level, best-selling domestic major cities, are exported to Europe, America, Middle East, southeast Asia and other countries and regions, favored by domestic and overseas customers trust and praise. Our company always adhere to "quality survival, reputation and promote development" as the enterprise objective, continuous reform and innovation. Welcome new and old customers at home and abroad, for processing manufacturing, negotiate business cooperation!

www.nagualware.com

0 notes