#Houseware Injection Mould

Text

How to Choose a Reliable Houseware Mould Manufacturer?

Experience and Expertise:

One of the first factors to consider is the manufacturer’s experience and expertise in the industry. Look for a company with a solid track record and a long history of manufacturing houseware mould. An experienced manufacturer will have a deep understanding of mould design, materials, and manufacturing processes, ensuring the production of high-quality mould.

R. D. Mould & Industries boasts a rich history spanning several years, demonstrating their deep understanding of mould design, materials, and manufacturing processes.

Customization Capabilities:

Every houseware product is unique, and a reliable mould manufacturer should be able to accommodate customization. R. D. Mould & Industries understands the importance of tailored solutions and offers customization options to meet diverse client requirements. Their team of skilled professionals works closely with clients to ensure that the mould are designed and manufactured to precise specifications.

Materials and Durability:

R D Mould & Industries involves considering the materials used by the manufacturer to make the mould. Material selection can significantly affect mould durability and lifespan. Trusted household mould manufacturers will have knowledge of different materials and recommend the most suitable options for your specific houseware mould products.

Product Range and Specialization:

Consider the product range and specialization of the manufacturer. R. D. Mould & Industries offers a diverse range of houseware mould, catering to various product categories such as kitchenware, storage containers, and more. Their specialization in houseware mould manufacturing ensures that they understand the specific requirements and challenges of this industry.

Conclusion:

Choosing a reliable houseware mould manufacturer is crucial for the success of your product manufacturing. R. D. Mould & Industries stands out as a trusted and reputable choice in the industry. With their extensive experience, specialization, customization capabilities, and commitment to quality, they are well-equipped to meet your houseware mould requirements. By partnering with R. D. Mould & Industries, you can have confidence in the reliability, precision, and timely delivery of your houseware mould.

#Houseware Mould#Plastic Houseware Mould#Houseware Mould Manufacturer#Houseware Mould Exporters#Plastic Food Container Mould Manufacturer#Houseware Injection Mould#Houseware Blow Mould

0 notes

Text

ONEMOLD: Leading the Way as a Plastic Injection Mould Maker

Whether is the product an automobile component, medical device, consumer electronic, or a packaging solution Injection Mould Maker has emerged to be the backbone of most industries in the manufacturing world today. ONEMOLD is the leading plastic injection mold maker that has revolutionized the way business production and design meet. But what makes ONEMOLD so unique? Accuracy Enters the Mould Space Precision Engineering

The success behind ONEMOLD is its quality in being accurately precise. INJECTION MOLDING APPLIES HIGH REQUIREMENTS as regards strict tolerances more complex and high-performance plastic parts have demanding requirements for exact allowances. ONEMOLD employs the use of state-of-the-art machinery, advanced CAD/CAM systems in every single mold, which indicates the highest standards are applied. Engineers work on very meticulous analysis of every project to fulfill even the toughest requirements.

Address: 28, 2nd floor, Ujagar Estate, Deonar.

State: Maharashtra

City: Mumbai

Country/Region: India

Zip: 400088

28, Ujagar Industrial Estate, Mumbai, INDIA

Every Industry Receives Customization

ONEMOLD understands that no two industries are alike. And, hence, with every industry in which they work, ONEMOLD provides specifically tailored solutions. Be it the automotive industry requiring that parts be sturdier or thermally resistant; or if it is the medical field requiring cleanroom-compliant moulds, ONEMOLD develops the customised solution tailor-made to specific requirements. Their expertise in mould manufacturing means versatility that leaves many rivals in the mould-making business in the dust.

One-stop shop from ONEMOLD:

ONEMOLD is not a molding company it is total project support at all stages right from design consultation to post-production services. The company makes sure that it gives total support to the customer at every stage of the process. The engineers at ONEMOLD have close coordination with the clients. It is these engineers who bond closely to ensure that the end product, as delivered by them, meets the client’s goals concerning design, functionality, and production efficiency. In this way, it is easier for clients to save costs, enhance the quality of their products, and bring timelines closer in manufacturing processes.

Injection Moulding Process at ONEMOLD

Prototype and Design

The ONEMOLD injection moulding process first begins with the design and prototyping phase. The company works with clients and an advanced 3D modeling software of their team to come up with a precise design of the desired component. Prototypes are then carried out to test the form, fit, and function before switching to full-scale production. This is a critical step for the early identification of possible flaws in the design, which saves time and money in the long run.

Mould Manufacturing

When the design is ready, ONEMOLD goes into manufacturing the mould. This is the magic part. Made from high-grade steel or aluminum, the moulds are precision machined according to the specifications of the project. ONEMOULD uses the most advanced CNC machining and EDM (electrical discharge machining) systems to produce some of the most accurately and durably built moulds in the business.

After preparing the molds, this is when the actual process of injection molding begins. ONEMOLD uses high-performance injection molding machines compatible with a range of thermoplastic materials. These machines inject hot melted plastic under pressure into the mold so that the final product will not have any flaw of whatsoever and will be just what is desired.

Why Choose ONEMOLD?

Quality Assurance

The operations of ONEMOLD have founded quality. They undergo severe and rigid quality control processes, therefore sending each mould and finished product to strict examinations. This way, it can always be relied upon by businesses to source highly performing products from ONEMOLD.

Sustainability

With awareness of the environment growing by the day, sustainability is a high priority for ONEMOLD. The production stream is kept as sustainable as possible, reducing waste and energy utilization as much as possible. This has a lot of positive effects on the environment besides reducing cost, which they pass down to their customers.

Global Reach

ONEMOLD’s reputation is huge both in its home market as well as all across the world where it has been making waves. The company has clients from around the world and makes efforts to give them the kind of Houseware Mould solutions that they need in order to remain competitive in this global marketplace. Be you a local startup or a multinational, ONEMOLD has the expertise and resources that could help fulfill your needs.

Conclusion:

Being a plastic injection mould maker, ONEMOLD is your first choice business partner in whatever sector. Having covered factors such as precision engineering, quality, and customer satisfaction, ONEMOLD has never been more established in the plastic injection moulding world. In a world where plastic injection moulding is threatened by such strong competition, the very choice of ONEMOLD means innovation, reliability, and excellence in every mould it creates for you.

0 notes

Text

Are you interested in molds? We can design a variety of injection molds for plastic thin wall products.We offer you thin wall container mould,high speed mould, IML thin wall mould.The minimum wall thickness we can make to 0.35mm. Contact us.

our wbsite:www.aeromoulds.com

#injectionmouldingmachine#injectionmoldingmachine

#injectionmoldingmachines#moldingmachine

#plasticmouldingmachine#plasticmoldingmachine#plasticinjectionmoldingmachine#plasticinjectionmoldingmanufacturer#injectionmoldingmachineparts#plasticindustries#injectionplastic#plasticinjection#injectionmachine#automotive#houseware#thinwallmould#wallthickness#disposableparts#thinwallbox#thinwallbucket#foodpackaging

#injectionmouldingmachine#injectionmoldingmachine#injectionmoldingmachines#moldingmachine#plasticmouldingmachine#plasticmoldingmachine#plasticinjectionmoldingmachine#plasticinjectionmoldingmanufacturer#injectionmoldingmachineparts#plasticindustries#injectionplastic#plasticinjection#injectionmachine#automotive#houseware#thinwallmould#wallthickness#disposableparts#thinwallbox#thinwallbucket#foodpackaging

0 notes

Text

5 Common Plastic Resins Used in Injection Molding

ABS With outstanding impact and mechanical strength, ABS (Acrylonitrile Butadiene Styrene) is used in a wide range of industries and applications, from automotive to piping. Metal coatings can easily adhere to this material, making it well suited for products such as desktop phones, shower heads, and handles. ABS does not have good chemical resistance, however, and should not be used in applications requiring electrical insulation or UV resistance.

Apart from Plastic Toy Mould Exporters We're also dealing in Plastic Toy Injection Mould And Plastic Toy Blow Mould & Etc.

Celcon (Acetal)

Celcon, a common brand name for Acetal, offers excellent surface lubricity, creep resistance (memory), and chemical solvent resistance. Ideal for food and beverage, mechanical, automotive, and household applications, this is our resin of choice for manufacturing K’NEX toy parts, as well as gears and bearings. It’s also often used in automotive applications and household appliances. It should not be used for applications in high heat environments.

Polypropylene

Polypropylene (PP) is known for its flexibility in packaging, fluid management and processing, and household goods, as well as some automotive applications. While polypropylene is flammable and vulnerable to UV radiation, it still offers good resistance to chemical solvents and electricity. Most grades of Polypropylene are flammable and degraded by UV radiation.

We R D Mould & Industries are a renowned Plastic Toy mould manufacturer in Ahmedabad,Gujarat, India, provide various types of Plastic Toy Mould Including Plastic Toy Injection Mould, Plastic Toy Blow Mould & Etc.

HIPS

High Impact Polystyrene (HIPS) provides tough, low-cost performance and highly customizable surfaces: It can be printed, glued, bonded, and decorated easily. This material is especially popular in merchandising applications and displays, printed graphics and prototypes. Although flammable, flame-retardant varieties are available.

LPDE

The most flexible version of polyethylene, LPDE, or Low-Density Polyethylene, offers moisture resistance and high impact strength. LPDE can be found in many consumer goods and housewares, as well as medical products and electronic wiring. It is difficult to bond, however, and should not be used in harsh weather or high-temperature applications.

0 notes

Text

Plastic containers come in a variety of shapes and sizes

When designing a container mould, it is important to consider the different types of tolerances that will be used. These tolerances refer to how much a particular dimension varies from another. If a dimensional Houseware mould Manufacturers deviation exceeds 5%, this may be considered a non-uniform deformation. To compensate for this difference, the design engineer will often use various materials with different coefficients of thermal expansion. However, this method can be expensive, so the design engineer should be aware of the costs associated with the process.

Plastic containers come in a variety of shapes and sizes. Using a container mould allows you to create any shape or size of container. These moulds can also be used to produce lids for containers. The lids can be produced in a number of shapes and sizes and are able to stack on top of one another. This allows you to save on shipping costs.

Plastic containers are commonly used in the food and beverage industry. These containers can range from small bottles and jars up to large containers that can hold several liters. Plastic injection moulding is a common technique used for producing these products. Injecting the plastic into the mould forces it to conform to the desired shape and wall thickness.

0 notes

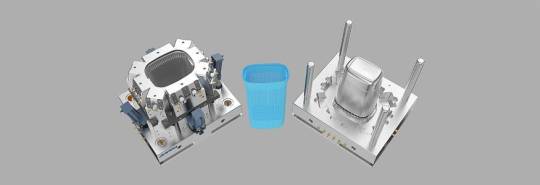

Photo

Houseware Mold Plastic Injection ABS Mop Bucket Moulding

One stop service from design to mould testing.

0 notes

Photo

The trend has emerged towards two colours plastic furniture milacron india offer omega 2 colour injection moulding machine especially to manufacture 2 colour houseware & furniture plastic products.

https://www.milacronindia.com/products/omega-tc/

0 notes

Text

Novel Mould offers the best plastic injection moulds manufacturer in India

We are a reputed manufacturer of dies, moulds, kitchenware, houseware, and other engineering components in Rajkot. We strive for customer satisfaction so all the products are strictly checked as per the standard of quality and management to offer quality assured products to our consumers.

https://www.atoallinks.com/2021/novel-mould-offers-the-best-plastic-injection-moulds-manufacturer-in-india/

0 notes

Link

Taizhou Huangyan Enjoy Plastic Co., Ltd.

86-576-82352780 18857617590

Xinlaiqiao Villiage, Jiangkou Subdistrict, Huangyan District, Taizhou, Zhejiang, China

Taizhou Huangyan Enjoy Plastic Co., Ltd. is a manufacturer of plastic houseware with well-equipped testing equipment and strong technical force.With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in plastic product and other industries.Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs.We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!We have many kind of plastic injection mould and produced by ourself machine. We can offer competitive price and Help customer do one -stop shop purchase

0 notes

Text

Ultimate Guide for Selecting the Right Injection Mould

Introduction:

Factors: Five Key Items to Consider Before Selecting a Mould

Speed:

Efficient production is essential for meeting market demands and maximizing profitability. When selecting an injection mold, consider the speed at which it can produce houseware products. Look for molds that offer fast cycle times, as this will help increase productivity and reduce manufacturing costs. R.D. Mould & Industry understands the importance of speed and provides molds designed for optimal production efficiency.

Costs:

Cost-effectiveness is a significant aspect of any manufacturing process. Evaluate the costs associated with the injection mold, including its initial purchase, maintenance, and long-term performance.

Stage:

The complexity of your houseware products and the stage of production should align with the capabilities of the injection mold. Consider whether you require a single-cavity mold or a multi-cavity mold to meet your production goals.

Geometry:

Houseware items come in various shapes and sizes, requiring molds that can accommodate diverse geometric designs. It is essential to select a mould that can accurately reproduce the intricate details of your houseware products

Quantity:

The anticipated production volume of your houseware items is a crucial factor in mold selection. Determine whether you require low-volume production or high-volume production molds. R.D. Mould & Industry understands the importance of quantity and offers molds designed for both small-scale and large-scale houseware exporter. They can cater to your specific production requirements.

Your Mold Selection Process:

Identify your houseware product requirements, including size, shape, and material.

Research reputable injection mould manufacturers like R.D. Mould & Industry, who specialize in houseware molds.

Evaluate the speed, costs, stage compatibility, geometry capabilities, and quantity options provided by the mold manufacturer.

Request quotes and compare the features and pricing of different molds.

Consider the manufacturer’s experience, reputation, and customer reviews.

Consult with the mold manufacturer to ensure they can meet your specific houseware production needs.

Make an informed decision based on the above factors and choose the mold that best fits your requirements.

Conclusion:

Selecting the right injection mold is a critical step in the houseware manufacturing process. By considering factors such as speed, costs, stage compatibility, geometry capabilities, and quantity options, you can ensure efficient and cost-effective production. R.D. Mould & Industry, a trusted company specializing in houseware molds, offers a wide range of options to meet your specific requirements. With their expertise and commitment to quality, they can help you achieve exceptional results in plastic houseware production We also manufacture different types of Houseware Blow Mould like,Plastic Round Food Container Mould,Plastic Square Food Container Mould,Multipurpose Plastic Storage Container Mould,Plastic Sweet Box Mould,Plastic Ice Cream Box & Cup Mould,Plastic Khajoor Box Mould, etc.

0 notes

Text

We always focuses on manufacturing high standard plastic moulds, like houseware molds, kitchenware molds, home appliances injection moulds...

More mold details, please contact us at any time. Mob/WhatsApp: 86-13867644770

0 notes

Text

HYS Mould- HYS International Limited

HYS is located in Bao'an District, Shenzhen, with an area of 45,000 square meters (construction area 80,000 square meters), fixed assets of more than 200 million and 1,300 employees or more. We are competitive in mould design, processing, injection moulding and information management. We use ERP / CAM system for design and processing, and PRO-E, UG, MOLDFLOW, CATIA, Powermill 9.0, Moldflow CAD Doctor and Communicator for assembly and analysis of product structure; we have more than 100 sets of world top high-precision moulding equipment , with a monthly output of 25,000 sets, which are widely applied to the mould production in automobiles , medical, houseware,home appliances, communication equipment.

Source: LinkedIn Public Company Page

0 notes

Text

How to Design plastic houseware mould.? What Are the Steps?

Introduction:

Plastic houseware items have become an integral part of our daily lives, offering convenience and functionality. Behind the production of these items lies the intricate process of mould design. One company that excels in this field is R D Mould & Industries. In this blog post, we will delve into the steps involved in designing a plastic houseware mould, offering insights into the process and highlighting the expertise of R D Mould & Industries.

Step 1: Conceptualization and Design Brief:

The first step in designing a plastic houseware mould is to clearly define the design requirements. This involves understanding the purpose of the houseware item, its size, shape, functionality, and any specific features or details. R D Mould & Industries works closely with clients to gather all the necessary information and create a comprehensive design brief.

Step 2: Mold Flow Analysis:

Before proceeding with the actual Houseware Mould Manufacturer, it is crucial to analyze the flow of molten plastic during the injection molding process. Mold flow analysis helps identify potential issues such as air traps, sink marks, or flow imbalances. R D Mould & Industries employs sophisticated simulation software to simulate the injection molding process, optimizing the design and ensuring efficient production.

Step 3: Prototype and Testing:

Once the mould design is complete, a prototype of the houseware item is manufactured using the newly designed mould. This step allows for testing the functionality, fit, and finish of the product. R D Mould & Industries has a well-equipped facility for prototype production and testing, ensuring that the final houseware mould design meets all the required specifications.

Step 4: Manufacturing and Production:

After the prototype has been approved, the final houseware mould design is used for mass production. R D Mould & Industries employs state-of-the-art manufacturing techniques and machinery to fabricate high-quality mould that are durable and long-lasting. The company adheres to strict quality control measures throughout the manufacturing process to ensure the production of flawless plastic houseware mould items.

Conclusion:Designing a plastic houseware mould requires a systematic approach, technical expertise, and attention to detail. R D Mould & Industries, with its extensive experience and commitment to excellence, excels in this field. By following the steps outlined above, R D Mould & Industries consistently delivers top-notch mould designs that meet the requirements of the houseware mould exporters. If you're looking for reliable and innovative mould design solutions, R D Mould & Industries is a company worth considering.

0 notes

Photo

The trend has emerged towards Two Colors Plastic Furniture. Milacron India Offers Omega 2 Colour Injection Moulding Machine especially to manufacture 2 Colour Houseware & Furniture Plastic Products.

https://www.milacronindia.com/products/omega-tc/

0 notes

Photo

Omega Split Barrel injection moulding machine esapecially to manufacture split barrel houseware and furniture. We used latest technology in our plastic chair manufacturing machine. The trend has emerged towards multi colour plastics furniture especially Double Colour Wooden Pattern Chairs. Milacron India offers Omega Split Barrel Injection Moulding Machine especially to manufacture Split Barrel Houseware & Furniture.

0 notes