#How to Implement 5S

Explore tagged Tumblr posts

Text

STOP WASTING TIME! GET ORGANIZED WITH 5S AND WORK SMARTER

Tools regularly misplaced, clutter filling your workspace, or an overall sense of frustration when trying to manage it all. Sound familiar? You're not alone, as people and businesses waste around 30 per cent of their day on inefficiencies and lost time, whether it's tools being misplaced and then found 20 minutes later, or not remembering where you put your laptop. But what if there was a simple, systematic, and repeatable means to improve everything, resulting in a more fruitful, and less stressful work environment with fewer workplace hazards?

The challenges and expectations of workplace efficiency have never been so important, and as we head into 2025, the push for efficiency and streamlined operations is greater than ever before. 5S is an applicable methodology from Japan, which is relevant to any organization striving for operating excellence, waste reduction, and improvements in productivity, and can help you achieve that.

In this blog, we explore why 5S is necessary for optimizing your workspace today, the purpose, framework, benefits, and the simple steps to apply 5S to your workspace.

The Need for 5S in Today's Workplace

Today's workplaces, whether on a manufacturing floor, in an office, or a service center, are changing rapidly and facing challenges such as:

Increasing complexity of workflows and demands: Also, leading to bottlenecks and confusion for everyone involved in the process.

Rapid technological change: Often meaning new tools and equipment that need to be implemented.

Recurring employee turnover: Need efficient onboarding and transfer of knowledge.

Persistent pressure to reduce costs and deliver quicker: Where every wasted minute counts.

Global overload and clutter: All of which mentally drain focus and make it more challenging to be productive.

These factors require solid functions for your workplace that will allow it to run smoothly and ultimately increase productivity while potentially decreasing errors, and providing a culture in which everyone focuses on being organized and proactive. 5S is a framework for creating functions to establish documentation that coincides with your objectives for efficiency while creating overall authenticity in your workplace.

What is 5S? Understanding the Five Pillars of Efficiency

5S is a referencing five Japanese words, all of which start with the letter "S," that defines a specific approach to workplace organization. The process is a cycle and not a one-and-done event.

Sort (Seiri): Get Rid of the Unnecessary. The first step is decluttering which means identifying and removing everything that is unneeded from the workplace. If something is not required to do the task at hand, move it or throw it away. Clutter takes up space, and removing clutter also reduces visual and physical clutter.

Set in Order (Seiton): A Place for Everything. Once you have removed anything that is not needed, it is now time to arrange everything you need in a logical and efficient manner. Everything should have a clearly designated place, and everything should be easily recognizable to find, use, and return. Consider placement, flow of use, frequency of use, and ergonomics.

Shine (Seiso): Cleanliness as Inspection This pillar involves cleaning your workplace, tools, and equipment. Not only is cleaning involved, it is an act of inspection. The act of cleaning should look for other potential issues (i.e. leaks, worn parts, loose connections), finding issues before they escalate into bigger problems.

Standardize (Seiketsu): Be Consistent This step must consist of procedures and visual controls to aid and keep the previous sets of "S's" consistent. This step promotes consistency in following the same best practices, closing the gaps and establishing a systematic way to establish and maintain the new organized state as the "new normal", preventing a return to the old state.

Sustain (Shitsuke): Be Disciplined and Make it a Habit The last and most important S! This pillar must focus on making 5S a habit and adjusting it to organizational culture. The discipline and commitment on an ongoing basis must be supported and embrace by leadership to ensure the principles of the S's are followed daily and improved continuously.

Why 5S Matters More Than Ever for Your Productivity in 2025

Get Rid of Search Time, Improve Output: In 2025 every minute will count. The use of 5S will eliminate time spent searching for tools, documents, or materials. By sorting the unnecessary and organizing the essential, people will be able to go immediately to what they need and use that time saved to get more work done.

Decrease Errors and Rework: Keeping the workplace clean and organized with standardized methods (Shine & Standardize) decreases the likelihood of making a mistake. With fewer errors made there is less time wasted doing rework, quality checks, and correcting issues, which ultimately contributes to a more positive first-pass yield.

Better Safety and Reduce Accident: Clutter is a safety risk. The 5S process will eliminate barriers, create paths with the proper markings, and ensure equipment is clean and routinely inspected. Establishing a safe workplace creates less risk for accident, less downtime for employees away from injuries, and ultimately less costs associated with accidents.

Improve Employee Morale and Engagement: Operating in a clean, organized, efficient work environment will minimize employee stress and frustration. When an employee's workspace is well controlled, they will feel more valued and empowered. Job satisfaction will improve, with better focusing attention, and have more pride in their work.

Decrease Training and Onboarding Time: New employees can learn and adapt to stand organizational standards faster with 5S methods of visual controls and standardized procedures. The onboarding time will significantly be reduced with employees being a fast contributor.

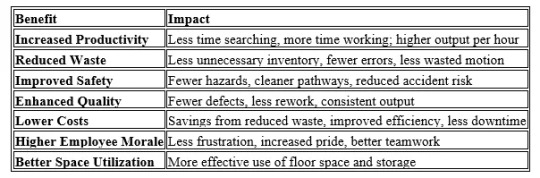

Benefits of 5S for Your Workplace

Here’s a breakdown of the tangible and intangible benefits 5S offers your organization in 2025:

How to Implement 5S in Your Organization: A Step-by-Step Blueprint

Step 1: Obtain Leadership Buy-in. Senior management must actively support 5S which means we need them there with us and to communicate the importance of the exercise. They must also provide the resources that will be needed to sustain a program.

Step 2: Create a 5S Team. Build a cross-functional 5S team consisting of people from different departments. This team will lead the process, educate others, and facilitate the implementation.

Step 3: Fully Educate Everyone and Raise Awareness. All employees must be educated about the principles of 5S, the benefits, and their role in implementing it. It is important that each employee understands "why" they are doing it not just "how."

Step 4: Identify a Pilot Area Start small! Choose a reasonable pilot area (e.g. one workstation, a tool crib, or a section in an office) to help with quick wins, learn some lessons and build enthusiasm before rolling out a broader implementation.

Step 5: Implement 5 S's Systematically (Sort, Set in Order, Shine) Walk the organized area. Conduct "Red Tag" event for Sort. Use visual controls and logical arrangement for Set in Order. Build cleaning and inspection into the daily routine for Shine.

Step 6: Standardize and Audit Create procedures, checklists, and visual standards so that the organized state can be maintained. Conduct a regular internal audit to determine how many standards you are adhering to, and where improvements can be made.

Step 7: Sustain and Continuous Improvement Make 5S a habit. Incorporate into daily routines, performance reviews of staff, and team meetings. Consider continuous improvement (Kaizen) and give ownership to employees to identify other improvements.

How 4C Consulting Helps You Implement 5S for Maximum Impact

Sustaining 5S is not just a cleanup, but it's a commitment to a culture of discipline and efficiency. 4C Consulting can help.

Our experience in operational excellence and real-world experience makes us qualified to help organizations navigate through the entire 5S process quickly and effectively.

Our Proven Approach Includes:

Tailored Workplace Assessment: We conduct a thorough assessment of your current workplace arrangement and operations to identify areas of wasted time and the potential for implementing 5S's principles.

Interactive 5S Workshops & Training: Our consultants conduct in-depth hands-on training sessions for all levels, from leaders to frontline operators, so that everyone understands and can effectively apply the 5S principles.

Process Mapping & Visual Control Design: We support you in mapping your current workflows and designing intuitive visual controls (i.e. shadow boards, markings on the floor, observable labelling systems) that elaborate on how to truly "Set in Order" your workplace.

Pilot Project Support & Implementation: We provide on-site support for your initial 5S pilot projects and guide your team as they develop and execute each "S" to achieve demonstrable results.

Standardization & Sustainability frameworks: We help you to develop standardization methods, auditing checklists, and accountability programs, that will support you maintaining and building upon the gains from your efforts in developing 5S.

Regardless if you are a small office or a larger manufacturing plant, 4C Consulting makes sure that 5S achieves sustainable time savings, enhanced productivity, and a more engaged workforce. We don't simply help make your space organized—we help you create a culture of waste reduction that drives sustainable operational excellence.

#5S Implementation#5S Workplace Organization#5S Methodology#Benefits of 5S#How to Implement 5S#5S Lean Manufacturing

1 note

·

View note

Video

youtube

#CardGame | How #5s can #improve #productivity?

#youtube#https://youtu.be/dTWQOvTTorY?si=QggmZrT8HEO1_kn0#CardGame | How 5s can improve productivity? 5s is a concept aimed at enhancing work methodology. By implementing sort techniques it is poss

0 notes

Text

What is 5S? Organizing Workspaces with Lean Methods

If you've ever stepped into a chaotic and cluttered workspace, you know how frustrating it can be to navigate through the mess. From misplaced tools to tangled wires, disorganized workspaces can hinder productivity and create unnecessary stress. That's where 5S comes in – a set of lean methods that aims to streamline and organize workspaces for optimal efficiency. In this article, we'll dive into the world of 5S and explore how it can revolutionize the way you work.

youtube

Understanding 5S: Sort, Set in Order, Shine, Standardize, Sustain

So what exactly is 5S? It's a methodology that originated in Japan and stands for Sort, Set in Order, Shine, Standardize, and Sustain. Each "S" represents a specific step in the process of organizing workspaces.

Step 1: Sort

The first step of 5S is to sort through all items in your workspace. This involves separating necessary items from unnecessary ones. It's like decluttering your workspace and getting rid of anything that doesn't serve a purpose. By doing so, you create an environment that promotes efficiency and reduces distractions.

youtube

Step 2: Set in Order

Once you've sorted everything out, it's time to set things in order. This means assigning a designated place for each item based on its frequency of use or importance. The goal is to make it easy for anyone to find what they need quickly without wasting time searching through piles of clutter.

Step 3: Shine

The third step involves shining or cleaning your workspace thoroughly. It's not just about removing dust quality management or wiping down surfaces; it's quality management about maintaining cleanliness as an ongoing practice. A clean workspace not only looks more appealing but also helps prevent accidents and promotes a healthy working environment.

Step 4: Standardize

Standardization is the key to ensuring that the 5S practices are consistently followed. It involves creating clear guidelines and procedures for maintaining the organized workspace. This step helps everyone in the team understand their responsibilities and ensures that the system remains in place even when faced with changes or challenges.

Step 5: Sustain

The final step of 5S is to sustain the organized workspace. This requires ongoing commitment and continuous improvement. By regularly reviewing and refining the 5S practices, you can ensure that your workspace remains navigate to this website organized and efficient in the long run.

The Benefits of Implementing 5S

You might be wondering, why bother with all this effort? Well, implementing 5S offers numerous benefits that can significantly impact your work environment and productivity. Let's delve into some of them:

youtube

2 notes

·

View notes

Text

Mastering the Lean Six Sigma Black Belt: Certification, Training & Career Benefits

In the modern world of business and industry, organizations are constantly seeking ways to improve quality, reduce waste, and increase efficiency. One of the most powerful and recognized methodologies for achieving these goals is Lean Six Sigma. At the advanced level of this methodology stands the Lean Six Sigma Black Belt professional with deep expertise in process improvement and data-driven decision-making. But what exactly is a Lean Six Sigma Black Belt, and how can obtaining this certification benefit your career? This guide will answer those questions and more.

Understanding Lean Six Sigma Black Belt

A Lean Six Sigma Black Belt is a professional who is highly skilled in leading complex improvement projects and facilitating organizational change. They have advanced knowledge of Lean principles (which focus on reducing waste) and Six Sigma methodologies (which focus on reducing variation and improving quality).

Black Belts are often full-time project leaders, responsible for strategic planning, coaching Green Belts and Yellow Belts, and delivering measurable business results. They apply statistical tools, project management strategies, and root cause analysis to identify problems, define solutions, and implement sustainable improvements.

What is Lean Six Sigma Black Belt Certification?

The Lean Six Sigma Black Belt certification is a formal recognition of an individual’s ability to lead process improvement projects using Lean Six Sigma techniques. This certification validates the person’s knowledge of:

Advanced DMAIC methodology (Define, Measure, Analyze, Improve, Control)

Statistical tools and software (like Minitab or Excel)

Project selection and prioritization

Team leadership and change management

Process mapping and control charts

Hypothesis testing and regression analysis

Many reputable institutions offer Lean Six Sigma Black Belt certification, including IASSC, ASQ, and various accredited training providers. While certification exams vary, they typically include both a theoretical exam and a practical project demonstrating real-world application.

Lean Six Sigma Black Belt Training: What to Expect

Lean Six Sigma Black Belt training is intensive and comprehensive. It prepares candidates not only to pass certification exams but also to lead high-impact projects with confidence and precision.

A typical Lean Six Sigma Black Belt course covers:

The complete DMAIC framework

Lean tools such as Value Stream Mapping and 5S

Advanced statistical methods (DOE, ANOVA, control charts)

Risk management and cost-benefit analysis

Leadership and stakeholder engagement

Practical project work or case studies

Training formats vary and include classroom sessions, online courses, blended learning, or corporate in-house programs. Many courses span 4 to 6 weeks, though self-paced online programs allow flexibility.

Why Take a Lean Six Sigma Black Belt Course?

Enrolling in a Lean Six Sigma Black Belt course is a strategic career move for professionals in manufacturing, healthcare, finance, IT, logistics, and service industries. Here are the key benefits:

Career Advancement: Black Belts are in high demand for leadership roles in quality management, operations, and continuous improvement.

Higher Earning Potential: According to industry surveys, certified Black Belts often earn significantly more than their non-certified peers.

Organizational Impact: You’ll gain the skills to lead projects that reduce costs, improve quality, and increase customer satisfaction.

Credibility and Recognition: Certification enhances your professional credibility and opens doors to new opportunities.

Problem-Solving Mastery: You’ll be equipped to handle complex challenges with analytical tools and structured thinking.

Who Should Pursue a Lean Six Sigma Black Belt Certification?

This certification is ideal for professionals who already have some experience with process improvement or have completed a Lean Six Sigma Green Belt. Suitable candidates include:

Quality managers

Process engineers

Project managers

Operations leaders

Business analysts

Healthcare administrators

While not mandatory, prior knowledge of Lean Six Sigma principles (often gained at the Green Belt level) is highly recommended before pursuing the Black Belt.

Final Thoughts

In an era where efficiency and excellence are critical, becoming a Lean Six Sigma Black Belt is a valuable investment in your professional future. Whether you're looking to climb the corporate ladder, lead impactful change, or sharpen your analytical skills, a Lean Six Sigma Black Belt certification offers a clear path to achieving those goals.

By completing a Lean Six Sigma Black Belt training program and passing a recognized certification exam, you’ll join a global network of professionals who are driving innovation and improvement across industries. Choose a comprehensive Lean Six Sigma Black Belt course today, and take the next step toward becoming a leader in quality and operational excellence.

0 notes

Text

The Power of Lean: Why Every Professional Needs a Lean Implementer Certification in 2025

In a world where efficiency is everything, businesses are constantly looking for ways to do more with less. That’s why lean methodology has become a core strategy across industries and the need for skilled professionals with a Lean Implementer Certification is higher than ever. Whether you're in IT, manufacturing, finance, or healthcare, earning the Certified Lean Implementer credential gives you the skills to cut waste, improve processes, and become a true change-maker in your organization.

Why Lean Matters More Than Ever in 2025 💡

Organizations today face rising costs, increasing customer expectations, and pressure to deliver faster. That’s why companies are turning to lean certification programs to find leaders who can think strategically and act efficiently. With a lean implementer certification, you don’t just learn theory, you master tools that directly improve how work gets done.

From identifying non-value-added tasks to creating streamlined workflows, a certified lean implementer helps organizations stay competitive, responsive, and profitable in a fast-paced world.

What You’ll Gain from a Lean Implementer Certification 🎓

By taking the lean implementer course, you’ll gain practical, job-ready knowledge that includes:

✅ How to eliminate waste in processes ✅ How to drive continuous improvement ✅ How to apply Lean tools like 5S, Value Stream Mapping, and Kaizen ✅ How to lead process improvement initiatives across departments

And most importantly, the lean certification helps you become someone companies trust to boost performance and lead change.

Who Needs a Certified Lean Implementer? 🧑💼🏭

This certification is perfect for:

🔹 Project Managers 🔹 Business Analysts 🔹 Quality Specialists 🔹 Operations Managers 🔹 Engineers 🔹 IT Professionals 🔹 Healthcare Administrators

Whether you're early in your career or an experienced professional, the Certified Lean Implementer certification gives you a recognized edge in the job market.

Real Results from Lean in Action 🚀

✔️ A financial services firm saved $1.2 million in operational costs after a certified lean implementer redesigned their loan processing workflow. ✔️ A hospital reduced patient wait times by 35% through Lean-driven scheduling and resource allocation. ✔️ A software company improved product delivery speed by 40% using Lean tools combined with Agile frameworks.

Future-Proof Your Career with Lean Skills 🌐

As businesses continue evolving, lean skills will be essential not optional. Professionals who hold a lean implementer certification show they’re ready to handle real-world challenges, improve performance, and lead with confidence.

This isn't just another certificate it's a proven way to:

✔️ Grow your career ✔️ Make measurable impact ✔️ Stand out to top employers ✔️ Be part of strategic decision-making

Ready to Start Your Lean Journey?

Now is the perfect time to enroll in the Certified Lean Implementer Certification and join the ranks of professionals driving real change in their organizations.

For more information: https://www.gsdcouncil.org/certified-lean-implementer

Contact no: +41 41444851189

0 notes

Text

Lean Manufacturing Training for Operational Excellence

Seicho Consulting’s Lean Manufacturing Training is engineered to help manufacturing organizations streamline operations, eliminate waste, and boost productivity. Our program is based on proven Lean principles and practices that enhance efficiency across production lines.

Participants learn how to identify value-added versus non-value-added activities, implement 5S for workplace organization, and conduct value stream mapping for continuous improvement. With a hands-on approach, we ensure that lean concepts are not just understood but embedded into day-to-day operations.

This training is ideal for plant managers, floor supervisors, engineers, and operations teams who want to adopt a culture of continuous improvement. By reducing bottlenecks, improving workflow, and minimizing errors, our lean training contributes directly to higher output and customer satisfaction.

Seicho’s approach includes real-life case studies, Gemba walks, and on-site workshops to deliver actionable insights. Our expert trainers guide teams in developing KPIs and sustainability plans for lasting change.

#LeanManufacturing#OperationalExcellence#ContinuousImprovement#SeichoConsulting#5STraining#ManufacturingEfficiency

0 notes

Text

Title: Boost Workplace Efficiency with 5S Training by Advance Innovation Group

In today’s highly competitive market, organizations need to ensure maximum efficiency, safety, and productivity across all functions. One of the most effective methods to achieve this is through the implementation of the 5S methodology. At Advance Innovation Group, we offer specialized 5S Training programs that empower individuals and businesses across India to create organized, clean, and productive workspaces.

What is 5S?

5S is a workplace organization method originating from Japan. The term "5S" refers to five Japanese words that represent the key steps of this methodology:

Seiri (Sort): Remove unnecessary items from the workplace.

Seiton (Set in Order): Organize and arrange items so they are easy to find and use.

Seiso (Shine): Clean the workspace and inspect it regularly.

Seiketsu (Standardize): Establish standards and best practices.

Shitsuke (Sustain): Develop habits to maintain the established procedures.

These five steps help reduce waste, enhance safety, and increase operational efficiency.

Why Choose 5S Training?

5S Training goes beyond simple housekeeping. It lays the foundation for lean manufacturing and continuous improvement. Here's why enrolling in 5S Training with Advance Innovation Group is a strategic move:

Increased Efficiency: Save time and energy by maintaining an organized workspace.

Improved Safety: Reduce accidents by eliminating clutter and hazards.

Enhanced Quality: Consistency and cleanliness lead to fewer mistakes and defects.

Employee Engagement: Involving employees in 5S processes increases ownership and accountability.

Cost Savings: Minimize waste and optimize resource usage.

Who Should Attend?

Our 5S Training is suitable for:

Manufacturing and Production Staff

Operations Managers

Quality Assurance Teams

Facility Managers

Office Administrators

Lean and Six Sigma Practitioners

Whether you're from the manufacturing, IT, service, healthcare, or education sectors, 5S Training can be tailored to suit your specific operational needs.

What to Expect from Our 5S Training

At Advance Innovation Group, we ensure that our training is practical, engaging, and results-driven. Participants will:

Understand the history, purpose, and principles of 5S

Learn to conduct 5S audits and workplace assessments

Participate in hands-on exercises and real-life simulations

Develop an actionable 5S implementation plan for their organization

Receive certification upon successful completion

Why Advance Innovation Group?

With over a decade of experience, Advance Innovation Group has been a trusted training provider in quality management, Six Sigma, and process improvement. Our 5S Training programs are:

Led by seasoned industry experts

Supported with practical toolkits and templates

Customized to align with your business goals

Available both online and offline for flexible learning

Client Testimonials

"The 5S training from AIG transformed how we operate. Our shop floor is more efficient and employees are more motivated than ever!" – Rahul Verma, Plant Manager

"Implementing 5S principles helped us reduce inventory waste and improve productivity by 30%. Highly recommend AIG for professional training." – Meenakshi Singh, Operations Lead

Enroll Today

If you're ready to create a cleaner, safer, and more efficient workplace, it's time to enroll in our 5S Training program. Let Advance Innovation Group be your partner in driving operational excellence.

Contact Us: 📞 +91 7838656001 🌐 www.advanceinnovationgroup.com

Advance Innovation Group – Empowering Organizations, One Process at a Time.

Keywords: 5S Training, 5S Certification, Workplace Organization, Lean Tools, Advance Innovation Group, Productivity Improvement, Operational Excellence India.

0 notes

Text

The Importance of Lean and Six Sigma in ISO-Based Quality Systems

Organizations today operate in highly competitive and fast-changing environments. To remain successful, businesses must deliver high-quality products and services consistently, while keeping operations lean, efficient, and cost-effective. ISO standards provide the structural foundation for maintaining quality and compliance, but Lean and Six Sigma offer the tools and techniques to drive real improvements within that framework.

When combined, ISO, Lean, and Six Sigma become a powerful trio, helping organizations to not only meet but exceed quality expectations.

ISO and Its Emphasis on Quality

The International Organization for Standardization (ISO) has developed standards across a broad range of industries. ISO 9001 is the most recognized and widely implemented quality management system (QMS) standard globally. It helps organizations improve customer satisfaction, boost efficiency, and support continual improvement.

ISO 9001 is built on seven quality management principles:

Customer focus

Leadership

Engagement of people

Process approach

Improvement

Evidence-based decision-making

Relationship management

These principles guide organizations toward building systems that prioritize quality, but ISO does not dictate how to improve processes. That’s where Lean and Six Sigma come in.

Lean: Reducing Waste and Increasing Value

Lean is a methodology aimed at maximizing value while minimizing waste. The main objective is to eliminate activities that do not add value to the customer or end product. Common types of waste Lean seeks to remove include:

Overproduction

Waiting time

Transportation

Overprocessing

Excess inventory

Defects

Underutilized talent

Lean tools such as Value Stream Mapping, 5S (Sort, Set in order, Shine, Standardize, Sustain), and Kanban help visualize and streamline processes. When Lean principles are integrated into an ISO QMS, they align perfectly with the ISO principle of continual improvement and customer focus.

Six Sigma: Achieving Precision and Reducing Variation

While Lean focuses on speed and efficiency, Six Sigma concentrates on precision and quality. Six Sigma uses statistical methods to identify the root causes of problems, reduce process variation, and eliminate defects. Its primary goal is near-perfect process performance.

The DMAIC methodology is the cornerstone of Six Sigma:

Define the problem or improvement opportunity.

Measure the current process and gather relevant data.

Analyze the data to identify root causes of issues.

Improve the process by implementing solutions.

Control the improved process to ensure lasting results.

Six Sigma supports ISO’s evidence-based decision-making by providing detailed insights into process behavior and performance.

Integrating Lean and Six Sigma with ISO

Combining ISO with Lean and Six Sigma results in a stronger, more agile quality management system. ISO provides the structure and accountability; Lean brings speed and efficiency; and Six Sigma ensures accuracy and consistency.

Here’s how they complement each other:

ISO requires monitoring and measurement—Six Sigma provides the tools to do so accurately.

ISO values customer satisfaction—Lean ensures customer value is delivered with minimal waste.

ISO encourages risk-based thinking—Six Sigma’s analytical techniques help manage and mitigate risk effectively.

By leveraging all three approaches, organizations build a culture of continuous improvement that’s both structured and effective.

Practical Benefits of Integration

Enhanced Process Efficiency Lean eliminates non-value-added steps, resulting in faster, more cost-effective operations.

Improved Quality Control Six Sigma reduces variation, leading to fewer defects and more consistent outcomes.

Stronger Decision-Making ISO emphasizes data-driven decisions. Six Sigma provides the analytical tools, while Lean offers real-time insights.

Employee Engagement All three systems encourage employee involvement in identifying and solving problems, which boosts morale and innovation.

Customer Satisfaction Lean ensures customer value, Six Sigma ensures quality, and ISO ensures systems are aligned to meet and exceed expectations.

Implementation Strategies

Organizations should approach integration strategically. Here are some steps to consider:

Assess Current Systems: Evaluate existing QMS, Lean practices, and Six Sigma initiatives to find alignment opportunities.

Define Goals: Clarify what the organization wants to achieve—better quality, reduced costs, faster delivery?

Train Teams: Equip employees with the necessary knowledge of Lean, Six Sigma, and ISO.

Apply Tools Selectively: Not every tool fits every situation. Choose the ones most relevant to your process.

Monitor and Improve: Use ISO’s framework to monitor outcomes and Lean/Six Sigma tools to keep improving.

Challenges to Watch Out For

Integrating multiple systems can be complex. Resistance to change, lack of training, and unclear goals can hinder progress. It’s essential for leadership to be fully committed and for implementation teams to communicate effectively throughout the organization.

Proper planning, strong communication, and ongoing evaluation are key to overcoming these challenges and achieving successful integration.

Conclusion

Lean and Six Sigma are not just process improvement tools—they are philosophies that, when integrated with ISO standards, create a robust and responsive quality management system. This powerful combination enables organizations to deliver better value to customers, improve operational performance, and sustain long-term success. By embracing Lean, Six Sigma, and ISO together, businesses can thrive in an increasingly demanding global landscape.

0 notes

Text

Top Industrial & Retail Applications for Magnetic Labels

Did you know that 58% of retailers and D2C manufacturers have below 80% inventory accuracy? Keeping things organized in a fast-paced industrial or retail environment is a constant battle. Labels fall off, adhesive wears out, product placements change and before you know it, you are stuck reprinting and replacing labels more often than you would like. If you have been relying on traditional paper or adhesive labels, these issues can bother you. However, there’s a smarter, cleaner, and more flexible solution- magnetic labels. These simple yet formidable tools can stick with you through all the changes your supply chain throws your way, and we are going to understand why they might just be the upgrade your workspace needs.

Source: https://www.unleashedsoftware.com/blog/inventory-management-statistics/

#1 Warehouse Organization and Inventory Management

This is probably where magnetic labels shine the brightest. If you have ever seen a warehouse, you know how they are constantly in a state of flux- new stocks come in, items are relocated, and layouts are updated. Instead of creating new sticky labels every time you make a change, magnetic labels allow you to easily re-label shelves, bins, and racks without any residue or hassle. Besides, they work wonders on metal shelving- you can just slap them on and move them around as needed.

#2 Manufacturing Facilities

In manufacturing settings, clear and adaptable labeling is a must. Magnetic labels can be used to mark tool storage areas, machine components, production zones, and quality control sections. If the processes shift or equipment is relocated, the labels can be moved with zero downtime, and it’s a quite simple way to maintain order while keeping up with operational changes.

#3 Retail Store Shelving and Pricing

In retail stores or warehouses, product placement and pricing tends to change quite often. This is where a magnetic barcode label can make it easy for professionals to update pricing, promotions, and product info without printing new tags every time. They offer a clean, professional look while giving store staff the ability to make instant changes on the floor.

#4 Cold Storage and Freezers

Magnetic labels also work spectacularly in cold environments, too! Adhesives can fail in cold storage or freezer conditions, but magnetic labels hold firm. Whether you are storing meat, dairy, or medical supplies, magnetic labels keep things visible and organized without the worry of falling off or smudging.

#5 Lean Manufacturing and 5S Systems

For companies implementing Lean or 5S principles, visual organization is critical. Magnetic labels support these systems by helping clearly identify workstations, tool locations, parts bins, and workflow paths. They are color-coded, customizable, and can be shifted around with minimal effort, which makes continuous improvement easier to manage.

Conclusion

Yes, magnetic labels can be a game-changer for retail and industrial key players in terms of efficiency, flexibility, and cleanliness. Whether you are running a massive warehouse or managing a retail change, these labels can bring order to chaos. Want to give them a try? Start your journey with Adazon today!

0 notes

Text

0 notes

Text

Streamline Your Operations with 5S Certification: A Guide by 4C Consulting

5S Certification stands as a hallmark of operational excellence, offering businesses a roadmap to heightened efficiency and enhanced performance. Rooted in the principles of Sort, Set in Order, Shine, Standardize, and Sustain, this methodology transcends mere workplace organization—it instills a culture of meticulousness and continuous improvement. By systematically addressing inefficiencies, eliminating waste, and standardizing processes, 5S Certification empowers organizations to optimize their operations and drive tangible results. In today's hypercompetitive landscape, where margins for error are slim and demands for efficiency are high, embracing 5S Certification isn't just advantageous—it's imperative for staying ahead of the curve.

Understanding 5S Certification

5S, derived from five Japanese terms—Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain)—is a methodology aimed at organizing the workplace for efficiency and effectiveness. By meticulously arranging the workspace, eliminating clutter, and maintaining cleanliness, 5S creates an environment conducive to optimal performance and safety.

Why Your Business Needs 5S Certification

In today's hypercompetitive landscape, businesses cannot afford to overlook opportunities for improvement. Here's why 5S Certification is indispensable:

Enhanced Efficiency: The meticulous organization and standardized processes promoted by 5S lead to heightened efficiency. With streamlined workflows and reduced waste, businesses can accomplish more with fewer resources.

Improved Safety: A clutter-free and well-organized workspace minimizes hazards and promotes a safer environment for employees. By adhering to 5S principles, companies can mitigate the risk of accidents and injuries.

Cost Reduction: Waste comes in various forms—unused resources, inefficient processes, or unnecessary movement. By implementing 5S, businesses can identify and eliminate waste, resulting in significant cost savings.

Quality Enhancement: Standardized processes and a focus on cleanliness contribute to improved product quality. Consistency in operations reduces defects and rework, enhancing customer satisfaction and loyalty.

Employee Engagement: Empowering employees to participate in 5S initiatives fosters a sense of ownership and pride in their work environment. Engaged employees are more motivated, productive, and aligned with organizational goals.

Benefits of 5S Certification

The advantages of obtaining 5S Certification extend far beyond the shop floor. They include:

Competitive Advantage: Companies with 5S Certification demonstrate their commitment to excellence and continuous improvement. This distinction can set them apart from competitors and attract discerning customers who value efficiency and quality.

Regulatory Compliance: In industries subject to stringent regulations, adherence to 5S principles can facilitate compliance with health, safety, and environmental standards. Certification provides assurance to regulatory bodies and stakeholders.

Enhanced Reputation: A reputation for efficiency, quality, and safety can enhance brand perception and credibility. 5S Certification serves as tangible evidence of a company's dedication to operational excellence and responsible business practices.

Risk Mitigation: By systematically addressing potential risks and hazards, organizations can minimize the likelihood of disruptions, downtime, or costly incidents. 5S Certification contributes to a resilient and robust business infrastructure.

Continuous Improvement Culture: 5S is not a one-time initiative but a journey toward continuous improvement. Certification instills a culture of accountability, innovation, and collaboration, driving sustained growth and success.

How 4C Consulting Facilitates 5S Certification

At 4C Consulting Private Limited, we understand the transformative power of 5S Certification. With a proven track record of implementing ISO standards at over 2000 clients and delivering more than 10,000 hours of ISO training, we are your trusted partner in achieving operational excellence. Here's how we can help you embark on your 5S journey:

Expert Guidance: Our team of seasoned consultants possesses deep expertise in lean methodologies and process optimization. We'll work closely with your organization to assess current practices, identify improvement opportunities, and develop a tailored 5S implementation plan.

Comprehensive Training: Education is key to successful 5S implementation. Through engaging workshops, seminars, and hands-on training sessions, we equip your workforce with the knowledge and skills needed to embrace 5S principles and drive sustainable change.

Customized Solutions: We recognize that every business is unique, with its own set of challenges and objectives. Our consultants will collaborate with you to design customized 5S solutions that align with your organizational culture, goals, and industry requirements.

Ongoing Support: Our commitment to your success extends beyond certification. We provide ongoing support and guidance to ensure the continued effectiveness of your 5S initiatives. Whether you need troubleshooting assistance, performance monitoring, or refinement of processes, we're here for you every step of the way.

Certification Assistance: Navigating the certification process can be daunting, but with 4C Consulting by your side, it becomes seamless. We'll help you prepare for audits, address any non-conformities, and achieve 5S Certification with confidence and ease.

In today's dynamic business environment, achieving operational excellence is non-negotiable. 5S Certification offers a roadmap to efficiency, safety, and quality—a competitive edge that can propel your business to new heights. With the guidance and expertise of 4C Consulting, you can embark on your 5S journey with confidence, knowing that you have a trusted partner by your side. Streamline your operations, elevate your performance, and unlock the full potential of your organization with 5S Certification. Contact us now.

0 notes

Text

How 5S implementation plans drive Environmental Responsibility?

5S Implementation empowers Lean Manufacturing by fostering sustainability, streamlining workflows, minimising waste, and supporting eco-conscious operations.

For more details read our blog:

#5simplementation#5s#5smethodology#5saudit#5slean#5sleanmanufacturing#5sprocess#sustainability#5simplementationplan#leanmanufacturing#sixsigmalean#leanpractices#oeemanufacturing#leankaizen#leanstrategy#leankanban#leanmaintenance

0 notes

Text

Week 12 | 111424

Week 12 of our academic journey brought a deep dive into the essential principles of 5S, software quality management, and their application in a real-world case study: HealthTrack, a Medical Records Management System. This activity emphasized how structured approaches can elevate the reliability and performance of software, especially in critical sectors like healthcare.

Originating from lean manufacturing, 5S is a workplace organization method focusing on efficiency, productivity, and safety. Here’s a brief recap of its components:

1. Sort (Seiri): Remove unnecessary items.

2. Set in Order (Seiton): Organize tools and materials for easy access.

3. Shine (Seiso): Maintain cleanliness to prevent clutter.

4. Standardize (Seiketsu): Establish consistent practices.

5. Sustain (Shitsuke): Ensure long-term adherence to these practices.

When applied to software development, 5S ensures that processes are clear, resources are optimized, and teams work in harmony.

Software quality management (SQM) plays a pivotal role in the lifecycle of any system. It encompasses three main components:

1. Quality Planning: Defining quality standards and benchmarks.

2. Quality Assurance (QA): Ensuring processes are followed to achieve these standards.

3. Quality Control (QC): Testing and validation to ensure the product meets user expectations.

In the case of HealthTrack, SQM principles ensured the software was not only functional but also reliable, secure, and user-friendly.

The case study revolved around HealthTrack, a system designed to manage medical records efficiently and securely. This is particularly crucial in healthcare, where errors or inefficiencies can have life-altering consequences.

This week’s activity underscored the importance of combining structured methodologies like 5S with rigorous software quality management practices. In the context of HealthTrack, these approaches ensured that the system was not only functional but also reliable and secure—a non-negotiable in the medical field.

Implemented robust QA processes, including automated and manual testing.

Focused on compliance with healthcare data regulations like HIPAA.

Integrated user feedback loops to ensure continuous improvement.

#CPE #SDE

1 note

·

View note

Text

Lean Six Sigma Yellow Belt Certification: The Secret Weapon for Reducing Operational Costs in 2025

In today’s digital-first economy, businesses are rushing to automate and innovate but speed without strategy leads to chaos. That’s where Lean thinking comes in. And the professionals who lead this transformation? Those with a Certified Lean Implementer certification.

As companies focus on agility, digital transformation, and operational excellence, the demand for experts with lean implementer certification is growing across industries. Whether it’s IT, healthcare, finance, or manufacturing every sector needs structured, waste-free systems to stay competitive.

The Role of a Certified Lean Implementer in Digital Transformation

Digital tools alone can’t fix broken processes. In fact, they often expose the cracks faster. That’s why digital success starts with Lean principles.

A certified lean implementer plays a critical role in:

✅ Streamlining workflows before automation ✅ Aligning teams around value-driven processes ✅ Removing waste from digital initiatives ✅ Creating a sustainable improvement culture

Before adding AI, cloud systems, or ERP tools, smart companies bring in Lean-certified professionals to lay a solid foundation.

Why This Certification Is Trending in 2025

Here’s why the lean implementer certification is in high demand right now:

Hybrid Work Environments need better workflows, not just more tools

Customer Experience is directly tied to process speed and accuracy

Digital Projects fail without operational clarity

Cross-functional Collaboration is a must and Lean breaks silos

Your Lean certification shows that you’re ready to lead transformation with structure, not guesswork.

What You’ll Learn from the Lean Implementer Course 🎓

The lean implementer course equips you with real-world tools like:

🔹 Value Stream Mapping 🔹 5S & Kaizen 🔹 Root Cause Analysis 🔹 Continuous Improvement Techniques 🔹 Practical Waste Elimination

It’s not just about theory, it's about action. You’ll know how to spot problems, fix them, and prevent them from coming back.

Real-World Impact 🌍

Companies that apply Lean the right way see:

🚀 Faster delivery timelines 📉 Lower operational costs 🎯 More satisfied customers 🔄 Agile and adaptable teams

And the people who lead these results? Professionals with a Certified Lean Implementer badge.

Ready to Future-Proof Your Career? 🌟

If you want to be more than just “another employee” if you want to drive change, create impact, and stay relevant in a fast-changing world the Lean Implementer Certification is your launchpad.

✔️ Globally recognized ✔️ Industry-neutral skills ✔️ Practical and job-ready ✔️ Trusted by top employers

For more information: https://www.gsdcouncil.org/certified-lean-implementer

Contact no: +41 41444851189

0 notes

Text

Lean Management Consulting: Building a Culture of Continuous Improvement

In today’s volatile and complex business environment, organizations must be agile, efficient, and relentlessly focused on customer value. That’s where Lean Management comes into play—not just as a toolkit, but as a transformational management system.

At Seicho Consulting, we don’t just implement Lean—we help you build a culture of continuous improvement that drives strategic outcomes, enhances operational performance, and engages people at every level.

🚀 What is Lean Management?

Lean Management is more than reducing waste—it's a mindset.

It’s about:

Aligning strategy with execution

Empowering people to solve problems at the source

Structuring operations to flow smoothly

Delivering consistent value with minimal effort and resources

Whether you’re a manufacturer, service provider, or administrative organization, Lean helps you transform how your teams think, act, and grow.

🔧 Our Lean Management Services

At Seicho Consulting, we offer a full suite of Lean Management Consulting solutions tailored to your industry, scale, and growth stage:

✅ Lean Transformation Strategy & Roadmap

We co-create a structured rollout plan for Lean adoption, fully aligned with your long-term business objectives.

✅ Leadership Coaching & Change Management

We guide your leadership team in becoming Lean change agents, ensuring transformation is not just top-down but sustainable.

✅ Gemba Walks & Visual Management Systems

We improve transparency and accountability with on-site observation and visual systems that expose process gaps and flow inefficiencies.

✅ Team Engagement & Problem Solving Skills

Empowered teams drive improvement. We help your staff build the capability to identify and eliminate problems at the root.

✅ KPI Development & Performance Tracking

We design clear, actionable KPIs that reflect true business performance and guide real-time decision-making.

✅ Layered Audits & Sustainment Plans

Lean doesn’t end with implementation. We install a structured audit and sustainment system to protect and evolve your Lean culture.

🏭 Industries We Serve

Our Lean Management approach has helped transform:

Manufacturing & Process Industries

Healthcare & Service-based Organizations

Administrative & Office Functions

SMEs and Corporates seeking cultural change

Whether you’re improving shop floor operations or streamlining service workflows, Lean principles are universally applicable.

📈 The Impact of Lean Management

By applying Lean thinking across your value stream, you unlock:

🔄 Reduced operational waste

⚡ Faster and more consistent output

🧠 Increased employee ownership and problem-solving

📊 Data-driven agility and continuous learning

💰 Higher value at lower operating costs

🌟 Why Choose Seicho Consulting?

What sets us apart is our depth and discipline:

✔ Hands-on experience across 50+ organizations

✔ Custom strategies for your industry, size, and structure

✔ Integration with TPM, 5S, VSM, TQM, and ERP systems

✔ Focus on culture transformation, not just tool implementation

✔ Tactical and strategic approach—ground-level change backed by C-suite alignment

💬 Let’s Build Your Lean Culture

Lean isn’t a one-off initiative. It’s a way of thinking, managing, and leading. If you're looking to make your organization more efficient, more engaged, and more aligned with customer value—we’re ready to help.

📞 Contact Seicho Consulting today to schedule a consultation and start your journey toward continuous improvement.

#LeanManagement#LeanManagementConsulting#ContinuousImprovement#OperationalExcellence#BusinessTransformation#LeanThinking#ProcessImprovement#Kaizen#GembaWalk#VisualManagement#LeanCulture#LeadershipDevelopment#SeichoConsulting#WasteReduction#LeanStrategy#BusinessConsulting#ChangeManagement#ProductivityImprovement#ManufacturingConsulting#ServiceExcellence

0 notes