Don't wanna be here? Send us removal request.

Text

7 QC Tools for Quality Improvement in Manufacturing & Services Industries

In our competitive business climate today, consistently providing a quality product or service is not a choice, it is necessary. Whether in the manufacturing or service industry, the task of fulfilling expectations of a customer requires tools that help you to identify the problem, analyze the data, and the process of improvement. This is where the 7 QC (Quality Control) Tools come into play.

The 7 QC Tools are simple, effective, and applicable to everyone; they are the basis for quality improvement for all industries. Let’s take a look at each of these tools and how quality can provide value to you in your work.

What Are the 7 QC Tools?

The 7 QC Tools are basic statistical tools developed by Kaoru Ishikawa, a Japanese quality expert, to improve product and service quality. They are:

Cause-and-Effect Diagram (Ishikawa or Fishbone Diagram)

Check Sheet

Control Chart

Histogram

Pareto Chart

Scatter Diagram

Flow Chart (Process Mapping)

These tools help teams in problem identification, root cause analysis, monitoring processes, and decision-making — critical to achieving Total Quality Management (TQM) and continuous improvement.

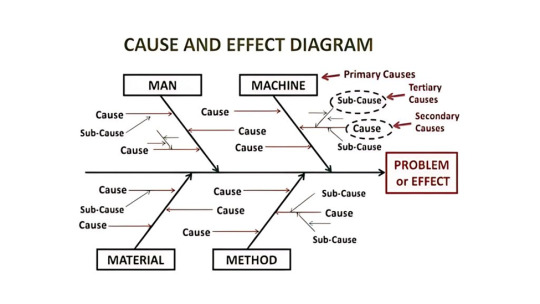

1. Cause-and-Effect Diagram (Fishbone Diagram)

Also known as the Ishikawa Diagram, this tool is used to identify the root causes of a problem by categorizing possible causes into groups such as:

Man

Machine

Method

Material

Measurement

Environment

📈 Use Case:

In a manufacturing plant, if there’s a defect in the product, the Fishbone Diagram helps break down and analyze every possible factor that could be causing it.

In a service company, it could be used to find why customer complaints have increased.

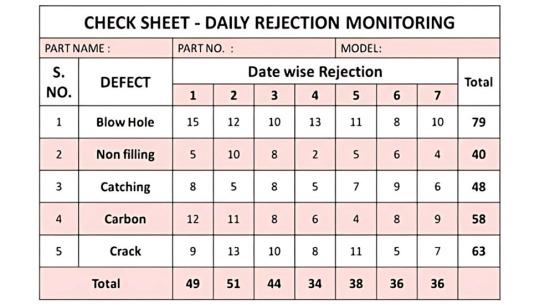

2. Check Sheet

A Check Sheet is a structured, prepared form used to collect real-time data at the location where it is generated. It's one of the simplest and most effective tools for tracking how often a problem occurs.

📈 Use Case:

In manufacturing, it might track the number of defects per shift.

In services, a call center might use it to log the types of issues customers report.

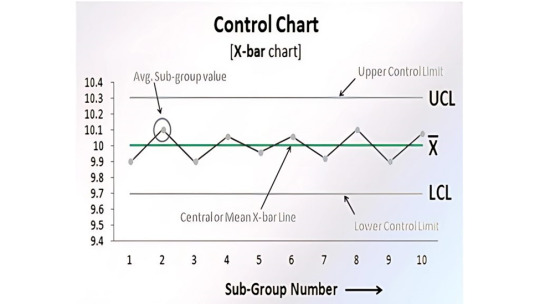

3. Control Chart

Control Charts are used to monitor process variation over time and determine whether a process is in a state of control.

It distinguishes between:

Common cause variation (normal)

Special cause variation (abnormal)

📈 Use Case:

A manufacturing process using machinery can track the consistency of product dimensions.

In services, a control chart could monitor average call handling time to ensure it stays within set limits.

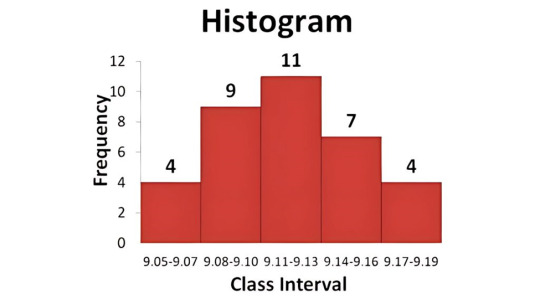

4. Histogram

A Histogram is a graphical representation of data distribution. It shows how often each different value in a set of data occurs.

📈 Use Case:

In manufacturing, it helps identify the spread of measurement values, like length or weight.

In services, it can show customer satisfaction ratings to identify performance trends.

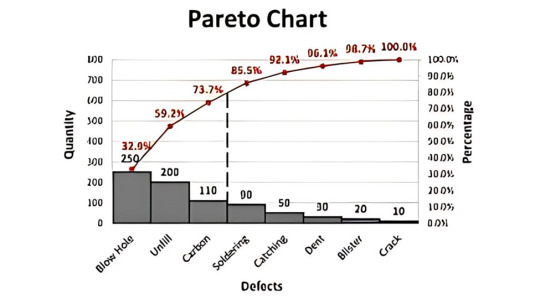

5. Pareto Chart

Based on the 80/20 rule, the Pareto Chart helps prioritize problems by showing which causes contribute most to an issue.

It ranks issues from most to least significant, so teams can focus on the "vital few" rather than the "trivial many."

📈 Use Case:

In manufacturing, it helps identify which types of defects occur most frequently.

In services, it can identify the top reasons for customer complaints or service delays.

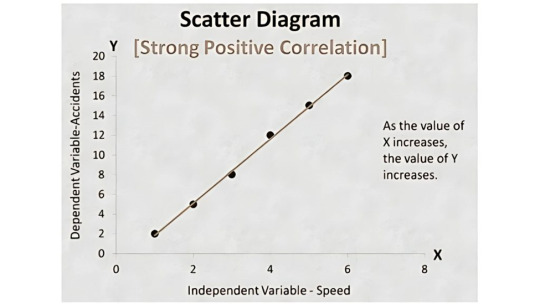

6. Scatter Diagram

A Scatter Diagram shows the relationship between two variables. It helps determine if a change in one factor affects another.

📈 Use Case:

In manufacturing, you could study the relationship between machine maintenance frequency and product quality.

In services, it might analyze how employee training hours affect customer satisfaction scores.

7. Flow Chart (Process Mapping)

A Flow Chart maps out every step in a process, helping visualize workflows and identify unnecessary steps, delays, or bottlenecks.

📈 Use Case:

In manufacturing, it can map out an assembly process to find inefficiencies.

In services, it can improve the flow of customer onboarding or complaint resolution processes.

Benefits of Using 7 QC Tools in Manufacturing

Reduces defects and rework

Increases productivity and process control

Improves product consistency

Increases the effectiveness of decision making when using data to support decisions

Improves customer satisfaction and retention

Benefits of 7 QC Tools in Services Industry

Improves service delivery time

Reduces customer complaints

Improves employee performance through better processes

Enables proactive problem-solving

Supports a culture of continuous improvement

How to Implement the 7 QC Tools in Your Organization

Step 1: Train Employees

Start with basic training on each QC tool so that employees understand when and how to use them.

Step 2: Identify Problems

Pick a real problem that affects your quality, such as high defect rates or customer dissatisfaction.

Step 3: Choose the Right Tool

Each tool has a unique function. Select based on what you want to analyze — root cause, trends, relationships, etc.

Step 4: Analyze Data

Use the tool to collect and interpret data. Look for patterns, trends, or anomalies.

Step 5: Take Action

Based on the analysis, make informed decisions and implement process improvements.

Step 6: Review & Improve

Monitor the results of your changes and keep refining your processes.

How 4C Consulting Can Help

With experience of working with over 2500+ clients and delivering more than 15,000 hours of quality training, 4C Consulting is your expert partner in implementing QC tools, ISO standards, and quality improvement frameworks.

Our consultants will:

Provide hands-on training on 7 QC Tools

Help create customized checklists, charts, and templates

Assist in integrating these tools into your Quality Management System

Support your team in problem-solving and performance tracking

Ready to improve your quality processes? 👉 Talk to our experts today for a free consultation!

#7 QC Tools#Quality improvement tools#QC tools in manufacturing#QC tools in service industry#How to use 7 QC tools#Basic quality control tools#Problem-solving tools for quality#7 QC tools implementation#Quality management tools

1 note

·

View note

Text

What Is Ecovadis and Why Your Business Needs It

Ecovadis is one of the platforms to rate business sustainability and improvement. Today, businesses are judged based on their ethical practices and environmental impacts. Different than most other platforms, Ecovadis provides the opportunity to modern manufacturers, suppliers and exporters to grow and maintain compliance in international market.

🌍 What is Ecovadis?

Ecovadis is an international platform that assesses a company’s sustainability performance on the four following themes:

1. Environment

2. Labor & Human Rights

3. Ethics

4. Sustainable Procurement

It gives out scorecards as well as providing a rating (Bronze, Silver, Gold, or Platinum) reflecting the company’s CSR policies, practices and outcomes. Over 100,000+ companies worldwide are already part of the Ecovadis network.

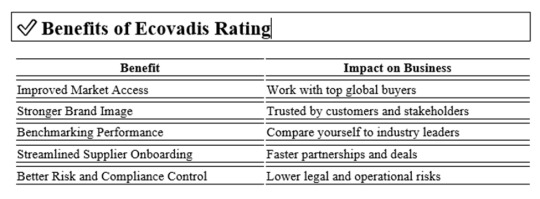

📌 How Ecovadis Can Impact Your Business

1. Fostering Trust All Over The World

Ecovadis ratings are now used by international buyers to assess and choose responsible suppliers. Having a strong rating increases the chances of working with the best global clients.

2. Continuous Improvement

Sustainability systems enhance over time and improve due to the detailed scorecard’s identification of strengths and weaknesses.

3. Competitive Advantage

Having responsible rated companies gives buyers an edge by eliminating supply chains of unresponsible companies.

4. Improvement of Brand Reputation

Your business can now be ranked as an ethical and transparent business leader because of having high ecovadis scores.

5. Compliance is Guaranteed

Ecovadis helps companies adhere to rising global legislations concerning ethics, human rights, environmental protection, and sourcing by ensuring proper practices.

What Does Ecovadis Evaluate?

For businesses applying for Ecovadis, the assessment is done according to the following four categories:

1. Environment

Energy consuming reporting

Waste and water management systems

Reduction of emissions

Policy, reporting and compliance of environment management systems

2. Labor & Human Rights

Employment relations

Occupational health and safety

Workforce equity and non-discrimination

Policies on children and forced labor

3. Ethics

Anti-corruption policies

Data privacy and protection

Business ethics

4. Sustainable Procurement

Conduct of suppliers

Social and environmental audits of suppliers

Procurement risk management

📝 Steps to Achieve an Ecovadis Certification

Step 1: Registration and Profile Completion

Sign up on Ecovadis, and create an organizational profile by providing the requisite details.

Step 2: Upload Relevant Documents

Upload all files related to policies, procedures, audits, training sessions, and supplier management.

Step 3: Evaluation by Ecovadis

Ecovadis evaluates your submissions with experts and scores them based on the evidence provided.

Step 4: Issuance of Scorecard and Rating

You’ll be issued a digital scorecard which highlights your evaluated strengths, areas of improvement, and rating.

Step 5: Maintain and Improve

In the subsequent cycles, strive to receive feedback and implement changes while maintaining document accuracy.

💼 How 4C Consulting Can Help You Attain Ecovadis Success

Achieving global sustainability standards is a challenge most businesses face. We understand these concerns at 4C Consulting and extend end-to-end support on the Ecovadis journey backed by experience with over 2500 clients and 15,000 hours of training provided.

🔍 Supported Services Offered by Ecovadis

⬤ Gap Analysis – We assess your processes and compare them with Ecovadis requirements.

⬤ Documentation Support – We assist in the collection and preparation of policies, SOPs, reports, and supplier information needed.

⬤ Training & Awareness – Train your employees on CSR, ethics, and sustainability.

⬤ Implementation Assistance – Establish processes, controls, and procurement frameworks.

⬤ Scorecard Improvement Strategy – Customized action plans designed for each client's specific needs to increase their Ecovadis rating.

⬤ Audit Support – Conduct mock audits and provide expert feedback to prepare for the Ecovadis assessment.

With a defined strategy, industry insights, and a dedicated team, 4C Consulting guides you towards achieving the Ecovadis certification in the most efficient manner.

📢 Ready To Begin The Ecovadis Journey?

Let sustainability be the cornerstone of your business. Work with 4C Consulting to enhance your Ecovadis rating and surpass client expectations while strengthening your stance as a responsible market leader.

#Ecovadis certification#Ecovadis scorecard#Ecovadis rating system#Ecovadis consultant India#Ecovadis implementation#Ecovadis training support#How to improve Ecovadis score

1 note

·

View note

Text

Understanding the 7 QC Tools: The Foundation of Quality Improvement

In every quality-based company, problem-solving involves going beyond just resolving an issue. It requires deep diving into understanding why the issue arose in the first place. This is exactly where the 7 Quality Control (QC) Tools come into play.

Designed in Japan, these tools offer a practical, visual, and data-oriented method for problem-solving, analysis of processes, and continual improvement. Be it managing production lines, performing compliance audits, or spearheading digital transformation projects, the 7 QC Tools assist teams in clearly and systematically eliminating root causes, minimizing variation, and improving performance.

All seven tools contribute to the enhancement of evaluating processes and inefficiencies for the sake of achieving ongoing operational excellence. Their collective application builds a comprehensive system that can be used in any field, including but not limited to, healthcare, logistics, and information technology.

The 7 QC Tools for Quality Improvement

These tools form the foundation of any successful Quality Management System (QMS). Their straightforward nature as well as flexibility make them indispensable for any team that aims at building a culture of quality.

1. Cause-and-Effect Diagram (Ishikawa or Fishbone Diagram)

This tool aids in outlining every potential cause a given problem may have. By grouping causes into manpower, methods, machines, measurement, materials measurement and environment, teams deepen their understanding of the issue.

Example: A sealing two-hundred boxes of country's best raw honey fails repeatedly. A packaging team takes this diagram to help overcome this issue.

2. Check Sheet

As simple as it gets, check sheets allow customers to identify all types of orders, including defects, errors, and occurrences systemically.

Example: A logistics company tracks and identifies peak periods for late deliveries using check sheets.

3. Control Chart

A process is stable when the control upper and lower limits are constant, while in need of corrective action when they change. Control charts display process behavior over time.

Example: A pharmaceutical company control charts to avoid inconsistent temperature control during production.

4. Histogram

Example: IT support teams resolve tickets and average the time taken to do so.

5. Pareto Chart

Example: A call center finds out that two service lines account for a majority of customer complaints through Pareto analysis.

6. Scatter Diagram

Example: An HR manager tests a theory about onboarding hours and early-stage employee error reduction by increasing onboarding hours.

7. Flowchart

A flowchart is one of the ways to visualize processes step-by-step. It helps teams pinpoint inefficiencies, bottlenecks, and redundancies.

Example: A hospital maps out its discharge process to identify and eliminate delays.

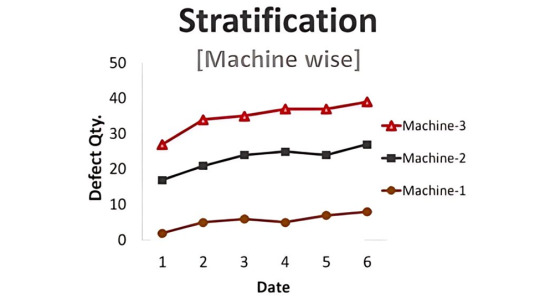

Where Can These Tools Be Used?

Finally, all industries can use the 7 QC tools, even if they were primarily used in manufacturing.

In ESG compliance: Monitor sustainability KPIs and supplier risk.

In HR: Streamline hiring and employee performance monitoring using flowcharts and control charts.

In IT: Use histograms and Pareto charts to improve response times for help desk services and reduce system outages.

In logistics: Identify service-related delays, optimize routes, and improve service.

These tools allow all organizations, regardless of industry, to practice fact-based decision making, which is crucial in any organization committed to quality.

How to Implement the 7 QC Tools Effectively

The good news is that you don't need expensive tools and certifications to start. Most of these can be implemented using Excel, Google Sheets, or even pen and paper.

Steps to Implement:

1. Identify the problem – Frame the issue you are experiencing as specifically as possible.

2. Select the right QC Tool – Match the problem or analysis with the appropriate tool.

3. Train your team – Make sure the relevant personnel know how to use the selected tools.

4. Collect accurate data – Focus on achieving consistency as well as completeness.

5. Analyze and act – Review all the data and decide what information will lead to improvement.

With some support from leadership and basic training, these tools can easily be integrated into your team's daily routines and problem-solving habits.

Why the 7 QC Tools Matter

The 7 QC tools are incredibly powerful due to how basic they are. They:

• Enable root cause analysis

• Support data-driven decisions

• Promote continuous improvement

• Foster collaboration across teams

• Enhance quality, efficiency, and compliance

In today's world with growing complexities, intense competition, and increasing customer expectations, these tools can serve as a cornerstone for operational excellence and strategic transformation.

How 4C Consulting Can Help You Implement the 7 QC Tools

At 4C Consulting, we focus on integrating quality into the heart of your operations. We have successfully completed over 2,500 ISO implementations and delivered over 15,000 hours of expert training, so we have the experience and deep industry knowledge to help.

Here's how we help your journey with the 7 QC Tools:

✅ Gap Assessment – Identify where your existing processes are relative to your goals.

✅ Tailored Training – Teach your teams to properly use and maintain the QC tools with confidence.

✅ Tool Selection & Deployment – Select the appropriate tools for your specific problems.

✅ Real-Time Application Support – Get hands-on help with real-life projects.

✅ Ongoing Improvement Coaching – Foster an environment that promotes quality, spanning multiple departments.

Looking to aid with process improvement, variability reduction, and establishing an organization-wide continuous improvement culture?

Master the 7 QC Tools and more with 4C Consulting.

👉 Begin your journey to better quality today.

#7 QC Tools#Seven Quality Control Tools#7 QC Tools for Quality Improvement#Implementing 7 QC Tools#7 QC Tools Examples#Quality Management Tools

1 note

·

View note

Text

STOP WASTING TIME! GET ORGANIZED WITH 5S AND WORK SMARTER

Tools regularly misplaced, clutter filling your workspace, or an overall sense of frustration when trying to manage it all. Sound familiar? You're not alone, as people and businesses waste around 30 per cent of their day on inefficiencies and lost time, whether it's tools being misplaced and then found 20 minutes later, or not remembering where you put your laptop. But what if there was a simple, systematic, and repeatable means to improve everything, resulting in a more fruitful, and less stressful work environment with fewer workplace hazards?

The challenges and expectations of workplace efficiency have never been so important, and as we head into 2025, the push for efficiency and streamlined operations is greater than ever before. 5S is an applicable methodology from Japan, which is relevant to any organization striving for operating excellence, waste reduction, and improvements in productivity, and can help you achieve that.

In this blog, we explore why 5S is necessary for optimizing your workspace today, the purpose, framework, benefits, and the simple steps to apply 5S to your workspace.

The Need for 5S in Today's Workplace

Today's workplaces, whether on a manufacturing floor, in an office, or a service center, are changing rapidly and facing challenges such as:

Increasing complexity of workflows and demands: Also, leading to bottlenecks and confusion for everyone involved in the process.

Rapid technological change: Often meaning new tools and equipment that need to be implemented.

Recurring employee turnover: Need efficient onboarding and transfer of knowledge.

Persistent pressure to reduce costs and deliver quicker: Where every wasted minute counts.

Global overload and clutter: All of which mentally drain focus and make it more challenging to be productive.

These factors require solid functions for your workplace that will allow it to run smoothly and ultimately increase productivity while potentially decreasing errors, and providing a culture in which everyone focuses on being organized and proactive. 5S is a framework for creating functions to establish documentation that coincides with your objectives for efficiency while creating overall authenticity in your workplace.

What is 5S? Understanding the Five Pillars of Efficiency

5S is a referencing five Japanese words, all of which start with the letter "S," that defines a specific approach to workplace organization. The process is a cycle and not a one-and-done event.

Sort (Seiri): Get Rid of the Unnecessary. The first step is decluttering which means identifying and removing everything that is unneeded from the workplace. If something is not required to do the task at hand, move it or throw it away. Clutter takes up space, and removing clutter also reduces visual and physical clutter.

Set in Order (Seiton): A Place for Everything. Once you have removed anything that is not needed, it is now time to arrange everything you need in a logical and efficient manner. Everything should have a clearly designated place, and everything should be easily recognizable to find, use, and return. Consider placement, flow of use, frequency of use, and ergonomics.

Shine (Seiso): Cleanliness as Inspection This pillar involves cleaning your workplace, tools, and equipment. Not only is cleaning involved, it is an act of inspection. The act of cleaning should look for other potential issues (i.e. leaks, worn parts, loose connections), finding issues before they escalate into bigger problems.

Standardize (Seiketsu): Be Consistent This step must consist of procedures and visual controls to aid and keep the previous sets of "S's" consistent. This step promotes consistency in following the same best practices, closing the gaps and establishing a systematic way to establish and maintain the new organized state as the "new normal", preventing a return to the old state.

Sustain (Shitsuke): Be Disciplined and Make it a Habit The last and most important S! This pillar must focus on making 5S a habit and adjusting it to organizational culture. The discipline and commitment on an ongoing basis must be supported and embrace by leadership to ensure the principles of the S's are followed daily and improved continuously.

Why 5S Matters More Than Ever for Your Productivity in 2025

Get Rid of Search Time, Improve Output: In 2025 every minute will count. The use of 5S will eliminate time spent searching for tools, documents, or materials. By sorting the unnecessary and organizing the essential, people will be able to go immediately to what they need and use that time saved to get more work done.

Decrease Errors and Rework: Keeping the workplace clean and organized with standardized methods (Shine & Standardize) decreases the likelihood of making a mistake. With fewer errors made there is less time wasted doing rework, quality checks, and correcting issues, which ultimately contributes to a more positive first-pass yield.

Better Safety and Reduce Accident: Clutter is a safety risk. The 5S process will eliminate barriers, create paths with the proper markings, and ensure equipment is clean and routinely inspected. Establishing a safe workplace creates less risk for accident, less downtime for employees away from injuries, and ultimately less costs associated with accidents.

Improve Employee Morale and Engagement: Operating in a clean, organized, efficient work environment will minimize employee stress and frustration. When an employee's workspace is well controlled, they will feel more valued and empowered. Job satisfaction will improve, with better focusing attention, and have more pride in their work.

Decrease Training and Onboarding Time: New employees can learn and adapt to stand organizational standards faster with 5S methods of visual controls and standardized procedures. The onboarding time will significantly be reduced with employees being a fast contributor.

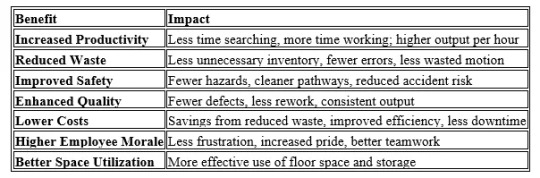

Benefits of 5S for Your Workplace

Here’s a breakdown of the tangible and intangible benefits 5S offers your organization in 2025:

How to Implement 5S in Your Organization: A Step-by-Step Blueprint

Step 1: Obtain Leadership Buy-in. Senior management must actively support 5S which means we need them there with us and to communicate the importance of the exercise. They must also provide the resources that will be needed to sustain a program.

Step 2: Create a 5S Team. Build a cross-functional 5S team consisting of people from different departments. This team will lead the process, educate others, and facilitate the implementation.

Step 3: Fully Educate Everyone and Raise Awareness. All employees must be educated about the principles of 5S, the benefits, and their role in implementing it. It is important that each employee understands "why" they are doing it not just "how."

Step 4: Identify a Pilot Area Start small! Choose a reasonable pilot area (e.g. one workstation, a tool crib, or a section in an office) to help with quick wins, learn some lessons and build enthusiasm before rolling out a broader implementation.

Step 5: Implement 5 S's Systematically (Sort, Set in Order, Shine) Walk the organized area. Conduct "Red Tag" event for Sort. Use visual controls and logical arrangement for Set in Order. Build cleaning and inspection into the daily routine for Shine.

Step 6: Standardize and Audit Create procedures, checklists, and visual standards so that the organized state can be maintained. Conduct a regular internal audit to determine how many standards you are adhering to, and where improvements can be made.

Step 7: Sustain and Continuous Improvement Make 5S a habit. Incorporate into daily routines, performance reviews of staff, and team meetings. Consider continuous improvement (Kaizen) and give ownership to employees to identify other improvements.

How 4C Consulting Helps You Implement 5S for Maximum Impact

Sustaining 5S is not just a cleanup, but it's a commitment to a culture of discipline and efficiency. 4C Consulting can help.

Our experience in operational excellence and real-world experience makes us qualified to help organizations navigate through the entire 5S process quickly and effectively.

Our Proven Approach Includes:

Tailored Workplace Assessment: We conduct a thorough assessment of your current workplace arrangement and operations to identify areas of wasted time and the potential for implementing 5S's principles.

Interactive 5S Workshops & Training: Our consultants conduct in-depth hands-on training sessions for all levels, from leaders to frontline operators, so that everyone understands and can effectively apply the 5S principles.

Process Mapping & Visual Control Design: We support you in mapping your current workflows and designing intuitive visual controls (i.e. shadow boards, markings on the floor, observable labelling systems) that elaborate on how to truly "Set in Order" your workplace.

Pilot Project Support & Implementation: We provide on-site support for your initial 5S pilot projects and guide your team as they develop and execute each "S" to achieve demonstrable results.

Standardization & Sustainability frameworks: We help you to develop standardization methods, auditing checklists, and accountability programs, that will support you maintaining and building upon the gains from your efforts in developing 5S.

Regardless if you are a small office or a larger manufacturing plant, 4C Consulting makes sure that 5S achieves sustainable time savings, enhanced productivity, and a more engaged workforce. We don't simply help make your space organized—we help you create a culture of waste reduction that drives sustainable operational excellence.

#5S Implementation#5S Workplace Organization#5S Methodology#Benefits of 5S#How to Implement 5S#5S Lean Manufacturing

1 note

·

View note

Text

A Comprehensive Guide to SOC 2 Compliance: How to Protect Your Data and Build Customer Trust

In today's world of technology, protecting sensitive data is not only a regulatory obligation, but a vital priority for any real business. For organizations that collect customer data, particularly in technology or SaaS companies, SOC 2 compliance provides the de facto standard for demonstrating your organization’s commitment to protecting data and the integrity of its operations. This guide provides comprehensive coverage of all you need to know about SOC 2 compliance: what it is; why it matters; how to achieve it; and the benefits it provides to both your organization and your customers.

What is SOC 2 Compliance?

SOC 2, or Service Organization Control 2, is a security framework created by the American Institute of Certified Public Accountants (AICPA) that outlines an organization’s controls that are related to security, availability, processing integrity, confidentiality and privacy of customer data. SOC 2 is different than generic certifications as it is uniquely personalized to reflect the internal controls and process that your organization utilizes, providing a complete and applicable assessment of your data protection efforts.

The Five Trust Service Criteria form the foundation of SOC 2 compliance—security, availability, processing integrity, confidentiality, and privacy.

Why SOC 2 Compliance Matters

1. Builds Customer Trust

In a time of frequent data breaches, customers want to trust that their data is being managed securely. SOC 2 certification means your organization has gone through serious security checks and can hopefully build levels of trust, great business relationships and grow business.

2. Reduces Risk

SOC 2 will help you discover areas of concern within your systems and allow you to address them, therefore reducing the chance for a cyber-attack, data leaks, and compliance violations.

3. Competitive Advantage

Many organizations will not partner with the vendors who were not SOC 2 compliant and due to this, entering into non-competitive environment with SOC 2 certification is advantageous and potentially very lucrative - spreading your brand name into new market shares.

4. Regulatory Alignment

SOC 2 is not a regulatory requirement but the controls in SOC 2 typically have similarities with regulatory requirements, for example, GDPR, HIPAA, CCPA and other standards that you have to contend with on your way to compliance.

The Five Trust Service Criteria

A SOC 2 Audit is a process to evaluate your organization based on five principles. These principles are:

Security: Protecting the systems from unauthorized access.

Availability: Making certain systems are up and accessible.

Processing Integrity: Monitoring the processing is complete and accurate.

Confidentiality: Protecting confidential information from unauthorized access.

Privacy: Personal information has been processed in accordance with privacy policies.

How to Achieve SOC 2 Compliance: Step-by-Step

Identify Project Scope

Identify the services, systems and locations that will fall into the scope of the SOC 2 audit. You will want to emphasize those areas where sensitive data is processed or stored.

Perform a Gap Analysis

You should assess your current controls against the SOC 2 criteria to identify where there are gaps, weaknesses or areas they require remediation.

Implement Controls

Develop or improve policies, procedures and offering technical safeguards to address meeting the SOC 2 requirements, such as access controls, encryption, monitoring, incident response, etc.

Educate Staff

Train employees to understand the importance of their role in maintaining security and compliance through training initiatives that need to be carried out regularly.

Conduct Internal Audits

You should audit controls internally so you can verify that they are working as intended sooner rather than later before the official SOC 2 audit.

Obtain Certified Auditor

Hire a CPA firm independent from your organization that is familiar with SOC 2 audits to perform the official assessment and provide the SOC 2 report.

A clear roadmap to achieving SOC 2 compliance, from scoping to successful audit completion.

Types of SOC 2 Reports

• Type I Report – Evaluates the design of controls at a specific point in time.

• Type II Report – Assesses the operating effectiveness of the controls over a defined period of time (usually 6 months).

Most clients and partners prefer and require a Type II report because of the depth of the report and the comfort it provides.

Benefits of SOC 2 Compliance for Your Organization

• Improved Client Confidence – enforces your dedication to security and data privacy.

• Reduced Operational Risk – the security gaps will be identified and closed as early as possible.

• Improved Business Processes – SOC 2 often facilitates a more operationally efficient and risk-managed organization.

• Marketing Edge – if you emphasize your SOC 2 status, you may separate yourself from competition.

• Improved Vendor Relationships – many companies will prefer or require companies with SOC 2 status.

How 4C Can Assist in Attaining SOC 2 Compliance

Achieving SOC 2 compliance can be challenging and time-consuming, but with the right partner the process can be more efficient and easier. Here at 4C Consulting, we specialize in the SOC 2 compliance journey for organizations. We work to protect sensitive information, meet SOC 2 compliance requirements, and put processes in place to ensure the continual trust of your clients.

We have a talented service team who will provide you with tailored services that include:

Gap Analysis: We will review all your systems and controls leveraging SOC 2 requirements. This will also quantify any areas of improvement while ensuring that no gaps are major.

Policies & Procedures Development: We will help you develop better security policies and procedures that relate to the SOC 2 trust principles while offering in your business environment.

Implementation: We can help you implement the technical and organizational controls. All access management, data encryption, and incident response plans should be in place.

Employees Training: We can provide your employees with training to develop awareness and security best practices to support SOC 2 compliance.

Audit Preparation: We will help prepare your staff and documentation for the SOC 2 audit and work efficiently with certified auditors to assist you through the entire SOC 2 certified process.

4C Consulting provides expert guidance and hands-on support throughout your SOC 2 compliance journey.

By collaborating with 4C Consulting, you will work with a trusted advisor who is dedicated to mitigating your compliance efforts, reducing your risks, and allowing your business to confidently demonstrate your commitment to data security. We can help you turn SOC 2 compliance from a headache to an advantage over your competitors.

Ready to start your SOC 2 journey? Contact us today for a consultation.

#SOC 2 compliance#SOC 2 certification#SOC 2 audit process#SOC 2 Type II report#SOC 2 requirements#How to get SOC 2 compliant

1 note

·

View note

Text

#ISO 9001 for manufacturing#ISO 9001 certification 2025#benefits of ISO 9001 in manufacturing#quality management system for manufacturers#ISO 9001 implementation guide

1 note

·

View note

Text

#What is 5S#5S methodology#5S steps#5S in the workplace#5S implementation#5S lean manufacturing#Benefits of 5S

1 note

·

View note

Text

Understanding ISO 14064: A Guide to Greenhouse Gas (GHG) Management and Reporting

In today’s world, where climate change and environmental sustainability are top priorities, businesses are under increasing pressure to measure, manage, and reduce their greenhouse gas (GHG) emissions. One of the most recognized international standards for GHG accounting and verification is ISO 14064. This standard helps organizations accurately quantify and report emissions while building trust with stakeholders.

What is ISO 14064?

ISO 14064 is a globally accepted standard developed by the International Organization for Standardization (ISO) for greenhouse gas accounting and verification. It provides clear guidance to organizations on how to quantify, monitor, report, and verify GHG emissions and removals. The standard is divided into three parts:

ISO 14064-1: Specifies principles and requirements at the organization level for quantification and reporting of GHG emissions and removals.

ISO 14064-2: Focuses on GHG projects and provides guidance for quantifying, monitoring, and reporting emission reductions or enhancements of removals.

ISO 14064-3: Provides requirements and guidance for validating and verifying GHG assertions.

By implementing ISO 14064, companies can take a structured and transparent approach to managing their carbon footprint.

Why is ISO 14064 Important?

With increasing global concerns about environmental degradation and regulatory requirements around climate change, companies can no longer afford to ignore their environmental impact. Here’s why ISO 14064 is important:

Compliance: Aligns with global reporting frameworks such as the Carbon Disclosure Project (CDP), Science-Based Targets, and more.

Credibility: Offers a third-party verifiable approach that enhances the trustworthiness of GHG statements.

Risk Mitigation: Helps identify carbon-related risks and opportunities.

Market Demand: Consumers and investors increasingly prefer environmentally responsible organizations.

Who Should Implement ISO 14064?

ISO 14064 is suitable for any organization, regardless of its size, sector, or location, that wants to:

Demonstrate environmental responsibility.

Comply with national or international climate-related regulations.

Attract climate-conscious stakeholders and customers.

Integrate GHG emissions data into ESG and sustainability reporting.

Industries like manufacturing, construction, energy, transportation, FMCG, and agriculture find ISO 14064 particularly useful.

Key Benefits of ISO 14064 Implementation

1. Enhanced Transparency and Accountability

ISO 14064 allows organizations to transparently report their emissions data, increasing stakeholder confidence.

2. Supports Climate Action Goals

It helps organizations contribute to national and international targets, such as the Paris Agreement or Net-Zero Commitments.

3. Improved Efficiency

GHG reporting often highlights inefficiencies in energy or process management, providing opportunities for operational improvement.

4. Competitive Advantage

Certification to ISO 14064 demonstrates environmental leadership and can set your organization apart in tenders and sustainability indices.

5. Foundation for Carbon Credits or Offsetting

ISO 14064 provides a credible basis for trading carbon credits or participating in voluntary carbon offset programs.

ISO 14064 Implementation Process

At 4C Consulting, we simplify the ISO 14064 implementation process into the following key steps:

Step 1: Gap Assessment

Assess existing processes against ISO 14064 requirements.

Identify gaps and improvement areas.

Step 2: GHG Inventory Development

Define organizational and operational boundaries.

Identify direct and indirect emission sources (Scope 1, 2, and 3).

Calculate emissions using approved methodologies.

Step 3: Documentation & Internal Controls

Develop GHG inventory management plans.

Implement data collection systems and assign responsibilities.

Step 4: Training & Awareness

Train internal teams on GHG quantification, recordkeeping, and reporting practices.

Step 5: Internal Audit & Verification

Conduct internal audits to verify emission calculations.

Prepare for third-party validation as per ISO 14064-3.

Step 6: Certification & Continuous Improvement

Facilitate third-party verification or certification.

Establish a system for periodic monitoring and improvement.

How 4C Consulting Can Help

With 2500+ clients and over 15,000 hours of ISO training delivered, 4C Consulting brings deep domain expertise in implementing ISO standards, including ISO 14064.

Our expert consultants offer:

Tailored ISO 14064 Implementation

Assistance in developing a robust GHG Inventory

Preparation for third-party verification

Support with ISO 14064 audits and internal controls

Training and awareness programs for staff

End-to-end documentation support including ISO 14064 manual

We ensure a smooth, efficient, and cost-effective ISO 14064 implementation aligned with your organization’s goals and sustainability strategy.

#ISO 14064 Implementation#GHG Reporting Standard#Greenhouse Gas Management#ISO 14064 Certification#ISO 14064 Consultant#GHG Inventory#ISO 14064 Audit#GHG Verification Services#ISO 14064 Standard Requirements#Carbon Emission Reporting

1 note

·

View note

Text

Understanding ESG: Why Environmental, Social, and Governance Matters for Every Business

In today's fast-changing business landscape, Environmental, Social, and Governance (ESG) factors have become crucial for companies striving for long-term success. ESG is more than just a trend—it's a strategic framework that helps organizations operate responsibly while building trust with stakeholders, investors, and customers.

In this blog, we’ll explore what ESG is, why it matters for every business, how it benefits organizations, and how companies can successfully integrate ESG into their operations.

What is ESG?

ESG stands for Environmental, Social, and Governance. It is a set of non-financial criteria used to evaluate how a business considers its impact on the world and its internal ethical standards.

✅ Environmental

This focuses on how a company affects the natural environment. It includes:

Energy usage and carbon emissions

Waste management

Water conservation

Sustainable sourcing

Climate change policies

✅ Social

This examines how a company manages relationships with:

Employees

Suppliers

Customers

Communities

It includes:

Labor practices

Workplace diversity and inclusion

Human rights

Consumer protection

Community engagement

✅ Governance

This relates to how a company is run. It includes:

Leadership structure

Executive compensation

Internal controls

Shareholder rights

Ethics and anti-corruption policies

Why ESG Matters for Every Business

1. Investor Expectations

Today’s investors look beyond financial performance. They want to invest in companies that are ethical, transparent, and socially responsible. ESG disclosures are becoming a key component in investor decision-making.

2. Regulatory Compliance

Governments around the world are introducing stricter ESG-related regulations. Companies that ignore ESG risk non-compliance, penalties, or loss of market access.

3. Brand Reputation

Consumers are increasingly loyal to brands that care about the environment, human rights, and corporate transparency. ESG builds brand trust and improves public image.

4. Risk Management

ESG helps identify risks early—be it environmental disasters, labor strikes, or governance scandals. Managing these proactively protects the business.

5. Long-term Profitability

Sustainable practices often lead to operational efficiencies, cost savings, and increased customer loyalty. ESG isn’t a cost—it’s an investment in the future.

Benefits of ESG Implementation

Integrating ESG principles can bring multiple benefits, such as:

Improved stakeholder trust

Better access to capital

Enhanced employee retention and productivity

Reduced operational costs

Increased innovation and market opportunities

Lower reputational and regulatory risks

Steps to Implement ESG in Your Business

If you’re considering ESG integration, follow these practical steps:

✅ Step 1: Assess Current ESG Performance

Conduct a baseline assessment of where your organization stands in terms of environmental impact, social responsibility, and governance practices.

✅ Step 2: Set Clear ESG Goals

Define measurable goals such as reducing carbon footprint, improving employee diversity, or strengthening board independence.

✅ Step 3: Develop an ESG Strategy

Integrate ESG into your business strategy. Align it with company values and stakeholder expectations.

✅ Step 4: Engage Stakeholders

Involve employees, investors, customers, and suppliers in your ESG journey. Transparency and collaboration are key.

✅ Step 5: Measure and Monitor Progress

Use ESG metrics and key performance indicators (KPIs) to track progress. Regular audits and reports help in staying accountable.

✅ Step 6: Report Transparently

Adopt global ESG reporting standards such as:

GRI (Global Reporting Initiative)

SASB (Sustainability Accounting Standards Board)

TCFD (Task Force on Climate-related Financial Disclosures)

ESG and Small Businesses: Is It Relevant?

Yes—ESG is for all businesses, regardless of size. While large corporations are often in the spotlight, small and medium enterprises (SMEs) can also gain a competitive edge through ESG by:

Enhancing customer loyalty

Attracting talent

Building strong local community relationships

Gaining supplier preference from ESG-conscious buyers

Common Challenges in ESG Adoption

While ESG is beneficial, organizations may face some hurdles:

Lack of awareness or expertise

Limited resources or budget

Difficulty in measuring non-financial impacts

Resistance to change within the organization

Partnering with ESG consultants or experts can help businesses overcome these challenges efficiently.

How 4C Consulting Can Help in ESG Implementation

With experience in implementing ESG frameworks for diverse industries, 4C Consulting offers end-to-end ESG support including:

ESG gap analysis

Strategy development

ESG training and awareness programs

ESG reporting and disclosures

ESG audits and risk assessments

Whether you're beginning your ESG journey or enhancing your existing efforts, 4C Consulting ensures compliance, transparency, and sustainable value creation.

#ESG Implementation#ESG Reporting#ESG Consultant#ESG Audit#ESG Strategy#ESG for Businesses#Environmental Social Governance#ESG Training#ESG Standards#Sustainable Business Practices

1 note

·

View note

Text

Why IATF 16949 Is a Must for Automotive Suppliers in 2025

In today’s fast-evolving automotive landscape, maintaining consistent product quality, safety, and reliability is no longer optional—it’s essential. As we move into 2025, global automotive suppliers are under growing pressure to align with stringent quality standards. Among these, IATF 16949 stands out as the gold standard for quality management in the automotive sector. If you’re an automotive supplier aiming for long-term success, IATF 16949 certification is not just a smart move—it’s a necessity.

What Is IATF 16949?

IATF 16949 is a globally recognized standard developed by the International Automotive Task Force (IATF) in conjunction with ISO. It harmonizes the various quality system requirements within the global automotive industry and is based on ISO 9001, with additional requirements tailored specifically for automotive production and relevant service parts organizations.

The standard focuses on defect prevention, continuous improvement, and reducing variation and waste in the automotive supply chain.

Why IATF 16949 Matters More Than Ever in 2025

1. OEM Expectations Are Rising

Leading Original Equipment Manufacturers (OEMs) are increasingly requiring IATF 16949 certification from their suppliers. In 2025, this trend is set to intensify as companies seek to minimize risk and ensure uniform quality across their global supply chains. Suppliers without IATF 16949 certification may find themselves locked out of lucrative contracts.

2. Complexity in Supply Chains

The modern automotive supply chain is vast and complex, involving numerous vendors, locations, and technologies. IATF 16949 brings standardization, enabling smoother collaboration and integration between suppliers and OEMs across the globe.

3. Electric Vehicles & Technological Disruption

The shift to electric vehicles (EVs) and autonomous driving systems demands higher precision, safety, and performance. These cutting-edge components leave no room for defects or inconsistencies. IATF 16949 provides a structured approach to ensure flawless quality even in the most advanced manufacturing environments.

4. Regulatory Pressure

Environmental and safety regulations are tightening globally. With stricter laws on vehicle emissions, safety features, and traceability, IATF 16949 helps suppliers stay compliant through its systematic approach to quality and risk management.

Key Requirements of IATF 16949 Standard

Customer-specific requirements

Risk-based thinking

Product safety protocols

Contingency planning

Supplier management and development

Embedded software quality assurance

Change and configuration management

Warranty and field failure analysis

These requirements ensure that suppliers not only meet but exceed industry expectations.

Benefits of IATF 16949 Certification

✅ 1. Improved Product Quality

The core objective of IATF 16949 is to enhance product and process quality. This leads to fewer defects, reduced rework, and greater customer satisfaction.

✅ 2. Global Market Access

Certification opens the door to international markets, allowing suppliers to partner with major global automotive brands who mandate IATF 16949 as a requirement.

✅ 3. Risk Mitigation

By identifying and addressing risks early, the standard helps avoid recalls, penalties, and brand damage.

✅ 4. Operational Efficiency

Standardized processes, leaner operations, and improved supply chain collaboration lead to cost savings and increased productivity.

✅ 5. Competitive Advantage

In a crowded market, being IATF 16949 certified sets your company apart, enhancing your reputation and making you a preferred supplier.

IATF 16949 Implementation Process

Implementing IATF 16949 involves several key steps:

1. Gap Analysis

Evaluate existing systems and processes against the IATF 16949 requirements.

2. Planning & Resource Allocation

Form a cross-functional team, define roles, and allocate resources for implementation.

3. Documentation Development

Prepare the IATF 16949 manual, quality policy, objectives, procedures, and records as required.

4. Employee Training

Conduct IATF 16949 training for staff to understand the standard, their responsibilities, and how to contribute to compliance.

5. Internal Audits

Perform audits to identify gaps and ensure readiness for the final certification audit.

6. Management Review

Top management evaluates audit results, customer feedback, and overall system performance.

7. Certification Audit

A third-party body conducts the official IATF 16949 audit and, upon successful completion, issues the certification.

How 4C Consulting Can Help

With extensive experience across 2500+ successful ISO implementations and 15,000+ hours of training delivered, 4C Consulting is a trusted partner in the journey to IATF 16949 certification.

Our IATF 16949 Services Include:

Gap analysis and implementation roadmap

IATF 16949 documentation (manual, procedures, forms)

Customized in-house IATF 16949 training

Internal auditor training and support

Pre-certification audit readiness

Post-certification continual improvement support

Whether you're a Tier 1, Tier 2, or emerging automotive supplier, our IATF 16949 consultants offer end-to-end support tailored to your needs.

Final Thoughts

In 2025, the automotive industry will continue to evolve at a rapid pace. Suppliers that prioritize quality, consistency, and compliance will not only survive but thrive. IATF 16949 is more than a certification—it’s a strategic enabler of growth, reputation, and long-term partnerships with global OEMs.

If you're ready to align your operations with world-class quality standards, it’s time to embrace IATF 16949.

#IATF 16949 Implementation#IATF 16949 Certification#IATF 16949 Training#IATF 16949 Consultant#IATF 16949 Audit#IATF 16949 Standard Requirements#Automotive Quality Management System

1 note

·

View note

Text

How an IMS Can Save Time, Cost & Effort in ISO Management

In today’s competitive business landscape, managing multiple ISO standards—such as ISO 9001 (Quality), ISO 14001 (Environmental), and ISO 45001 (Occupational Health & Safety)—can be complex, time-consuming, and resource-intensive. But what if you could streamline your compliance processes, reduce costs, and boost overall efficiency?

This is where an Integrated Management System (IMS) becomes a game-changer.

What is an Integrated Management System (IMS)?

An Integrated Management System is a unified framework that combines two or more ISO standards into a single, coherent system. Instead of running multiple parallel systems, IMS allows businesses to manage all their compliance obligations through one set of policies, processes, and objectives.

For example, you can integrate:

ISO 9001 – Quality Management

ISO 14001 – Environmental Management

ISO 45001 – Occupational Health & Safety Management

How IMS Saves Time in ISO Management

Time is one of the most valuable business resources. IMS can significantly reduce duplication of tasks and streamline compliance activities:

✅ Centralized Documentation

You don’t need separate manuals and records for each standard. One documented system covers all.

✅ Combined Audits

Instead of separate internal and external audits for each ISO, integrated audits reduce audit frequency and preparation time.

✅ Unified Training & Meetings

Conduct one management review meeting, one internal audit, and one training session covering all systems.

✅ Faster Decision-Making

With all data and KPIs available in one dashboard, leadership can make informed decisions faster.

How IMS Helps Reduce Cost

Implementing and maintaining multiple ISO systems can be expensive. IMS significantly cuts down both direct and hidden costs:

🔹 Lower Audit & Certification Costs

Integrated external audits are more efficient, reducing certification body costs.

🔹 Reduced Administrative Burden

Less paperwork, fewer templates, and unified policies minimize man-hours and overheads.

🔹 Optimized Resource Utilization

Staff can focus on value-adding tasks instead of juggling multiple systems.

🔹 Minimal Compliance Risk

With standardized processes, the chances of non-conformities are reduced, saving costs associated with penalties or rework.

How IMS Reduces Operational Effort

IMS leads to a more streamlined, efficient, and resilient organization:

✅ Aligned Objectives Across Standards

Your quality, safety, and environmental goals are aligned under one strategy.

✅ Better Risk Management

A holistic view of organizational risks improves mitigation planning and reduces disruption.

✅ Consistent Process Improvement

Cross-functional teams work more efficiently under a single process map, improving productivity.

✅ Improved Communication & Culture

When everyone works toward shared goals, employee engagement and accountability increase.

Real Business Benefits of IMS

Organizations that implement IMS experience:

Up to 30% faster audit completion

20–40% reduction in document preparation time

Cost savings of up to 25% on ISO-related activities

Increased customer confidence and stakeholder trust

How 4C Consulting Helps in IMS Implementation

At 4C Consulting, we specialize in helping organizations of all sizes implement Integrated Management Systems tailored to their unique needs.

Our services include:

Gap Analysis and Process Mapping

Customized IMS Manual & Documentation

Integrated Internal Audits & Training

Certification Support & Mock Audits

With over 3000+ successful implementations and 15,000+ hours of ISO training, our experts ensure your journey to IMS is seamless, efficient, and impactful.

Ready to Simplify Your ISO Management?

If you're managing multiple ISO standards separately, it's time to rethink your approach. An IMS not only saves time, cost, and effort—it also drives long-term business value.

Talk to our IMS experts today and get your Free 1-hour consultation.

#IMS Implementation#Integrated Management System#IMS Consultant India#ISO Integration Services#ISO 9001 14001 45001 Integration#Cost-saving through IMS#Simplified ISO Audits#IMS for Manufacturing / Construction / Healthcare

1 note

·

View note

Text

How EcoVadis Rating Enhances Your Company’s Sustainability and Supply Chain Credibility

In today’s competitive and environmentally conscious world, sustainability is no longer optional — it’s a core business priority. Companies across industries are seeking to measure, report, and improve their sustainability practices. That’s where EcoVadis comes in — a globally recognized platform that assesses environmental, social, and ethical performance across the supply chain.

This blog explores the importance of EcoVadis ratings, how they benefit your business, and how you can leverage expert support to improve your score and reputation.

What is an EcoVadis Rating?

An EcoVadis rating is an independent assessment of your organization’s Corporate Social Responsibility (CSR) performance. It evaluates your policies, actions, and results across four key pillars:

Environment

Labor & Human Rights

Ethics

Sustainable Procurement

Companies are scored on a scale from 0 to 100 and awarded a medal rating (Bronze, Silver, Gold, or Platinum) based on their overall performance.

Why EcoVadis Matters to Your Business

More than 100,000 companies across 175 countries use EcoVadis to evaluate sustainability. Here’s why it matters:

✅ 1. Boosts Supplier Credibility

Buyers prefer working with suppliers who have strong sustainability credentials. An EcoVadis rating helps your business stand out as a trusted and responsible partner.

✅ 2. Opens New Business Opportunities

Global companies like Nestlé, Coca-Cola, and Johnson & Johnson require or prefer EcoVadis-rated suppliers. Your rating can help you qualify for high-value contracts.

✅ 3. Enhances Transparency and Accountability

EcoVadis promotes responsible business practices and provides a structured framework for improving them.

✅ 4. Supports ESG & Compliance Goals

As Environmental, Social, and Governance (ESG) standards become regulatory priorities, an EcoVadis rating ensures you’re ahead of compliance requirements.

✅ 5. Drives Continuous Improvement

The EcoVadis platform provides detailed feedback and benchmarking, guiding your company to continuously improve its sustainability performance.

How the EcoVadis Assessment Process Works

Here’s a simplified breakdown of the EcoVadis journey:

1. Registration & Questionnaire You register on the platform and receive a tailored questionnaire based on your business size, location, and industry.

2. Document Submission You upload supporting evidence like policies, reports, certifications, and audit results.

3. Evaluation EcoVadis analysts assess your submissions using their methodology aligned with global standards such as ISO 26000, GRI, and UNGC.

4. Scoring & Medal Awarding You receive a scorecard showing your overall score and medal (if applicable), plus feedback and improvement areas.

5. Improvement & Reassessment Based on the insights provided, you work on identified gaps and apply for a reassessment to improve your score.

EcoVadis Rating Levels Explained

Reaching higher medal levels means better business credibility and increased visibility in the global supply chain network.

How 4C Helps You Achieve EcoVadis Success

At 4C Consulting, we specialize in guiding organizations like yours through the EcoVadis assessment and improvement process. With experience across 2500+ clients and 15,000+ hours of sustainability and ISO training, we offer:

✅ EcoVadis Readiness Assessment

We evaluate your current CSR practices, identify gaps, and help you prepare comprehensive documentation for the EcoVadis assessment.

✅ Policy & Procedure Development

Our experts assist in drafting and enhancing sustainability policies that align with EcoVadis requirements and global best practices.

✅ Sustainability Training & Awareness

We deliver customized training for your teams to help them understand sustainability goals, reporting methods, and performance indicators.

✅ Documentation Support

From HR policies to supplier code of conduct and environmental data, we guide you in preparing evidence that adds weight to your assessment.

✅ Score Improvement Strategy

If you’ve already received an EcoVadis score and want to improve it, we design a corrective action plan to help you climb from Bronze to Silver or Gold.

✅ Ongoing Compliance Monitoring

We offer continuous support to keep your sustainability documentation up to date for future assessments or client audits.

With 4C’s expert guidance, achieving and improving your EcoVadis rating becomes a smooth and strategic journey.

Final Thoughts

EcoVadis is more than just a sustainability rating — it’s a business enabler. It validates your ESG efforts, builds supplier trust, and opens doors to global opportunities. Whether you are a first-time applicant or aiming for a higher medal, 4C Consulting provides the roadmap and expertise to support you every step of the way.

#EcoVadis Rating#EcoVadis Certification#EcoVadis Scorecard#ESG Supplier Rating#EcoVadis Consultant India#EcoVadis Assessment Process#Corporate Sustainability Rating#Sustainable Procurement

1 note

·

View note

Text

Improve Your Process Quality with These 7 QC Tools

In today’s competitive market, businesses must consistently deliver high-quality products and services. Whether you’re in manufacturing or service delivery, improving your processes is key to meeting customer expectations and reducing errors. That’s where the 7 QC (Quality Control) Tools come in.

These tools are simple yet powerful techniques that help you identify problems, analyze them, and find solutions for continuous improvement.

What Are the 7 QC Tools?

The 7 QC Tools are a set of problem-solving methods used widely in quality management and process improvement. Originating from Japan, these tools are easy to understand and apply—even if you don’t have a technical background.

Here are the 7 QC Tools:

Cause and Effect Diagram (Fishbone or Ishikawa Diagram)

Check Sheet

Control Chart

Histogram

Pareto Chart

Scatter Diagram

Flowchart (Process Diagram)

🔍 1. Cause and Effect Diagram (Fishbone Diagram)

Purpose: To identify root causes of a problem.

This tool helps teams brainstorm and categorize potential causes of a problem, showing how different factors (like manpower, machine, materials, methods) affect the outcome.

📌 Use when: You know the problem but not the reason behind it.

Example: High rejection in a production line — the diagram helps identify causes like machine calibration or operator error.

📝 2. Check Sheet

Purpose: To collect and organize data easily.

A check sheet is a simple form used to record the frequency of problems or defects. It helps in understanding where to focus improvement efforts.

📌 Use when: You need to collect real-time data on process issues.

Example: Tracking the number of defects per day or per machine.

📊 3. Control Chart

Purpose: To monitor process variation over time.

Control charts help you identify whether a process is stable or if there are abnormal variations that need attention.

📌 Use when: You want to control a process over time and ensure consistency.

Example: Monitoring the weight of a packaged product to stay within limits.

📈 4. Histogram

Purpose: To visualize the frequency of data.

Histograms show how data is distributed and help spot patterns, such as whether most defects fall within a certain range.

📌 Use when: You want to understand the distribution of a dataset.

Example: Measuring the delivery time of shipments and checking how consistent they are.

🎯 5. Pareto Chart

Purpose: To identify the most significant problems.

Based on the 80/20 rule (80% of problems come from 20% of causes), a Pareto chart helps you focus on the issues that have the biggest impact.

📌 Use when: You want to prioritize improvement efforts.

Example: Identifying that most customer complaints come from just two major issues.

🔗 6. Scatter Diagram

Purpose: To find relationships between two variables.

This diagram helps you determine if there's a correlation between two elements (e.g., machine speed and defect rate).

📌 Use when: You suspect that two variables are related.

Example: Analyzing if more training hours lead to fewer production errors.

🔄 7. Flowchart (Process Diagram)

Purpose: To visualize the steps in a process.

Flowcharts help understand how a process flows and where delays, defects, or confusion might occur.

📌 Use when: You want to document and improve a process.

Example: Mapping the customer complaint handling process to identify bottlenecks.

🚀 Why Use the 7 QC Tools?

The 7 QC Tools are popular for a reason—they’re simple, effective, and proven. Here’s why every business should use them:

✅ Easy to Use No complex software or technical skills needed—these tools are simple enough for anyone to understand and apply.

✅ Make Smarter Decisions They turn raw data into useful insights, helping you base decisions on facts instead of guesswork.

✅ Drive Continuous Improvement By identifying and fixing problems early, these tools help your team keep improving over time.

✅ Trusted Across Industries The 7 QC Tools are widely used in ISO 9001, Lean, Six Sigma, and other quality systems around the world.

✅ Save Time and Reduce Waste By targeting the real cause of issues, you reduce rework, improve efficiency, and save valuable resources.

🧠 How to Start Using the 7 QC Tools

Getting started with the 7 QC Tools is easier than you think. Follow these simple steps to improve your process quality:

Identify the Problem Start by clearly defining the issue you're facing. Be specific—whether it’s late deliveries, defects, or process delays.

Gather the Right Data Use tools like a Check Sheet or Flowchart to collect data and understand how the process works.

Find the Root Cause Use a Fishbone (Ishikawa) Diagram to dig deeper and identify the possible causes behind the problem.

Monitor Trends Over Time Use a Control Chart to see if the problem is consistent or just a one-time issue. A Histogram can help visualize data distribution.

Focus on What Matters Most Apply the Pareto Chart to find out which causes are having the biggest impact—so you can tackle them first.

Look for Relationships Use a Scatter Diagram to explore if two factors are connected—for example, training hours and error rate.

Take Action & Improve Once you understand the issue, take corrective actions. Then monitor the results and repeat the cycle for continuous improvement.

🏁 Final Thoughts

The 7 QC Tools are essential for any organization that wants to improve quality, reduce waste, and satisfy customers. Whether you’re in manufacturing, logistics, healthcare, or services—these tools can help you find problems and fix them faster.

Start small. Pick one problem in your process, apply one or two tools, and see the improvement for yourself!

#7 QC Tools#Quality Control Tools#Process Improvement Techniques#Problem Solving in Manufacturing#Lean Tools for Quality#ISO 9001 Tools#Root Cause Analysis Tools

1 note

·

View note

Text

#ISO 37001:2025#ISO 37001 Transition Guide#ISO 37001:2025 Updates#ISO 37001 Compliance#ISO 37001 Certification#ISO 37001 Implementation#ISO 37001 Climate Change Amendment

1 note

·

View note

Text

#IATF 16949:2024 Certification#Automotive Quality Management System#Electric Vehicle Manufacturing Standards#IATF 16949 Risk-Based Approach#Supplier Management for EV Industry#EV Manufacturing Compliance

1 note

·

View note

Text

#ECOVADIS SCORING METHODOLOGY#ECOVADIS RATING#ECOVADIS SUSTAINABILITY RATINGS#21 ECOVADIS CRITERIA#ECOVADIS ASSESSMENT

1 note

·

View note