#Hydraulic Power Pack

Text

Top Hydraulic Jack Manufacturers: Who Leads the Industry?

If you’re looking for a hydraulic power pack manufacturer, go no further than Zenith Hydromatic. We are a respected and well-known company in the hydraulic power pack manufacturing industry.

We provide high-quality hydraulic power packs with customization possibilities. Call +91 8200534779 or visit our website to get a price quote for the hydraulic power pack.

0 notes

Text

What Are The Key Parts Of Hydraulic Powerpacks And Pumps?

Before we delve into the parts that prove to be the backbone of some of the best hydraulic powerpacks and pumps, let’s understand what these devices are defined as. The hydraulic powerpack is understood as a single-handed assembly of three elements. This includes a hydraulic pump, a drive motor and a hydraulic fluid tank. Check out this article to learn what are the key parts of hydraulic powerpacks and pumps. https://bit.ly/3rZEp1J

0 notes

Text

POORNI HYDROMACS MFG CO was established in 2006 when it was just a novice. By time it emerged out to be the leader in today’s present-day marketplace of hydraulic machinery. Our company is a sole proprietorship company. We have about 10 dedicated and hardworking staffs in our market who work day and night to offer you the best hydraulic and suspension machines.

1 note

·

View note

Text

https://www.adlandpro.com/ad/42447765/Hydaulic-Power-Pack-in-PuneHydraulic-Power-Pack-Manufacture__Other_438__around_pune.aspx#.ZD1KWHZBzIU

#Hydraulic Power Pack#Hydraulic Power Pack Manufacturers in Pune#Hydraulic Power Pack Suppliers in Pune#Hydraulic Power Pack Dealers in Pune#Hydraulic Power Pack Manufacturers in Belgaum#Hydraulic Power Pack Suppliers in Belgaum#Hydraulic Power Pack Dealers in Belgaum

0 notes

Text

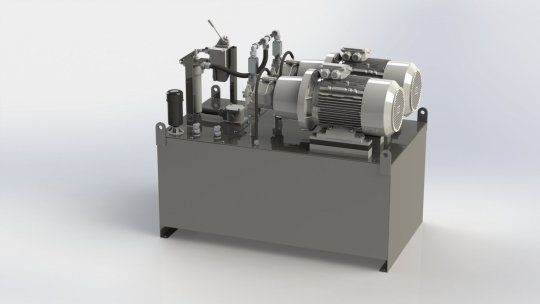

What Is Inside A Hydraulic Power Pack & How Does it Work?

A hydraulic power pack is a mobile energy storage device that supplies power to a hydraulic mechanism. The job of an electric battery, which stores energy for a circuit to draw on as needed, is the easiest way to understand what a hydraulic power pack is. Many industrial devices and applications use hydraulic power packs, particularly where there is no easy access to an electrical supply.

Several hydraulic mechanisms can be connected to a single power pack, however certain hydraulic systems need two or more power packs to function.

Components of a Power Pack and How They Work

1) Power Source

By pulling power from an electrical source, such as a generator, external motor, or the mains, a hydraulic power pack can be charged. While alternating current power packs simply plug into the electrical grid, direct current power packs operate from a generator or renewable energy source. Some power backs can also get their power from air motors or internal combustion engines.

The purpose of hydraulic power packs is to run continuously while recharging as necessary.

2) Motor

The control valve distributes the energy that the motor distributes to the power pack and the hydraulic system. The motor will often use some sort of shaft to deliver power when under rotational force.

3) Sensors

The safety and control sensors that are included with power packs include;

burden sensors

torque limits that are automatic

controls for time adjustment delays.

Acceleration and deceleration controls.

Operators can programme these sensors to reduce risk factors, like automatic shutoff on overheating, that could harm the machine, or to boost automation.

4) Control Valve

The power pack will always provide hydraulic power through some sort of control valve that runs to another machine, regardless of the specific control methods it offers. The control valve may have additional controlling elements, such as pressure valves, directional control valves, or flow control valves, depending on the specific power pack in issue.

Auxiliary Components

A power pack is integrated into the hydraulic system via auxiliary parts. Couplings, a manifold block, and air intake vents are some examples.

reservoir tanks, suction pipes, and return pipes are examples of fluid control components.

0 notes

Text

Check Valve Manufacturer in Gujarat

We have established ourselves as a renowned manufacturer and supplier of Hydraulic Power Pack. Power Pack Hydraulic Cylinder Manufacturer in Ahmedabad, Gujarat. Rexonhydraulics - Hydraulic Cylinder, Hydraulic Power Pack & Hydraulic Pressure Jack Manufacturer from Ahmedabad, Gujarat, India.

#Hydraulic Power Pack and Hydraulic cylinder#Hydraulic Power Pack and Hydraulic cylinder Manufacture#Hydraulic Power Pack Manufacture#Fly Ash Bricks making Machine Manufacturer#Fly Ash Bricks making Machine#Rexroth Pump Dealer Manufacturer#Rexroth Pump Dealer#Hydraulic Cylinder#Hydraulic Cylinder Manufacturer#Rexroth Valve Dealer#Rexroth Valve dealer manufacturer#Hydraulic Power Pack Manufacturer#Hydraulic Power Pack#Semi-automatic fly ash bricks making machine#Semi-automatic fly ash bricks making machine manufacturer#Paver Block Making Machine#Paver Block Making Machine Manufacturer#Fully automatic bricks making machine#Fully automatic bricks making machine manufacturer

0 notes

Text

Sort of hydraulic Power pack manufacturers pune We fabricate :

They have a wide application range. delight's hydraulic power pack manufacturers pune are planned agreeing an incorporated particular arrangement of valves for the different capabilities.This features the hardware's minimized nature, the groundwork of its superior exhibition levelThe essential parts of the power packs are:a complex block with holes for different sorts of valvesan exceptionally calm, high-effectiveness gear siphonan electric engine (DC or AC)a supply (plastic or steel)a few discretionary extrasBenefits of Compact power pack:Smaller and secluded development, set number of parts, speedy and simple get togetherMost extreme adaptability - various circuits can be worked from only the couple of essential formsValve holes adjust to worldwide normsAdvancement of engine siphon unit produce expanded effectiveness and low working commotion levelUncompromising hydraulic Power pack manufacturersUtilized where there required constant creation , numerous tasks , high tensions are required , are to be done by drive pack on modern machines , process plants like steel businesses , concrete plants , machine apparatus fabricating organizations , shaping , projecting plants , Rubber industry , parts producing machines , food and medications ventures , water medicines , and a lot more , there power pack are furnished with return line channels , heat exchangers unit water cooled or air cooled relying on the applications , being redone we can fabricate them to give the result we wanted from the chambers or servo frameworks making them energy proficient and successful

#hydraulic power pack#Hydraulic Power Unit Market#Hydraulic power pack manufacturers#hydraulic power pack pune#hydraulic power#hydraulic power pack manufacturers pune

0 notes

Text

What are H frame Hydraulic Pres Machine Used For

Radhey Krishan Industries is a leading manufacturer of H Frame Hydraulic Presses, offering robust and versatile solutions for various industrial applications. These presses are designed to deliver exceptional performance, durability, and precision, making them indispensable in numerous sectors.

**Automotive Industry**: In the automotive sector, H Frame Hydraulic Presses from Radhey Krishan Industries are essential for stamping, bending, and forming metal parts. They are used to manufacture components like car frames, engine parts, and body panels, ensuring high strength and uniformity. The precision and reliability of these presses contribute to improved vehicle safety and performance.

**Aerospace**: The aerospace industry demands high accuracy and strength in its components. H Frame Hydraulic Presses are used for forming and shaping lightweight materials such as aluminum and titanium. These presses help in creating structural components, engine parts, and other critical elements, ensuring that they meet stringent quality and safety standards.

**Metalworking**: In general metalworking, these presses are used for a variety of tasks including cutting, punching, and pressing operations. Their adaptability and high pressure capabilities allow them to handle different types of metals and alloys, making them a versatile tool in workshops and factories.

**Plastic and Rubber Molding**: H Frame Hydraulic Presses are also used in the molding of plastic and rubber products. They ensure consistent pressure and temperature, which is crucial for the quality and precision of molded parts. This makes them ideal for producing items like gaskets, seals, and other rubber components.

**Electrical Industry**: The electrical industry utilizes these presses for assembling and manufacturing components such as switchgear, insulators, and other electrical parts. The precise control over pressure and positioning ensures that components meet the required specifications and standards.

**Agricultural Machinery**: In the production of agricultural machinery, H Frame Hydraulic Presses are used to form and shape heavy-duty parts. Their ability to handle large-scale and high-pressure tasks makes them suitable for producing durable and reliable agricultural equipment.

Radhey Krishan Industries' H Frame Hydraulic Presses are known for their sturdy construction, advanced features, and user-friendly operation. With a focus on innovation and quality, they provide solutions that enhance productivity and efficiency across various industries. Whether you need custom designs or standard models, Radhey Krishan Industries delivers presses that meet your specific industrial needs with precision and excellence.

For More Information

Plot No. F-445, MG Road Industrial Area, UPSIDC, Ghaziabad - 201002, Uttar Pradesh, India.

Contact Us :- +91-7836842828

Visit our Website :- [email protected]

#h frame hydraulic press machine manufacturer#hydraulic power pack machine manufacturer#h frame hydraulic press machine#best hydraulic press machine

0 notes

Text

Power Unleashed A Comprehensive Guide to Hydraulic Power Packs

Hydraulic power packs are a vital component in various industries, providing the force needed to operate machinery and equipment. In this comprehensive guide, we will delve into the world of reliable hydraulic power packs, exploring their inner workings, importance in different sectors, and the best practices for selecting, installing, and maintaining these powerful systems.

Understanding Hydraulic Power Packs

Hydraulic power packs are essentially self-contained units that consist of a reservoir, pump, motor, and control valves. These components work together to generate and control hydraulic power, which is then utilized to perform work in various applications.

The operation of hydraulic power packs revolves around the principle of Pascal's law, which states that when pressure is applied to a fluid in an enclosed system, that pressure is transmitted equally in all directions.

When the motor in the power pack activates, it drives the pump, which in turn pressurizes the hydraulic fluid. This pressurized fluid is then directed to the required components, such as hydraulic cylinders or motors, where it exerts force to perform the desired work.

There are different types of hydraulic power packs, each designed for specific applications. These include standard power packs, compact power units, and custom-built power packs tailored to meet unique operational requirements in industries such as construction, manufacturing, and agriculture.

Choosing the Right Hydraulic Power Pack

Selecting the right hydraulic power pack is crucial for ensuring optimal performance and efficiency in operations. Factors such as the required power output, flow rate, and pressure levels must be carefully considered to match the power pack to the specific application and equipment it will be driving.

By choosing the right hydraulic power pack, businesses can benefit from increased productivity, reduced downtime, and improved energy efficiency. Customizing the power pack to meet the exact demands of the machinery it operates will also contribute to prolonging the lifespan of the equipment and minimizing maintenance costs.

Installation and Maintenance Tips

Proper installation and regular maintenance are essential for the longevity and performance of hydraulic power packs. A step-by-step guide should be followed during installation, including mounting the power pack, connecting hydraulic hoses, and ensuring proper alignment of the components.

Regular maintenance procedures, such as checking fluid levels, inspecting for leaks, and replacing filters, should be carried out to prevent system failures and maintain the power pack's efficiency. Additionally, understanding common issues and implementing preventive measures is crucial for addressing potential problems before they escalate.

Safety Precautions and Best Practices

Safety is paramount when working with hydraulic power packs. Adhering to safety guidelines, such as wearing the appropriate personal protective equipment and understanding the risks associated with hydraulic systems, is imperative for preventing accidents and injuries.

Best practices for safe operation and maintenance involve proper training for personnel, conducting regular risk assessments, and implementing safety protocols in the workplace. By prioritizing safety, businesses can create a secure environment for their employees while ensuring the smooth functioning of hydraulic systems.

Advancements in Hydraulic Power Pack Technology

Recent technological advancements have led to significant improvements in hydraulic power pack technology. These advancements have focused on enhancing efficiency, reducing environmental impact, and increasing the sustainability of hydraulic systems.

The integration of smart technologies, such as IoT (Internet of Things) sensors and predictive maintenance algorithms, has revolutionized the monitoring and control of hydraulic power packs. These innovations enable real-time performance tracking, early fault detection, and timely maintenance, ultimately optimizing the operational efficiency of hydraulic systems.

Looking toward the future, trends in hydraulic power pack technology are expected to further enhance energy efficiency, incorporate renewable energy sources, and integrate advanced control systems for seamless automation and precision in operations.

Final Words

As we navigate through the intricacies of design and application, it becomes clear that hydraulic power packs are the unsung heroes powering our modern world. Whether you're a seasoned engineer or an enthusiast eager to harness hydraulic power packs, this comprehensive guide has laid the foundation for understanding and unleashing the potential of these remarkable systems.

Embrace the power, master the mechanics, and witness the impact of hydraulic innovation first-hand. The force is now in your hands.

Source: Power Unleashed A Comprehensive Guide to Hydraulic Power Packs

0 notes

Text

Seek Roemheld Suppliers in India | Oewin

Oriental Engineering Works provides economical industrial solutions to its customers. We offer hydraulic cylinders, pumps, valves, Roemheld work holding, and tools at the best prices being the only distributor of Roemheld in India. For more details, visit us!

#roemheld suppliers in India#roemheld workholding#hydraulic cylinder#Hydraulic power pack manufacturers in India

0 notes

Text

Our cutting-edge hydraulic power packs are designed to maximize the efficiency and output of your hydraulic systems.

Ditch the outdated equipment and experience the smooth operation only our advanced technology can deliver!

Visit the website https://www.zenithhydromatic.com/product-category/hydraulic-power-pack/ to order or call us at +91 8200534779 today!

0 notes

Text

Hydraulic Power Pack

#The hydraulic power pack manufacturers in pune unit manufactured by us is composed of an oil tank.#https://saynakhydraulics.in/mainproducts.php?id=77#Hydraulic Power Pack manufacturers in pune#https://saynakhydrualic.blogspot.com/2022/10/hydraulic-power-pack.html#hydraulicpowerpack#powerpack#hydraulics

0 notes

Text

#Hydraulic Power Pack#Hydraulic Power Pack Manufacturers in Pune#Hydraulic Power Pack Suppliers in Pune#Hydraulic Power Pack Dealers in Pune#Hydraulic Power Pack Manufacturers in Belgaum#Hydraulic Power Pack Suppliers in Belgaum#Hydraulic Power Pack Dealers in Belgaum

0 notes

Text

Hydraulic intensifier improve their system performance?

Hydraulic intensifiers are also known as hydraulic boosters.The pumps are powered by a hydraulic power source that is at low pressure and works with a pump.Pump operation is set at a certain pressure, and from this, intensifiers generate an increased output pressure.They are commonly used in hydraulic power packs. It is easy to install the intensifiers because they are designed in a compact manner. Various types of intensifiers are available, including in-line models that fit standard pipe clamps, CETOP models, flange-on models, and cartridge type intensifiers.Different hydraulic intensifier models are available for flows ranging from 0.3 gpm to 21 gpm. They can be used in high flow systems if they are built into a bypass. Typically, they are used in systems that generate pressures between 1,000 and 7,300 psi.Several models can increase the end pressure between 20,000 and 60,000 psi.

0 notes

Text

Rexonhydraulics - Hydraulic Cylinder, Hydraulic Power Pack & Hydraulic Pressure Jack Manufacturer from Ahmedabad, Gujarat, India.

#Hydraulic Power Pack and Hydraulic cylinder#Hydraulic Power Pack and Hydraulic cylinder Manufacture#Hydraulic Power Pack Manufacture#Fly Ash Bricks making Machine Manufacturer#Fly Ash Bricks making Machine#Rexroth Pump Dealer Manufacturer#Rexroth Pump Dealer#Hydraulic Cylinder#Hydraulic Cylinder Manufacturer#Rexroth Valve Dealer#Rexroth Valve dealer manufacturer#Hydraulic Power Pack Manufacturer#Hydraulic Power Pack#Semi-automatic fly ash bricks making machine#Semi-automatic fly ash bricks making machine manufacturer#Paver Block Making Machine#Paver Block Making Machine Manufacturer#Fully automatic bricks making machine#Fully automatic bricks making machine manufacturer

0 notes

Text

Hydraulic power pack manufacturer in Pune

We are Manufacturer, Supplier and Exporter of Hydraulic Power Packs, Hydraulic Power Packs for Assel Mill, Hydraulic Clamping VMC Fixture, Portable Small Power packs. Our arrangement is arranged in Aurangabad, Maharashtra, India. We offer prevalent quality, simple to work and proficient water driven power pack which is utilized for SPMS and scissor lifts. Our scope of water driven power packs are fabricated according to pressure reach and stream range given by client. These machines are made according to the necessity of our clients.

We are hydraulic power pack manufacturers in pune offer high performing Assel factory water driven power packs which are accessible in 100 ton limit. This pressure driven power pack machine is utilized for inclining instrument, material dealing with and cinching component. Accessible in different details and limits, our Assel factory pressure driven powerpack machines can be tweaked to suit the exceptional.

#hydraulic power pack#hydraulic power pack pune#Hydraulic power pack manufacturers#hydraulic power pack manufacturers in pune

0 notes