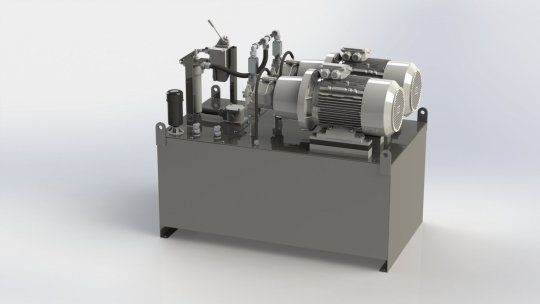

#Hydraulic Power Pack and Hydraulic cylinder Manufacture

Text

Check Valve Manufacturer in Gujarat

We have established ourselves as a renowned manufacturer and supplier of Hydraulic Power Pack. Power Pack Hydraulic Cylinder Manufacturer in Ahmedabad, Gujarat. Rexonhydraulics - Hydraulic Cylinder, Hydraulic Power Pack & Hydraulic Pressure Jack Manufacturer from Ahmedabad, Gujarat, India.

#Hydraulic Power Pack and Hydraulic cylinder#Hydraulic Power Pack and Hydraulic cylinder Manufacture#Hydraulic Power Pack Manufacture#Fly Ash Bricks making Machine Manufacturer#Fly Ash Bricks making Machine#Rexroth Pump Dealer Manufacturer#Rexroth Pump Dealer#Hydraulic Cylinder#Hydraulic Cylinder Manufacturer#Rexroth Valve Dealer#Rexroth Valve dealer manufacturer#Hydraulic Power Pack Manufacturer#Hydraulic Power Pack#Semi-automatic fly ash bricks making machine#Semi-automatic fly ash bricks making machine manufacturer#Paver Block Making Machine#Paver Block Making Machine Manufacturer#Fully automatic bricks making machine#Fully automatic bricks making machine manufacturer

0 notes

Text

In today's fast-paced industrial landscape, the demand for efficient and reliable hydraulic systems continues to grow. Hydraulic cylinders play a crucial role in numerous applications, and choosing the right manufacturer is essential to ensure optimal performance and durability. As a leading hydraulic cylinders manufacturer, we specialize in providing high-quality hydraulic cylinder and power pack solutions. In this article, we will delve into the importance of hydraulic cylinders, the key features that set apart high-quality products, the role of a leading manufacturer, an overview of hydraulic power pack solutions, tips for selecting the right hydraulic solutions, and future trends in the industry.

Understanding Hydraulic Cylinders and Their Importance

Hydraulic cylinders are mechanical devices that convert the hydraulic energy from fluids under pressure into linear force and motion. They are widely used in various industries, including construction, agriculture, mining, and manufacturing. Their importance lies in their ability to generate immense force, execute precise movements, and deliver consistent performance. Whether it's lifting heavy loads, pushing or pulling objects, or controlling machinery, hydraulic cylinders provide the necessary power and control.

In the construction industry, hydraulic cylinders play a vital role in heavy equipment such as excavators, bulldozers, and cranes. These cylinders enable the machines to lift and move heavy materials with ease. Without hydraulic cylinders, the construction process would be much slower and more labour-intensive.

In the agricultural sector, hydraulic cylinders are used in farming equipment like tractors and harvesters. These cylinders help in tasks such as lifting and lowering attachments, adjusting the height of implements, and controlling the steering mechanism. They enhance the efficiency and productivity of farming operations, allowing farmers to accomplish tasks quickly and effectively.

Mining operations heavily rely on hydraulic cylinders for various applications. From underground mining equipment to surface mining machinery, hydraulic cylinders are used for tasks like rock drilling, material handling, and ore extraction. The power and precision of hydraulic cylinders make them indispensable in the mining industry, where productivity and safety are of utmost importance.

0 notes

Text

#Hydraulic Press manufacturers in Belgaum#Hydraulic Press suppliers in Belgaum#Hydraulic Press dealers in Belgaum#Hydraulic cylinder manufacturers in Belgaum#Hydraulic Power Pack manufacturers in Belgaum

0 notes

Text

Seek Roemheld Suppliers in India | Oewin

Oriental Engineering Works provides economical industrial solutions to its customers. We offer hydraulic cylinders, pumps, valves, Roemheld work holding, and tools at the best prices being the only distributor of Roemheld in India. For more details, visit us!

#roemheld suppliers in India#roemheld workholding#hydraulic cylinder#Hydraulic power pack manufacturers in India

0 notes

Photo

telescopic cylinder supplier pune

0 notes

Text

China Manufacturer servo valve PSSV-0890-DF0056 for steam turbine

China Manufacturer servo valve PSSV-0890-DF0056 for steam turbine

Selection of advanced technology, absolutely first-class service quality, YOYIK over the years to the same faith. The main technical backbone are retired senior engineer, senior mechanic. Many of them have participated in the planning, production and installation of power stations such as Gezhouba, Ertan and Three Gorges, and provided high-quality equipment selection, construction planning, installation and dispensing of hundreds of hydropower stations and overhaul of thermal power plants. , After-sales service and other train services.

Yoyik can offer many spare parts for power plants as below:

#DF-servo valve PSSV-0890-DF0056-DF

vacuum pump compressor 30-WS

vane vacuum pump F3-V10-IS6S-IC-20

three screw pump HSND280-46

manual vacuum pump P-545

sealing oilVacuum pump reducer M02225.0BMCC1D1.5A

pressure hose S100-AC-AC-0050

water pump 100-80-160

Proportional Relief valve E-RI-TERS-PS-01H/I 20

Pin assembly of centrifugal pump coupling 70LY-34*2(1)

Gearbox with motor XLED63-595-0.37

sealing ring HB4-56J8-164

industrial vacuum pump HSNH440Q2-46NZ

sealing ring HB4-56J8-159

electric motor centrifugal water pump DFB100-65-260-03

Spare Part Kit DN200/M3231

Globe valve J941H-16C

vacuum pump 225v 30-WS

stator cooling water pump 65-250B

burgmann mechanical seal 8b1d

electric transfer oil pump Y200L-2/30KW/IP44

electric vacuum pump YCZ50-25

hydraulic pump piston PVH098R01AJ30A250000002001AB010

globe throttle check valve LJC65C-4.0P

one-way valve DIF-L20H

Gear oil pump CB-1.2

china hydraulic pump 70LY-34*2-1

AST/OPC solenoid valve coil CCP115M 19W 115VDC

transfer pump fuel YW80-65-160X2.5

chemical pump centrifugal DFB100-80-250-03

centrifugal pump impeller DFB-80-300

hydraulic power 80AYZ-70

high pressure centrifugal pump DFB-80-300

twin screw pump HSNH940-46

shaft seal mechanical BKMFX108A

water pump YCZ50-25

oil pump 80AYZ-43

servo valve PSSV-0890-DF0056

pressure hose SMS-15/N1/4-610mm-B

BALL BEARING SINGLE ROW RADIAL DEEP GROOVE NO.6206

radial piston pump hydraulic PVH98QIC-RSM-1S-10-C25-31

reciprocating piston pump PV29-2R5D-COO

Ejection oil solenoid valve 2YV

piston pumps PV29-2L-5D-C00

oil seal SKEAL KIT F3-V10

TERTIARY OIL PUMP (TOP) 125LY-36-1

manhole self-sealing gasket (2#HP Heater) JG-1050-1

fluid transfer pump YW80-65-160X2.5

seals (cylinder diaphragm, packing, valve sealing gasket) 0125ZMAW16BQ13UNOERHDN125

pressure hose SMS-12/N1/4-305mm-C

single screw pump 3GR25X4

chemical centrifugal pump -50-250C

Gasket HZB253-640-02-07 part no.:46

sealing oil vacuum pump TXM012263BAVV1

DDV valve R40K02MONSM2

vacuum pump 256v P1825B

solenoid valve GS060600V+CCP230M

high pressure oil pump 80LY-80-B

CORROTION RESISTANT CENTRIFUGAL PUMP YCZ50-250C

pressure hose S100-AC-FB-0040

valve D664Z4723

Globe valve 20FJ-1.6PA2

pressure hose SMS-10/12-305mm-C

three screw pump HSNH440-46NZ

high pressure piston pump PVH740ICRSF-IS-10-1

piston pump parts 160SCY14-1B

unloading valve F3-CV1-25-D16-L-40

centrifugal pump vertical ISG150-160

AST solenoid valve HY-FXF-10.04V

Coupling of screw pump HSG940*2-42

Solenoid valve S203CH98V5CG4-KCX37\3/8

wet solenoid directional valve 4WE6D6X/OFEW220-50NZ4/V

radial piston pump hydraulic PVH74QIC-RSF-1S-10-C25

industrial vacuum pump P-2335

servo valve PSSV-0890-DF0056

DFYLSYC-2024-3-5-A

0 notes

Text

Understanding the Function of a Hydraulic Machine - HEICO

In the realm of industrial machinery, hydraulic systems stand out as the unsung heroes powering various heavy-duty operations. From construction equipment to manufacturing processes, Hydraulic Machines play a pivotal role in facilitating the smooth and efficient movement of machinery. As such, comprehending the function of a hydraulic system is essential for appreciating its significance in diverse sectors.

What is a Hydraulic System?

A Hydraulic System operates through the transmission of force via a pressurized fluid, typically oil. It consists of a network of interconnected components including pumps, actuators, valves, hoses, and cylinders. The fundamental principle behind hydraulic systems is Pascal's Law, which states that pressure exerted on a confined fluid is transmitted undiminished in all directions.

Functionality of Hydraulic Systems:

Transmission of Power: The primary function of a hydraulic system is to transmit power from one point to another. This is achieved by using hydraulic fluid to create pressure, which in turn drives pistons, cylinders, or motors to perform mechanical work.

Amplification of Force: Hydraulic systems are renowned for their ability to amplify force. Through the use of hydraulic cylinders and actuators, a relatively small input force can generate a significant output force, making them ideal for lifting heavy loads and performing strenuous tasks with ease.

Control of Motion: Hydraulic systems offer precise control over the speed and direction of motion. By manipulating the flow of hydraulic fluid through valves and control mechanisms, operators can regulate the movement of machinery with accuracy and efficiency.

Versatility and Adaptability: Hydraulic System is incredibly versatile and can be tailored to suit a wide range of applications. From hydraulic presses and lifts to excavators and cranes, hydraulic technology is integral to the functioning of various industrial and commercial equipment.

Hydraulic Machines Manufacturers in Delhi:

In the bustling industrial landscape of Delhi, we are the best Hydraulic Machine Manufacturers specializing in meeting the diverse needs of businesses across different sectors. These manufacturers leverage advanced technologies and engineering expertise to design and fabricate High-Quality Hydraulic Systems that ensure optimal performance and reliability.

Among the prominent players in the field is Heico, a leading manufacturer and supplier of hydraulic machines in Delhi. With a commitment to innovation and excellence, Heico has carved a niche for itself in the industry by delivering cutting-edge solutions that surpass client expectations. From hydraulic presses and power packs to cylinders and valves, HEICO offers a comprehensive range of products designed to enhance productivity and efficiency in various industrial applications.

Also Read: A Comprehensive Guide to Hydraulic Machine

Best Hydraulic Machines – Uses, Working Principles, Types & Applications

Conclusion:

In conclusion, the function of a hydraulic system extends far beyond mere mechanical operations. HEICO is one of the best Hydraulic Machine Suppliers in Delhi, enabling them to perform a myriad of tasks with precision and power. From construction sites to manufacturing facilities, hydraulic systems play an indispensable role in driving progress and productivity.

As industries continue to evolve, the demand for efficient hydraulic solutions will only continue to grow, reaffirming the importance of understanding and appreciating the function of these intricate systems.

#hydraulic machines#hydraulic machine#Hydraulic Machine in Delhi#Hydraulic Machines Price#Hydraulic Machines Manufacturer

0 notes

Text

HydroDyne Industries, ISO 9001:2015, Udyam Registration Certificate

Hydraulic Valves, Pressure Control Valves, Direct Acting Relief Valves, Manufacturer, Supplier, Exporter, Mumbai, India.

Hydraulic Valves, Pressure Control Valves, Direct Acting Relief Valves, Pilot Operated Relief Valves, Dual Cross Over Relief Valves, Dual Cross Over Relief Valve, Accumulator Unloading Valves, High Low Pump Unloading Valves, Pressure Reducing Cum Relieving Valves, Load And Motion Control Valves, Single Pilot Operated Check Valve, Dual Pilot Operated Check Valve, Single Operated Overcenter Valves, Dual Operated Overcenter Valves, Flow Control Valves, Flow Divider Valve, Needle Valve, Check Valve, Flow Restrictor with Check Valve, Priority Valve, Shuttle Valve, Fixed Speed Pressure Compensated Cylinder Lowering Valve, Adjustable Speed Pressure Compensated Cylinder Lowering Valve, Sequence Valve, Directional Control Valve, 2 Way Solenoid Valve, Rotary Directional Control Valve, Safety Control Valve, Hose Burst Valve, Pilot Operated Pump Unloading Valve, Special Valve, Cable Reel Control Valve, Rock Breaker Valve, Motor Mounted Flange Faced Overcenter Valve, Forklift Bale Clamp Valve, Garbage Compactor Dual Pressure Valve, Boom Holding Block, Boom Lowering Block, Hot Flush Valves, Manifold Blocks, Hydraulic Manifold Blocks, Hydraulic Cylinders, Welded Construction With Threaded Gland Cylinder, Streamline Hydraulic Cylinder, Welded Flange Construction Cylinders, Tie Rod Construction Cylinders, Mill Duty Cylinders, Telescopic Cylinders, Custom Made Cylinders, Hydraulic Power Packs, Large Power Packs, Customized Power Packs, Small Powerpacks, Mini Power Packs, Compact Power Packs, Hydraulic Rotary Joints, Multi Passage Rotary Joint, Rotary Joint with Hydraulic Outputs, Rotary Joint with Electrical Outputs, 3 Customized Rotary Joint, Hand Pumps, Inline Body Hand Pumps, Inline Tank Mounted Hand Pumps, Hydraulic Pumps, High Pressure Hydraulic Tools, Hydraulic Intensifiers, Hydraulic Accessories, Hydraulic Systems, Hydraulic Actuators, Mumbai, Maharashtra, India.

0 notes

Text

Power Unleashed A Comprehensive Guide to Hydraulic Power Packs

Hydraulic power packs are a vital component in various industries, providing the force needed to operate machinery and equipment. In this comprehensive guide, we will delve into the world of reliable hydraulic power packs, exploring their inner workings, importance in different sectors, and the best practices for selecting, installing, and maintaining these powerful systems.

Understanding Hydraulic Power Packs

Hydraulic power packs are essentially self-contained units that consist of a reservoir, pump, motor, and control valves. These components work together to generate and control hydraulic power, which is then utilized to perform work in various applications.

The operation of hydraulic power packs revolves around the principle of Pascal's law, which states that when pressure is applied to a fluid in an enclosed system, that pressure is transmitted equally in all directions.

When the motor in the power pack activates, it drives the pump, which in turn pressurizes the hydraulic fluid. This pressurized fluid is then directed to the required components, such as hydraulic cylinders or motors, where it exerts force to perform the desired work.

There are different types of hydraulic power packs, each designed for specific applications. These include standard power packs, compact power units, and custom-built power packs tailored to meet unique operational requirements in industries such as construction, manufacturing, and agriculture.

Choosing the Right Hydraulic Power Pack

Selecting the right hydraulic power pack is crucial for ensuring optimal performance and efficiency in operations. Factors such as the required power output, flow rate, and pressure levels must be carefully considered to match the power pack to the specific application and equipment it will be driving.

By choosing the right hydraulic power pack, businesses can benefit from increased productivity, reduced downtime, and improved energy efficiency. Customizing the power pack to meet the exact demands of the machinery it operates will also contribute to prolonging the lifespan of the equipment and minimizing maintenance costs.

Installation and Maintenance Tips

Proper installation and regular maintenance are essential for the longevity and performance of hydraulic power packs. A step-by-step guide should be followed during installation, including mounting the power pack, connecting hydraulic hoses, and ensuring proper alignment of the components.

Regular maintenance procedures, such as checking fluid levels, inspecting for leaks, and replacing filters, should be carried out to prevent system failures and maintain the power pack's efficiency. Additionally, understanding common issues and implementing preventive measures is crucial for addressing potential problems before they escalate.

Safety Precautions and Best Practices

Safety is paramount when working with hydraulic power packs. Adhering to safety guidelines, such as wearing the appropriate personal protective equipment and understanding the risks associated with hydraulic systems, is imperative for preventing accidents and injuries.

Best practices for safe operation and maintenance involve proper training for personnel, conducting regular risk assessments, and implementing safety protocols in the workplace. By prioritizing safety, businesses can create a secure environment for their employees while ensuring the smooth functioning of hydraulic systems.

Advancements in Hydraulic Power Pack Technology

Recent technological advancements have led to significant improvements in hydraulic power pack technology. These advancements have focused on enhancing efficiency, reducing environmental impact, and increasing the sustainability of hydraulic systems.

The integration of smart technologies, such as IoT (Internet of Things) sensors and predictive maintenance algorithms, has revolutionized the monitoring and control of hydraulic power packs. These innovations enable real-time performance tracking, early fault detection, and timely maintenance, ultimately optimizing the operational efficiency of hydraulic systems.

Looking toward the future, trends in hydraulic power pack technology are expected to further enhance energy efficiency, incorporate renewable energy sources, and integrate advanced control systems for seamless automation and precision in operations.

Final Words

As we navigate through the intricacies of design and application, it becomes clear that hydraulic power packs are the unsung heroes powering our modern world. Whether you're a seasoned engineer or an enthusiast eager to harness hydraulic power packs, this comprehensive guide has laid the foundation for understanding and unleashing the potential of these remarkable systems.

Embrace the power, master the mechanics, and witness the impact of hydraulic innovation first-hand. The force is now in your hands.

Source: Power Unleashed A Comprehensive Guide to Hydraulic Power Packs

0 notes

Text

Zenith Hydromatic - Design and Manufacture of Hydraulic system equipment

Established in the year 1995, Zenith Hydromatic design and manufacture custom Hydraulic Cylinder, Power Pack, Hydraulic Jack, Pallet Pump, Hydraulic Scissor Lift Table and assembly modules that are the heart of every applications hydraulic system with comprehensive knowledge and advice to deliver the perfect system for your task.

With over 25+ years solid experience of technique, R&D skills, customer services for your custom design and after-sales service

For More Visit us at https://www.zenithhydromatic.com/ or Connect us at 094263 26091

1 note

·

View note

Text

Stainless Steel 304L Pipes & Tubes Exporters In Mumbai

Nascent Pipe & Tubes is the fundamental manufacturers of the SS 304/304L/304H Pipes & Tubes. In any case, we are giving and exchanging the Pipes & Tubes and loads to the clients open beginning with one side of the world then onto the following. We are nearly considered among the momentous stockist and specialist of the wide levels of Pipes & Tubes. The Pipes & Tubes are open in different subtleties as per the requests for the clients. Choices like surface fulfillment, end finish, focuses, shapes, sizes, length, and strength are there.

Pipes & Tubes open are almost used in current applications. The best way that the endeavors are spreading fluids among the applications is with the help of the changed piece of the Pipes & Tubes. This is dumbfounding for supply the gas and the fluids which are fitting. The line is the unfilled portions which are used in the applications with the round cross-region that convey the things easily. The fixations and the broadness of the line are noted by the application in which it is used.

Abutting this, the chambers are the strain hardware that is utilized in current applications. The chambers and Pipes & Tubes are open in many shapes and sizes. A piece of the shapes where the Pipes & Tubes and loads are open are shot, square, square shape that is having the unfilled pieces. Also, the essential contrast among the Pipes & Tubes comes in the wall thickness, material, end affiliations, and others.

The SS 304 Alloy steel is utilized in the improvement of the line. Notwithstanding, the Alloy is involved chromium and nickel contents which are giving the Pipes & Tubes different properties. Thusly, the SS 304L is the low carbon content than the 304 Alloy steel. This is the means by which it is shocking at having the intergranular utilize hindrance cutoff. Essentially, the SS 304H is the high-temperature application utilized blend which is there with the high-temperature strength and the capacity to work in the raised temperatures.

The Alloy is the explanation that the SS 304/304L/304H Pipes & Tubes and Cylinders are having various properties. A piece of the properties which the Pipes & Tubes are having are breaking down obstruction, grand flexibility, strength, power in the raised temperatures, and fundamental force.

Specification Of Stainless Steel 304/304L/304H Seamless Welded Pipes & Tubes

Stainless Steel Pipe Specification : ASTM A312, A358 / ASME SA312, SA358

SS Tube Specification : ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554

Pipe Size :1/8” NB to 24” NB, 1/4” OD to 24” OD sizes.

Tube Size :1/2" OD to 8" OD.

Thickness Range :0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type :Seamless / ERW / Welded / Fabricated Pipes

Form : Round, Square, Rectangular, Oval, Hydraulic Etc

Length :Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

Outside Finish :2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Inspection, Test Reports :Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :Sizes and Specifications other than above can be manufactured on request

Visit Website:

Email: [email protected]

#Stainless Steel 304/304L/304H Pipes & Tubes#Stainless Steel 304/304L/304H Pipes & Tubes Manufacturers#Stainless Steel 304/304L/304H Pipes & Tubes Suppliers#Stainless Steel 304/304L/304H Pipes & Tubes Stockists#Stainless Steel 304/304L/304H Pipes & Tubes Exporters#Stainless Steel 304/304L/304H Pipes & Tubes Manufacturers In India#Stainless Steel 304/304L/304H Pipes & Tubes Suppliers In India#Stainless Steel 304/304L/304H Pipes & Tubes Stockists In India#Stainless Steel 304/304L/304H Pipes & Tubes Exporters In India#Stainless Steel 304/304L/304H Pipes & Tubes Manufacturers in Mumbai#Stainless Steel 304/304L/304H Pipes & Tubes Suppliers in Mumbai#Stainless Steel 304/304L/304H Pipes & Tubes Stockists in Mumbai#Stainless Steel 304/304L/304H Pipes & Tubes Exporters in Mumbai

0 notes

Text

Rexonhydraulics - Hydraulic Cylinder, Hydraulic Power Pack & Hydraulic Pressure Jack Manufacturer from Ahmedabad, Gujarat, India.

#Hydraulic Power Pack and Hydraulic cylinder#Hydraulic Power Pack and Hydraulic cylinder Manufacture#Hydraulic Power Pack Manufacture#Fly Ash Bricks making Machine Manufacturer#Fly Ash Bricks making Machine#Rexroth Pump Dealer Manufacturer#Rexroth Pump Dealer#Hydraulic Cylinder#Hydraulic Cylinder Manufacturer#Rexroth Valve Dealer#Rexroth Valve dealer manufacturer#Hydraulic Power Pack Manufacturer#Hydraulic Power Pack#Semi-automatic fly ash bricks making machine#Semi-automatic fly ash bricks making machine manufacturer#Paver Block Making Machine#Paver Block Making Machine Manufacturer#Fully automatic bricks making machine#Fully automatic bricks making machine manufacturer

0 notes

Text

#Hydraulic Power Pack manufacturers in Pune#Hydraulic Power Pack suppliers in Pune#Hydraulic Power Pack dealers in Pune#Hydraulic Cylinder manufacturers in Pune#Hydraulic Cylinder suppliers in Pune#Hydraulic Cylinder dealers in Pune

0 notes

Text

Hydraulic Cylinder Manufacturer in India | Oewin

OEW is the hydraulic jack manufacturer in India and provides an exclusive range of heavy-duty hydraulic jack and hydraulic types of equipment all over India.

#hydraulic cylinder suppliers in india#hydraulic jack suppliers#hydraulic power pack suppliers#hydraulic power pack manufacturers in india

0 notes

Text

How does a Hydraulic Power Pack Machine Works?

What is Hydraulic Power Pack Machine?

A hydraulic power pack machine, often referred to simply as a hydraulic power pack or hydraulic power unit (HPU), is a compact device used to generate hydraulic power for various machinery and equipment. It plays a crucial role in powering hydraulic systems, which are widely used in industries for applications such as lifting, pressing, bending, cutting, and more.

Here's how a typical hydraulic power pack Machine works:

Prime Mover: The power pack is typically driven by an electric motor or an internal combustion engine (diesel or gasoline). The prime mover provides the mechanical energy required to run the hydraulic system.

Reservoir: The power pack has a hydraulic fluid reservoir (often a tank) that stores hydraulic oil. This oil serves as the working fluid for the hydraulic system.

Hydraulic Pump: The prime mover drives a hydraulic pump. The pump is responsible for drawing hydraulic oil from the reservoir and pressurizing it. The pressurized oil is then delivered to the rest of the hydraulic system.

Directional Control Valves: A hydraulic power pack is equipped with directional control valves. These valves control the direction of hydraulic fluid flow in the system. By actuating these valves, you can determine which hydraulic components (such as cylinders or motors) will receive pressurized oil and in which direction.

Pressure Relief Valve: For safety and to prevent system damage from excessive pressure, a pressure relief valve is usually included in the power pack. It releases excess pressure back into the reservoir if the pressure in the system becomes too high.

Hydraulic Actuators: The high-pressure hydraulic oil from the power pack is routed to hydraulic actuators, which can include hydraulic cylinders, hydraulic motors, or other hydraulic devices. These actuators convert the hydraulic energy back into mechanical work, whether it's linear motion in the case of cylinders or rotational motion in the case of motors.

Return Flow: After the hydraulic fluid has done its work, it returns to the reservoir, completing the hydraulic circuit. The cycle can repeat as needed based on the control of the directional valves and the operation of the hydraulic actuators.

Filtration and Cooling: Most hydraulic power packs include filtration systems to remove contaminants from the hydraulic oil, ensuring the system's reliability. They may also include cooling systems (such as heat exchangers or fans) to dissipate heat generated during operation.

The specific operation of a hydraulic power pack can vary depending on the application, whether it's powering a hydraulic press, a hydraulic lift, a conveyor system, or any other hydraulic machinery. The key is that it generates and controls high-pressure hydraulic fluid to perform work in various industrial and mobile applications.

Best Hydraulic Power Pack Machine Manufacturer in India

If you are looking for the best Hydraulic Power Pack Machine manufacturer in India, look no further than Radhey Krishan Industries. With a proven track record of excellence, Radhey Krishan Industries is a leading manufacturer and supplier of hydraulic power pack machines in India. Their commitment to quality, innovative design, and customer satisfaction sets them apart in the hydraulic machinery industry. Whether you require hydraulic power packs for industrial, commercial, or specialized applications, Radhey Krishan Industries offers reliable and efficient solutions to meet your specific needs. Trust in their expertise to deliver top-notch hydraulic power pack machines that ensure optimal performance and power your hydraulic systems effectively.

For any type of queries, please contact us!

Website - www.radheykrishanindustries.com

Email - [email protected] Contact - +91-7836842828

#best hydraulic press machine#hydraulic power pack machine manufacturer#hydraulic power pack machine manufacturer in India#hydraulic power pack machine Supplier#hydraulic power pack machine Supplier in India#best hydraulic power pack machine manufacturer in India

1 note

·

View note

Text

China supply servo valve G761-3026B for turbine generator

China supply servo valve G761-3026B for turbine generator

Deyang YOYIK skill is strong, the production of strict accordance with national standards. With the power station forging, mining metallurgy, rolling, cement and spare parts spare parts, metallurgy, rolling and other products improve the production and operation system. For hundreds of water technology change, hydropower, thermal power plant overhaul supply of high-quality equipment selection, equipment commissioning, construction plans, spare parts, after-sales service, such as through-train service. The company to undertake hydropower stations, thermal power plant unit capacity transformation, technical transformation and overhaul projects. Look forward to the major manufacturers to inquire.

Yoyik can offer many spare parts for power plants as below:

#DF-servo valve G761-3026B-DF

Valve disc LXF125/1.8

butterfly valve 125DSF4PB3

Accumulator bladder 10L OD190*H425MM φ22MM

hydrogen temp Regulating valve 250ZXN016BQ12SERH

variable vane pump F3-20V5A-1C22R

centrifugal pumps -50-250

vacuum hand pump P-1931A

globe throttle check valve KJC40C-2.5P

rotary piston pump A3H56-FR01KK-10-X33

screw pump diagram HSNH440-46NZ

pump vacuum P-1433

centrifugal pump types 50-250C

oil transfer gear pump Y112M-2/4KW/IP44

centrifugal pumps 50-250

MOOG SERVO VALVE G761-3000B

pressure hose SMS-10/12-1829mm-C

seals (cylinder diaphragm, packing, valve sealing gasket) KS125ZXQ016L13NOERH

rotary piston pump A10VS018DFR1/31RPPA12K01

coupling XL3

reciprocating piston pump A10VS0100DR/31R-PPA12NOO

OIL THROWER HZB200-430-01-02

relief valve MS50-1

piston plunger pump 10PCY14-1B

600MW turbine starting oil pump (MSP)Guide bearing 150LY-23

servo valve SM4-20 (15)57-80/40

pressure hose S100-AC-FB-0080

Governor O-ring DH00.006

mechanic seal water pump G50

electric oil transfer pump 3G80*6GR40

AST solenoid valve C9506000

piston pump parts PVH074R01AA10A250000002001AB010A

globe throttle check valve LJC25-1.6P

electric vacuum pump P-1753

multistage centrifugal pumps DFB125-80-230

globe valve WJ50F1.6P

electric motor with hydraulic pump 250S65

servo valve G761-3026B

axial piston pumps PVH74QIC-RSM-1S-1X-C25-31

variable vane pump F3-SV10-1P5P-00

Accumulator Bladder for EH Oil Tank NXQ-AB-10/31.5-L-E

roots vacuum pump 30-WS-COML

screw pump diagram ACG052N7NVBP

vacuum pump 272v P-545

vacuum pump ac 30WS

stator cooling water pump impeller YCZ65-250B

metering piston pump PVH74QZC-RSM-1S-1XC25-31

centrifugal pump vertical SLQ-63

stainless steel globe throttle check valve (welded) LJC40-1.6P

EH oil main pump PVH74 (QI)C-RSM-1S-1X-C25-31

centrifugal pump DFB100-80-250-03

Shutoff valve HF02-02-01Y

mechanical seal for water pump 1D56-H75/95-00 00 11

oil pump gasket 125LY-43BH

hydraulic pump repair 80AY60

solenoid valve E321F32 220VDC 8W

vacuum oil pump P-1259

chemical centrifugal pump DFB125-80-250-20

dc centrifugal pump DFB100-65-260-03

AC lube pump impellersealing ring 125LY-35

Lubrication Oil Pump 2CY-29/0.36-2

metering piston pump PVH74QIC-RSF-1S-10-C25

mechanic seal water pump 104G-40

multi stage centrifugal pump DFB100-80-250

pump Recirculating solenoid valve D12T11G0P 110VDC 8W 3-10bar

screw pump stainless HSNH120-46

mechanical seal pump 104G-40

reciprocating piston pump PVP76368R2MVP10

pipe joint 12N2621-2-5

solenoid valve CCP230M 230VDC 19W PAT5002253

screw pump stainless DLZB820-R64A-3

vacuum pump parts P-1433

hydraulic pump piston PVH74ROIA-RSM-IS-10-C25-3

oil change pump 125LY-40-B

servo valve G761-3026B

DFYLSYC-2024-3-5-A

0 notes