#Fly Ash Bricks making Machine Manufacturer

Text

Check Valve Manufacturer in Gujarat

We have established ourselves as a renowned manufacturer and supplier of Hydraulic Power Pack. Power Pack Hydraulic Cylinder Manufacturer in Ahmedabad, Gujarat. Rexonhydraulics - Hydraulic Cylinder, Hydraulic Power Pack & Hydraulic Pressure Jack Manufacturer from Ahmedabad, Gujarat, India.

#Hydraulic Power Pack and Hydraulic cylinder#Hydraulic Power Pack and Hydraulic cylinder Manufacture#Hydraulic Power Pack Manufacture#Fly Ash Bricks making Machine Manufacturer#Fly Ash Bricks making Machine#Rexroth Pump Dealer Manufacturer#Rexroth Pump Dealer#Hydraulic Cylinder#Hydraulic Cylinder Manufacturer#Rexroth Valve Dealer#Rexroth Valve dealer manufacturer#Hydraulic Power Pack Manufacturer#Hydraulic Power Pack#Semi-automatic fly ash bricks making machine#Semi-automatic fly ash bricks making machine manufacturer#Paver Block Making Machine#Paver Block Making Machine Manufacturer#Fully automatic bricks making machine#Fully automatic bricks making machine manufacturer

0 notes

Text

https://karanengineering.com/

Fly Ash Brick Making Machine manufacturers

2 notes

·

View notes

Text

Top Model in automatic fly ash brick making machine in India

In this growing field and profession, the use of technology has become crucial. Specifically, the Automatic Fly Ash Brick Making Machine in India has proved to be an innovative solution to the brick making industry by revolutionizing the whole process of making bricks. These machines provide not only capacity and product quality but are vital tools for any contemporary manufacturer of bricks.

Automated manufacturing of bricks is important to increase productivity and improve the quality of bricks being produced. An automatic fly ash brick making machine in India can increase the production rate many folds in comparison to the manual production line while also decreasing the overall cost of labor. These machines work without much variation, meaning that human factors like tiredness do not affect the quality of the bricks produced.

Key Features to Look

The productivity of a fly ash brick making machine defines the number of bricks that it is capable of churning within a given period of time. This is important in regard to large orders, as the ability to produce a large quantity of products in a short amount of time is quite valuable. Look for the machines which can produce large numbers of bricks within a short time to enable you meet the market demand.

One of the most important factors that may determine the level of efficiency of a brick making machine and the ease of its operation is the degree of its automation. It requires little human interjection while providing quality control for the bricks as well as cutting cost on labor. Choose machines that incorporate the key aspects of automation such as the feeding, mixing, molding, and ejection systems.

Energy efficiency is the key to minimizing cost and ensuring that the best practices are followed at all times. An automatic fly ash brick making machine with low energy intake supports high production without wasting much energy. Look for machines made with efficiency features to reduce the cost of your electricity bill and the effects on the environment.

It is of great importance for a user to be able to operate, control or even maintain the fly ash brick making machine easily. Choose machines with clear physical controls, documented procedures, and easily accessible service parts. Maintenance is important in order to avoid failures and to work in the best conditions, so, select a model that will guarantee easy maintenance processes.

Brick machinery is the top name in brick making machine industry. Brick machinery offers various types of Automatic fly ash brick making machine in India with advanced technology. Brick machinery has range of product with advanced automation features that gives you satisfied output and high production. Here we are presenting you some of our best machines.

Top Models of Automatic Fly Ash Brick Making Machine in India

FAM-1440 Automatic Fly Ash Brick Making Machine

The FAM-1440 Automatic Fly Ash Brick Making Machine is one of the most efficient models which is quite popular among users due to its high performance and maximum longevity. This machine is technically designed to lower operational complexities and require very little maintenance. That makes it perfect for medium to large manufacturing operations; the FAM-1440 is capable of producing up to 1920 bricks per hour. According to users, the FAM-1440 is easy to use and dependable.

FAM-1080 Automatic Fly Ash Brick Making Machine

The FAM-1080 is another top model from Brick Machinery that is specifically designed to be versatile and highly efficient in its operations. It involves high levels of automation and control in an effort to produce high standard dimensioned bricks with minimal deviations. The FAM-1080 can produce up to 1440 bricks per hour, making it best choice to use in small to medium industries. The FAM-1080 has been positively received by customers who have complimented it as being well built and reliable.

FAM-2520 Automatic Fly Ash Brick Making Machine

FAM-2520 is the model with the highest technical level and automation rate among all of them and is considered to be the most successful and perspective one. This machine is intended for high-production mode and is amazing in its functionality and quality of the produced bricks. The FAM-2520 has a production capacity of up to 3360 bricks per hour and is suitable for large scale operations. The FAM-2520 has been praised highly in terms of its high production output and performance.

Each of the machines has special features aimed at improving your production of bricks making them worthy of consideration.We would like to invite you to also check out some of the most popular models and determine whether they will fit your need. For further details, please visit or get in touch with us at Brick Machinery to know how we may meet your needs.

#fly ash brick making machine#brick making machine#brickmakingmachine#automatic fly ash brick making machine in India#fly ash brick plant manufacturers#fly ash brick making machine in gujarat#fly ash brick plant#block making machine#brick making machine in india#brick making machine manufacturer#brickmachine

0 notes

Text

#Bricks Machine Manufacturer Morbi#brick machine manufacturer in gujarat#bricks machine manufacturer rajkot#fly ash brick making machine manufacturer#automatic fly ash brick making machine#fly ash brick making machine fully automatic#fly ash brick making machine supplier#paver block machine manufacturer morbi#paver making machine for sale#paver block making machine manufacturers#automatic paver block making machine

1 note

·

View note

Text

The Ultimate Startup Guide for Fly Ash Brick Manufacturing

🔥 Wanna be your own boss? Start by mastering the art of Fly Ash Brick Manufacturing! 🧱💼 Let's unlock your entrepreneurial potential! 💥 #SmallBusinessTips #flyashbrickmachine #manufacturingbusiness #flyashbricksmakingmachine

With India’s construction industry adopting sustainable practices, the popularity of eco-friendly fly ash bricks is rising. Previously, clay bricks dominated the market; however, cement bricks have gradually become favoured, and now fly ash bricks are gaining traction. Fly ash is a coal combustion byproduct, and India has it in abundance, making it ideal for brick production. Launching a fly ash…

View On WordPress

#automatic fly ash bricks machine#best business ideas#business ideas#fly ash brick machine#fly ash brick making#fly ash bricks#fly ash bricks business#fly ash bricks business plan#fly ash bricks machine#fly ash bricks making business#fly ash bricks making machine#fly ash bricks manufacturing process#how to start a fly ash brick manufacturing business#how to start fly ash brick business#manufacturing business ideas 2024#manufacturing business ideas in india#mini manufacturing business ideas#new business ideas#new business ideas 2024#small business ideas

0 notes

Text

Brick vs Block: Which Construction Material Is Right for You?

Introduction

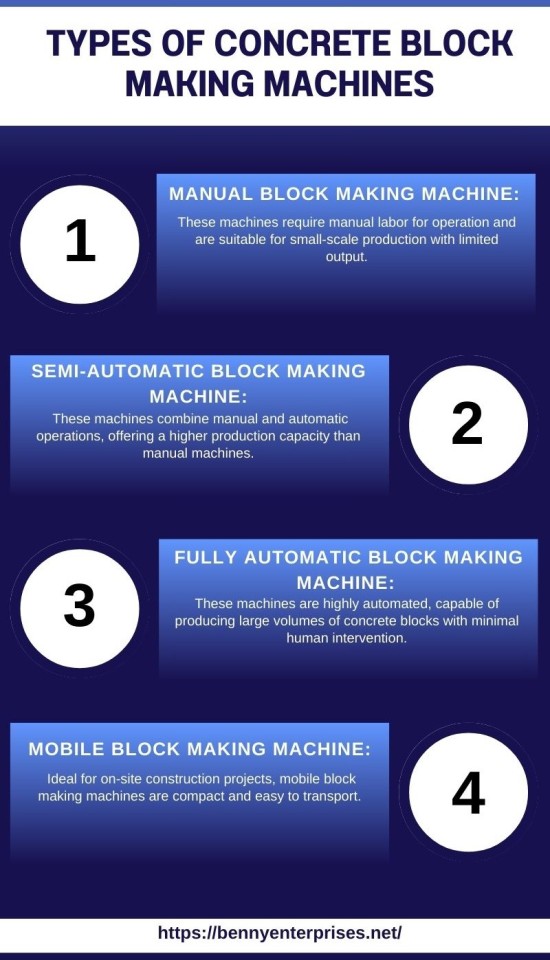

Choosing the right construction material is a crucial decision for builders and contractors. Concrete bricks and blocks are two popular choices, each with its own set of advantages and applications.

In this blog, we will compare these two construction materials to help builders make informed decisions that align with their project requirements. Additionally, we'll explore the importance of selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers.

Concrete Bricks:

Concrete bricks are widely used in construction due to their versatility and aesthetic appeal. Here are some key benefits and applications of concrete bricks:

1. Aesthetics: Concrete bricks come in a variety of colors and textures, making them an excellent choice for projects that prioritize aesthetics. They can be used to create visually appealing facades, accent walls, and even decorative elements within a structure.

2. Precision: Concrete bricks are manufactured to precise dimensions, ensuring uniformity and ease of installation. This precision makes them ideal for intricate brickwork patterns and designs.

3. Durability: Concrete bricks are known for their strength and durability, making them suitable for load-bearing applications. They can withstand harsh weather conditions, which is essential for structures exposed to the elements.

4. Thermal Insulation: Concrete bricks offer good thermal insulation properties, helping to regulate indoor temperature and reduce energy consumption. This makes them a popular choice for residential construction.

5. Soundproofing: Due to their density, concrete bricks also provide effective soundproofing, which is valuable in reducing noise transfer between rooms or from the outside.

Applications of Concrete Bricks:

Residential homes

Commercial buildings

Retaining walls

Fireplaces

Garden walls

Decorative features

Concrete Blocks:

Concrete blocks, often referred to as cinder blocks or concrete masonry units (CMUs), have their own unique advantages and applications:

1. Structural Strength: Concrete blocks are favored for their structural strength and load-bearing capacity. They are commonly used in the construction of foundations, retaining walls, and other structural elements.

2. Cost-Efficiency: Concrete blocks are generally more cost-effective than bricks. Their larger size means fewer blocks are needed to cover a given area, reducing material and labor costs.

3. Speed of Construction: Due to their size, concrete blocks can be laid quickly, speeding up the construction process. This efficiency is particularly beneficial for large-scale projects.

4. Fire Resistance: Concrete blocks offer excellent fire resistance, which is a critical factor in building safety. They can withstand high temperatures and provide valuable fire protection.

5. Minimal Maintenance: Concrete blocks require minimal maintenance over the years, making them a low-maintenance option for long-lasting structures.

Applications of Concrete Blocks:

Foundations

Basement walls

Retaining walls

Commercial buildings

Industrial facilities

Warehouses

Selecting Reliable Concrete Brick and Block Making Machine Manufacturers

In addition to choosing the right construction material, it's essential to consider the machinery and equipment used in the manufacturing process. High-quality concrete bricks and blocks depend on the reliability of the production equipment. Here's why selecting trustworthy Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is crucial

1. Product Quality: Reliable manufacturers produce machines that meet industry standards, ensuring the consistent production of top-quality bricks and blocks.

2. Efficiency: Modern brick and block making machines offer improved efficiency and output. Investing in machinery from reputable manufacturers can lead to increased productivity and reduced production costs.

3. Support and Service: Established manufacturers often provide comprehensive support and maintenance services for their equipment, minimizing downtime and optimizing machine performance.

4. Innovation: Leading manufacturers invest in research and development, resulting in innovative features and technologies that can enhance the quality and efficiency of brick and block production.

5. Compliance: Ensure that the machinery you purchase complies with safety and environmental regulations in your region.

Conclusion

Both materials have their strengths and applications. Concrete bricks offer versatility and aesthetics, while concrete blocks provide structural strength and cost-efficiency. The choice between these two construction materials depends on your project's specific needs.

Additionally, selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is essential to ensure the consistent production of high-quality building materials. By carefully considering both the construction material and the machinery used in production, builders and contractors can make informed decisions that lead to successful and durable construction projects. Whether it's the material or the machinery, quality, and reliability are key to building a solid foundation for any construction venture.

Benny Enterprises is the best option for your best brick-making machine and block-making machine manufacturers we are also well known for being the best Fly ash brick making machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more.

Contact us for further…

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes

Text

#fly ash brick making machine manufacturers#velan flyash bricks manufactures & suppliers in coimbatore#advantage of flyash bricks#flyash bricks manufacturers near me#flyashbricksprice#disadvantage of flyash bricks

0 notes

Text

High-Quality Hydraulic Brick Machines Manufacturers from Rexnear Systems

Rexnear Systems is a leading Hydraulic Brick Machine Manufacturers that are designed to produce high-quality bricks with ease. Our machines are built to last and can handle a wide range of brick-making tasks, from small-scale production to large-scale projects.

Our hydraulic brick machines are engineered to be highly efficient and reliable. They are capable of producing a wide range of brick sizes and styles, including standard bricks, perforated bricks, and interlocking bricks. Our machines are also designed to be user-friendly, with intuitive controls and easy-to-use features that make the brick-making process simple and straightforward.

At Rexnear Systems, we pride ourselves on the quality of our hydraulic brick machines. We use only the best materials and components in our machines, ensuring that they are durable and long-lasting. We also offer a range of customization options, so you can choose the machine that best meets your needs.

If you're looking for a high-quality hydraulic brick machine, look no further than Rexnear Systems. Our machines are reliable, efficient, and easy to use, making them the perfect choice for any brick-making project. Contact us today to learn more about our machines and how they can benefit your business.

Call Us: +91-8750287752,9990342299

Email id: [email protected]

Address: Plot No. 358 B, Udyog Kendra – 1, Ecotech – 3, Greater Noida - Uttar Pradesh (India.) - 201306

URL: https://www.flyashbrickmakingmachines.in/hydraulic-brick-machine.html

#Fly Ash Brick Making Machine Manufacturers#Hydraulic Brick Machine Manufacturers#Tile Press Paver Block Machine Manufacturers

0 notes

Text

Ultra tile machines are widely known as Fly Ash Brick Making Machine Manufacturers. Deals in manufacturing and exporting a affordable price range of Fly Ash Brick Manufacturing Machines using basic raw materials and electric components. Our offered by Ultra Tile hold some special attributes like low maintenance, precise in performance and a longer functional life.

#Fly Ash Brick Making Machine Manufacturers#Concrete Block Making Machine Manufacturers#PVC Rubber Mould Manufacturers

0 notes

Text

Fly Ash Bricks Making Machine

We are one of the leading Fly ash Bricks Making Machines Manufacturer in India. Our machines are known for their high performance and efficiency. They are easy to operate and require low maintenance. We offer a wide range of machines to meet the different needs of our customers.

We are leading a best Fly ash Bricks Making Machines in India

Fly ash Bricks Making Machines are used to produce bricks from fly ash. Fly ash is a by-product of thermal power plants that is rich in calcium oxide. When mixed with water and lime, it forms a compound that is similar to cement. Fly ash bricks are stronger and more durable than traditional clay bricks. They are also environment-friendly as they help to reduce pollution. The machines that are used to make fly ash bricks are simple and easy to operate. They are available in a variety of sizes and capacities to meet the needs of different customers.

https://www.chamundaengiworks.com/

https://www.chamundaengiworks.com/high-vibro-paver-block-making-machine.html

https://www.chamundaengiworks.com/concrete-block-making-machine.html

https://www.chamundaengiworks.com/brick-making-machine.html

https://www.chamundaengiworks.com/solid-block-making-machine.html

https://www.chamundaengiworks.com/automatic-material-weight-batching-plant.html

0 notes

Text

Rexonhydraulics - Hydraulic Cylinder, Hydraulic Power Pack & Hydraulic Pressure Jack Manufacturer from Ahmedabad, Gujarat, India.

#Hydraulic Power Pack and Hydraulic cylinder#Hydraulic Power Pack and Hydraulic cylinder Manufacture#Hydraulic Power Pack Manufacture#Fly Ash Bricks making Machine Manufacturer#Fly Ash Bricks making Machine#Rexroth Pump Dealer Manufacturer#Rexroth Pump Dealer#Hydraulic Cylinder#Hydraulic Cylinder Manufacturer#Rexroth Valve Dealer#Rexroth Valve dealer manufacturer#Hydraulic Power Pack Manufacturer#Hydraulic Power Pack#Semi-automatic fly ash bricks making machine#Semi-automatic fly ash bricks making machine manufacturer#Paver Block Making Machine#Paver Block Making Machine Manufacturer#Fully automatic bricks making machine#Fully automatic bricks making machine manufacturer

0 notes

Text

0 notes

Text

Top Brick Making Machine Manufacturers in the Market

The construction of bricks has been an important industry for many years, as bricks have been the fundamental underpinning of infrastructures and construction. With the increasing trend in the quality of construction material, there is need the proper methods in the making of bricks. This is where brick making machine come into game, helping in making the process much easier while at the same time improving the quality of the bricks.

Most brick making machine manufacturers have designed highly efficient machines that minimize on human effort, time and produce bricks in equal size and shape. These brick making machines are very essential in order to satisfy the increasing production and demand for quality bricks. Whether you are in need of a new brick making machine in India or somewhere else, selecting the right supplier for your company can have a huge impact on the output of your business.

Technological Development in Brick Manufacturing

Modern technology has improved on the brick making machines especially those being produced by the best brick making machine manufacturers in India and other parts of the world. Some key improvements include:

Automation and Robotics: The adoption of robotics and automation in brick making machines has enhanced efficiency, accuracy and safety in handling the machines.

Energy Efficiency: Current machinery is designed to consume less power both in terms of energy use and in terms of time and manpower.

Customization and Flexibility: The newly developed equipments in this industry provide more versatility in terms of mold variations and product standard to suit different constructions.

Selecting the best brick making machine manufacturers are very important in any construction work that you are undertaking so that you get quality machines. Let know more about prominent brick making machine manufacturer that have engraved their names in the list of Brick Making Machine in India.

Brick Machinery

Brick Machinery is a popular brand in the brick making machine in the market due to its superior products and advanced technology. Brick machinery establishes as a leading company of Fly Ash Brick Making Machine in India. They offer manual, semi-automatic and fully automatic machines for different operational capacity. Brick machinery is popular in the list of brick making machine manufacturers due to their ability to offer tailored propositions that suit specific demand.

Are you ready to move to the next level of optimizing your construction projects with the high-quality brick making machine? Please visit brick machinery website today and learn more about the range, the modern brick making machine from Brick Machinery. Brick Machinery is one of the most prominent brick making machine manufacturers and suppliers who provide the latest models of brick making machine.

#brick making machine#brick making machine manufacturers#fly ash brick making machine#brickmakingmachine#brick making machine manufacturer#brickmachine#brick

0 notes

Text

SnPC Machines BMM410 with a production more than 25K bricks in just 01 hour.

Brick making machine: BMM410

instagram

BMM410 is a fully automatic red clay brick making machine by Snpc companies which has greatly revolutionize brick production due to its high speed and less raw material requirement. It can produce 24000 brick/hr with a reduction of 45%cost and natural resources like water, it requires only one-third of water for brick making as required during manual production. This machines requires a fuel consumption of 16-18 liters/hour for its working. Raw material needed for its working can be mud, clay or mixture of clay and fly ash. This machine is widely used by itta Bhatta, brick making factories or brick kiln and clay brick manufacturers around the globe. Different types of brick produced by this machines are clay brick, fly ash brick etc. Different types of brick this machine can produce are red bricks, clay bricks, fly ash brick. This machine give kiln owner to produce brick independently anywhere anytime. This machine consumer 16-18 liters of fuel for its working. Other mobile brick making machines are BMM-160, BMM-310, SBM-180 with different production capacities. Consumers can order from any state, Country or can visit us for their own satisfaction. Thankyou for visiting us.

8826423668

#Brick making machine#clay bricks#fast brick production#Team SnpC#SnPC Machines#top quality bricks#BMM410#BMM310#SBM180#construction machinery#building material suppliers#Instagram

7 notes

·

View notes

Text

Concrete Blocks - Manufacturing, Classification & Uses

Concrete blocks are nowadays replacing bricks in masonry construction, notably in many multi-storeyed buildings. They are available in three types namely solid, hollow and cellular, widely used for the construction of filler walls and boundary walls in RC framework.

Concrete blocks are usually made in large sizes to make blockwork faster and consume less cement in joints than the brickwork. If the percentage of the voids is more than 25%, then they are hollow blocks and blocks with voids less than 25% are only perforated blocks.

The cellular concrete blocks are generally referred to as lightweight aerated concrete blocks. All these blocks are extensively used for compound walls and non-loadbearing walls.

Hollow blocks are specially made for loadbearing walls, which are useful in reducing a dead load of masonry in buildings. Blocks can also be with cement and sand called cement-sand blocks or with cement and soil called soil-cement blocks which are of low strength and use for low-cost construction.

Manufacturing of Concrete Blocks

BIS recommends a fineness modulus of the combined aggregate between 3.6 to 4 and coarse aggregates used are of size 6 to 12 mm. Lean mixes up to 1:8 are generally used. Concrete mix for concrete blocks should not be richer than one part of the cement to six parts of the volume of combined aggregate.

Concrete blocks can be handmade and also machine-made. The cast block is then cured in a water tank or yard for at least 14 days (water need to be changed at least every 4 days).

After curing, the blocks are dried for 4 weeks before being used in masonry construction. They should be stacked with voids in the horizontal direction to facilitate easy drying, or they should be steam cured and dried.

The whole process allows the complete shrinkage of the block to take place they are laid on the wall, which is very important for strong walls.

Classification of Concrete Blocks

Hollow concrete blocks

Open and Closed cavity-type hollow concrete blocks are classified into three grades:

Grade A - They possess a minimum density of 1500 kg/m³ and are used for load-bearing walls.

Grade B - They have a density below 1500 kg/m¬³ and used for load-bearing walls.

Grade C - These blocks are used for non-load bearing walls and have density more than 1000 kg/m³.

All these blocks are available in decorative facings like fluted facing to provide artistic effects.

Solid concrete blocks

They should be manufactured for specific concrete strength of 4.0 and 5.0 N/mm² in 28 days. These blocks are used as load-bearing walls and have a density of not less than 1800 kg/m³.

Paver blocks

These blocks are solid concrete blocks of different shapes specially made for exterior ground paving on sidewalks, parking lots, driveways, petrol pumps, industrial floors, etc.

AAC Blocks

AAC blocks refer as Autoclaved Aerated Concrete Blocks. These blocks are also termed as light-weight hollow blocks.

They are prepared as solid blocks from cement, water and materials like ground sand, pulverized fly ash together with additives to aerate and stabilize the air bubbles.

The final result is a mixture of thick liquid which is then poured into steel moulds to form large cakes. After some time, the mixture sets and ready to cut into a serious of individual blocks of required size using taut steel wires.

Very light blocks for partition and moderate-weight blocks for light loadbearing walls can be obtained from aac blocks. These blocks do not shrink on drying as the material is obtained by autoclaving.

The autoclaved cement product is crystalline, which is different from the product obtained by normal wet curing or by ordinary steam curing.

Sizes and Tolerances

The nominal dimensions of concrete block as per BIS are as follows:

Length - 600, 500, 450 or 400 mm

Height - 100 or 200 mm

Width - 50, 75, 100, 150, 200, 250 or 300 mm

Actual sizes will be less than 10 mm of mortar thickness. For Concrete and Hollow concrete blocks nominal length 390 mm and height 190 mm. The thickness for loadbearing walls is 190 mm, compound walls 140 mm and for filler walls 90 mm.

These dimensions can easily be achieved in machine-made blocks than handmade blocks. The width of blocks use for load-bearing walls is 200 mm and for parapet or filler walls is 100 mm.

Points to Remember:

The mortar strength should not be more than the strength of the blocks. With high mortar strength, cracks will be less and very large, but with low mortar strength, cracks will be small and distributed.

We should use only blocks that are cured properly for at least 14 days and dried for 4 weeks to avoid shrinkage during construction.

We should not wet the blocks while placing in masonry construction.

Freshly-made and uncured concrete blocks should never be allowed on the work.

Blockwork, particularly ordinary cement sand blocks and soil-cement blocks should not be used as loadbearing walls for concrete slab roof which favours to expand and contract with temperature.

The maximum difference in sizes allowed is ±5 mm in length and ±3 mm in height and width.

They should be protected from rains while being stored as they absorb moisture by wetting and shrinking on drying.

The main disadvantage of concrete blocks is shrinkage due to the movement of moisture content which is not present in bricks. As these blocks are much larger than bricks, any foundation movement will cause blockwork to crack more than the brickwork.

Cement blocks, Concrete blocks, Hollow concrete blocks, solid concrete blocks, Paver blocks, AAC blocks Concrete blocks in Hyderabad

#aac Blocks#aac blocks online#aac block size#Cement blocks#Concrete blocks#Hollow concrete blocks#solid concrete blocks#Paver blocks#AAC blocks

2 notes

·

View notes

Text

Selecting the right concrete block making machine for your construction business is a significant decision that can impact your productivity, profitability, and overall success. Benny Enterprises is the best choice for all your needs, we are the finest Concrete Brick Making Machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes