#hydraulic power pack machine manufacturer

Text

What are H frame Hydraulic Pres Machine Used For

Radhey Krishan Industries is a leading manufacturer of H Frame Hydraulic Presses, offering robust and versatile solutions for various industrial applications. These presses are designed to deliver exceptional performance, durability, and precision, making them indispensable in numerous sectors.

**Automotive Industry**: In the automotive sector, H Frame Hydraulic Presses from Radhey Krishan Industries are essential for stamping, bending, and forming metal parts. They are used to manufacture components like car frames, engine parts, and body panels, ensuring high strength and uniformity. The precision and reliability of these presses contribute to improved vehicle safety and performance.

**Aerospace**: The aerospace industry demands high accuracy and strength in its components. H Frame Hydraulic Presses are used for forming and shaping lightweight materials such as aluminum and titanium. These presses help in creating structural components, engine parts, and other critical elements, ensuring that they meet stringent quality and safety standards.

**Metalworking**: In general metalworking, these presses are used for a variety of tasks including cutting, punching, and pressing operations. Their adaptability and high pressure capabilities allow them to handle different types of metals and alloys, making them a versatile tool in workshops and factories.

**Plastic and Rubber Molding**: H Frame Hydraulic Presses are also used in the molding of plastic and rubber products. They ensure consistent pressure and temperature, which is crucial for the quality and precision of molded parts. This makes them ideal for producing items like gaskets, seals, and other rubber components.

**Electrical Industry**: The electrical industry utilizes these presses for assembling and manufacturing components such as switchgear, insulators, and other electrical parts. The precise control over pressure and positioning ensures that components meet the required specifications and standards.

**Agricultural Machinery**: In the production of agricultural machinery, H Frame Hydraulic Presses are used to form and shape heavy-duty parts. Their ability to handle large-scale and high-pressure tasks makes them suitable for producing durable and reliable agricultural equipment.

Radhey Krishan Industries' H Frame Hydraulic Presses are known for their sturdy construction, advanced features, and user-friendly operation. With a focus on innovation and quality, they provide solutions that enhance productivity and efficiency across various industries. Whether you need custom designs or standard models, Radhey Krishan Industries delivers presses that meet your specific industrial needs with precision and excellence.

For More Information

Plot No. F-445, MG Road Industrial Area, UPSIDC, Ghaziabad - 201002, Uttar Pradesh, India.

Contact Us :- +91-7836842828

Visit our Website :- [email protected]

#h frame hydraulic press machine manufacturer#hydraulic power pack machine manufacturer#h frame hydraulic press machine#best hydraulic press machine

0 notes

Text

Check Valve Manufacturer in Gujarat

We have established ourselves as a renowned manufacturer and supplier of Hydraulic Power Pack. Power Pack Hydraulic Cylinder Manufacturer in Ahmedabad, Gujarat. Rexonhydraulics - Hydraulic Cylinder, Hydraulic Power Pack & Hydraulic Pressure Jack Manufacturer from Ahmedabad, Gujarat, India.

#Hydraulic Power Pack and Hydraulic cylinder#Hydraulic Power Pack and Hydraulic cylinder Manufacture#Hydraulic Power Pack Manufacture#Fly Ash Bricks making Machine Manufacturer#Fly Ash Bricks making Machine#Rexroth Pump Dealer Manufacturer#Rexroth Pump Dealer#Hydraulic Cylinder#Hydraulic Cylinder Manufacturer#Rexroth Valve Dealer#Rexroth Valve dealer manufacturer#Hydraulic Power Pack Manufacturer#Hydraulic Power Pack#Semi-automatic fly ash bricks making machine#Semi-automatic fly ash bricks making machine manufacturer#Paver Block Making Machine#Paver Block Making Machine Manufacturer#Fully automatic bricks making machine#Fully automatic bricks making machine manufacturer

0 notes

Text

Torque Wrenches, Hydraulic Torque Wrench, Impact Sockets, India

9 Torc : Manufacturer and Exporter of Torque Wrenches, Impact Sockets, Bloting Tools, Pipe Cutting Machines, Non Sparking Tools, Mumbai, India.

Torque Wrench, Torque Wrenches, Hydraulic Torque Wrench, Impact Sockets, Standard Impact Sockets, Slugging Wrench, Ring Type Slugging Wrench, Open Type Slugging Wrench, Impact Accessories, Thin Wall Impact Sockets, Impact Accessories, Manual Torque Wrench, Manual Torque Multiplier, Slim Type Manual Torque Multiplier, Hydraulic Torque Wrench, Square Drive Torque Wrench, Hex Drive Torque Wrench, Hydraulic Power Pack, Bolt Tensioners, Non Sparking Tools, Pipe Cutting Machine, Impact Wrench, Pneumatic Impact Wrench, Nut Splitter, Standard Nut Splitter, Angle Head Nut Splitter, Crowfoot Wrench, Crowfoot Wrenches, Mumbai, India.

www.9torc.com

0 notes

Text

It is not easy to grasp the function of a Hydraulic Power Pack. That’s why we’ve made this effort to explain everything in terms you can grasp. You can rest assured that you’ve selected the most suitable power source for all of your machinery. Repairing or replacing an aeroplane can be an expensive ordeal. That is why you must purchase only top-notch components. With this, you can remain in the sky. This will keep your equipment in top shape for many years to come. Here we will talk about hydraulic power packs.

A Hydraulic Power Pack: What Is It?

Hydraulic power, as we now know, is a means of assisting with massive lifting. A hydraulic power pack, in its most basic form, is a device that increases the output power of machinery. They are available in a wide range of sizes and shapes. Choosing the right one for your requirements can seem like a daunting task. Because many machines use power packs. They can reach lengths comparable to those of a car. Others are about the same size as a standard hurricane generator.

How Does It Operate?

The hydraulic power pack is a unified unit that converts and transfer’s power. We’ll get a crash course in hydraulics, mechanics, and electricity. However, to gain a better grasp, we must initially analyse each main component independently. The internal components of a hydraulic power pack are its most crucial aspects. Several parts come together to make hydraulic power packs work.

0 notes

Text

Motor Graders' Power: Using It for Yourself

Motor graders are extremely powerful and precise devices that are essential in today’s world of road building and upkeep. Ensuring smooth and safe transportation networks is greatly dependent on these massive construction sector players, who shape highways and level surfaces. Let’s take a closer look at the world of Motor Graders and discover how they use force to overcome the most difficult terrain..

Revealing Motor Graders’ Potential

The motor grader, a powerful tool that can handle grading jobs with unmatched efficiency, is the central component of road building operations. Motor Graders, outfitted with state-of-the-art hydraulics and cutting-edge technology, can quickly and precisely convert rough terrain into smooth, level surfaces.

Evolution in Practice: Compliance with CEV Stages

The progress of Motor Graders in recent years has been characterized by an emphasis on environmental sustainability. As stricter emissions rules, such the CEV Stage regulations, have been implemented, manufacturers have embraced creative ways to reduce their carbon footprint while optimizing performance.

CAT Motor Graders are Leading the Pack

Within the upper echelons of the Motor Grader industry, CAT (Caterpillar) is a leading example of excellence. CAT Motor Graders are recognized for their exceptional strength, unparalleled longevity, and state-of-the-art engineering, representing the pinnacle of engineering excellence.

The Skill of Accurate Grading

Grading is an art form that requires accuracy and dexterity; it’s not just about leveling surfaces. Motor Graders are superior in this field because of their complex hydraulic systems and well tuned controls.

Getting to Know the Ground

Because of their innovative traction control systems and changeable blade angles, Motor Graders can easily handle a variety of terrains, from gentle slopes to high inclines. Because of its adaptability, operators can attain exact grades in even the most difficult circumstances.

Improving Driver Comfort: Top-Rated Cabs

Every Motor Grader has an operator behind the controls who is essential to maximizing its power. Manufacturers give operator comfort top priority when designing their equipment, incorporating top-notch cabins into them to guarantee optimal productivity and efficiency. These roomy, climate-controlled chambers with ergonomic design allow operators to work ceaselessly for long stretches of time without feeling tired.

Innovations Advancing Development

Motor Graders maintain their advancement in tandem with technology. Manufacturers are always innovating to provide machines that are more dependable, efficient, and ecologically friendly than they have ever been.

The Ascent of Independent Assessment

The creation of autonomous motor graders is among the most important developments in recent years. Without the need for direct human assistance, these state-of-the-art devices use sophisticated sensors and GPS technology to explore building sites and do grading duties with exactitude.

Greener Alternatives: Electric Motor Graders

Manufacturers are looking at environmentally friendly alternatives to the conventional diesel-powered Motor Graders in response to growing environmental concerns. Electric motor graders operate with no emissions, cutting down on pollution and carbon impact without sacrificing efficiency or performance.

The Prospects for Highway Development

Looking ahead, we see a bright future for road construction, driven by the producers of motor graders’ unwavering creativity and inventiveness. Dedicated to sustainability, efficiency, and accuracy, these road warriors will remain important in forming the infrastructure of the future.

Embracing Sustainability: Green Building Methodologies

A paradigm revolution towards greener, more sustainable practises is occurring in the building industry in an era characterised by climate change and environmental degradation. Manufacturers of motor graders are leading this movement by developing cutting-edge technology that maximize efficiency while minimizing negative effects on the environment.

Overcoming the Obstacles Ahead

The need for strong, dependable roads will only increase as transportation networks become more and more strained by urbanization and population expansion. Our highways will continue to be accessible, effective, and safe for future generations thanks to the efforts of motor graders who are up to the job.

In summary

Motor Graders are the ultimate performers in the vast theater of road construction. These road warriors, with their unmatched strength, agility, and power, are the engine powering the flawless, uninterrupted highways that link our globe. Motor grader manufacturers will keep coming up with new ideas as environmental concerns grow and technology develops, making sure that our roads continue to be essential to modern society.

0 notes

Text

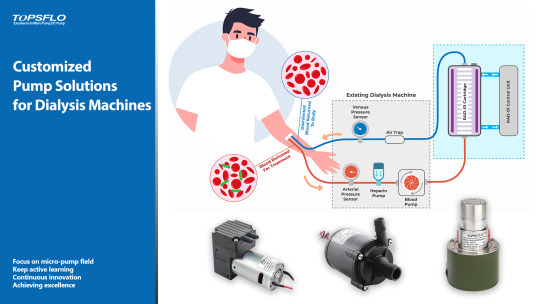

𝗠𝗶𝗰𝗿𝗼 𝗣𝘂𝗺𝗽 𝗮𝗻𝗱 𝗙𝗹𝘂𝗶𝗱𝗶𝗰 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀 𝗳𝗼𝗿 𝗠𝗲𝗱𝗶𝗰𝗮𝗹 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆 - 𝗛𝗲𝗺𝗼𝗱𝗶𝗮𝗹𝘆𝘀𝗶𝘀 𝗣𝘂𝗺𝗽

Overview

Hemodialysis serves as a vital renal replacement therapy for individuals battling chronic renal failure. Over the years, the prevalence of chronic renal failure has risen steadily, particularly due to factors like diabetic nephropathy, hypertensive nephropathy, and renal artery stenosis. This surge in patients necessitates hemodialysis treatment to sustain life.

Dialysis is a life-sustaining treatment for patients with end-stage kidney failure whose kidneys can no longer function. The dialysis machines removing water, solutes, and toxins from the blood. Dialysis works on the principles of diffusion across a semipermeable membrane. Blood flows by one side of a semipermeable membrane and a dialysate on the opposite side. The two main types of dialysis are hemodialysis and peritoneal dialysis.

In peritoneal dialysis, wastes and water are removed from the blood inside the body using the peritoneum as a natural semipermeable membrane.

However, in hemodialysis, the patient’s blood is pumped through a dialyzer. Blood flows through fibers, while dialysis solution flows around the outside of the fibers. The patient’s blood is cleaned in a dialyzer machine from waste products such as urea, creatinine, potassium, and extra fluid pass through the membrane, while the blood cells, protein, etc. remain in the blood.

Choosing the Right Dialysis Pumps

In hemodialysis machines, two circuits are crucial: the blood circuit for extracorporeal circulation lines and the hydraulic circuit for managing dialysis fluid. The hydraulic circuit involves various pumps, TOPSFLO offers a range of pumps engineered to meet OEM specifications for dialysis devices (Model recommendations are as follows):

1. Centrifugal Pumps

2. Diaphragm Gas Pump

3. Magnetic Drive Gear Pumps

External gear pumps are widely acclaimed for their pivotal role in powering dialysis machines, particularly in the medical sector. These pumps operate through the synchronization of two identical gears, commonly referred to as the "motor" and "driven" gears. The motor gear, propelled by a motor, in turn, drives the other gear, facilitating fluid transport by trapping small volumes between the gear teeth and the outer housing wall. This mechanism efficiently moves fluid from the inlet side to the outlet side, making external gear pumps a preferred choice for applications requiring precise fluid pressurization and minimal pressure fluctuations.

The distinctive advantages of external gear pumps contribute to their suitability for health technology applications, notably in hemodialysis machines. These advantages include exceptional priming capacity, ensuring swift initiation of fluid movement. Moreover, these pumps exhibit compatibility with wide temperature variations, a critical feature considering the temperature fluctuations experienced during post-treatment washing. Additionally, the compact size of external gear pumps further enhances their appeal for medical applications, offering an efficient and space-saving solution for fluid management in hemodialysis machines.

Pumps can operate at a temperature of 38°C throughout the dialysis cycle to prevent thermal shock to the patient. Their quiet operation is crucial for patient comfort. Stable performance, vacuum maintenance, and differential pressure are critical factors for the machine's operation, especially biocompatibility. The disinfectants in dialysis equipment pack strength, yet their corrosiveness poses challenges. Enter TOPSFLO pumps, crafted from materials demonstrated to endure numerous chemical heat clean cycles, ensuring unwavering performance. The outcome? A durable pump boasting biocompatibility, minimal noise, and significant reductions in long-term maintenance costs. Choose us for a pump solution where materials make the difference, offering reliability and longevity.

TOPSFLO pumps precisely and safely manage fluids within dialysis systems. As one of leaders in micro pump and fluidic solutions for the medical industry, TOPSFLO collaborates with customers to provide technical solutions, ensuring critical parameters for safety and performance are met.

Conclusion

TOPSFLO's commitment to innovation and collaboration makes it a reliable partner in the development of medical devices. For more information or to discuss a new project, welcome to have a consultation.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

#hemodialysis#dialysis machine#hemodialysis machine#centrifugal pumps#gear pumps#diaphragmairpump#medical pump#Youtube

0 notes

Text

Top Picks: Caterpillar's 5 Best Machines for Excavation

Excavation is a critical aspect of construction and heavy industries, requiring robust machinery capable of handling digging, lifting, and material movement tasks with precision and efficiency. Caterpillar Inc., a renowned manufacturer with a legacy spanning over a century, has consistently delivered reliable and efficient equipment tailored for such endeavors. Caterpillar machines are celebrated for their durability, performance, and adaptability, making them the preferred choice for excavation projects worldwide.

In this detailed examination, we delve into the top 5 Caterpillar machines specifically designed for excavation tasks. From medium hydraulic excavators to large-scale models, each machine offers a unique set of features and benefits to meet diverse project requirements.

Medium Hydraulic Excavators:

Leading the pack is the Caterpillar 323D3 Hydraulic Excavator, a powerhouse known for its versatility and performance in various excavation jobs. Powered by the Cat C7.1 engine, this excavator delivers exceptional power and efficiency. Its hydraulic system ensures precise control over the machine's movements, enhancing productivity and accuracy on the job site. Equipped with a range of work tools and configurations, including normal, mass excavation, and scrap and demolition, the 323D3 excels in a variety of excavation activities.

The 323D3 is equipped with modern technology like Cat Connect, allowing operators to monitor productivity in real time. The high-resolution touchscreen display provides valuable insights into the machine's performance and maintenance schedules, enabling proactive maintenance and minimizing downtime. Additionally, the cab is designed for operator comfort and safety, featuring a climate control system, adjustable seats, and advanced safety features.

Fuel efficiency is a key focus of the 323D3, with features like automatic engine shutdown helping to reduce fuel consumption during idle times. Overall, the 323D3 Hydraulic Excavator offers unmatched performance, versatility, and fuel efficiency for excavation projects.

Small Hydraulic Excavators:

For precise digging in confined spaces, the Caterpillar 313D2 L Hydraulic Excavator is the perfect choice. With a maximum digging depth of 5.58 meters and a maximum reach of 8.89 meters, this compact excavator is ideal for small to medium-sized excavation operations. Powered by a fuel-efficient Cat C4.4 engine, the 313D2 L delivers reliable performance while minimizing fuel consumption.

The hydraulic system ensures smooth and precise control over the machine's movements, allowing operators to complete tasks accurately and efficiently. The cab is equipped with a climate control system, adjustable seats, and a high-resolution touchscreen display, providing operators with real-time information on the machine's performance and maintenance needs.

Large Hydraulic Excavators:

The Caterpillar 350 Hydraulic Excavator, recently launched, is a robust heavy machinery designed for a range of excavation tasks, particularly overburden removal and large quarry operations. Powered by a Cat C9.3 engine, this excavator delivers up to 414 horsepower while complying with strict emissions regulations.

With a bucket size of 3.2 to 3.4 cubic meters, the 350 Hydraulic Excavator can move large volumes of earth and materials with ease. The hydraulic system offers precise and smooth operation, allowing the excavator to reach impressive heights and depths.

The cab is equipped with a sizable high-resolution monitor, providing real-time machine data and an intuitive control system for operator comfort and productivity. Advanced safety features, including a rearview camera and proximity sensors, enhance job site security and reduce accidents.

Caterpillar continues to lead the way in providing innovative and reliable equipment for excavation projects. With

a wide range of machines designed to meet the diverse needs of the construction and excavation industries, Caterpillar remains a trusted partner for contractors and operators worldwide.

In addition to the models highlighted in this guide, Caterpillar offers a range of other products, including the 330GC in the 30-35 ton segment, the 374 in the 65-75 ton segment, and the 395 in the 90+ ton segment, catering to every excavation and loading requirement in the construction, infrastructure, overburden, and mining industries.

0 notes

Text

Understanding the Function of a Hydraulic Machine - HEICO

In the realm of industrial machinery, hydraulic systems stand out as the unsung heroes powering various heavy-duty operations. From construction equipment to manufacturing processes, Hydraulic Machines play a pivotal role in facilitating the smooth and efficient movement of machinery. As such, comprehending the function of a hydraulic system is essential for appreciating its significance in diverse sectors.

What is a Hydraulic System?

A Hydraulic System operates through the transmission of force via a pressurized fluid, typically oil. It consists of a network of interconnected components including pumps, actuators, valves, hoses, and cylinders. The fundamental principle behind hydraulic systems is Pascal's Law, which states that pressure exerted on a confined fluid is transmitted undiminished in all directions.

Functionality of Hydraulic Systems:

Transmission of Power: The primary function of a hydraulic system is to transmit power from one point to another. This is achieved by using hydraulic fluid to create pressure, which in turn drives pistons, cylinders, or motors to perform mechanical work.

Amplification of Force: Hydraulic systems are renowned for their ability to amplify force. Through the use of hydraulic cylinders and actuators, a relatively small input force can generate a significant output force, making them ideal for lifting heavy loads and performing strenuous tasks with ease.

Control of Motion: Hydraulic systems offer precise control over the speed and direction of motion. By manipulating the flow of hydraulic fluid through valves and control mechanisms, operators can regulate the movement of machinery with accuracy and efficiency.

Versatility and Adaptability: Hydraulic System is incredibly versatile and can be tailored to suit a wide range of applications. From hydraulic presses and lifts to excavators and cranes, hydraulic technology is integral to the functioning of various industrial and commercial equipment.

Hydraulic Machines Manufacturers in Delhi:

In the bustling industrial landscape of Delhi, we are the best Hydraulic Machine Manufacturers specializing in meeting the diverse needs of businesses across different sectors. These manufacturers leverage advanced technologies and engineering expertise to design and fabricate High-Quality Hydraulic Systems that ensure optimal performance and reliability.

Among the prominent players in the field is Heico, a leading manufacturer and supplier of hydraulic machines in Delhi. With a commitment to innovation and excellence, Heico has carved a niche for itself in the industry by delivering cutting-edge solutions that surpass client expectations. From hydraulic presses and power packs to cylinders and valves, HEICO offers a comprehensive range of products designed to enhance productivity and efficiency in various industrial applications.

Also Read: A Comprehensive Guide to Hydraulic Machine

Best Hydraulic Machines – Uses, Working Principles, Types & Applications

Conclusion:

In conclusion, the function of a hydraulic system extends far beyond mere mechanical operations. HEICO is one of the best Hydraulic Machine Suppliers in Delhi, enabling them to perform a myriad of tasks with precision and power. From construction sites to manufacturing facilities, hydraulic systems play an indispensable role in driving progress and productivity.

As industries continue to evolve, the demand for efficient hydraulic solutions will only continue to grow, reaffirming the importance of understanding and appreciating the function of these intricate systems.

#hydraulic machines#hydraulic machine#Hydraulic Machine in Delhi#Hydraulic Machines Price#Hydraulic Machines Manufacturer

0 notes

Text

Title: Unveiling the Powerhouse: The Swaraj Tractor Revolution

Introduction: In the heartlands of rural India, where agriculture is not just a profession but a way of life, the name "Swaraj" resonates with power, reliability, and trust. Swaraj Tractors, a brand that has become synonymous with robust performance and innovative solutions, has been a driving force behind the agricultural revolution in the country. In this blog, we'll delve into the rich history, key features, and the enduring impact of Swaraj Tractors on Indian agriculture.

A Legacy of Innovation: The journey of Swaraj Tractors began in 1971 when it was established as a division of the Punjab Tractors Limited (PTL), a joint venture between the Government of Punjab and Canadian agricultural equipment manufacturer International Harvester. The objective was clear – to empower farmers with cutting-edge technology and reliable machinery that would enhance productivity in the fields. Over the years, Swaraj Tractors has consistently delivered on this promise, introducing a range of tractors equipped with advanced features to meet the evolving needs of Indian farmers. The brand's commitment to innovation has been a driving force, making Swaraj a name that farmers trust for their agricultural endeavors.

Power-packed Performance: One of the key factors that set Swaraj Tractors apart is their emphasis on delivering high-performance machines. These tractors are designed to handle the diverse and demanding tasks of Indian agriculture, from plowing and seeding to harvesting. The power-packed engines, efficient transmission systems, and sturdy build make Swaraj Tractors reliable partners in the fields. Swaraj tractors are available in a variety of models, catering to different farm sizes and requirements. Whether it's the compact Swaraj 717 or the powerful Swaraj 963, each model is crafted with precision and attention to detail, ensuring that farmers have the right tool for the job at hand.

Innovative Features for Modern Agriculture: Swaraj Tractors have continually evolved to incorporate the latest advancements in agricultural technology. From advanced hydraulics for precise control of implements to ergonomic designs for operator comfort, these tractors are a testament to the brand's commitment to providing holistic solutions. The incorporation of digital technology has also been a notable feature in Swaraj Tractors. Modern models come equipped with digital displays, GPS guidance systems, and connectivity options, allowing farmers to optimize their operations and make data-driven decisions for improved efficiency.

Sustainability and Environmental Consciousness: In an era where sustainability is a top priority, Swaraj Tractors have embraced eco-friendly practices. The engines are designed to comply with emission norms, and the brand is actively involved in promoting sustainable farming practices. Swaraj Tractors not only empower farmers but also contribute to a greener and more sustainable future for agriculture.

The Impact on Indian Agriculture: Swaraj Tractors have played a pivotal role in the transformation of Indian agriculture. By providing farmers with reliable, efficient, and technologically advanced machinery, the brand has contributed to increased productivity, reduced manual labor, and improved overall living standards in rural communities.

Conclusion: As we look towards the future of agriculture in India, Swaraj Tractors stand tall as a symbol of progress and resilience. The brand's legacy of innovation, commitment to performance, and focus on sustainability make Swaraj Tractors an indispensable partner for the farmers who feed the nation. In the fields of India, where the heartbeat of the nation echoes, Swaraj Tractors continue to drive the wheels of progress, embodying the spirit of self-reliance and empowerment.

Toll Free number1800 425 0735

Address: Swaraj Division, Mahindra & Mahindra Ltd., Phase IV, Industrial Area, S.A.S Nagar (Mohali), Punjab -160055.

0 notes

Text

#Hydraulic Power Pack Machine#Hydraulic Power Pack Machine Manufacturer#Hydraulic Power Pack Machine Manufacturer in India#Best Hydraulic Power Pack Machine Manufacturer in India#Hydraulic Power Pack Machine Supplier in India#Best Hydraulic Power Pack Machine Supplier in India#Hydraulic Power Pack Machine Manufacturer in Ghaziabad#Hydraulic Power Pack Machine Supplier in Ghaziabad

1 note

·

View note

Text

Rexonhydraulics - Hydraulic Cylinder, Hydraulic Power Pack & Hydraulic Pressure Jack Manufacturer from Ahmedabad, Gujarat, India.

#Hydraulic Power Pack and Hydraulic cylinder#Hydraulic Power Pack and Hydraulic cylinder Manufacture#Hydraulic Power Pack Manufacture#Fly Ash Bricks making Machine Manufacturer#Fly Ash Bricks making Machine#Rexroth Pump Dealer Manufacturer#Rexroth Pump Dealer#Hydraulic Cylinder#Hydraulic Cylinder Manufacturer#Rexroth Valve Dealer#Rexroth Valve dealer manufacturer#Hydraulic Power Pack Manufacturer#Hydraulic Power Pack#Semi-automatic fly ash bricks making machine#Semi-automatic fly ash bricks making machine manufacturer#Paver Block Making Machine#Paver Block Making Machine Manufacturer#Fully automatic bricks making machine#Fully automatic bricks making machine manufacturer

0 notes

Text

Double Speed Hand Pumps, Hydraulic Power Pack, Manufacturer, India

Double Speed Hand Pumps, Hydraulic Power Pack, Hydraulic Jacks, Mechanical Infringing Track Jack, Hydraulic Torque Wrenches, Hydraulic Power Packs For CNC Machines, Shell And Tube Hydraulic Water Oil Cooler Heat Exchangers, Hydraulic Mobile Floor Cranes, Manufacturer, Supplier, Exporter, Belgaum, Karnataka, India.

Double Speed Hand Pump, Double Speed Hand Pumps, Hydraulic Power Pack, Hydraulic Power Packs, Hydraulic Jack, Hydraulic Jacks, Hydraulic High Pressure Jack

0 notes

Text

How Industrial Chiller manufacturers are playing a pivotal role in various diversified industries?

One of the fundamental needs of the food, pharmaceutical, beverage, chemical, medical, water treatment, and many other sectors is an industrial chiller. For industrial process cooling applications, they are necessary. Depending on the use and industry, premium chiller versions are manufactured along with basic models. Manufacturers produce goods that work well in both outdoor and indoor settings. Today, India has many reputable water chiller manufacturers who provide durable, comprehensive, long-lasting, and energy-efficient goods.

Food, pharmaceuticals, beverages, chemicals, medical, water processing, and many more sectors all need industrial chillers as a basic component. They are required for applications involving industrial process cooling. High-quality chiller versions are produced based on the use and industry.

Modern industry requires complex equipment and high-tech technologies. Reputable industrial chiller manufacturers in India, who are renowned for their commitment to innovation and technology, are fulfilling industrial demand and have expanded their operations throughout India.

Types of Industrial Chillers

Water Chillers

The use of water chillers is essential in many industrial operations. Quality water chillers are renowned for their high levels of precision and productivity. They are the result of years of study and development by a team with strong technological skills. Based on user requirements, manufacturers can design both standard and custom items with extreme emphasis on post-implementation support, cost-effectiveness, and quality.

It would help if you searched for a top-tier water chiller manufacturer in the nation when you consider investing in sophisticated and technologically complex industrial chillers for your company. Businesses seek out technologically cutting-edge goods that fit their needs, provide value for money, and provide a high return on investment. The main issue with chiller goods is performance and productivity. To provide the highest performance regardless of their size or application, quality products overcome these constraints and produce goods that pass through rigorous quality inspections.

Brine Chiller

Vegetables, Fruits, fish, and meat are preserved by using brine solution. This liquid is commonly used in large refrigerators that are used for the transportation of food items from place to place. Brine is used in industrial operations as a coolant as it is known to lower freezing temperatures. The refrigeration system that uses brine solution to cool surrounding temperature is known as brine chiller. For central air conditioning in various industrial applications, brine chillers are used. Pharmaceutical industries, Marine air conditioning, and textile industries are some of the sectors where brine chillers are used.

Oil Chiller

An oil chiller is an industrial unit that cools different types of oils such as lubricating oil, and hydraulic oil in specific machine tools. Large machines using gears and bearings get overheated during operational use. This leads to machines getting thermally deformed because of high rotational impact. The accuracy and efficiency of the machine are affected when machine parts are displaced. The oil also gets degraded during overheating which in turn affects the machine. Oil chillers are used commonly in sectors such as the automobile industry, power plants, and aerospace industries.

To maintain precise oil temperature in the power packs used in water-driven frameworks of CNC machine tools, quick presses, pressure-driven fuelled particular purpose machines, and pressure-driven equipment, advanced cooling hydraulic oil chillers are used.

Glycol Chiller

Glycol chillers are specialized chilling systems that are used to cool beverages and alcohol. They lower the temperature of a product rapidly and use its anti-freezing properties as these are the main requirements in beverage industries. The chiller is also used in supermarkets for chilling of soft drinks.

Commercial Heat Pump

Some of the examples of heat pumps are freezers and air conditioners. This device transfers heat to an outlet from where the heat is released into the atmosphere. The refrigerant is moved through the medium to remove the heat and changes its functions spontaneously.

Conclusion

Industrial Chiller Manufacturers in India are playing a pivotal role for almost all the industrial sectors have one technical issue in common. The issue faced by all is the problem of heat generation in industries irrespective of their sizes and sector. Chillers of different types have taken the initiative to address this problem.

0 notes

Text

In today's fast-paced industrial landscape, the demand for efficient and reliable hydraulic systems continues to grow. Hydraulic cylinders play a crucial role in numerous applications, and choosing the right manufacturer is essential to ensure optimal performance and durability. As a leading hydraulic cylinders manufacturer, we specialize in providing high-quality hydraulic cylinder and power pack solutions. In this article, we will delve into the importance of hydraulic cylinders, the key features that set apart high-quality products, the role of a leading manufacturer, an overview of hydraulic power pack solutions, tips for selecting the right hydraulic solutions, and future trends in the industry.

Understanding Hydraulic Cylinders and Their Importance

Hydraulic cylinders are mechanical devices that convert the hydraulic energy from fluids under pressure into linear force and motion. They are widely used in various industries, including construction, agriculture, mining, and manufacturing. Their importance lies in their ability to generate immense force, execute precise movements, and deliver consistent performance. Whether it's lifting heavy loads, pushing or pulling objects, or controlling machinery, hydraulic cylinders provide the necessary power and control.

In the construction industry, hydraulic cylinders play a vital role in heavy equipment such as excavators, bulldozers, and cranes. These cylinders enable the machines to lift and move heavy materials with ease. Without hydraulic cylinders, the construction process would be much slower and more labour-intensive.

In the agricultural sector, hydraulic cylinders are used in farming equipment like tractors and harvesters. These cylinders help in tasks such as lifting and lowering attachments, adjusting the height of implements, and controlling the steering mechanism. They enhance the efficiency and productivity of farming operations, allowing farmers to accomplish tasks quickly and effectively.

Mining operations heavily rely on hydraulic cylinders for various applications. From underground mining equipment to surface mining machinery, hydraulic cylinders are used for tasks like rock drilling, material handling, and ore extraction. The power and precision of hydraulic cylinders make them indispensable in the mining industry, where productivity and safety are of utmost importance.

0 notes

Text

Understanding Hydraulic Machines: How They Work and HEICO's Best Offer

Hydraulic Machines have revolutionized industries worldwide, offering powerful solutions for a myriad of tasks ranging from construction to manufacturing. With their robust capabilities and efficient design, hydraulic machines have become indispensable in modern engineering. In this article, we'll delve into what hydraulic machines are, how they work, and explore the top-notch offerings from HEICO in Delhi.

What are Hydraulic Machines?

Hydraulic Machines an devices that utilize the power of hydraulic fluid to perform various mechanical tasks. They are widely employed in industries where heavy lifting, pressing, cutting, or shaping is required. These machines operate on the principles of Pascal's Law, which states that pressure applied to a confined fluid is transmitted undiminished in all directions.

How Hydraulic Machines Work

The core components of a hydraulic system include a hydraulic fluid, a reservoir, a pump, valves, actuators, and hydraulic cylinders. Here's how these components work together:

Hydraulic Fluid: Typically, oil-based fluids are used due to their excellent lubricating properties and resistance to compression.

Reservoir: The fluid is stored in a reservoir, ensuring a constant supply for the system.

Pump: The pump pressurizes the hydraulic fluid, generating the force necessary to drive the system.

Valves: Valves control the direction and flow of the hydraulic fluid, regulating the movement of actuators and cylinders.

Actuators and Hydraulic Cylinders: These components convert hydraulic energy into mechanical energy, enabling the machine to perform specific tasks such as lifting heavy objects, bending metal, or crushing materials.

When the pump applies pressure to the hydraulic fluid, it travels through the system, activating the actuators or cylinders to execute the desired action. The precise control afforded by hydraulic systems makes them ideal for tasks requiring immense force and accuracy.

Best Hydraulic Machine by HEICO

HEICO, a renowned Hydraulic Machine Manufacturer, offers top-tier solutions tailored to meet diverse industrial needs. Among their extensive range of products, one standout offering is their Hydraulic Press Machine.

The HEICO Hydraulic Press Machine is engineered with precision and durability in mind. It boasts a robust frame, advanced hydraulic components, and intuitive controls, ensuring optimal performance and reliability. Whether it's metal fabrication, molding, or assembly processes, this machine delivers exceptional results with unparalleled efficiency.

Conclusion

Hydraulic machines have revolutionized the way industries operate, providing powerful solutions for a wide array of tasks. Understanding the principles behind hydraulic systems sheds light on their versatility and effectiveness in modern engineering. With HEICO's superior Hydraulic Press Machine leading the pack, businesses in Delhi can harness the power of hydraulic technology to elevate their operations.

For businesses in Delhi looking to invest in hydraulic machines, HEICO offers the best Hydraulic Machine Prices without compromising on quality. Their commitment to excellence and customer satisfaction makes them a trusted choice among hydraulic machine manufacturers in the region.

In conclusion, hydraulic machine continue to play a pivotal role in shaping the industrial landscape, driving efficiency, productivity, and innovation across various sectors. As technology advances, we can expect hydraulic systems to evolve further, empowering industries with even greater capabilities and performance.

#Hydraulic Machines#Hydraulic Machines Prices#Hydraulic Machines Price#Hydraulic Machine Manufacturer

0 notes

Text

Metal Plate Rolling Machines: Working, Intricacies & Functionalities

Have you ever wondered how these huge tanks and machines are built? In childhood, I thought they just melted iron or metal and let it dry. Little did I know about the concept of metal plate rolling machines.

Metal plate rolling machines give the conical and cylindrical shapes or bend the metal plates at required angles. This is how workshops worldwide utilize metal plate rolling machines for manufacturing.

We know what you are thinking. “How does that happen? Sheets are fine, but how do you roll or bend a metal plate?” It’s due to the malleability and ductile strength of metal plates.

Malleability is a metal’s ability to be formed into sheets. Ductile strength is how much pressure a metal plate can take to be rolled and not break.

But how does it work?

How does the machine roll these thick and hard metal plates?

We will answer all the questions making circles in your mind. However, to understand how a plate rolling machine works, let’s first understand what functions different parts of a plate rolling machine serve.

In-Depth Look at Different Parts of a Plate Rolling Machine

These machines are extremely heavy-duty, and their build is as solid. Every part of these machines plays an important role in plate rolling.

Let’s explore what these 20 parts of a plate rolling machine do:

1) Frame — It is the body of a plate rolling machine. Provides stability and structural support.

2) Upper Roll — Upper roll is mostly an idler. It rotates at its place and doesn’t move up, down or toward sides.

3) Bottom Rolls — They move up, down, and sideways to adjust the metal plate and roll it at a desired angle to form a cylinder, cone, or arc.

4) Side Rolls — Side rolls support metal plates to maintain uniform rolling.

5) Support Rolls — Same as side rolls, they provide support for metal plates.

6) Drive System — Transfers power from the hydraulic system to rolls for rotation and movement.

7) Control Panel — All the rotational, pressure and other machine controls are housed here.

8) Hydraulic System — Powers roll movements and control precision in plate rolling.

9) Guide Rolls — Makes sure the alignment of a metal plate is accurate while passing through rolls

10) Pinch Rolls — Their dedicated function is to feed the plate into the machine.

11) Pre-Bending Rolls — Utilized for pre-bending on the plate edges.

12) Anti-Deflection System — Negates powers causing plate deflection and minimizes deflection during the rolling process.

13) Lateral Guide System — Ensures proper alignment of the metal plate

14) Clamping System — It holds the metal plate firm while the rolling job is underway.

15) Digital Display — DRO (Digital Readout) displays measurements and settings of different pressure and motor systems. Also helps in repeating a job if the reading are pre-recorder.

16) Lubrication System — To reduce wear and tear, the lubrication system keeps rolls, motors, and other parts prone to depreciation lubricated.

17) Cooling System — Cools down hydraulic oil, which is getting circulated between the hydraulic power pack and all hydraulic cylinders/hydro motors.

18) Material Handling System — Makes it easier to load and unload metal plates to and from the machine.

19) Tilting Table — Helps feed metal plates at a fixed angle. Largely used for heavy/thick metal plates.

20) Conveyors — Makes it easier to feed longer metal plates to the plate rolling machines.

For some parts of these machines, you would think they do the same thing. However, the case is this machine does only one work, i.e., rolling metal plates. So many parts only coordinate and perform this function to achieve near-perfect accuracy for rolled metal plates.

Moving forward to how a plate-bending machine works.

Working Mechanism of a Plate Rolling Machine: Explained!

The number of rolls in a plate rolling machine varies depending on the requirements of a workshop. Generally, there are either 3 or 4 rolls in plate rolling machines. It is because these machines roll metal plates of thicknesses that are required in most applications.

There have also been 5, 6, 7, and even 8 rolls in a single plate rolling machine! It is to be noted that the requirement for these types of machines is scarce. They are only custom-made due to a lack of buyers. 3 and 4 roll plate rolling machines are the most commonly used machines. Therefore, today we will understand the working of 3 and 4-roll plate rolling machines.

Part 1 — How Does a 3-Roll Plate Rolling Machine Work?

A 3-roll plate rolling machine is your go-to choice for rolling thin metal plates up to 3–4 inches. It provides precision and is more cost-effective than a 4-roll plate rolling machine. The only thing to remember is the thickness of the plate you want to roll.

You need to perform three steps while rolling a metal plate on a 3-roll plate rolling machine.

Pre-bending

Center alignment

Roundness correction.

An operator will obtain the metal plates and check for defects. It is important to do so to steer clear of failed rolling attempts in the future. They will also check for material quality and specifications to be at par with national or international standards.

The operator will turn on the machine after checking the lubrication system. They will derive the machine’s status by observing the rolls and the pressure by looking at a Digital Readout. The machine is now ready for pre-bending.

Step 1: Pre-Bending on 3-Roll Plate Rolling Machine

The side rolls are placed closer, and a metal plate is fed to the machine to receive the initial bend. Now the machine is turned on to commence the metal plate rolling process.

The top roll exerts pressure on the plate, while the side rolls apply pressure to the sides. To achieve the desired curvature, the operator adjusts the angle and placement of the metal plate.

Here’s an image to understand how pre-bending shapes the tail and edge of a metal plate.

Step 2: Center Alignment on a 3-Roll Plate Rolling Machine

Upon the completion of pre-bending, it is now time to align the metal plate in the center so that the power is distributed uniformly throughout the surface.

The operator will now adjust the side rolls to put the plate firmly. Next, they will check alignment and fine-tune adjustments.

Once the operator is satisfied with the center-aligning of the plate, they will secure it in place using the clamp system.

Step 3: The Real Rolling Process

Pressure and rotation parameters are now set, and the plate is in place. Next, the operator lets the plate pass through the rolls.

Step 4: After-Rolling Roundness Correction

The metal plate might have some deflection. They check if a perfect cylindrical or an arc is forming. If it isn’t, there is a need for roundness correction. The operator now asks the laborers to make sure both ends meet correctly.

Let’s move to the working of the 4-roll plate bending machine.

Part 2 — How Does a 4-Roll Plate Rolling Machine Work?

The most beneficial thing about 4-roll plate rolling machines is that they give desired results within a single feed. It means that a workshop can get its rolling job done in half the time compared to a 3-roll plate rolling machine, which has to be fed twice for pre and post-bending and rolling.

There are three bottom rolls and a top roll. More bottom rolls result in better accuracy and precision throughout the rolling procedure.

Once the operator has obtained the metal plate, they will check for the material, its ductile strength, and malleability. After confirming that the metal plate meets national or international standards (according to where the machine will be used), they will set the diameter, pressure, and rotational parameters for the metal plate.

The Single-Step Rolling Process

Pre-bending, rolling, and post-bending are all done in a single feed. The operator inserts the metal plate between the top and bottom rollers.

Pre-pinching is done upon the metal plate entering the machine. Then it rolls into a desired cylindrical or conical shape.

Once the rolling process is complete, the metal plate gets post-bent, ending the process of rolling.

It is necessary to understand that both these machines can roll the same thickness of metal plates (a 4-roll plate rolling machine can also roll thicker ones with better precision), but 4-roll cousins are beneficial as they save half the time.

A 3-roll plate rolling machine would be a good choice if one is tight on their budget. Otherwise, there is no better investment than a 4-roll plate rolling machine. Talking about investments. It is necessary to perform maintenance of your machine. The machine manual will have the directions for maintenance. But we have some tips for you to keep your plate rolling machine’s efficiency at its best.

Quick Maintenance Tips for Plate Rolling Machines

Follow these 6 essential tips for machine maintenance.

1) Inspecting the plate rolling machine — Check the bearings, gears, rollers, frame, hydraulic systems, and other parts of the machine.

2) Take precautionary protocols for machine maintenance — Don’t use solvents or inflammable materials, and make sure grease doesn’t disperse in the air.

3) Perform detailed inspection before rolling the metal plate — Check if external parts, indicator lights, and the pressure gauge are working properly. Also, check for leakage in tubes and pipes.

4) Perform weekly maintenance of the plate rolling machine.

5) Perform monthly maintenance of the machine.

6) Annual maintenance is extremely important as you need to check if any part needs replacement.

You can also read our informative article “A Complete 6-Step Guide to Maintenance of Plate Rolling Machine” to learn more about machine maintenance.

To Conclude

Plate rolling machine is a highly mechanical equipment. You must know which machine your workshop requires to make the most out of it. While a 3-roll machine is cheaper, a 4-roll plate rolling machine will double the productivity. Your choice can always depend on your priority needs.

We hope this article has helped you with questions in your mind. Feel free to ask any questions and contact us, Himalaya Machinery, if you have a plate rolling machine requirement.

original source :https://www.himalayamachine.com/post/metal-plate-rolling-machines-working-intricacies-functionalities

#3 roll bending machine#3 roller plate rolling machines#plate bending machine price#3 roll plate rolling machine#banding machine#plate bending machine#3 roll plate bending machine#4roll bending machine#roll bending machine#4 roll plate bending machine

0 notes