#Hydrostatic & Performance Tests

Text

Witness Inspection: Quality Assurance at its Best!

Look no further! AQSS-USA's Witness Inspection services are here to uphold the utmost standards of quality and compliance.

+1 713-789-0885 | [email protected] |

#witness inspection services#oil and gas inspection services#hydrostatic & performance tests#aerospace and defense inspection services#witness inspection#gap and internal auditing services#third party industrial inspection services#welding inspection services#nuclear inspection services#first article inspection services

2 notes

·

View notes

Text

#Oil and gas Auditing Services#oil and gas inspection Services#Aerospace and defense inspection Services#Nuclear Inspection Services#Quality Auditing Services#Quality Inspection Services#Factory Acceptance Test#NDE Inspection Services#NDT Inspection Services#First Article Inspection Services#Heat Treatment Services#Hydrostatic & Performance Tests#Welding Inspection Services#expediting services

0 notes

Text

How to Identify High-Quality ERW Pipes: Key Factors to Consider

When looking for a supplier of ERW (Electric Resistance Welded) pipes, it is crucial to pick high-quality items that may be customized to your needs. Because of its reliability, strength, and low price, ERW pipes have found widespread use in many different fields. This blog will help you choose which ERW pipes are of the highest quality by outlining the criteria you should use to make your selection. Tube Trading Co. is a great ERW Pipe Dealer in Gujarat, for those who are in search of a trustworthy ERW pipe dealer. We are a reliable ERW pipe provider, supplier, and distributor in Gujarat, and we stock a comprehensive inventory to meet your requirements.

· Manufacturing Standards:

Maintaining strict quality control during production is a vital part of making high-quality ERW pipes. Pipes should meet the standards set forth by the American Society for Testing and Materials (ASTM), the Indian Standards (IS), or any other applicable organizations. To put your mind at ease, Tube Trading Co. checks each batch of ERW pipes we produce to make sure it conforms to all applicable requirements.

· Material Quality:

The performance and durability of ERW pipes are profoundly affected by the quality of the raw materials used in their construction. The best ERW pipes are fabricated from high-quality steel that is both durable and resistant to corrosion. Tube Trading Co. only buys its raw materials from reliable vendors, so you know you're getting high-quality ERW pipes from the most distinguished ERW Pipe Provider in Gujarat.

· Welding Technique:

The welding method used to construct ERW pipes has a major impact on the durability of the finished product. Look for pipes that have been welded using precise processes to produce strong, uniform welds. Tube Trading Co. utilizes cutting-edge welding methods and meticulously supervises the welding process to produce durable ERW pipes suitable for a wide range of applications.

· Dimensional Accuracy:

For a trouble-free assembly and optimal fit with other parts, precise dimensions are required. The dimensions of high-quality ERW pipes, including their OD, ID, and wall thickness, are all precisely measured. The ERW pipes sold by Tube Trading Co. are guaranteed to have precise dimensions for a snug fit and superior performance in your machinery.

· Surface Finish:

Surface Finish High-quality ERW pipes always have a homogeneous and polished surface finish. A smooth, well-finished surface reduces the potential for corrosion, improves the visual appeal, and allows for more effective fluid or gas flow. The ERW pipes sold by Tube Trading Co. – a renowned ERW Pipe Supplier in Gujarat have excellent surface quality, guaranteeing their practicality and aesthetic appeal.

· Testing and Certification:

Look for pipes that have been put through a battery of tests, such as hydrostatic, ultrasonic, and eddy currents. The ERW pipes' quality and dependability have also been verified by third-party certificates. Tube Trading Co. has certifications proving the quality of their ERW pipes and conducts rigorous testing to ensure this.

Advantages of using ERW Pipes:

ERW (Electrical Resistance Welded) pipes are widely used because of their many benefits, including;

● Cost-Effective: When compared to other pipe options, such as seamless pipes, the price of ERW pipes is far lower. ERW pipes have lower production costs because of their simpler and more efficient manufacturing method.

● High Strength: The strength and durability of ERW pipes are well-known. The welding procedure employed during production fortifies the connection between the pipes, making them resistant to stress and pressure.

● Versatility: The wide range of sizes, shapes, and wall thicknesses available for ERW pipes makes them an extremely flexible material.

● Easy Installation: Due to their uniform dimensions and tight tolerances, ERW pipes are a breeze to set up. Their exact OD, ID, and wall thickness assure a snug fit and the ability to work with a wide variety of other parts.

● Corrosion Resistance: Longevity Improvement & Environmental Protection Coatings/Materials that resist corrosion can be used during the production of ERW pipes.

● Environmentally Friendly: Due to its efficient production method, ERW pipes are regarded as environmentally benign. When compared to conventional pipe production methods, they result in less waste and fewer carbon emissions.

Final Thoughts:

Taking into account the aforementioned criteria when shopping for ERW pipes will help you choose products of the highest quality that are suited to your demands. The ERW pipes sold by Tube Trading Co., an excellent ERW Pipe Distributor in Gujarat, are of the highest quality, manufactured to exacting standards, and boasting exceptional material quality, precise dimensions, superb surface finish, and thorough testing. When you work with Tube Trading Co., you can rest assured that your ERW pipe solutions will last for years to come.

#ERW Pipe Dealer in Gujarat#ERW Pipe Provider in Gujarat#ERW Pipe Supplier in Gujarat#ERW Pipe Distributor in Gujarat#distributor#Jindal pipes#steel industry#steel companies#industrial#plumbing industry#construction structure#construction sites

6 notes

·

View notes

Text

Stainless Steel 316 Seamless Tubes Stockists In Mumbai

Metinox Overseas: Premier Stainless Steel 316/316L Seamless Tubing Manufacturer, Supplier, Stockist, and Exporter in Mumbai, India

Metinox Overseas stands out as a leading manufacturer, supplier, stockist, and exporter of Stainless Steel 316/316L Seamless Tubing in Mumbai, India. Our commitment to excellence ensures that each tube is meticulously tested and inspected by industrial experts, guaranteeing the highest quality standards, free from creases or damages, before reaching our esteemed clients.

Comprehensive Testing for Superior Quality

At Metinox Overseas, we prioritize quality through rigorous testing procedures for our Stainless Steel 316L Seamless Tubes. Our comprehensive array of tests includes:

Eddy Current Testing

Hydrostatic Testing or Ultrasonic Examination

Non-Destructive Testing (NDT)

Chemical and Physical Property Inspections

Additionally, we perform:

Chemical Analysis

Mechanical Tests

Rockwell Hardness Tests

Intergranular Corrosion Tests

Positive Material Identification (PMI)

Flattening and Flaring Tests

Third-Party Inspections

Exceptional Features and Applications

The inclusion of molybdenum in our alloys enhances corrosion resistance, making our Stainless Steel 316 Seamless Tubes ideal for various demanding applications. The austenitic structure of these tubes ensures exceptional toughness, while nickel and molybdenum significantly improve their strength and resistance to corrosion. These grades also exhibit excellent weldability, both with and without filler metal, offering versatility and ease of use in numerous applications.

Versatility of Stainless Steel 316/316L Grades

Stainless Steel 316/316L grades are highly sought after for their superior mechanical and corrosion properties. The straight 316 grade is suitable for pressure or structural applications, while the 316L grade, with its lower maximum carbon limit, is ideal for projects requiring long-term durability and sustainability. Notably, 316L is 100% recyclable, underscoring its environmental benefits. Our SS 316L Seamless Tubing is extensively used in process engineering, control lines, and heat exchangers, especially in aggressive environments where corrosion resistance is crucial.

Commitment to Excellence

At Metinox Overseas, our dedication to excellence goes beyond manufacturing top-quality products. We strive to provide our customers with informative, engaging, and optimized content for search engines. This ensures that when you choose Metinox Overseas, you're receiving not only premium-grade Stainless Steel 316 Seamless Tubes but also a wealth of valuable information.

Specifications of Stainless Steel 316 Tubes

Specifications: ASTM A213 / ASME SA213

Outside Diameter: 1/8″ OD to 2″OD, 3mm OD to 38mm OD

Thickness: 1mm to 3mm, 0.028 to 0.156 inches, SCH 5, SCH 10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS

Size: 1/2″ NB – 24″ NB

Type: Seamless / Capillary Tubes

Form: Round Tubes, Square Tubes, Rectangular Tubes

Length: Single Random, Double Random & Required Length

End: Plain End, Beveled End, Threaded

Finish: Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Equivalent Grades of Stainless Steel 316 Tubes

STANDARD: UNS S30403, WERKSTOFF NR. 1.4301, AFNOR Z7CN18‐09, EN X5CrNi18-10, JIS SUS 304, BS 304S31, GOST 08Х18Н10

Chemical Composition and Mechanical Properties

Chemical Composition: C: 0.08, Mn: 2.0, Si: 0.75, P: 0.045, S: 0.030, Cr: 18.0-20.0, Mo: –, Ni: 8.0-10.5, N: 0.10

Mechanical Properties: Tensile Strength (MPa) min 515, Yield Strength 0.2% Proof (MPa) min 205, Elongation (% in 50mm) min 40, Hardness Rockwell B (HR B) max 92, Brinell (HB) max 201

Contact Us

For the best in Stainless Steel 316 Seamless Tubes, trust Metinox Overseas for quality and reliability. Contact us at:

Phone: +91-98199 80997 / +91-70212 61928

Metinox Overseas is dedicated to maintaining its reputation for excellence in manufacturing, supplying, stocking, and exporting top-quality stainless steel seamless tubing. Trust Metinox Overseas for all your stainless steel tubing needs, where quality and reliability are guaranteed.

0 notes

Text

The Language Of Technology Is Universal, And Solis Tractors Are Fluent Speakers.

Solis Tractors are essential to the empowerment of small-scale farmers and the global acceleration of rural development. By virtue of their dedication to innovation, affordability, and community involvement, these tractors help farmers reach their maximum potential and conquer the numerous obstacles they encounter.

Solis Small Farm Tractors are not just machines; via increasing productivity, expanding access to technology, and stimulating economic growth, they are change agents that are changing people’s lives and means of subsistence in rural areas all over the world. Let’s continue to use innovation and mechanization to our advantage as we look to the future of agriculture to create a more wealthy and sustainable planet for future generations.

The language of technology is universal, and Solis Tractors are fluent speakers. From intuitive interfaces to state-of-the-art technology, these tractors embody the cutting edge of agricultural technology. Whether you are a tech-savvy farmer in Silicon Valley or a traditionalist in the heart of the Amazon rainforest, Solis Tractors’ technology bridges the gap.

Our range of tractors is known to be the mightiest and toughest among all the tractor brands in the tractor industry. These farm professionals aim to deliver exceptional results across all terrains with seamless controls. With Solis, you can transform your farming into a breadth-taking experience by taking your maneuvers beyond limitations..

One of the key features that sets Solis tractors apart is their compatibility with a wide range of implements and attachments.

Solis tractors can seamlessly accommodate these implements whether you need to plow, cultivate, seed, mow, or perform other tasks. This adaptability allows you to switch between different functions without needing multiple machines, saving time and money.

Safety is also a top priority. Solis tractors come with modern safety features, including rollover protection structures (ROPS) and seat belts to safeguard the operator in an accident. Furthermore, these tractors have well-designed lighting systems, enhancing visibility during night operations or adverse weather conditions.

Solis farm tractors are integrated with marvelous features that offer versatility and success in every maneuver and venture. Solis farm tractors are known to be the toughest among all the tractors in the industry, as these farm champions aim to deliver nothing less than exceptional results on all terrains with smooth controls.

Investing in farming equipment is a substantial decision, and farmers require machinery that can withstand the test of time. Solis Small Tractors For Sale are engineered with durability and constructed from high-quality materials that can endure the rigors of intensive use. Their reputation for reliability is further bolstered by comprehensive warranty coverage and responsive customer support.

The Solis H Series is a heavy-duty compact tractor that easily handles the most demanding hobby tasks. The tractor’s powerful engine and hydrostatic transmission provides the horsepower and torque needed to tackle even the most challenging tasks.

The tractor’s advanced hydraulics enable it to handle various attachments, making it even more versatile and valuable on the farm. With its power and performance capabilities, the Solis H Series can help farmers get more done in less time, increasing productivity and efficiency on the farm.

0 notes

Text

Which fabric is 100% waterproof? | Sofa Fabrics | Outdoor Fabrics | Cushions Fabrics | Chair Fabrics | Curtain Fabrics | Fire Retardant Fabrics | Asadeep Furnishing Pvt. Ltd.

Which fabric is 100% waterproof?

Have you ever been caught in a sudden downpour, only to find your supposedly waterproof jacket soaked through? The quest for 100% waterproof fabric is one that outdoor enthusiasts, athletes, and everyday adventurers alike are constantly pursuing. In this comprehensive guide, we delve into the world of waterproof fabrics to unravel the mystery behind what truly makes a fabric impervious to water. Discover the science, innovation, and practical tips that will equip you with the knowledge needed to stay dry in any weather condition.

Embark on a journey with us as we explore the intricacies of waterproof fabrics — from their composition and testing methods to debunking common misconceptions. Uncover the latest advancements in textile technology that promise unparalleled protection against moisture. By the end of this article, you will not only be informed but also empowered to make informed decisions when selecting 100% waterproof fabrics for your outdoor pursuits or everyday wear.

Decoding Waterproof Fabrics

When it comes to deciphering the realm of waterproof fabrics, it is crucial to understand the technology behind them. These high-performance textiles are designed to repel water and prevent moisture from seeping through, making them essential for outdoor enthusiasts, professionals in various industries, and everyday individuals seeking reliable protection against the elements.

From breathable membranes to durable water repellent (DWR) coatings, waterproof fabrics utilize advanced engineering to ensure maximum protection without compromising comfort. By delving into the intricacies of these textiles, we can appreciate the meticulous craftsmanship that goes into creating 100% waterproof fabrics that stand as a testament to human innovation and ingenuity.

The Anatomy of a Waterproof Fabric

Behind the seemingly simple facade of a waterproof fabric lies a complex construction designed to keep you dry in the harshest conditions. At its core, a waterproof fabric consists of multiple layers meticulously engineered to repel water while allowing moisture from sweat to escape, ensuring comfort and protection simultaneously.

Typically, the outer layer of a waterproof fabric is treated with a durable water repellent (DWR) coating, which causes water to bead up and roll off the surface. Beneath this lies a waterproof membrane such as Gore-Tex or eVent, serving as the barrier that prevents water from penetrating while still facilitating breathability.

Testing Waterproofness: What to Look For

When evaluating the waterproofness of a fabric, it’s essential to look beyond just its appearance. A key factor to consider is the fabric’s hydrostatic head rating, which measures its ability to withstand water pressure. Fabrics with a higher hydrostatic head rating are more likely to provide better waterproof protection. Additionally, seam sealing is crucial in preventing water penetration through stitching holes, ensuring complete waterproofness.

Another aspect to keep in mind when testing waterproofness is breathability. While it’s important for a fabric to keep water out, it should also allow moisture vapor to escape from within, preventing that clammy feeling.

Common Misconceptions about Waterproof Fabrics

One common misconception about waterproof fabrics is that they are all heavy and bulky. While some waterproof materials may have a heavier feel, advancements in technology have led to the development of lightweight, breathable fabrics that offer superior water resistance without sacrificing comfort or style. It’s important for consumers to explore the wide range of options available to find a fabric that meets their needs without compromising on performance.

Another myth surrounding waterproof fabrics is that they are not breathable. In reality, many modern waterproof textiles are designed with breathability in mind, allowing moisture vapor to escape while still keeping water out. By understanding the innovative construction techniques and materials used in creating waterproof fabrics, individuals can make informed decisions that align with both their practical requirements and aesthetic preferences.

Innovations in Waterproof Fabrics

Technology has propelled the evolution of waterproof fabrics to new heights, with cutting-edge innovations that push the boundaries of performance. From advanced membrane technologies like Gore-Tex to revolutionary eco-friendly coatings, the industry continues to redefine what it means to be truly waterproof.

One exciting development is the integration of nanotechnology into fabric production, creating ultra-thin layers that repel water on a molecular level. Additionally, the use of recycled materials in waterproof fabrics not only enhances sustainability but also showcases a commitment to environmental stewardship.

The Ultimate Guide to Caring for Waterproof Fabrics

Proper care and maintenance are essential for preserving the waterproof qualities of your fabrics. To keep your 100% waterproof fabric in top condition, start by regularly cleaning it with a gentle detergent or specialized cleaner recommended by the manufacturer. Avoid using harsh chemicals or bleach, as they can degrade the fabric’s water-resistant coating.

When it comes to drying your waterproof fabric, never machine dry or iron it, as excessive heat can damage the waterproof membrane. Instead, air-dry your fabric in a well-ventilated area away from direct sunlight.

Real-Life Applications of Waterproof Fabrics

Waterproof fabrics play a crucial role in various real-life applications, ranging from outdoor gear to medical devices. Outdoor enthusiasts rely on waterproof jackets and camping equipment to stay dry and comfortable in unpredictable weather conditions. In the medical field, waterproof fabrics are used in protective clothing, bandages, and hospital bedding to maintain hygiene standards and prevent liquid penetration.

Furthermore, waterproof fabrics find extensive use in the marine industry for sails, boat covers, and protective gear for sailors. In the automotive sector, waterproof materials are integrated into car interiors to enhance durability and resistance to spills.

Choosing the Right Waterproof Fabric for Your Needs

When selecting a 100% waterproof fabric, consider the intended use and environment. For outdoor activities like hiking or camping, opt for durable fabrics such as Gore-Tex or eVent that offer both waterproofing and breathability. For more casual wear, fabrics like polyurethane-coated nylon can provide adequate protection against rain showers.

It’s crucial to also assess the level of waterproofness required. Fabrics with a high hydrostatic head rating are ideal for heavy rain conditions, while those with taped seams offer extra protection against water penetration.

Investing in Quality: Benefits of 100% Waterproof Fabrics

When it comes to investing in quality, opting for 100% waterproof fabrics can bring a myriad of benefits. Not only do these fabrics provide unparalleled protection against moisture, but they also offer superior durability and longevity, making them a wise choice for those seeking long-term value and performance.

By choosing 100% waterproof fabrics, you are not only safeguarding yourself from the elements but also ensuring peace of mind knowing that your belongings are protected. Whether it’s a high-quality rain jacket or durable outdoor gear, investing in these fabrics means investing in reliability and resilience, allowing you to enjoy your adventures without worrying about the weather conditions.

Conclusion

As we conclude our exploration of waterproof fabrics, it becomes evident that the evolution of technology and innovation has revolutionized the way we protect ourselves from the elements. From cutting-edge materials to advanced manufacturing techniques, the world of waterproof fabrics continues to expand and improve.

#fabrics#textiles#asadeep#curtain fabric manufacturers in india#textile art#asadeepfurnishingdelhi#asadeepfurnishing#sofa upholstery fabric manufacturers in india#outdoor fabric manufacturers in india#chair fabric manufacturers in india

0 notes

Text

Unraveling the Power of Uniaxial Geogrids: Building Stronger Retaining Walls with Singhal Industries

In the realm of civil engineering and construction, retaining walls play a vital role in supporting soil and preventing erosion. However, the effectiveness and longevity of these walls depend largely on the materials used in their construction. One such material that is revolutionizing retaining wall design and construction is the uniaxial geogrid. Singhal Industries Pvt Ltd, a pioneering packaging company of Geogrid manufacturing in India with high-quality geogrids. Let's explore the significance of uniaxial geogrids in retaining wall projects and the role they play in ensuring stability and durability.

Understanding Uniaxial Geogrids:

Uniaxial geogrids are synthetic materials made from high-density polyethylene (HDPE) or polyester (PET) fibers, also known as HDPE uniaxial geogrid , woven or knitted into a grid-like structure. These geogrids are designed to provide reinforcement and stabilization to soil structures, improving their load-bearing capacity and preventing soil movement.

Role of Uniaxial Geogrid in Retaining Wall Design:

In retaining wall construction, uniaxial geogrids are typically used to reinforce the soil behind the wall, known as the backfill. By incorporating geogrids into the design, engineers can create stronger and more stable retaining walls capable of withstanding higher loads and resisting external forces such as earth pressure and surcharge loads.

Key Benefits of Uniaxial Geogrids:

Enhanced Stability: Uniaxial geogrids act as a stabilizing force within the soil, preventing lateral movement and reducing the risk of wall failure or collapse. This increased stability allows for the construction of taller and more slender retaining walls, maximizing land usage and minimizing excavation.

Improved Drainage: The open-grid structure of geogrids promotes efficient drainage within the backfill, preventing the buildup of hydrostatic pressure and water-related damage. This helps maintain the structural integrity of the retaining wall and prolong its service life.

Cost-Effectiveness: By reducing the need for extensive excavation and traditional reinforcement materials such as steel, uniaxial geogrids offer a cost-effective solution for retaining wall construction. Their lightweight and easy-to-install nature further contribute to overall project savings. Find out Geogrid prices India.

In conclusion, uniaxial geogrids play a crucial role in enhancing the stability and durability of retaining walls, making them indispensable in modern construction projects. With Singhal Industries' expertise in manufacturing high-quality geogrids, engineers and contractors can confidently design and build robust retaining walls capable of withstanding the test of time.

Frequently Asked Questions:

1.What is the price of geogrid fabric in India?

Singhal Industries offers competitive pricing for its Geogrid fabric products in India, with rates varying depending on factors such as material type, strength, and quantity ordered. Customers can request a quote from Singhal Industries based on their specific project requirements.

2.Who are the leading geogrid manufacturers in India?

Singhal Industries is recognized as one of the leading Geogrid manufacturers in India, known for its high-quality products and commitment to customer satisfaction. With state-of-the-art manufacturing facilities and a team of experienced professionals, Singhal Industries delivers innovative geogrid solutions tailored to meet the diverse needs of the construction industry.

3.What is the price of HDPE uniaxial geogrid?

The price of HDPE uniaxial geogrid may vary depending on factors such as strength, width, and quantity ordered. Singhal Industries offers competitive pricing for its HDPE geogrid products, ensuring cost-effective solutions without compromising on quality or performance. Customers can request pricing information from Singhal Industries based on their specific project requirements.

0 notes

Text

Orifice Flanges Exporters in India

Introduction

Universe Metal & Alloys has extensive experience in manufacturing and supplying all types of pipe fittings. The entire manufacturing process is supported by trained professionals who have extensive experience in handling different types of pipe fittings and other products.

Description

Universe Metal & Alloy stands tall as one of the leading Manufacturers, Suppliers, Stockists, and Exporters of Orifice Flanges in India. With a rich legacy and a commitment to quality, we have carved a niche for ourselves in the competitive metal market. Our dedication to Suppliers to international and national quality standards sets us apart, making us a trusted name in the industry.

At Universe Metal & Alloy, we take pride in our Stainless Steel Orifice Flanges, which are meticulously designed and developed to meet the diverse needs of various industries. Crafted with precision and excellence, our ASTM A182 Stainless Steel Orifice Flanges are renowned for their durability and reliability, making them ideal for a wide range of piping applications across sectors such as Chemical, Petrochemical, Building, Construction, and more.

Benefits:

Accuracy and Reliability: Orifice flanges provide precise flow measurement, which is essential for process control and optimization.

Versatility: Suitable for a wide range of applications, including water, oil, gas, and steam.

Cost-Effective: They offer an economical solution for flow measurement, especially in large-scale industrial applications.

Durability: Made from robust materials, these flanges can withstand harsh operating conditions, ensuring long-term performance.

Ease of Installation and Maintenance: Orifice flanges are designed for easy integration into existing piping systems and require minimal maintenance.

Specification:

ASME B16.5 Orifice Flange Size Chart1/2" (15 NB) to 48" (1200NB) DN10~DN5000grooved Orifice flange StandardsANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092Spectacle Flange Pressure Rating ANSIClass 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Spectacle FlangeSpectacle Flange Pressure Calculation in DIN6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Spectacle FlangeJIS5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Spectacle FlangeUNI6Bar 10Bar 16Bar 25Bar 40Bar grooved Orifice flangeEN6Bar 10Bar 16Bar 25Bar 40Bar Forged grooved Orifice flangeCoatingOil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized ASME B16.5 Orifice FlangeMost common types of Orifice FlangeForged / Threaded / Screwed / PlateTest CertificatesEN 10204/3.1B

Raw Materials Certificate

100% Radiography Test Report

Third Party Inspection Report, etcProduction technique

Forged, Heat treated and machined

Connect Type/ Flange Face TypeRaised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, GrooveSpecial designAs per your drawing

AS, ANSI, BS, DIN and JIS

15 NB (1/2″) to 200 NB (8″)

Equal and Reducing ConfigurationsTestDirect-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detectorEquipmentPress machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etcOriginIndian / West Europe / Japan / USA / KoreanManufacturer of

ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

Spectacle Flange: -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange

B.S: BS4504 , BS3293, BS1560, BS10

AS 2129: Table D; Table E; Table H

ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48

ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

American standard (ANSI)

German (DIN)

British standard (BS)

DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 Forged grooved Orifice flange

The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276

grooved Orifice flange Uses & application

Bitumen upgraders.

Heavy oil refineries.

Nuclear power (mostly seamless).

Petrochemicals and acids.

Export toIreland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc

Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175

Product Overview:

At Universe Metal & Alloys, our orifice flanges are designed and manufactured to the highest standards. Each product undergoes rigorous quality control to ensure it meets the specific requirements of our clients. Our orifice flanges are suitable for a variety of applications, including chemical processing, petroleum refining, power generation, and water treatment. With a commitment to excellence, we provide detailed product information, technical support, and competitive pricing to meet the needs of our customers.

Conclusion:

Orifice flanges are an indispensable component for accurate flow measurement in industrial piping systems. Universe Metal & Alloys is dedicated to delivering high-quality orifice flanges that meet the exacting standards of various industries.

For more information or to place an order, please contact us at [email protected] or call us at +91-22-66363360 / 66393788.

0 notes

Text

Peace of Mind: Your Go-To Fire Extinguisher Inspection Services Nearby

Introduction:

Fire extinguishers are crucial safety devices that can help prevent small fires from escalating into major disasters. However, like any piece of equipment, fire extinguishers require regular inspection and maintenance to ensure they are in proper working condition when needed. In this article, we'll delve into the importance of fire extinguisher inspection services, what they entail, and why they are essential for maintaining fire safety in various settings.

Importance of Fire Extinguisher Inspections:

Fire extinguisher inspections are a fundamental aspect of fire safety management. These inspections involve a thorough examination of each extinguisher to verify its operational status and compliance with safety standards. By conducting regular inspections, potential issues or defects can be identified early on, allowing for prompt repairs or replacements as needed. This proactive approach helps ensure that fire extinguishers are ready for use in the event of a fire emergency, providing peace of mind to property owners, occupants, and employees.

Frequency of Inspections:

The frequency of fire extinguisher inspections depends on various factors, including local regulations, the type of environment, and the specific hazards present. In general, fire extinguishers should be inspected at least annually by a qualified professional. However, certain environments, such as high-risk industrial settings or facilities with heavy foot traffic, may require more frequent inspections to ensure compliance and safety. Property owners should consult with fire safety experts to determine the appropriate inspection schedule for their specific needs.

What Happens During an Inspection:

During a fire extinguisher inspection, a trained technician conducts a comprehensive assessment of each extinguisher to verify its condition and functionality. This includes checking for visible signs of damage, such as dents, corrosion, or leaks, as well as ensuring that pressure gauges are within the recommended range. The technician also examines the extinguisher's accessibility, placement, and signage to ensure compliance with safety regulations. Additionally, certain types of extinguishers may require more specialized testing or maintenance procedures, such as hydrostatic testing for pressurized extinguishers.

Benefits of Professional Inspection Services:

While property owners may be tempted to conduct fire extinguisher inspections themselves, hiring a professional inspection service offers several advantages. Firstly, professional technicians have the expertise and training to identify potential issues that may not be apparent to untrained individuals. Their knowledge of fire safety regulations ensures that inspections are conducted in accordance with legal requirements, reducing the risk of non-compliance penalties or liabilities. Additionally, professional inspection services provide documentation of inspections and any recommended repairs or maintenance, which can be invaluable for record-keeping and insurance purposes.

Common Issues Detected During Inspections:

During fire extinguisher inspections, technicians commonly encounter a range of issues that may affect the extinguisher's performance or safety. These issues can include:

Improper placement or mounting of extinguishers, hindering accessibility in an emergency.

Missing or damaged signage indicating the location and type of extinguisher.

Excessive wear or corrosion on the exterior of the extinguisher, compromising its integrity.

Low pressure or over-pressurization of the extinguisher, affecting its ability to discharge effectively.

Expired or damaged inspection tags, indicating that the extinguisher has not been properly maintained or inspected.

Addressing these issues promptly through professional inspection services helps ensure that fire extinguishers remain reliable and effective in the event of a fire emergency.

Conclusion:

Fire extinguisher near me play a vital role in maintaining fire safety and compliance with regulations in various settings. By conducting regular inspections, property owners can identify and address potential issues with extinguishers before they escalate into serious problems. Hiring a professional inspection service offers numerous benefits, including expertise, compliance assurance, and documentation. Ultimately, investing in fire extinguisher inspection services provides peace of mind, knowing that your property is equipped with reliable and properly maintained fire safety equipment.

0 notes

Text

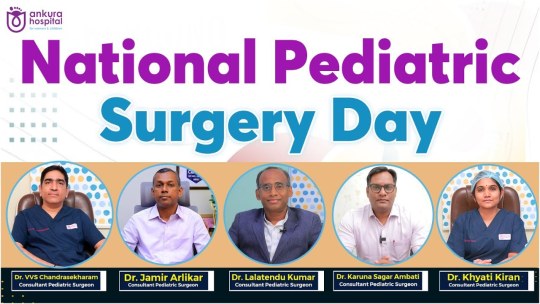

Ankura Hospital is well-recognized as the Best Pediatric Surgeon in Hyderabad. Our skilled and well-practiced doctors are specialized in providing advanced medical care to pediatric patients, from newborns to adolescents. They are extensively disciplined in medical specializations like Pediatric Neurology, Pediatric Rheumatology, Pediatric Cardiology, Pediatric Pulmonology, Pediatric Nephrology, Pediatric Endocrinology, Pediatric Dermatology, Pediatric Urology. One of the most important reasons behind Ankura’s success is our group of pediatric surgeons that is highly devoted and skilled in giving compassionate care and exclusive services to our young patients. Our team takes good care of the essential necessities of the children and their families.

Our division of Pediatric Urology at the Ankura Hospital is highly committed to providing the best quality surgical procedures for all types of genitourinary conditions in children. The common procedures performed by our Best Pediatric Urologist in Hyderabad include umbilical hernia repair, undescended testes, laparotomy for tumor or cyst excision, and ureteric reimplantation. Our Best Pediatric Surgeon in Hyderabad also holds expertise in hypospadias repair, circumcision, hydrostatic reduction of intussusception, collagen dressing for burns, or minor suturing.

Our pediatrics urologists not only have expertise in complex surgical procedures but also are skilled in advanced laparoscopic surgeries which are painless and scar-free. Our minimally invasive laparoscopic surgeries include laparoscopic repair of hernia, thoracoscopy CDH repair, laparoscopic appendectomy, orchiopexy, laparoscopic pyeloplasty, laparoscopic fundoplication and gastrostomy, and vescicoscopic ureteric reimplantation. Hence if you are willing to contact the Best Pediatric Urologist near me, the urology department of Ankura Hospital has got you covered.

Our pediatrics urologists specialize in cutting-edge services like urology, reconstructive urology, uro-oncology, kidney transplantation, and robotic surgery. We are standing out as the Best Pediatric Urologist in Hyderabad because of our state-of-the-art facilities. We understand that pediatric urologic conditions are more complex and sensitive as compared to adults. Our pediatric surgeons are practised enough to quickly identify and treat intricate conditions and minimize invasive tests and procedures.

Book an Appoint Now!

Ankura Hospital Hyderabad is the best pediatric surgeon & urologist nearby Best Pediatric Surgeon Hyderabad, Best Pediatric Urologist in Hyderabad, Best Pediatric Surgeon near me, Best Pediatric Urologist near me. For more information contact +91 9053 108 108.

youtube

#Best Pediatric Surgeon Hyderabad#Best Pediatric Urologist in Hyderabad#Best Pediatric Surgeon near me#Best Pediatric Urologist near me#Youtube

0 notes

Text

Expediting Services ,Speed Up Your Business with AQSS-USA!

Look no further than AQSS-USA's Expediting Services! We are your trusted partner in expediting solutions, ensuring your shipments reach their destinations in record time.

+1 713-789-0885 | [email protected]

#witness inspection services#hydrostatic & performance tests#welding inspection services#oil and gas inspection services#witness inspection#first article inspection services#nuclear inspection services#third party industrial inspection services#aerospace and defense inspection services#gap and internal auditing services

1 note

·

View note

Text

High-Quality Hydrostatic Pressure Test Pump Provided by Taruu

Discover the exceptional performance and reliability of the Hydrostatic Pressure Test Pump provided by Taruu. Designed for precision and durability, our test pump is ideal for testing the integrity and pressure-resistance of various systems, including pipelines, boilers, and pressure vessels.

Whether you're in the industrial, commercial, or residential sector, our Hydrostatic Pressure Test Pump ensures accurate results and long-lasting service. Trust Taruu for your pressure testing needs and experience unparalleled quality and efficiency.

Visit for more info : https://www.taruu.in/hydraulic-pressure-test-pump.html

Address : No. 5270 B, GB Road, New Delhi-110006, Delhi, India

Mail : [email protected]

Phone no : 91-98918 83887

0 notes

Text

Firefighting Pipes Manufacturers

Firefighting pipes are a specialized category of steel pipes used primarily in fire protection systems. They are designed to transport water and other extinguishing agents safely and efficiently to necessary points in a building or structure in case of fire. These pipes are subject to stringent manufacturing standards to ensure their reliability, durability, and resistance to heat and pressure.

Overview of Firefighting Pipe Manufacturing

1. Material Selection: Firefighting pipes are typically made from carbon steel or stainless steel, materials known for their high strength and resistance to heat. The choice of material often depends on the specific requirements of the fire protection system and the environment in which they will be installed.

2. Pipe Forming: Steel coils are uncoiled and flattened. The flat steel is then formed into pipe shapes using a process called Electric Resistance Welding (ERW). In this process, the edges of the steel are fused together using electric current and pressure.

3. Seam Welding: For firefighting pipes, the longitudinal seams are continuously welded to ensure watertight connections and to maintain the structural integrity under high pressure during use.

4. Galvanizing: To protect against rust and corrosion, which are critical in fire protection environments, the pipes are often galvanized. This involves dipping the formed pipes into a bath of molten zinc, creating a robust protective layer on the exterior and interior surfaces.

5. Threading and Grooving: Once the pipes are galvanized, they are threaded, grooved, or plain-ended depending on the connection method used in the installation. Threading and grooving are crucial for the secure attachment of fittings and couplings in fire protection systems.

6. Pressure Testing: To ensure that the pipes can withstand the operational pressures of firefighting systems, they undergo hydrostatic pressure tests. This test checks for leaks and verifies the strength and durability of the pipe.

7. Quality Control: Throughout the manufacturing process, quality control measures are strictly enforced. This includes checks on dimensions, material composition, and coating thickness to ensure that all specifications are met.

Applications of Firefighting Pipes

Fire Sprinkler Systems: These are the most common applications of firefighting pipes, used in residential, commercial, and industrial buildings to deliver water to sprinklers in the event of a fire.

Standpipe Systems: Used in large buildings, standpipe systems allow firefighters to connect hoses directly to a water supply, providing a consistent flow of water to combat fires on multiple floors.

Water Supply Lines: Firefighting pipes are also used in the external water supply lines that connect fire protection systems to public water sources.

Specialized Firefighting Systems: In facilities where standard water-based systems are not suitable, such as in chemical plants or data centers, firefighting pipes may carry other extinguishing agents like foam or gases.

Advantages of Firefighting Pipes

High Durability and Strength: Essential for withstanding the high pressures involved in firefighting applications.

Corrosion Resistance: Galvanizing provides protection against corrosion, crucial for maintaining the integrity and longevity of fire protection systems.

Safety and Reliability: Manufactured to meet strict standards, ensuring that they perform reliably in emergency situations.

Leading Firefighting Pipe Manufacturer: Hi-Tech Fire Pipes

Hi-Tech Fire Pipes is a prominent manufacturer known for producing high-quality firefighting pipes that meet or exceed international safety standards. With advanced manufacturing processes and a commitment to quality, Hi-Tech Fire Pipes ensures that its products provide maximum reliability and performance in fire protection systems. Their extensive range of firefighting pipes is designed to cater to various requirements, making them a trusted choice for builders, architects, and safety engineers worldwide.

More Read: Best Firefighting Pipes

0 notes

Text

Nitronic 50 Fasteners Manufacturers In India

INTRODUCTION:-

Shasan Piping Solution is a basic Manufacturers and exporters of the ferrous and nonferrous things. We likewise manage the whole family stainless steel and Nitronic 50 and XM 19 Fasteners.

We anyway, gathering the changed kind of the thing according to the bearing from the client and course. Nitronic 50 and XM 19 fastener are made with substance sytheses like carbon, nickel, silicon, manganese, chromium, aluminum, and sulfur.

DESCRIPTION:-

In the dynamic landscape of industrial fasteners, Nitronic 50 emerges as a top contender, renowned for its exceptional properties. In India, a cohort of manufacturers has embraced the challenge of producing Nitronic 50 fasteners to cater to diverse industrial needs.

BENEFITS:-

Corrosion Resistance: Exceptional resistance to corrosion in harsh environments, including seawater and chemical processing plants.

High Strength: Superior strength levels, even at elevated temperatures, making them suitable for high-stress applications.

Durability: Long-lasting performance due to its robust composition, ensuring reliability over extended periods.

Versatility: Suitable for a wide range of industries, including marine, aerospace, chemical, and pharmaceutical sectors.

Resistance to Galling: Reduced risk of galling and seizing, ensuring smooth operation and easy maintenance.

SPECIFICATION:-

ASTM: ASTM A 193/194 / ASME SA 193/194

Dimension Standard: DIN, ASTM, BS and all International Standards

Length: 3 mm to 200 mm

Bolt / Screw Size: M3 - M56 | 3/6" to 2" | Custom Sizes

Nuts Size: M02 to M33 | Custom Sizes

Washers Size: M3 - M56 | 3/6" to 2" | Custom Sizes

PRODUCT OVERVIEW:-

Types: Bolts, nuts, screws, washers, and studs, among others.

Sizes and Dimensions: Available in various sizes and dimensions to accommodate different applications.

Applications: Widely used in critical applications such as marine components, aerospace structures, chemical processing equipment, and medical devices.

Specialized Coatings: Optional coatings like passivation or electropolishing may enhance corrosion resistance further.

CONCLUSION:-

These fastener are sturdily organized and best for use in the substance district. These fastener are helpful in clinical updates on account of the properties like low charming porousness, use, opposition, and all the more clear strength. These fastener are adaptable, silly and Stainless for use in the savage conditions.

These safeguarded need to go through many tests, for example, influence test, hardness test, substance test, mechanical test, hydrostatic test, radiography test, radiating test, fixing test, etc also.

CONTACT US:-+91 22-6651 8642

EMAIL ID: [email protected]

WEBSITE: https://www.shasanpiping.com/nitronic-50-fasteners-manufacturers-exporters-suppliers-stockists.html

#Nitronic 50 Fasteners Manufacturers#Nitronic 50 Fasteners Suppliers#Nitronic 50 Fasteners Stockists#Nitronic 50 Fasteners Exporters

0 notes

Text

Fire Extinguishers 101: Your Guide to India's Fire Safety Rules and Requirements

🔥 Fire Safety Alert! 🔥

Adhering to the Bureau of Indian Standards (BIS) is crucial for fire extinguisher manufacturing, testing, and approval. 🏭

👉 Hydrostatic pressure, leakage, and discharge tests are mandatory to guarantee fire extinguisher integrity and performance.

Installation must meet IS 2190:2010 standards for accessibility and safety - it's not just about having extinguishers, but installing them right! 🚒

Fire extinguishers are a must in all commercial and industrial spaces. Regular inspections and maintenance can't be overlooked to ensure they're ready when needed. ⏰

Remember, after 15 years or any use, it's time for a replacement. Don't risk it!

Ignoring these regulations? Be prepared for fines up to Rs 50 lakhs and potential imprisonment. Safety first! ⚖️

Linkedin : #IndiaFireSafety #SafetyRulesIndia #FirePreventionIndia #FireSafetyRequirements #IndiaSafetyStandards

#IndiaFireSafety#FireSafetyRules#FireSafetyRequirements#SafetyFirst#FirePrevention#FireSafetyTips#FireSafetyAwareness#FireSafetyEducation#FireSafetyTraining#FireSafetyStandards#FireSafetyCompliance#FireSafetyRegulations#FireSafetyGuidelines#FireSafetyProcedures#FireSafetyInspection#FireSafetyEquipment#FireSafetyAwarenessCampaign#FireSafetyAwarenessMonth#FireSafetyAwarenessWeek#FireSafetyAwarenessProgram

0 notes

Text

Baldwin’s texcoat revolutionizes precision spraying with less energy consumption, Chemical Pickup and Water Usage

Graniteville Specialty Fabrics has set new standards by challenging the traditional pad finishing process. With Baldwin Technology’s cost-efficient and highly sustainable spray finishing technology, Graniteville Specialty Fabrics has been able to increase production efficiency, and minimize chemical and water waste. Based in Graniteville, South Carolina, Graniteville Specialty Fabrics produces coatings and coated fabrics that are resistant to water, fire, UV and weather for the military, marine and tent markets. The installation of Baldwin’s TexCoat G4 is part of a major facility upgrade to maximize production efficiency and capacity in the durable water-repellent finishing and coating line to meet growing customer demand for advanced engineered products.

With extensive sustainability benefits, unprecedented tracking and process control, and Industry 4.0 integration, the TexCoat G4 consistently provides high-quality fabric finishing, with no chemistry waste, as well as minimal water and energy consumption. This system utilizes non-contact precision-spray technology, ensuring precise finishing coverage with the exact amount of chemistry for reaching the optimal performance of the fabric. Changeovers (pad bath emptying, cleaning and refilling) are significantly reduced, resulting in substantial chemical conservation and increased productivity. “We were pleased to be a key partner in Graniteville Specialty Fabrics’ modernization project,” said Rick Stanford, Baldwin’s Vice President of Global Business Development, Textiles. “The team reached out to us, and it was clear that the TexCoat G4 was the right tool to help them minimize waste and increase productivity.” Doug Johnson, Graniteville Specialty Fabrics’ Executive Vice President of Development and Technical Services, said the company needed to increase its productivity and sustainability, without sacrificing fabric quality and performance. “Anytime you change from a traditional process like padding, it is human nature to be a little skeptical,” said Johnson. “Baldwin organized production-scale trials for us at a nearby TexCoat-equipped factory. We took the finished fabric and scrutinized the look and feel, and performed a battery of tests in our lab to American Association of Textile Chemists and Colorists spray-rating and hydrostatic-head standards. The results were impressive. Moreover, when we commissioned our TexCoat, we duplicated and exceeded the fabric performance realized during the trials.” “[TexCoat] allows us to have full control over where we spray the chemicals, and allows us to save money in the process” states James McKenzie, Graniteville Maintenance and Facilities Manager. “With the machine in production, it is a rocketship compared to a rock.”

0 notes